Linen spreading machine

A spreading machine and spreading technology, which is applied in the field of spreading machines, can solve the problems that the linen cannot maintain high flatness, the linen cannot be fully stretched, and the spreading effect of the spreading machine is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

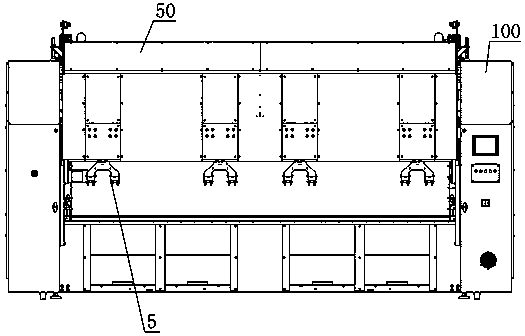

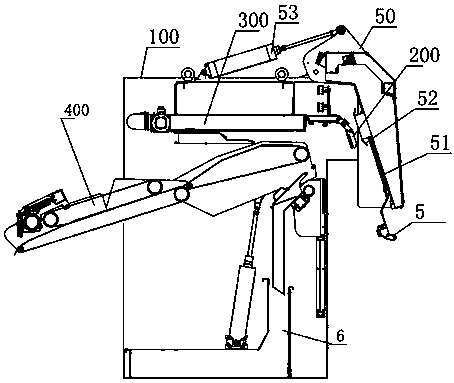

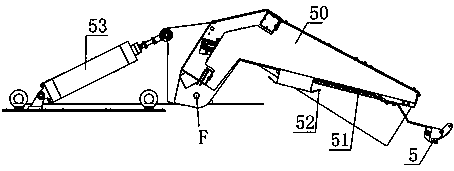

[0050] like figure 1 and figure 2 As shown, the spreading machine described in this embodiment includes: a frame 100, a linen spreading device 200 with a pair of spreading manipulators 2 is arranged on the upper end of the frame 100, and a pair of spreading manipulators 2 can hold the cloth The top ends of the grass spread out to the left and right sides. A cloth receiving device 300 with a cloth receiving mobile platform 3 is arranged on the frame 100 located under the rear side of the linen spreading device 200, and the cloth receiving mobile platform 3 can accept the dropped linen released from a pair of spreading manipulators 2 , a linen delivery device 400 is provided on the frame 100 below the cloth receiving device 300, the linen delivery device 400 can accept the linen dropped from the cloth receiving mobile platform 3, and transfer the linen from the linen delivery device 400 rear output. The upper section of the cloth connecting plate 50 is fixedly arranged on th...

Embodiment 2

[0062] The difference between this embodiment and the first embodiment lies in the partial structure of the spreading manipulator 2. The difference between the structure of the single spreading manipulator 2 in this embodiment and the first embodiment is that the connecting arm in the first embodiment 26 and synchronous belt drive are changed to swing drive device, details are as follows:

[0063] A swing driving device is arranged between the movable bracket 21 and the occlusal arm 22 of each spreading manipulator 2. Under the drive of the swing driving device, the spreading clamping mouth 20 can swing back and forth relative to the moving frame 21, thereby connecting with the cloth Manipulator 5 or cloth receiving mobile platform 3 realizes linen handover. like Figure 15 and Figure 16 As shown, the structure of the swing driving device described in this embodiment includes: a first connecting rod 91 and a second connecting rod 92, the rear ends of the first connecting ro...

Embodiment 3

[0069] like Figure 23 and Image 6 As shown, the difference between this embodiment and Embodiment 1 or Embodiment 2 is that: the structure of the cloth receiving device is: a conveying guide rail 36 is provided on the frame 100 located at the rear side of the spreading guide rail 210, and the conveying guide rail 36 is The guide rail 36 is horizontally arranged front and back, and a cloth receiving mobile platform 3 with a plurality of first air suction ports 33 is movably arranged on the conveying guide rail 36. The cloth receiving mobile platform 3 is driven by the fourth driving device. After the cloth moving platform 3 moves forward along the conveying guide rail 36, it can receive and absorb the linen released from the two spreading manipulators 2. Driven to move backwards to the top of the cloth conveying device 400 together with the cloth receiving mobile platform 3 . The fourth driving device can be driven by a motor, or other driving devices, as long as it can dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com