Double-surface milling machine tool with special three-direction fixing clamp

A fixed fixture and double-sided milling technology, which is applied in the direction of milling machines, milling machine equipment, clamping, etc., can solve the problems of ineffective clamping of multiple workpieces, affecting machining accuracy, and workpiece movement, so as to increase strength, improve machining accuracy, The effect of reducing the chance of pinching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

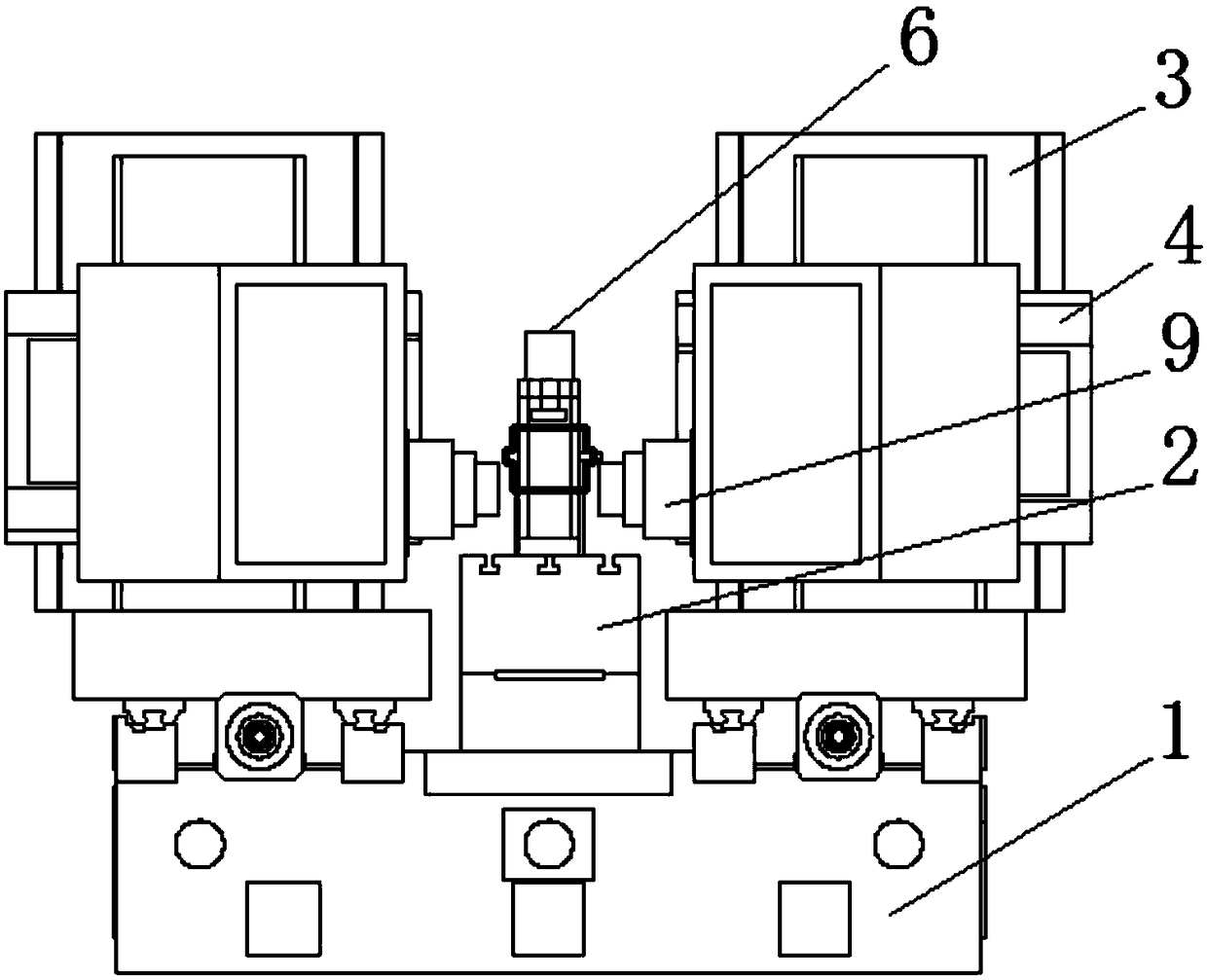

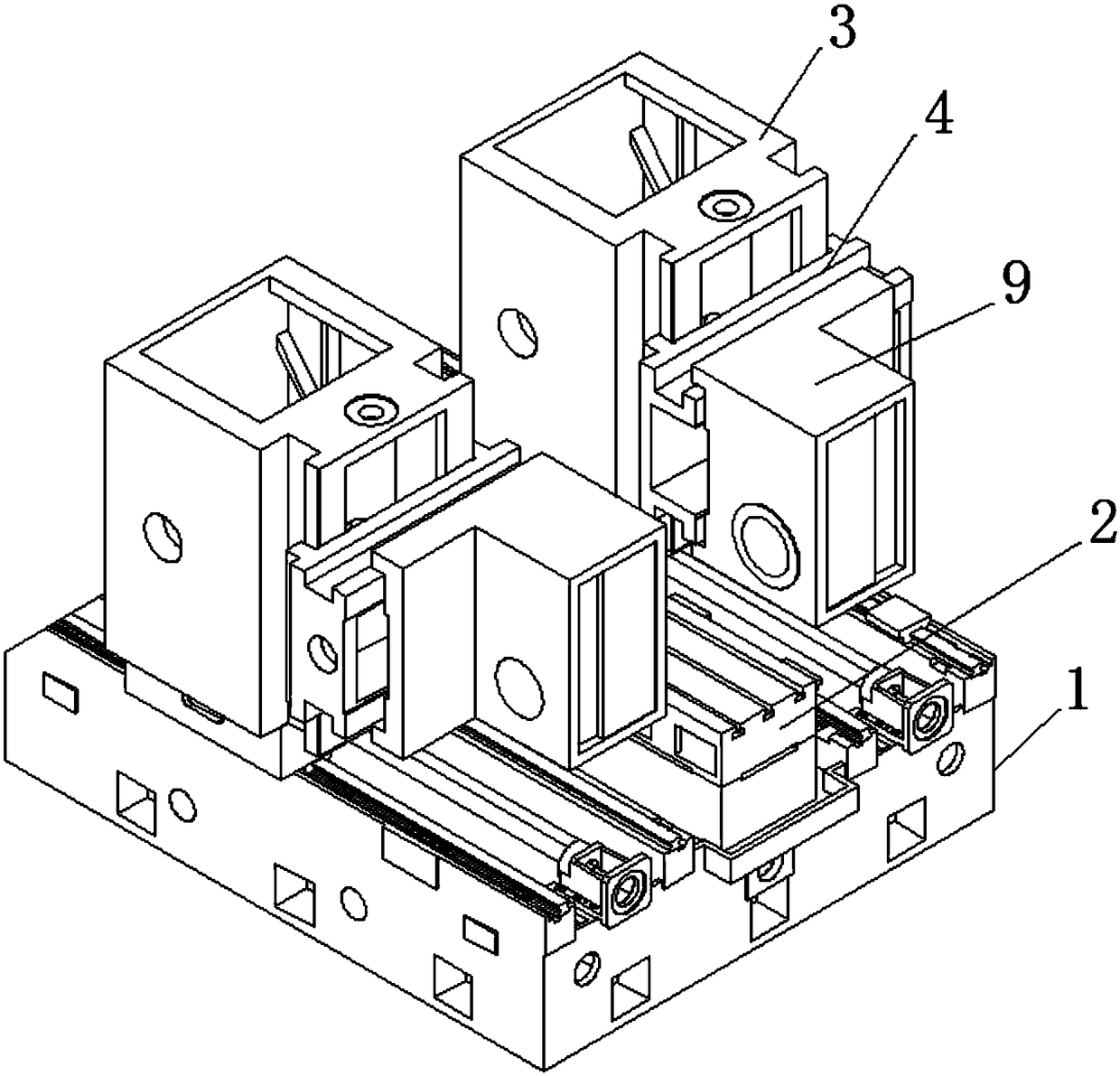

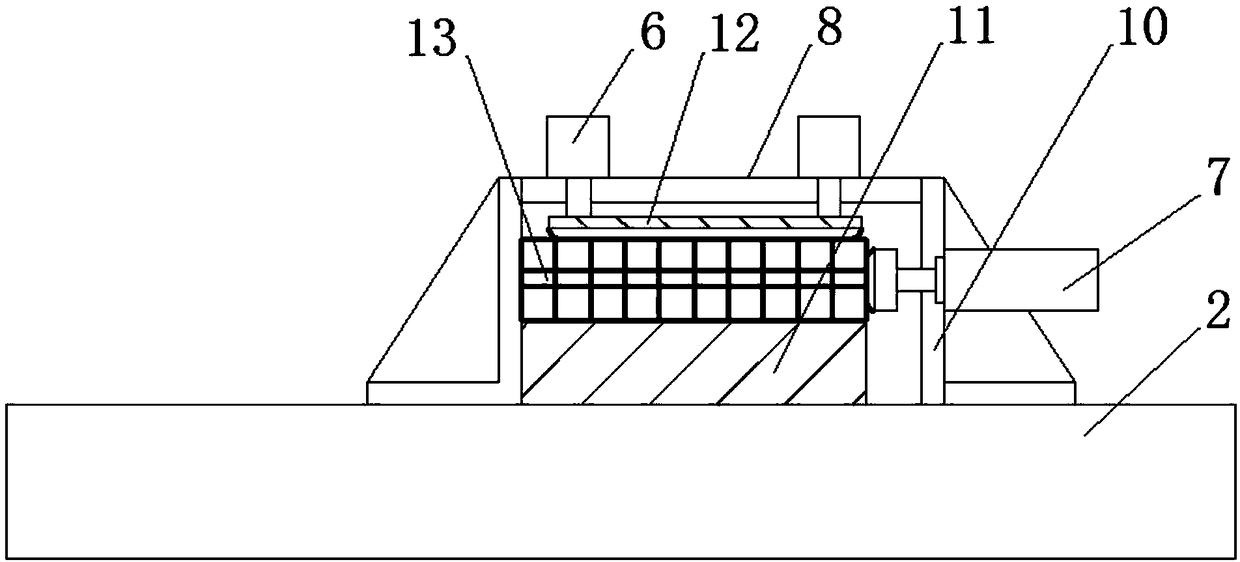

[0043] see Figure 1-2 , a double-sided milling machine tool with a special tripartite fixed fixture, comprising a double-sided milling machine body 1, the upper end of the double-sided milling machine body 1 is fixedly connected with a workbench 2, and the left and right upper ends of the double-sided milling machine body 1 are fixedly connected with Column 3, two columns 3 are respectively located on both sides of the workbench 2, one end of the column 3 is cut with a chute, and an electric sliding table is installed in the chute, the headstock slide plate 4 is slidingly connected with the column 3 through the electric sliding table, the headstock The outer end of the slide plate 4 is slidably connected to the headstock 9, and the connection between the headstock 9 and the headstock slide 4 is coated with a solid self-lubricating coating, such as a graphene coating, and the thickness of the solid self-lubricating coating is 0.4mm. The self-lubricating coating can reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com