Resin-bonded liner

a technology of reinforcing liner and reinforcing metal, which is applied in the direction of manufacturing converters, liquid transfer devices, furnaces, etc., can solve the problems of reducing the quality of steel, reducing and affecting the quality of finished steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

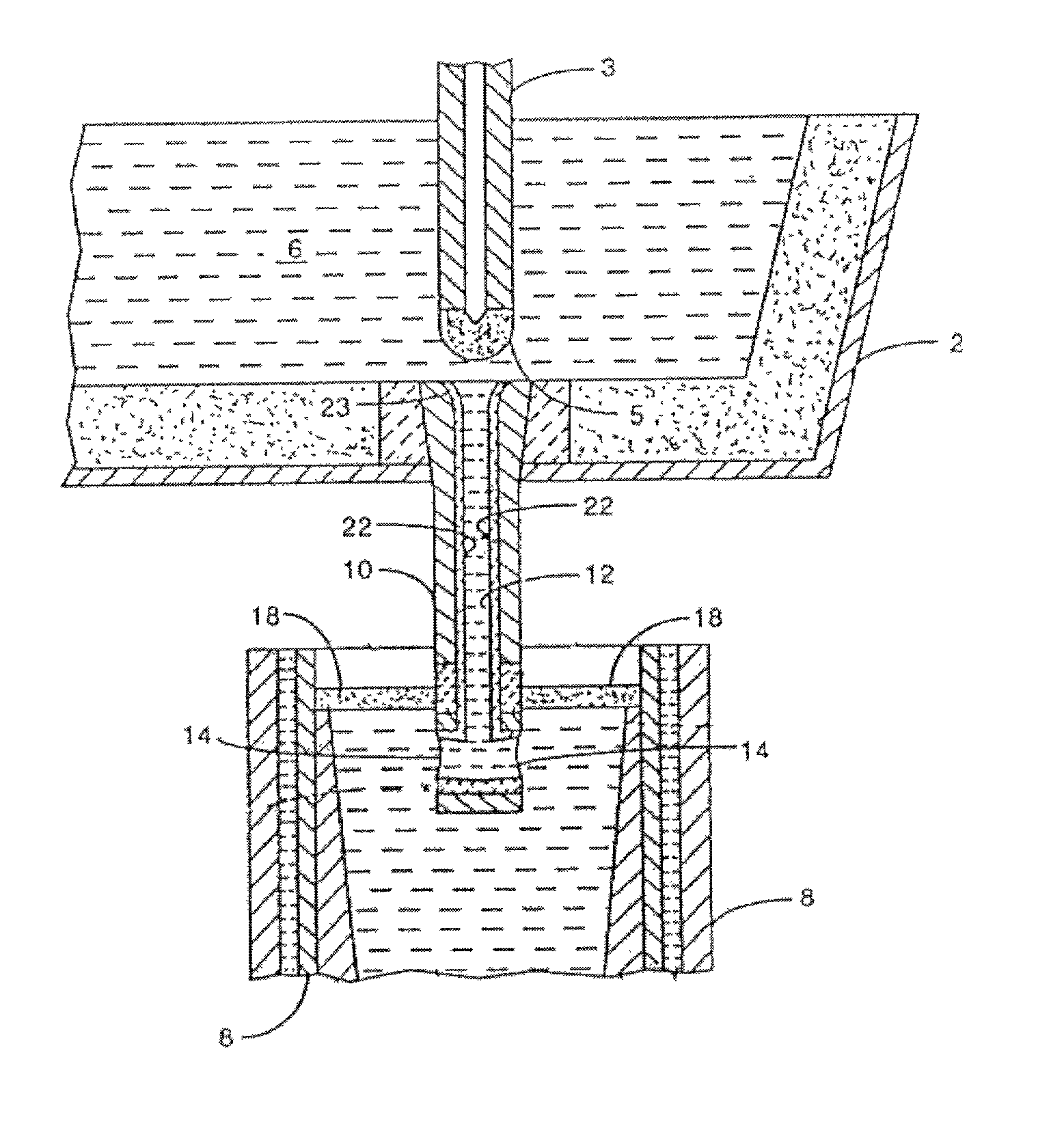

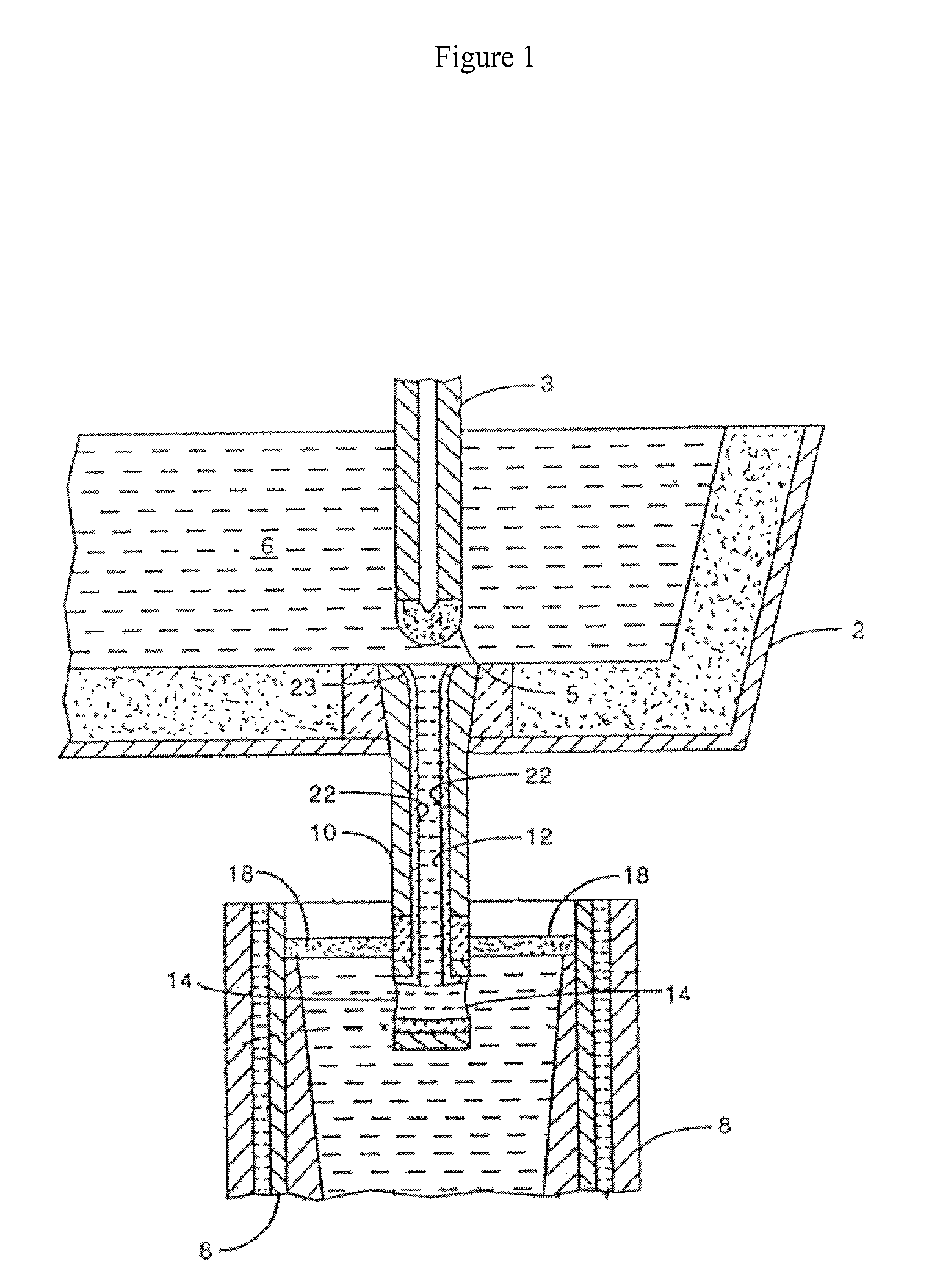

Image

Examples

example 2

[0036] A first tundish inner nozzle was made comprising a standard refractory composition. A second tundish inner nozzle was made having a casting channel comprising Mix A. Both nozzles were used to cast aluminum-killed steel. At the end of the casting campaign, the nozzles were removed and "pins" from each nozzle were inspected. A "pin" is a quantity of steel that has solidified in the casting channel after the gate is closed. The pin from the first nozzle included substantial alumina buildup along the casting channel. No alumina buildup was observed in the pin from the second nozzle, which comprised the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com