Cold static ignition under meagre coal and tiny oil, and steady burning burner in ultra low load

A burner, lean coal technology, applied in burners, burners burning powder fuel, combustion chambers, etc., can solve the problems of unrealized cold furnace ignition and ultra-low load stable combustion, and achieve easy market acceptance and investment costs. Low, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

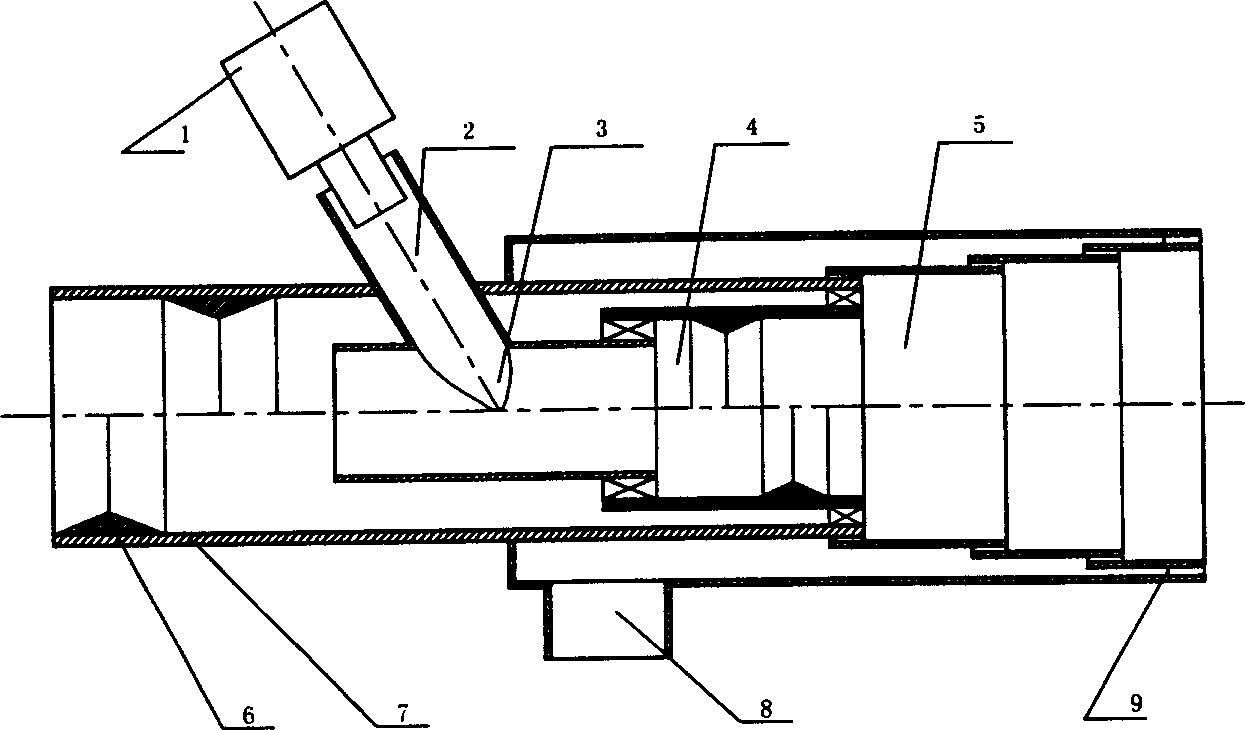

[0014] As shown in the accompanying drawings, the burner with lean coal and micro-oil cold ignition and ultra-low-load stable combustion has a pulverized coal pipeline 6, and a pulverized coal combustion chamber 3 connected to the pulverized coal pipeline 7 is provided in the pulverized coal pipeline 7. Chamber 4, an oil combustion chamber 2 and an oil burner 1 are arranged obliquely at the front end of the primary pulverized coal combustion chamber 3, and a third-stage pulverized coal combustion chamber 5 is connected to one end of the secondary pulverized coal combustion chamber 4 and the pulverized coal pipeline 7. A cooling air inlet duct 8 is provided outside the pulverized coal pipeline 7 and the third-stage pulverized coal combustion chamber 5, and a multi-stage annular seam cooling air film 9 is arranged between the third-stage pulverized coal combustion chamber 5 and the cooling air inlet duct 8. The other end of the powder pipeline 7 is provided with a coal powder str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com