Blast furnace

A blast furnace and furnace body technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as potential safety hazards, insufficient purity of molten iron, difficulty in burning and melting iron ore, coke, and flux for slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

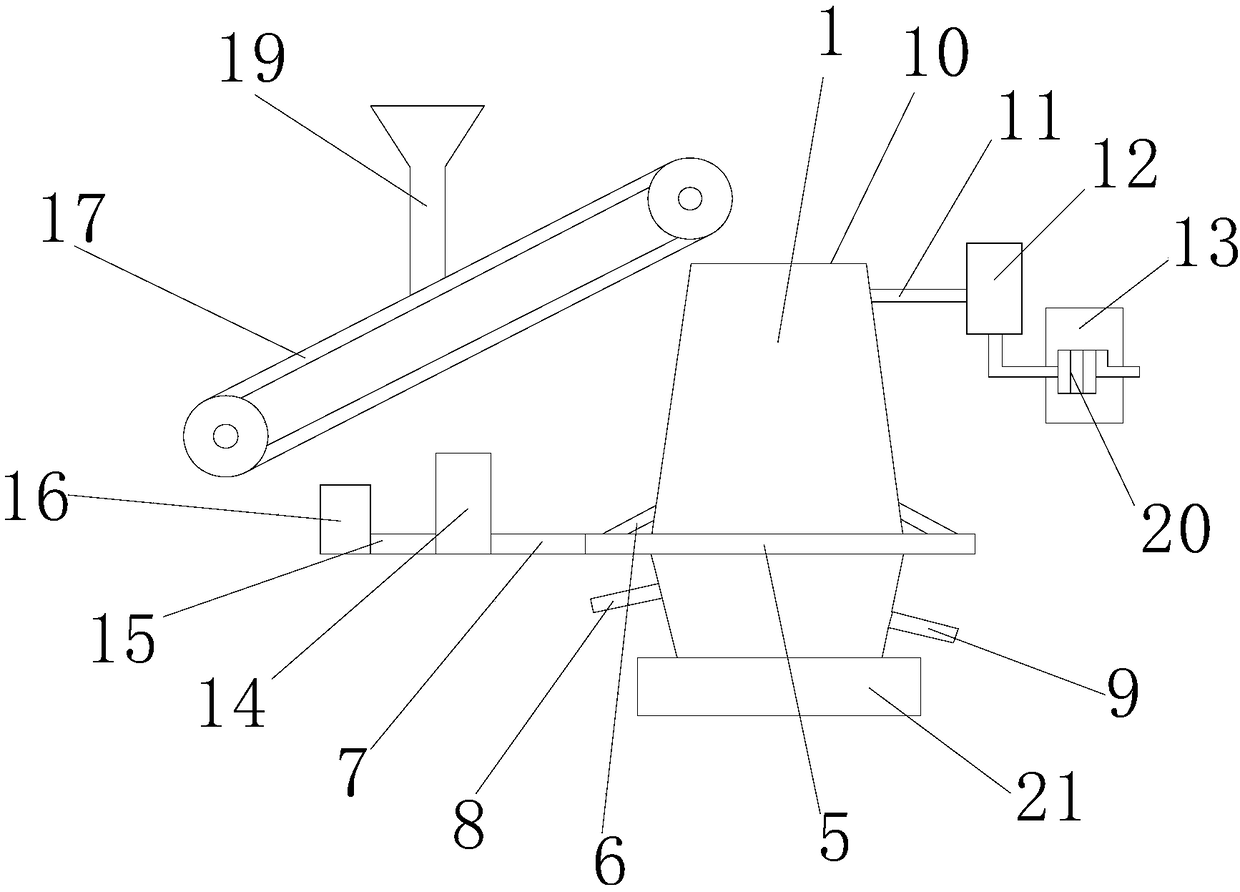

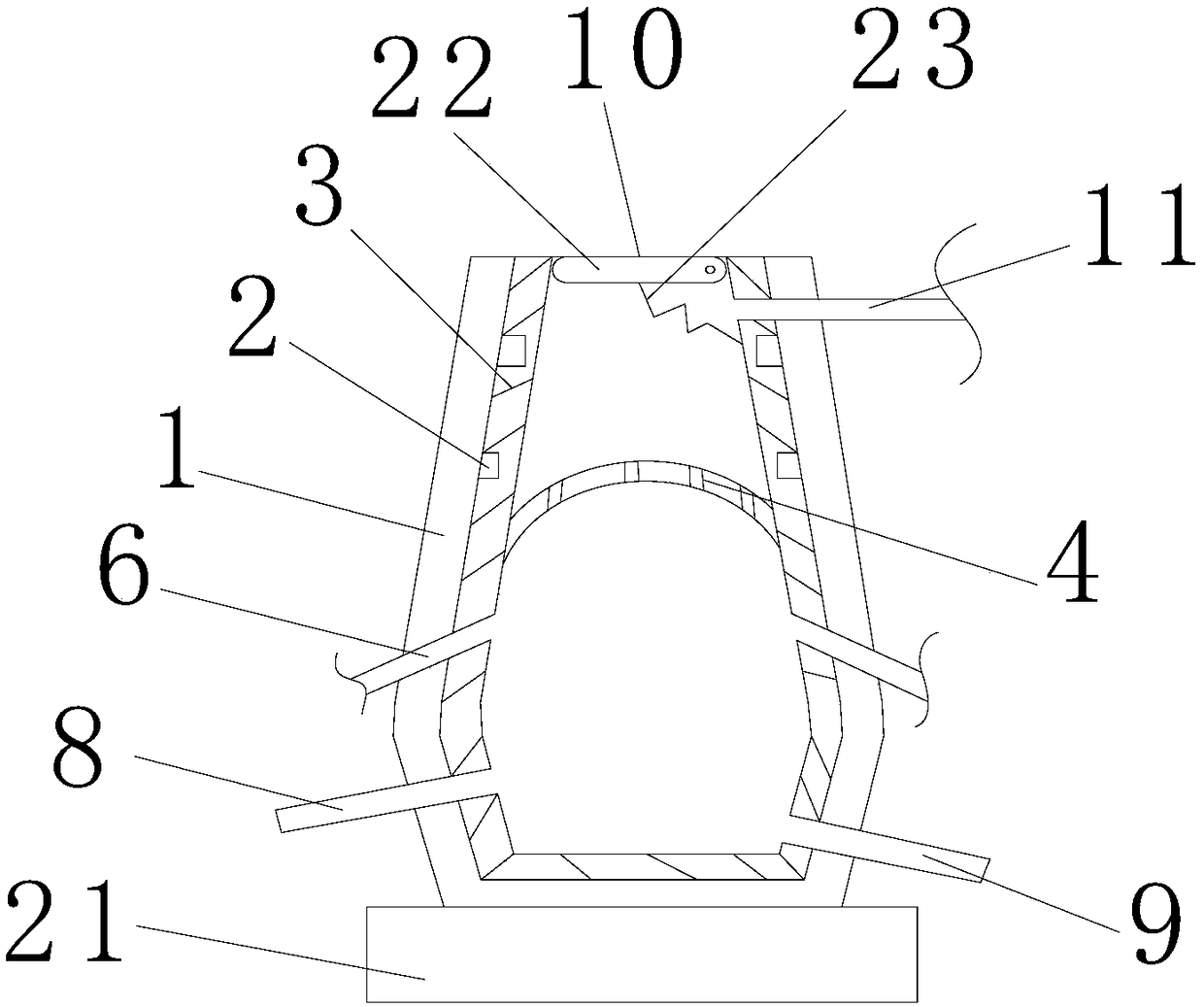

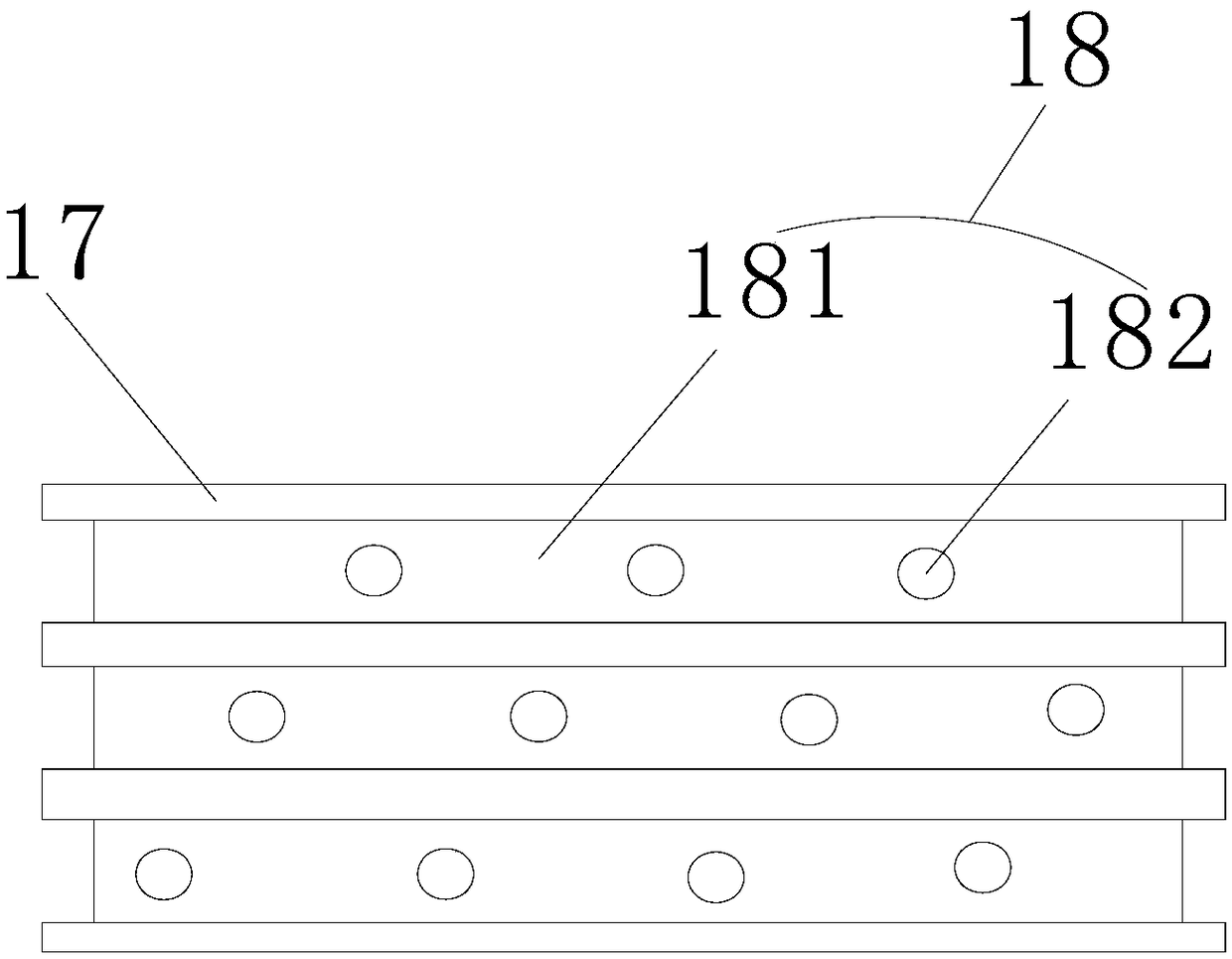

[0018] refer to figure 1 , 2, 3, a kind of blast furnace of the present invention, comprises furnace body 1, support plate 2, refractory brick layer 3, grate 4, ring furnace hot air pipe 5, hot air branch pipe 6, hot air pipe 7, slag outlet 8, tapping Port 9, feed port 10, waste gas pipe 11, dust collector 12, cooling water tank 13, hot blast stove 14, air intake pipe 15, blower 16, conveyor belt 17, storage tank 18, hopper 19, cooling pipe 20, furnace Seat 21, baffle plate 22 and spring 23, the side wall of the inner cavity of described furnace body 1 is fixedly provided with a plurality of supporting plates 2 from top to bottom, and the side wall of the inner cavity of described furnace body 1 is lined with refractory brick layer 3. The thickness of the refractory brick layer 3 is slightly larger than the width of the support plate 2 and wraps the support plate 2. The inner cavity of the furnace body 1 is fixed with a fire grate 4, and the outer part of the furnace body 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com