Patents

Literature

107results about "Internal forms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Free flowing dry back-up insulating material

Disclosed is a free flowing dry back-up material which comprises:from 67 to 96% by weight of fly-ash;from 2 to 15% by weight of a heat sensitive binder such as boric acid;from 2 to 7% by weight of a non-wetting agent such as calcium fluoride;from 0 to 10% by weight of a heat expandable material, viz. a material expandable as a function of the temperature such as vermiculite or graphite; andfrom 0 to 1% by weight of a dust suppressant such as kerosene.This material which is useful in particular in the aluminum industry has the advantages of being water free and free flowing, such avoiding the use of vibrator to position it into a shell. It also has a low density and a low thermal conductivity. Moreover, it is organic free as compared to the existing materials which use an organic binder to ensure a low temperature set; and it sets at a temperature lower than 400° F.

Owner:LES PROD CHIMS INDS DE HAUTE TEMPERATURE PYROTEK

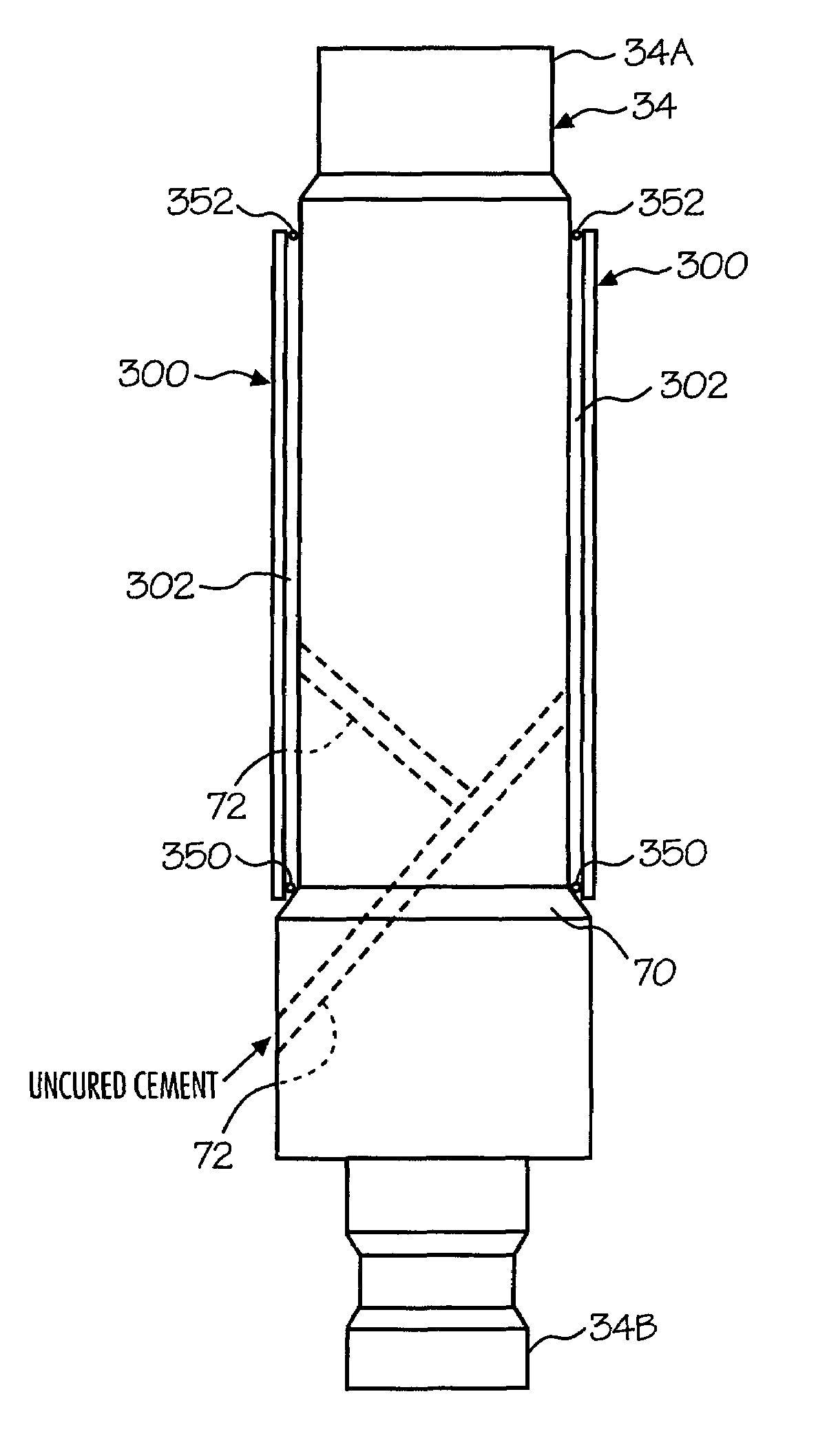

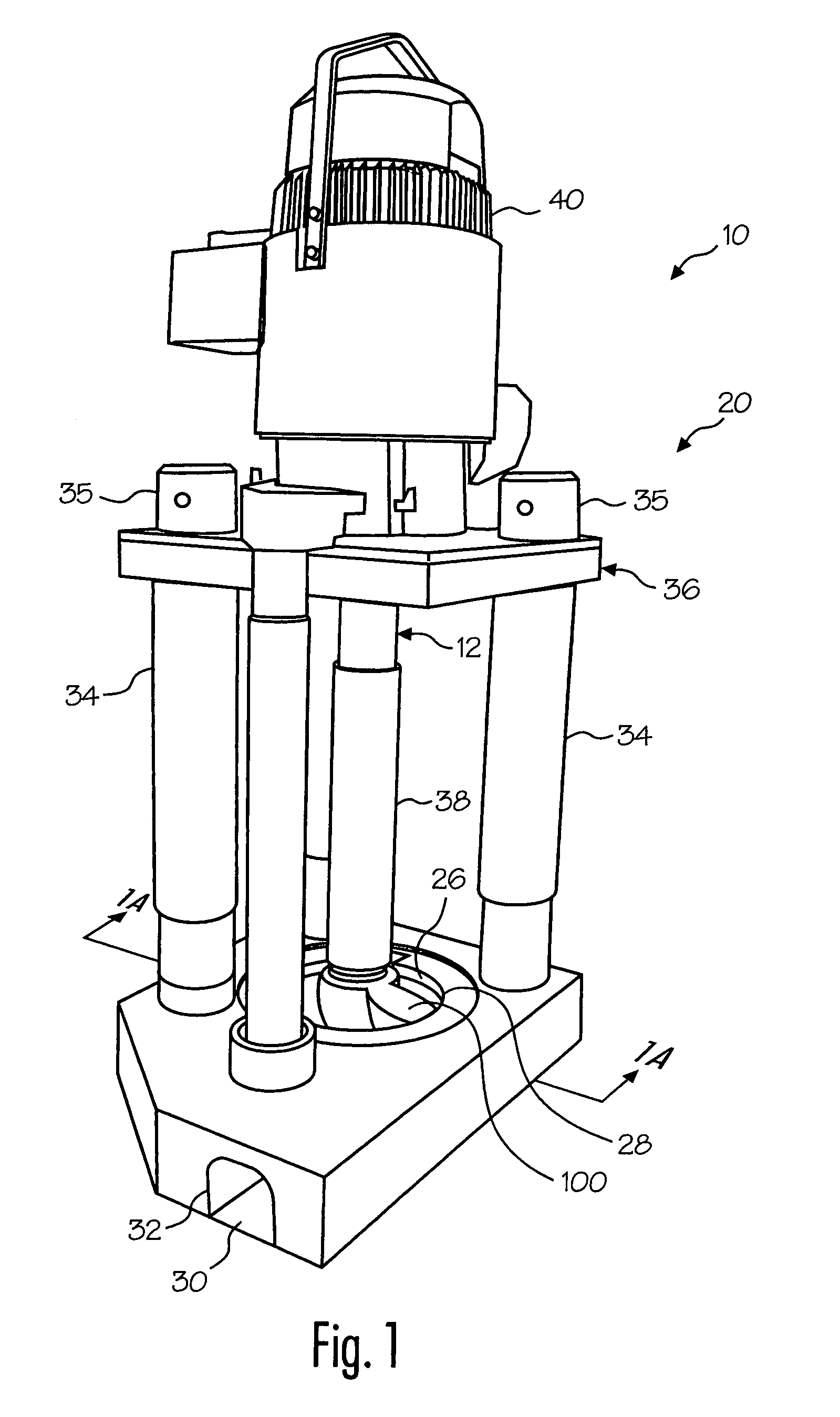

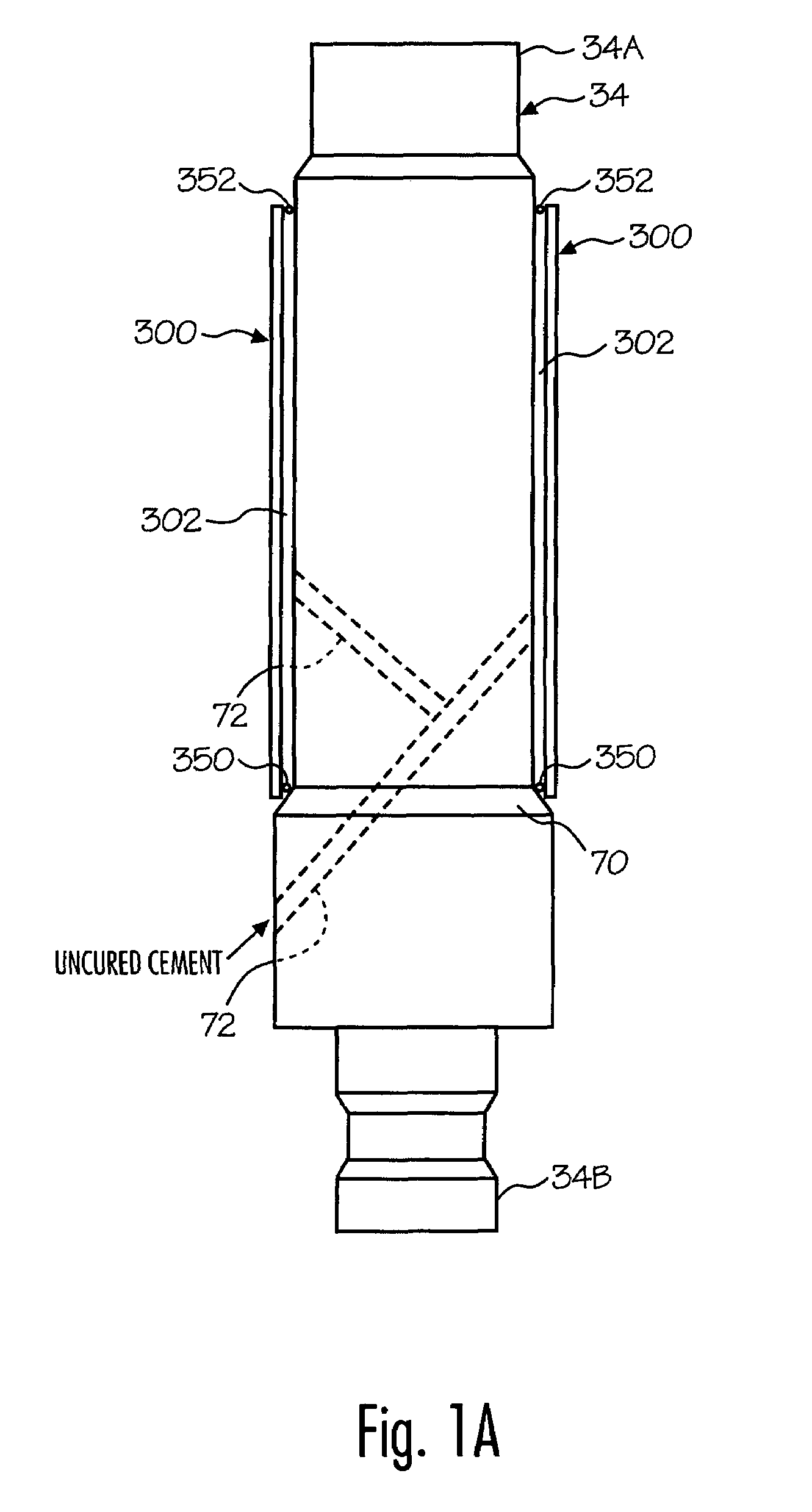

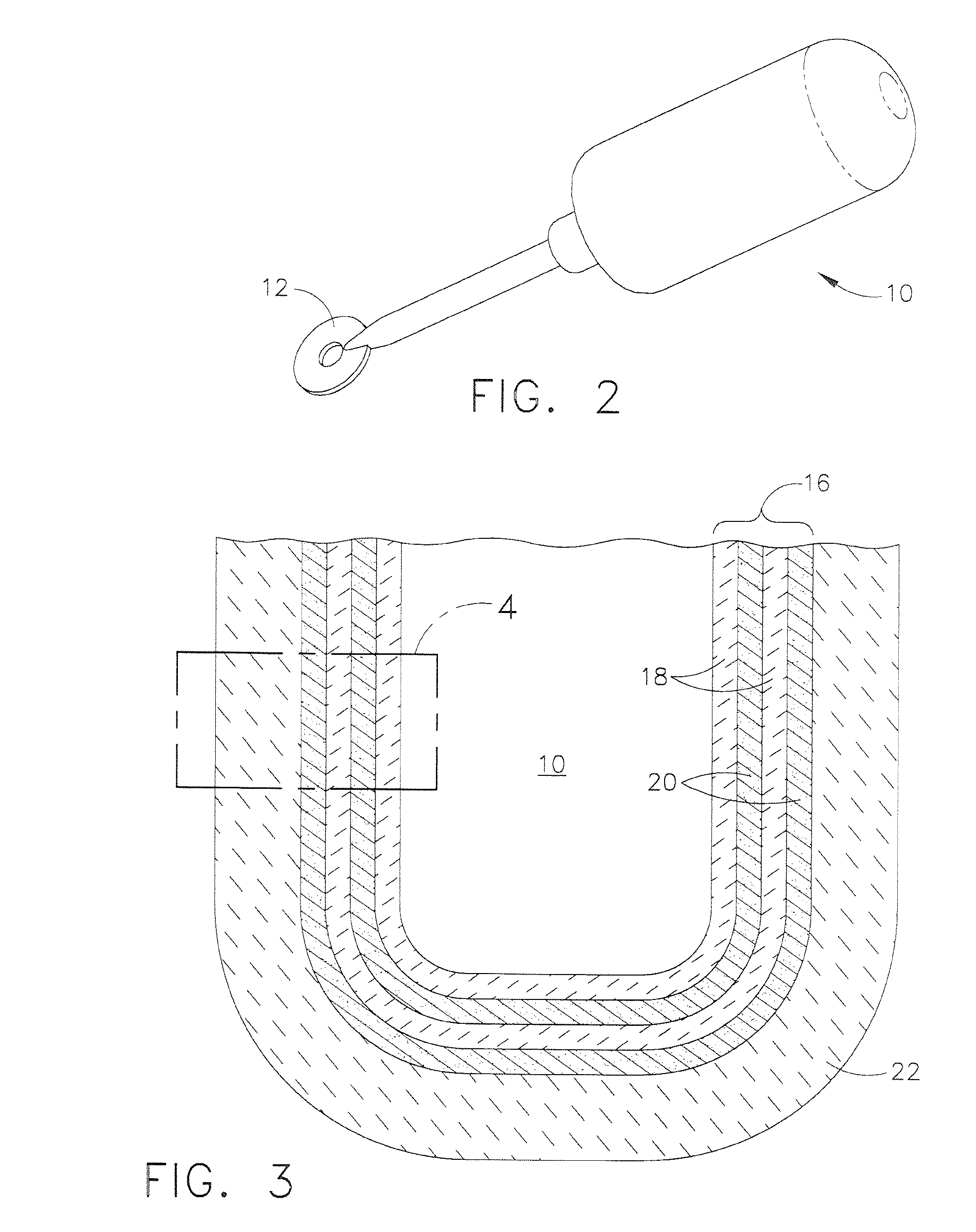

Protective coatings for molten metal devices

ActiveUS7507367B2Reduce componentsPrecise positioningSpecific fluid pumpsPump componentsMolten metalCoating

Disclosed are components covered with a protective coating for use in a molten metal bath (or comparable environment) and devices including such components. The protective coating is preferably a ceramic sleeve adhered to a non-coated component by cement. A component with the protective coating is more resistant to degradation in molten metal than is the component without the coating, and may be manufactured by the process of (a) placing the protective coating over the non-coated component, and (b) injecting cement into the space between the non-coated component and protective coating, wherein at least some of the cement is injected through a passage in either the non-coated component or the protective coating.

Owner:MOLTEN METAL EQUIP INNOVIATIONS LLC

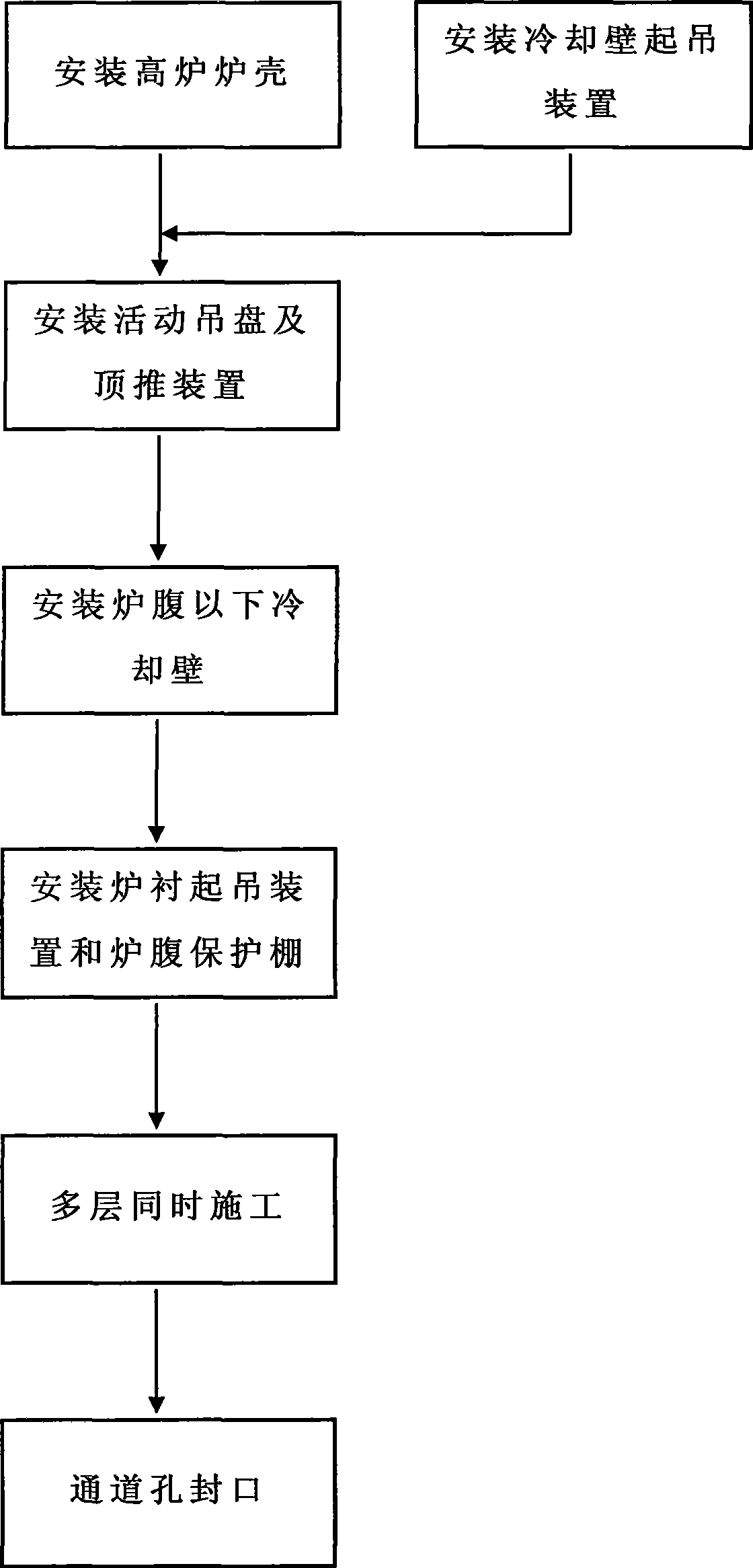

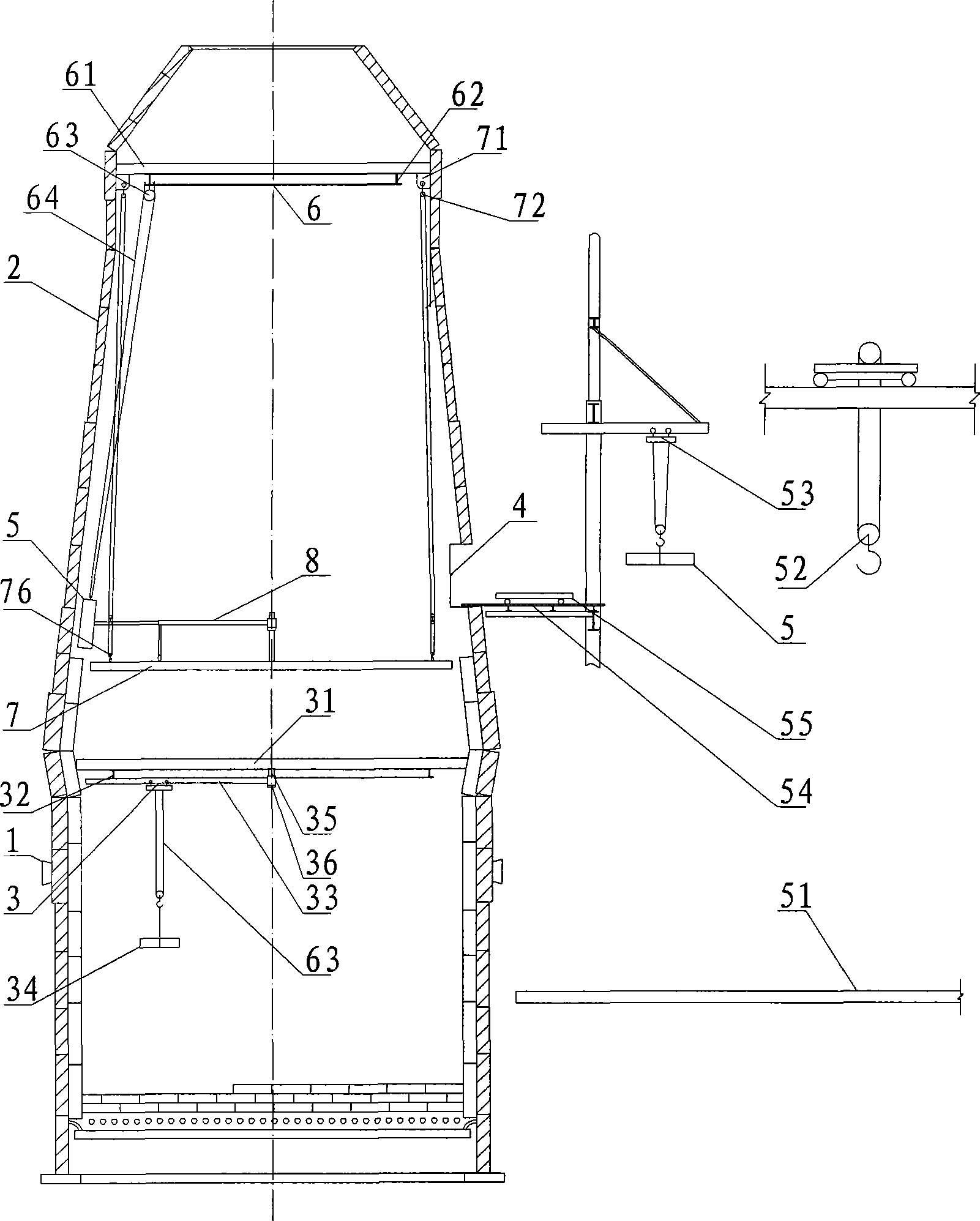

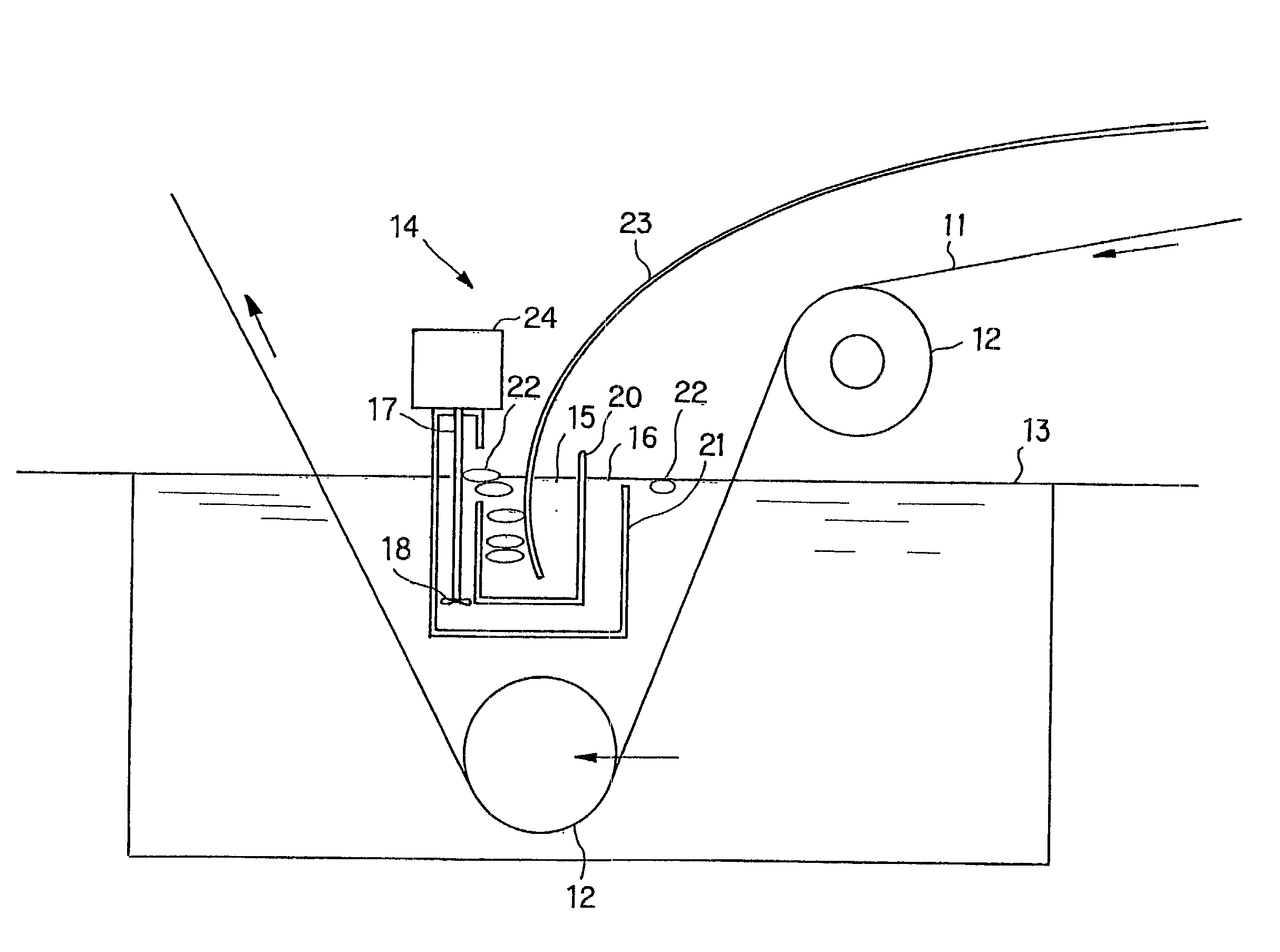

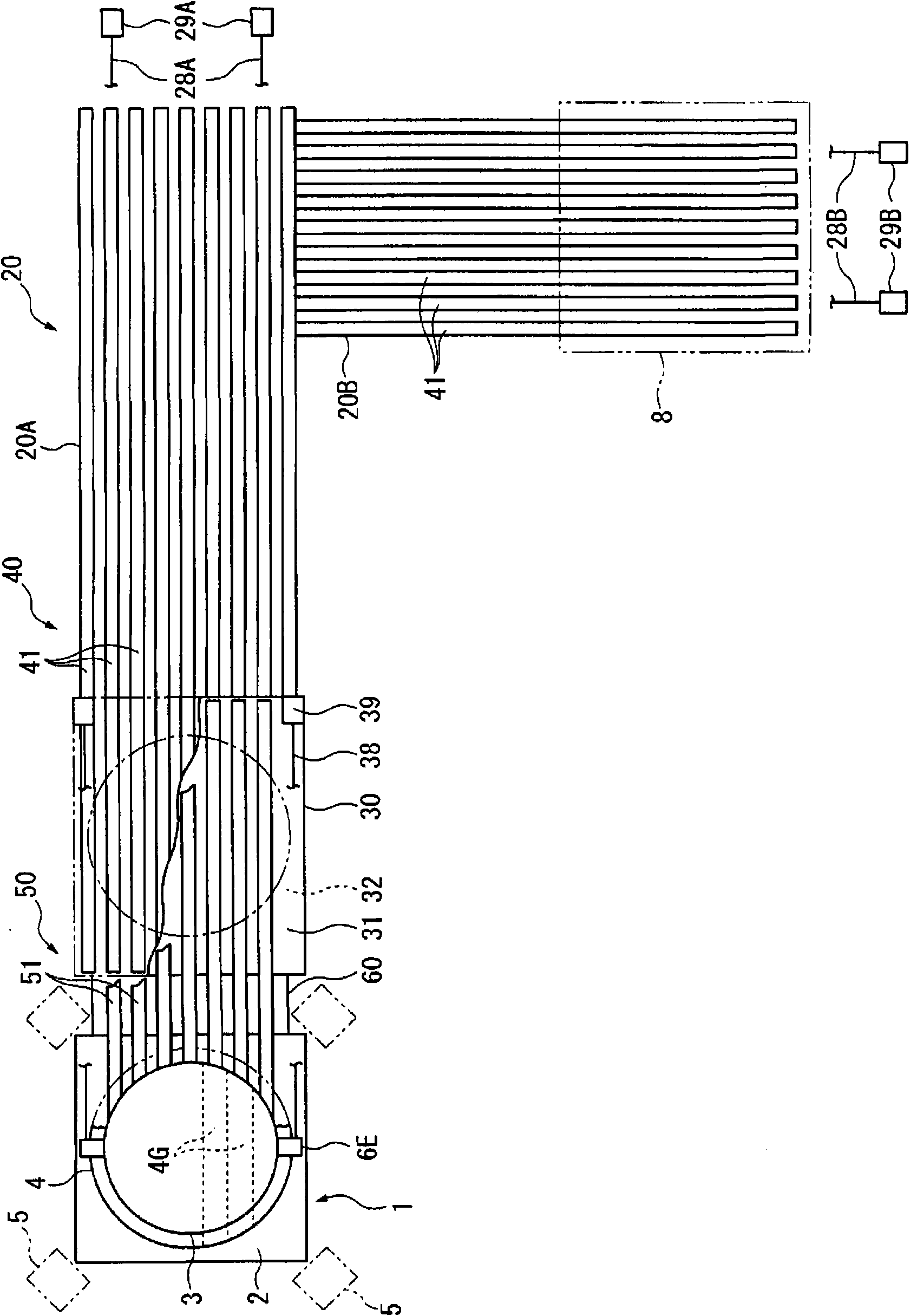

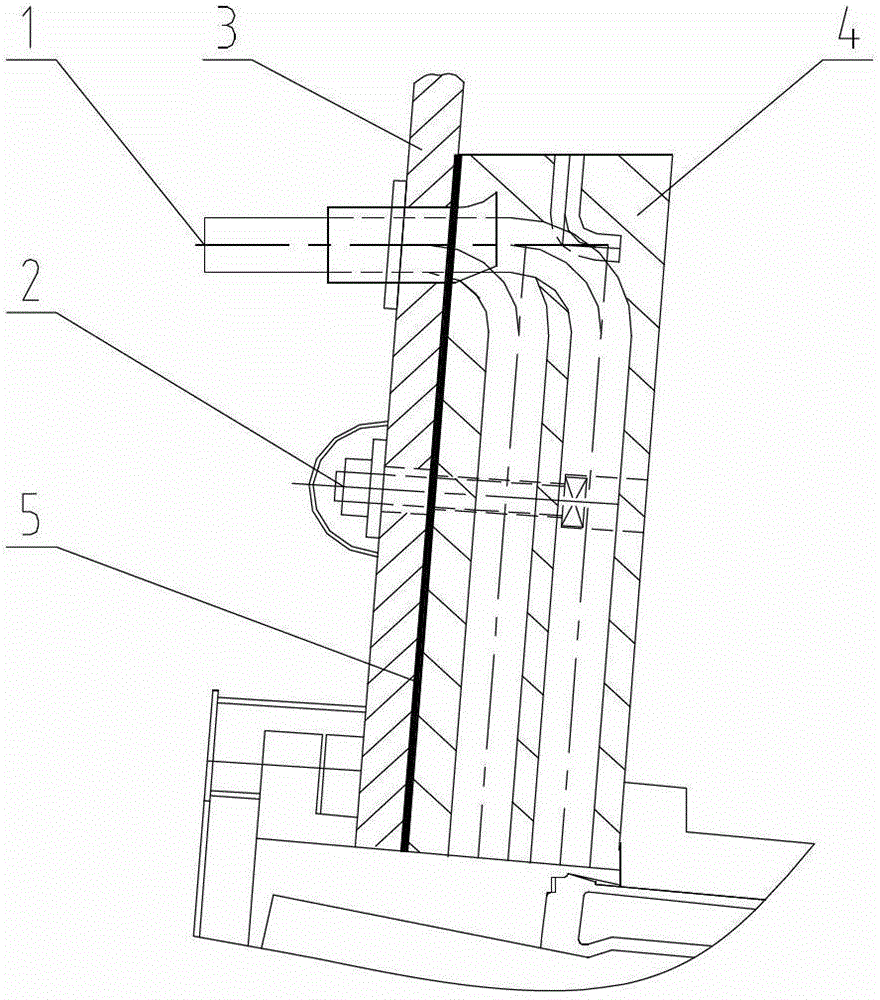

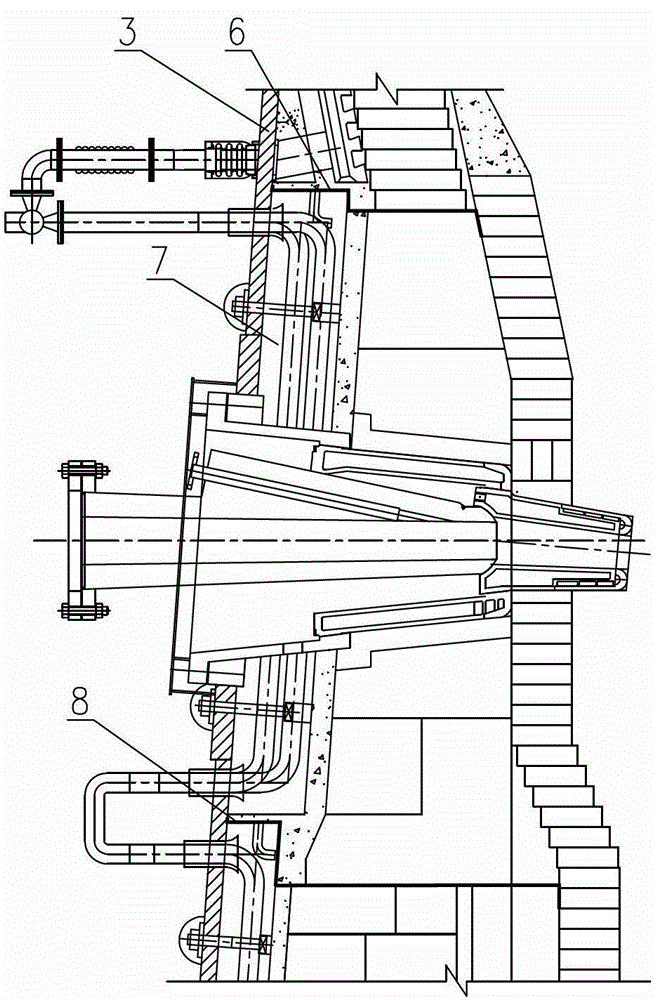

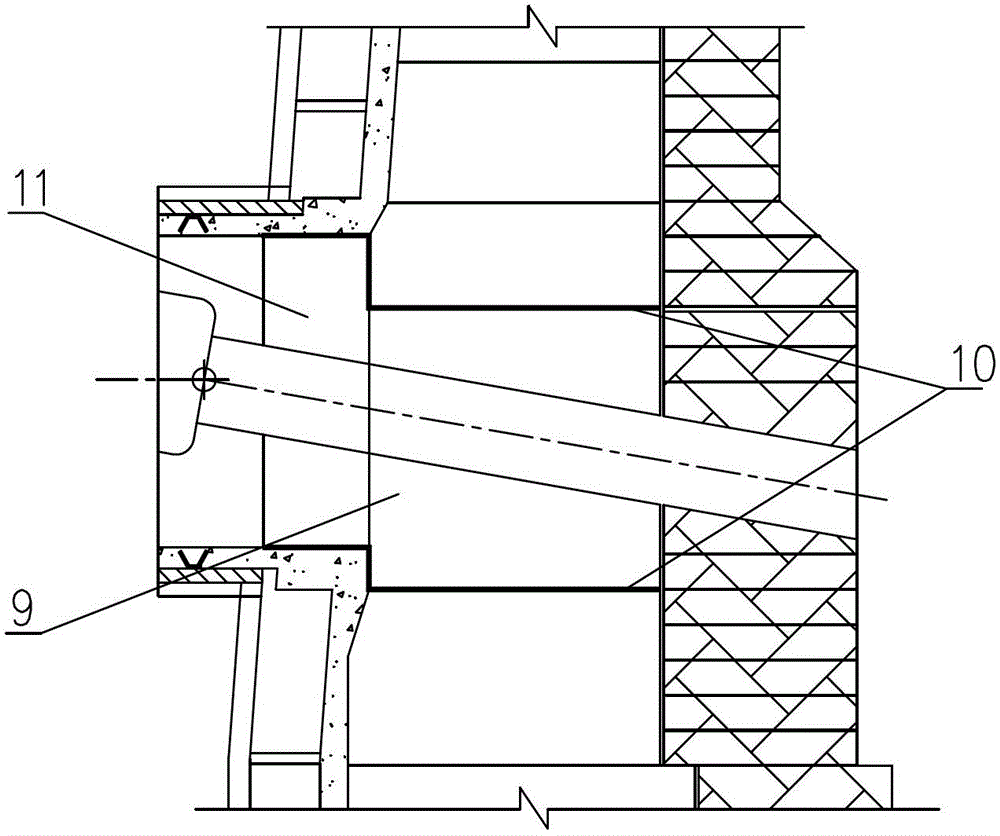

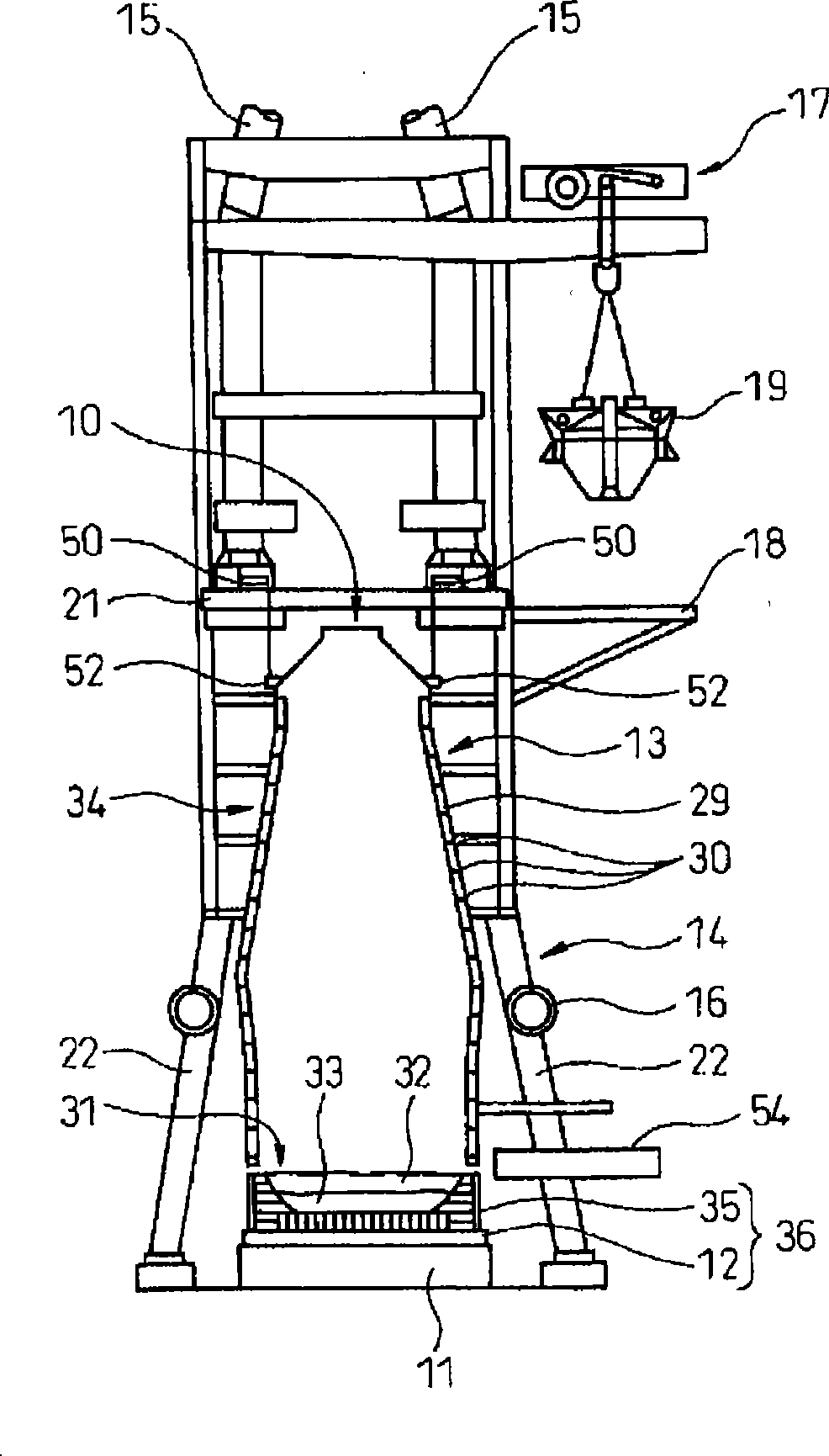

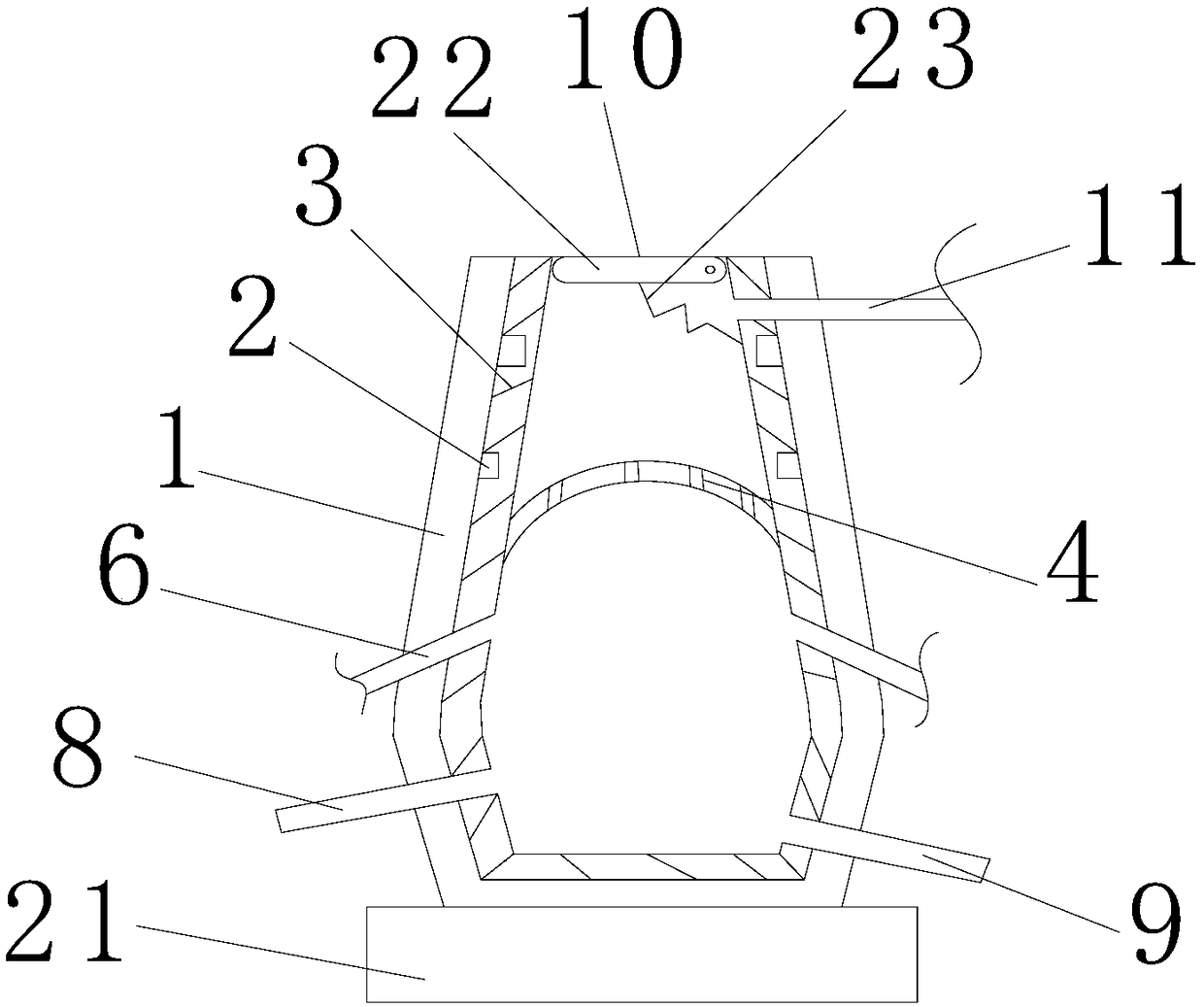

Construction method for internal cooling wall and furnace liner of blast furnace

InactiveCN101509049AReduce workloadSave the use of shift feesCooling devicesInternal formsEngineeringBlast furnace

The invention discloses a construction method for blast furnace internal cooling wall and furnace lining. Firstly, an access opening through which the blast furnace internal cooling wall enters into an internal furnace is arranged on the furnace mantle above a blast-furnace tuyere; the cooling wall under a furnace bosh is firstly arranged by ways that a cooling wall lifting appliance arranged at the furnace throat of the internal furnace and a lifting movable swinging tray swinged in the internal furnace firstly, and a furnace bosh protection shed and a furnace lining lifting appliance are arranged at the furnace bosh secondly. Then, and the cooling wall is arranged at the top part of the furnace bosh by the cooling wall lifting appliance and the movable swinging tray, meanwhile the furnace lining construction is carried out at the lower part of the furnace bosh by a furnace lining lifting appliance and the cooling wall except for the access opening is sealed so as to complete the construction of the cooling wall of the access opening. The construction method has the advantages of low cost, convenient operation, short construction period and high construction efficiency, etc.

Owner:五矿二十三冶建设集团有限公司

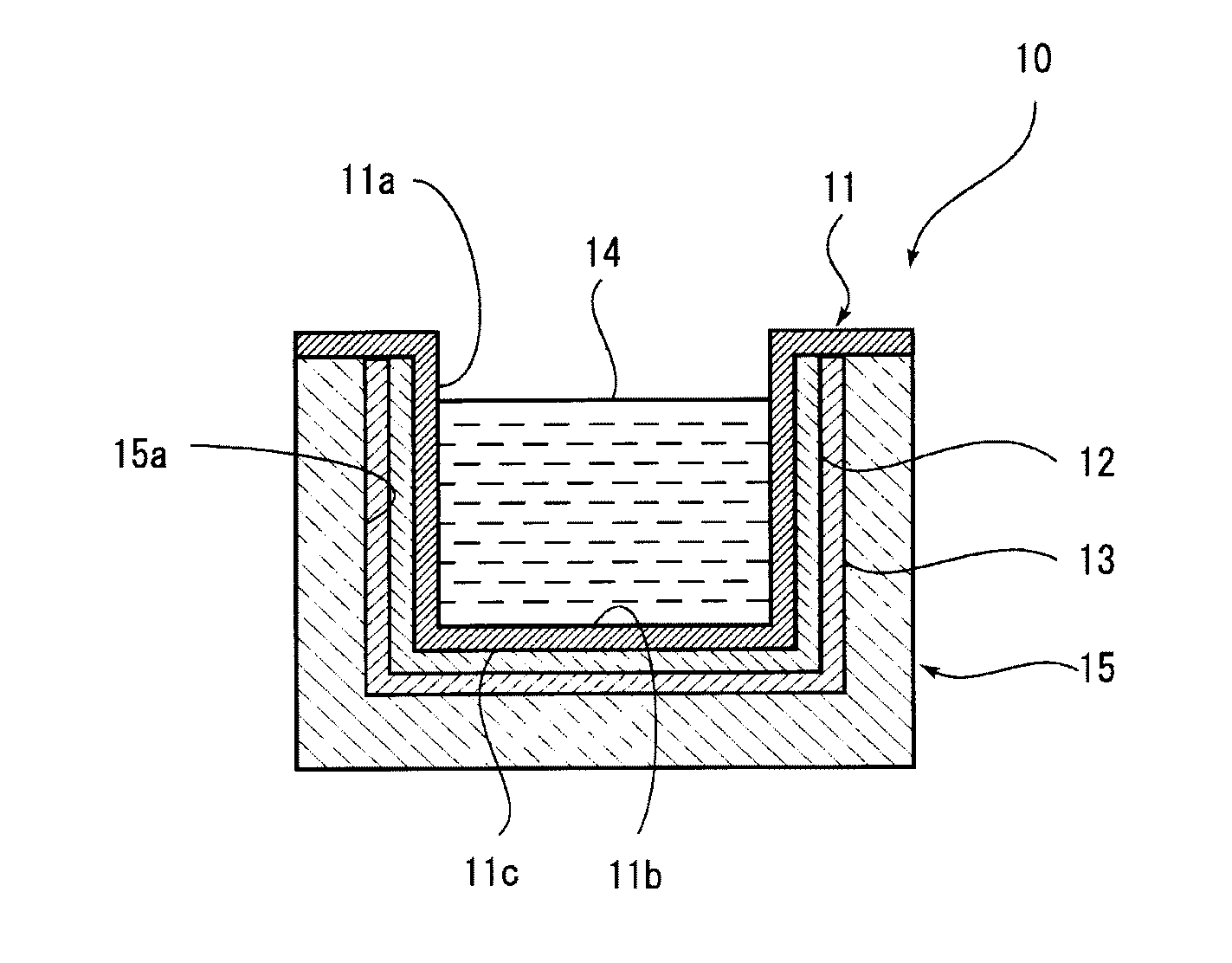

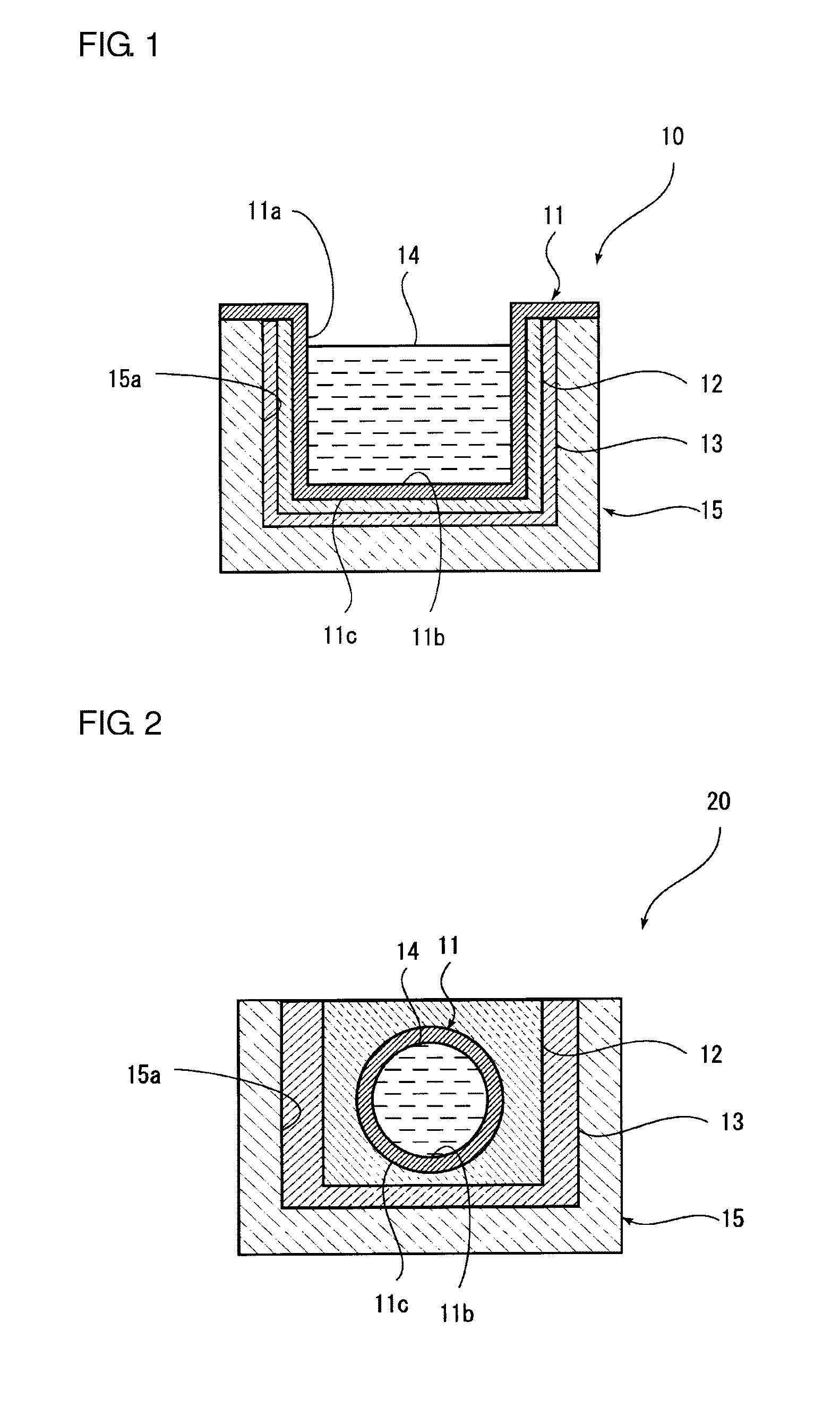

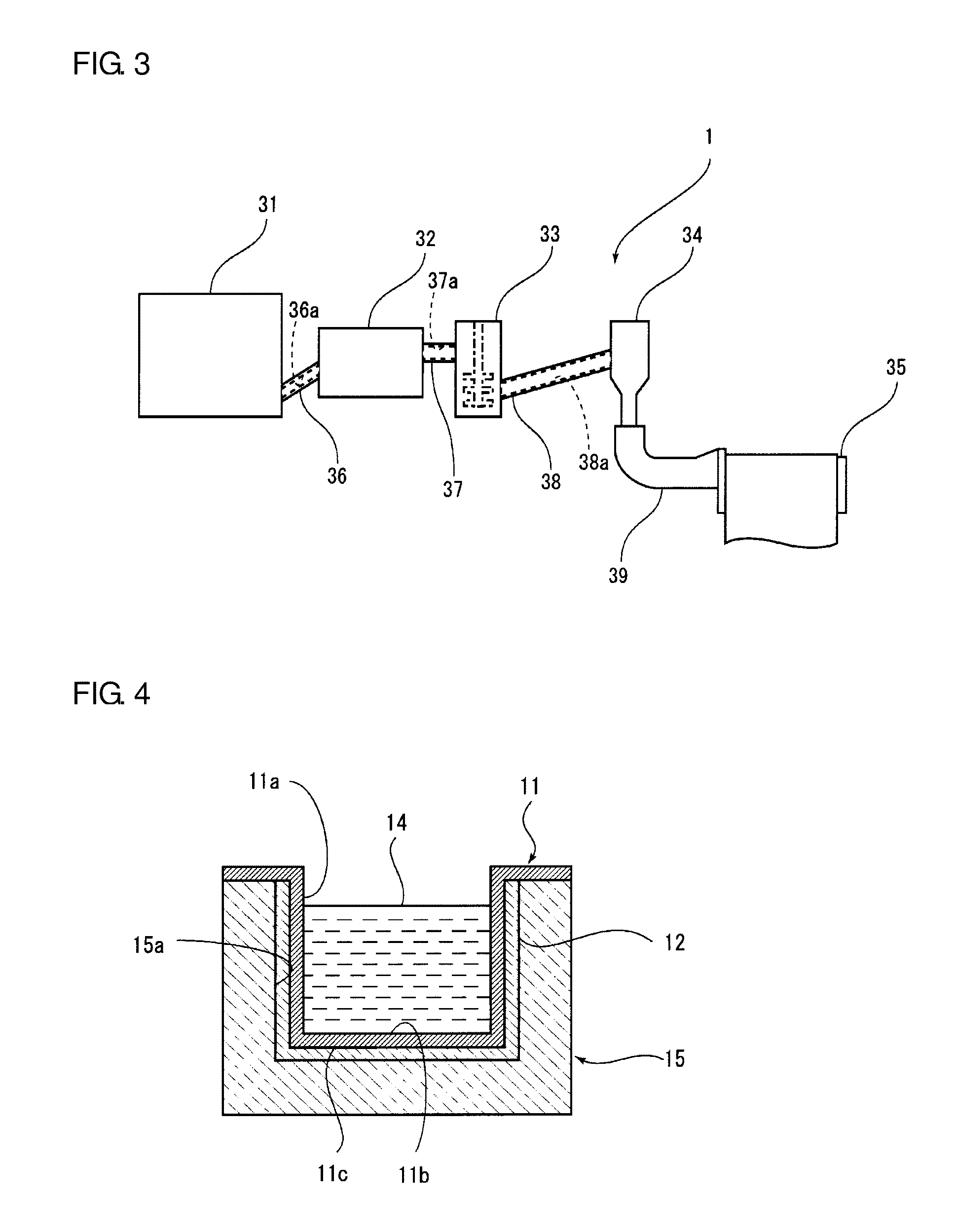

Container for evaporation of metal and method to manufacture thereof

A refractory container for evaporating metals, having improved useful life and corrosion resistance properties, the evaporation surface of the container having a plurality of grooves formed at the bottom surface. The grooves have either a depth of at least 1.2 mm, a width of at least 1.75 mm, or an interval spacing of at least 2.2 mm between adjacent grooves (or centers of adjacent grooves), and combinations thereof.

Owner:GENERAL ELECTRIC CO

Replacing method of blast furnace shell and water wall

ActiveCN101570802AQuick changeEasy to feedCooling devicesInternal formsWater coolingMaterials science

The invention discloses a rapid and efficient replacing method of a blast furnace shell and a water wall, which comprises the following steps: 1) installing support frames around the furnace body to prevent the furnace shell from sinking or slanting; 2) cutting the furnace shell which needs to be replaced, integratively removing the cut-out furnace shell and the water wall connected with the furnace shell; 3) installing a new furnace shell on the furnace body; and 4) after replacing the furnace shell, opening an inlet hole on the furnace shell, introducing the new water wall into the furnace body through the inlet hole and installing the new water wall on the inner wall of the furnace shell. The method directly and integratively removes the furnace shell and the water wall connected together and introduces the new water wall rapidly and conveniently into the furnace body, thus greatly shortening the repair and construction time, saving the use of mechanical devices and labor cost, and realizing rapid and efficient replacement of the blast furnace shell and water wall. The construction method of the invention in particular applies to small-sized blast furnaces with the volume of no more than 1000 cubic meters.

Owner:CHINA 19TH METALLURGICAL CORP

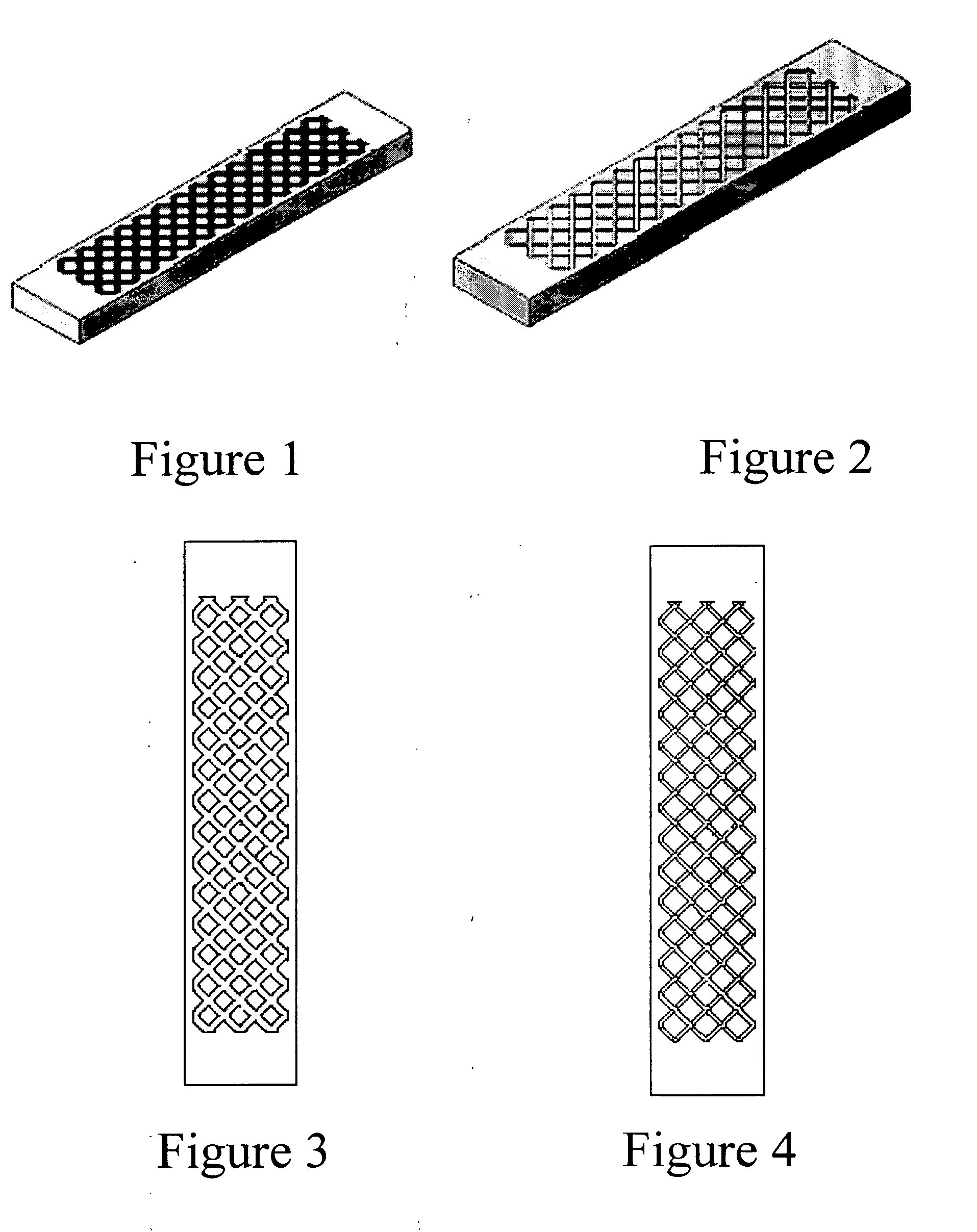

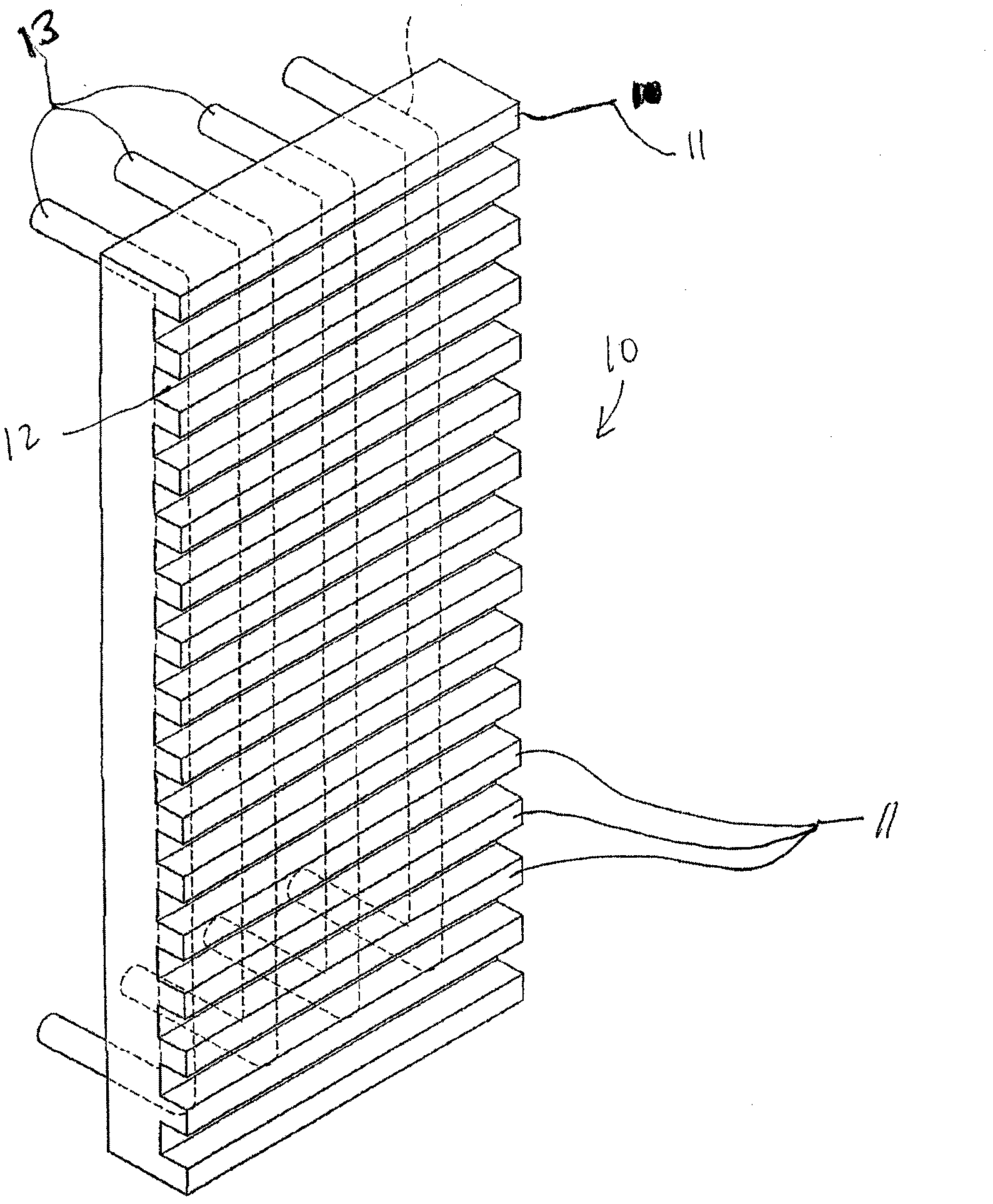

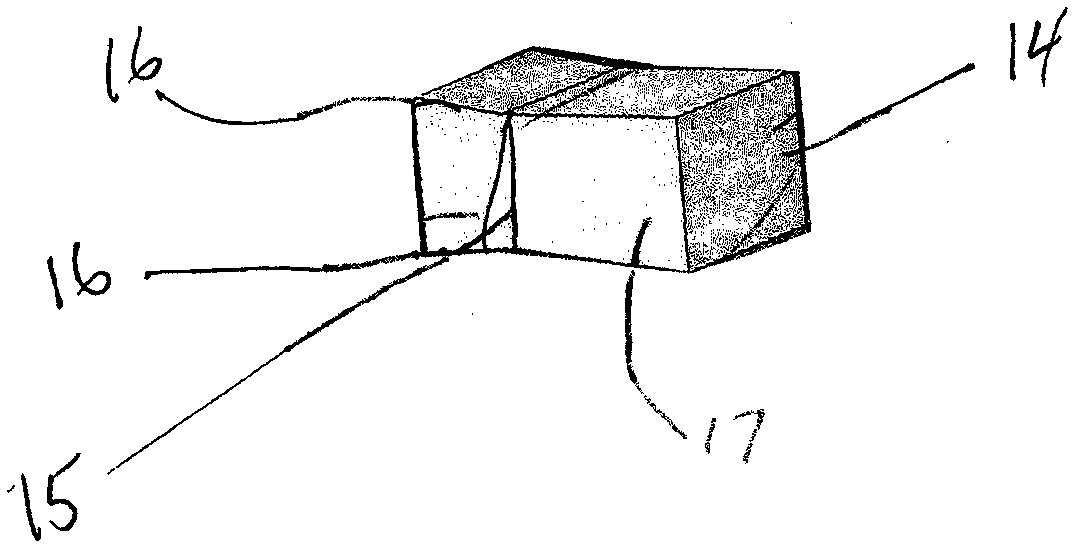

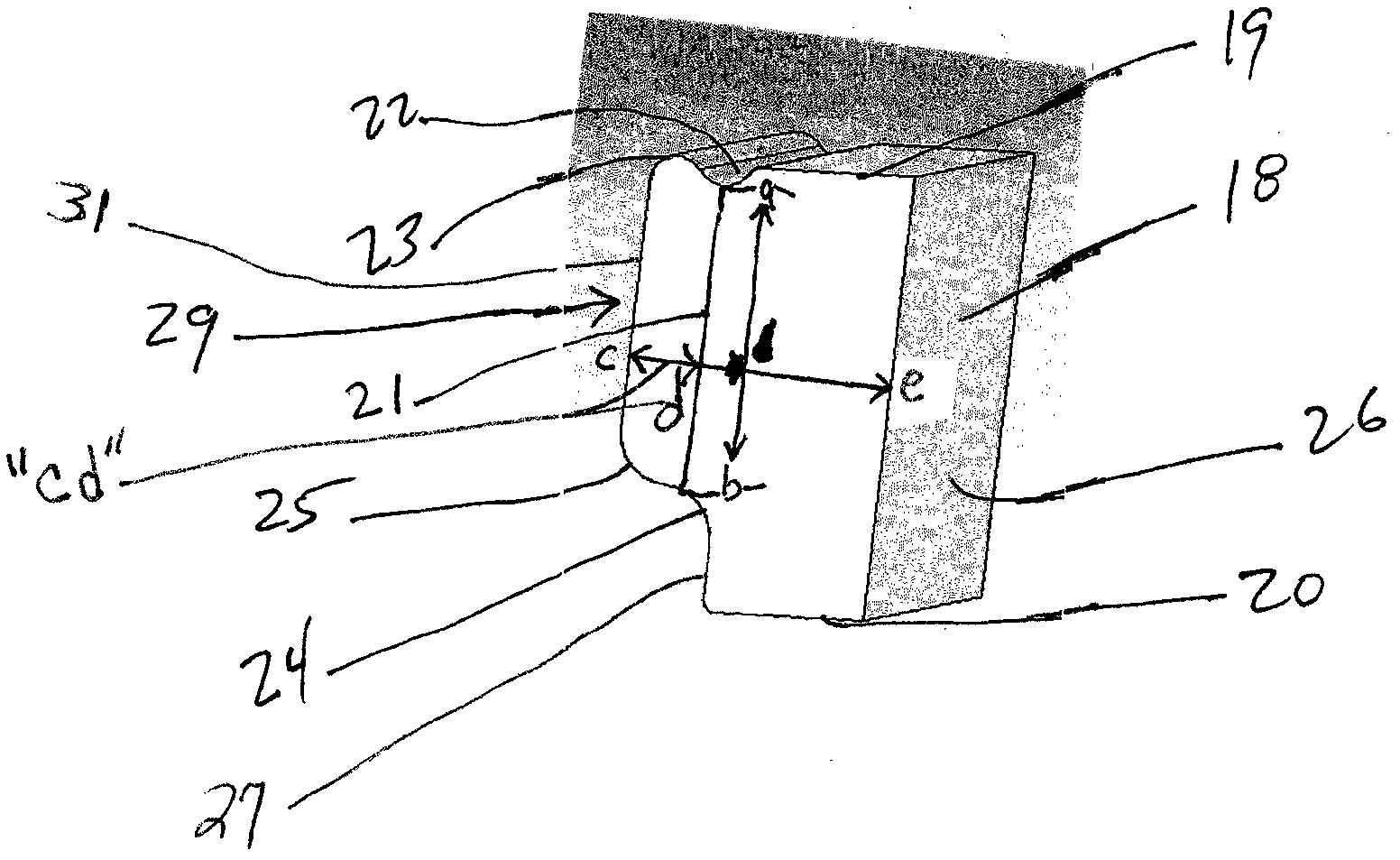

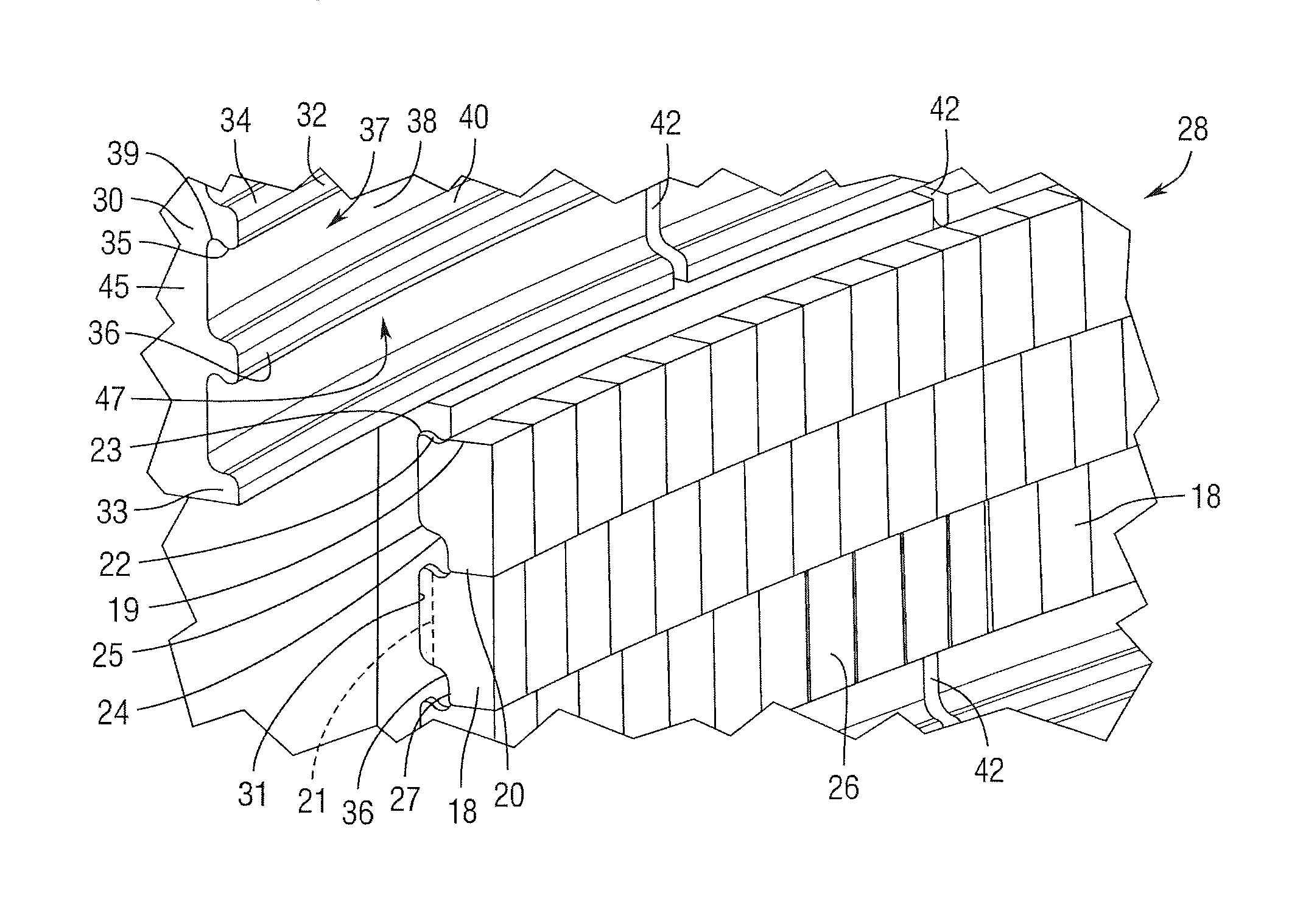

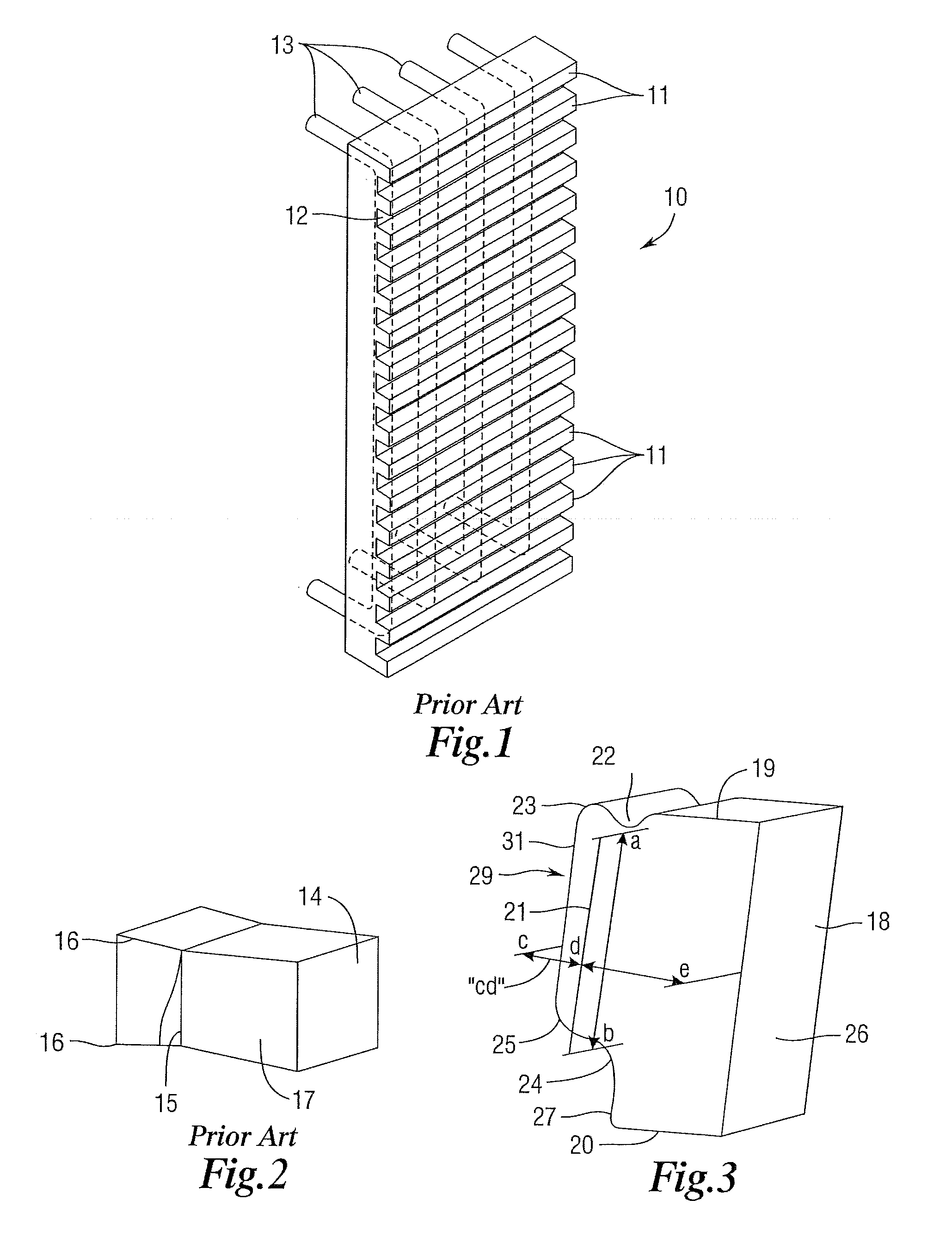

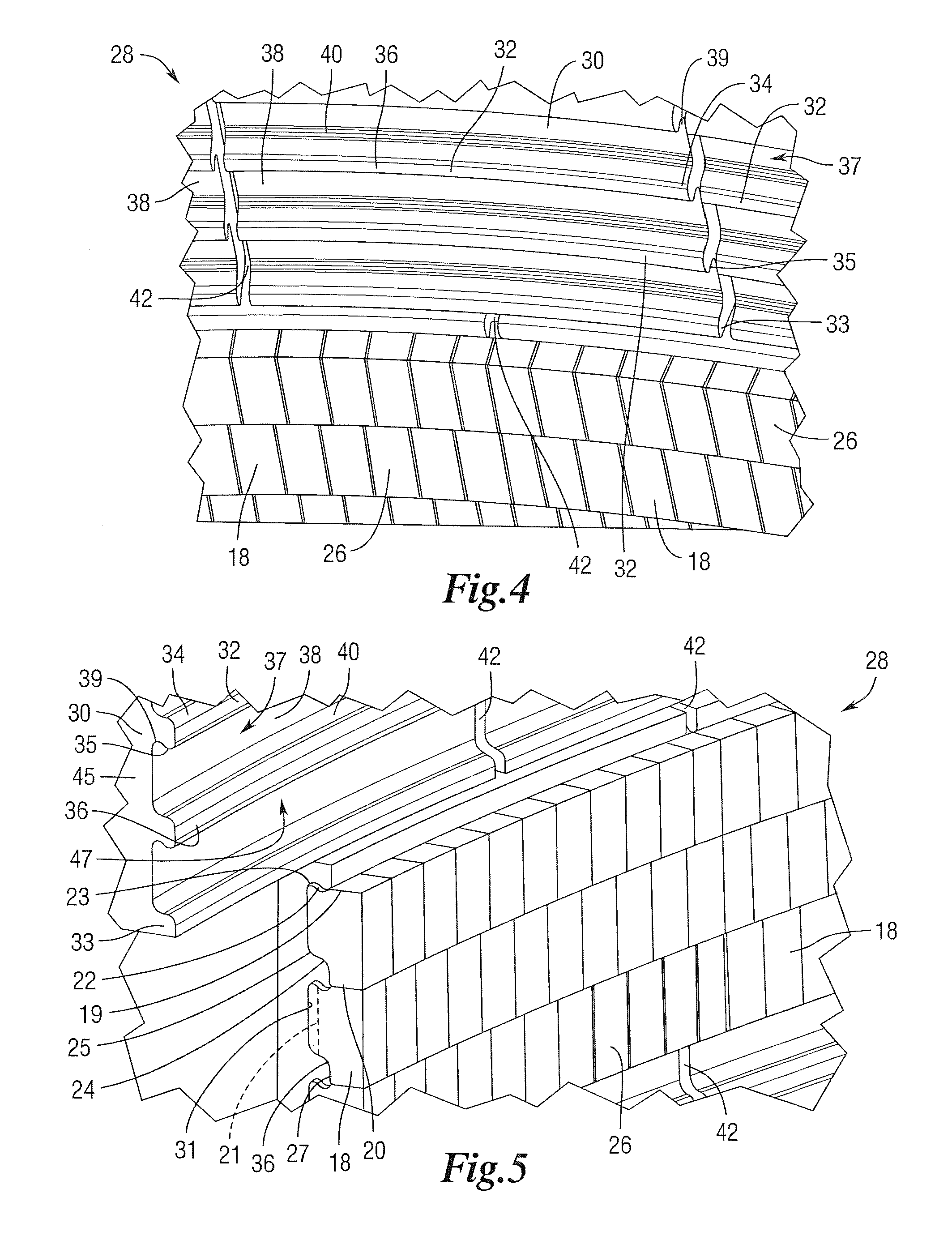

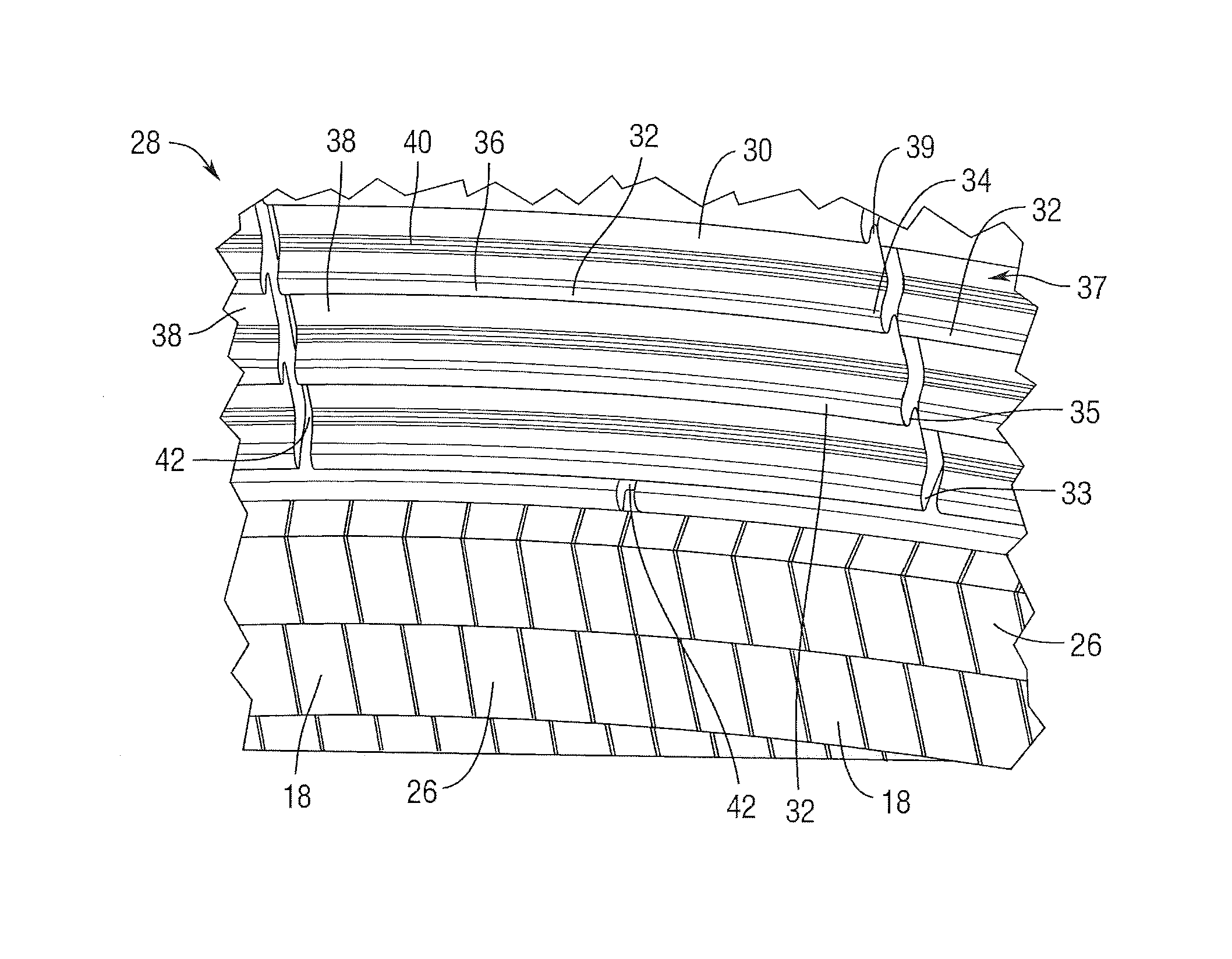

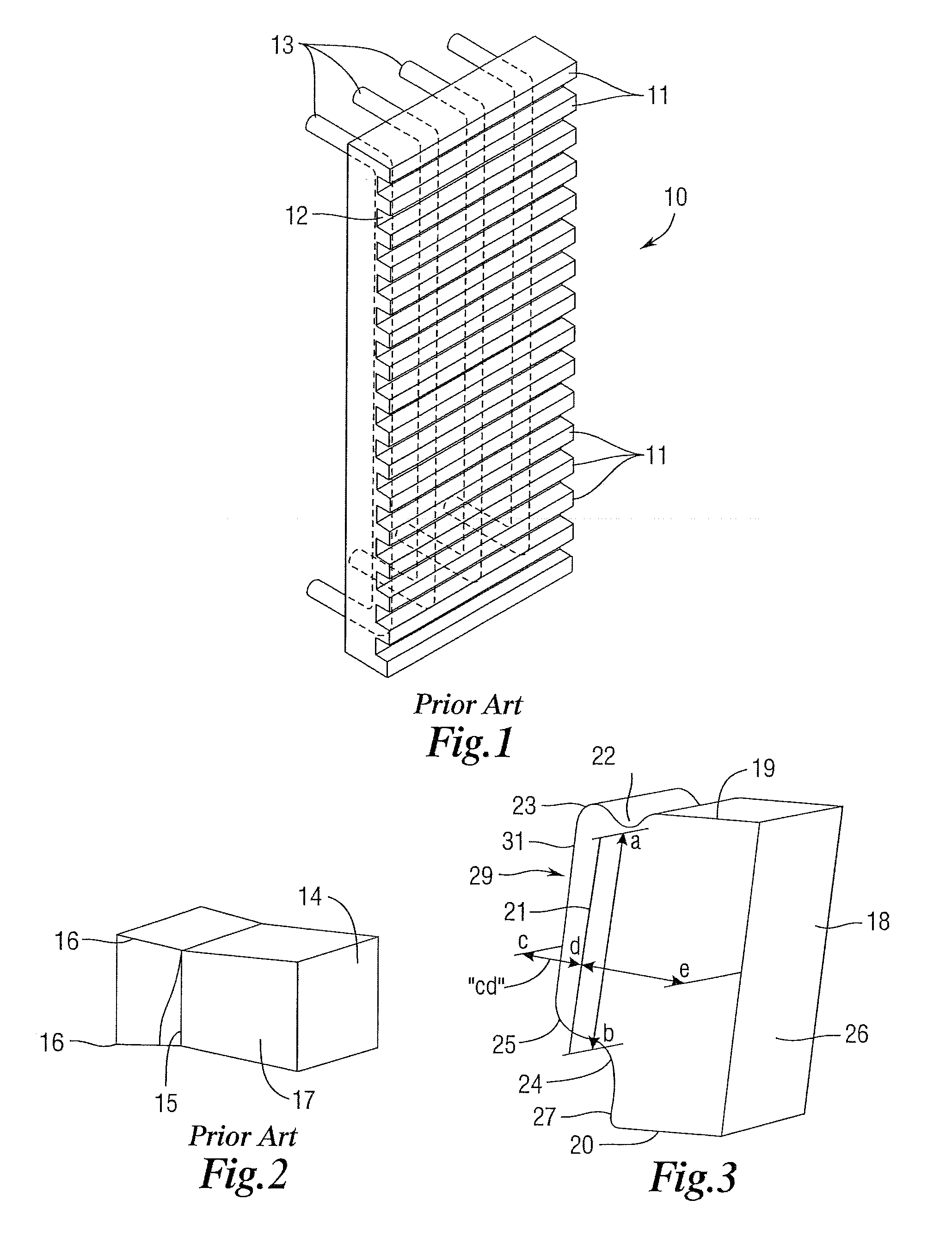

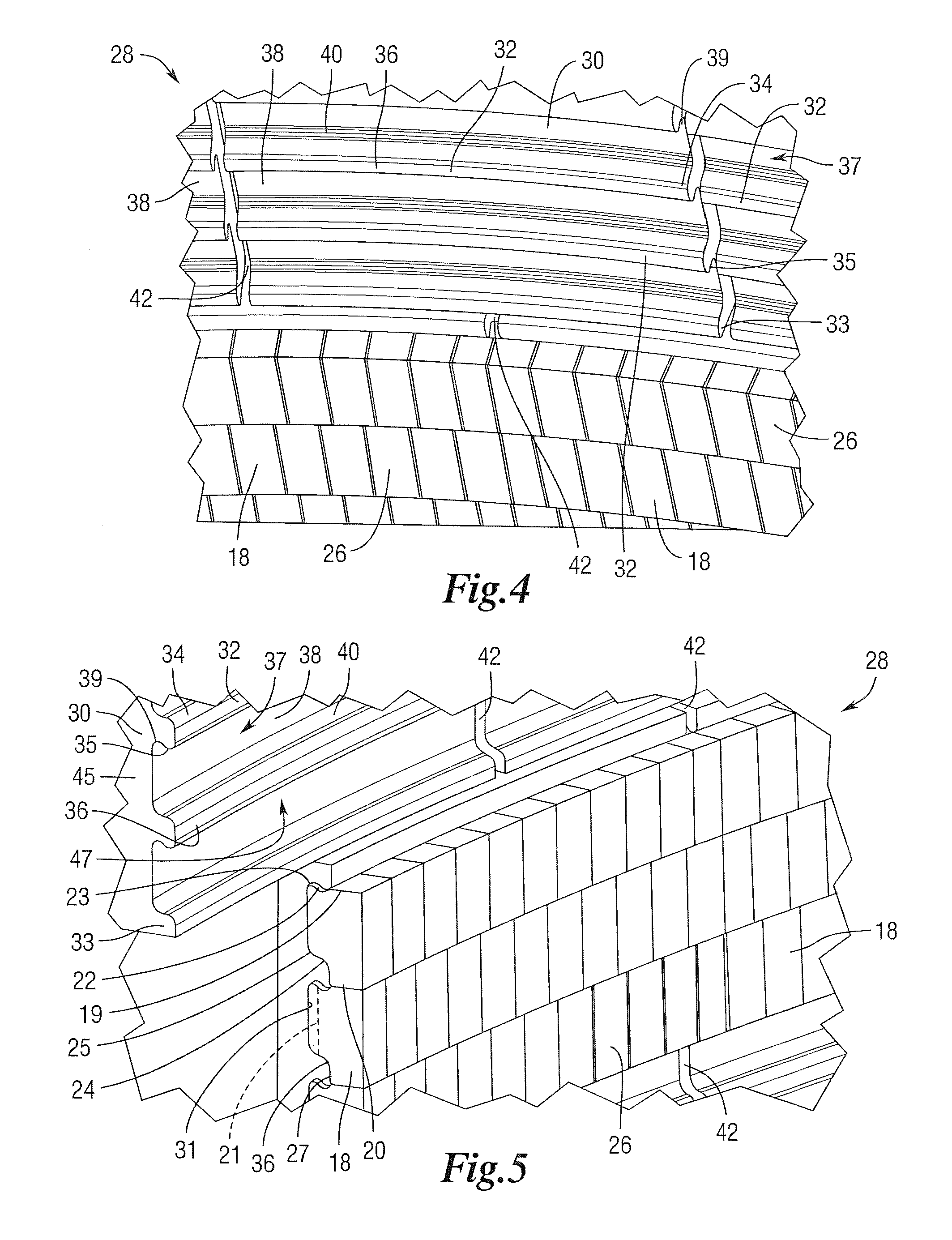

Apparatus and method for frame and brick constructions

A frame / brick and / or a stave / brick construction, having a frame having a plurality of ribs and a plurality of channels, wherein a front face of the frame defines a first opening into each of the channels, and a plurality of bricks wherein each brick is insertable into one of the plurality of channels via its first opening to a position, upon rotation of the brick, partially disposed in the one channel such that one or more portions of the brick at least partially engage one or more surfaces of the one channel and / or of a first rib of the plurality of ribs whereby the brick is locked against removal from the one channel through its first opening via linear movement without first being rotated.

Owner:BERRY METAL

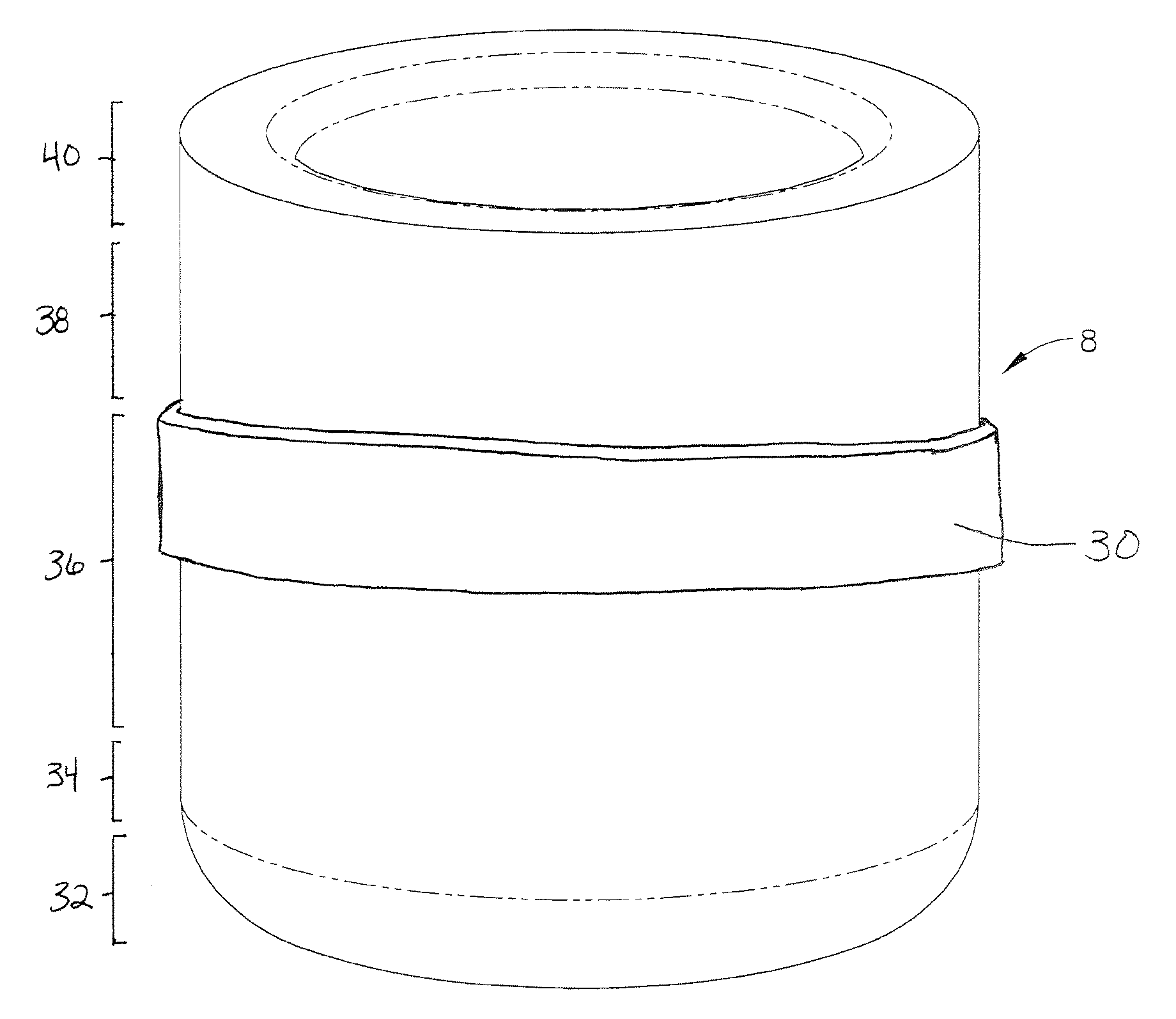

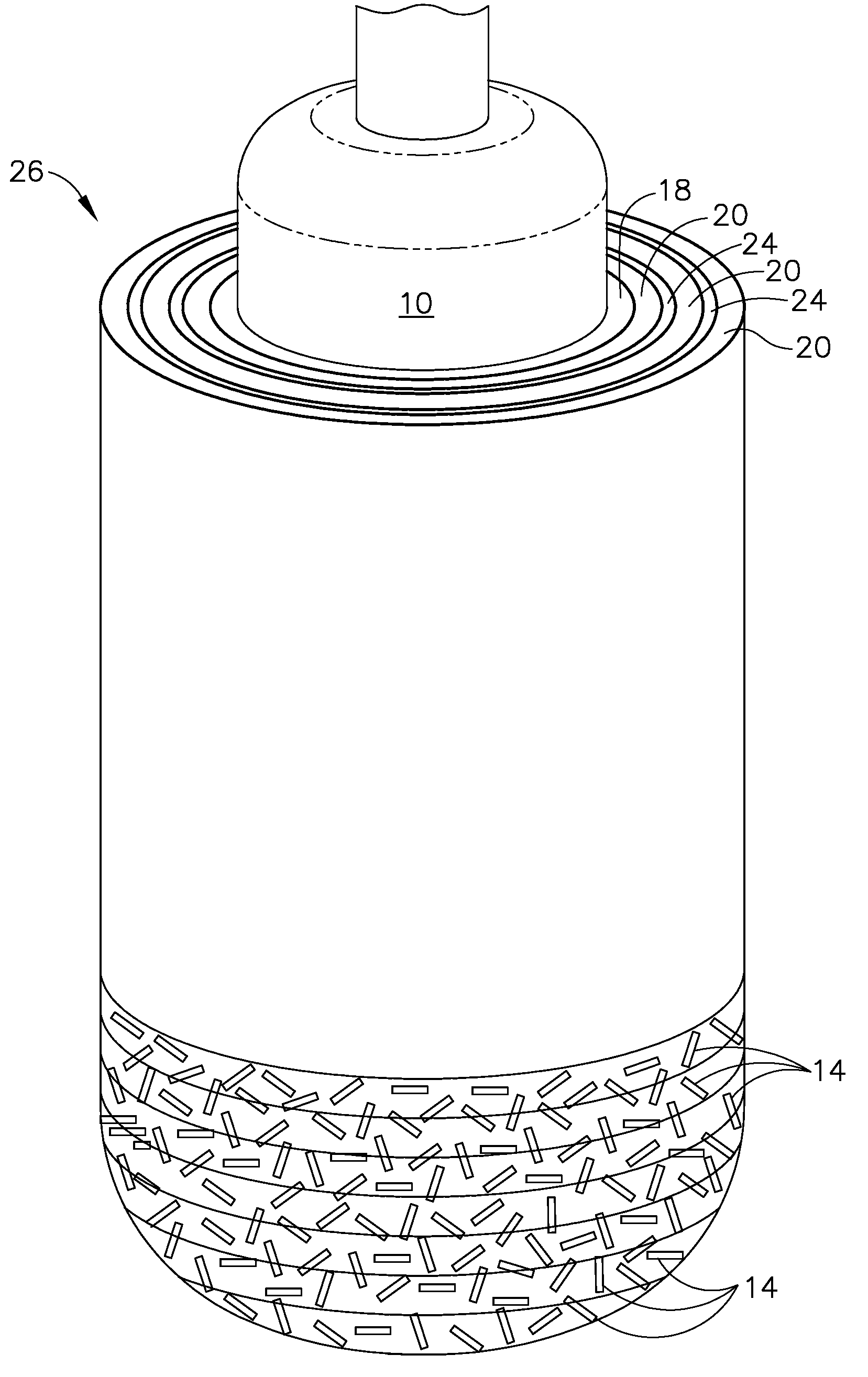

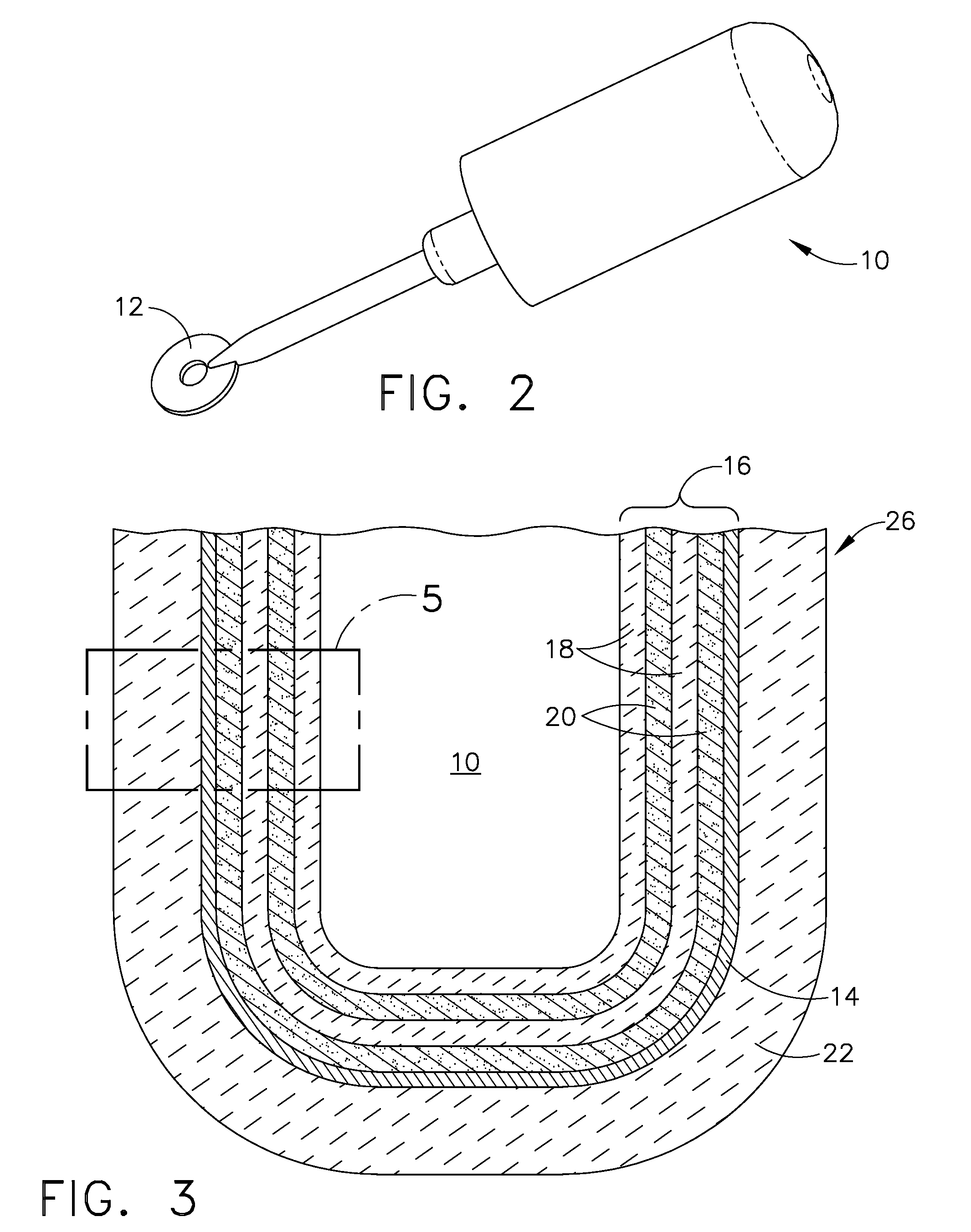

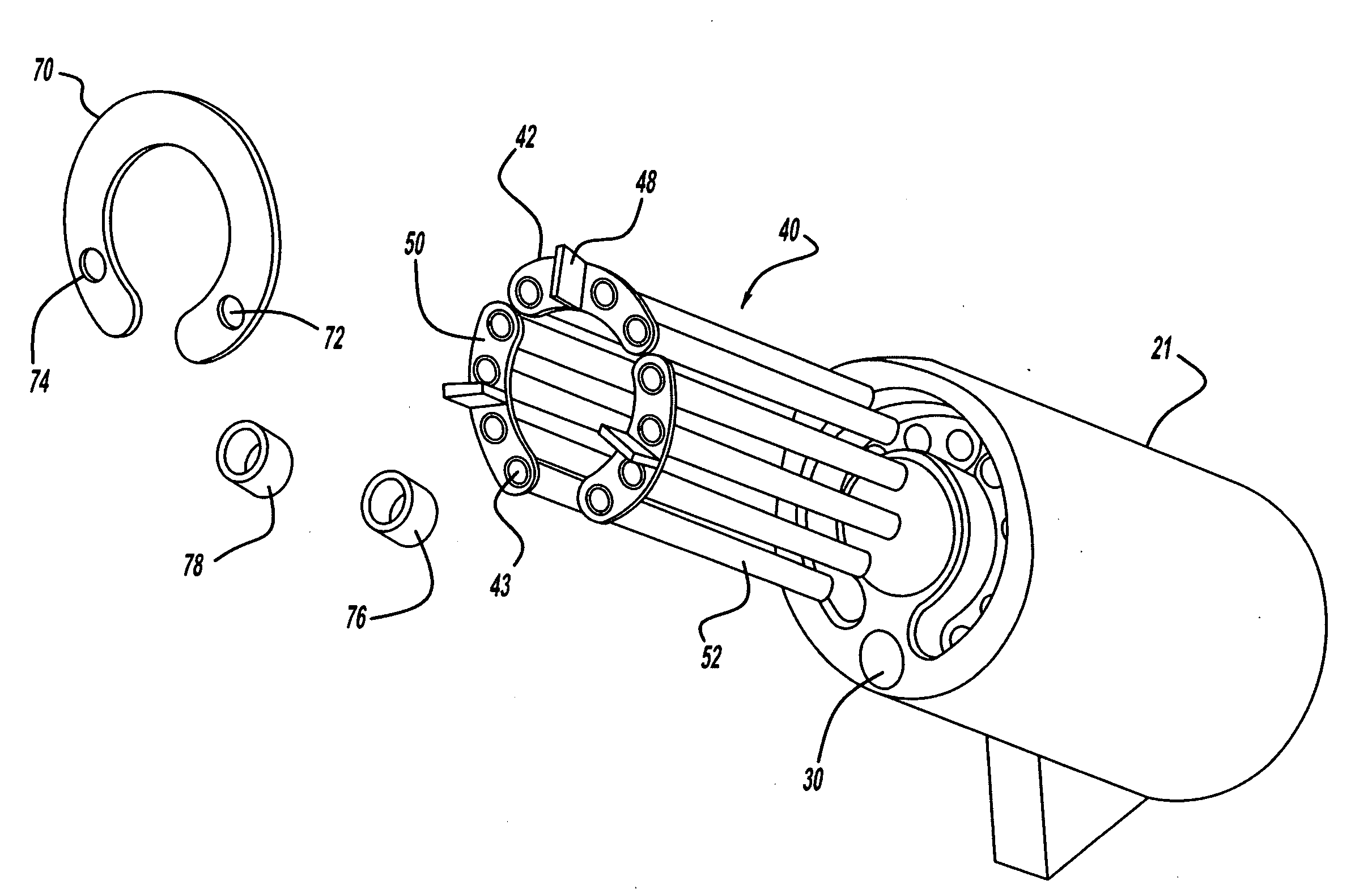

Refractory crucibles capable of managing thermal stress and suitable for melting highly reactive alloys

Refractory crucibles capable of managing thermal stress and suitable for melting highly reactive alloys having a facecoat, a backing, and at least one retaining ring applied about at least a portion of the backing of the crucible, the retaining ring comprising a composition selected from the group consisting of conductive materials, non-conductive materials, and combinations thereof.

Owner:GENERAL ELECTRIC CO

Apparatus and method for frame and brick constructions

A frame / brick and / or a stave / brick construction, having a frame having a plurality of ribs and a plurality of channels, wherein a front face of the frame defines a first opening into each of the channels, and a plurality of bricks wherein each brick is insertable into one of the plurality of channels via its first opening to a position, upon rotation of the brick, partially disposed in the one channel such that one or more portions of the brick at least partially engage one or more surfaces of the one channel and / or of a first rib of the plurality of ribs whereby the brick is locked against removal from the one channel through its first opening via linear movement without first being rotated.

Owner:BERRY METAL

Methods for making reinforced refractory crucibles for melting titanium alloys

Methods for making a reinforced refractory crucible for melting titanium alloys including providing a form, applying a facecoat to the form, the facecoat having at least one facecoat layer, applying a backing about the facecoat, the backing having at least one backing layer, applying at least one reinforcing element to at least a portion of the facecoat layer, the backing layer, or a combination thereof where the reinforcing element includes at least one composition selected from ceramic compositions, metallic compositions, and combinations thereof.

Owner:GENERAL ELECTRIC CO

SiC-C/C composite material, uses thereof, and method for producing the same

Provided are SiC-C / C composite materials which have such characteristics as a suitable kinetic coefficient of friction a corrosion resistance in strongly oxidizing and corrosive environment, a creep resistance, and a spalling resistance, a high hardness, and are hardly oxidized or abraded even when exposed to high temperatures with keeping the excellent impact resistance and light weight of the C / C composites. Furthermore, molten metal pumps are provided from which components do not dissolve into the molten metal even when used in molten metal and have sufficient thermal impact resistance and oxidation resistance. The SiC-C / C composite materials can be produced by a method comprising a step of heating a C / C composite and metallic silicon at high temperatures under reduced pressure with flowing an inert gas to grow silicon carbide and simultaneously filling metallic silicon into the remaining pores, a step of increasing the furnace inner pressure to about 1 atm. with or without cooling the furnace and further raising the furnace inner temperature to diffuse the produced silicon carbide or metallic silicon used for filling the pores into the C / C composite comprising carbon fibers and carbon component other than the carbon fibers from the matrix to react with these carbons, and at least the portions of the molten metal pumps contacting with molten metal are made of the SiC-C / C composite materials.

Owner:NGK INSULATORS LTD

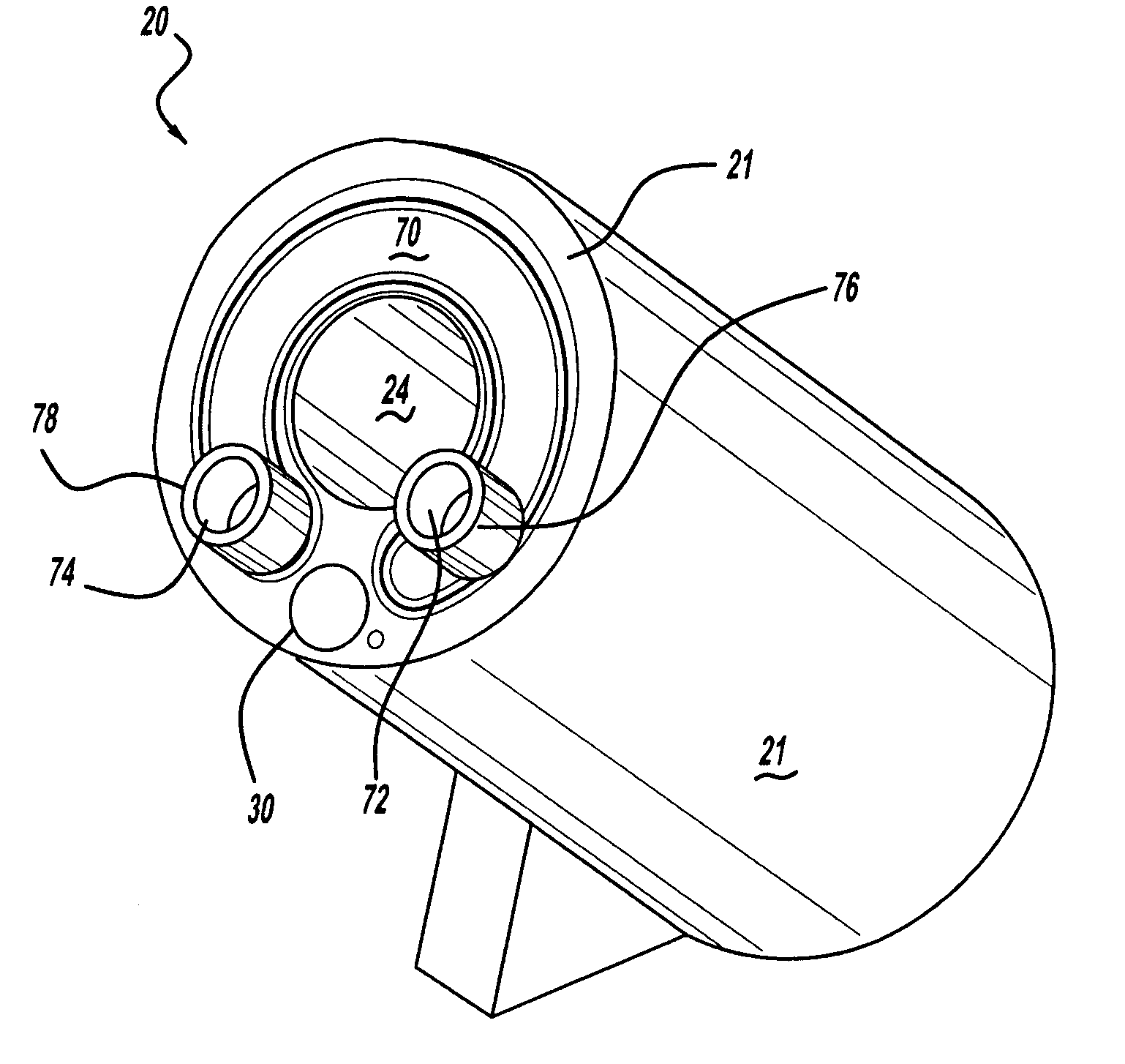

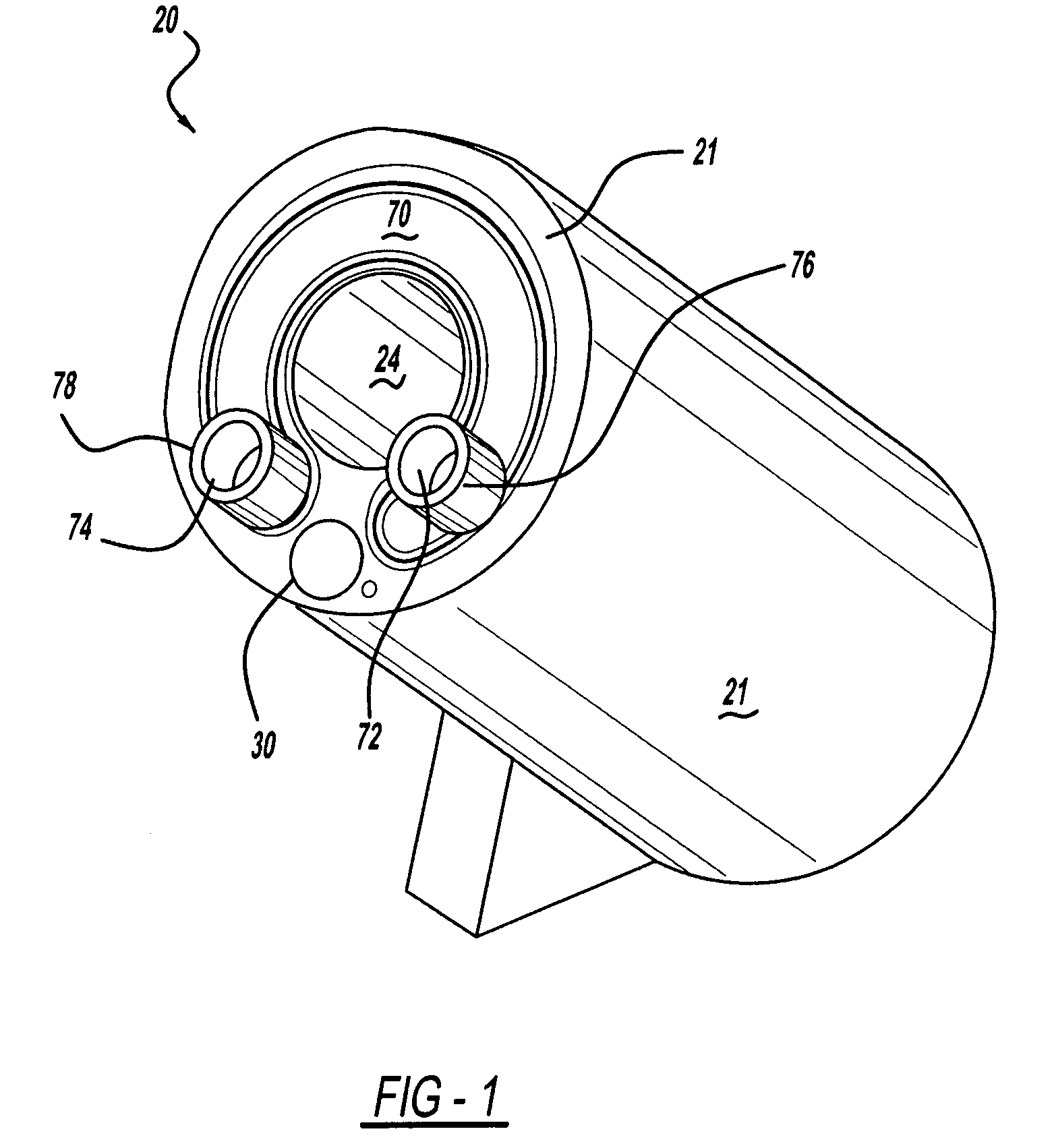

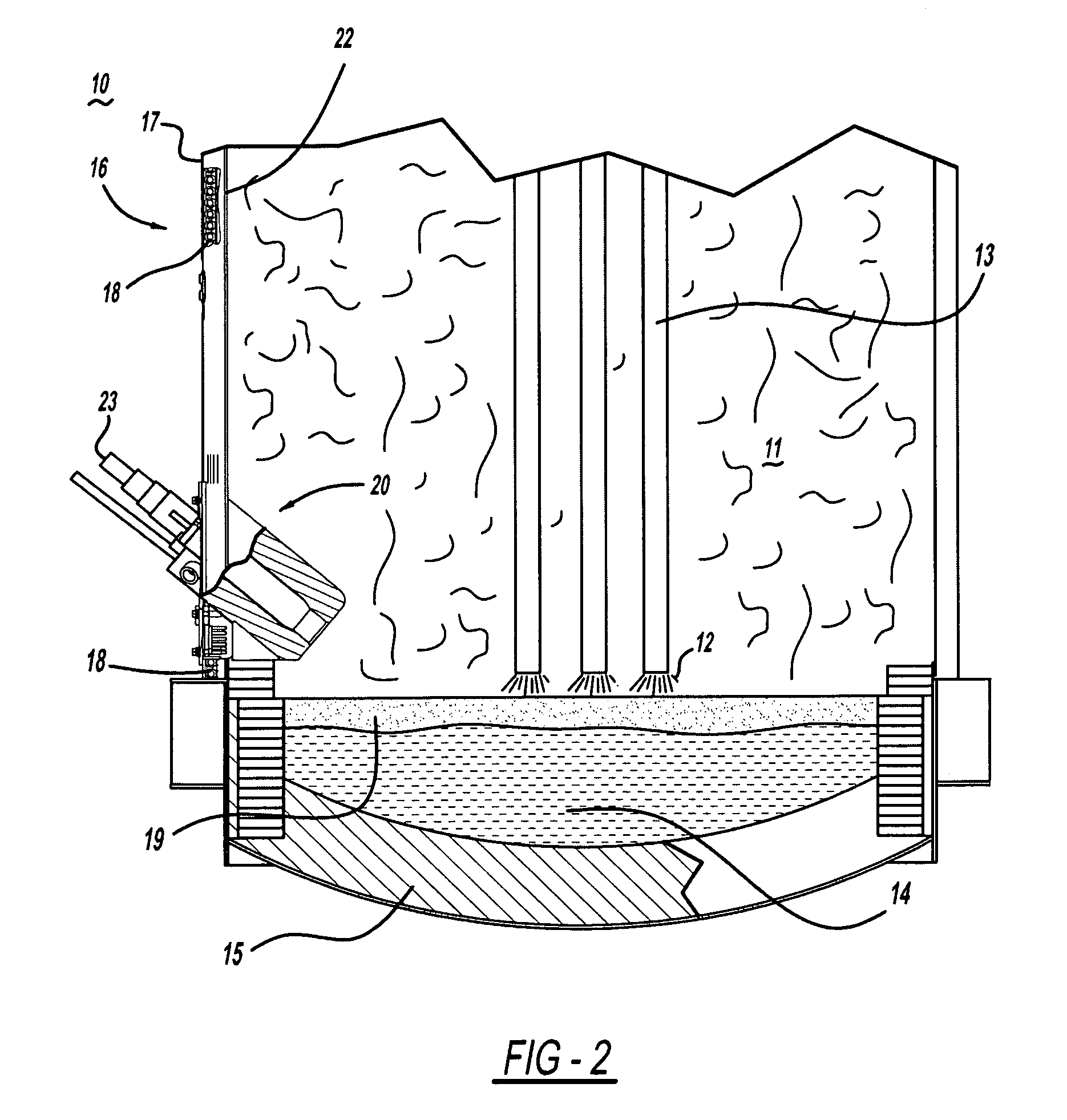

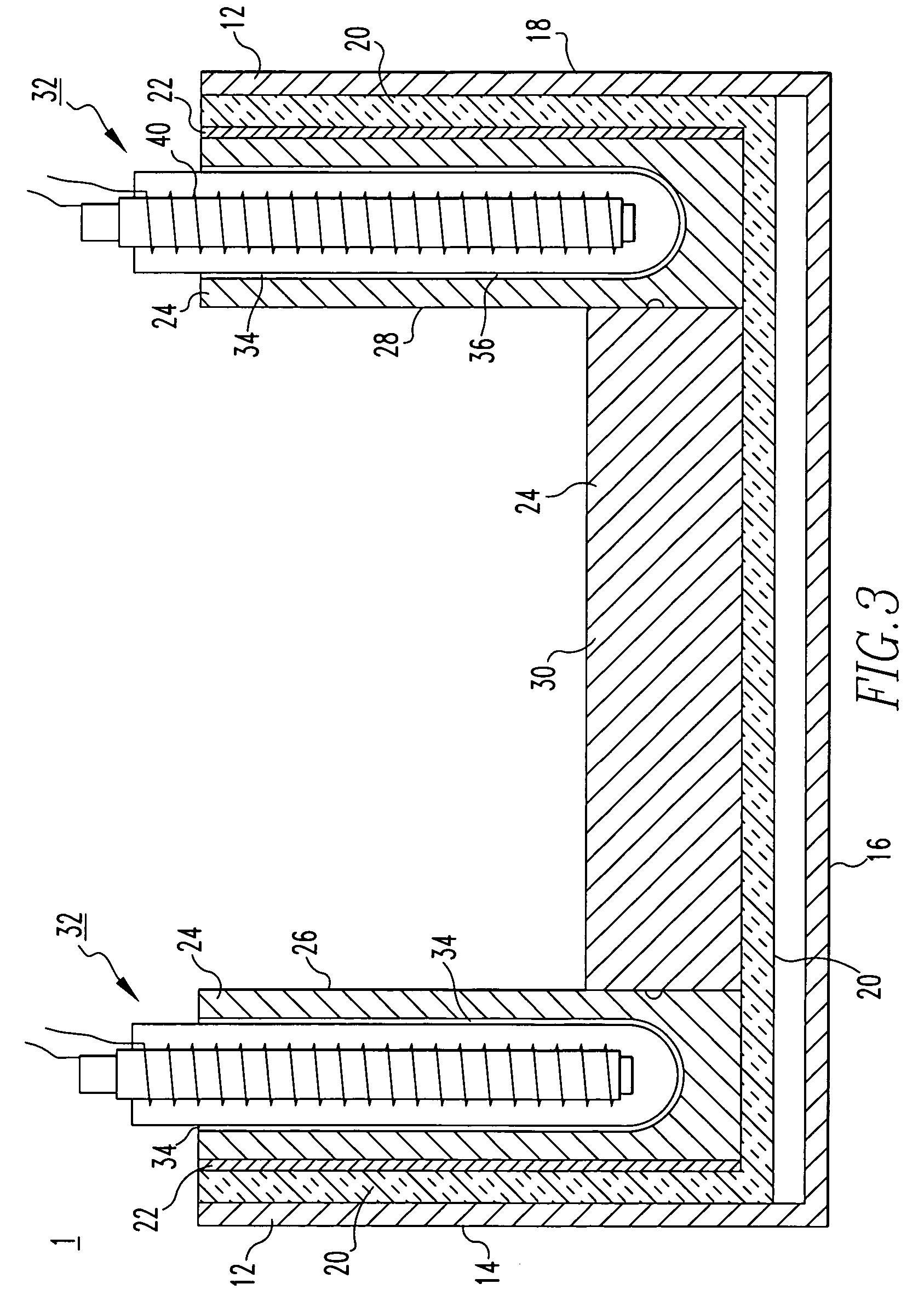

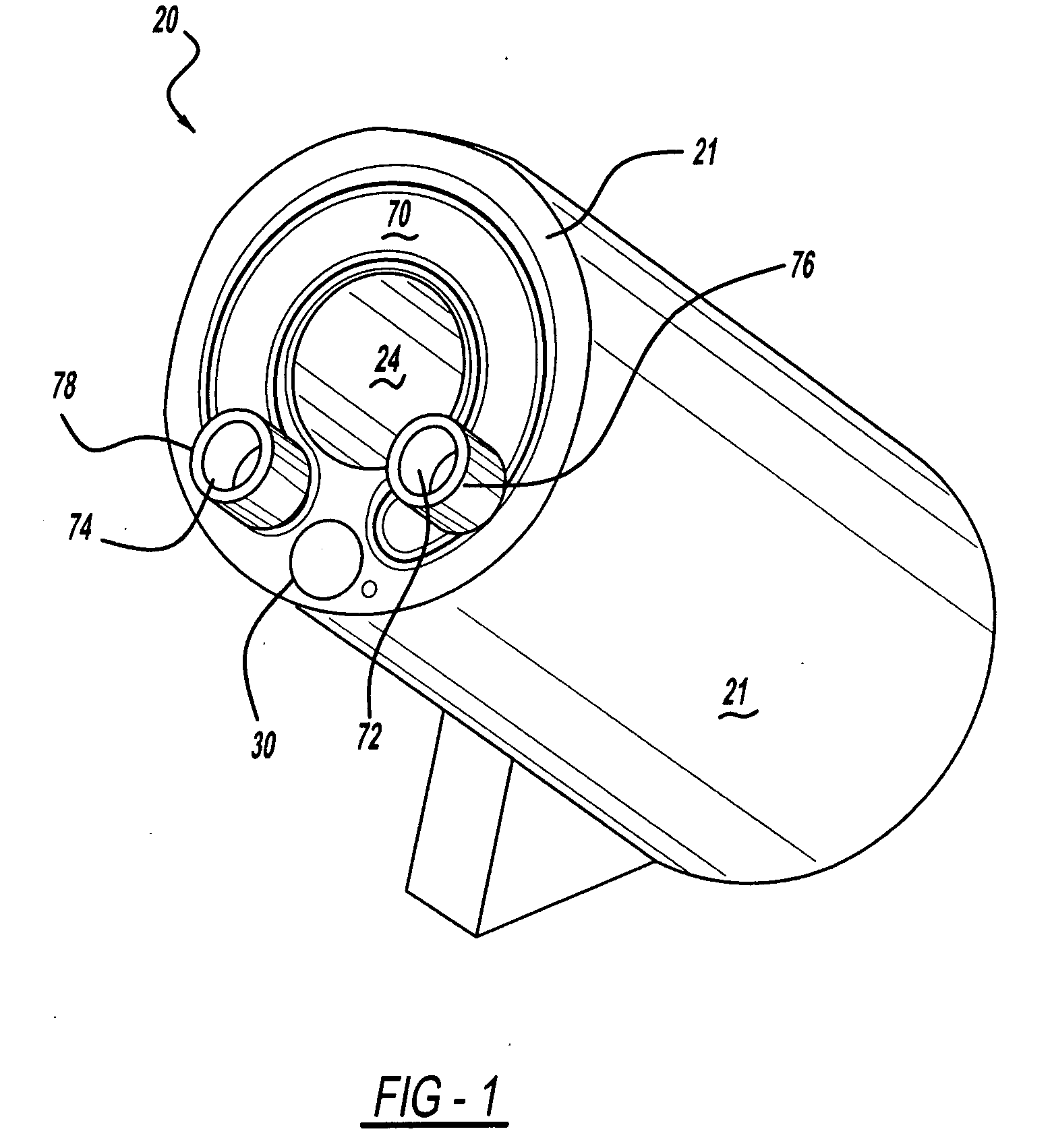

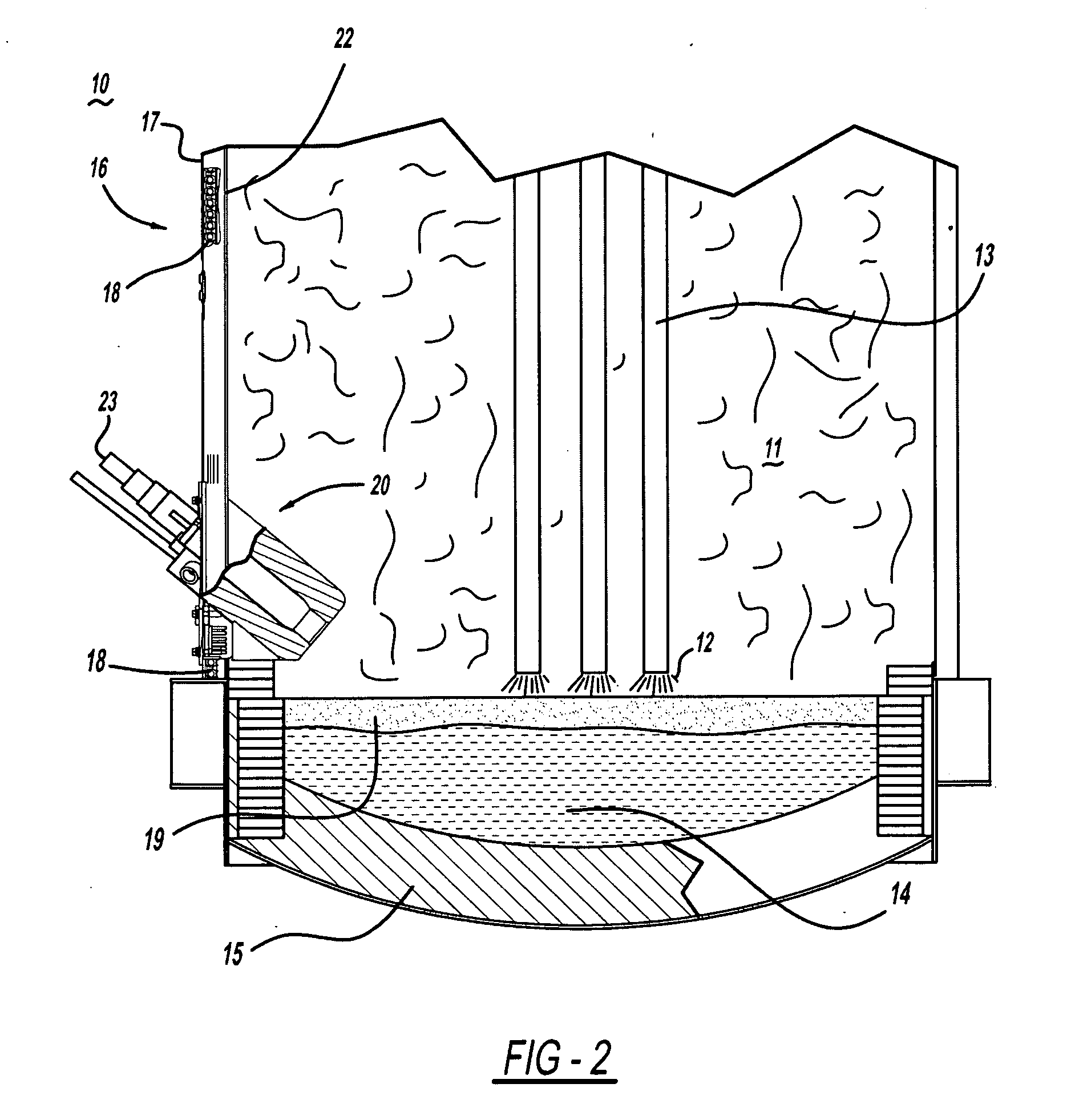

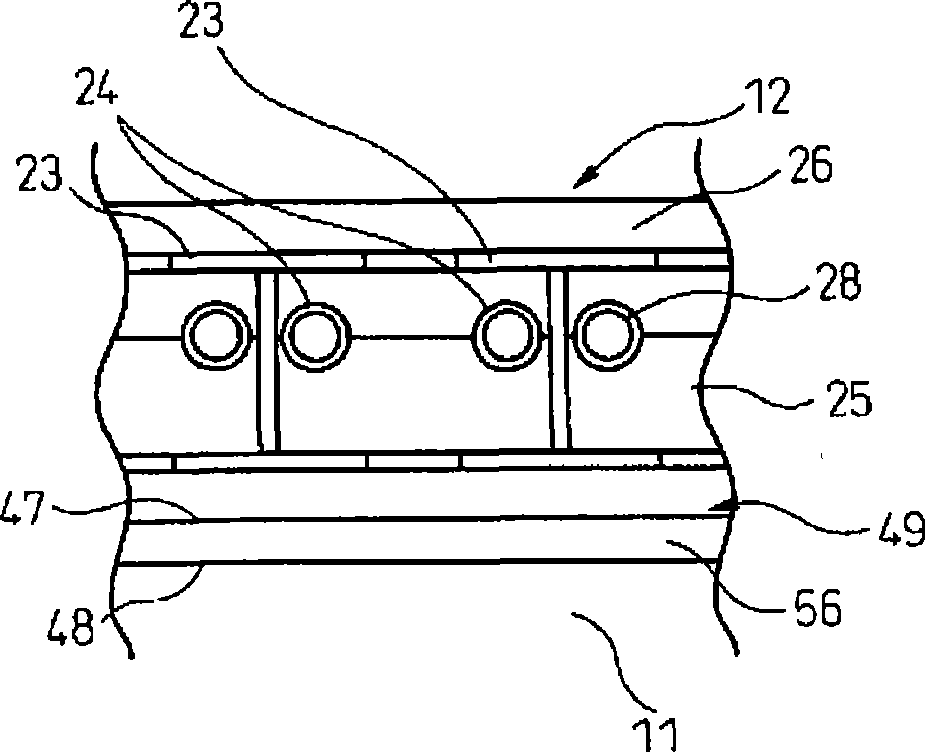

Forged copper burner enclosure

InactiveUS8142711B2Shorten the lengthNot prone to erosionFurnace componentsTuyeresParticulatesCombustor

A forged copper burner enclosure capable of being mounted within the side wall of a steel melting furnace for the purpose of providing an improved cooling characteristic to a burner lance. The burner enclosure is provided with a central passage adapted to receive a burner lance for injecting oxygen into the batch of molten metal of an electric arc furnace. The forged burner enclosure is positioned such that only a solid forged copper face is on the furnace side when installed. The burner enclosure has an optional through hole which can be used for the purpose of treating the metal melt with particulate supply ranging from slag forming materials to metallurgical materials. The burner enclosure further has a number of coolant holes and tubes which provide a unique bidirectional flow of cooling fluid through each hole and increases cooling fluid velocity while reducing stalling and hot spots of the cooling fluid thereby providing better heat transfer and physical characteristics over cast or weld-assembled burner enclosures.

Owner:NUCORE TECH

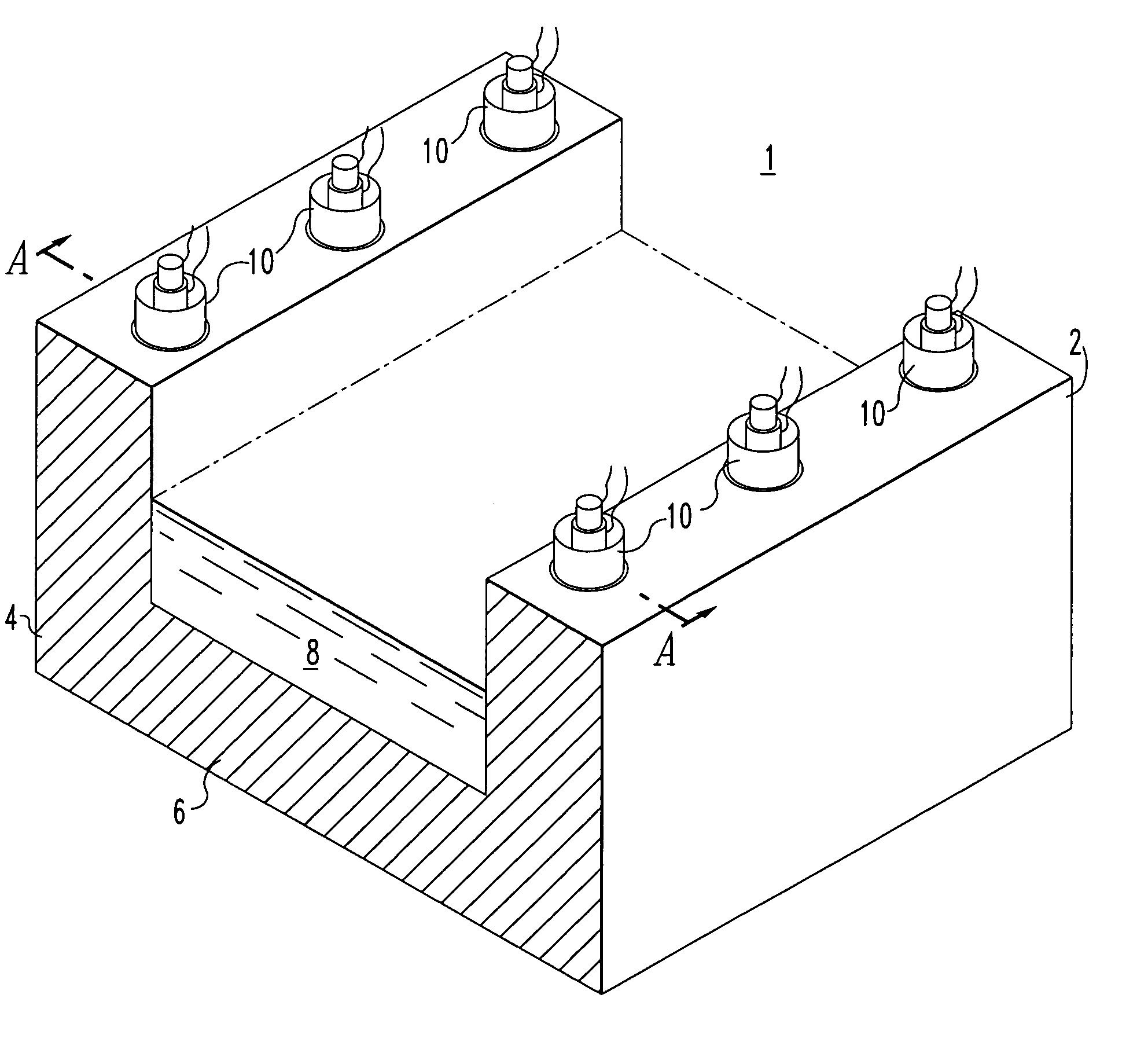

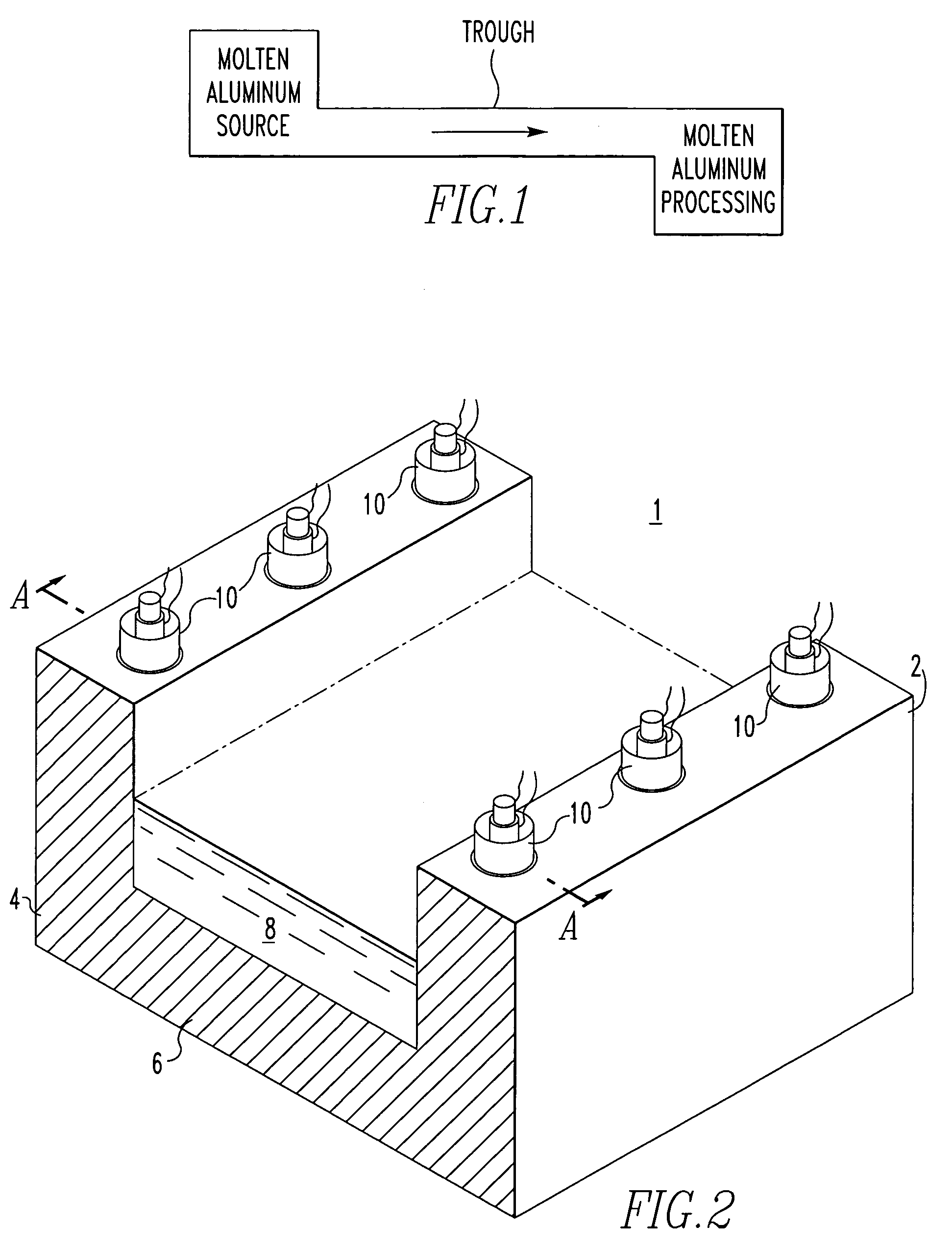

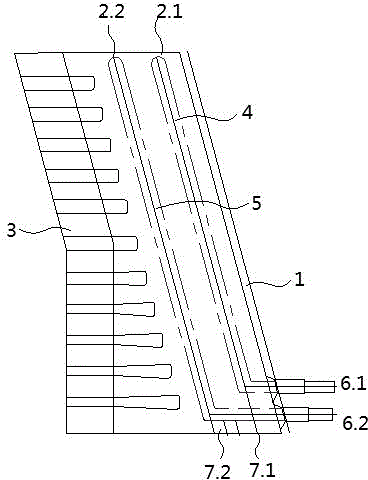

Heated trough for molten aluminum

InactiveUS7033538B2Improved refractory troughingBlast furnace detailsCharge manipulationMulliteBoron nitride

A method of heating molten aluminum flowing in a heated trough member comprising the steps of providing a source of molten aluminum and providing a rough member comprised of a first side and a second side, the first and the second sides having outside surfaces, the sides formed from a ceramic material resistant to attack by molten aluminum. The first side and second side have heating element receptacles provided therein with protection tubes provided in the receptacles. The protection tubes are comprised of a refractory selected from the group consisting of mullite, boron nitride, silicon nitride, silicon carbide, graphite, silicon aluminum oxynitride or a metal selected from Kovar® and titanium. Electric heating elements are positioned in the tubes. Molten aluminum is flowed along the trough member from the source and electric power is passed to the heating elements to heat the molten aluminum as it flows along the trough member.

Owner:ECKERT C EDWARD

Apparatus and method for frame and brick constructions

Owner:BERRY METAL

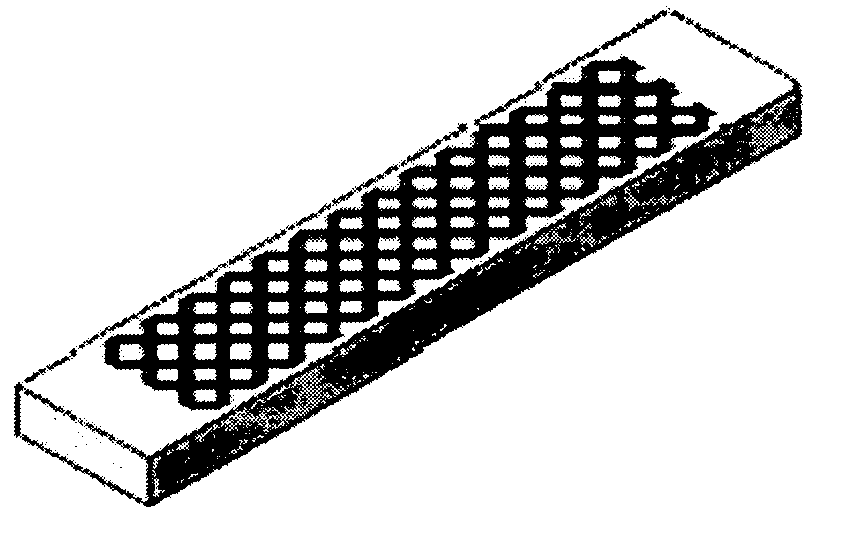

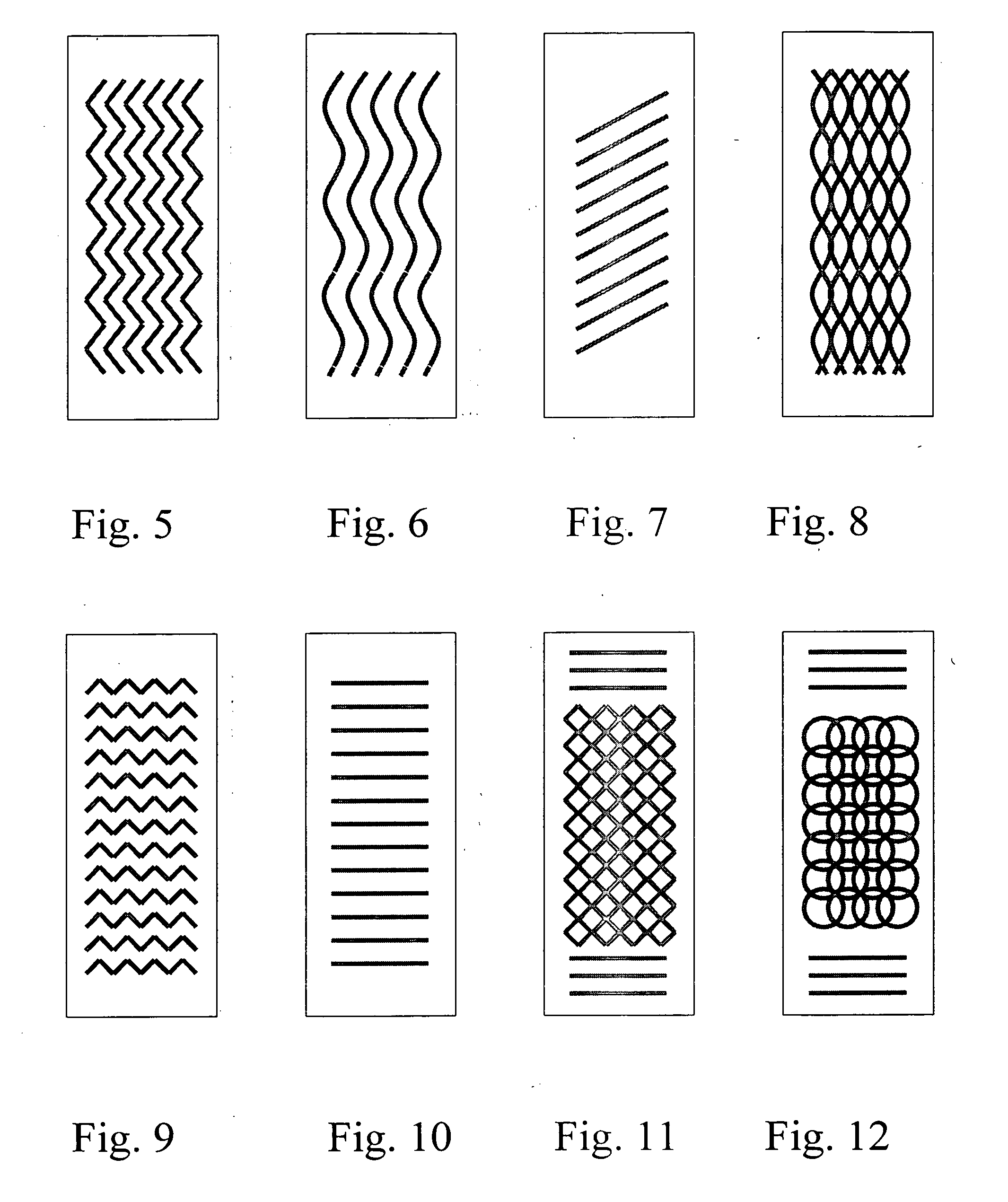

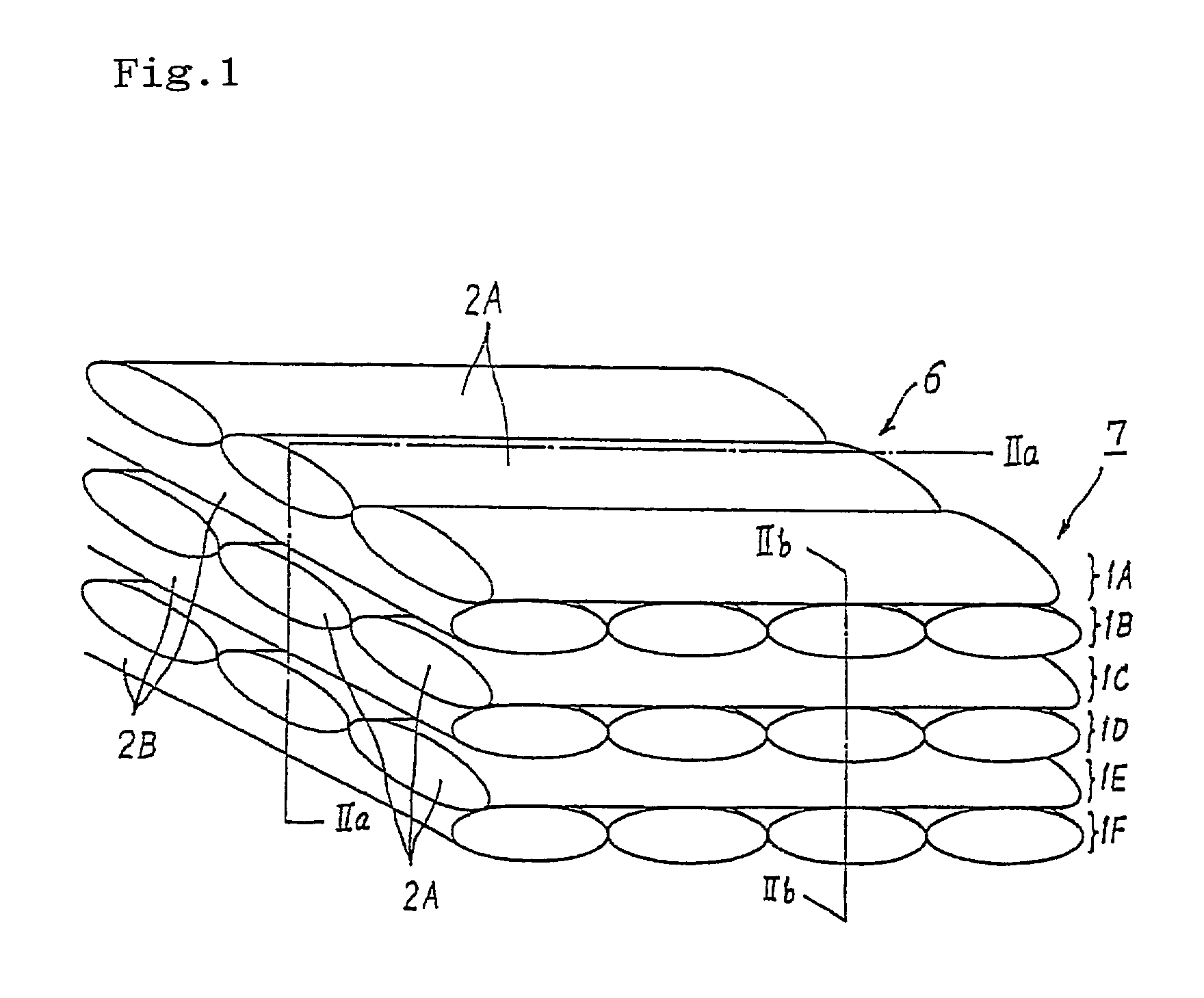

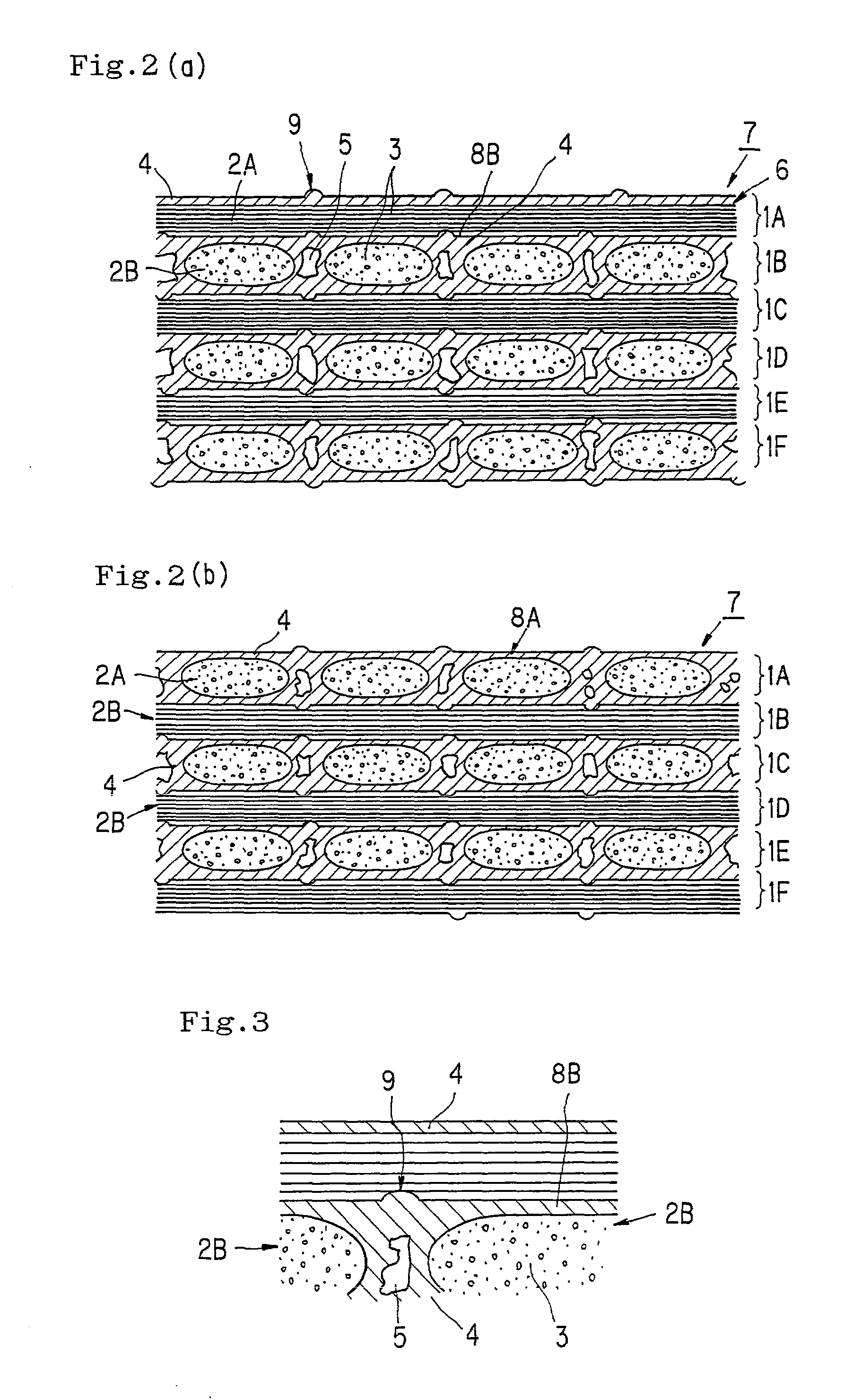

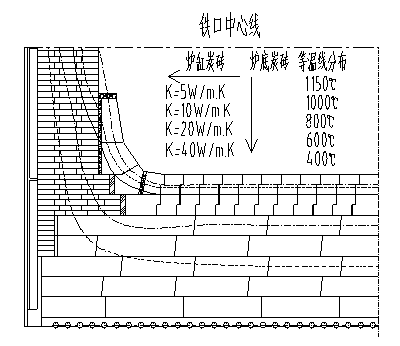

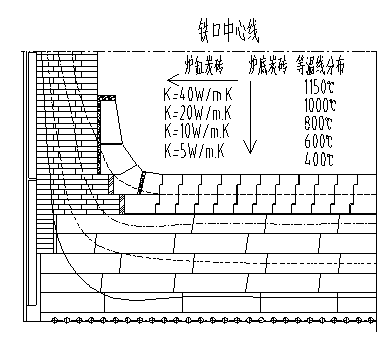

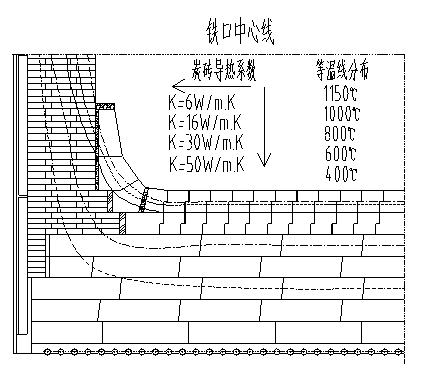

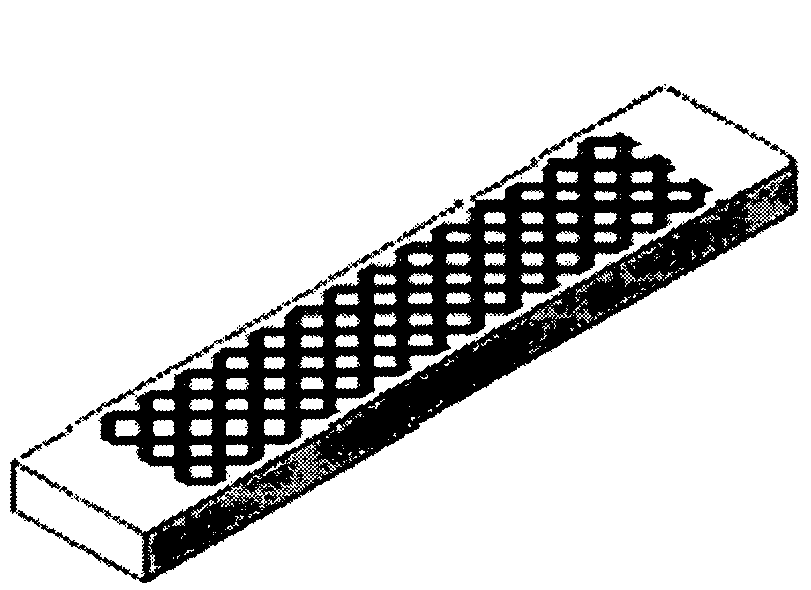

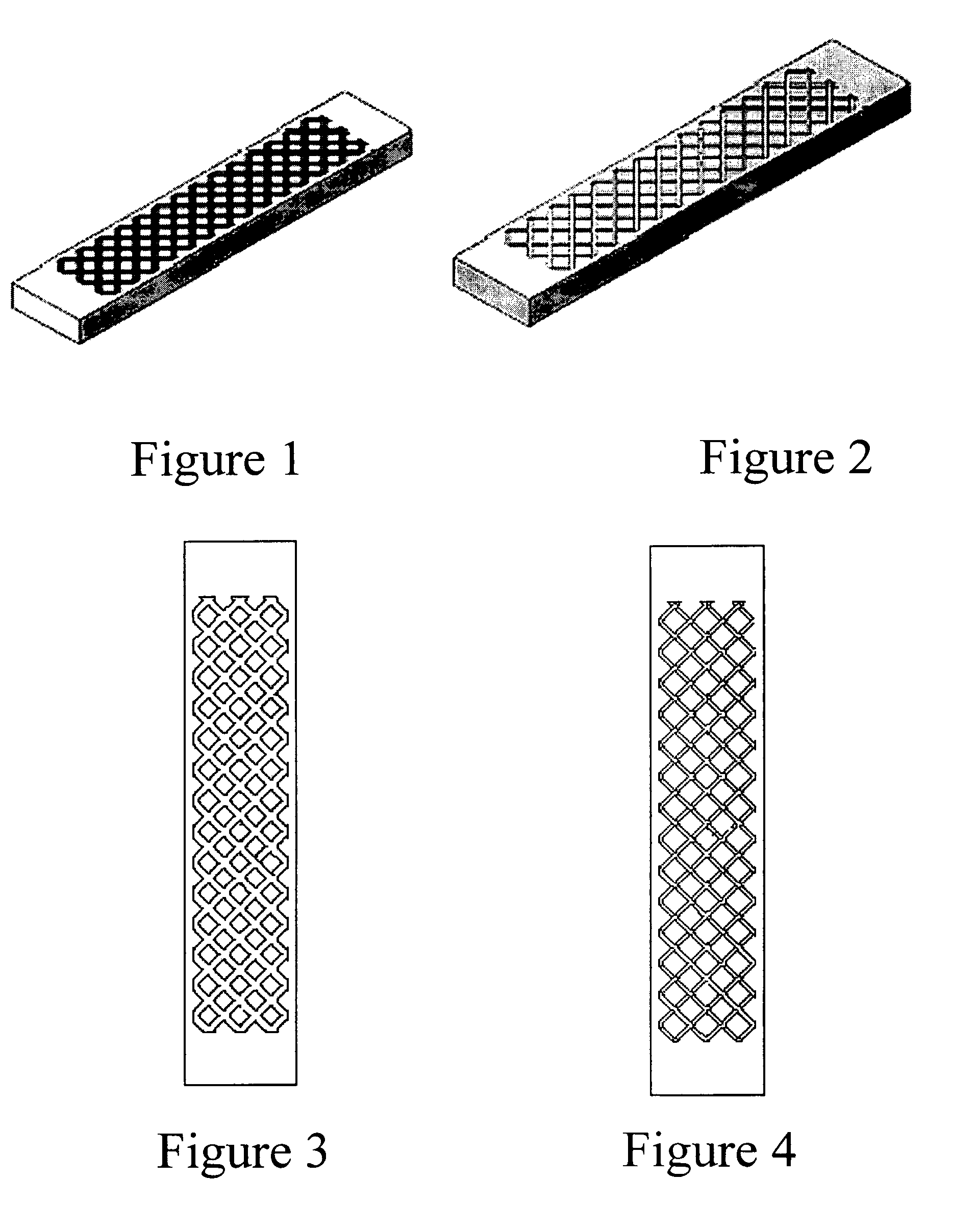

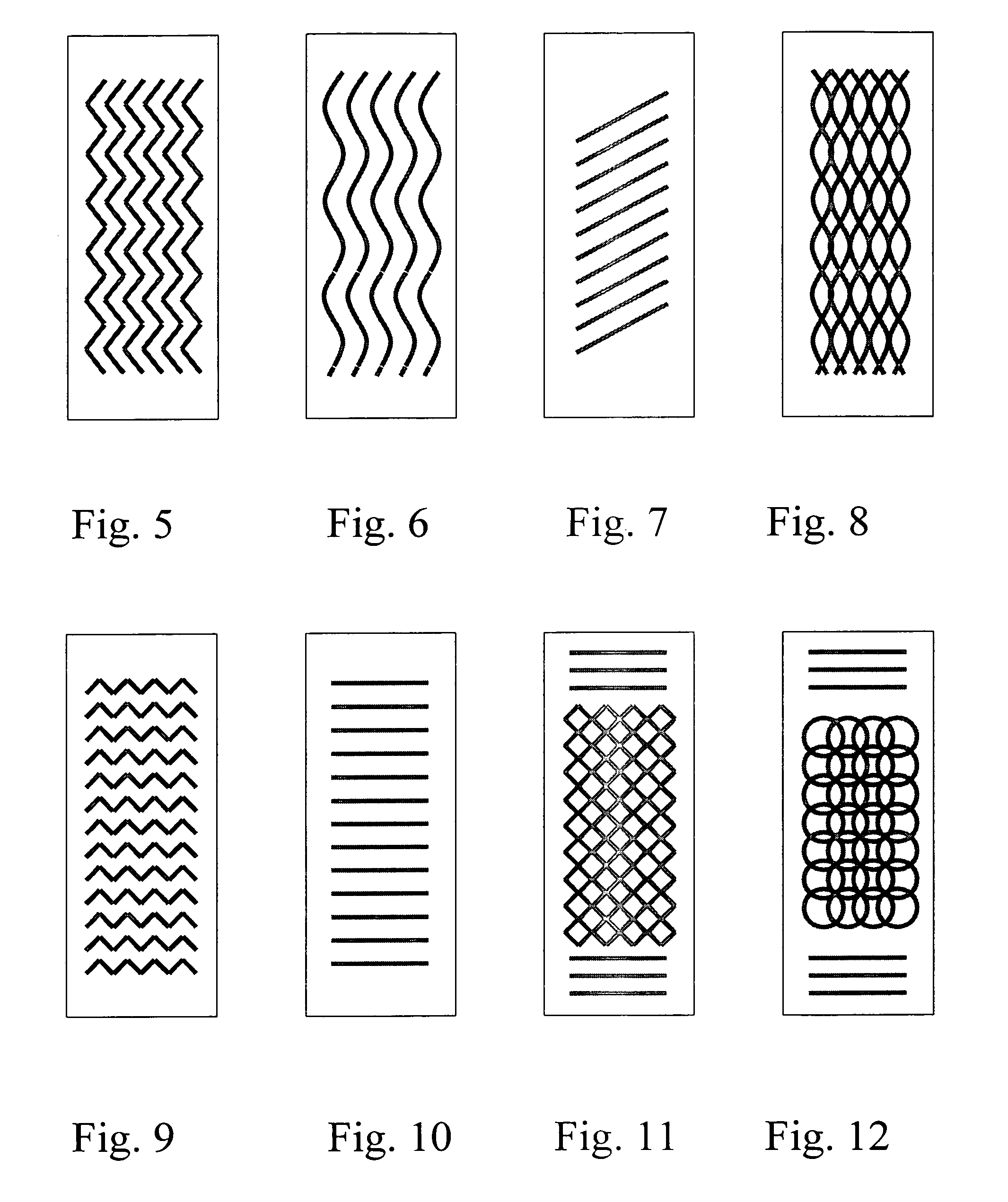

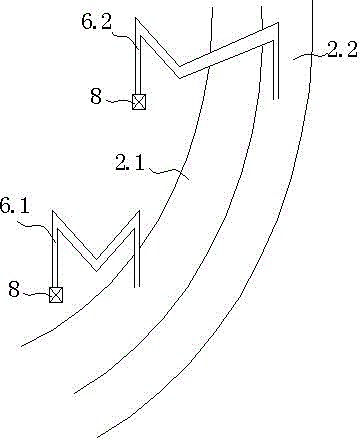

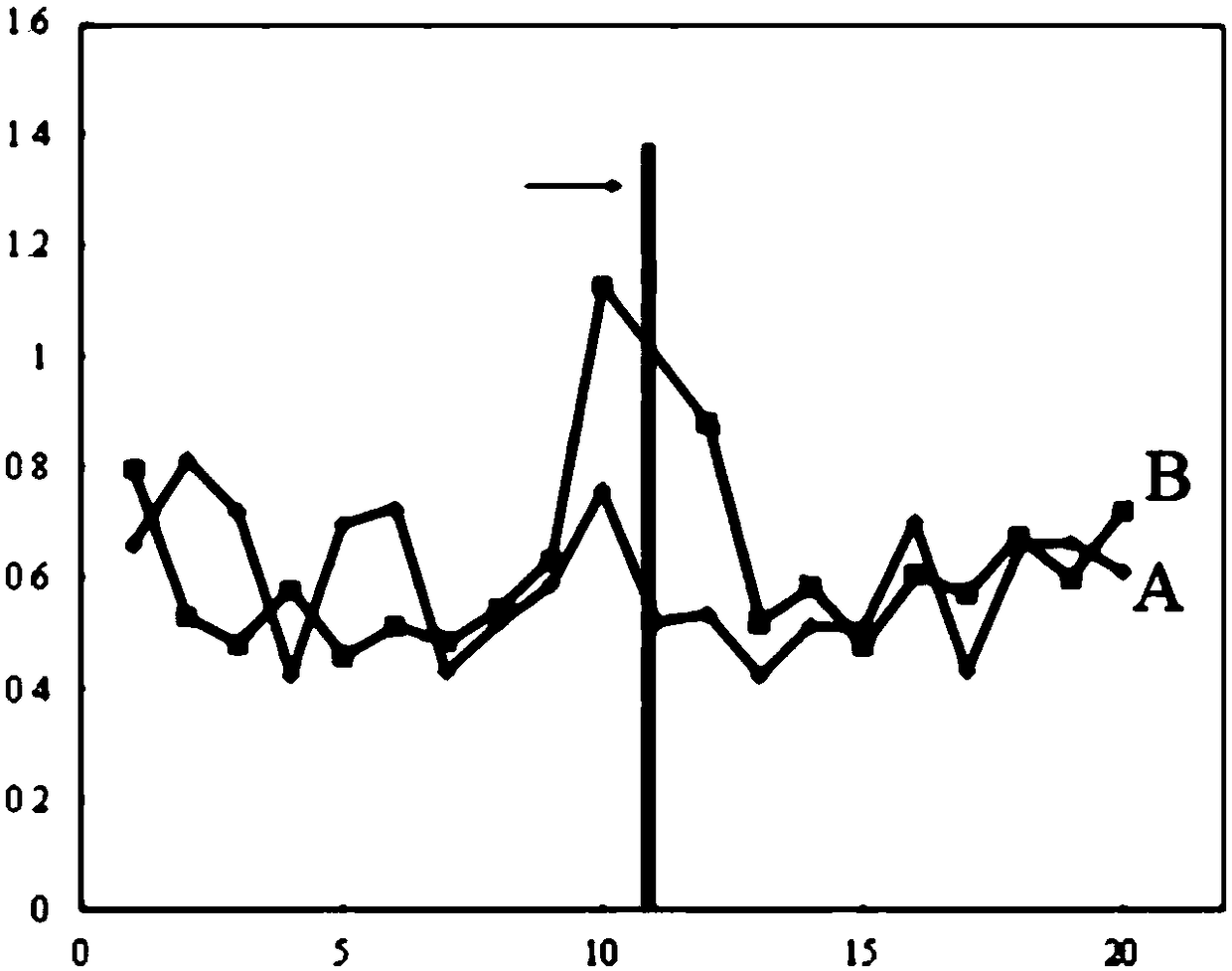

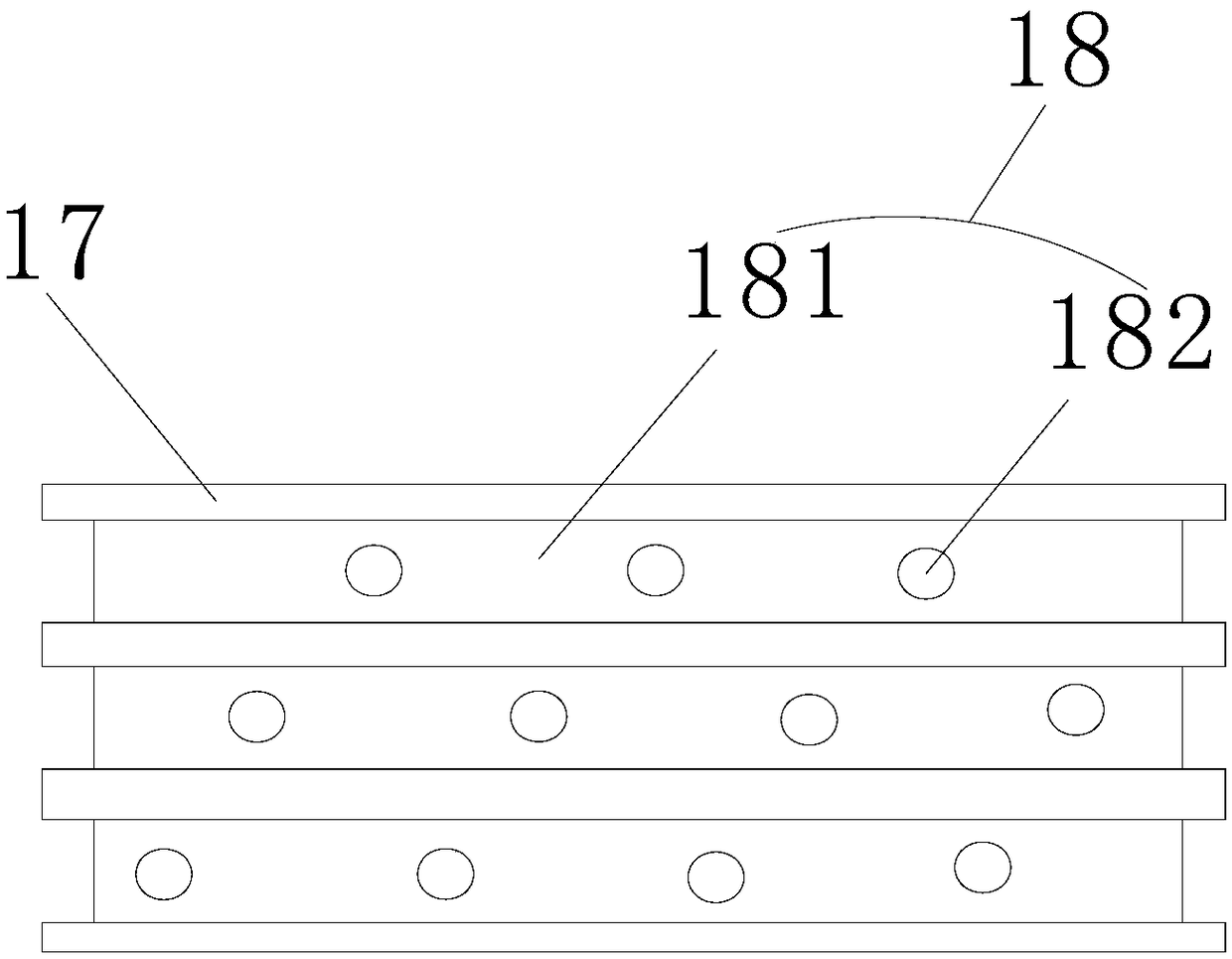

Blast furnace cold-intensifying and heat-avoiding type gradient brick distribution method

InactiveCN103305642AChange thermal conductivityChange layoutBlast furnace detailsInternal formsDistribution methodBrick masonry

The invention relates to a blast furnace cold-intensifying and heat-avoiding type gradient brick distribution method and belongs to the technical field of long life of iron-making blast furnaces. According to the technical scheme, the method comprises the following process steps of: (1) performing flat steel mesh installation and leveling layer construction on the blast furnace hearth and furnace bottom, and sequentially performing layered construction; (2) performing wall-to-wall furnace bottom graphite brick masonry construction on the layer I; (3) performing wall-to-wall furnace bottom carbon brick masonry construction on the layers II, III, IV and V; (4) performing furnace bottom ceramic cup pack-up block masonry construction; (5) performing furnace bottom and hearth side wall carbon brick masonry construction; and (6) performing hearth ceramic cup wall masonry construction. Because the brick layers of different heat conductivity coefficients are arranged at the hearth and the furnace bottom, the heat conductivity coefficient of each refractory material layer is gradually increased from the surface close to a molten iron heat surface to a cooling surface so as to form gradient. The method has the advantages and effects that the heat conductivity coefficient and an arrangement mode of the refractory material used by the hearth and the furnace bottom are changed, so that an optimal cooling or thermal insulating effect is achieved, and the service life of the hearth and the furnace bottom is prolonged.

Owner:宣化钢铁集团有限责任公司 +1

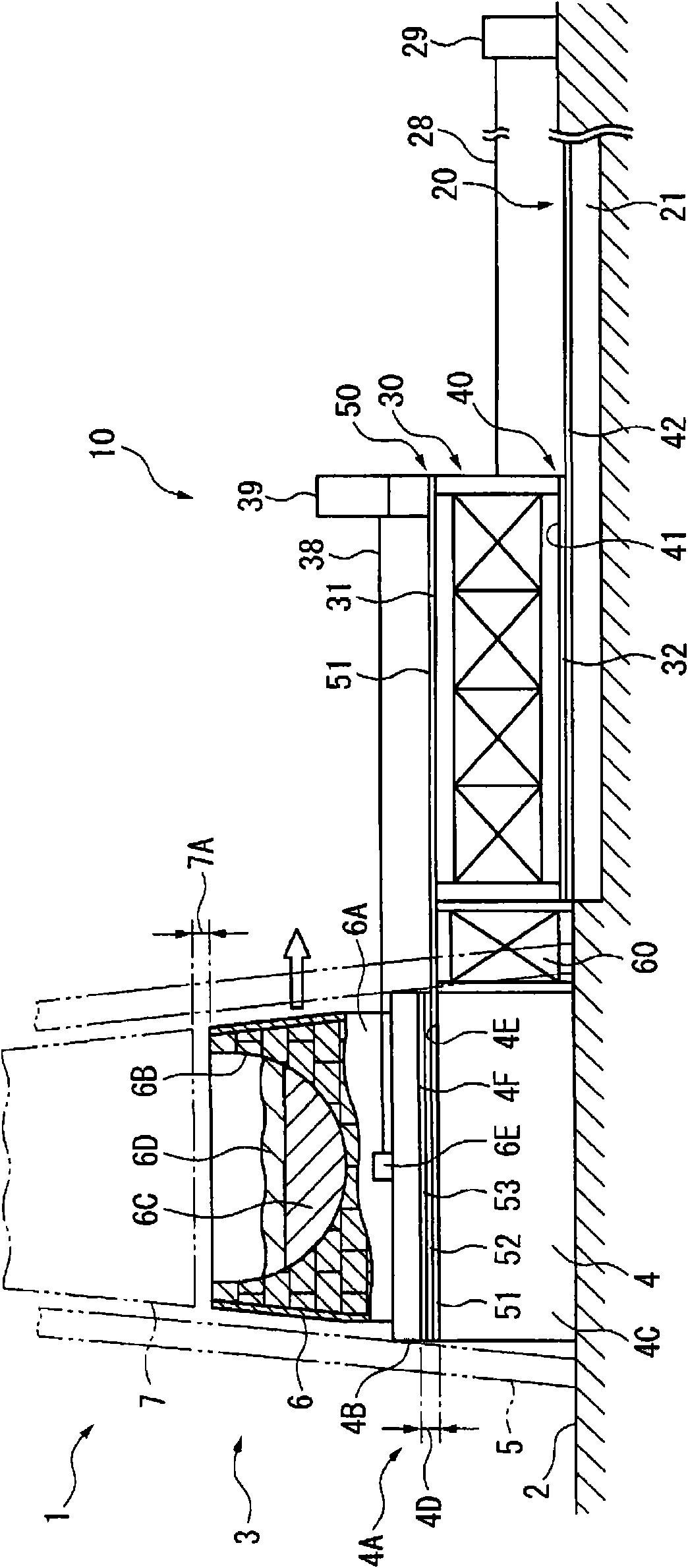

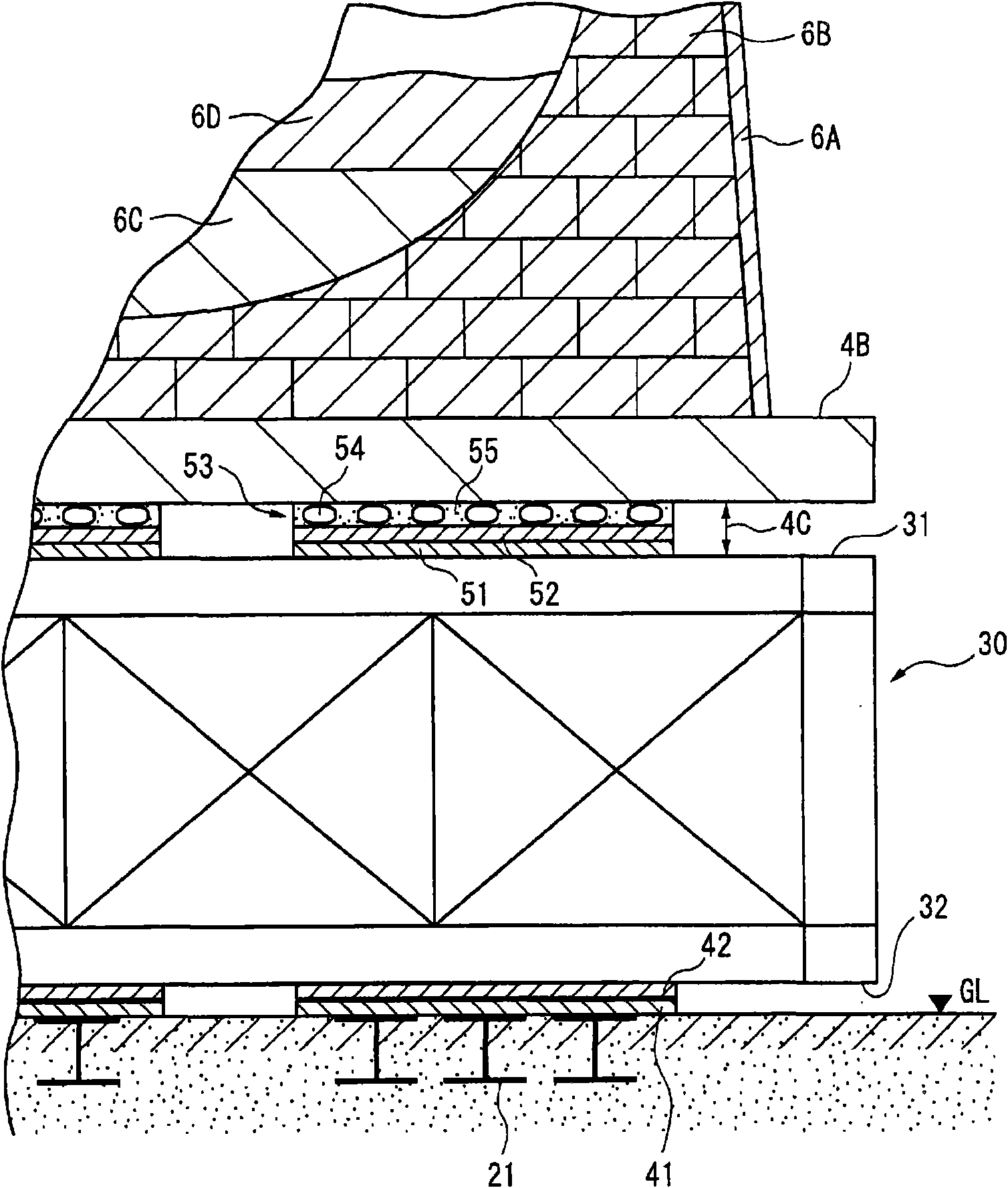

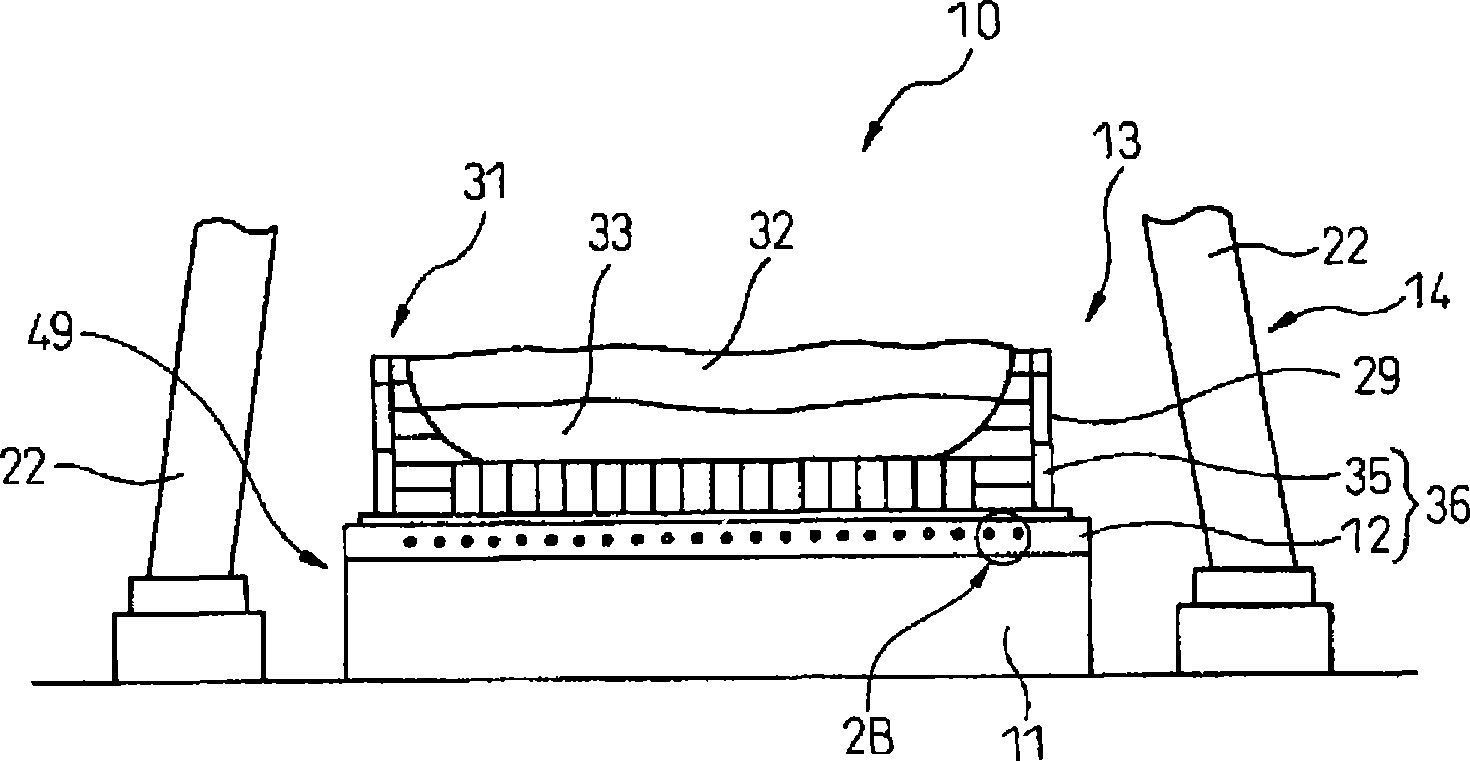

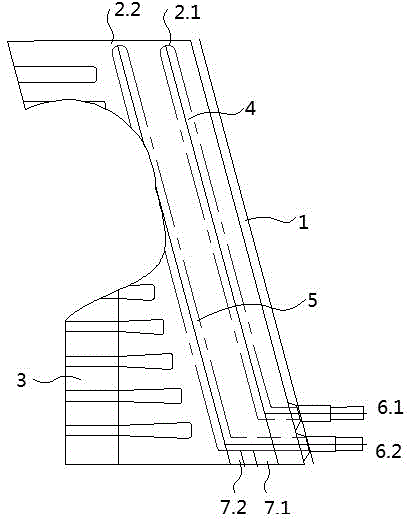

Ring block conveying apparatus, and remedy method for blast furnace casing

Provided are a ring block conveying apparatus using no dolly, and a remedy method for a blast furnace casing. This remedy method comprises a preparing step of installing both a conveying route (20) leading from an installation site (2) to a working site and a conveying frame (30) made slidable on the conveying route (20) and having a placing face (31) on the upper side, a separating step of cutting the portion of a foundation (4) of a furnace casing (3) horizontally at the height of the placing face (31) and cutting an upper portion (7) of the furnace casing (3) horizontally thereby to cut outa furnace bottom block (6), a transferring step of moving the furnace bottom block (6) horizontally to transfer the same onto the placing face (31), and a conveying step of moving the conveying frame(30) placing the furnace bottom block (6) thereon, along the conveying route (20) to the working site.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD +1

Forged Copper Burner Enclosure

InactiveUS20100252968A1Eliminate stallEliminating hot spotFurnace componentsTuyeresParticulatesElectric arc furnace

A forged copper burner enclosure capable of being mounted within the side wall of a steel melting furnace for the purpose of providing an improved cooling characteristic to a burner lance. The burner enclosure is provided with a central passage adapted to receive a burner lance for injecting oxygen into the batch of molten metal of an electric arc furnace. The forged burner enclosure is positioned such that only a solid forged copper face is on the furnace side when installed. The burner enclosure has an optional through hole which can be used for the purpose of treating the metal melt with particulate supply ranging from slag forming materials to metallurgical materials. The burner enclosure further has a number of coolant holes and tubes which provide a unique bidirectional flow of cooling fluid through each hole and increases cooling fluid velocity while reducing stalling and hot spots of the cooling fluid thereby providing better heat transfer and physical characteristics over cast or weld-assembled burner enclosures.

Owner:NUCORE TECH

Resin-bonded liner

In the continuous casting of molten metal, the invention describes a refractory article for reducing deposition of inclusions on a surface contacting the stream of molten metal. The article comprises a first composition and a second composition on at least a portion of the contacting surface. The second composition includes a resin-bonded refractory composition comprising a refractory aggregate and a reactive metal. The resin-bonded refractory composition reduces deposition of inclusions relative to standard carbon-bonded or castable refractories. The second composition is particularly effective as a nose of a stopper rod or a liner for a nozzle, shroud or slide gate plate.

Owner:VESUVIUS CRUCIBLE CO

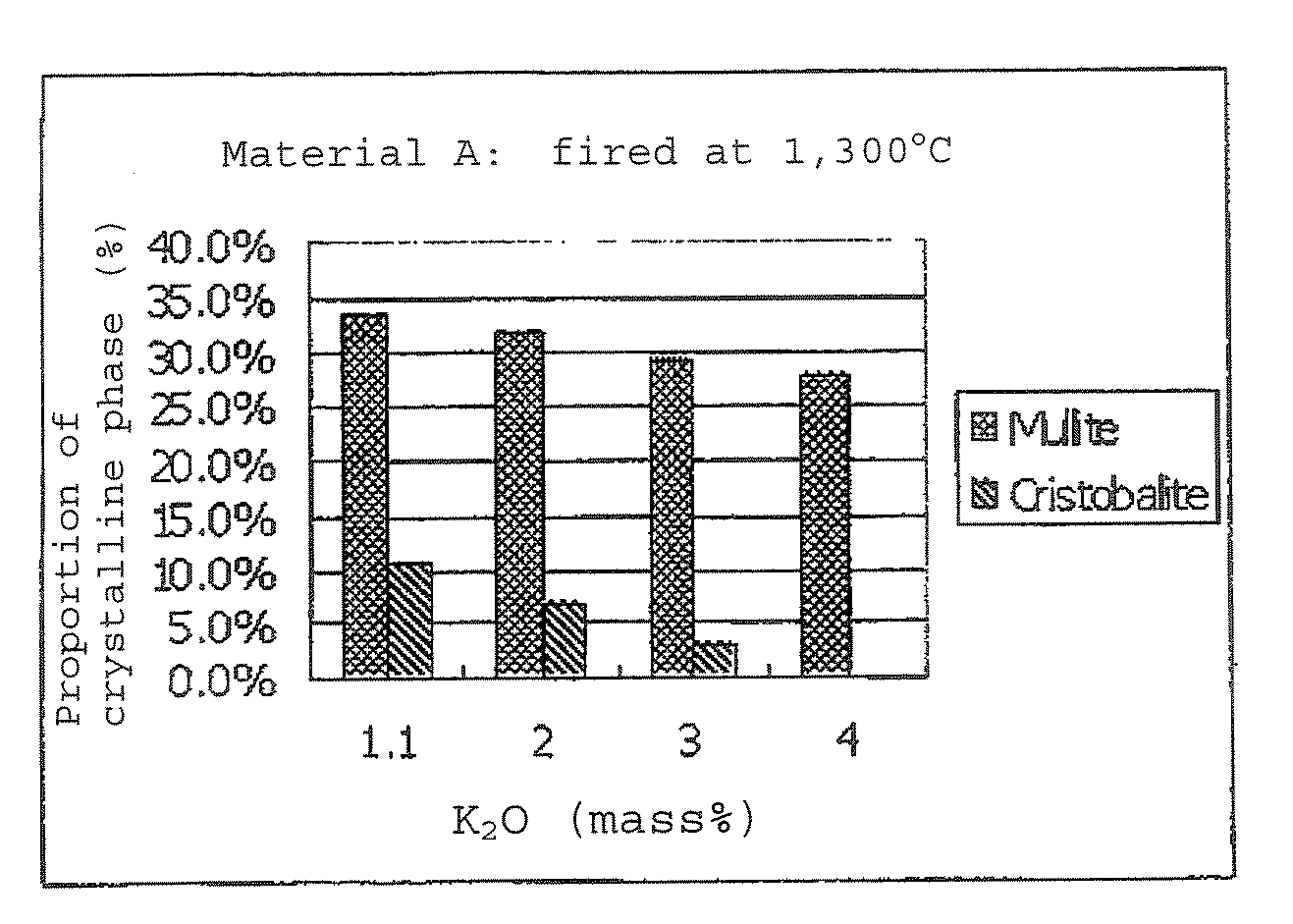

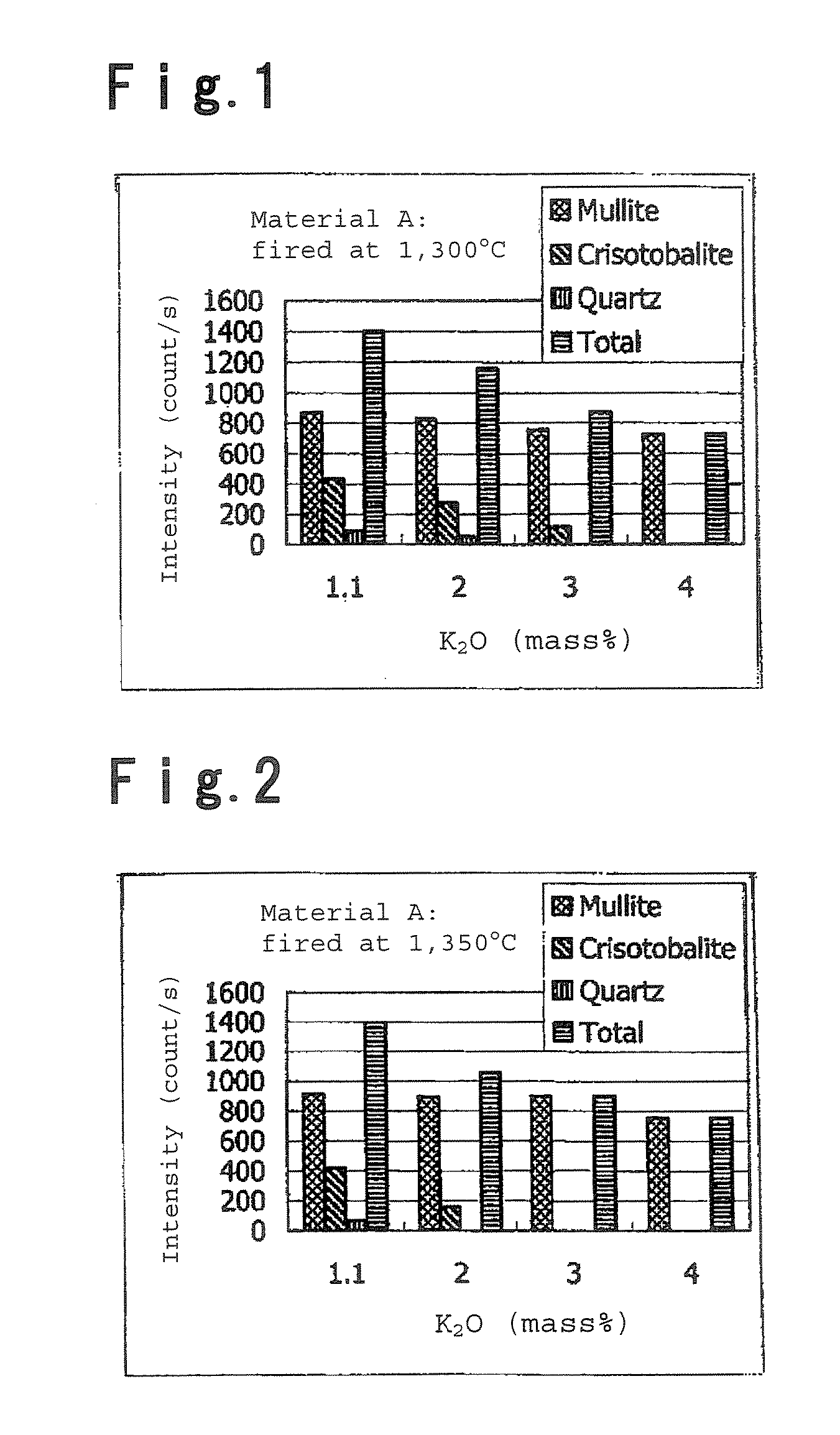

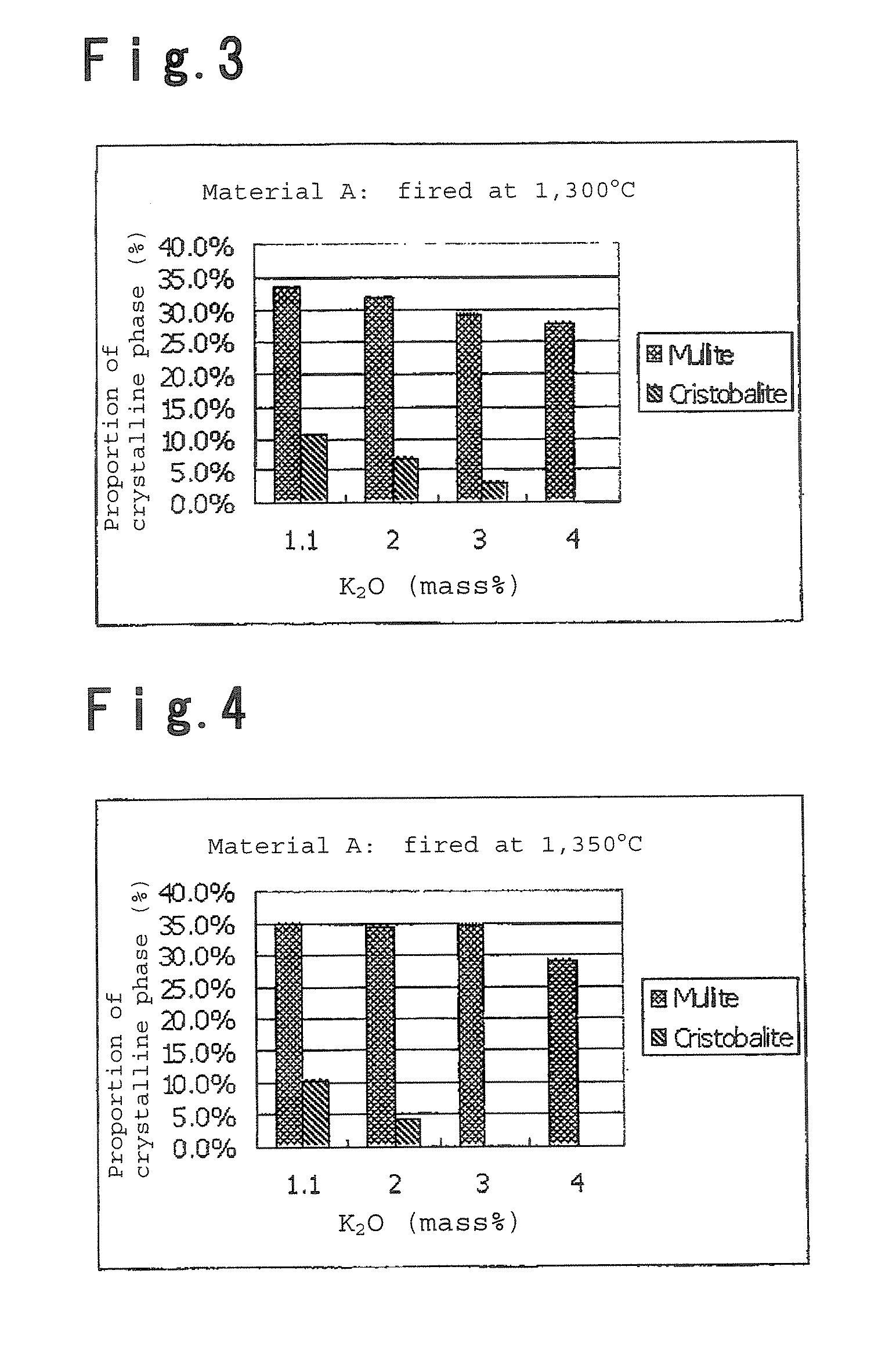

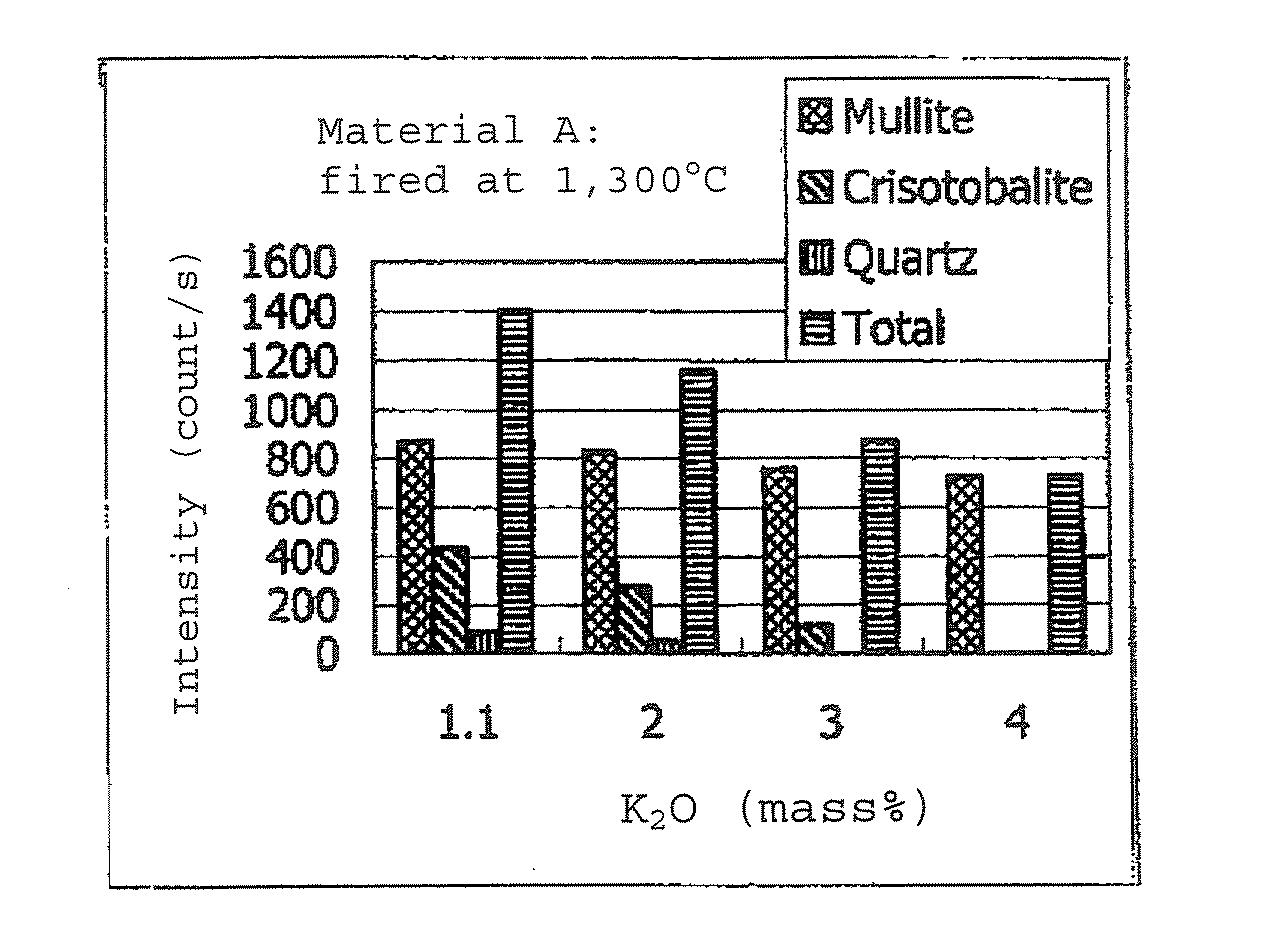

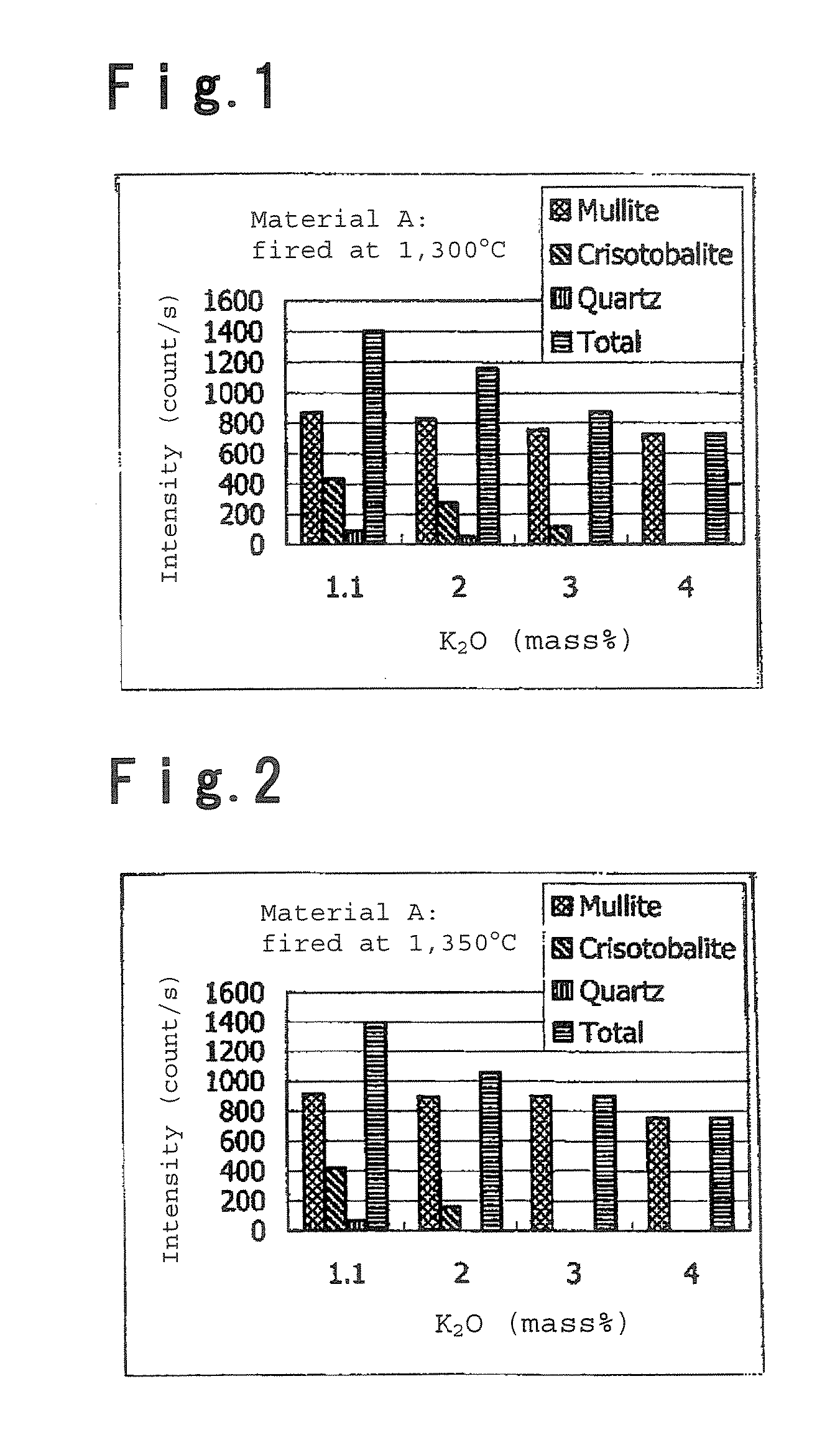

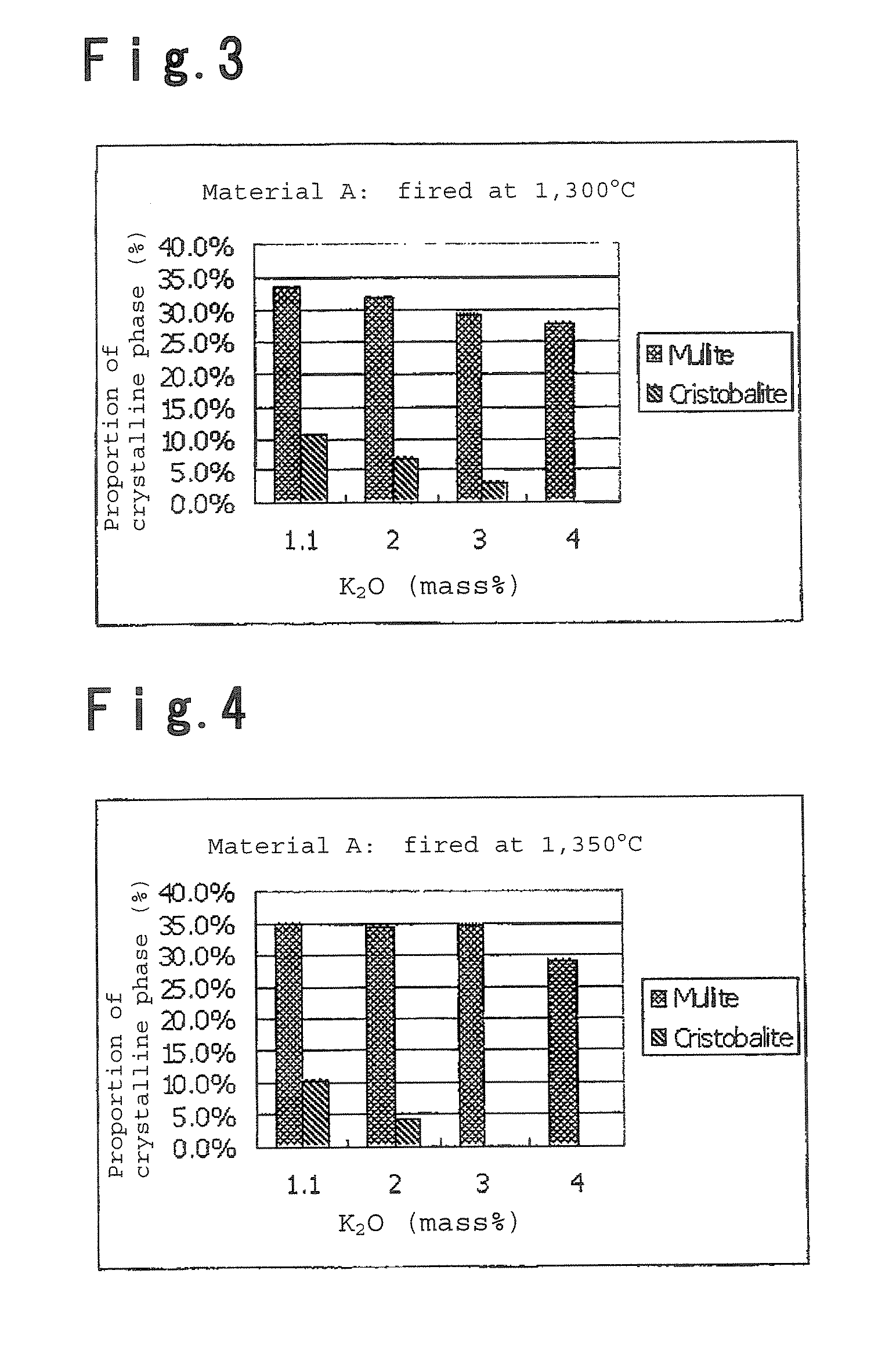

Float bath bottom refractory brick and process for its production

InactiveUS20070238603A1Quality improvementIncrease ratingsGlass pressing apparatusBlast furnace detailsFlat glassPotassium

It is to provide a process for producing a float bath bottom refractory brick which can suppress a reaction with Na2O from glass at the surface of the refractory brick and thereby prevents flaking phenomena, as a refractory brick to be used for a float bath bottom for production of plate glass by float process. A process for producing a float bath bottom refractory brick using a clayey material comprising from 30 to 45 mass % of Al2O3 and from 50 to 65 mass % of SiO2 and having a Na2O content of at most 1 mass %, wherein a potassium compound is added so that the K2O content in the float bath bottom refractory brick to be produced would be from 2 to 4 mass %.

Owner:ASAHI GLASS CO LTD

Method for prolonging service life of furnace hearth and furnace bottom of blast furnace

InactiveCN102719583AAvoid enteringReduce installation clearanceTuyeresCooling devicesLeaking waterBrick

The invention relates to the technical field of long service life of a blast furnace, in particular to a method for prolonging the service life of a furnace hearth and a furnace bottom of the blast furnace. The method is characterized by comprising the following steps of: improving the structure and the installation form of a cooling wall of the furnace hearth, arranging a water retaining device at the cooling wall of a tuyere zone and coating channel bricks at an iron notch zone, wherein in installation of the cooling wall of the furnace hearth, the cooling wall is tightly contacted with a furnace shell; a high-temperature-resistant resin sealant is coated between the cooling wall and the furnace shell, and is used for blocking water generated by leakage of the cooling wall from flowing towards the furnace hearth and the iron notch zone; baffle plates are respectively arranged above and below the cooling wall of the tuyere zone, so that the occurrence of the conditions of leaked-water scouring and gas blowby of the cooling wall are avoided; and steel-plate coating bodies are arranged at the peripheries of the channel bricks of the iron notch zone. Compared with the prior art, the method has the beneficial effects that the water generated by damage and leakage of cooling equipment is prevented from entering carbon bricks of the furnace bottom and the furnace hearth, and an enrichment channel with harmful elements formed by gas blowby at the iron notch is blocked, so that the corrosion process of carbon bricks of a furnace lining is slowed, and the service life of the blast furnace is prolonged.

Owner:鞍钢集团工程技术有限公司

Container for evaporation of metal and method to manufacture thereof

A refractory container for evaporating metals, having improved useful life and corrosion resistance properties, the evaporation surface of the container having a plurality of grooves formed at the bottom surface. The grooves have either a depth of at least 1.2 mm, a width of at least 1.75 mm, or an interval spacing of at least 2.2 mm between adjacent grooves (or centers of adjacent grooves), and combinations thereof.

Owner:GENERAL ELECTRIC CO

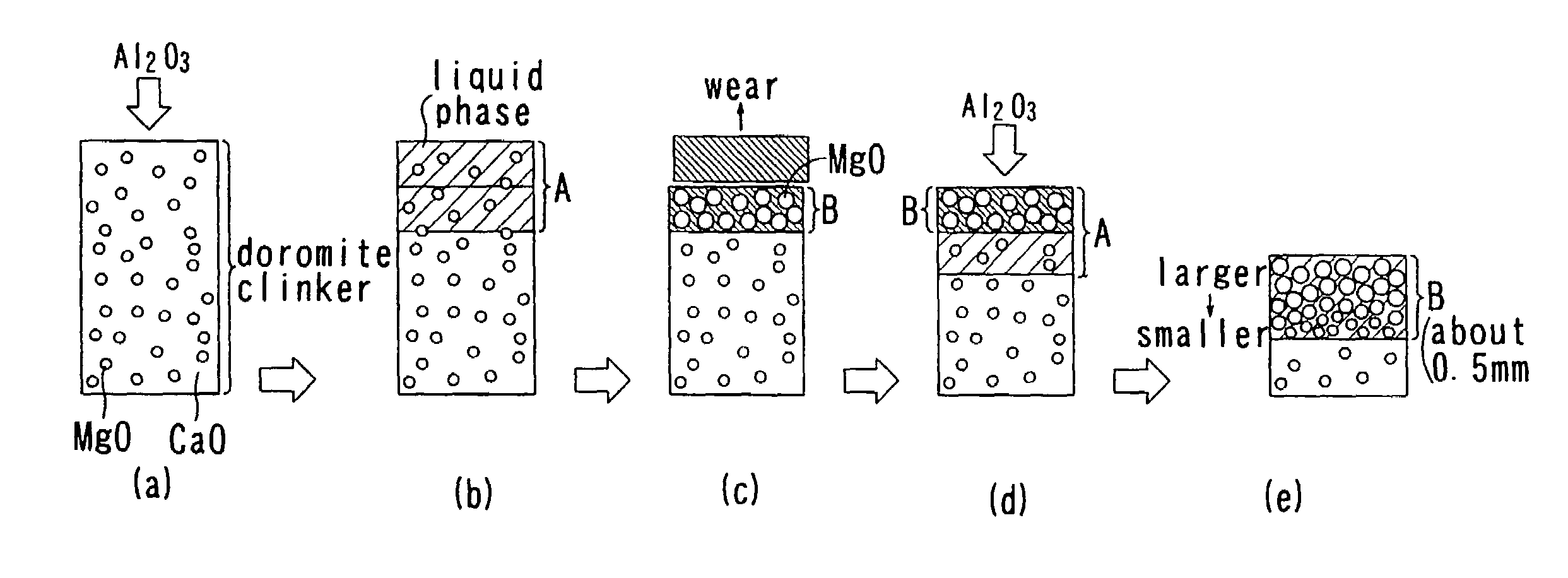

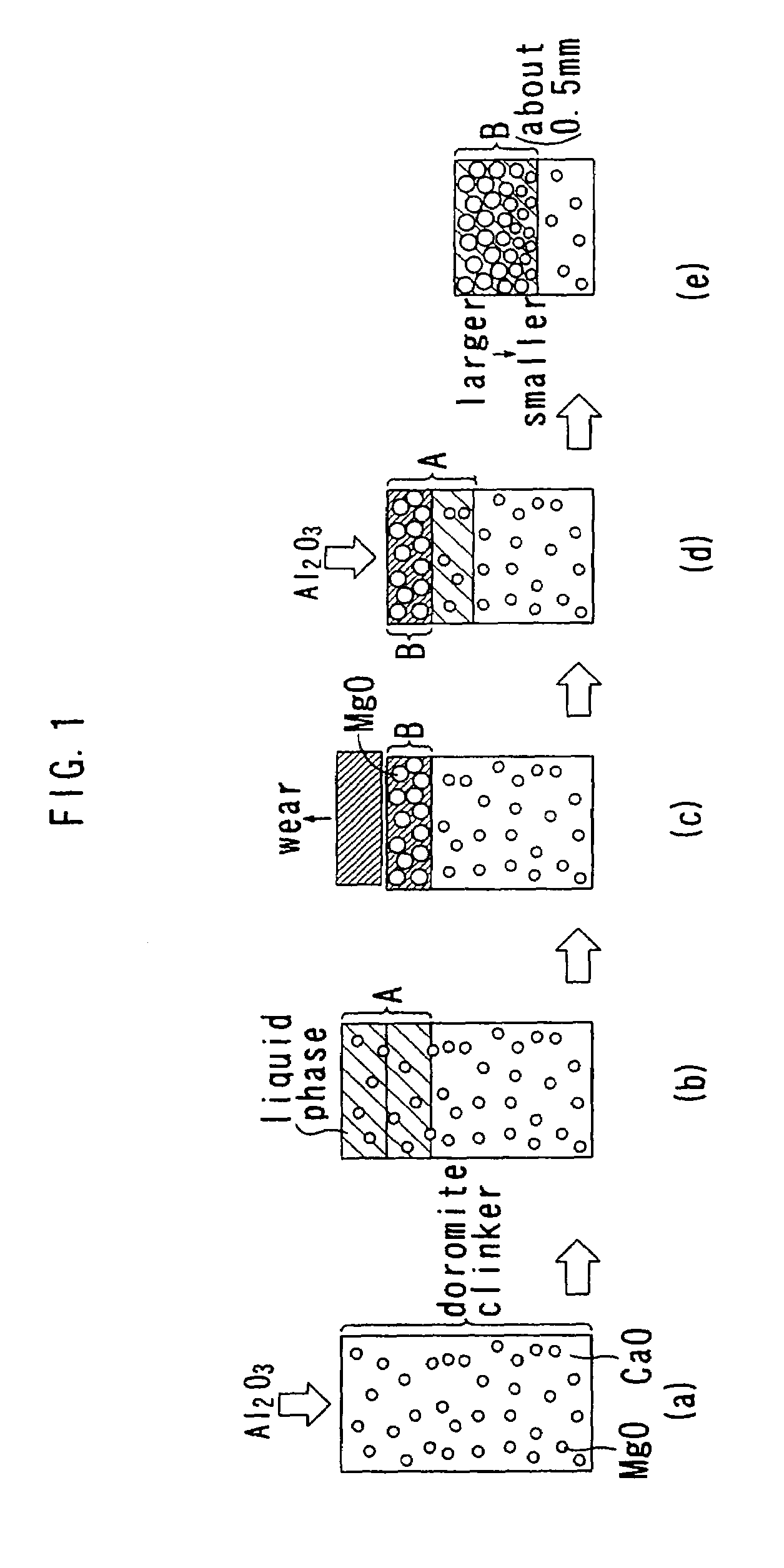

Nozzle for use in continuous casting

InactiveUS7591976B2Extend your lifeLow costMelt-holding vesselsMolten metal pouring equipmentsMixed materialsMolten steel

Disclosed is a continuous casting nozzle having a refractory portion formed to contain a dolomite clinker and arranged to define a surface region adapted to be in contact with molten steel, which is capable of protecting a working surface of the nozzle from alumina build-up due to alumina in molten steel, while improving corrosion resistance, even during long-term continuous casting of molten steel. The refractory portion is prepared by adding a binder to a mixed material and subjecting the obtained mixture to kneading, forming and heat treatment. The mixed material comprises a dolomite clinker which has an average particle size of 0.8 mm or less and a CaO content of 50 mass % or less. The mixed material has a ratio W1 / W2 of 0.33 or more, wherein W1 is a content by mass of CaO, and W2 is a content by mass of MgO. The mixed material comprises a dolomite clinker and a magnesia clinker. Alternatively, the mixed material comprises a dolomite clinker and a magnesia clinker. The mixed material has a ratio WD / WM in the range of 0.5 to 15, wherein WD is a mass % of dolomite clinker particles having a particle size of 1 mm or less in a particle size distribution of the dolomite clinker, and WM is a mass % of magnesia clinker particles having a particle size of 1 mm or less in a particle size distribution of the magnesia clinker. Further, the mixed material has a ratio W1 / W2 in the range of 0.33 to 3.0, wherein W1 is a content by mass % of a CaO component in the dolomite clinker, and W2 is a content by mass % of an MgO component in the magnesia clinker.

Owner:KROSAKI HARIMA CORP

Dismantling method of bottom section of blast furnace

ActiveCN101448961AReduce the number of daysReduce the number of working daysBlast furnace detailsInternal formsHorizontal forceEngineering

The dismantling method comprises steps 1-8. Step 1: a plurality of cutting sections are set in the direction parallel with the drawing direction on a horizontal cutting plane set in the foundation concrete at the bottom of a blast furnace. Step 2: a horizontal hole is bored in parallel with the drawing direction in the foundation concrete on the boundary of the cutting sections. Step 3: the foundation concrete in the cutting section is cut along the upper and lower horizontal planes by inserting a wire into adjoining horizontal holes. Step 4: an air gap portion is formed by discharging the foundation concrete between the upper and lower horizontal cutting planes. Step 5: a lateral movement member for carrying out the furnace bottom section is arranged in the air gap portion. Step 6: a furnace body load supporting member is provided in the gap between the upper surface of the lateral movement member and the upper horizontal cutting plane. Step 7: a lateral movement means equipped with the lateral movement member and the furnace body load supporting member is arranged over the entire region of a horizontal cutting portion by repeating the steps 2-6 or steps 3-6. Step 8: an upper mantel is separated from the furnace bottom, hoisted and carried out by imparting a horizontal force.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD

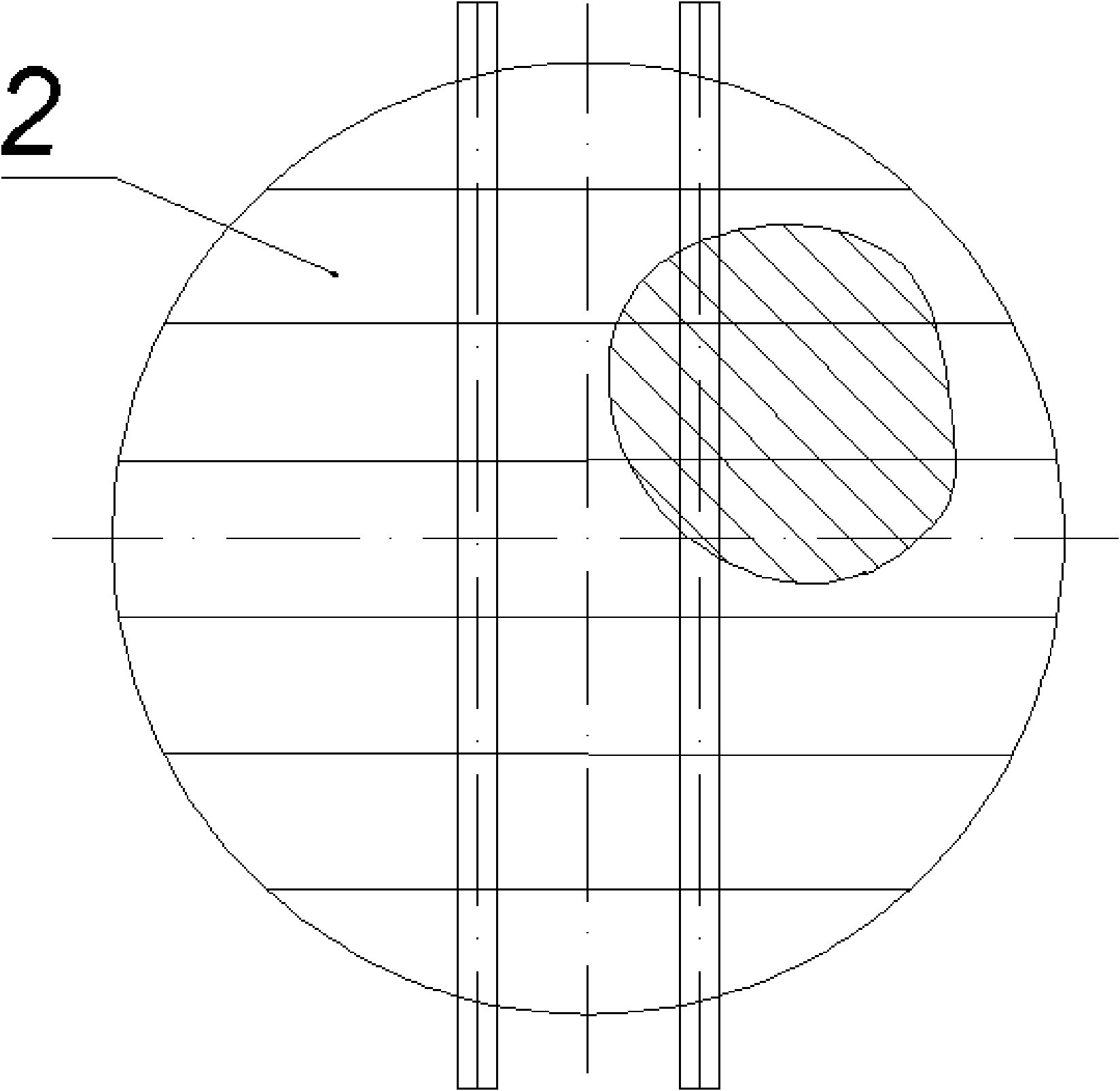

Blast furnace body structure for facilitating lining making through grouting

ActiveCN104789722AGuaranteed accuracy and reliabilityEasy to operateInternal formsWater leakageSlurry

The invention relates to a blast furnace body structure for facilitating lining making through grouting. The blast furnace body structure comprises a furnace housing, a cooling wall and a furnace lining from outside to inside in sequence, wherein the cooling wall at least comprises an outer-layer cooling wall propped against the furnace housing and an inner-layer cooling wall propped against the furnace lining; circulated cooling water pipes are independently arranged in the outer-layer cooling wall and the inner-layer cooling wall; the two ends of each circulated cooling water pipe are externally connected with a water inlet pipe and a water outlet pipe respectively; a ball valve is arranged at the water outlet of each water outlet pipe; a water lock is formed on each water outlet pipe. According to the blast furnace body structure, judging the cooling wall layer damaged by fire can be realized by detecting the water leakage condition correspondingly; through grouting slurry in the circulated cooling water pipe at the outermost layer of the cooling wall that water leakage exists, the slurry can overflow from the damage part of the circulated cooling water pipe to reach an eroded position of the furnace lining to realizing lining making, so that troubles that in the conventional lining making through grouting, the positioning and formation of a slurry pressing hole in a furnace housing are required before lining making are avoided, the operation of blast furnace lining making through grouting is simplified, and meanwhile, the accuracy and reliability of a grouting position are ensured.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Glass manufacturing container, glass manufacturing apparatus with the same and glass manufacturing method using glass manufacturing apparatus

InactiveUS8375748B2Residence of bubbles in the glass can be effectively reducedPot furnacesLayered productsElectron donorAlloy

A glass manufacturing container includes a container body and an electron donor. The container body is made of a precious metal or an alloy containing a precious metal and has an inner surface to be brought into contact with molten glass and an outer surface kept from contact with molten glass. The electron donor is electrically connected to the outer surface of the container body. The electron donor is made of an electron donating material capable of donating electrons to the container body at operating temperatures.

Owner:NIPPON ELECTRIC GLASS CO LTD

Float bath bottom refractory brick and process for its production

InactiveUS7708935B2Improvement in quality and rateFormation can be suppressedGlass pressing apparatusCeramic shaping apparatusFlat glassBrick

A process for producing a float bath bottom refractory brick which can suppress a reaction with Na2O from glass at the surface of the refractory brick and thereby prevent flaking phenomena, which process comprises adding a potassium compound to a clayey material comprising from 30 to 45 mass % of Al2O3 and from 50 to 65 mass % of SiO2 and having a Na2O content of at most 1 mass %, so that the K2O content in the float bath bottom refractory brick to be produced would be from 2 to 4 mass %; and a refractory brick useful for a float bath bottom for production of plate glass by a float process.

Owner:AGC INC

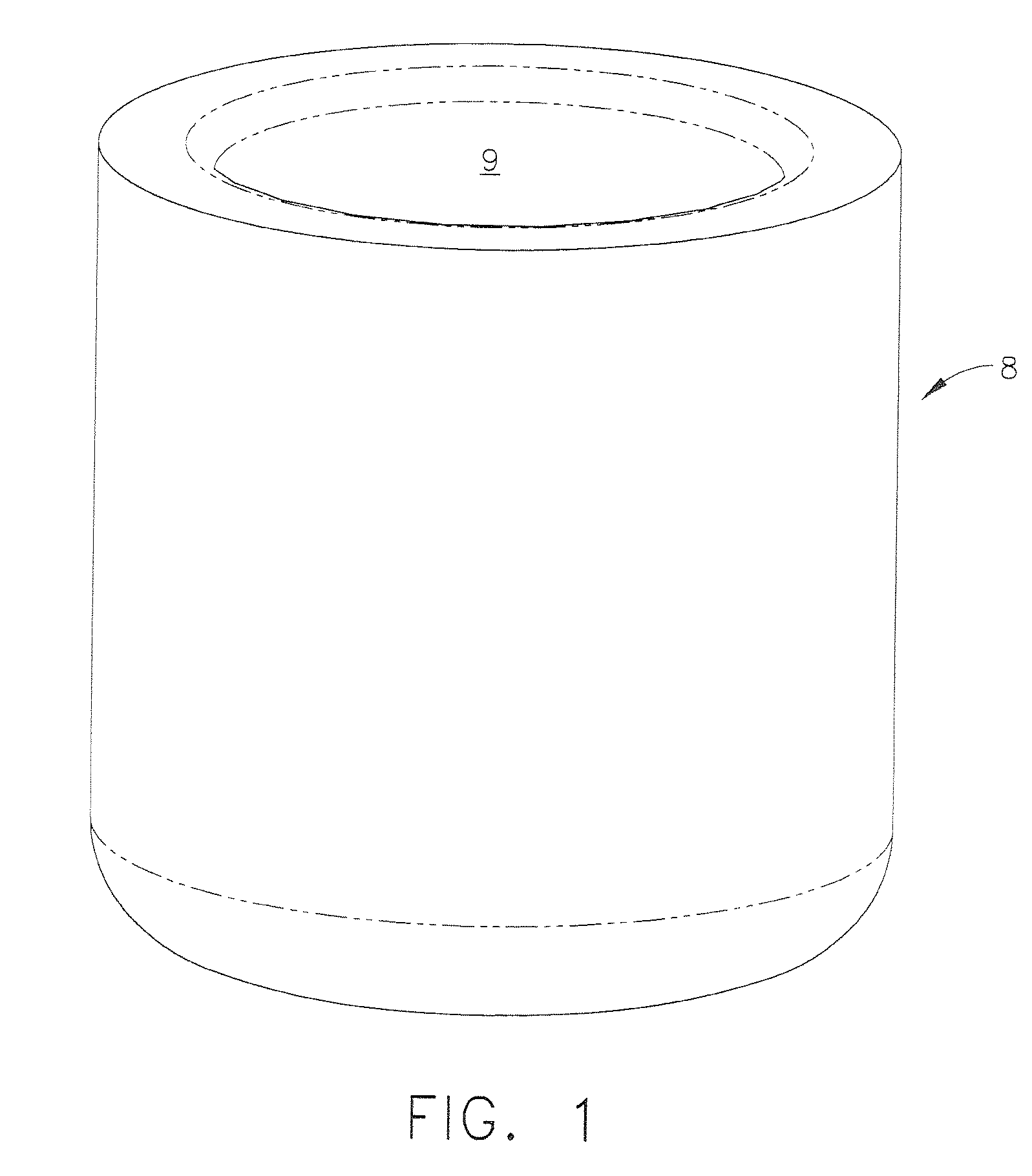

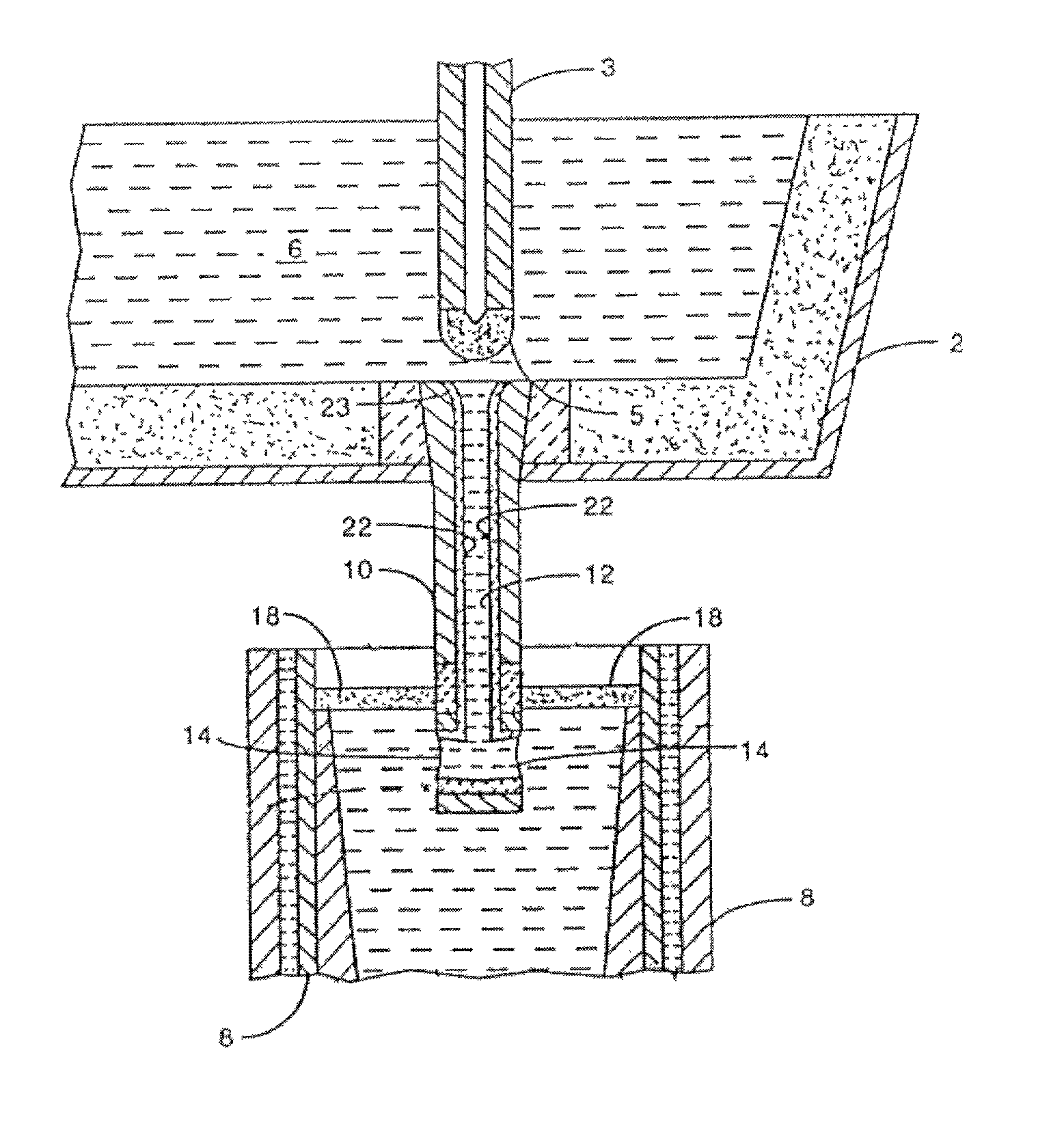

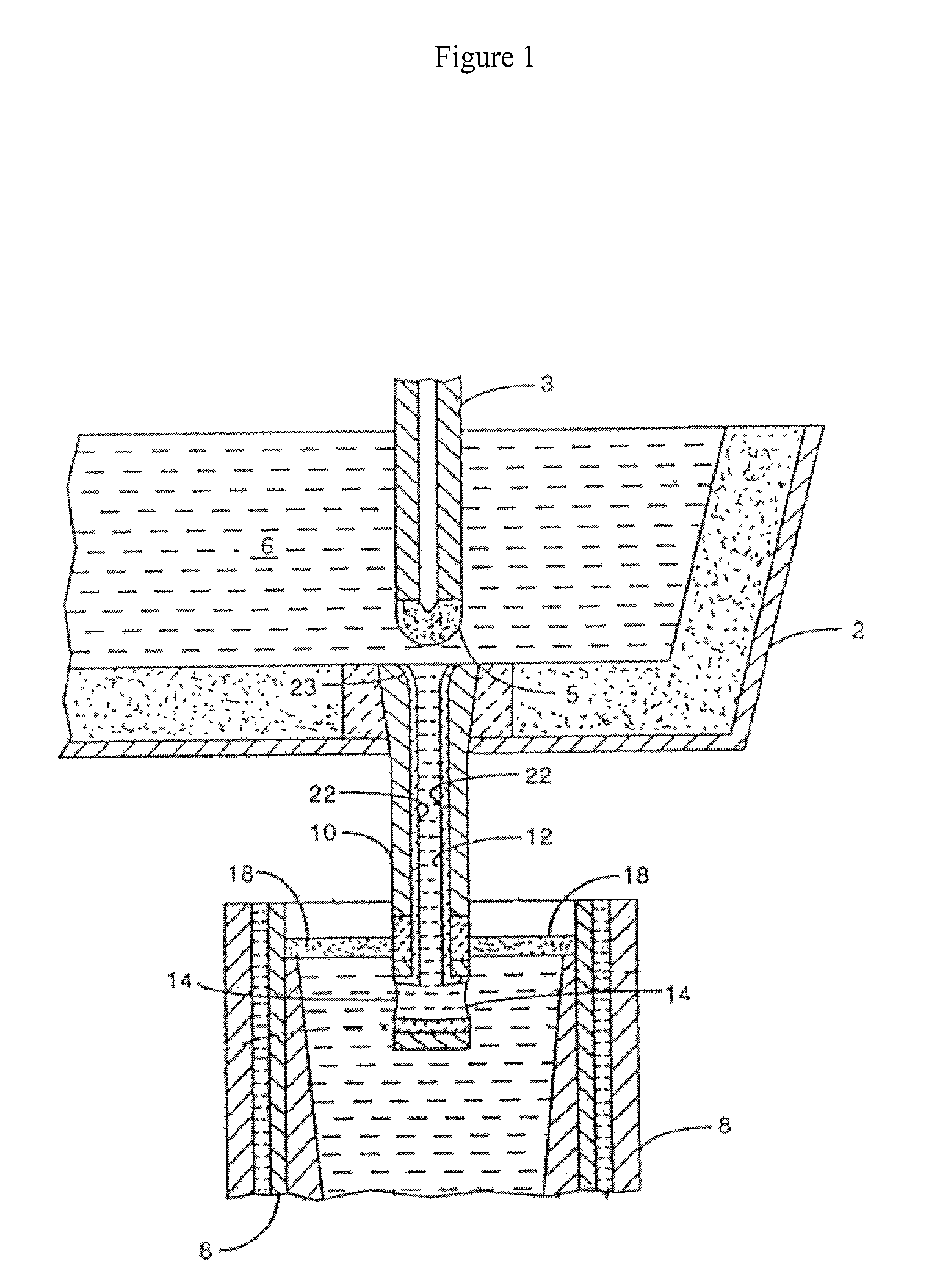

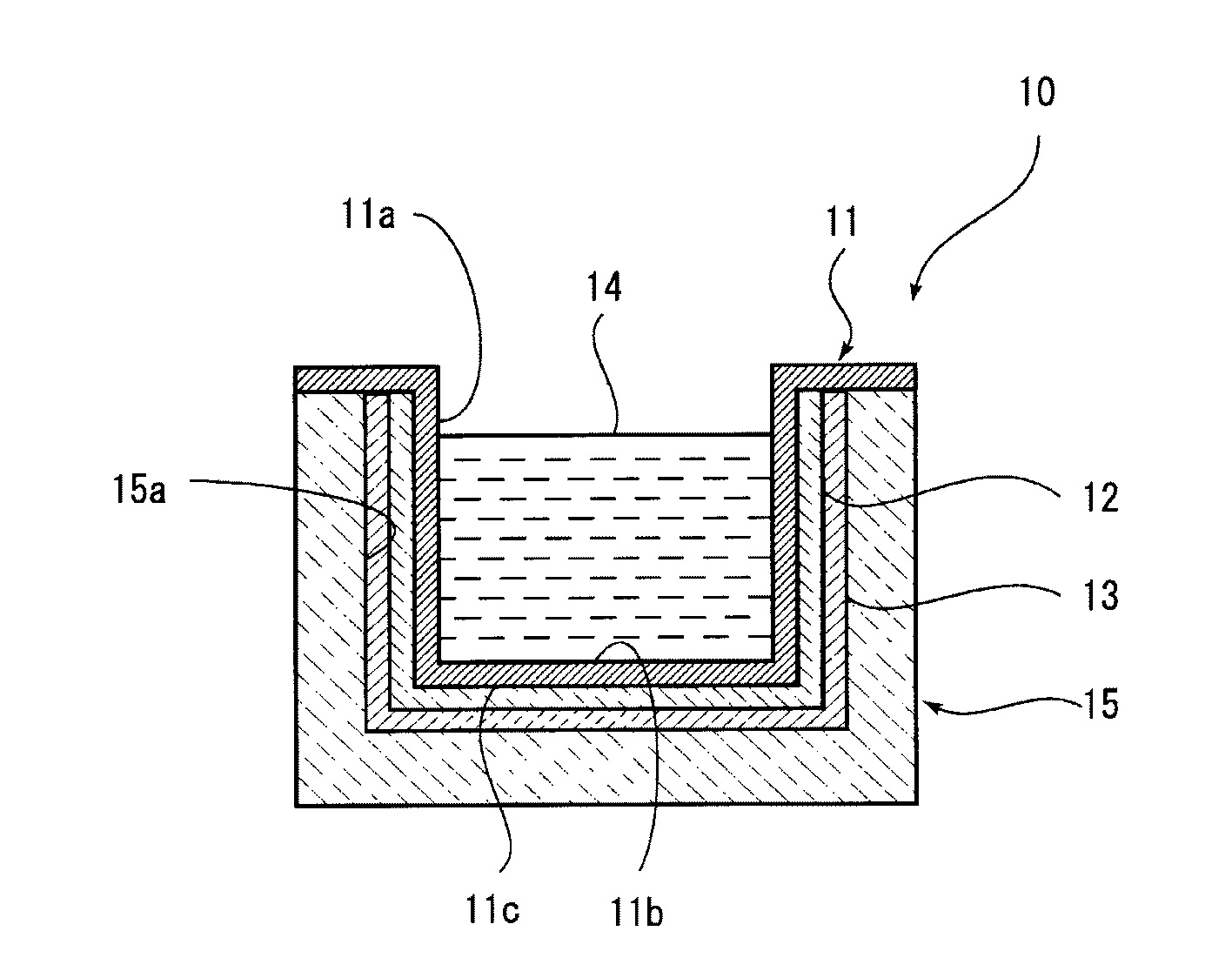

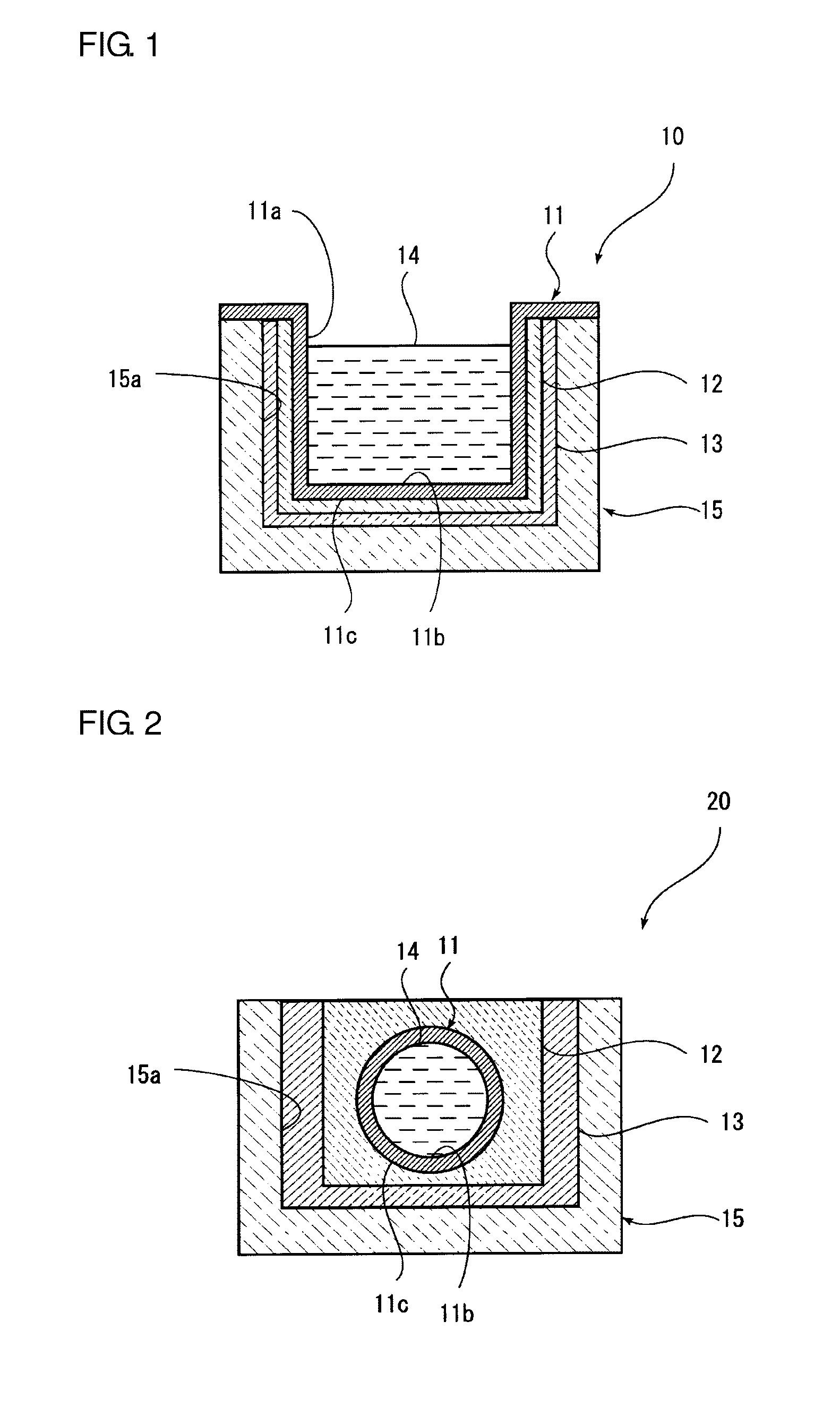

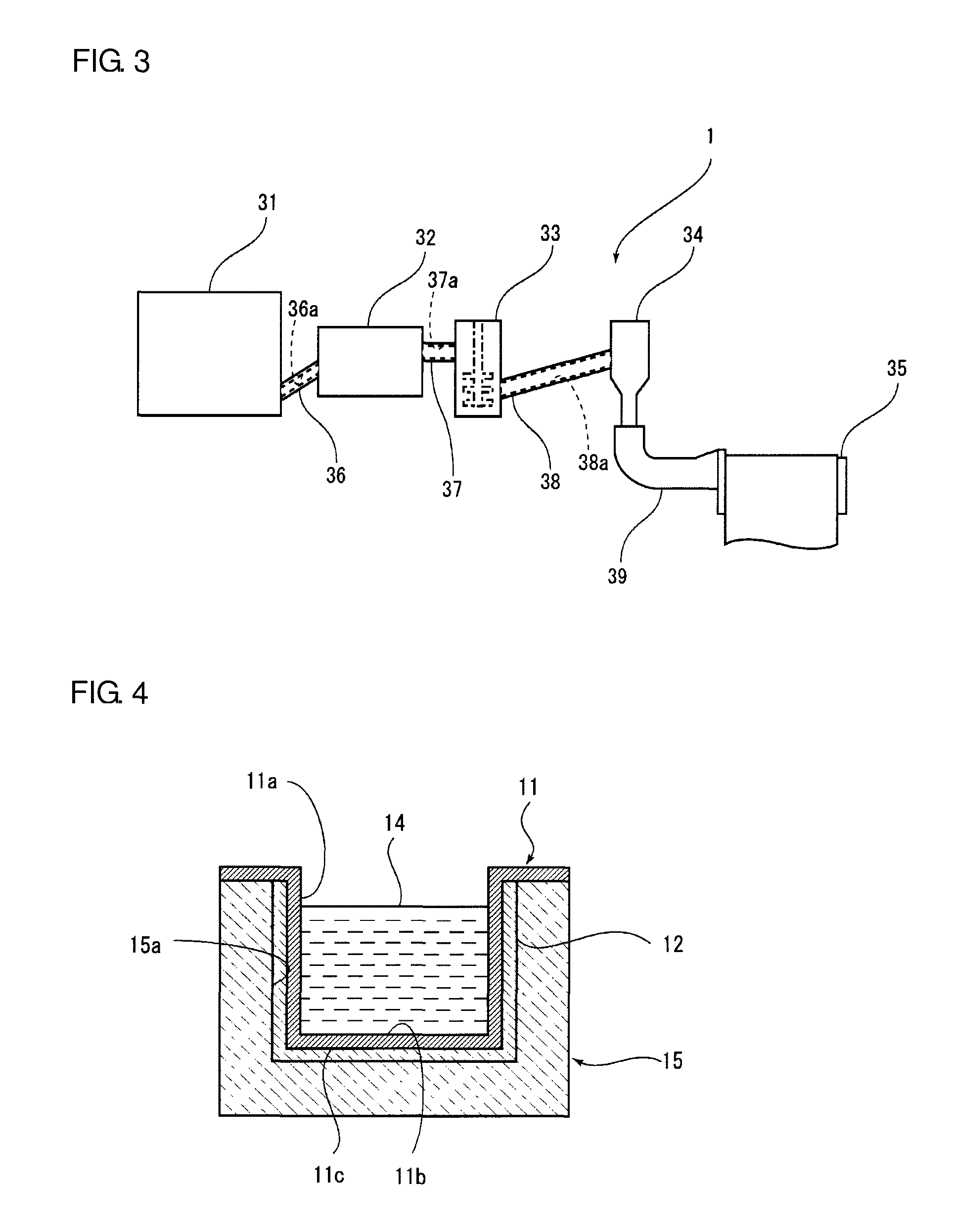

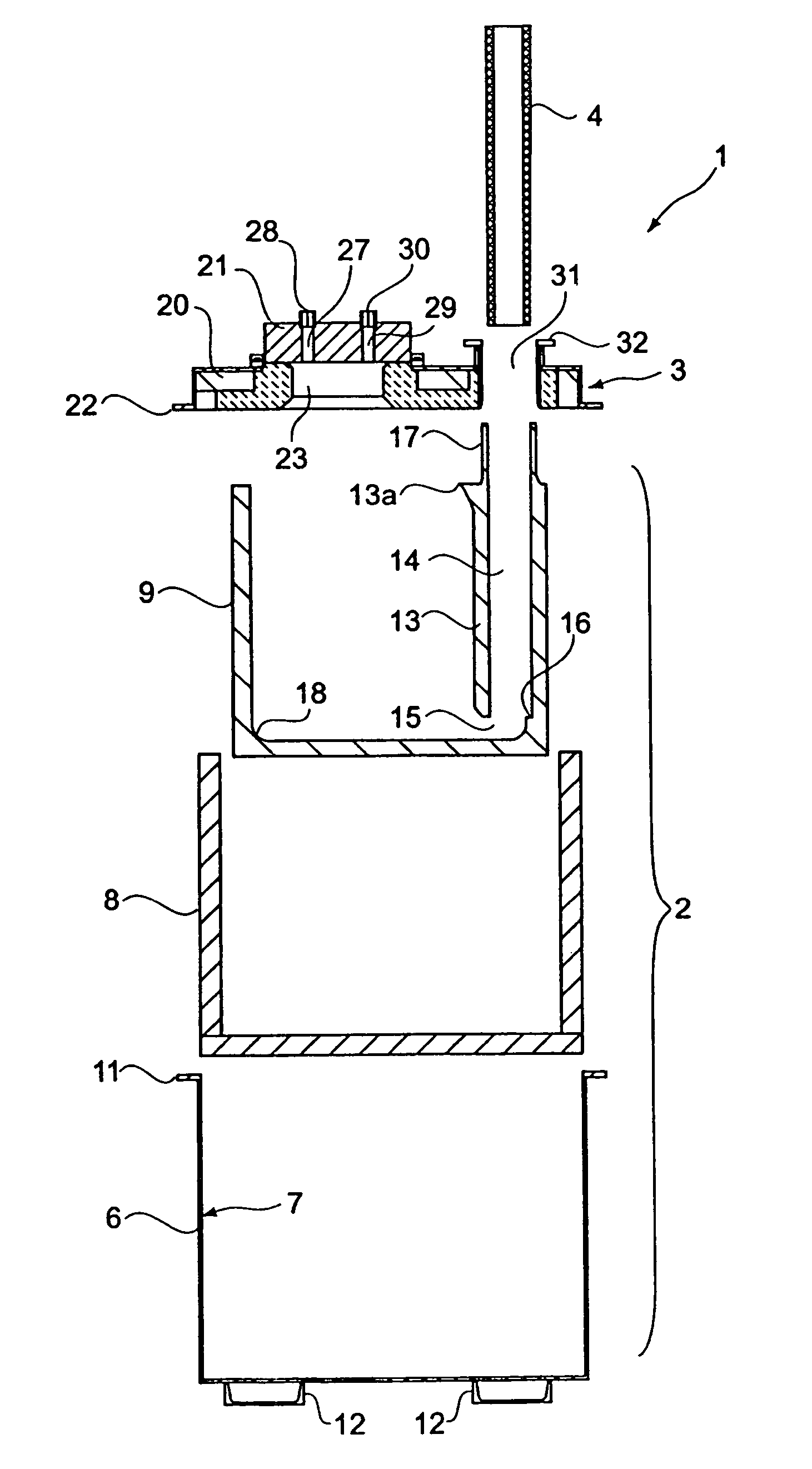

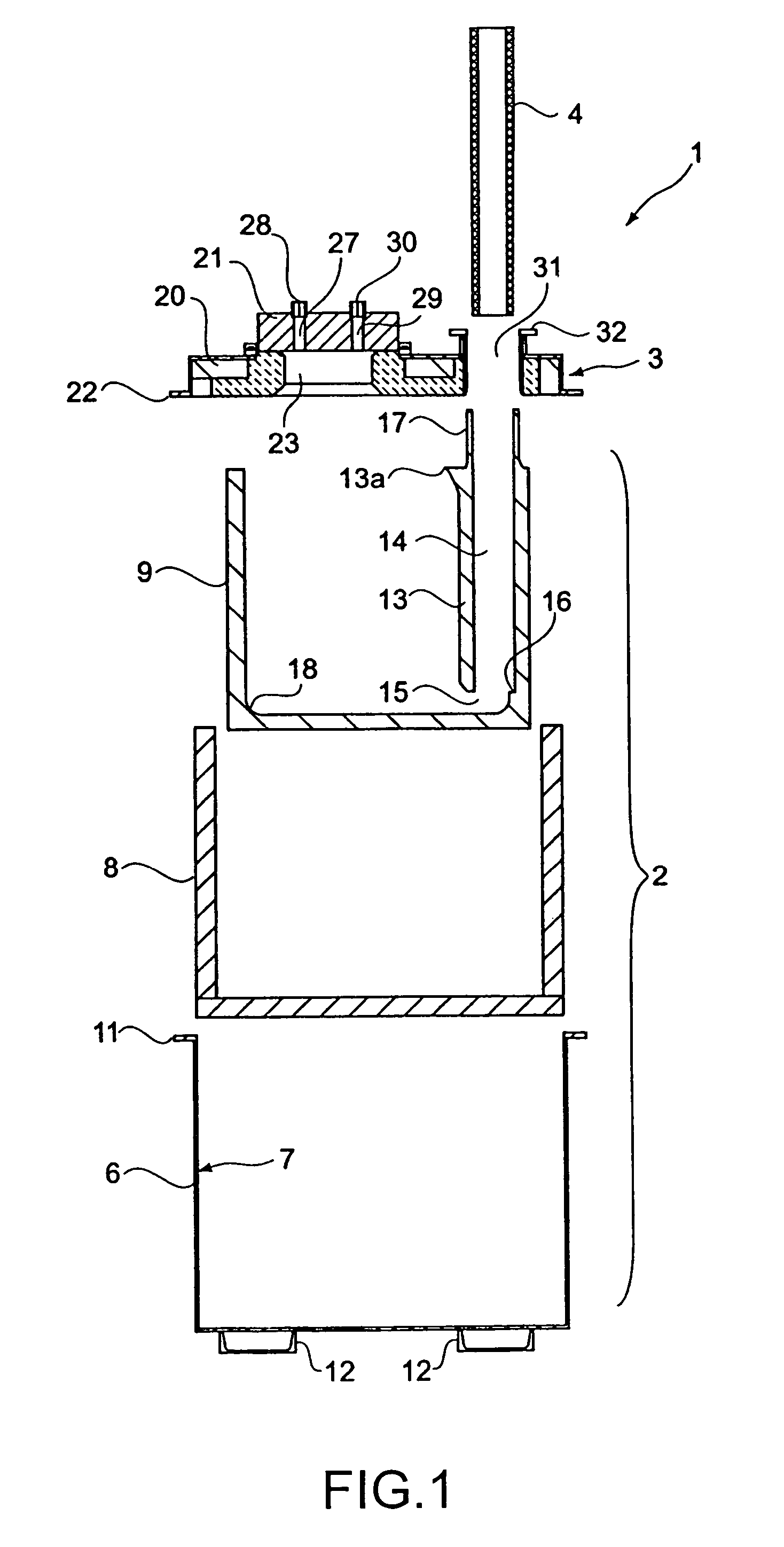

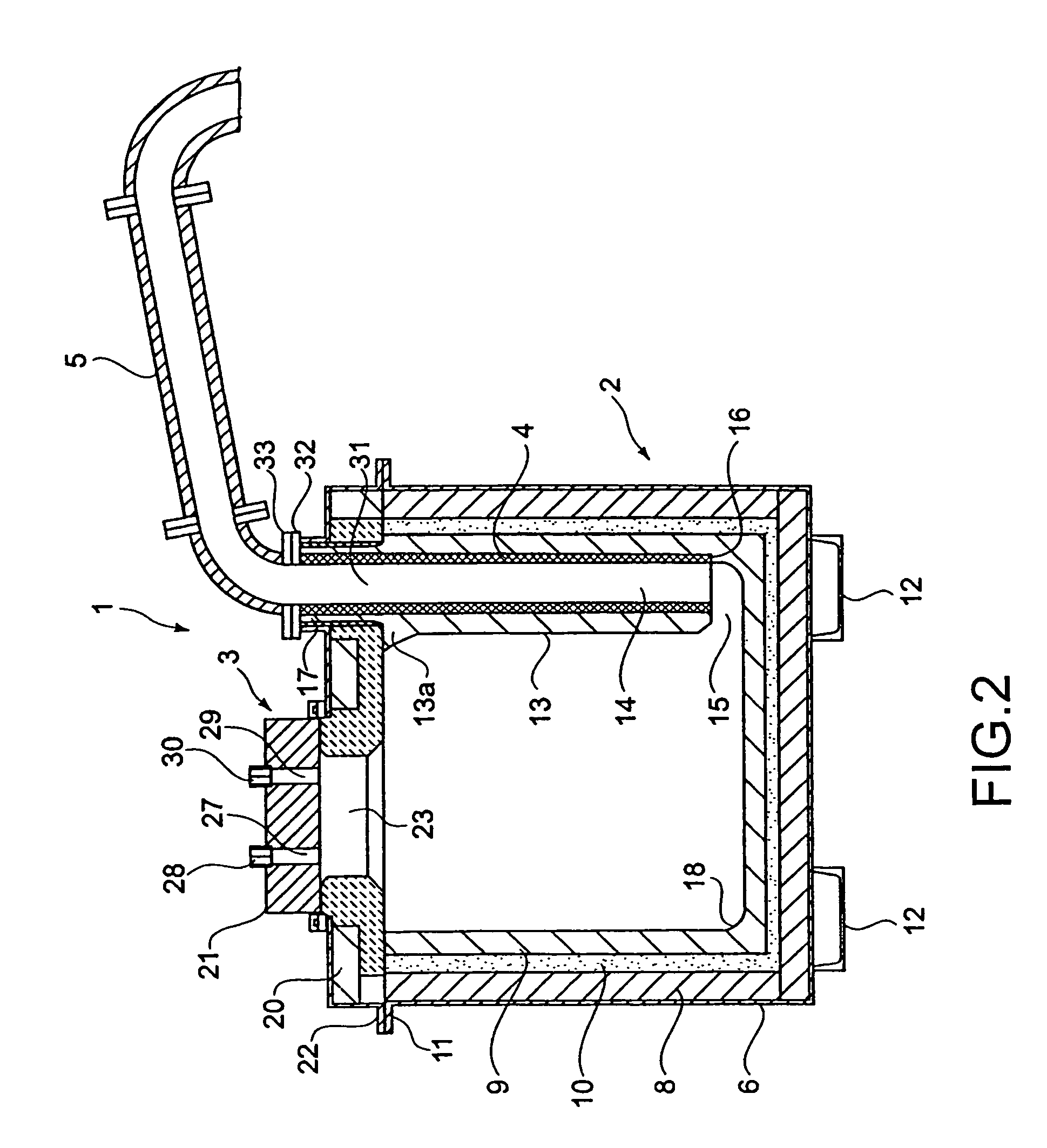

Container, storing bath and a method of producing the container

InactiveUS7507366B2Prevent pressureImprove manufacturing productivityMelt-holding vesselsMolten metal supplying equipmentsRefractoryEngineering

A container (1) and method of manufacturing, capable of preventing unexpected rise of pressure inside the container (1) caused by problems pertaining to the lining. The container has a structure such that the insulating wall (8) is laid on the inner side of the frame body (6), and the refractory storing bath (9) is detachably inserted through the opening (5) of the frame body into the container.

Owner:HOEI SHOKAI CO LTD

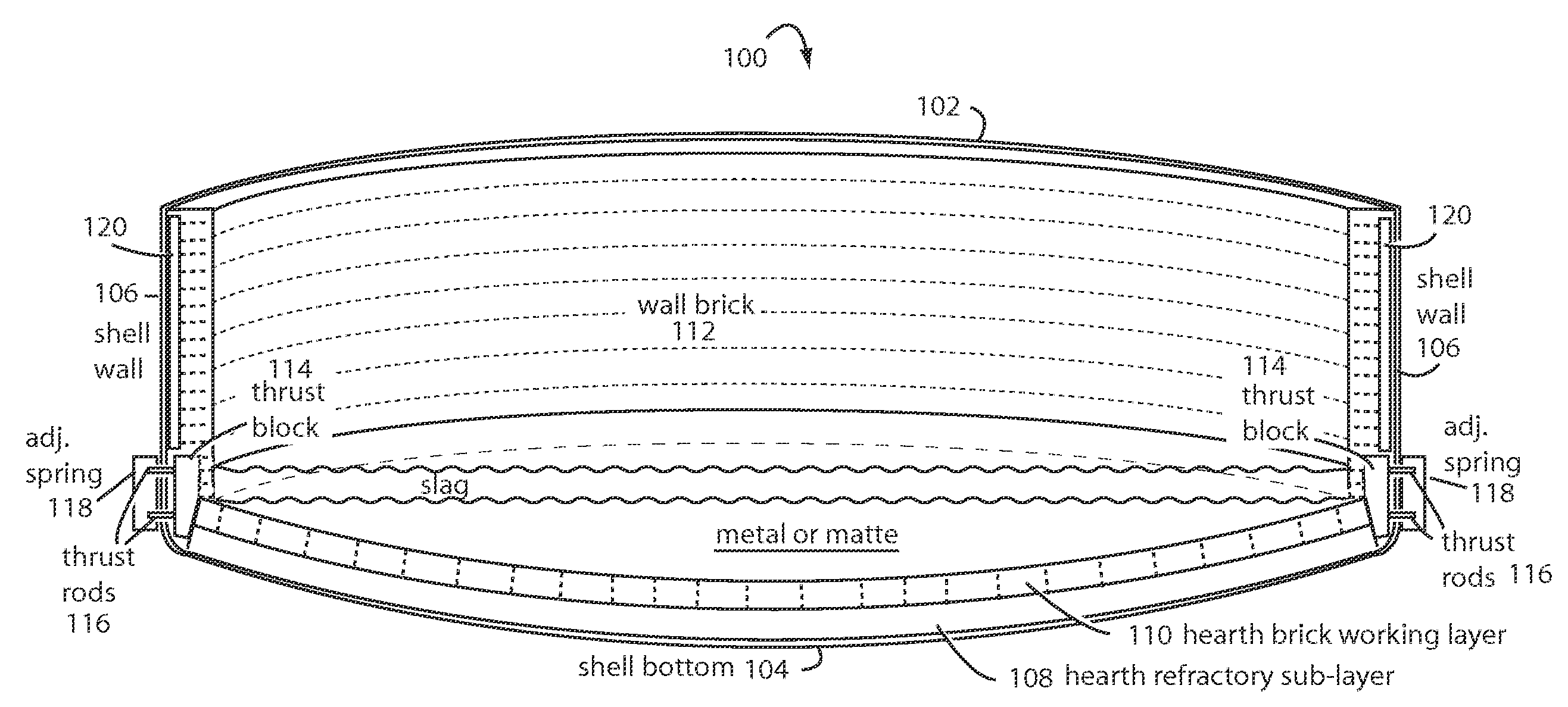

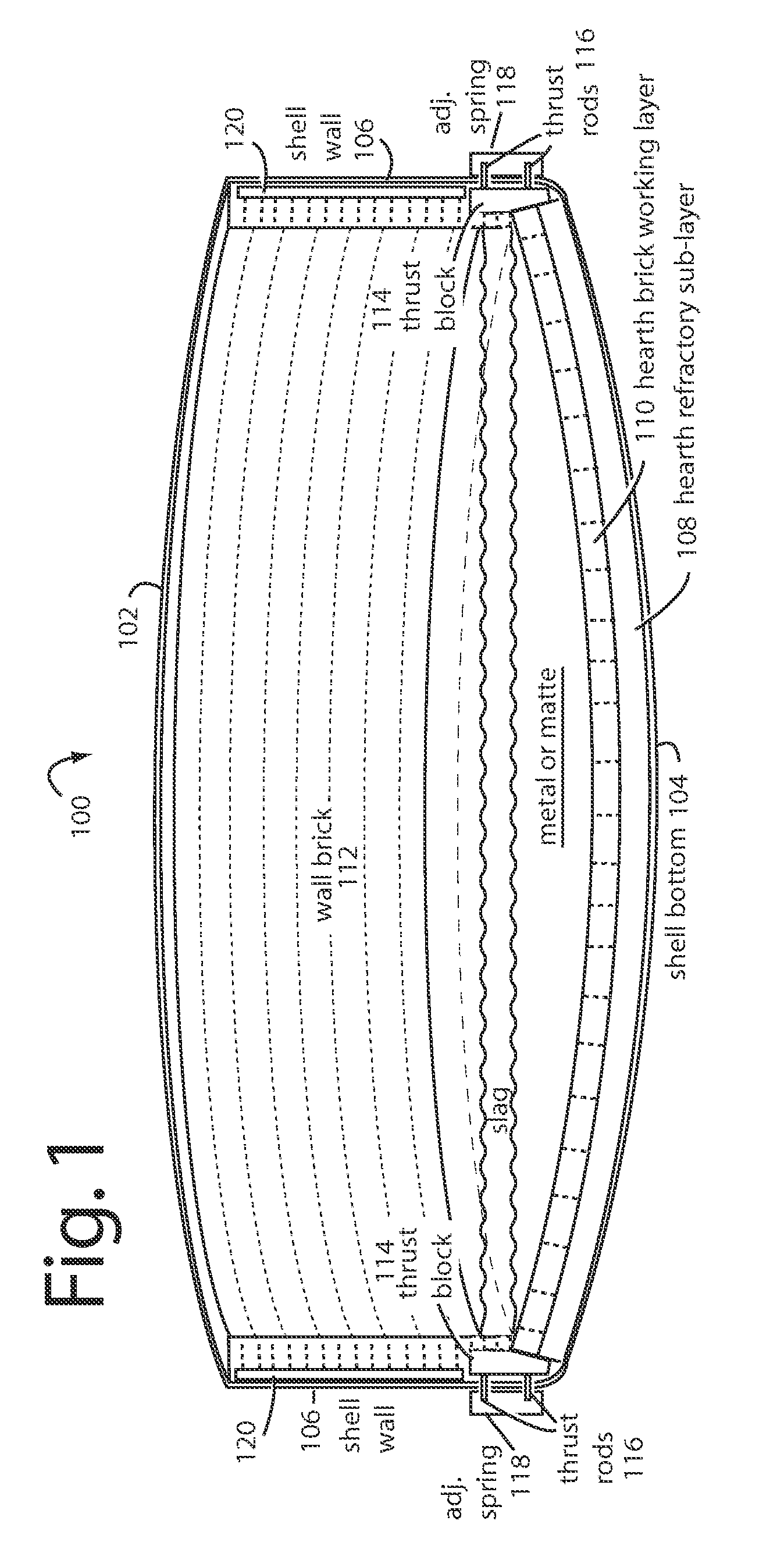

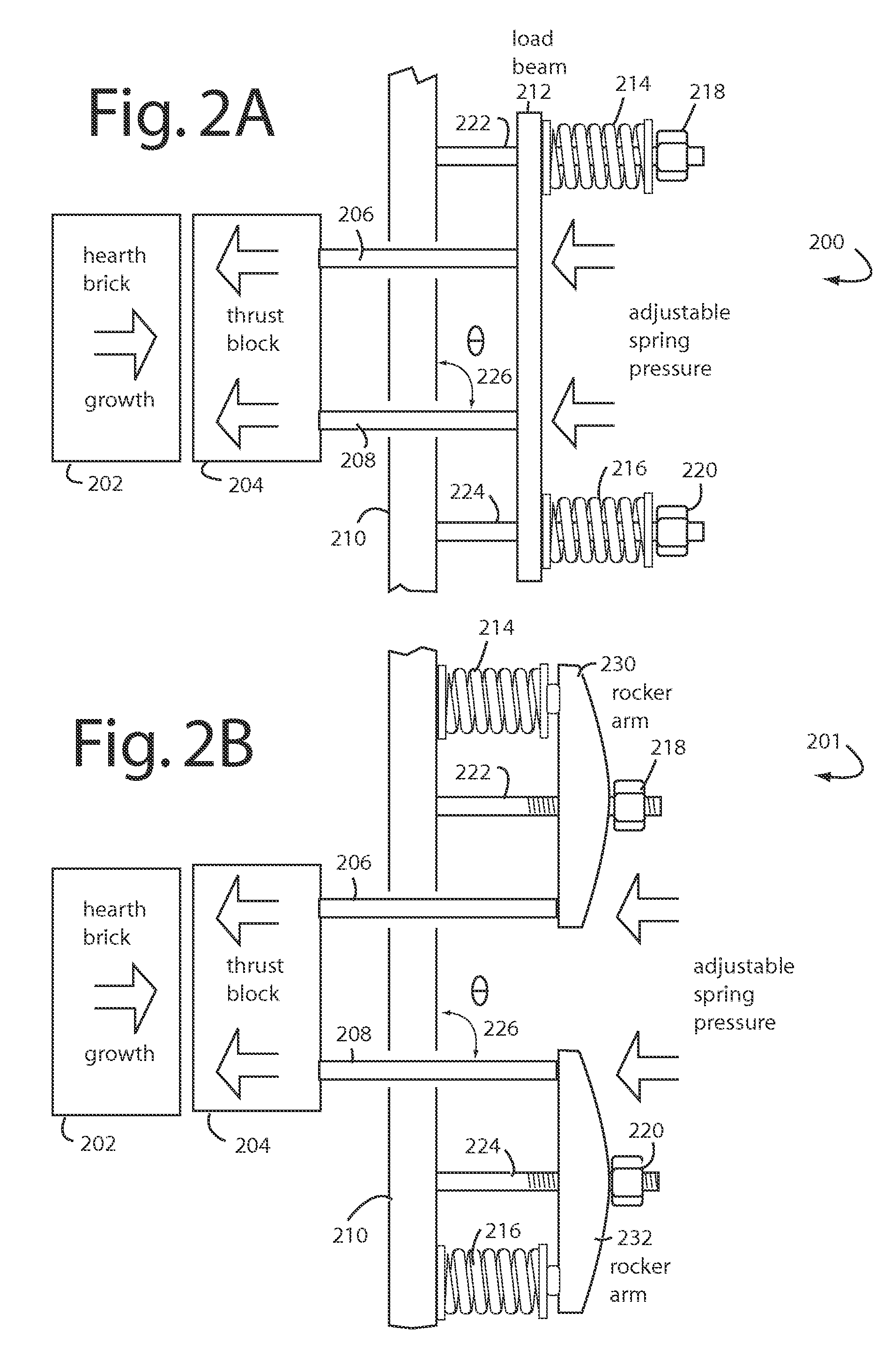

Furnace hearth compression

InactiveUS20080190336A1Less materialReduce expansionFurnace componentsBlast furnace detailsBrickHearth

A brick hearth system comprises a rigid containment shell in which a concave bottom is lined with a hearth refractory sub-layer and hearth brick working layer. The outer perimeter of the hearth refractory is ringed with thrust blocks to compress the whole toward the center and to thereby deny gaps from forming between the separate bricks. Many individual thrust rods penetrate the outer bottom of the containment shell, and such are used to transmit compression forces generated outside the shell to be applied against the thrust blocks in unison. Each thrust rod receives an adjustable amount of inward force from a spring, acting either directly or through a beam or rocker arm. These are anchored to and use the hoop strength of the containment shell as leverage. As the hearth brick working layer grows during its service life, the ring of thrust blocks grows in diameter as well inside the margins provided within the containment shell. The individual thrust rod springs are periodically adjusted to keep the pressures in the optimal range.

Owner:MACRAE TECH

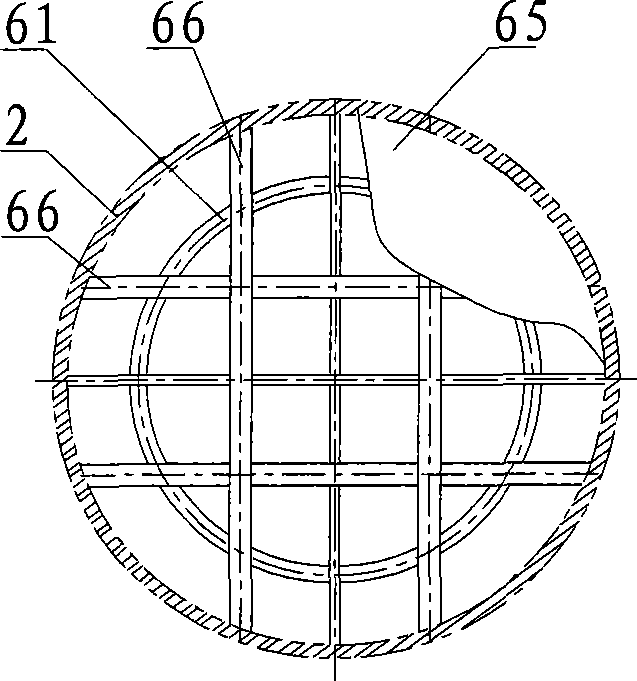

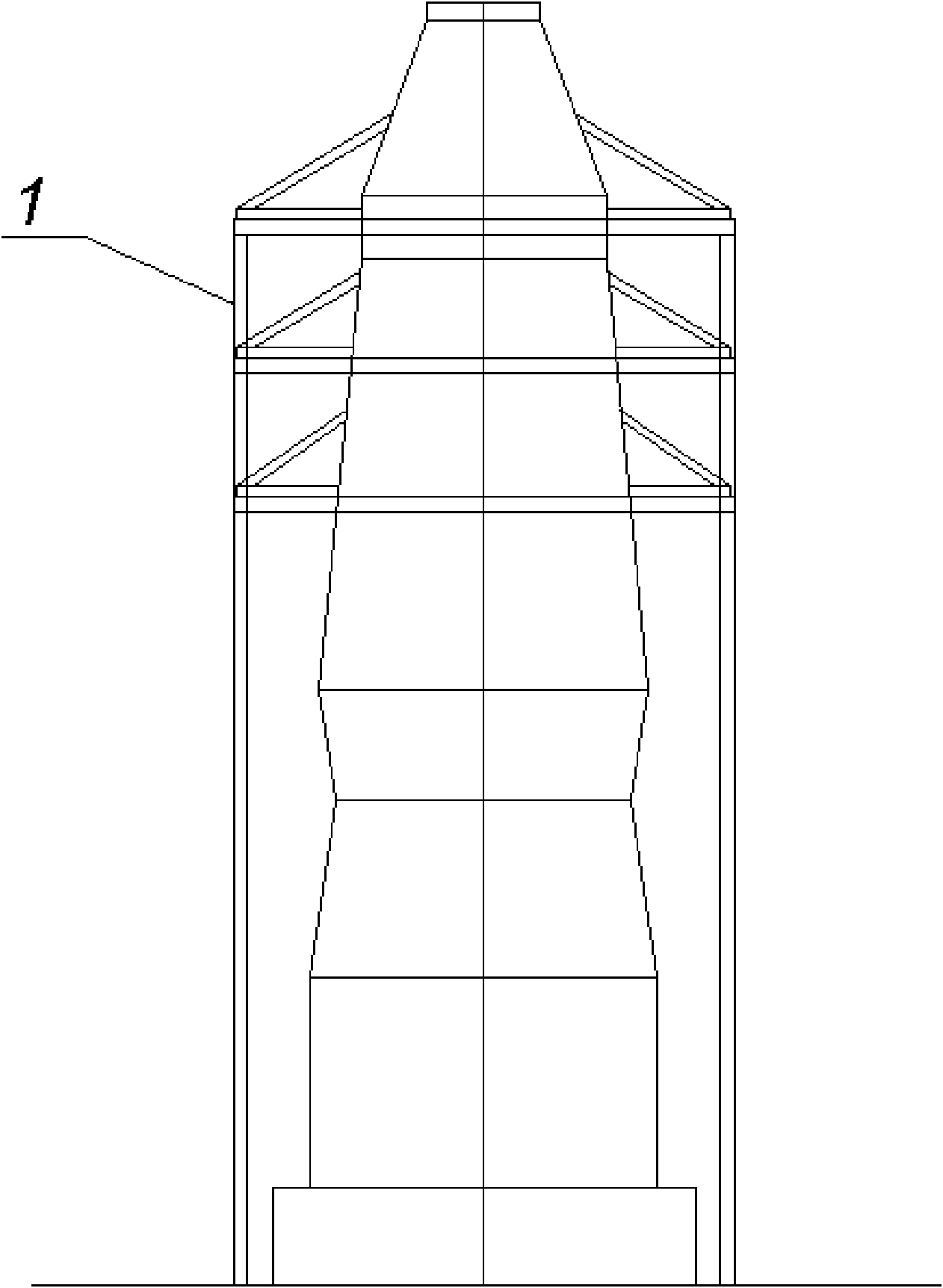

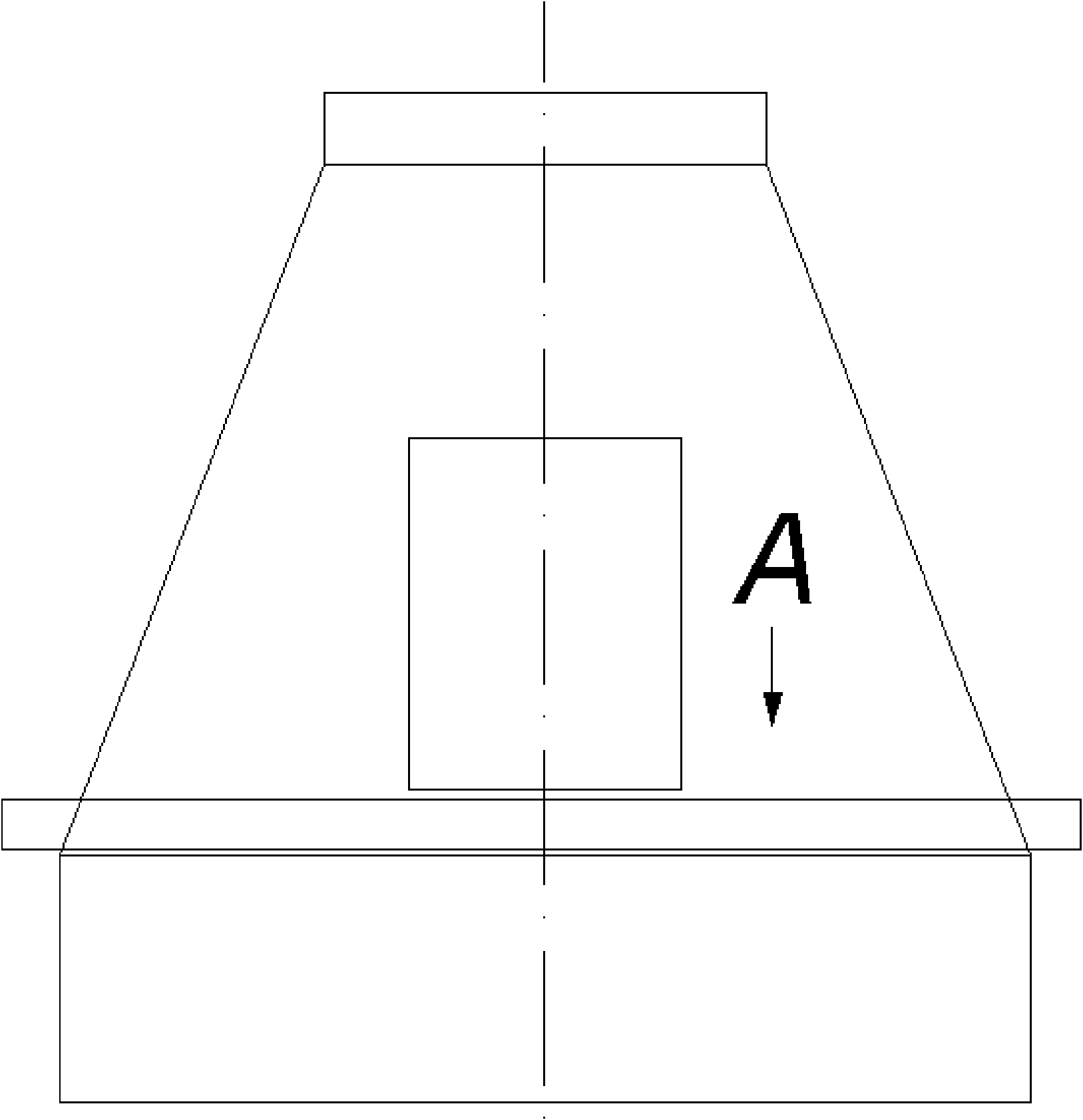

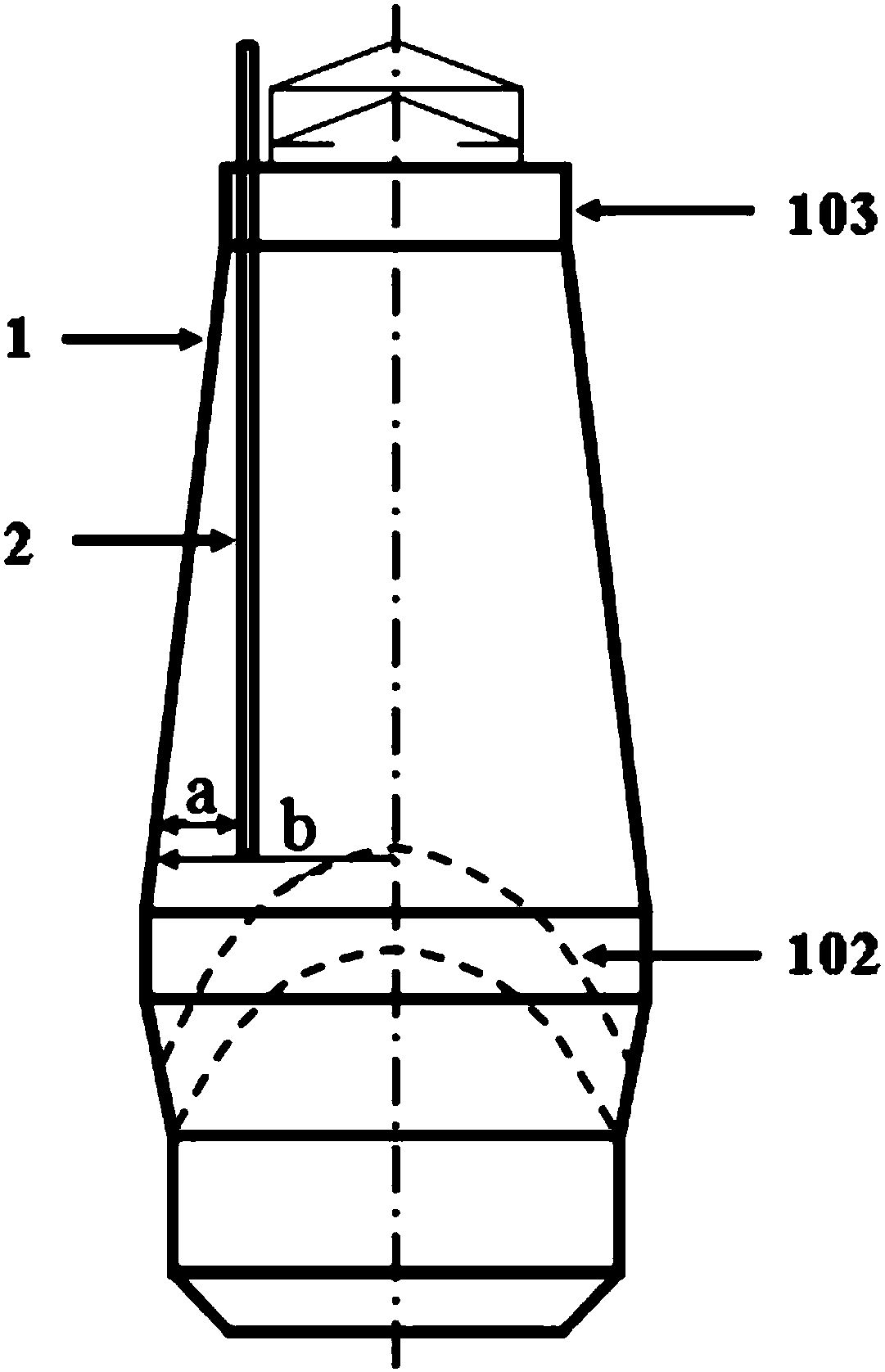

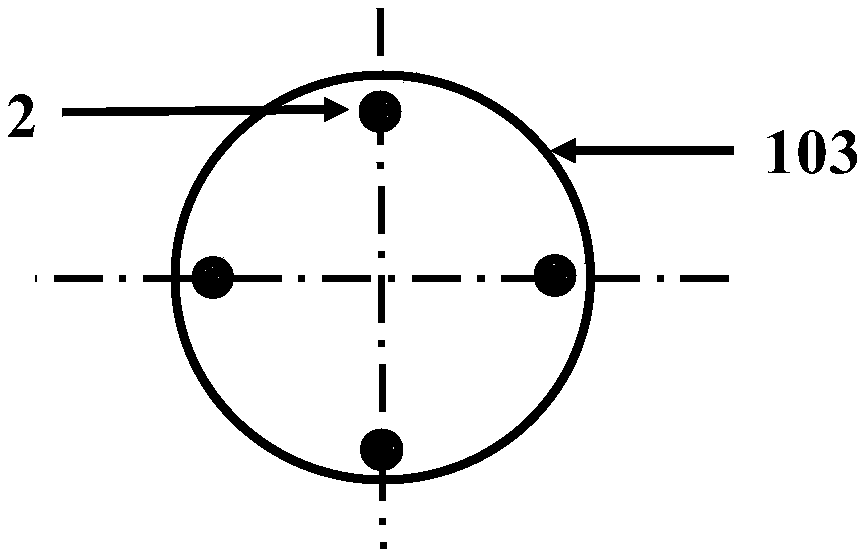

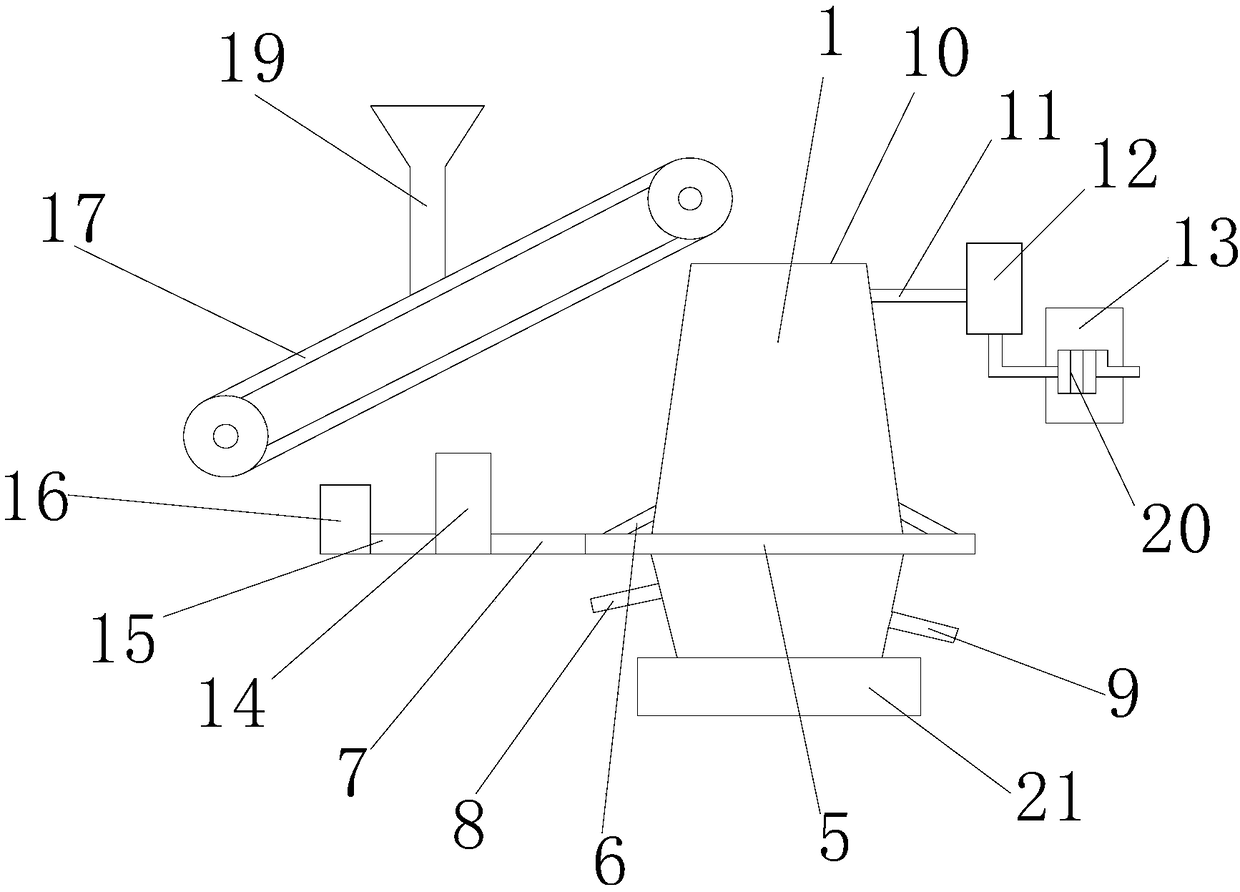

Vertical device for improving coal flow distribution in blast furnace

ActiveCN108265146AReduce total differential pressureImprove breathabilityInternal formsAir volumeEngineering

The invention belongs to the technical field of blast furnace iron making, and in particular, relates to a vertical device for improving coal flow distribution in a blast furnace. The vertical devicecomprises a furnace body, and multiple ventilation pieces arranged in the furnace body; the multiple vertical ventilation pieces are all solid columnar structural bodies; and the multiple vertical ventilation pieces are distributed at the top of the blast furnace in an array form, extend from top to bottom, and are inserted in a material column in the blast furnace by a period of distance. The vertical device for improving coal flow distribution in the blast furnace can improve the breathability of the material column of the blast furnace and reduce total pressure difference of the blast furnace to solve such problems as coal flow distribution and breathability of the material column, and improves the air blowing quantity and the yield under the precondition of guaranteeing invariable pressure difference of the material column to achieve the beneficial effect of improving the production benefit.

Owner:NORTHEASTERN UNIV LIAONING

Glass manufacturing container, glass manufacturing apparatus with the same and glass manufacturing method using glass manufacturing apparatus

InactiveUS20110048076A1Reduces the formation of air bubblesResidence of bubbles in the glass can be effectively reducedLayered productsGlass pressing apparatusElectron donorAlloy

A glass manufacturing container includes a container body and an electron donor. The container body is made of a precious metal or an alloy containing a precious metal and has an inner surface to be brought into contact with molten glass and an outer surface kept from contact with molten glass. The electron donor is electrically connected to the outer surface of the container body. The electron donor is made of an electron donating material capable of donating electrons to the container body at operating temperatures.

Owner:NIPPON ELECTRIC GLASS CO LTD

Blast furnace

InactiveCN108060283AImprove environmental performanceImprove compactnessBlast furnace detailsInternal formsSlagFire brick

The invention discloses a blast furnace. The blast furnace comprises a furnace body, supporting plates, a refractory brick layer, a fire gate, a ring-furnace hot air tube, a hot air branch tube, a hotair tube, a slag outlet, an iron outlet, a charge hole, a waste gas tube, a dust remover, a cooling water tank, a hot blast heater, a gas inlet tube, an air blower, a conveyor belt, a storage channeling slot, a discharge hopper, a cooling tube, a furnace base, a baffle plate and a spring, wherein the supporting plates are fixedly arranged on the side wall of the inner cavity of the furnace body from top to bottom; the side wall of the inner cavity of the furnace body is built with the refractory brick layer; the thickness of the refractory brick layer is a bit greater than width of the supporting plates and covers the supporting plates; the fire gate is fixedly arranged in the inner cavity of the furnace body; and the ring-furnace hot air tube is arranged on the outer side part of the furnace body. Compared with the prior art, the blast furnace has the advantages that connecting tightness between the refractory brick layer and the inner wall of the furnace body can be improved, raw material combusting and melting efficiency and effect are improved, in-batch feeding efficiency and effect of the raw materials are improved, energy consumption of a boiler is reduced, and environment-friendly performances of the blast furnace are improved.

Owner:XINCHANG SHENGXIA MACHINERY PLANT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com