PVC decorative board film laminating and unwinding mechanism

A technology of unwinding mechanism and decorative board, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc. It can solve the problems of troublesome disassembly and assembly of film rolls, low processing efficiency, troublesome debugging, etc., to achieve firm clamping, Easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

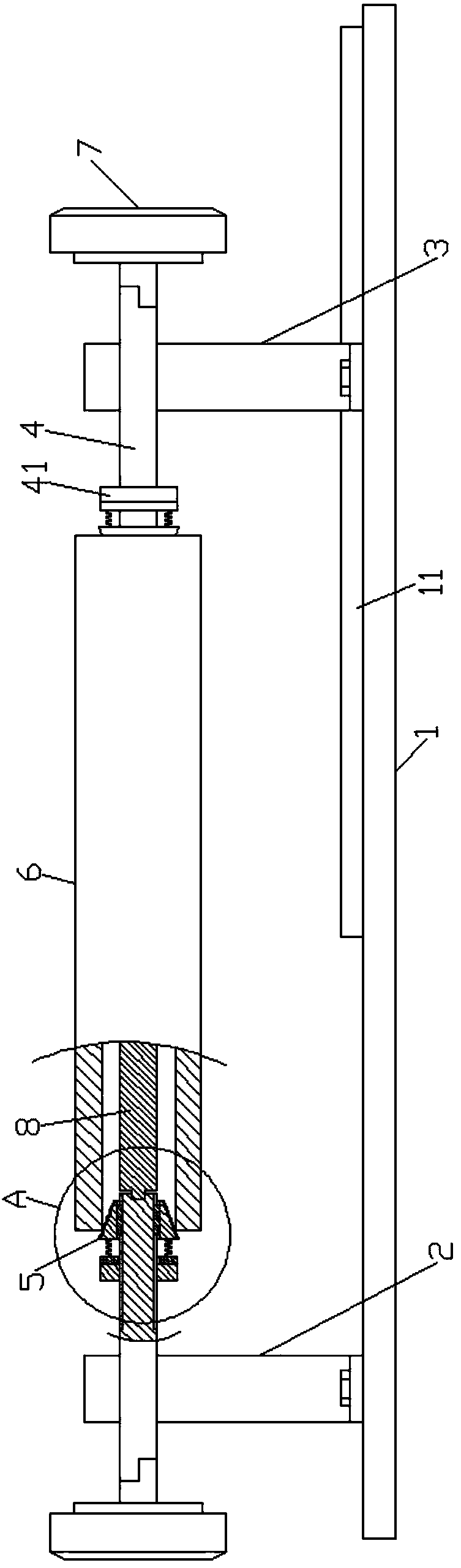

[0034] Example: such as figure 1 and 2 As shown, the unwinding mechanism of the PVC decorative board film in this embodiment includes a bottom plate 1, a first bearing seat 2 and a second bearing seat 3;

[0035] The above-mentioned first bearing seat 2 is fixedly installed on the above-mentioned bottom plate 1;

[0036] The above-mentioned second bearing seat 3 is slidably installed on the above-mentioned bottom plate 1, and can move close to or away from the above-mentioned first bearing seat 2 along the above-mentioned bottom plate 1;

[0037] The first bearing seat 2 and the second bearing seat 3 are rotatably installed with short shafts 4 respectively, and the short shafts 4 on the first bearing seat 2 and the second bearing seat 3 are arranged coaxially;

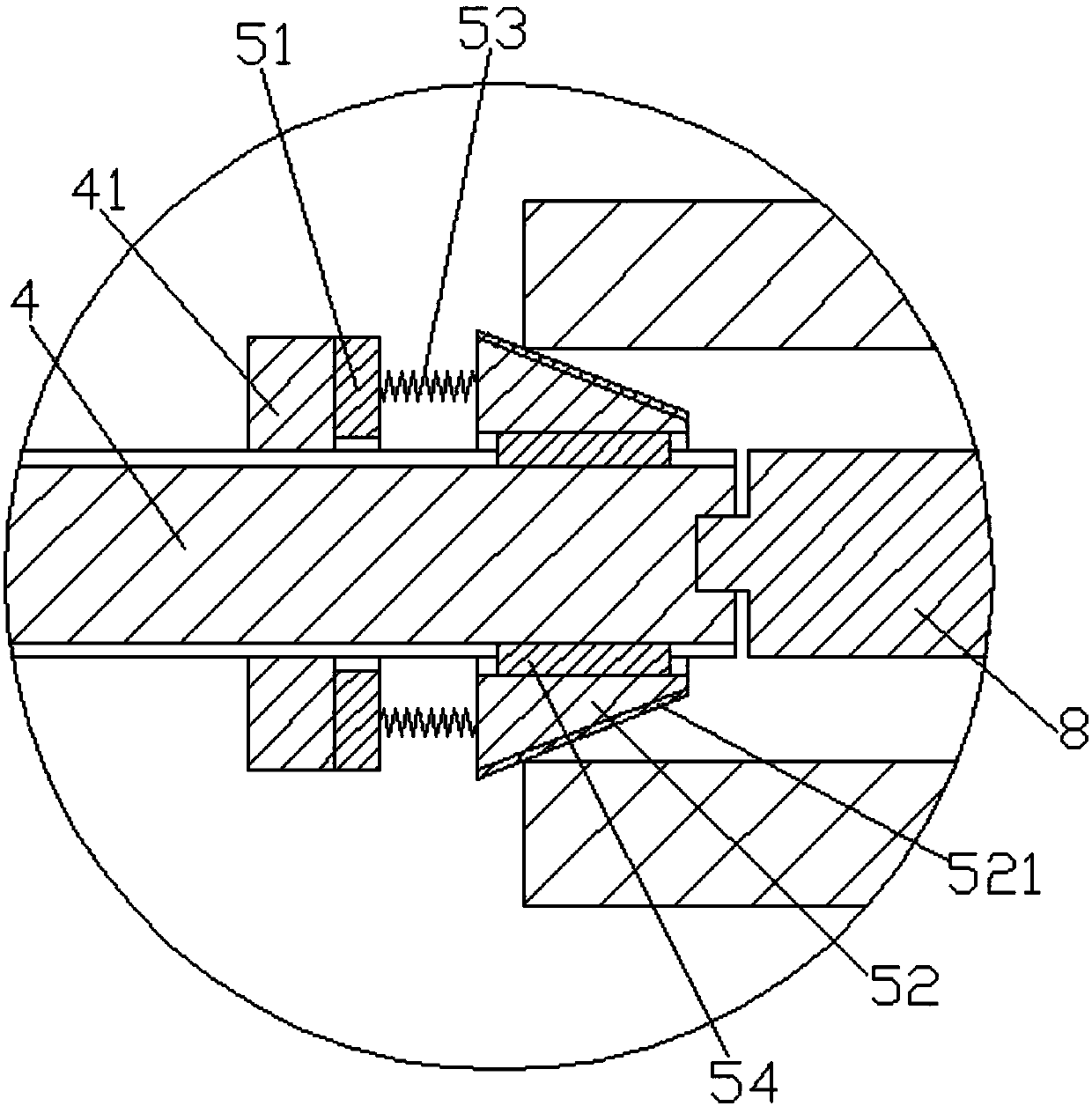

[0038] Threads are respectively provided on the outer peripheries of the ends of the two short shafts 4 that are close to each other, and adjusting nuts 41 are threadedly connected to each other;

[0039] Elastic cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com