Clamping and conveying type raw bamboo sawing machine

A conveying and bamboo machine technology, applied in circular saws, sawing components, sawing equipment, etc., can solve the problems of easy injury, complicated operation, poor safety and other problems for workers, to reduce the probability of injury, good safety, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

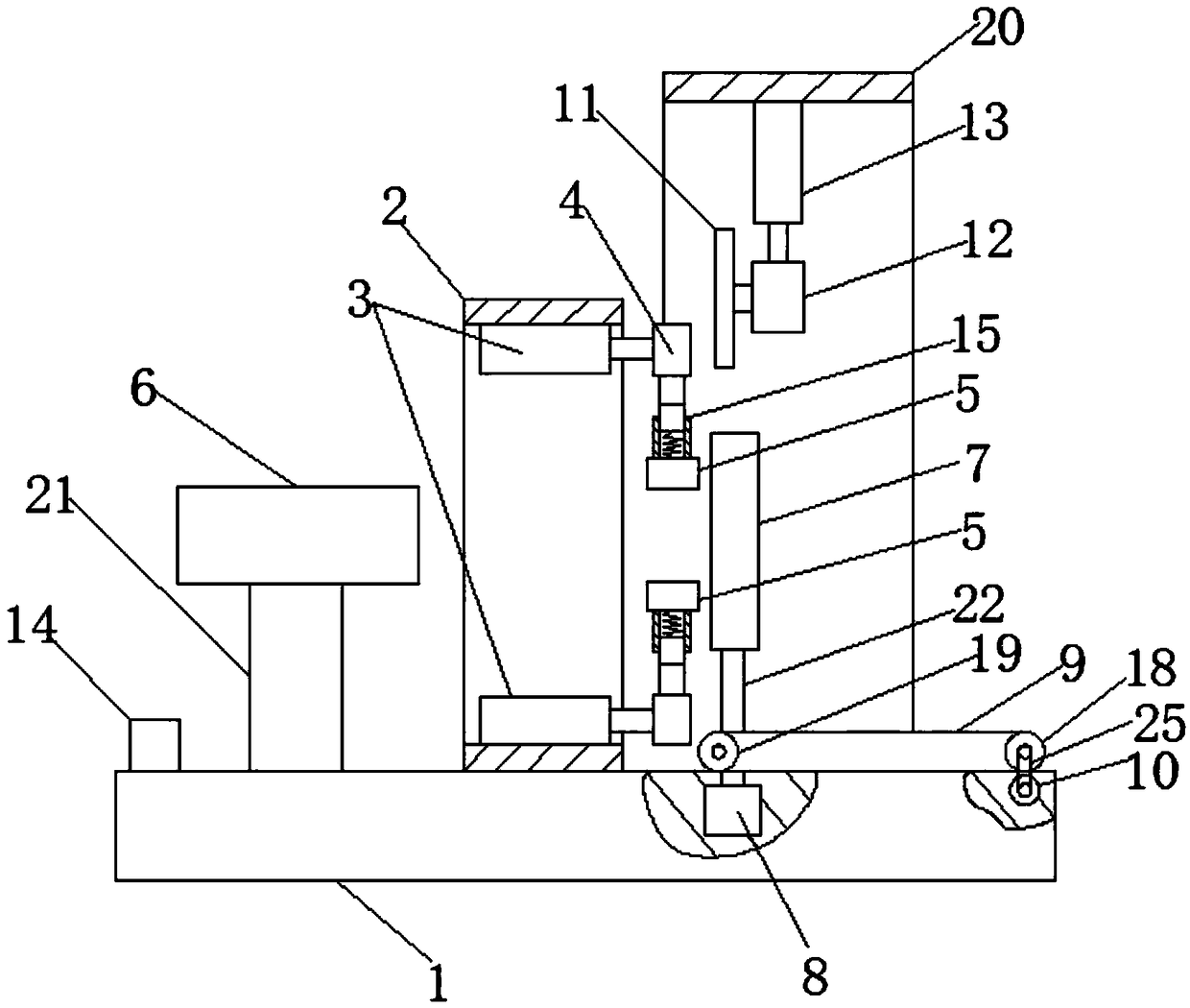

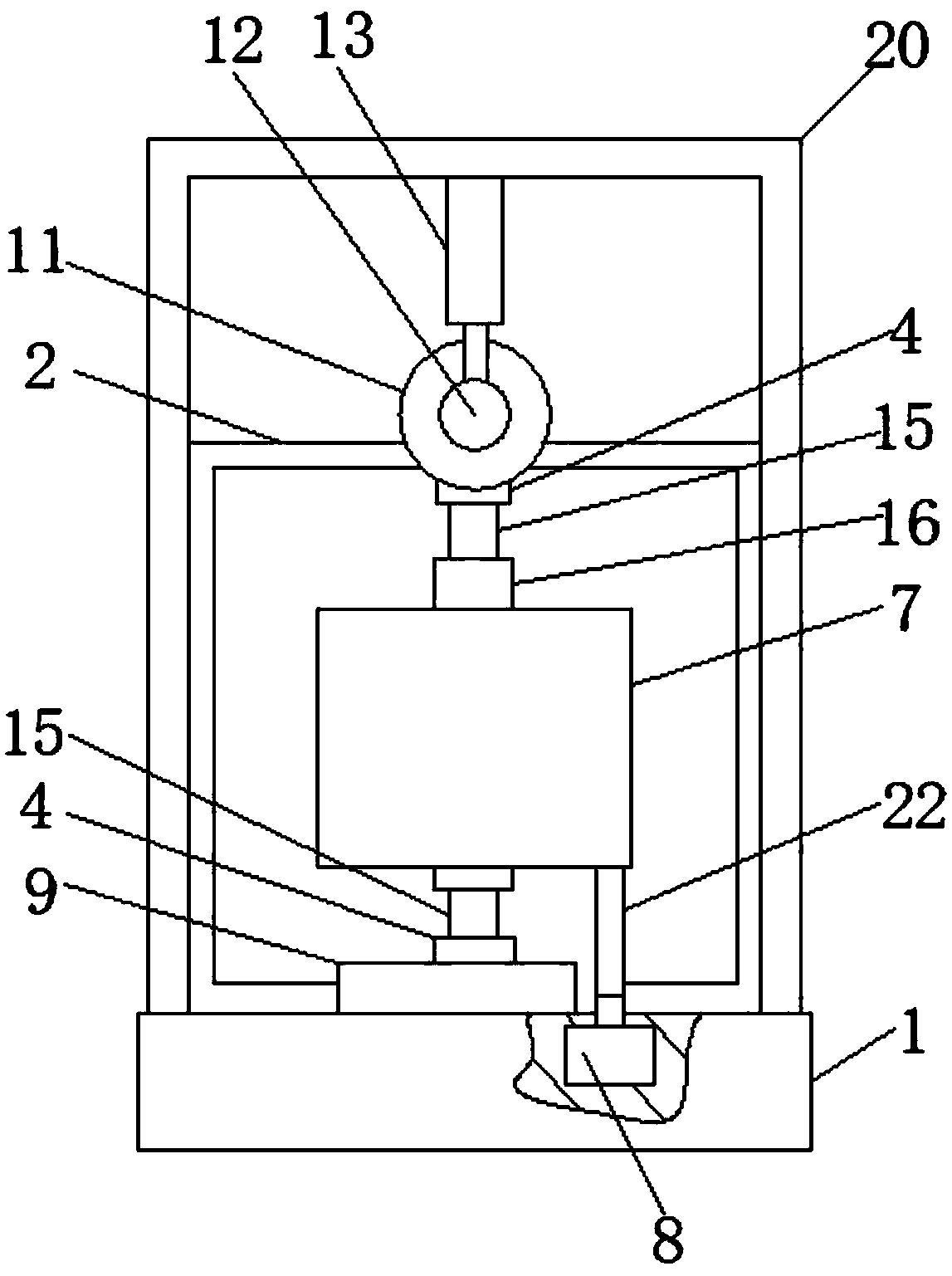

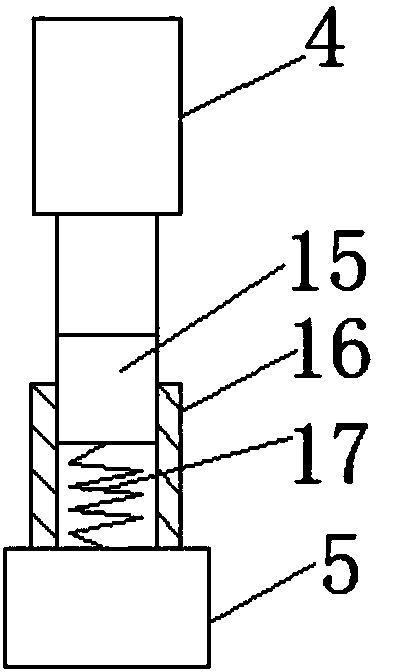

[0017] Example. A clamping and conveying type sawing bamboo machine, which is composed of Figures 1 to 5 As shown, including the base plate 1, the middle part of the base plate 1 is provided with a square frame 2; the upper and lower ends of the square frame 2 are connected to a No. 1 hydraulic cylinder 3, and the same side of the two No. 1 hydraulic cylinders 3 is connected to a No. 2 hydraulic cylinder 4; Each No. 2 hydraulic cylinder 4 is connected with a splint 5, and the two splints 5 are located between the two No. 2 hydraulic cylinders 4; one side of the square frame 2 is provided with a fixed cylinder 6, and the other side is provided with a baffle plate 7; No. 1 motor 8 is connected to the bottom of one side of the baffle plate 7, a conveyor belt 9 is arranged below the baffle plate 7, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com