Ring block conveying apparatus, and remedy method for blast furnace casing

A technology for a ring-shaped member and a conveying device, applied in the field of moving in or out, can solve the problems of high cost, limited use, and low utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

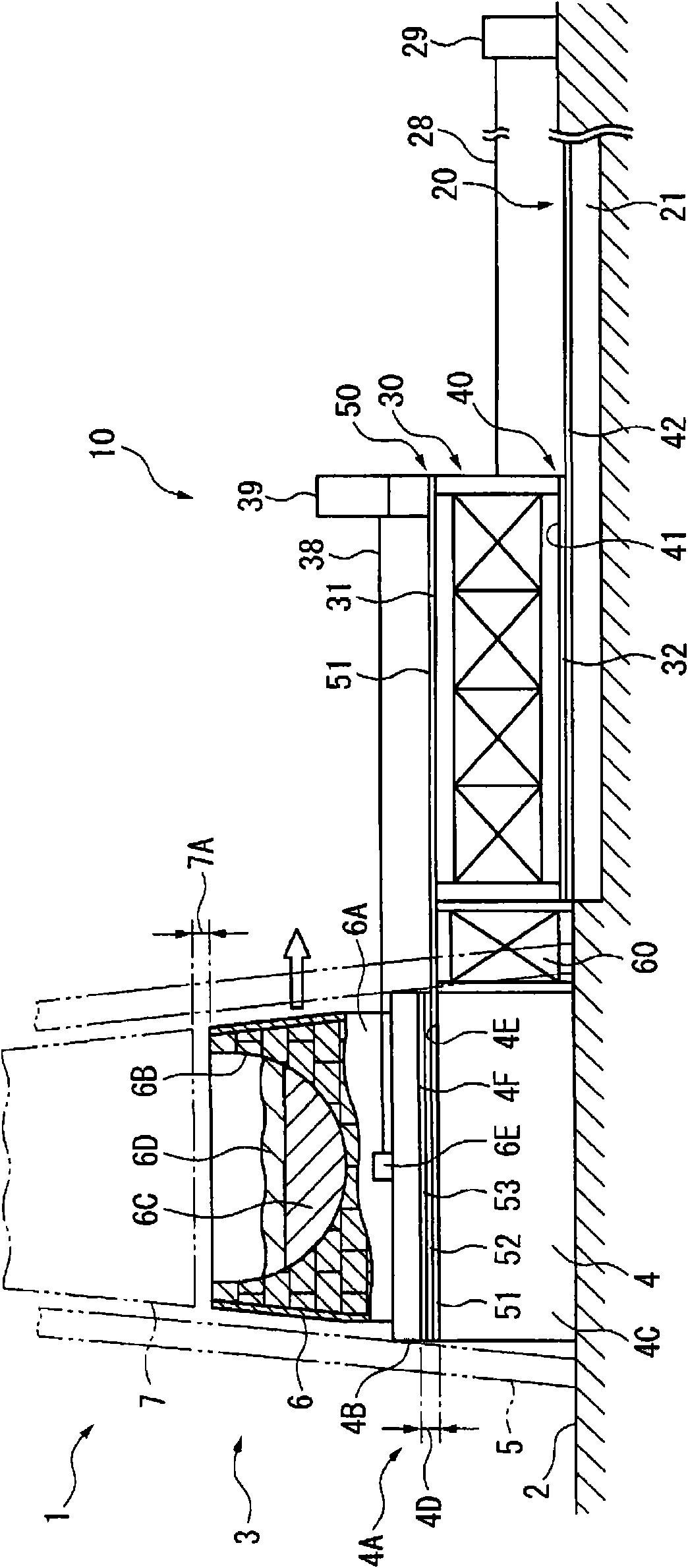

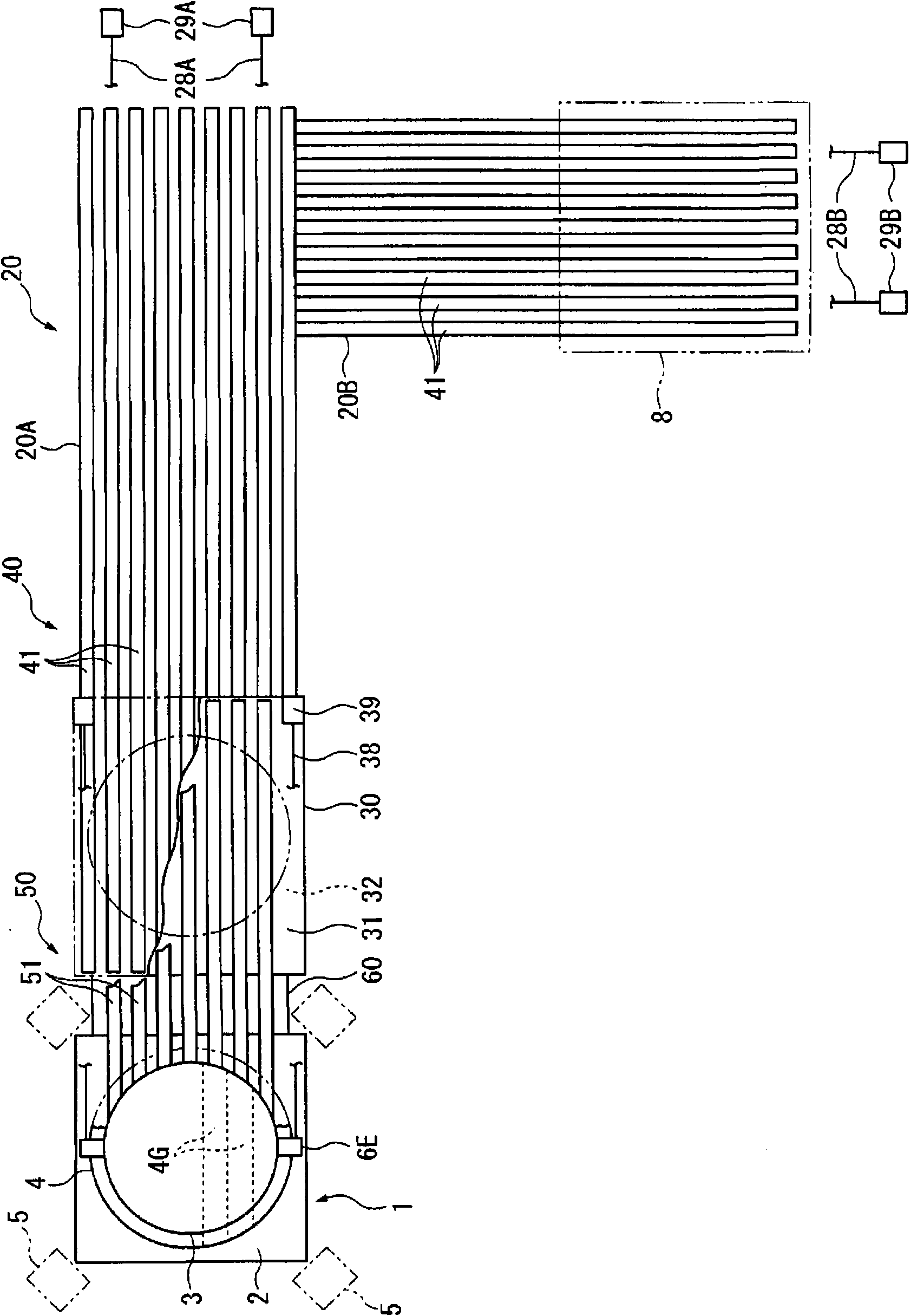

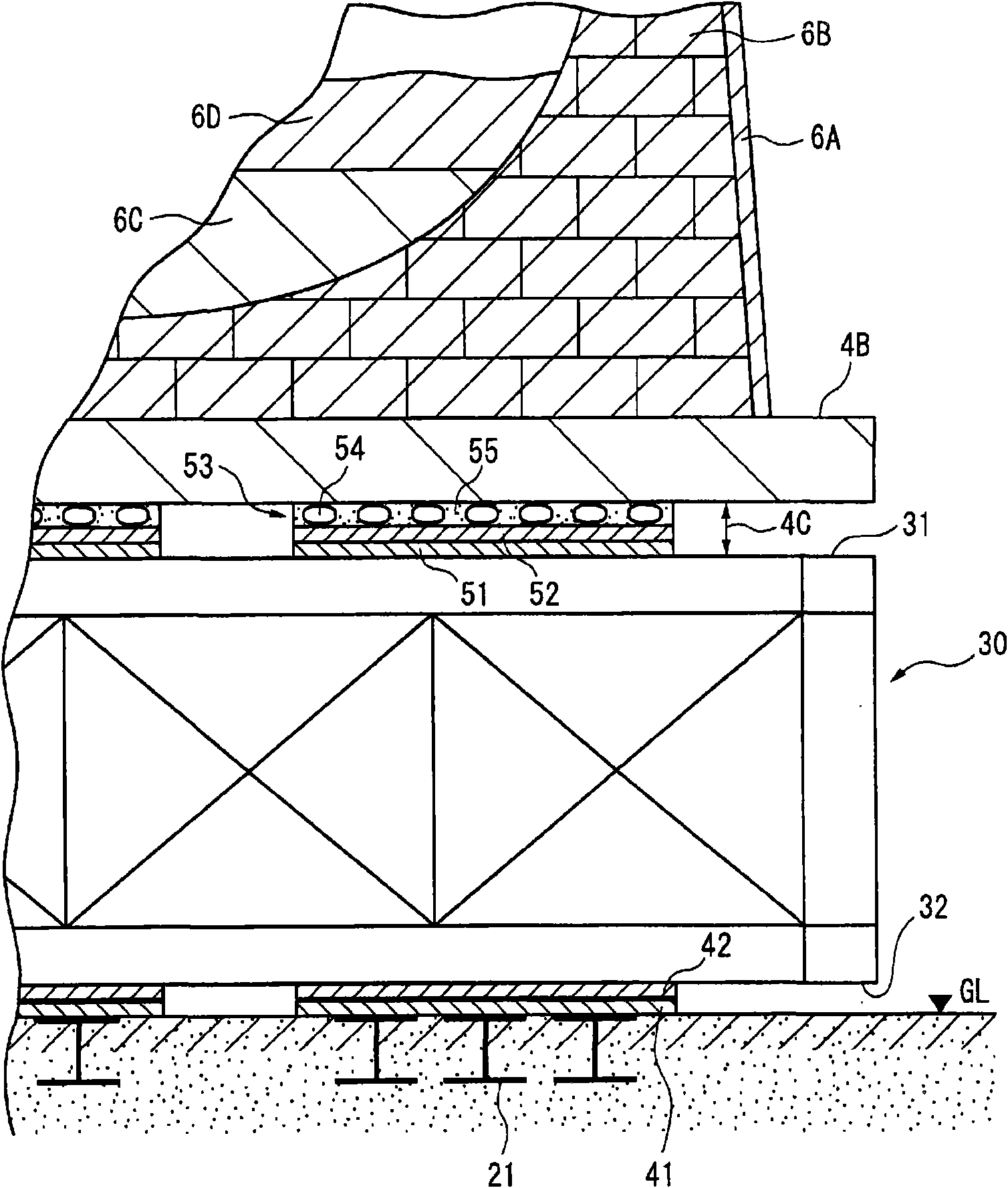

[0131] Such as figure 1 , 2 As shown, a blast furnace 1 is located at a construction site, and its furnace body 3 is built on a furnace foundation 4 . A furnace body tower 5 for supporting the furnace body 3 is arranged around the blast furnace 1 . When the furnace body 3 is disassembled, it is disassembled into the furnace bottom member 6 and the ring building member 7 above and carried out. When moving out the furnace bottom member 6 and the ring-laying member 7, the ring-laying member 7 can be hoisted by a jack (not shown) arranged on the furnace body tower 5 . Then, the unloaded furnace bottom member 6 and ring building member 7 are transported to a work site 8 far away from the furnace body 1, and both are disassembled separately.

[0132] A furnace shell 6A is provided on the outside of the furnace bottom member 6 , and refractory bricks 6B are provided on the inner periphery and bottom surface of the furnace bottom member 6 . After the blast furnace 1 is shut down, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com