Damage detection device for lasher vision conveying belt

A damage detection and conveyor belt technology, which is applied to conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems that the complexity of image processing algorithms cannot meet the needs of online real-time detection operations, economic losses, and high costs. The effect of easy installation and mobile detection, simple system structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

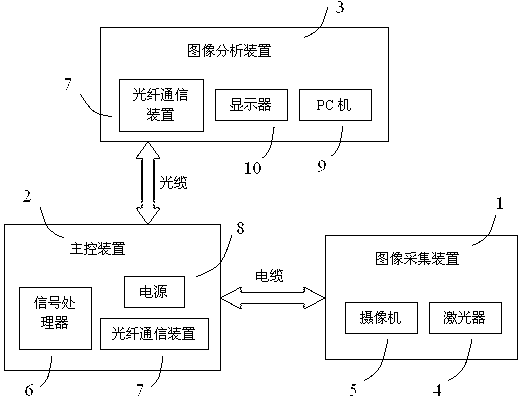

[0025] see figure 1 , the present invention relates to a laser vision conveyor belt damage detection device, which is mainly composed of an image acquisition device 1, a main control device 2 and an image analysis device 3, the image acquisition device 1 and the main control device 2 are connected by a cable, and the The image analysis device 3 is connected to the main control device 2 through an optical cable.

[0026] The image acquisition device 1 includes a laser 4 and a camera 5, and its function is to collect a laser image on the surface of the conveyor belt and transmit it to the main control device 2 for processing in real time. The laser 4 projects a red light with a wavelength of 650nm to the surface of the conveyor belt. Laser stripes are used as structured light for auxiliary measurement. The direction of the laser line is perpendicular to the conveying direction of the conveyor belt. The camera 5 is arranged on one side of the laser 4, and both the camera 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com