Method for concentrating extremely low-grade refractory magnetite

A magnetite and grade technology, applied in chemical instruments and methods, magnetic separation, wet separation, etc., can solve the problems of high iron ore yield, high ore hardness, fine embedded particle size, etc., and reduce the beneficiation ratio. , improve the recovery rate, reduce the effect of production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

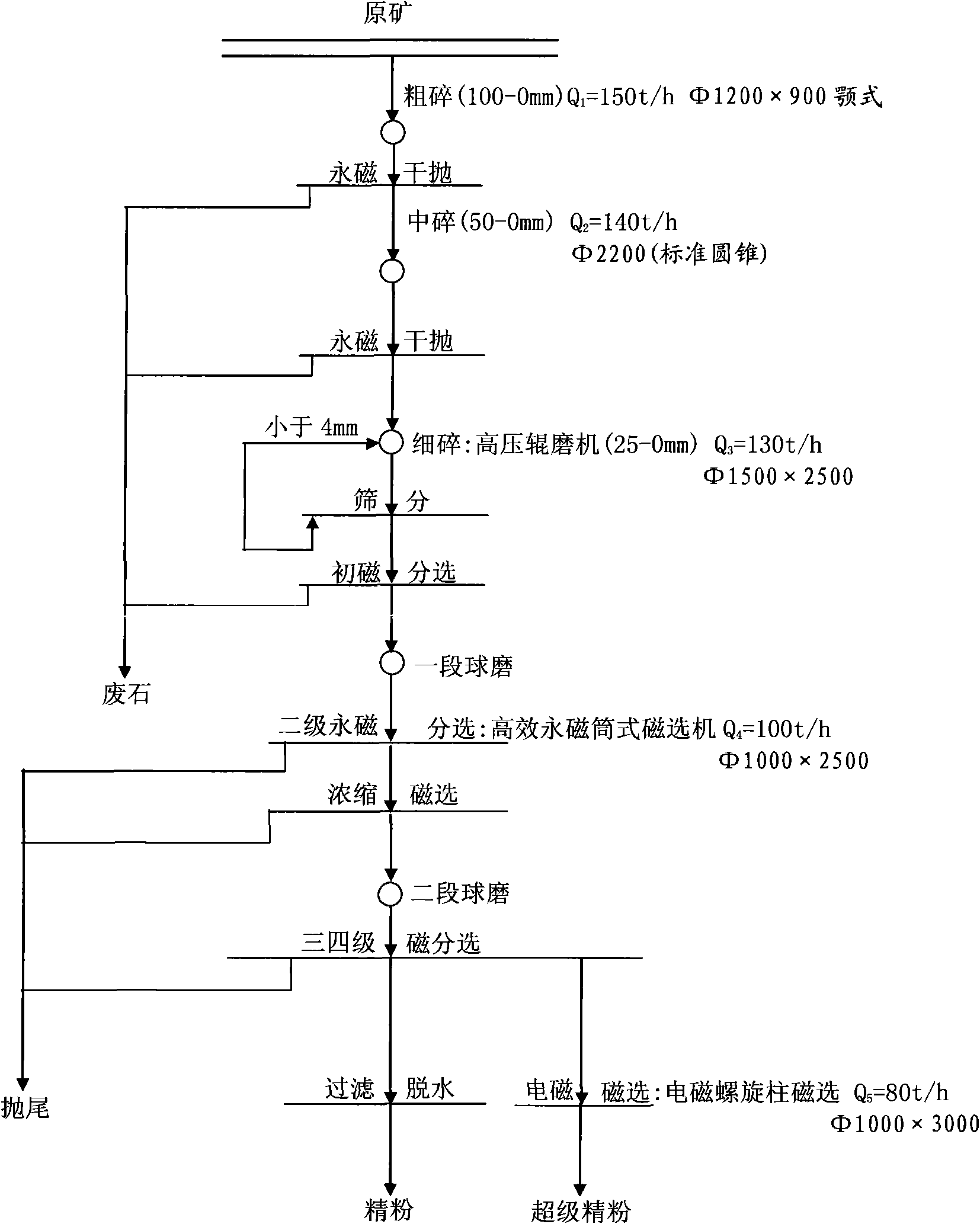

[0024] A kind of beneficiation method of extremely low-grade refractory magnetite, comprises the following steps:

[0025] (1) The extremely low-grade 450-0mm magnetite with fine-grained impregnated cloth is coarsely crushed underground by a jaw crusher. The bulk magnetic separator dry selects waste, and the 200-0mm product enters the standard cone crusher for secondary crushing;

[0026] (2) After secondary crushing, the products are discarded through dry selection of magnetic pulleys. After secondary crushing, the products are subjected to secondary crushing. After secondary crushing, they are screened. The products on the sieve larger than 255mm are returned to secondary crushing, and the products under the 255-0mm sieve enter High-pressure roller mill for closed-circuit fine crushing;

[0027] (3) Finely crushed and then sieved, the sieved products larger than 4mm are returned to finely crushed, and the 4-0mm sieved products enter the permanent magnetic powder ore dry mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com