Polyolefin resin nucleating agent and preparation method thereof

A technology of polyolefin resin and nucleating agent, applied in the field of polyolefin nucleating agent and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1 1,3: Preparation of 2,4-bis(3,4-dimethylbenzylidene)sorbitol-silica gel grafted nucleating agent.

[0065] In a four-port reaction kettle equipped with a stirrer, an addition funnel, a thermometer and a condenser, add 18.2g sorbitol, 100cm 3 Methanol, stirred to dissolve. Then, under stirring, add 28.3g of 3,4-dimethylbenzaldehyde, 1g of p-toluenesulfonic acid, 20.8g of tetraethyl silicate, react at 50°C for 7h, and neutralize the reaction system with aqueous sodium hydroxide solution. Make it pH ≥ 10, add tap water to wash, filter, and dry to obtain a white powder.

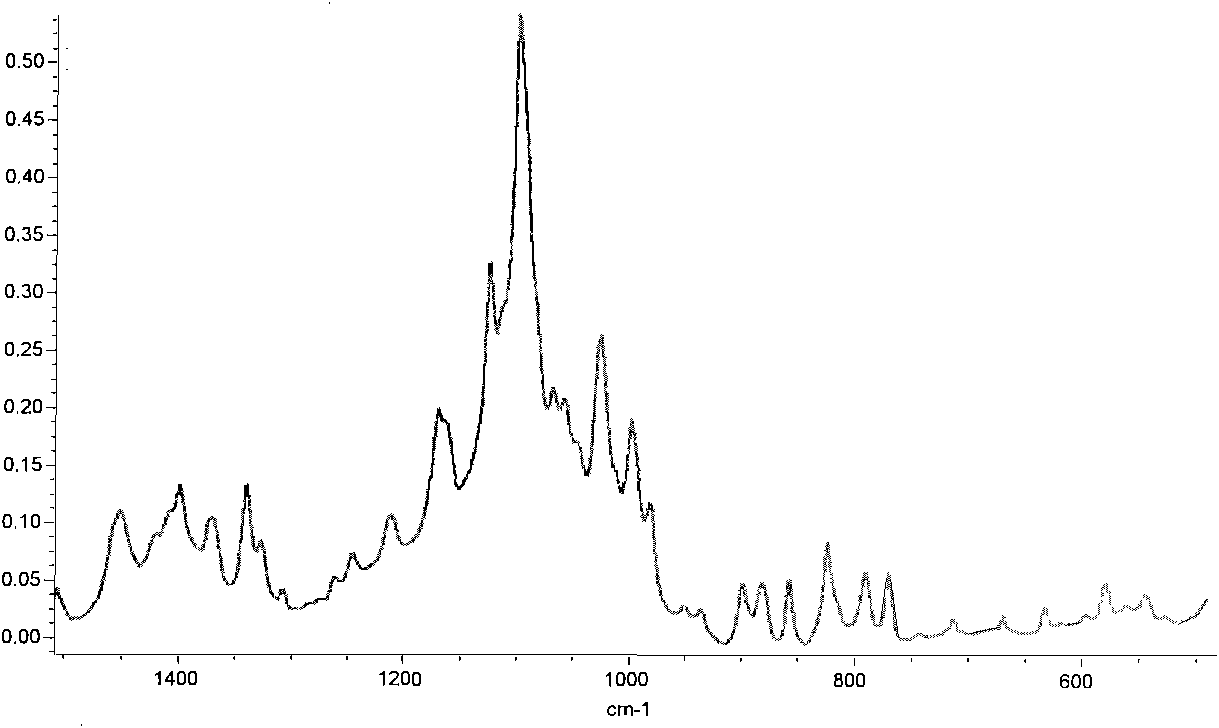

[0066] The FTIR spectrum of the sample is at 1090cm -1 There is a strong absorption of Si-O-Si nearby, and the infrared spectrum of the sample is shown in the attached figure 1 .

[0067] Under the same conditions, the sample prepared without adding tetraethyl silicate is called DMDBS.

Embodiment 2

[0068] Example 2 1,3: Preparation of 2,4-bis(p-methylbenzylidene)sorbitol-silica gel grafted nucleating agent.

[0069] In a four-port reaction kettle equipped with a stirrer, an addition funnel, a thermometer and a condenser, add 18.2 g of sorbitol and 100 cm of ethanol 3 , stir to dissolve. Then, under stirring, add 24.6g of p-tolualdehyde, 1.2g of benzenesulfonic acid, 20.8g of tetraethyl silicate, and react at 55°C for 7h, neutralize the reaction system with aqueous calcium hydroxide solution to make the pH≥ 10. Add tap water to wash, filter, and dry to obtain a white powder.

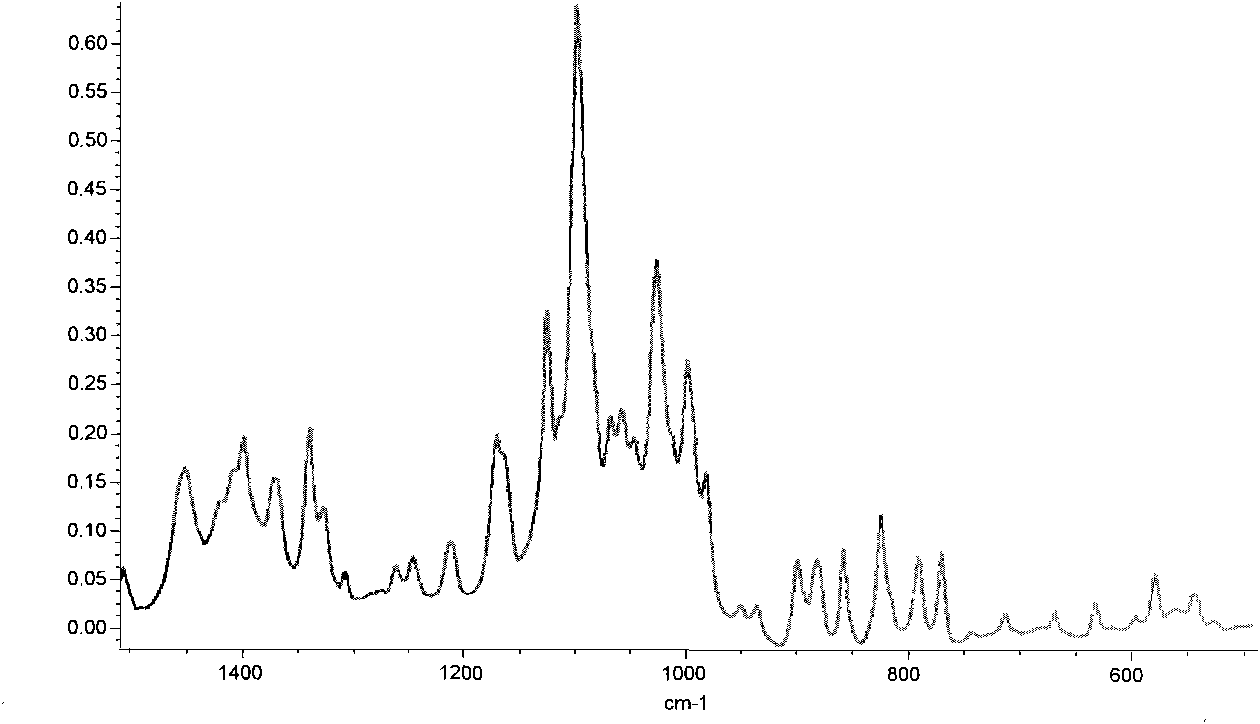

[0070] The FTIR spectrum of the sample is at 1090cm -1 There is a strong absorption of Si-O-Si nearby, and the infrared spectrum of the sample is shown in the attached figure 2 .

Embodiment 3

[0071] Example 3 1,3: Preparation of 2,4-bis(p-chlorobenzylidene)sorbitol-silica gel grafted nucleating agent.

[0072] In a four-port reaction kettle equipped with a stirrer, an addition funnel, a thermometer and a condenser, add 18.2 g of sorbitol and 100 cm of methanol 3 , stir to dissolve. Then, under stirring, add 26.4 g of p-chlorobenzaldehyde, 0.9 g of concentrated sulfuric acid, and 15.2 g of tetramethyl silicate. After reacting at 60° C. for 7 hours, neutralize the reaction system with aqueous potassium hydroxide to make the pH ≥ 10, Add tap water to wash, filter, and dry to obtain a white powder.

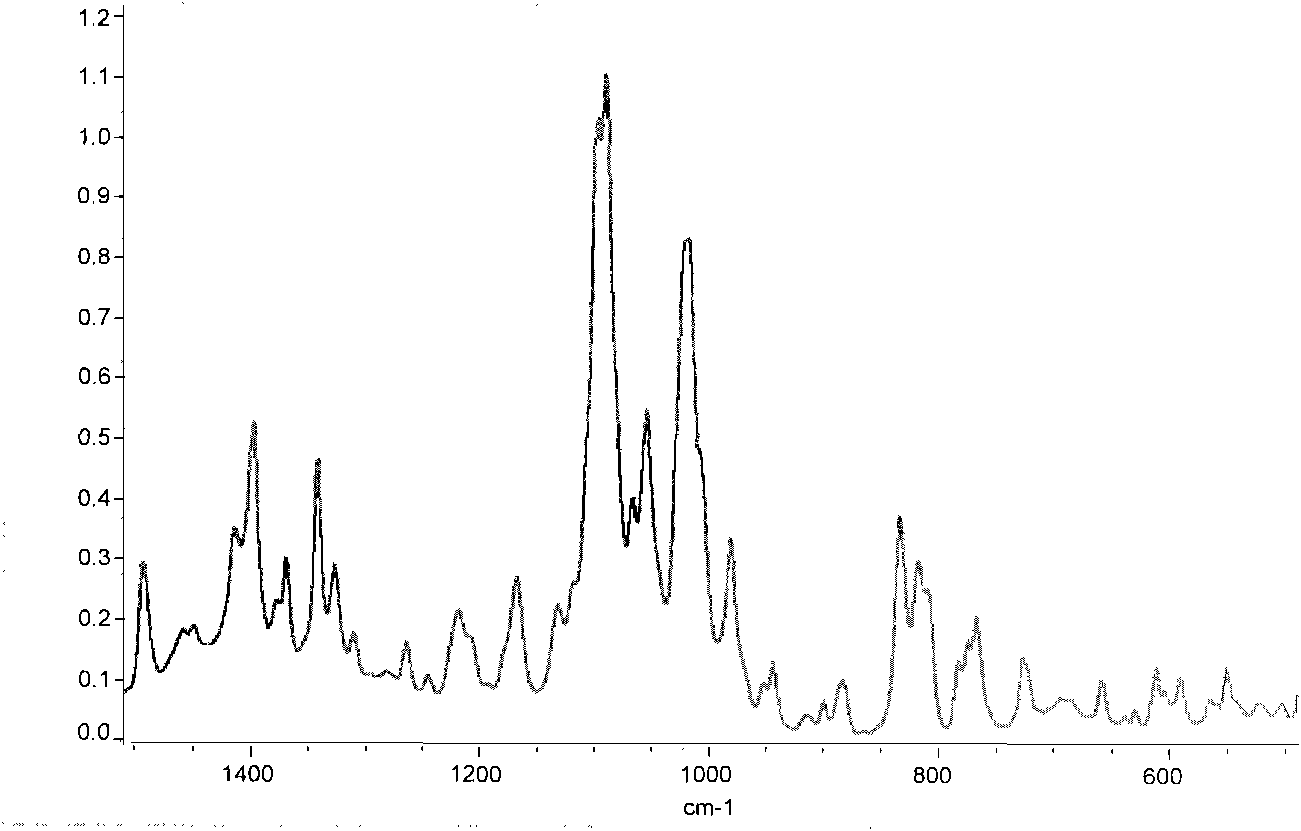

[0073] The FTIR spectrum of the sample is at 1090cm -1 There is a strong absorption of Si-O-Si nearby, and the infrared spectrum of the sample is shown in the attached image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com