Patents

Literature

113results about How to "Improve manufacturing productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

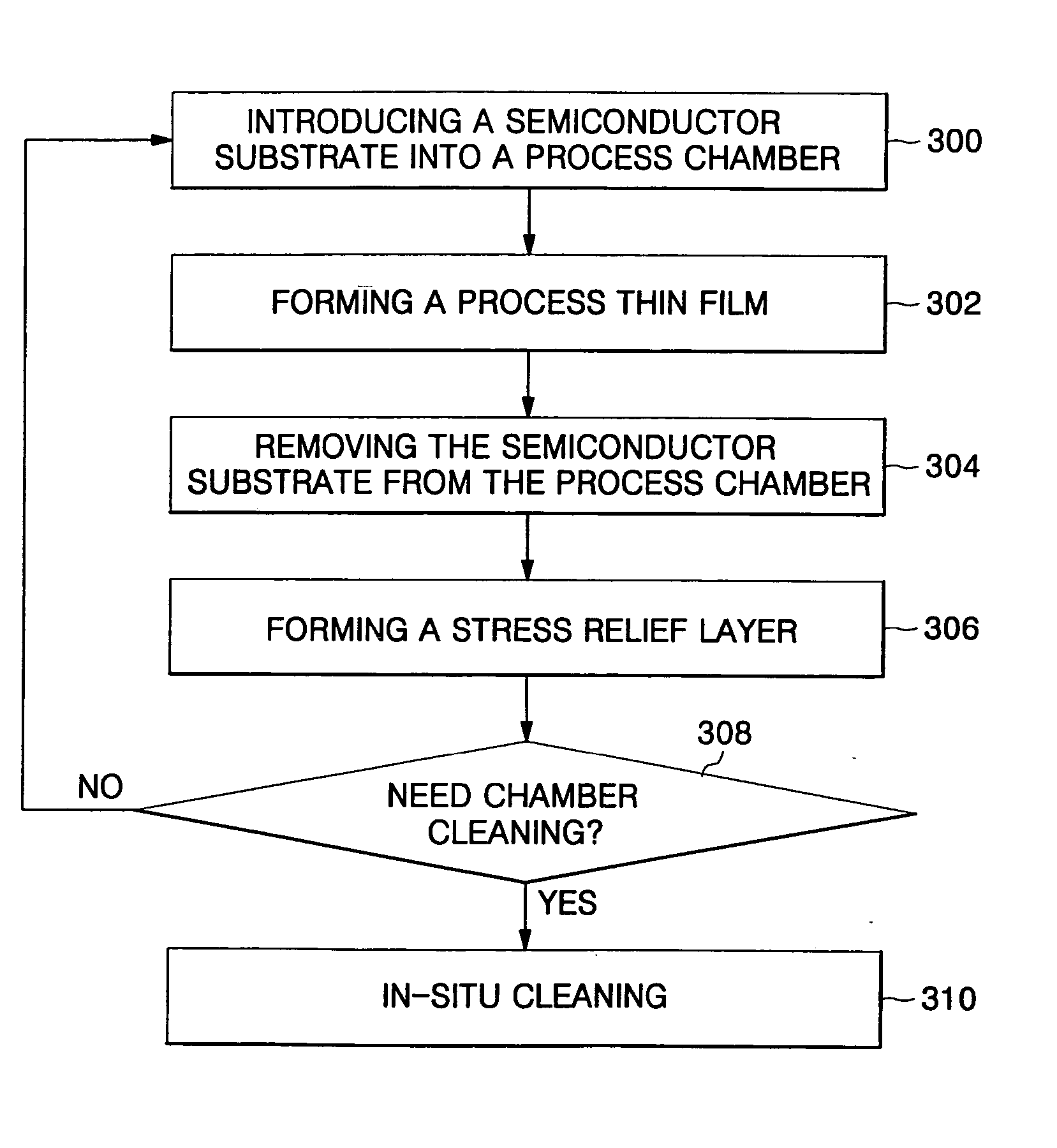

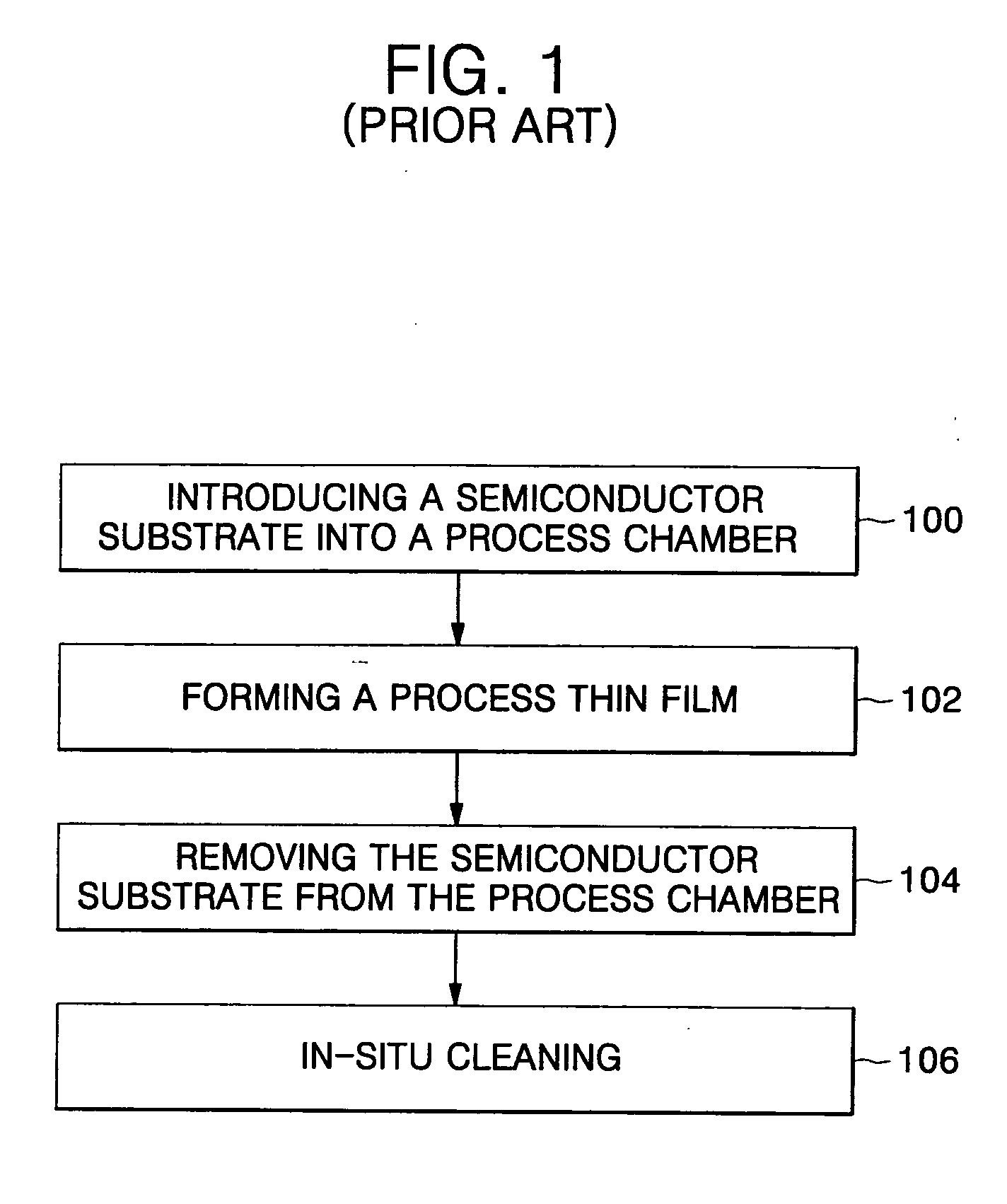

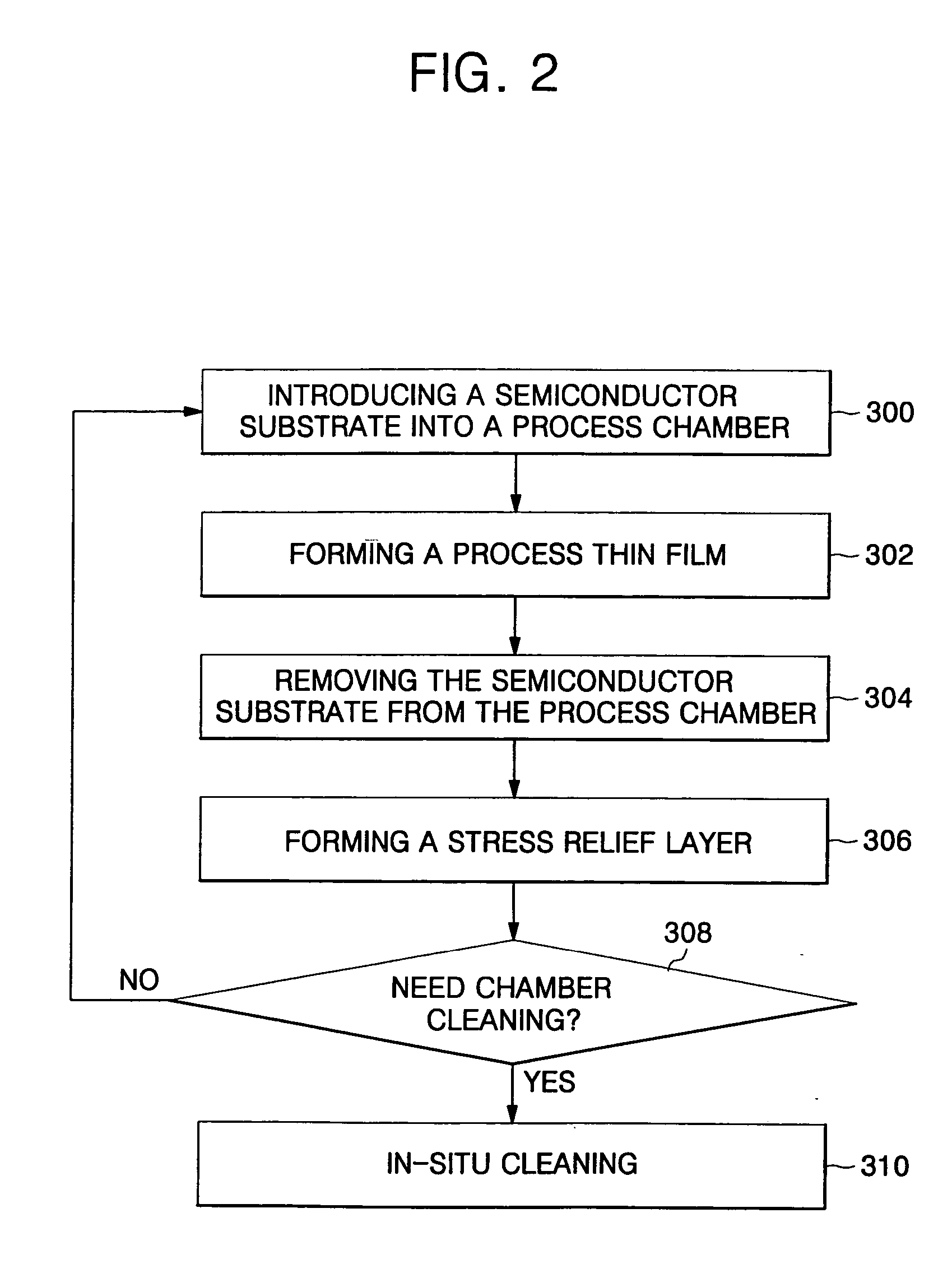

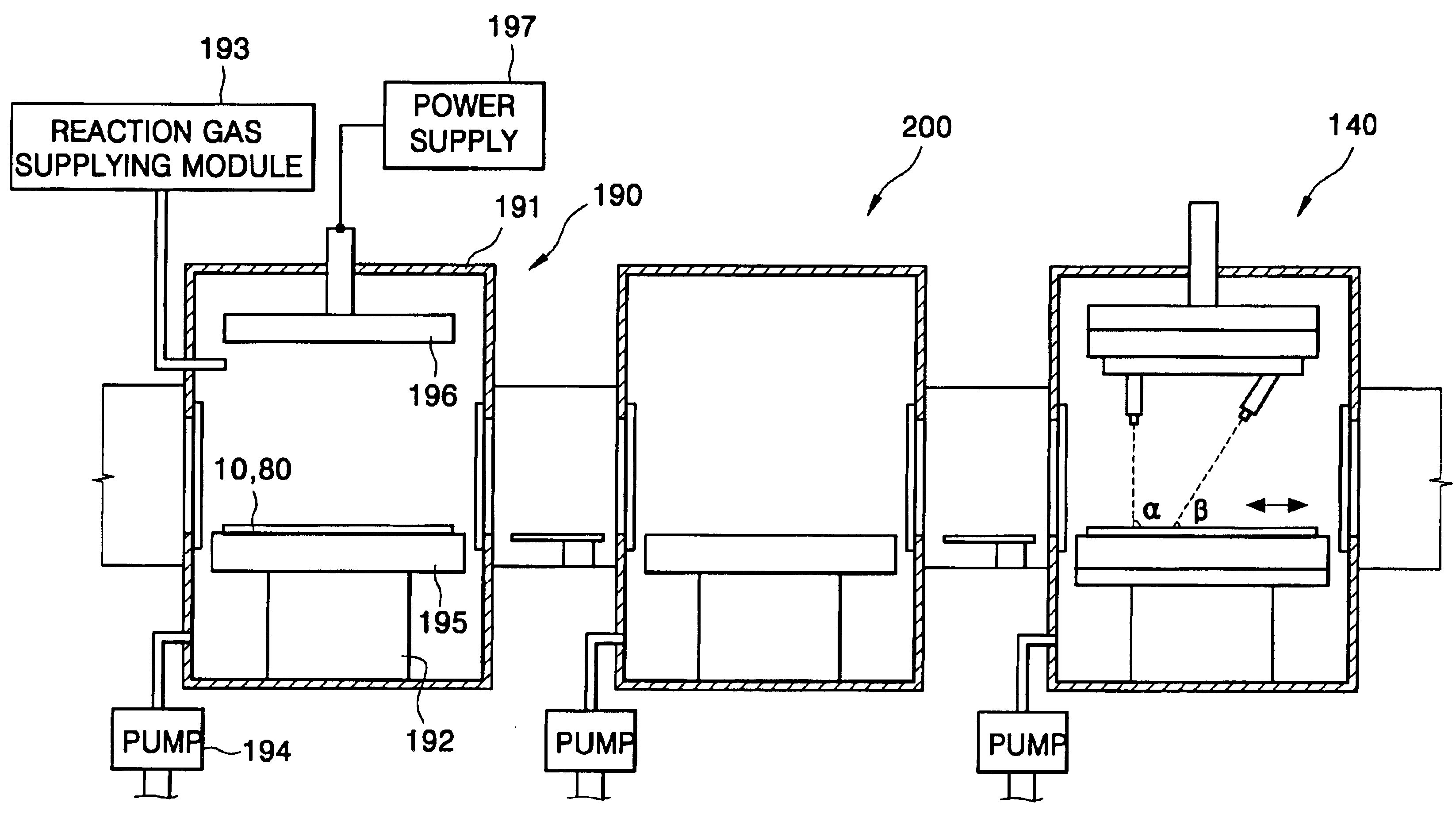

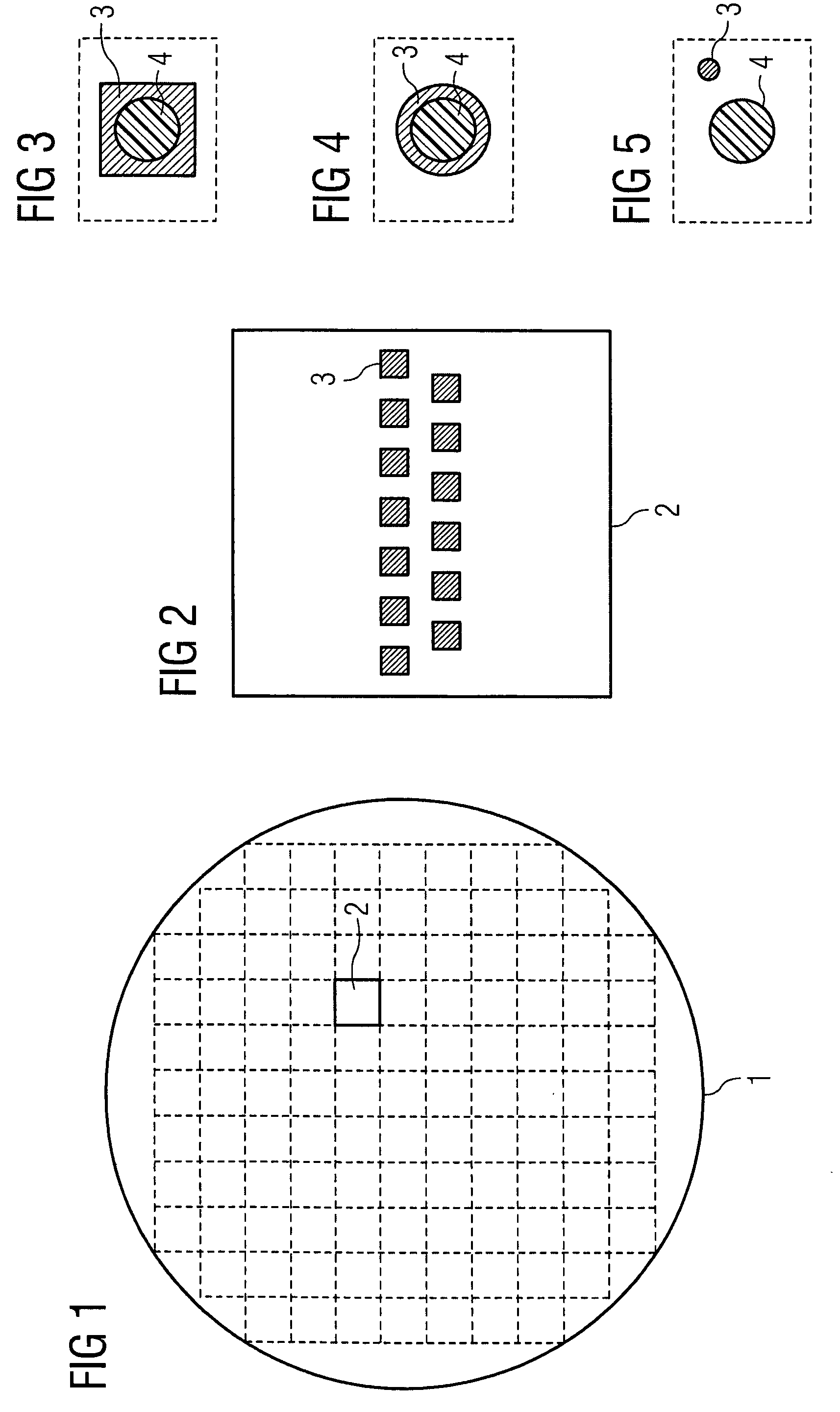

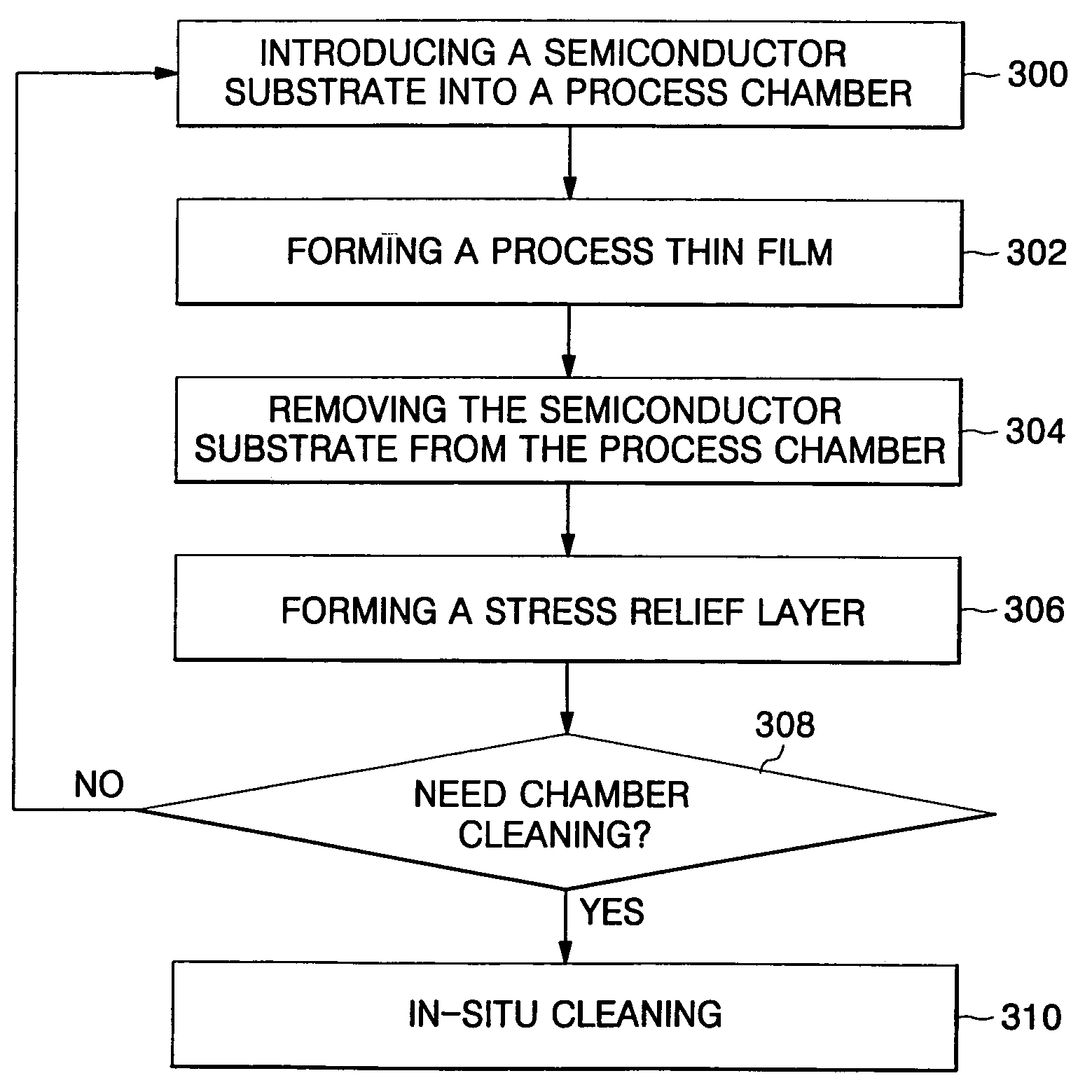

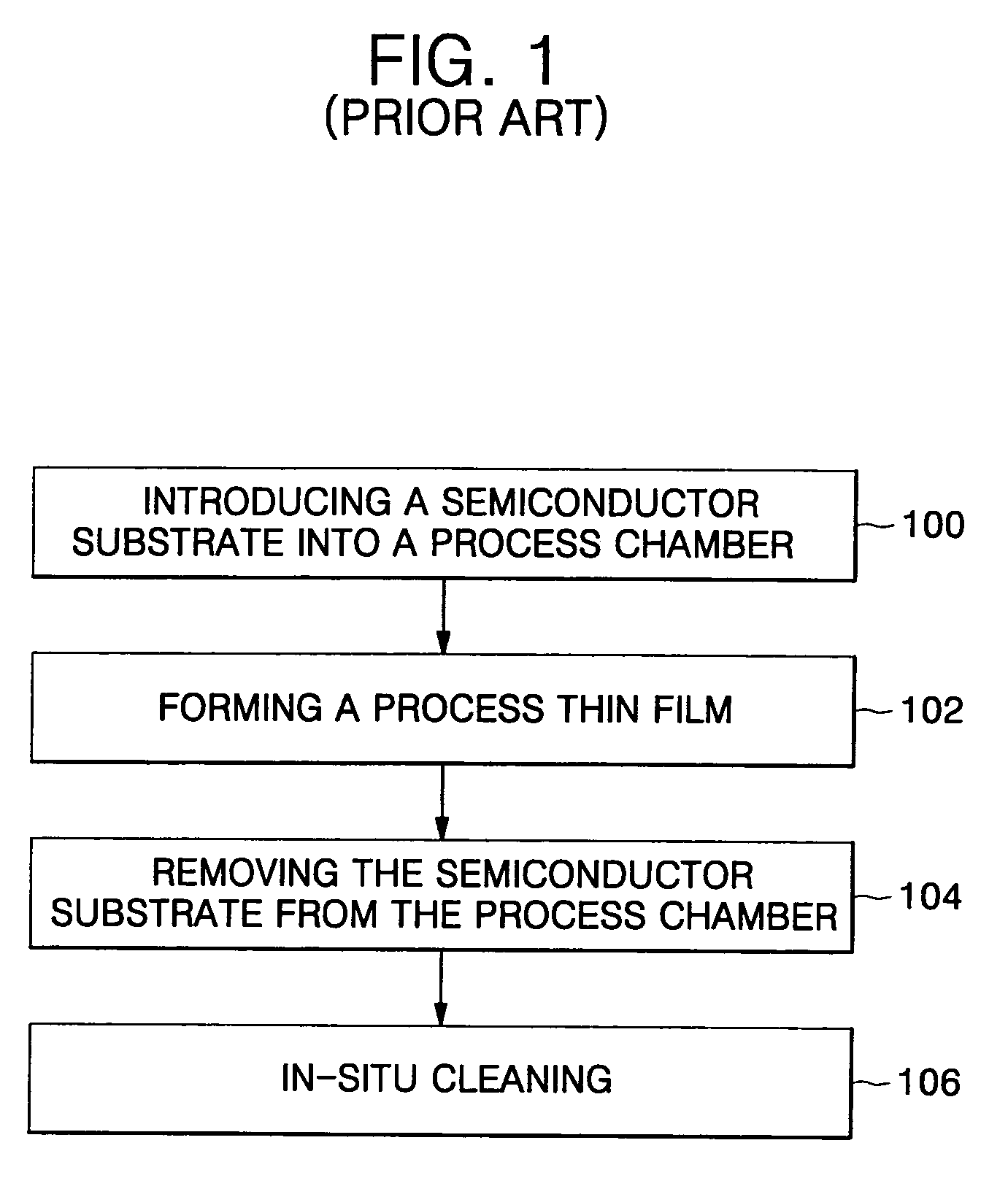

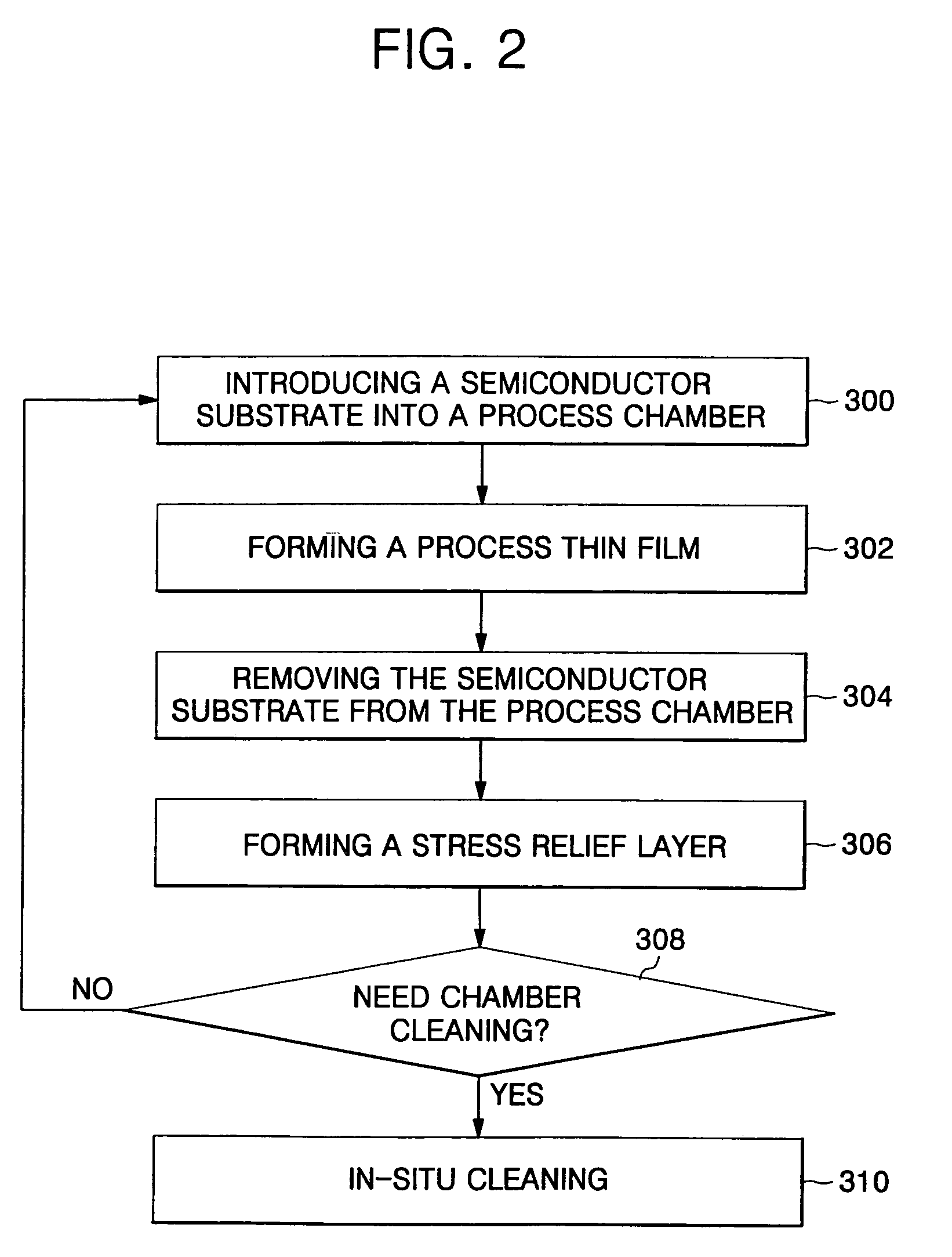

Method of forming thin film for improved productivity

ActiveUS20050130427A1Extended maintenance periodReduce processing timeElectrostatic cleaningSemiconductor/solid-state device manufacturingProduction rateStress relief

There is provided a method of forming a thin film for providing improved fabrication productivity. The method includes introducing a semiconductor substrate into a process chamber. A process thin film is formed on the semiconductor substrate, in which a chamber coating layer is formed on inner walls of the process chamber while the process thin film is formed. The semiconductor substrate is removed from the process chamber. A stress relief layer is formed on the chamber coating layer. After all of the above operations are repeatedly performed at least one time, an in-situ cleaning is performed on the chamber coating layer and the stress relief layer, which are alternately formed in stack on the inner walls of the process chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

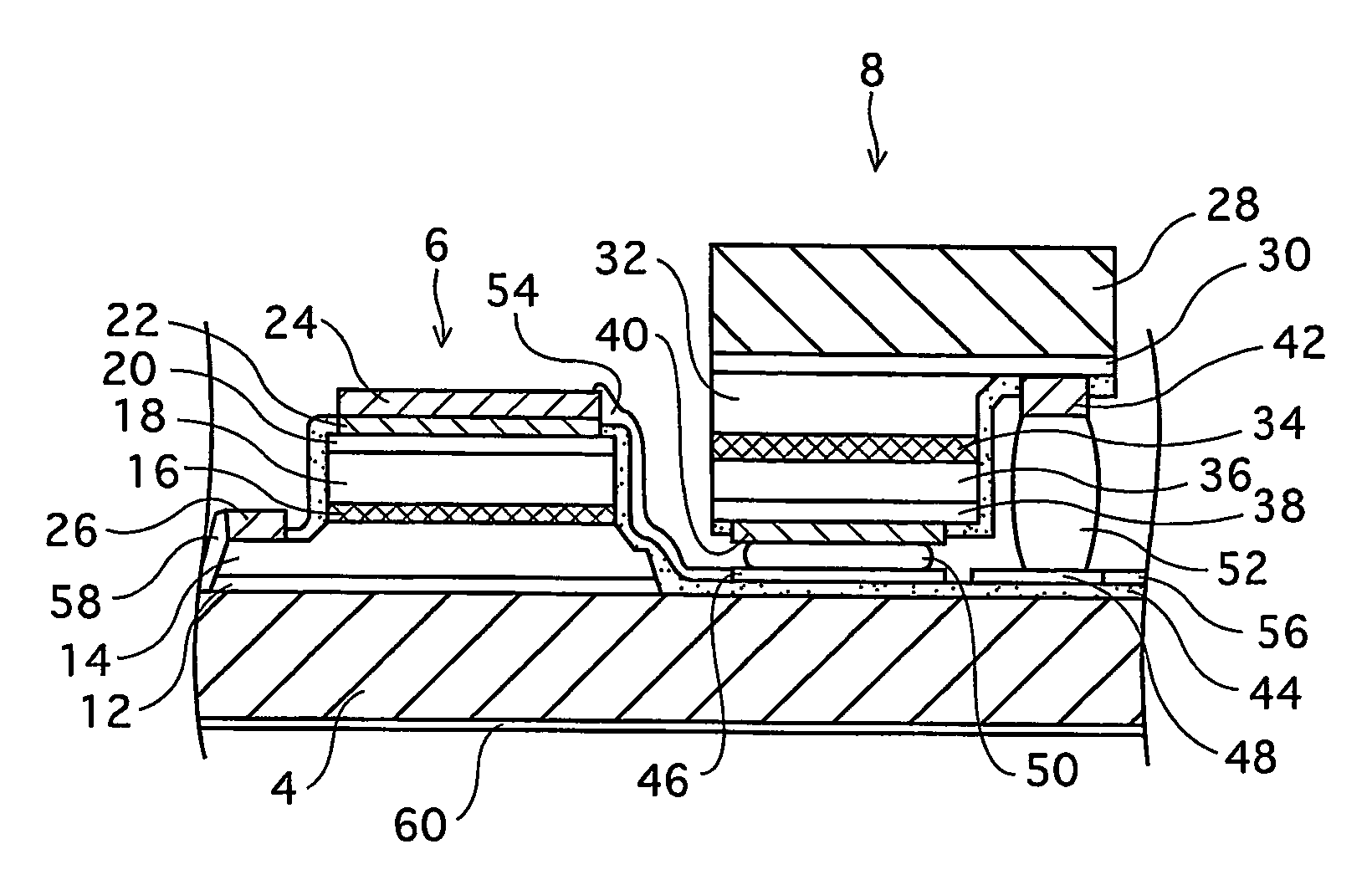

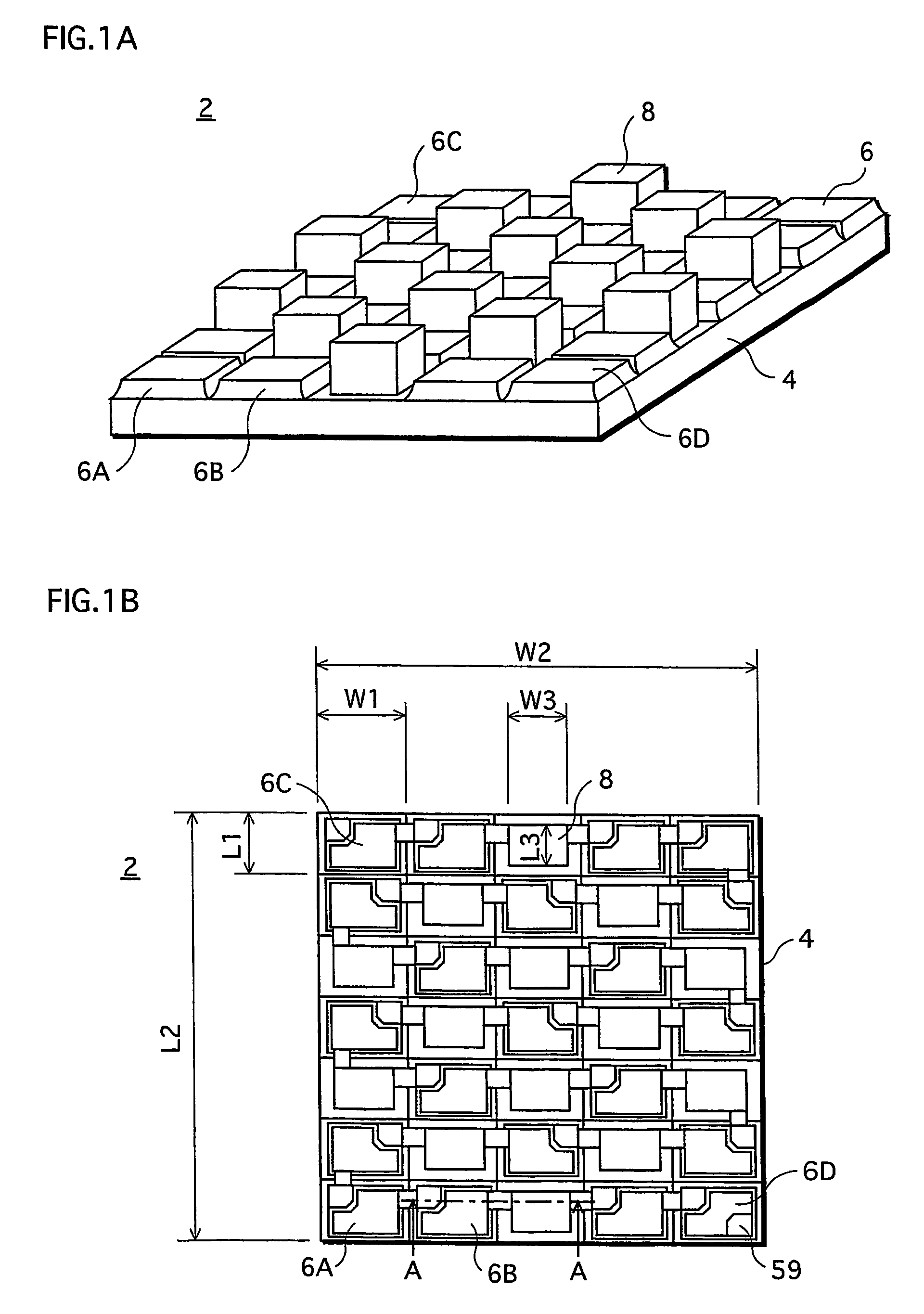

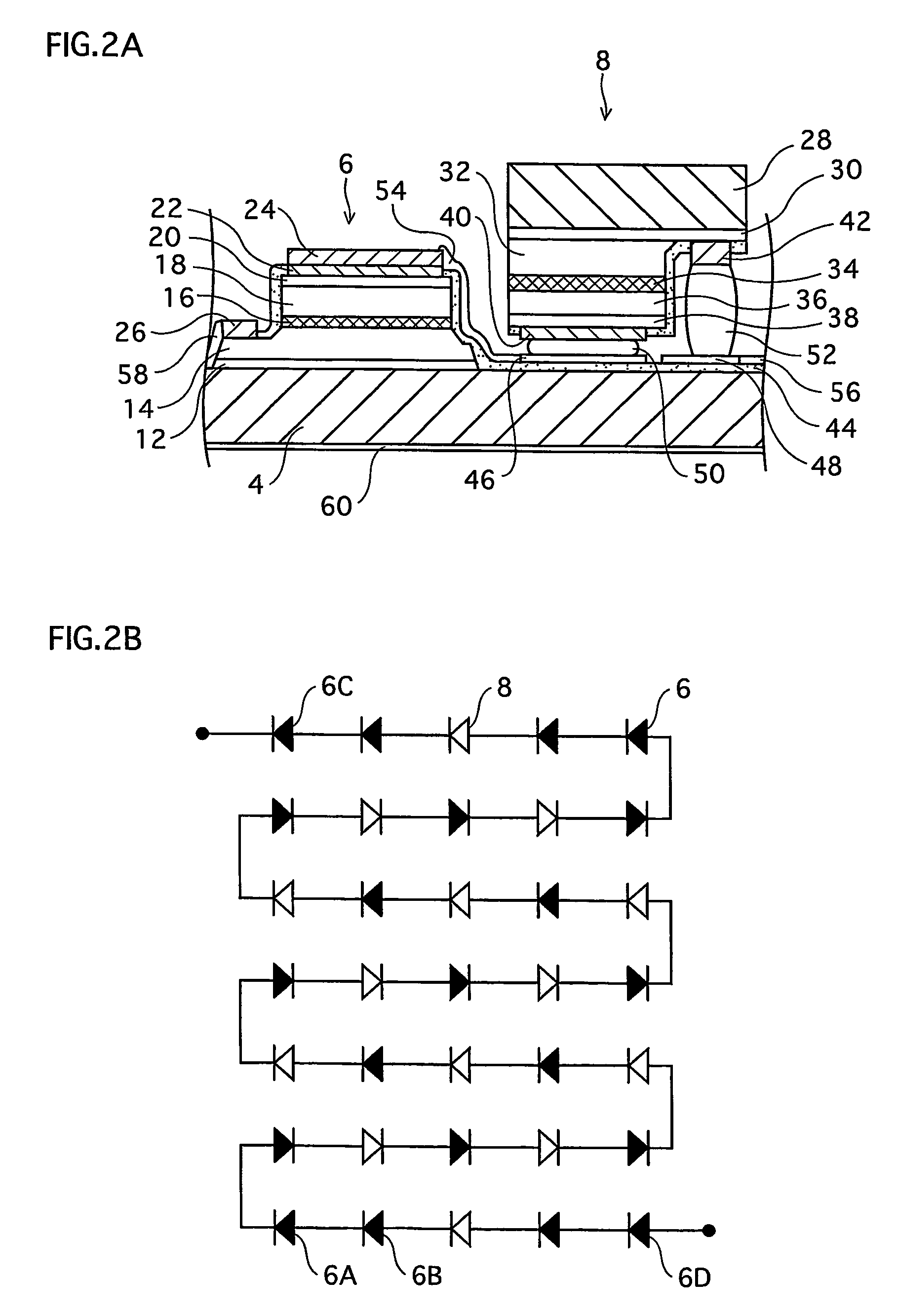

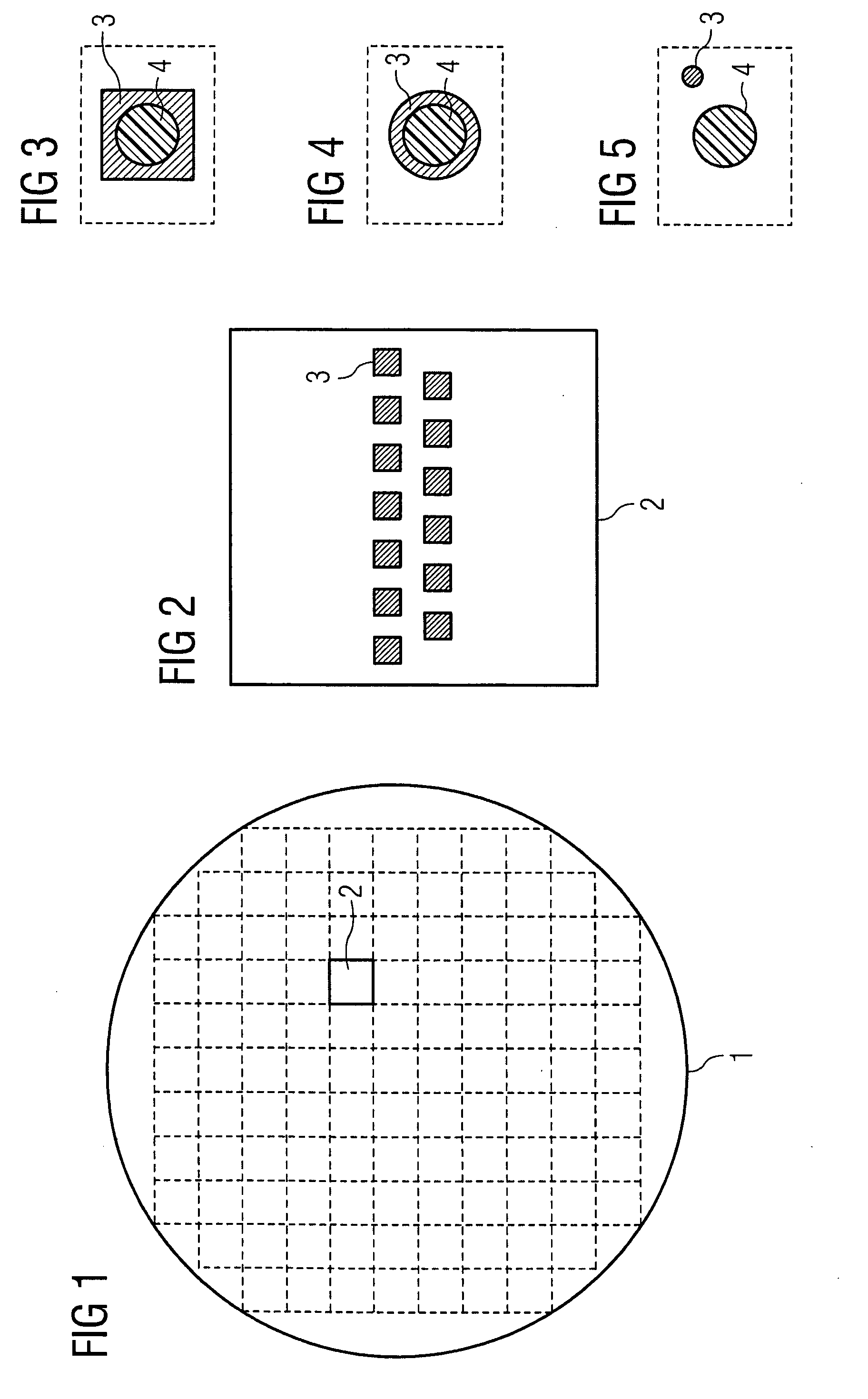

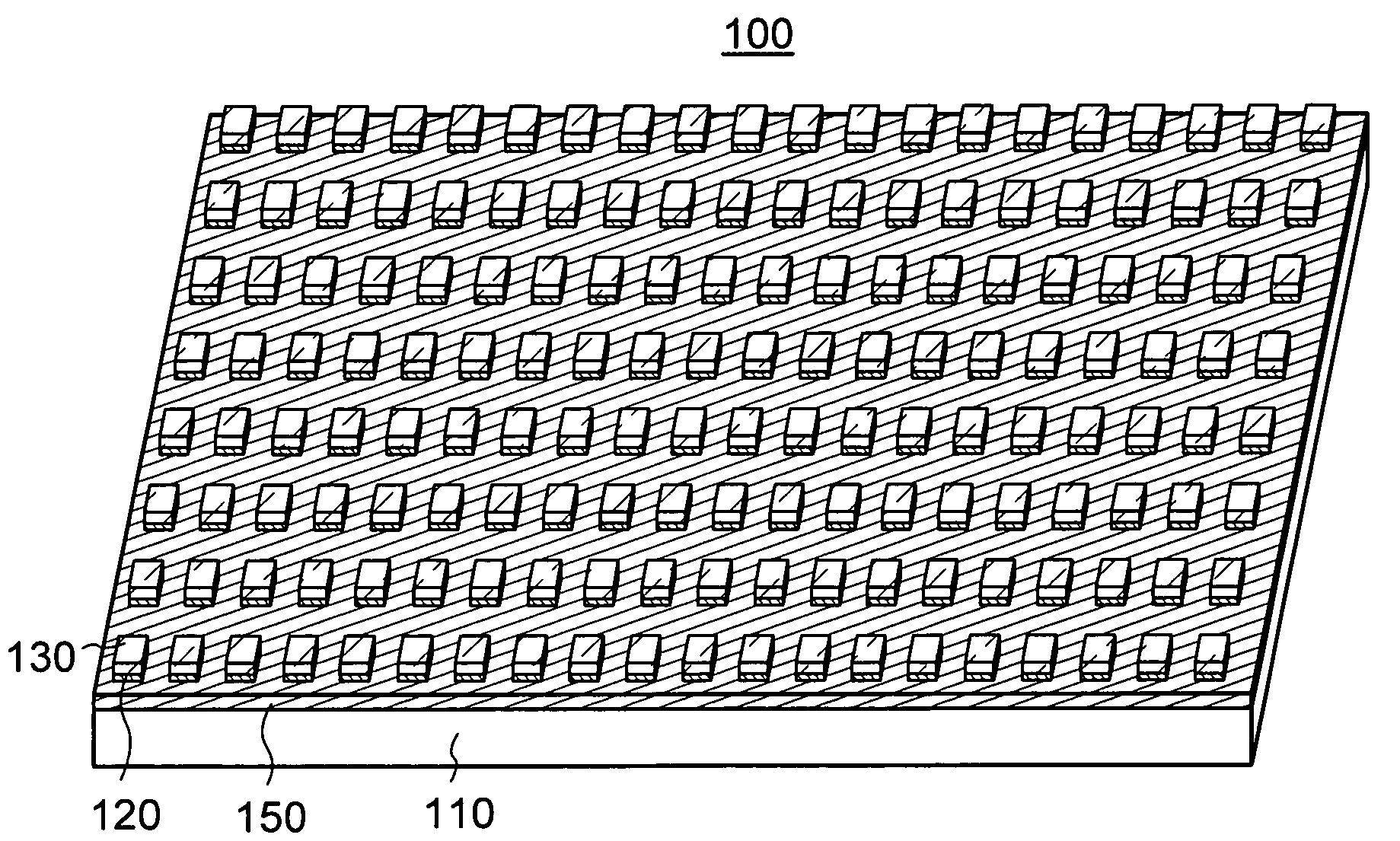

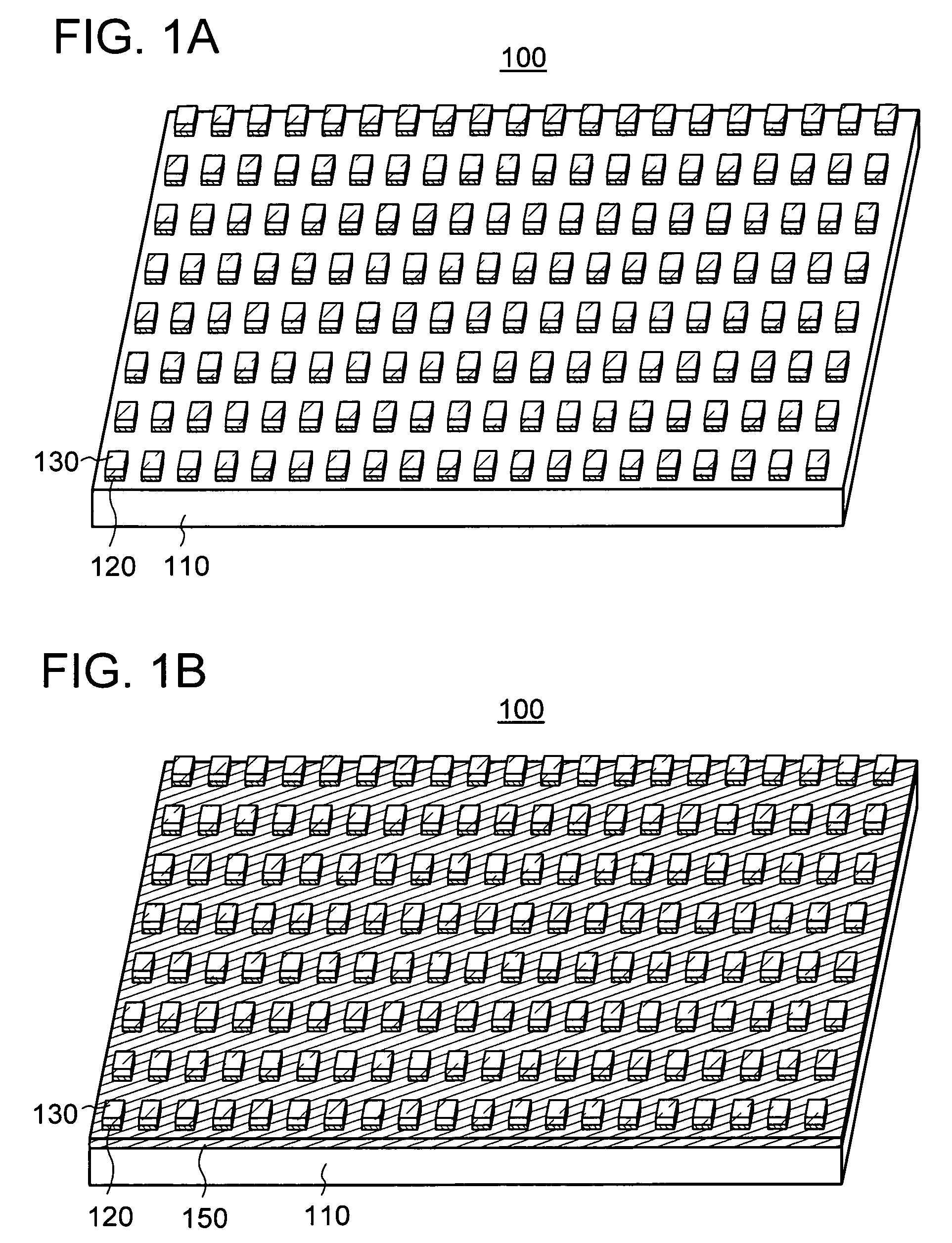

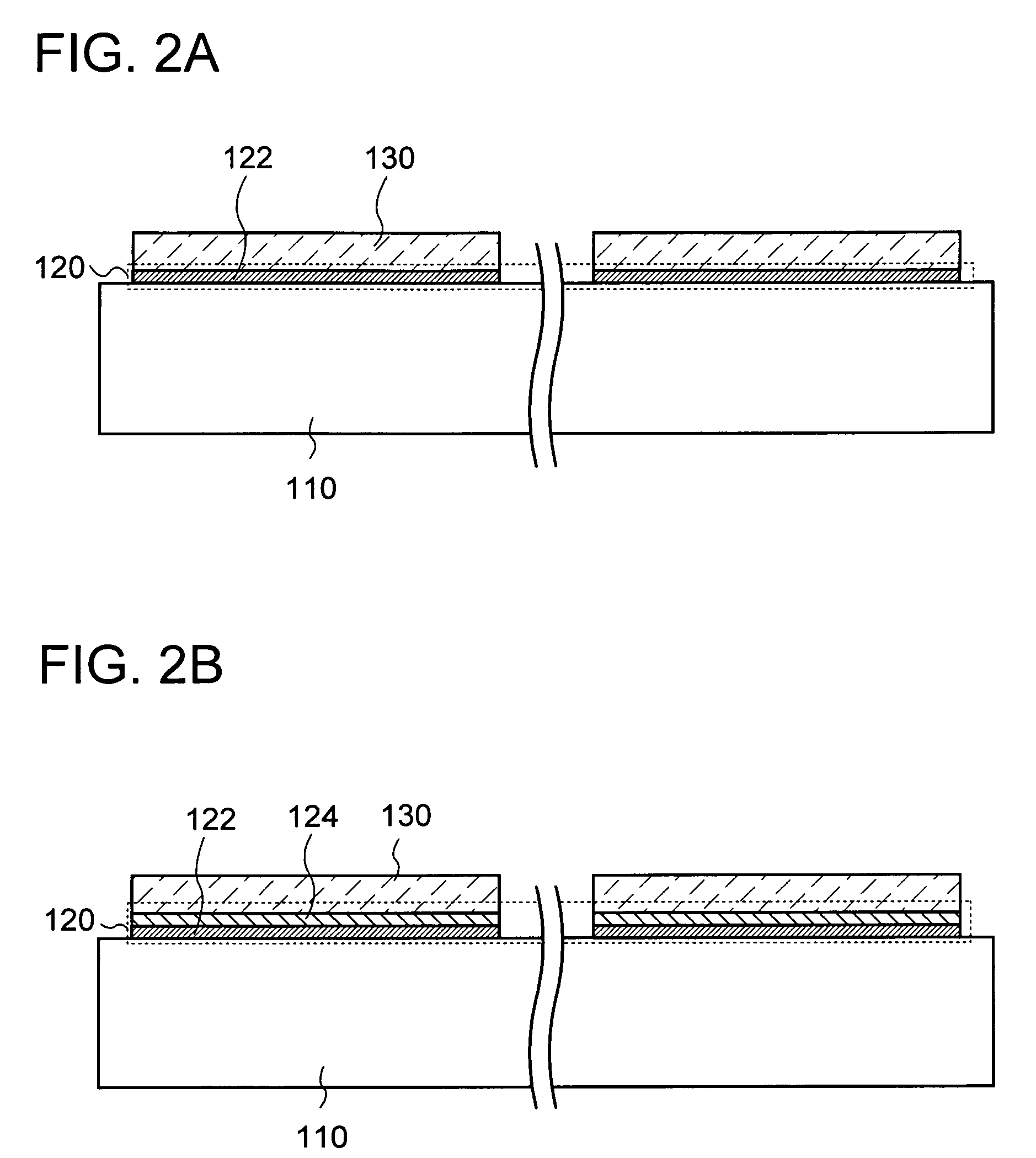

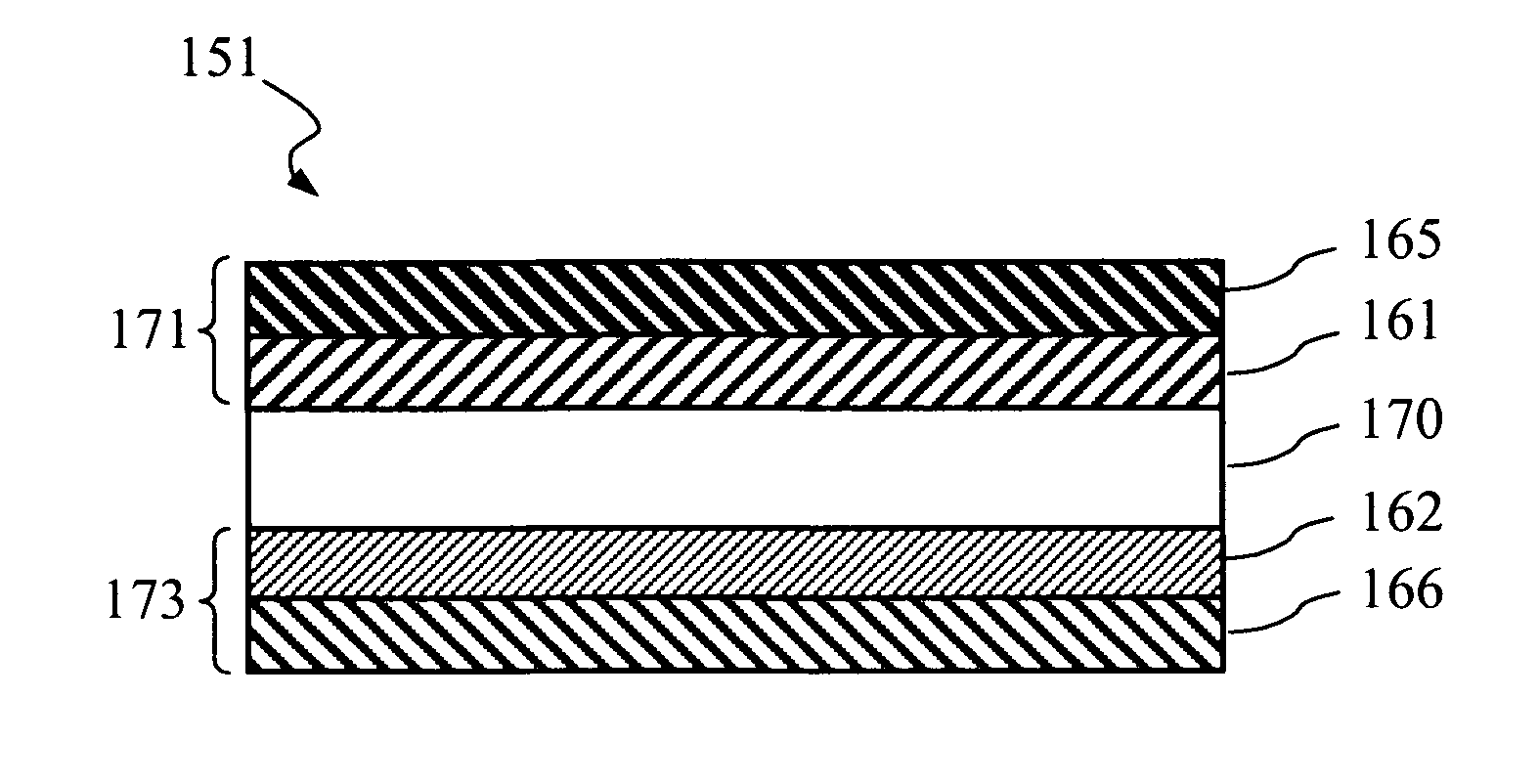

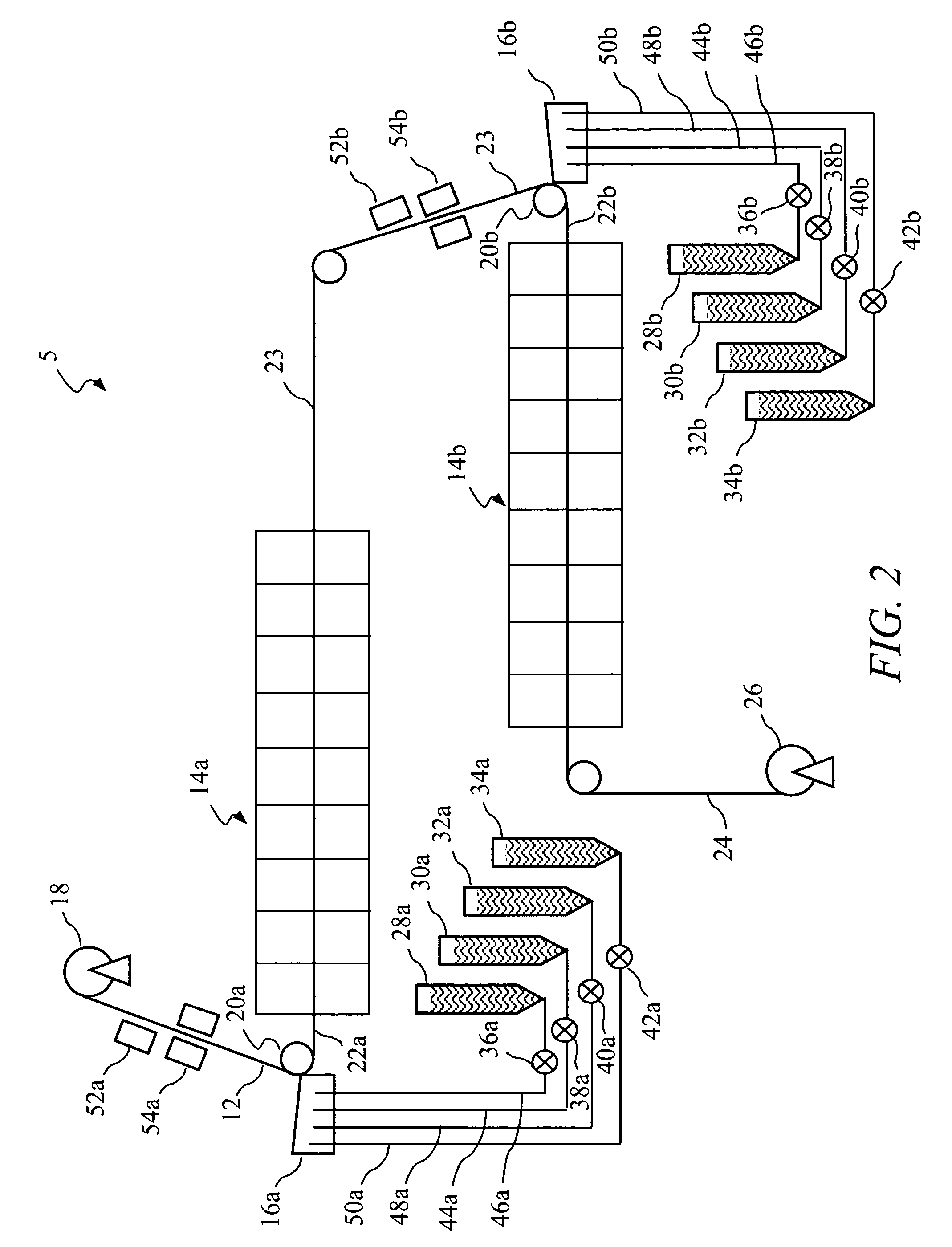

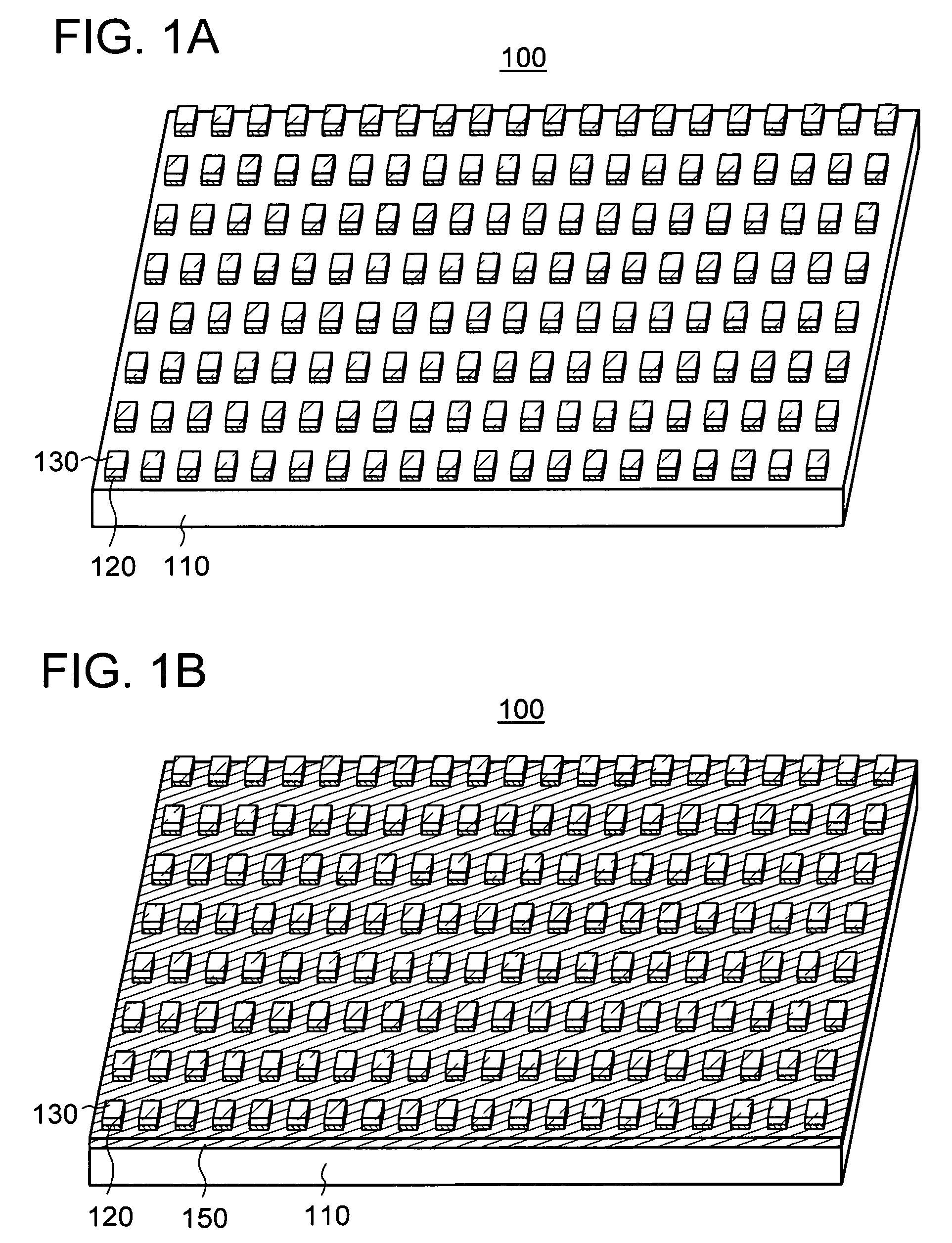

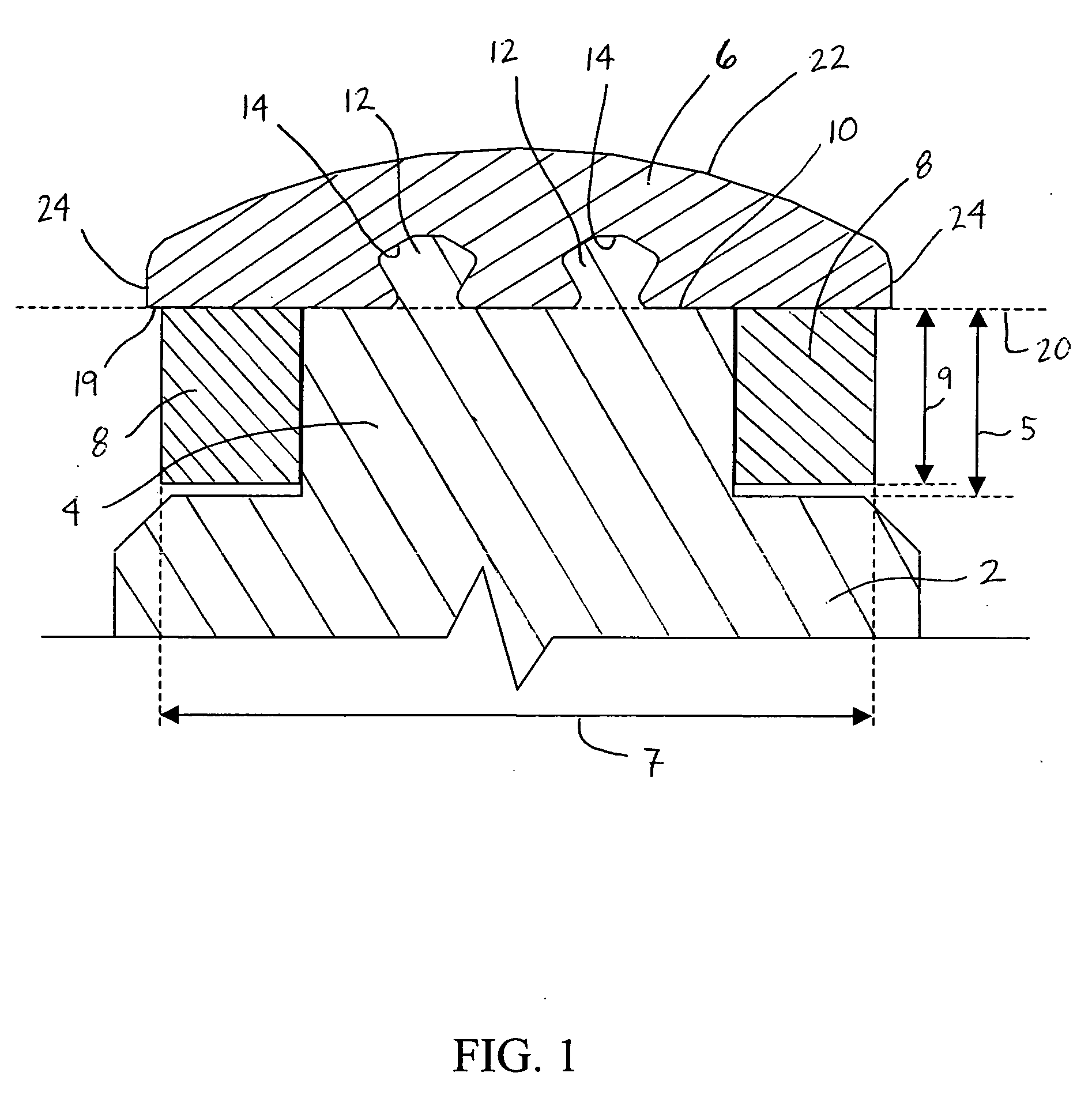

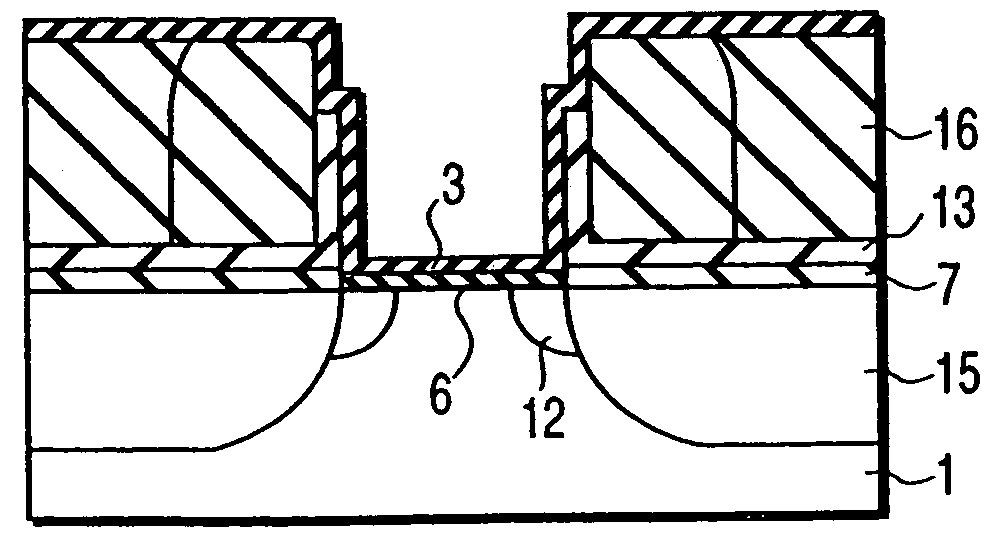

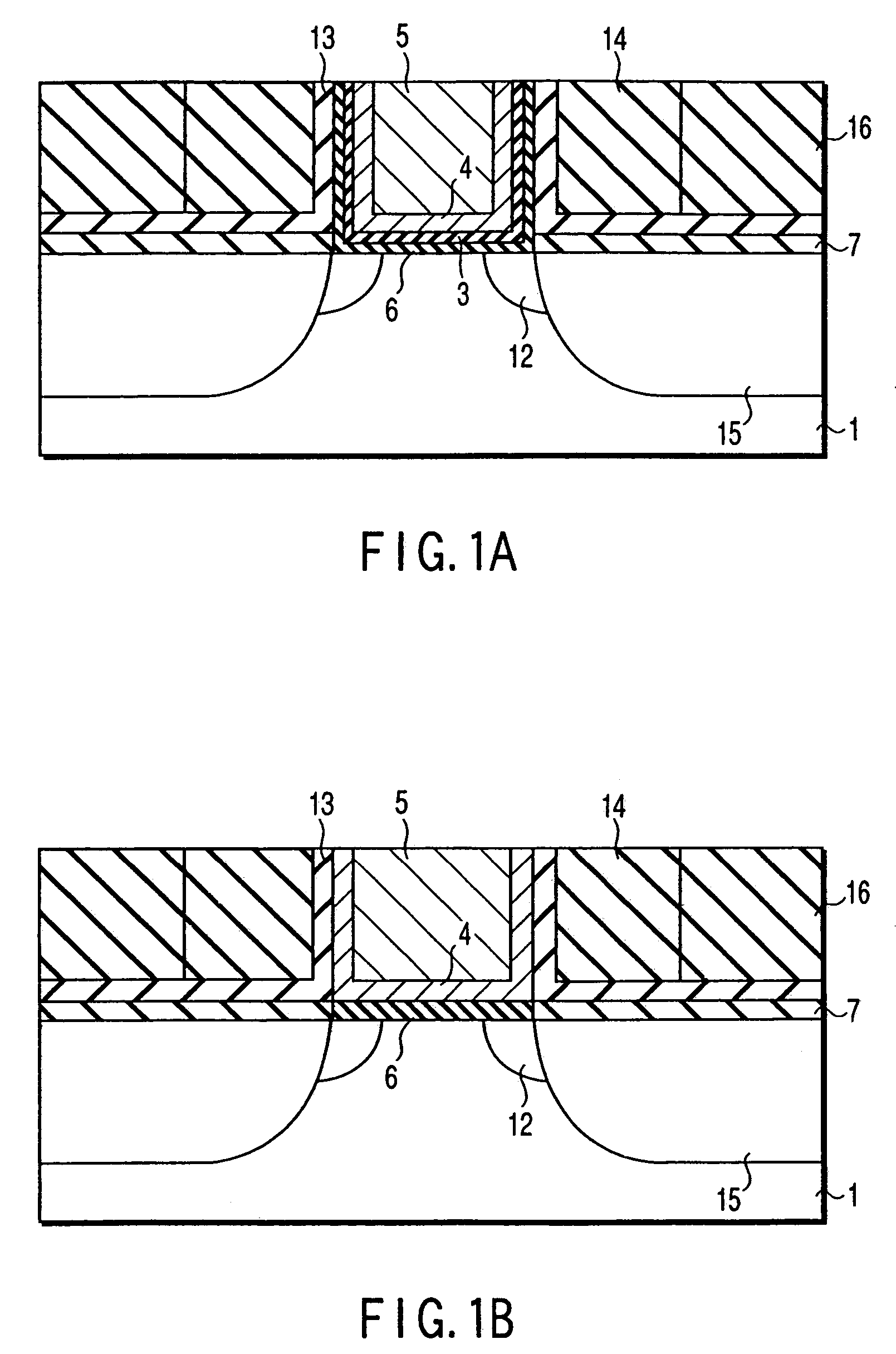

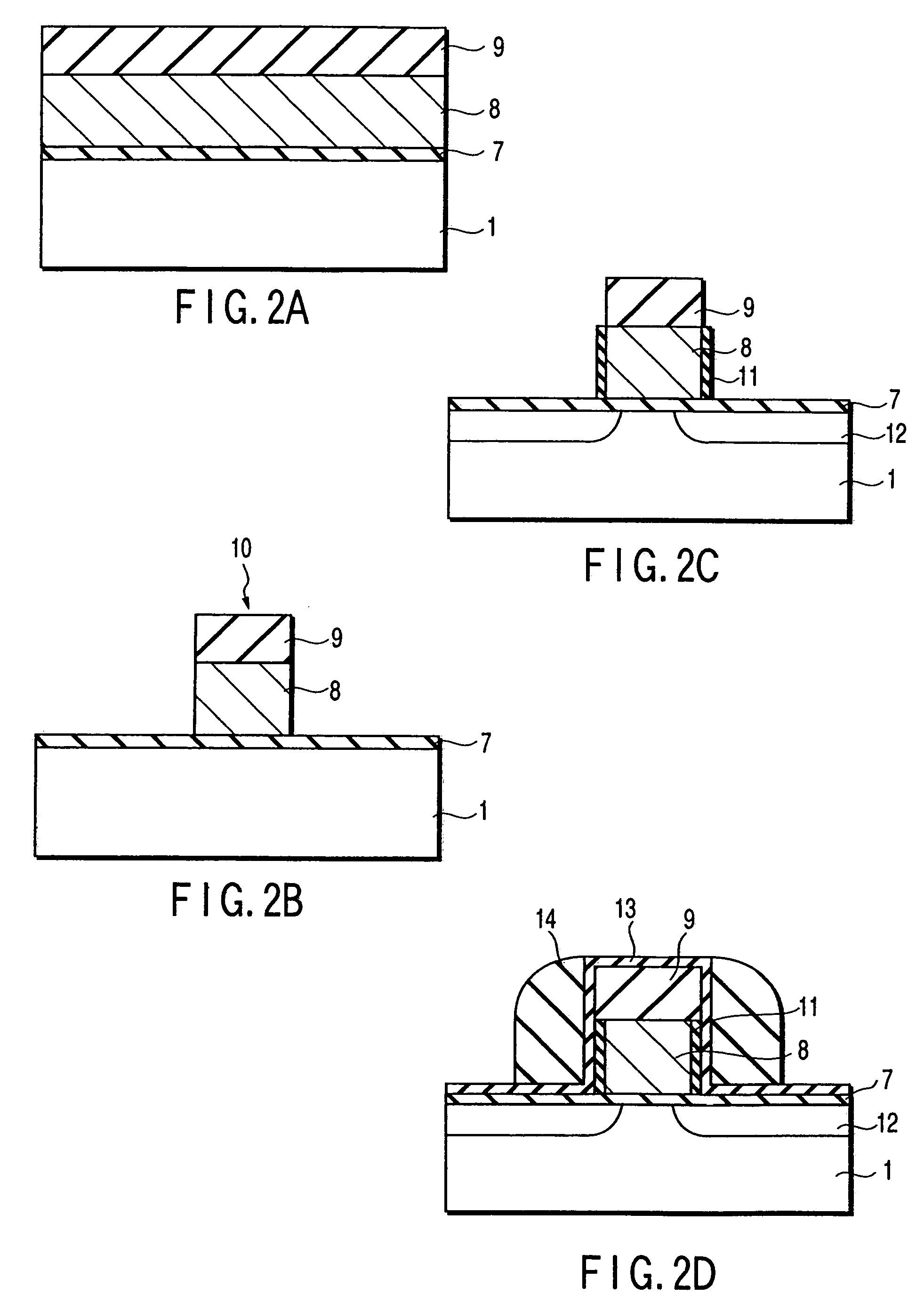

Semiconductor light emitting device, light emitting module and lighting apparatus

ActiveUS7473934B2Reduce color unevennessImprove manufacturing productivityPlanar light sourcesLight source combinationsLight equipmentLed array

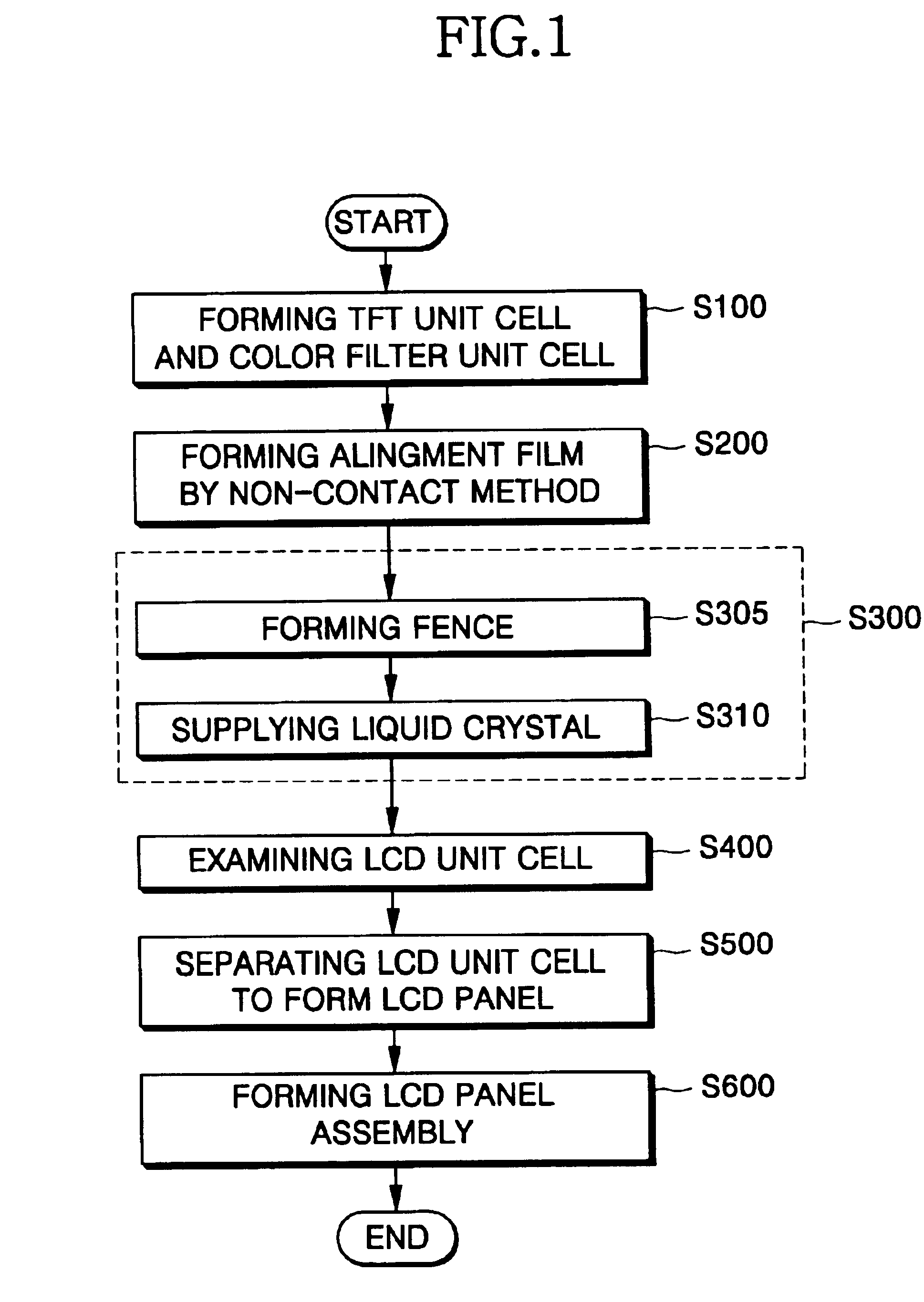

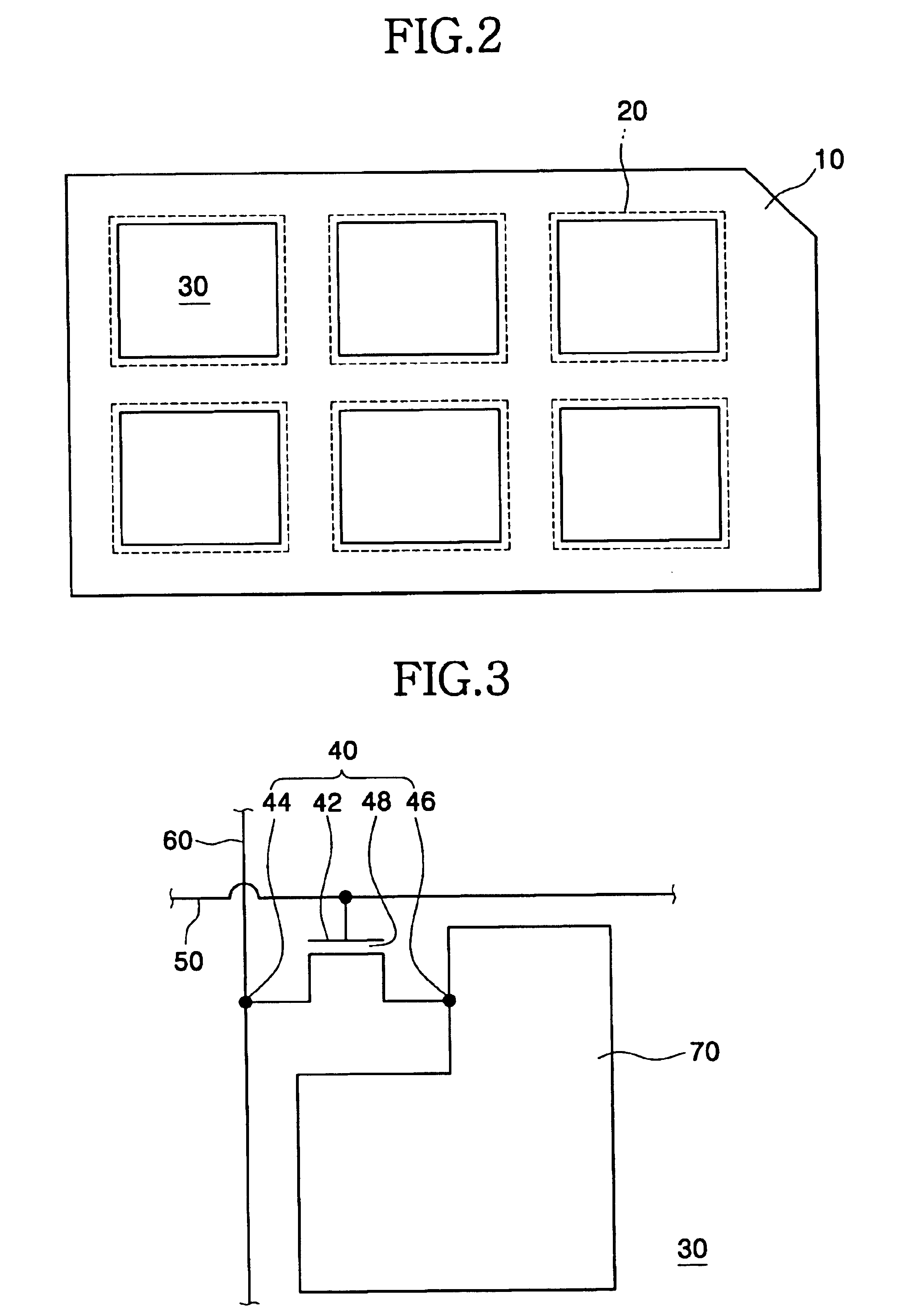

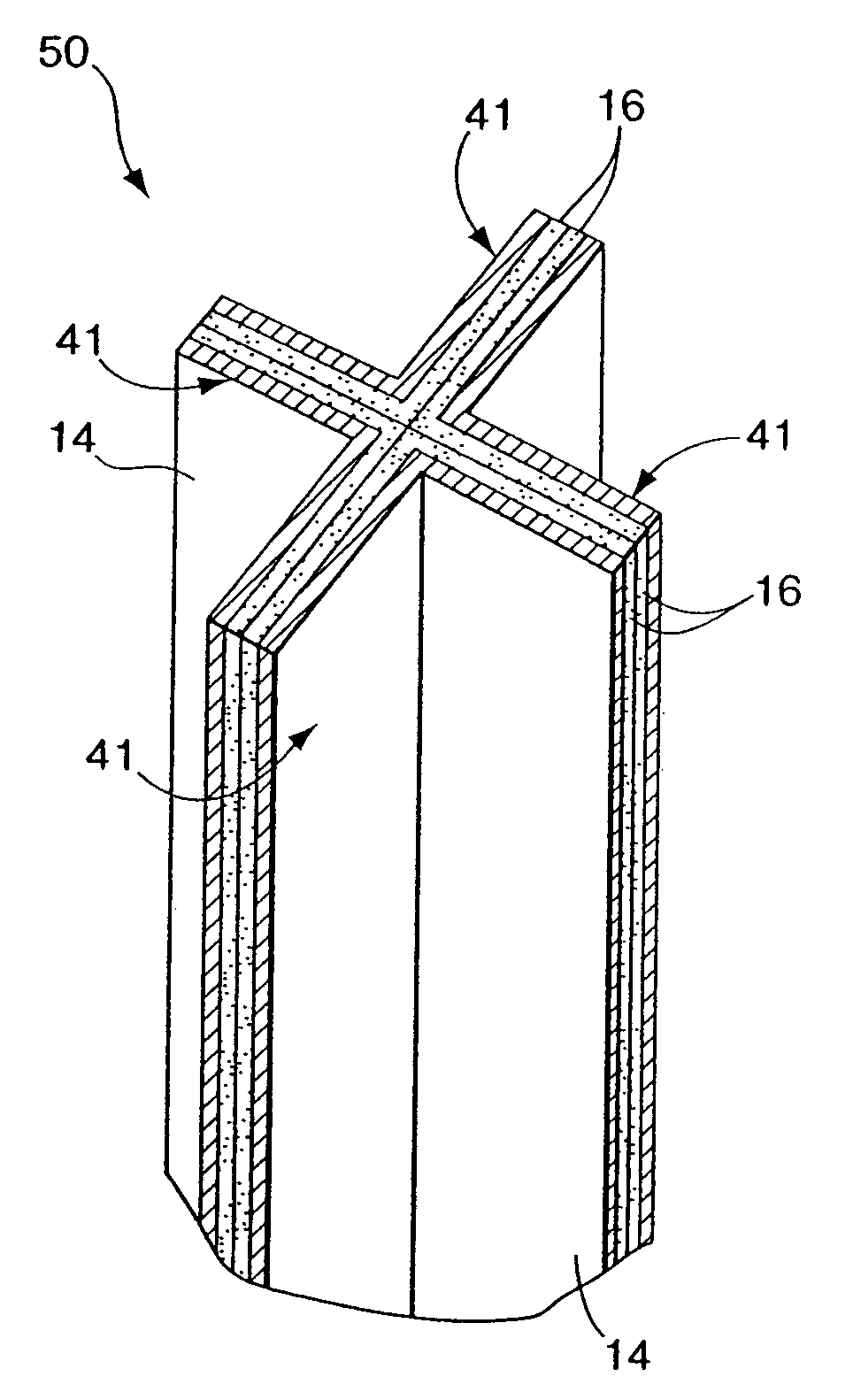

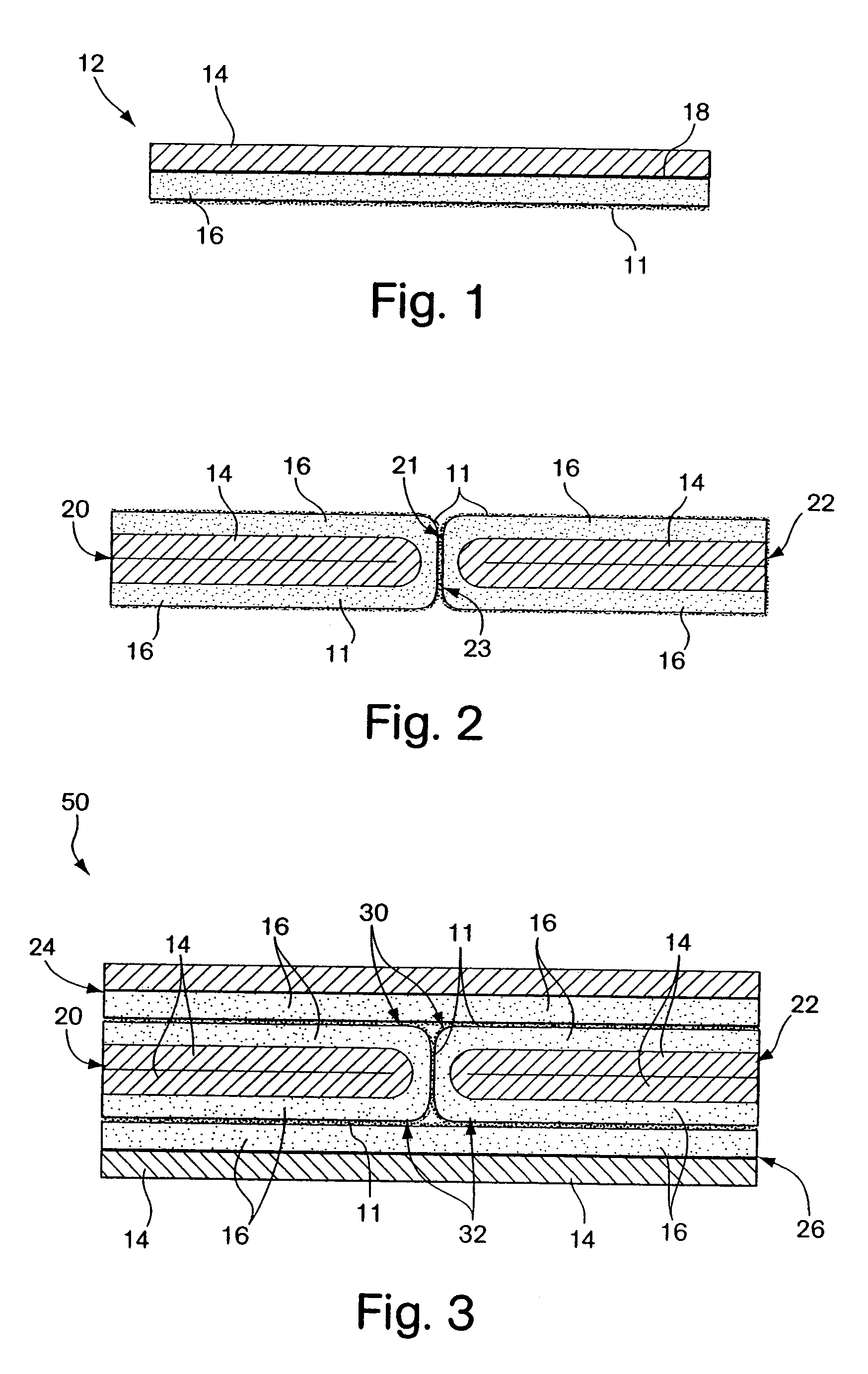

An LED array chip (2) includes blue LEDs (6) and red LEDs (8). The blue LEDs (6) are formed by epitaxial growth on an SiC substrate (4). Bonding pads (46 and 48) are formed on the SiC substrate (4) in a wafer fabrication process. The red LEDs (8) are separately manufactured from the blue LEDs (6), and flip-chip mounted on the bonding pads (46 and 48) formed on the SiC substrate.

Owner:PANASONIC CORP

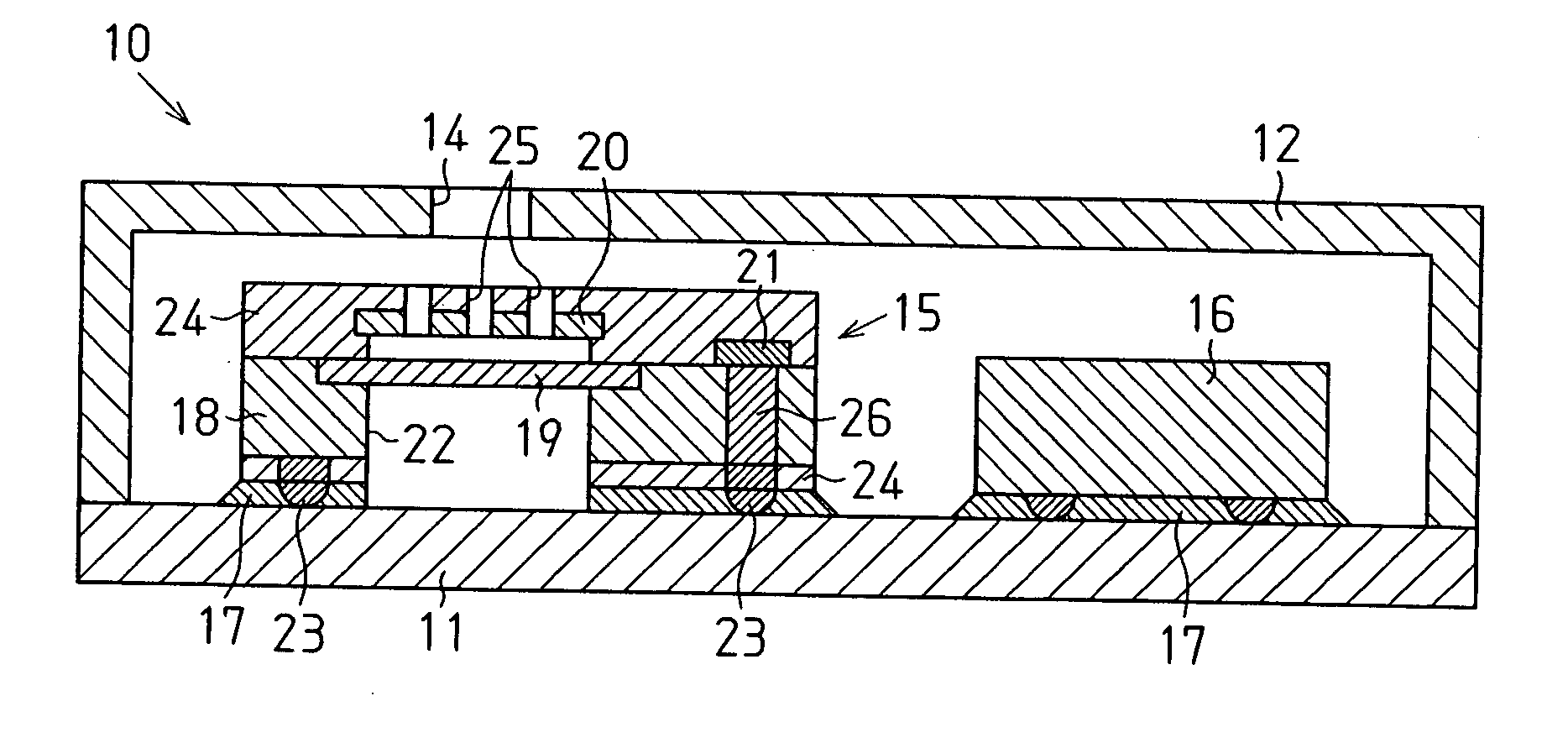

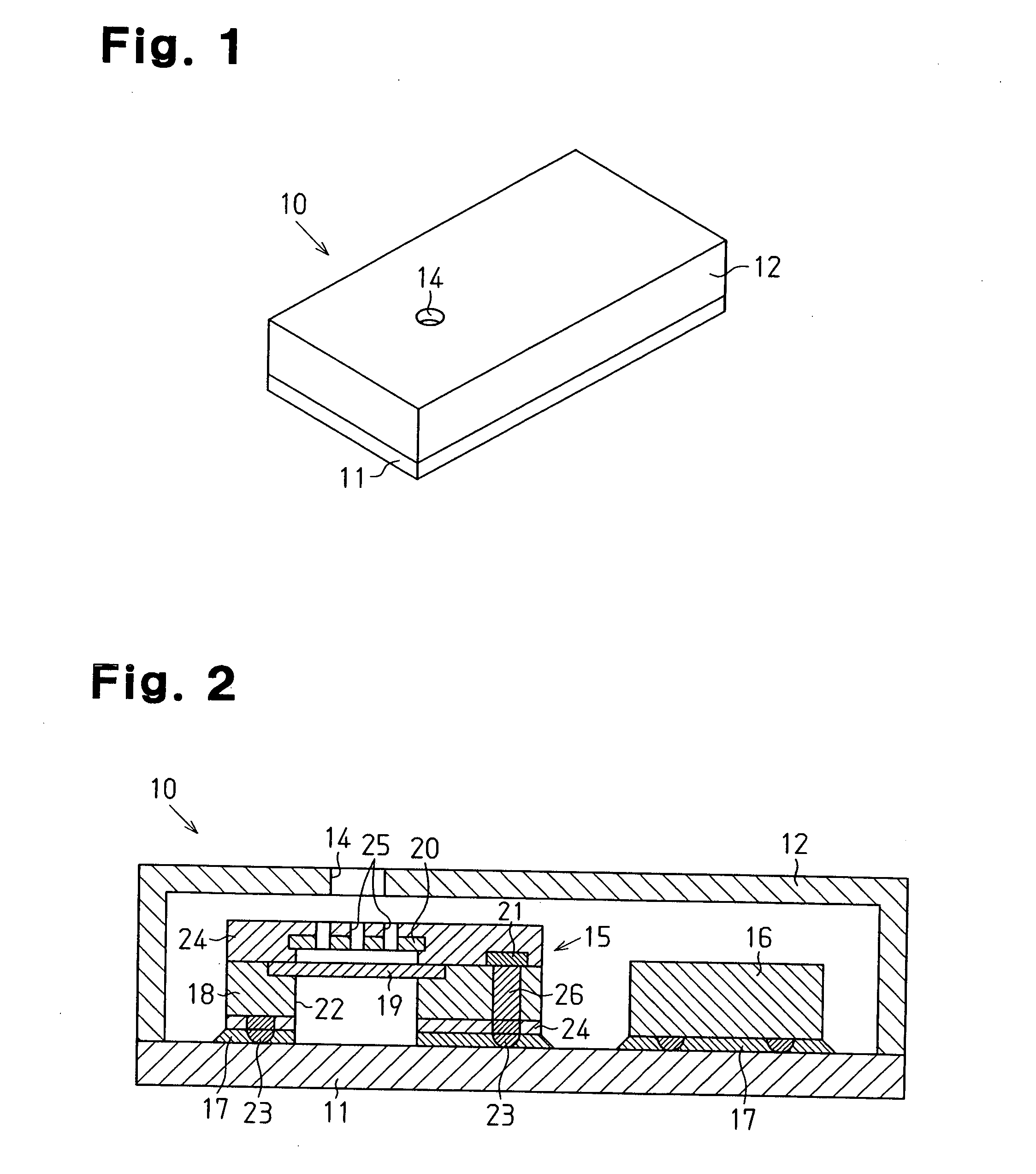

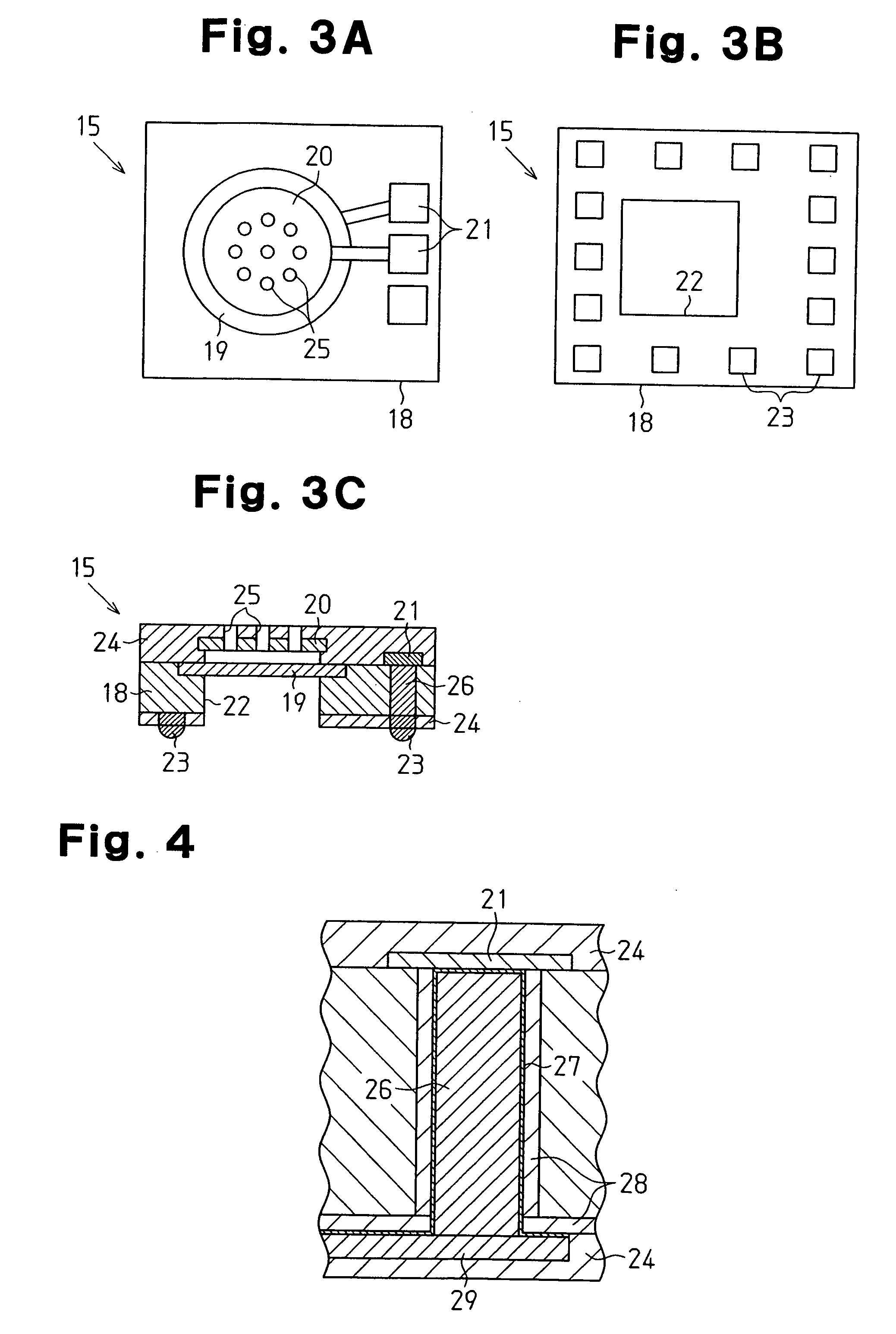

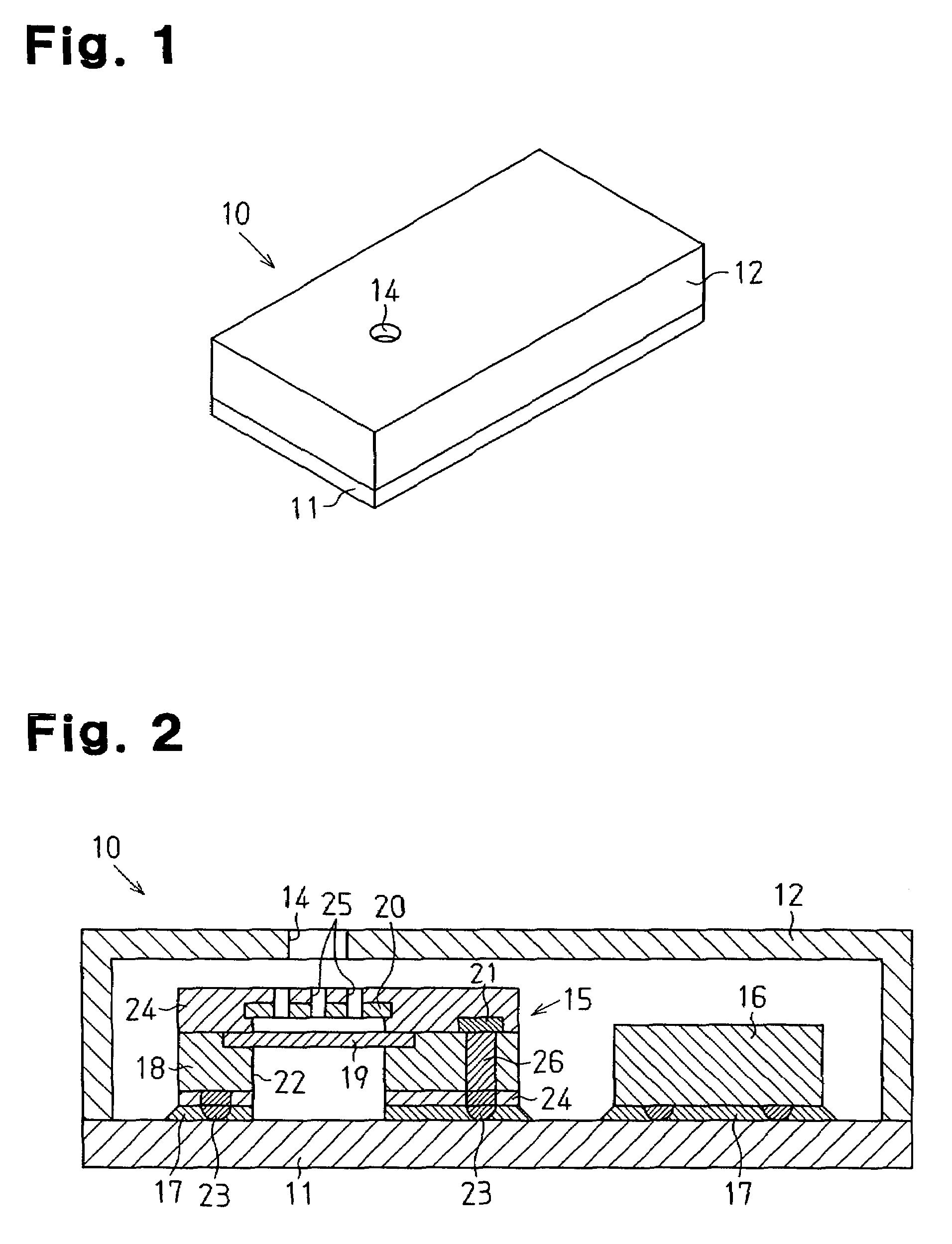

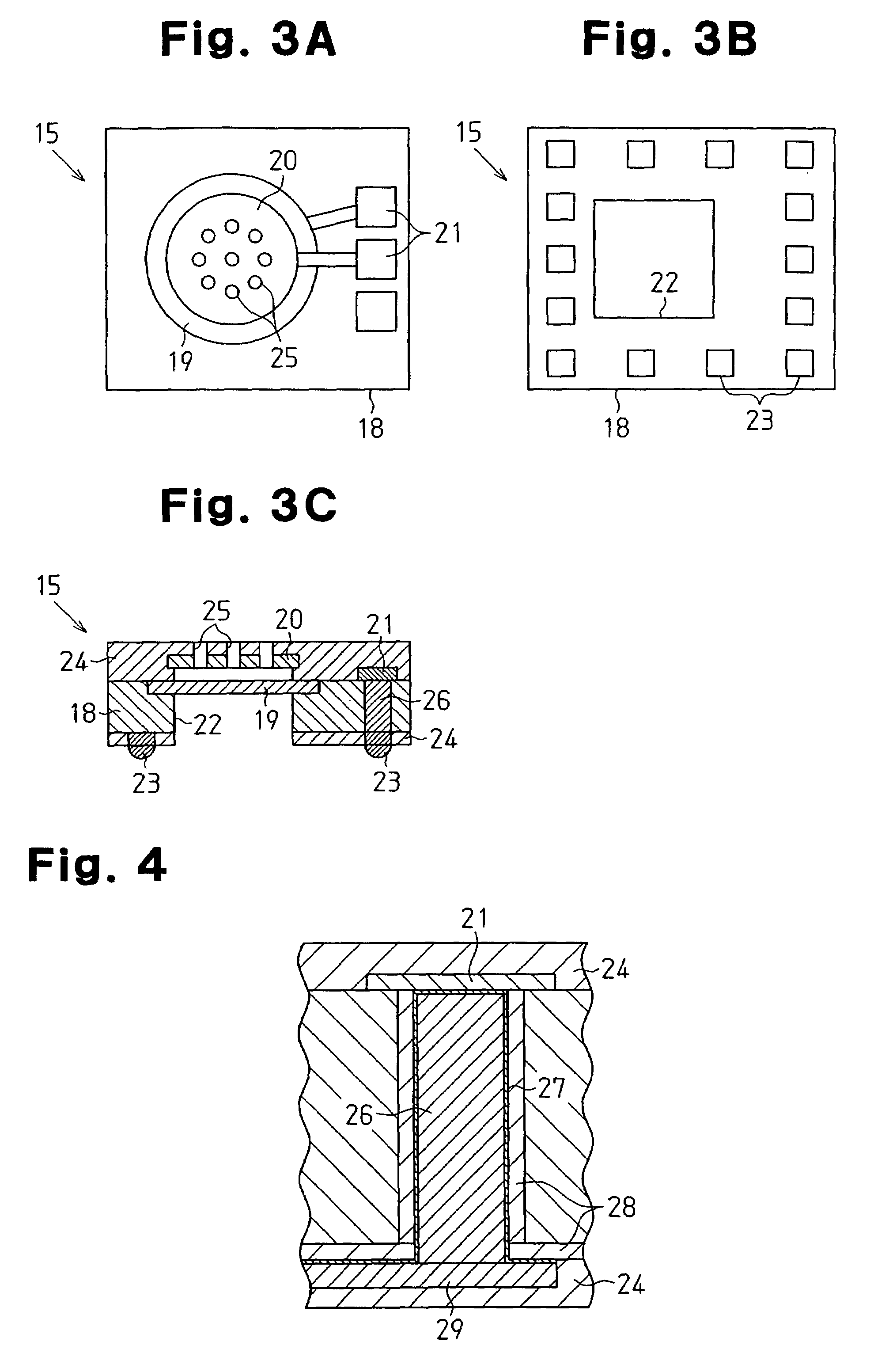

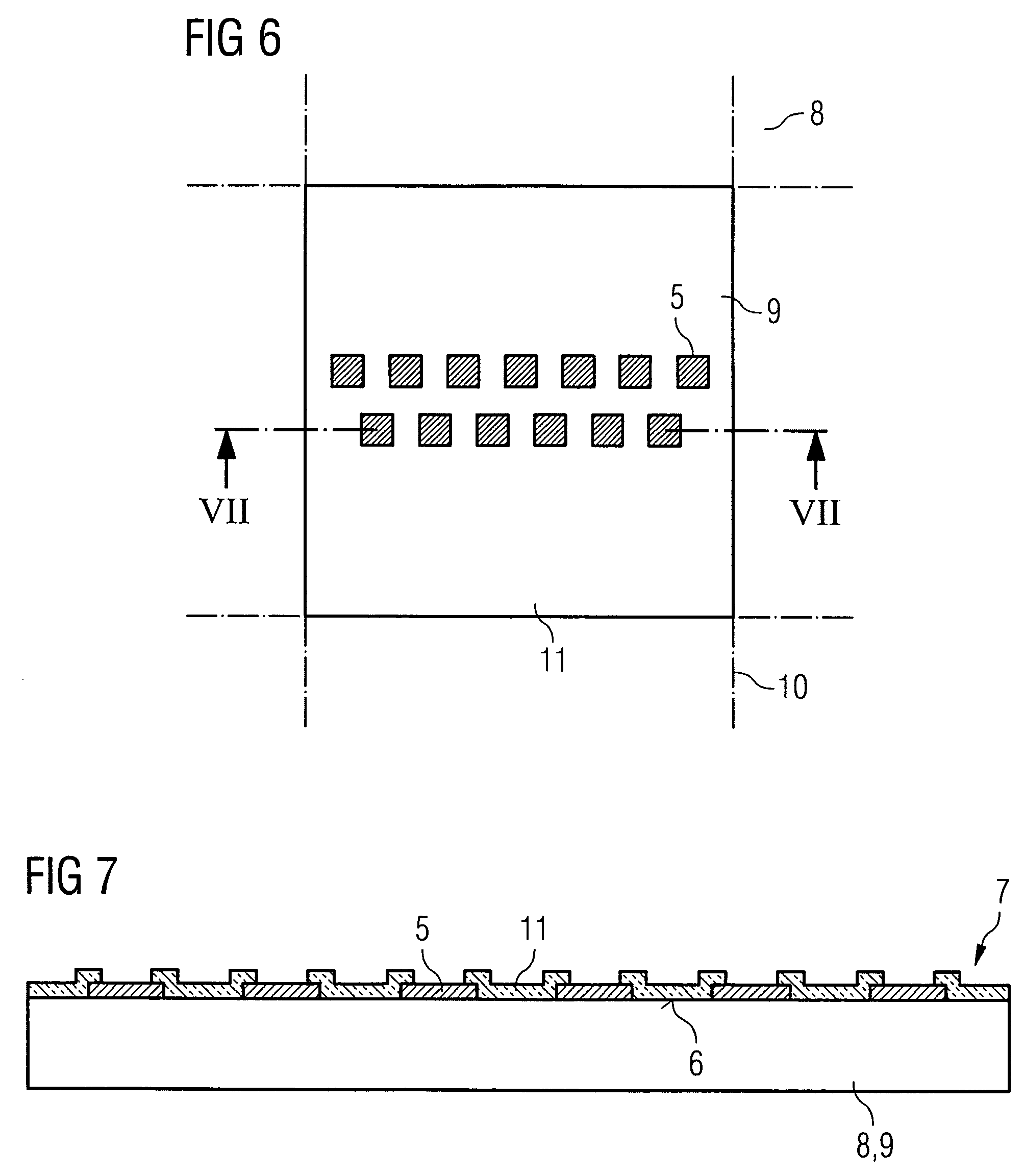

Semiconductor sensor

InactiveUS20060169049A1Increase productivityImprove manufacturing productivityFluid pressure measurement by electric/magnetic elementsSolid-state devicesProduction rateCapacitance

A semiconductor sensor for improving manufacturing productivity. Opposing electrodes, or a diaphragm electrode and a fixed electrode, form an electrostatic capacity sensing semiconductor microphone on a microphone chip. A through electrode is formed on the microphone chip by a conductor extending between the upper and lower surfaces of the semiconductor substrate. The through electrode directly and electrically connects a MEMS configuration formed by the diaphragm electrode to the wiring of a printed wiring board without using wire bonding.

Owner:SANYO ELECTRIC CO LTD

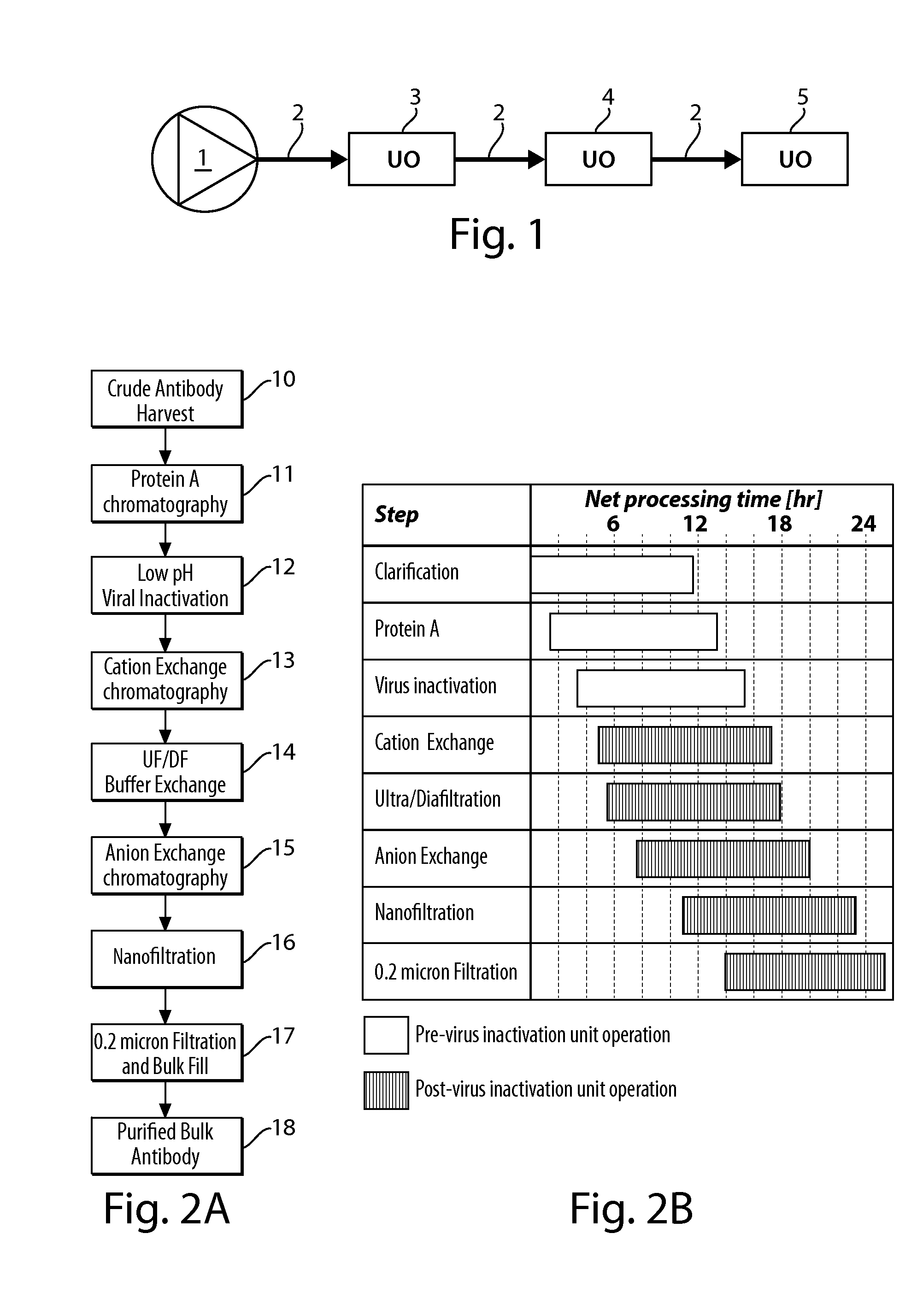

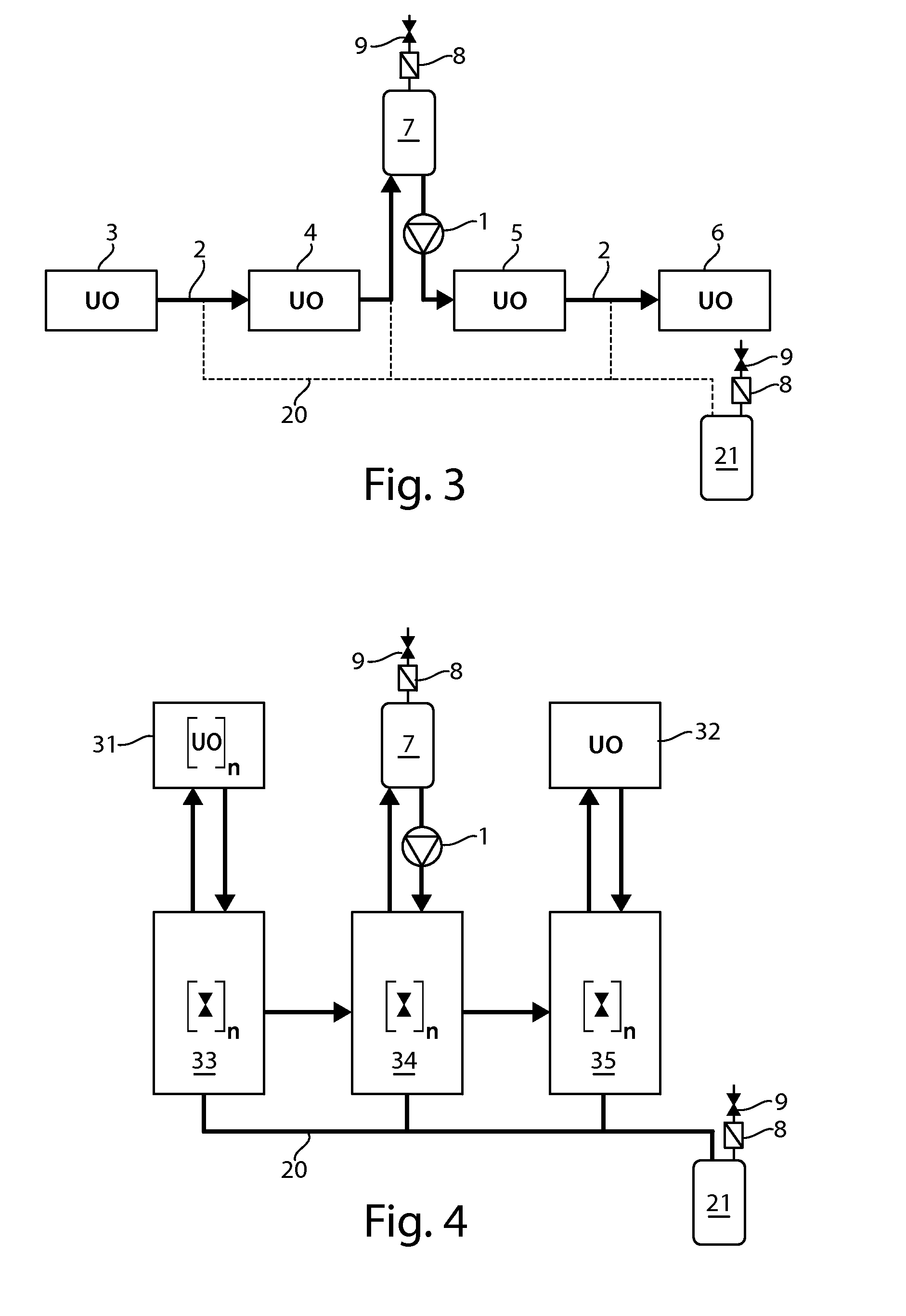

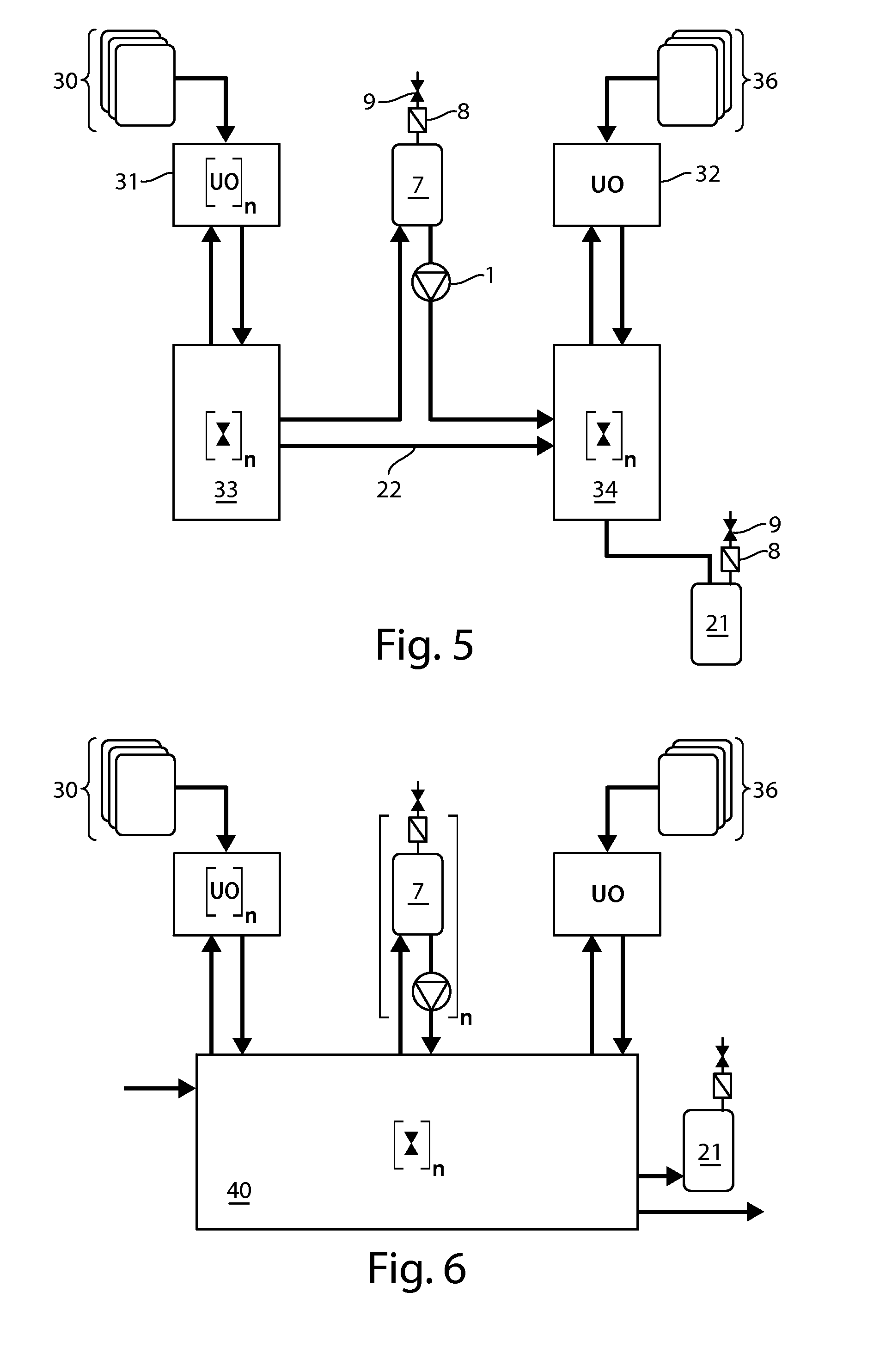

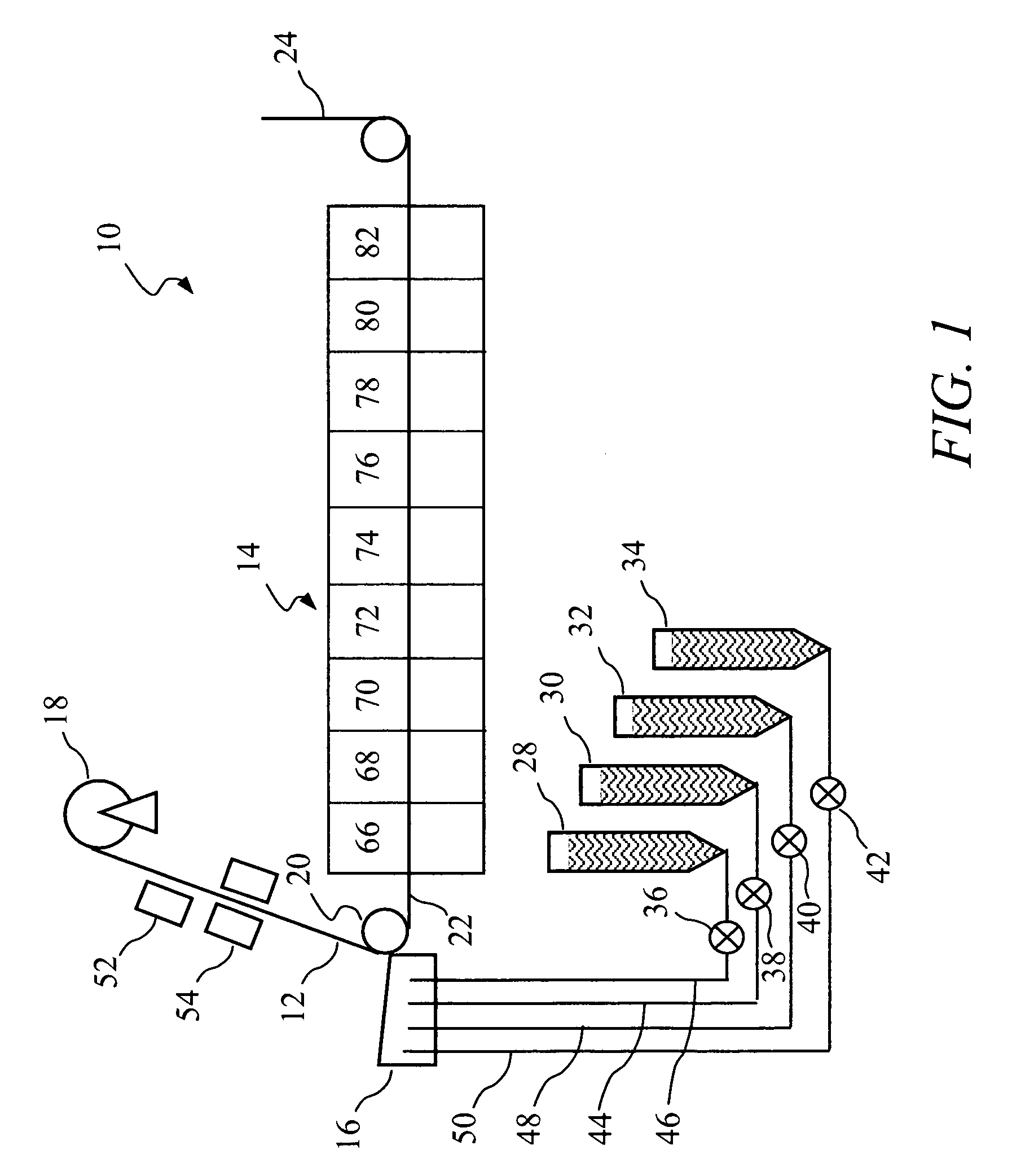

Continuous processing methods for biological products

InactiveUS20130260419A1Improve manufacturing productivityImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMonoclonal antibody

The present invention is directed to the development of continuous processing technology for the purification of biopharmaceuticals and biological products, such as monoclonal antibodies, protein therapeutics, and vaccines. Methods for continuous processing of a biological product in a feed stream toward formulation of a purified bulk product are described.

Owner:SARTORIUS STEDIM CHROMATOGRAPHY SYST LTD

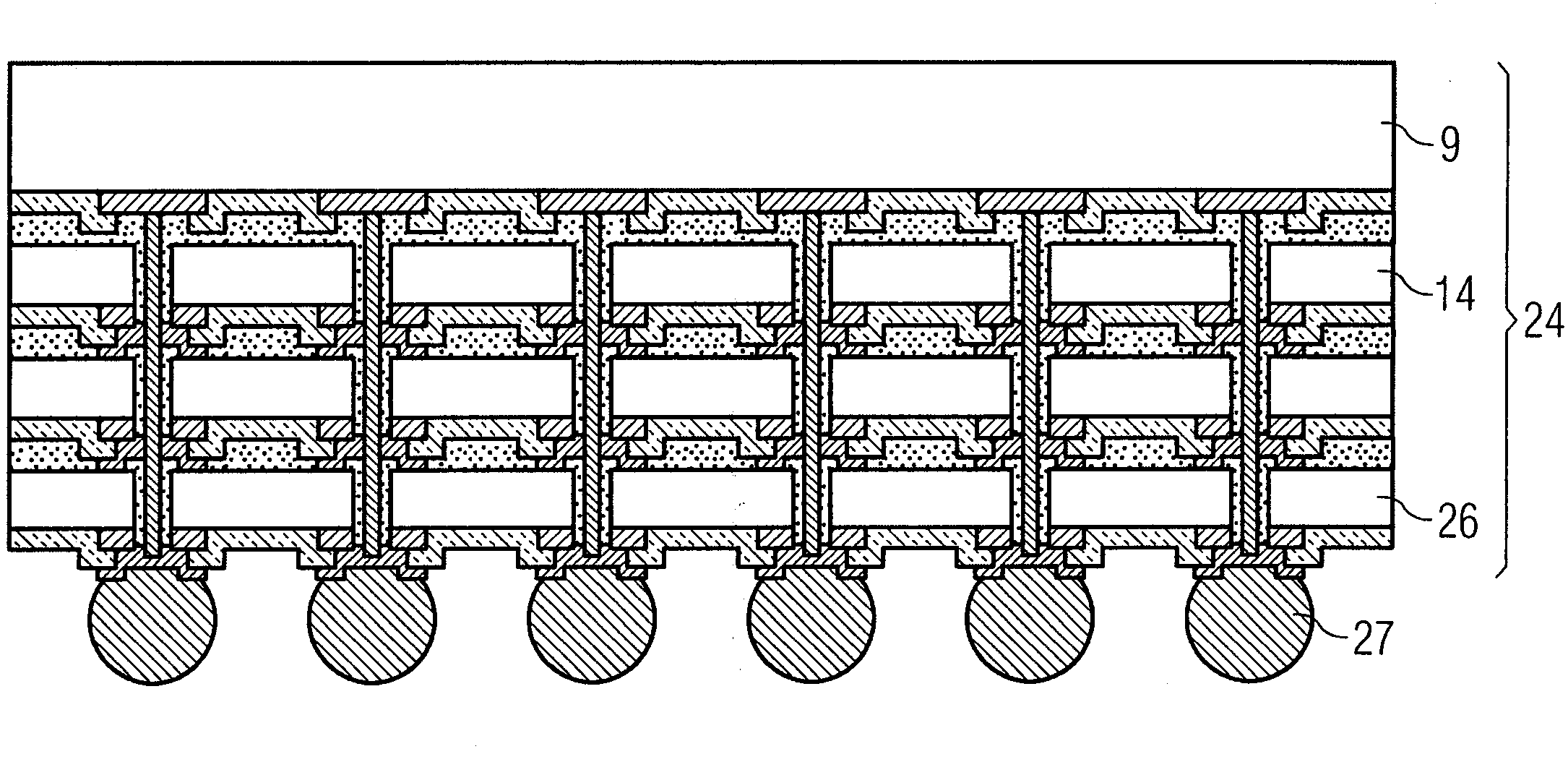

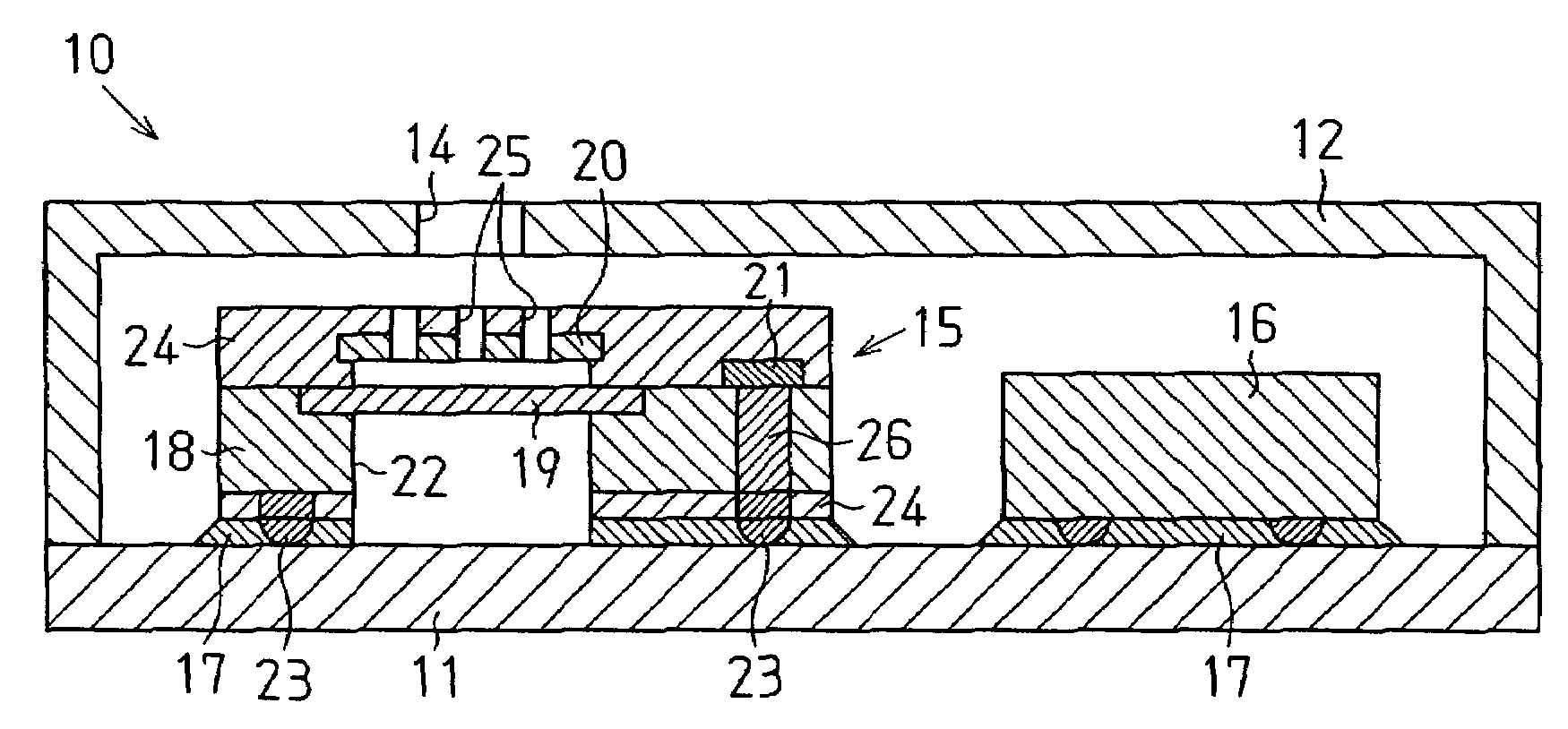

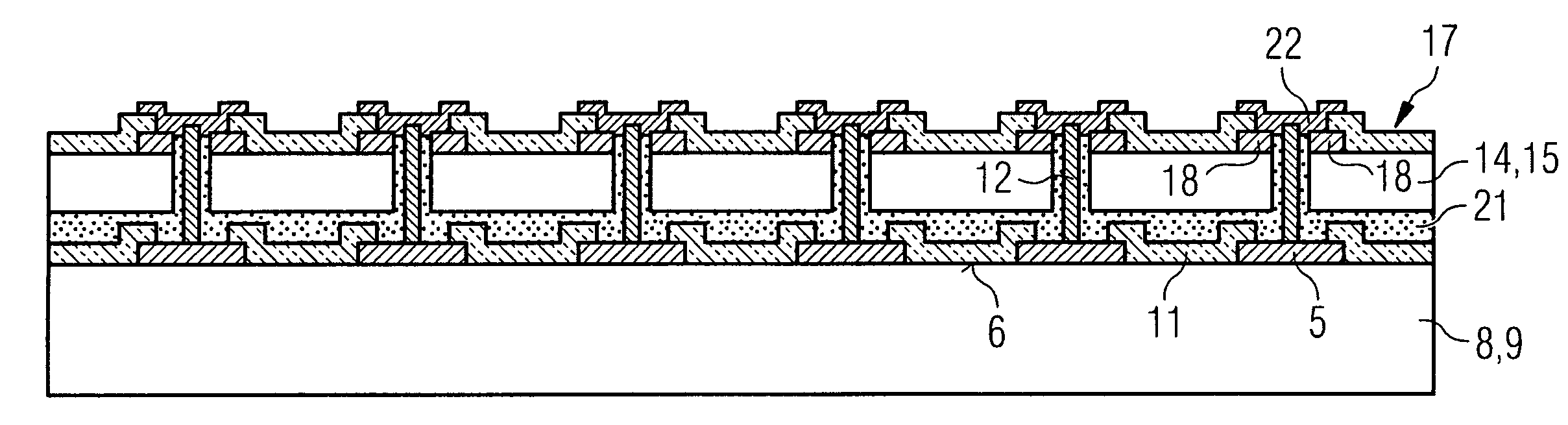

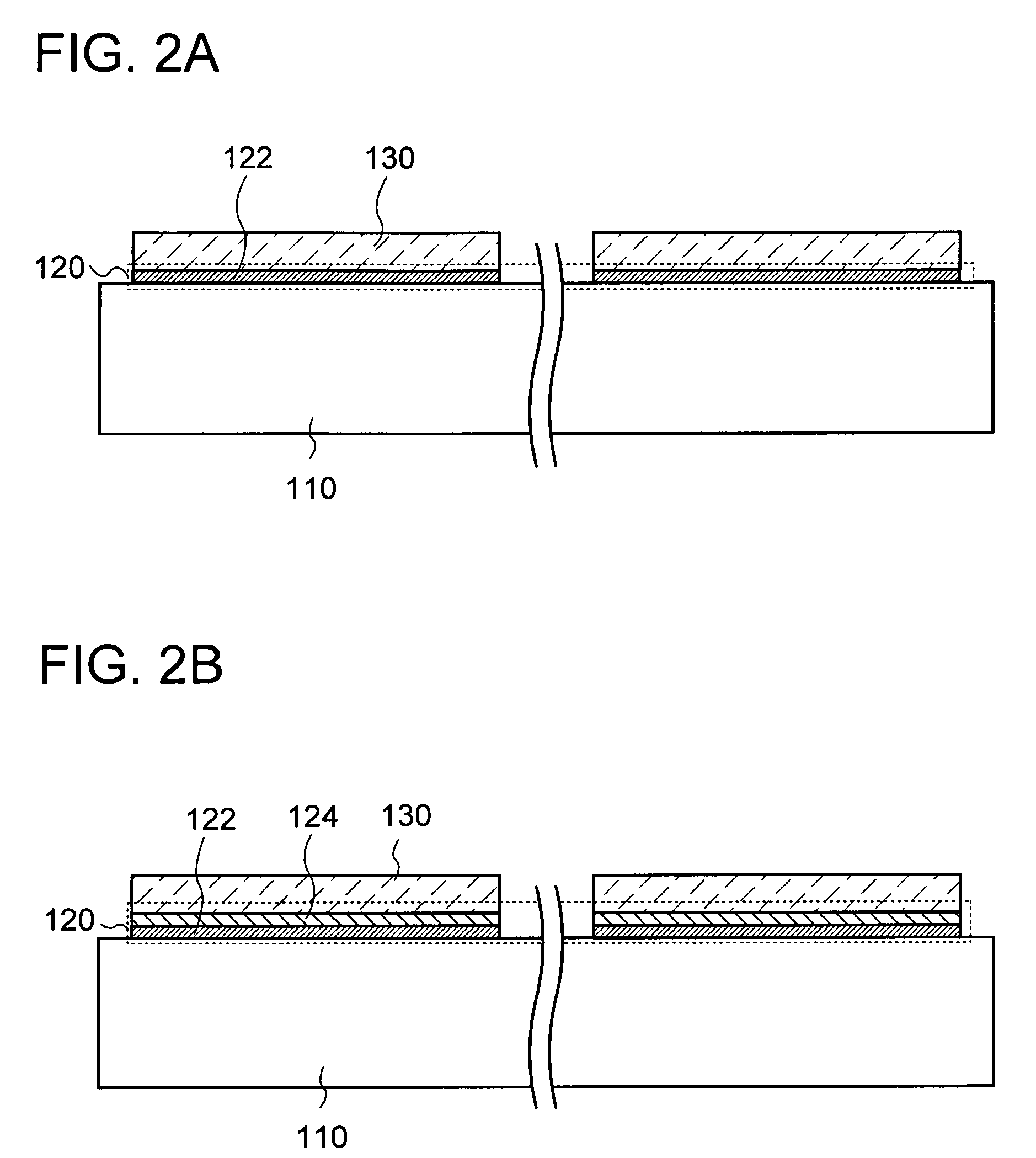

Semiconductor device with stacked chips and method for manufacturing thereof

InactiveUS20080032448A1Improve manufacturing productivitySemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A semiconductor device includes a first semiconductor device and a second semiconductor device. Through-holes in the second semiconductor device extend from an upper side of the second semiconductor device adjacent contact pads to a bottom side of the second device. Tower contact bumps are electrically connected to contact pads of the first semiconductor device. The second semiconductor device is arranged adjacent the first semiconductor device so that the tower contact bumps are disposed within the through-holes and are electrically connected with contact pads of the second semiconductor device.

Owner:POLARIS INNOVATIONS LTD

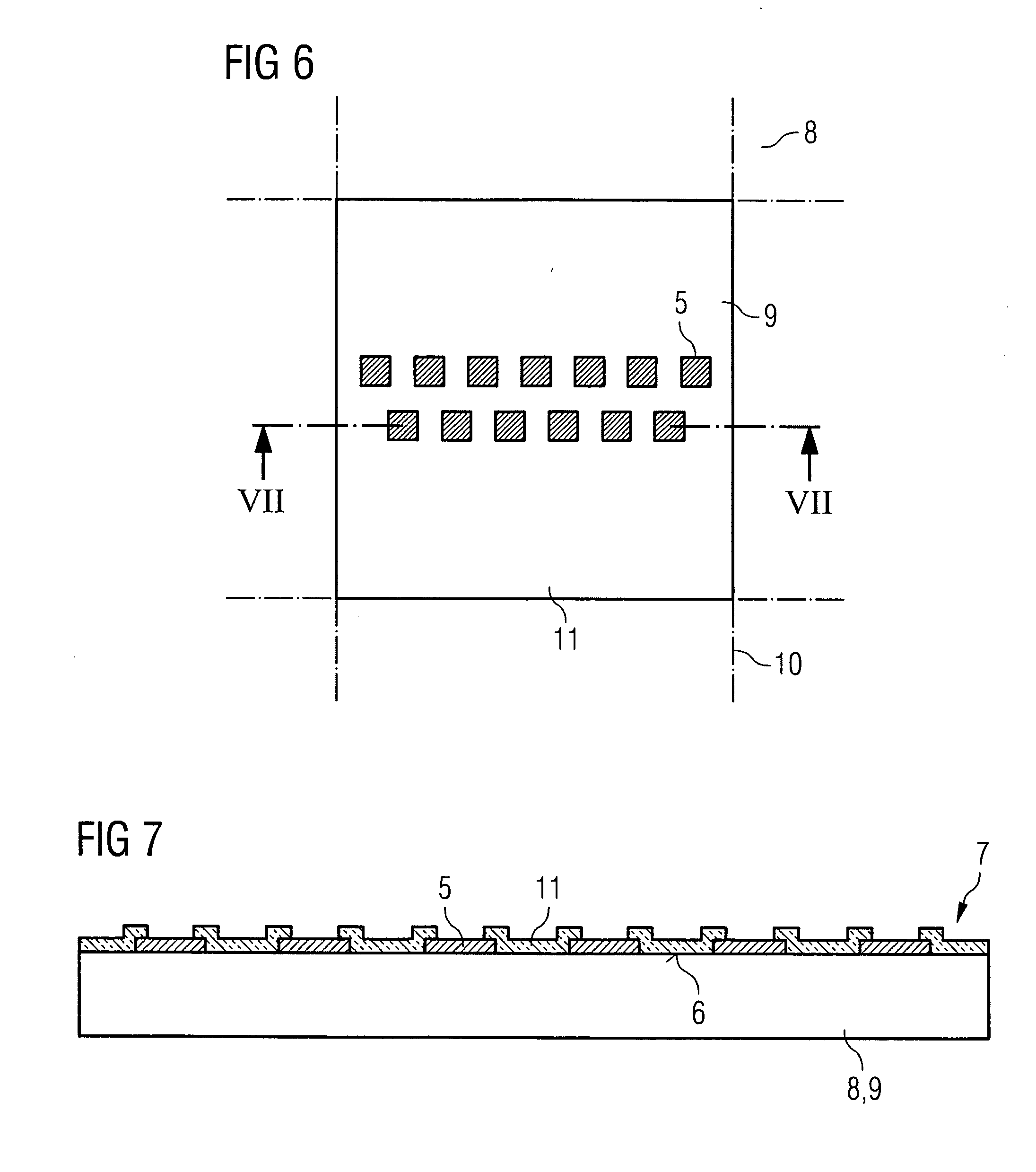

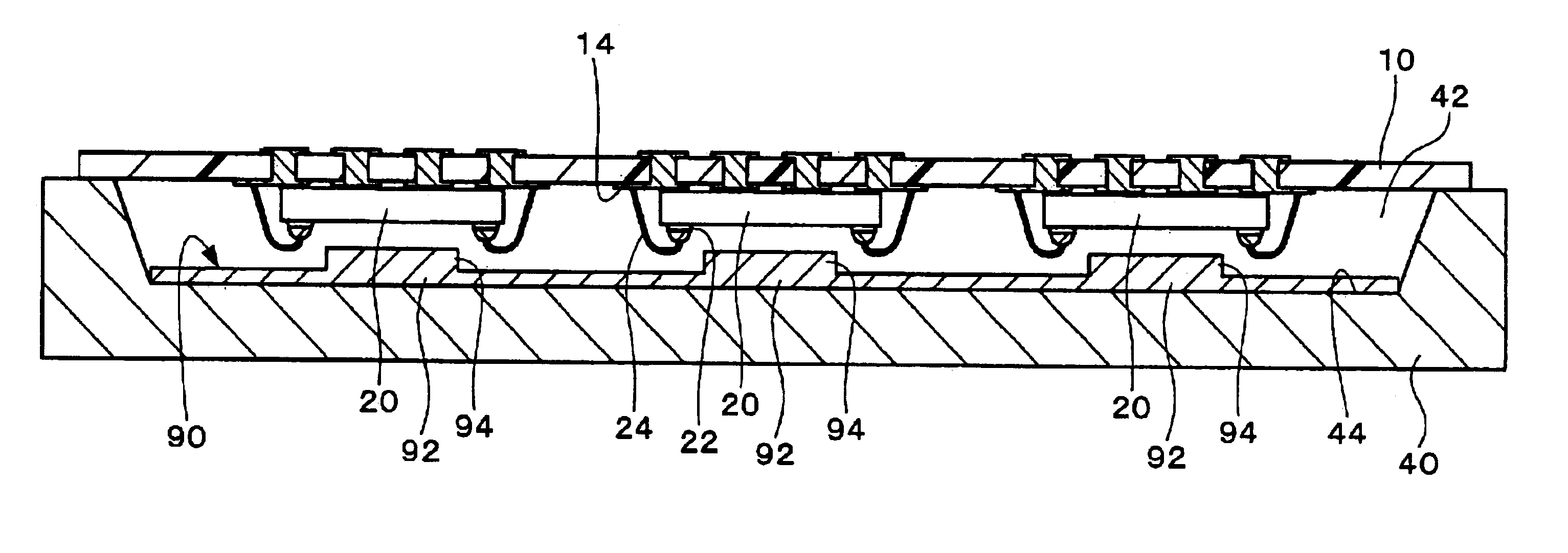

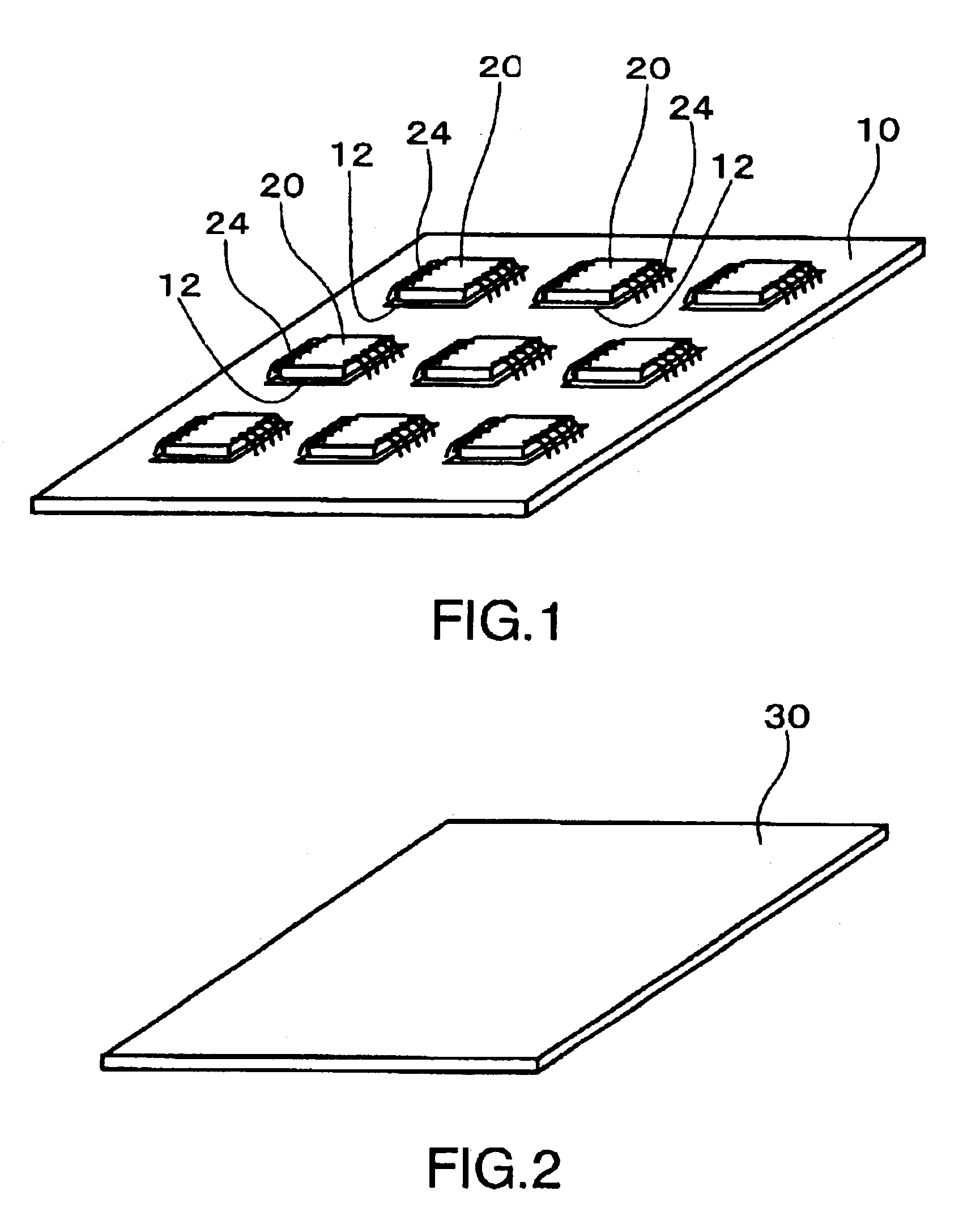

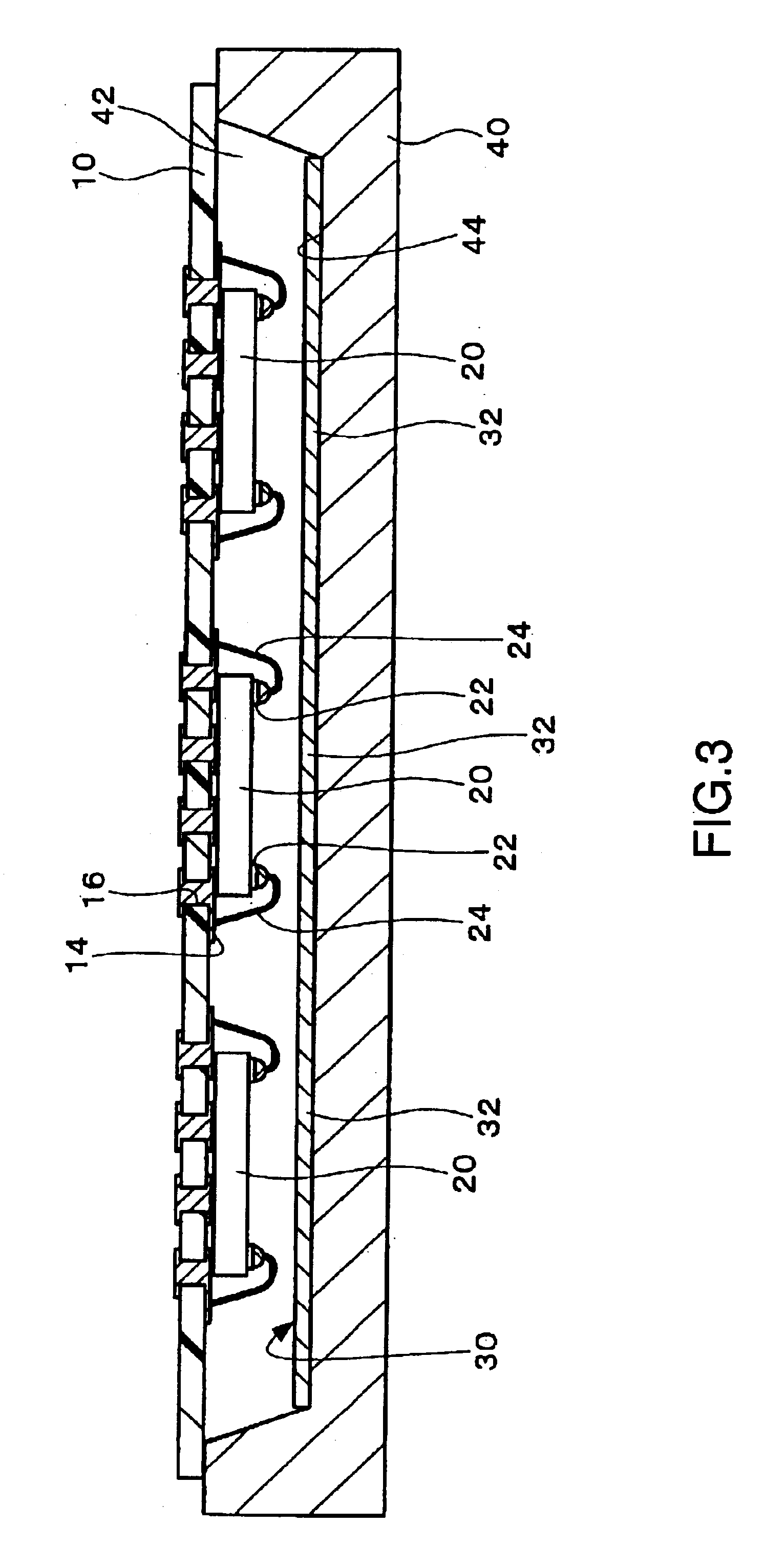

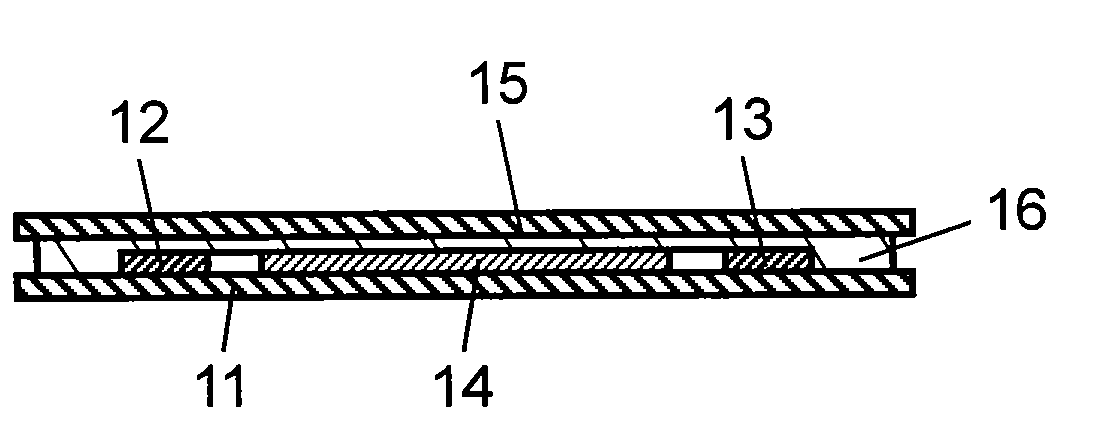

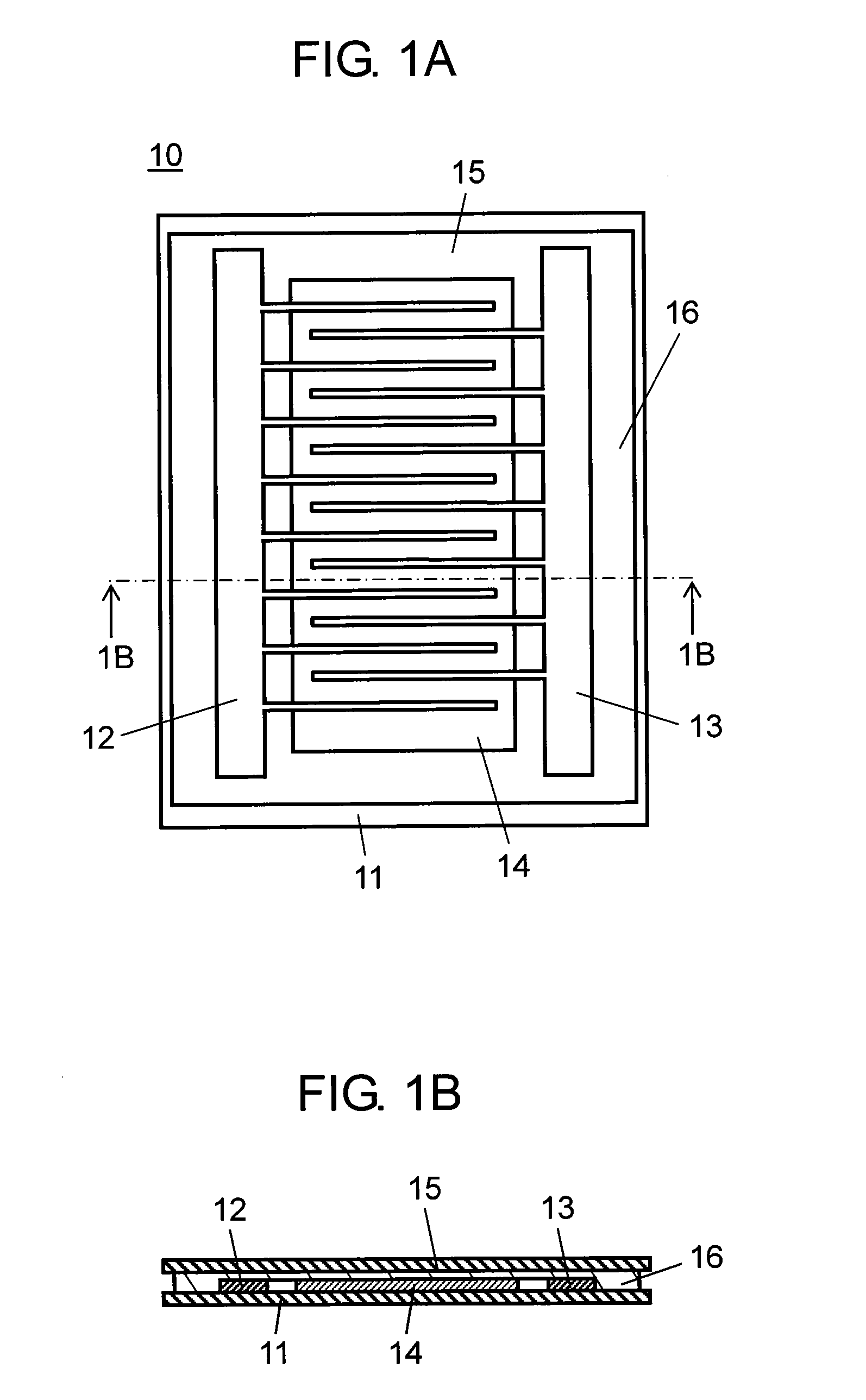

Semiconductor device and manufacturing method for the same, circuit board, and electronic device

InactiveUS6921683B2Improve productivityImprove manufacturing productivitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

To improve the productivity of manufacturing semiconductor devices having a heat sink, the semiconductor device manufacturing method includes: (a) setting an integral heat radiation body set 30 of multiple heat radiation bodies 32 in a mold 40 cavity 42; (b) setting a substrate 10 on which multiple semiconductor chips 20 are mounted in a planar arrangement in the mold 40 so that the multiple semiconductor chips 20 are located inside the cavity 42; and (c) sealing the multiple semiconductor chips 20 and affixing the heat radiation body set 30 by filling the cavity 42 with a sealant.

Owner:SEIKO EPSON CORP

PTC resistor

InactiveUS20100038357A1Increase flexibilityIncreased durabilityOhmic-resistance electrodesHeating element materialsCross-linkConductive materials

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

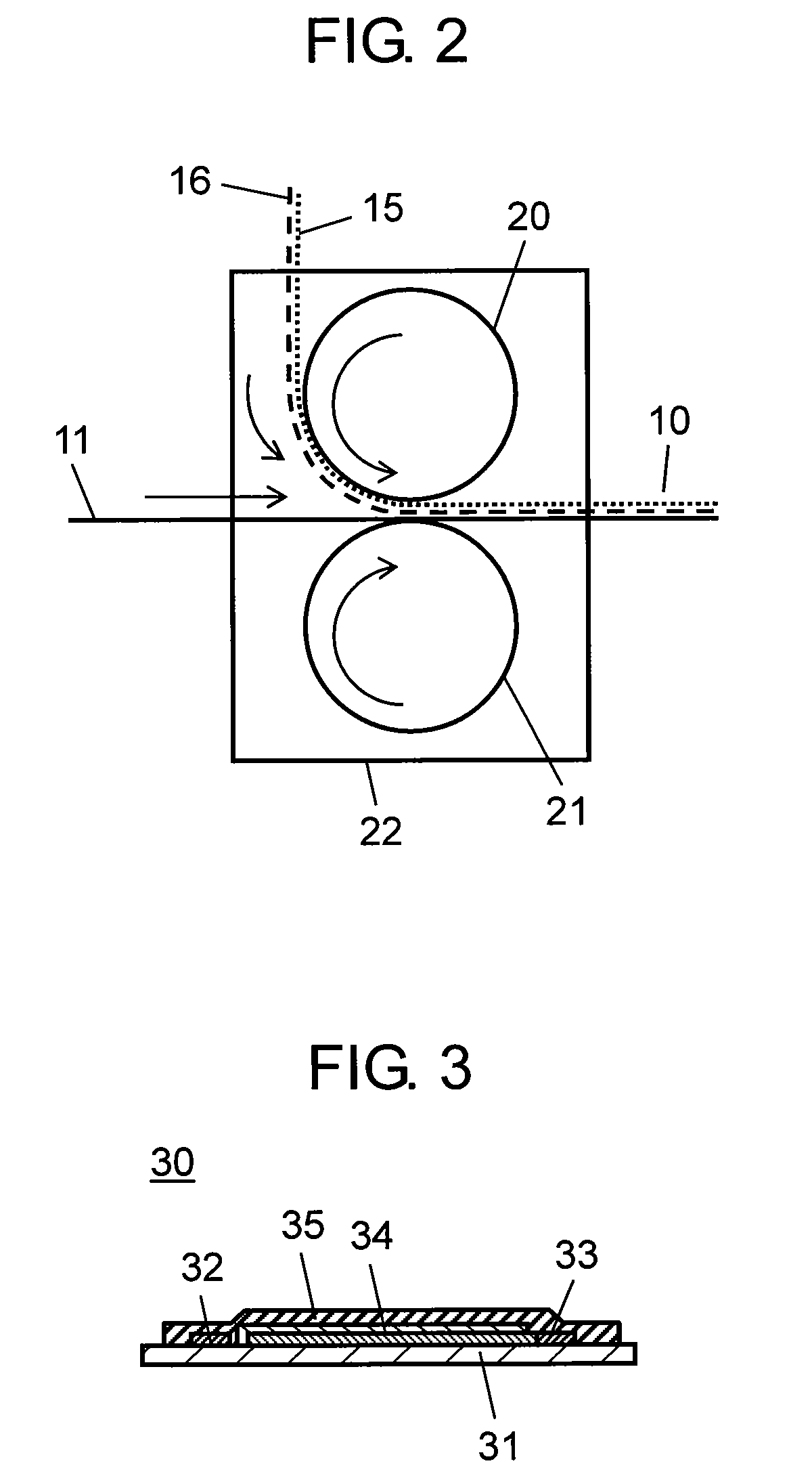

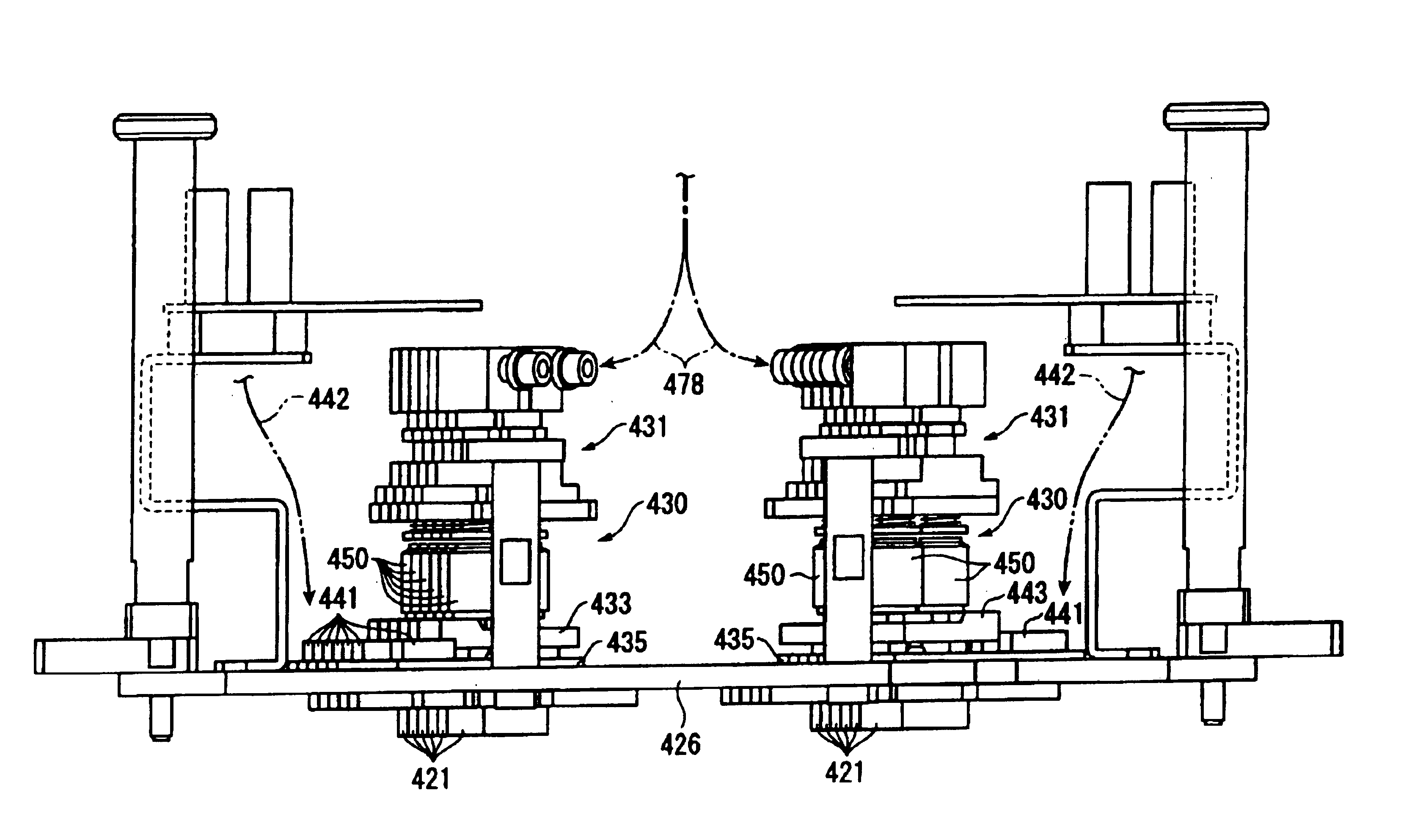

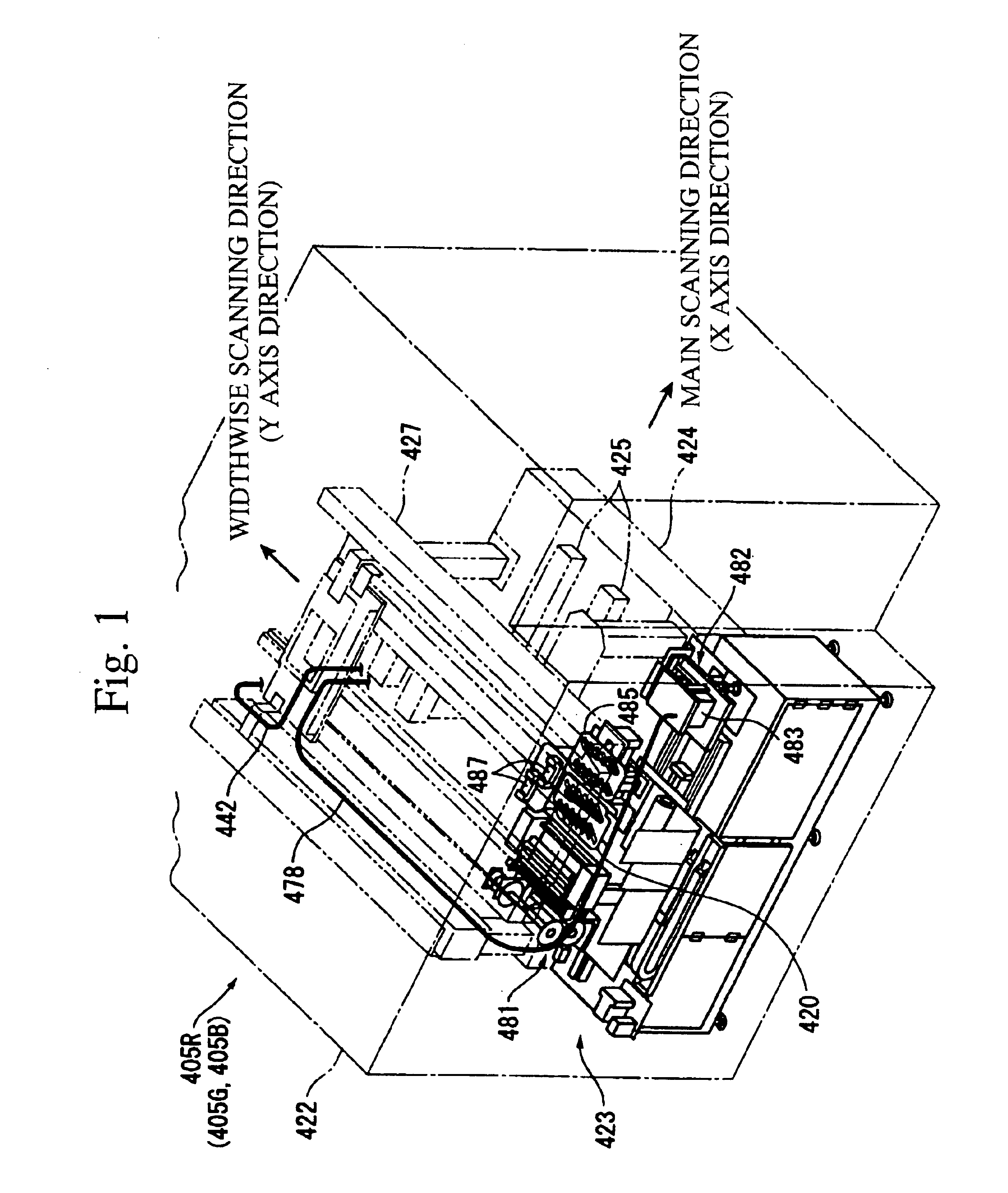

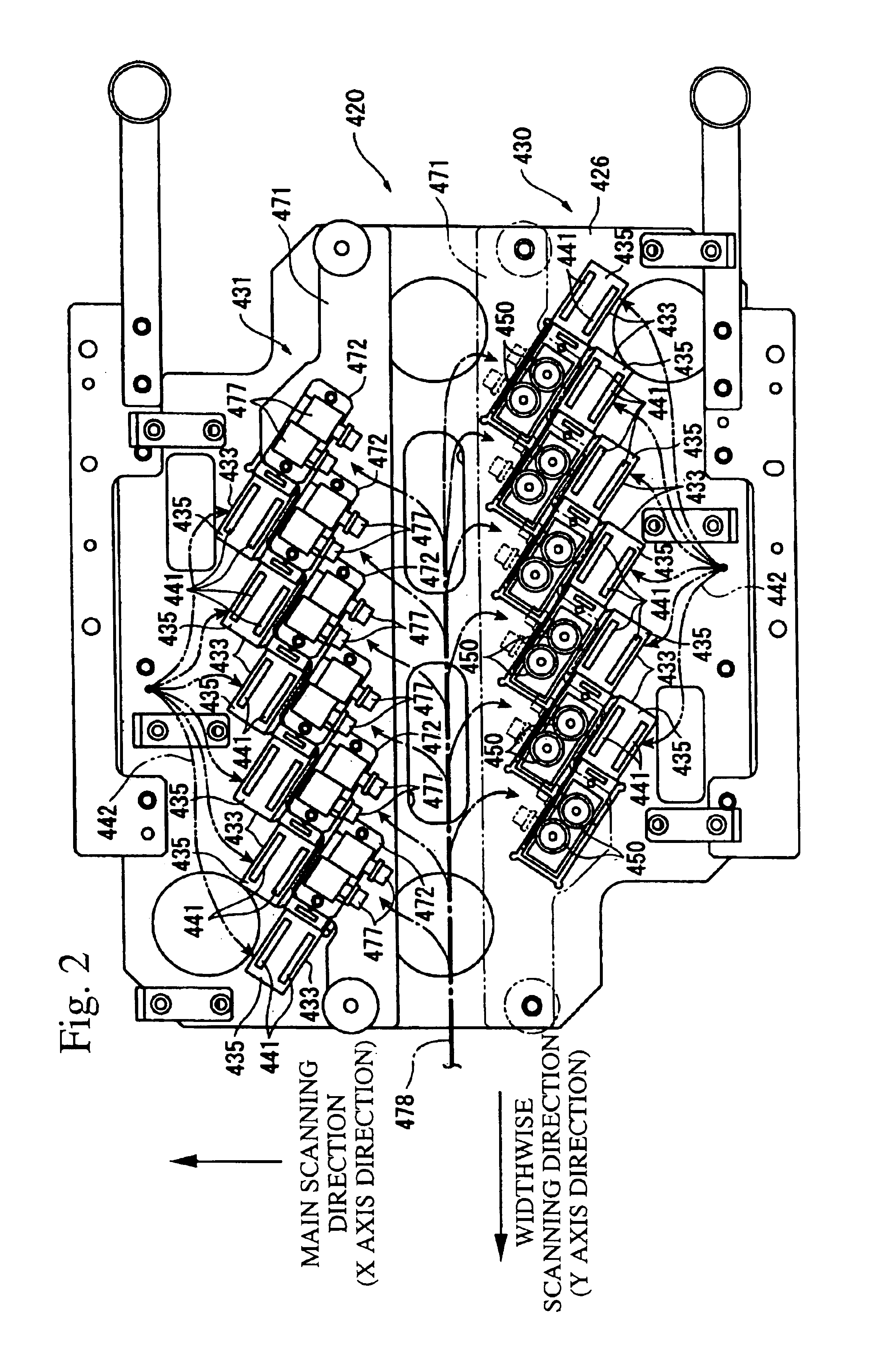

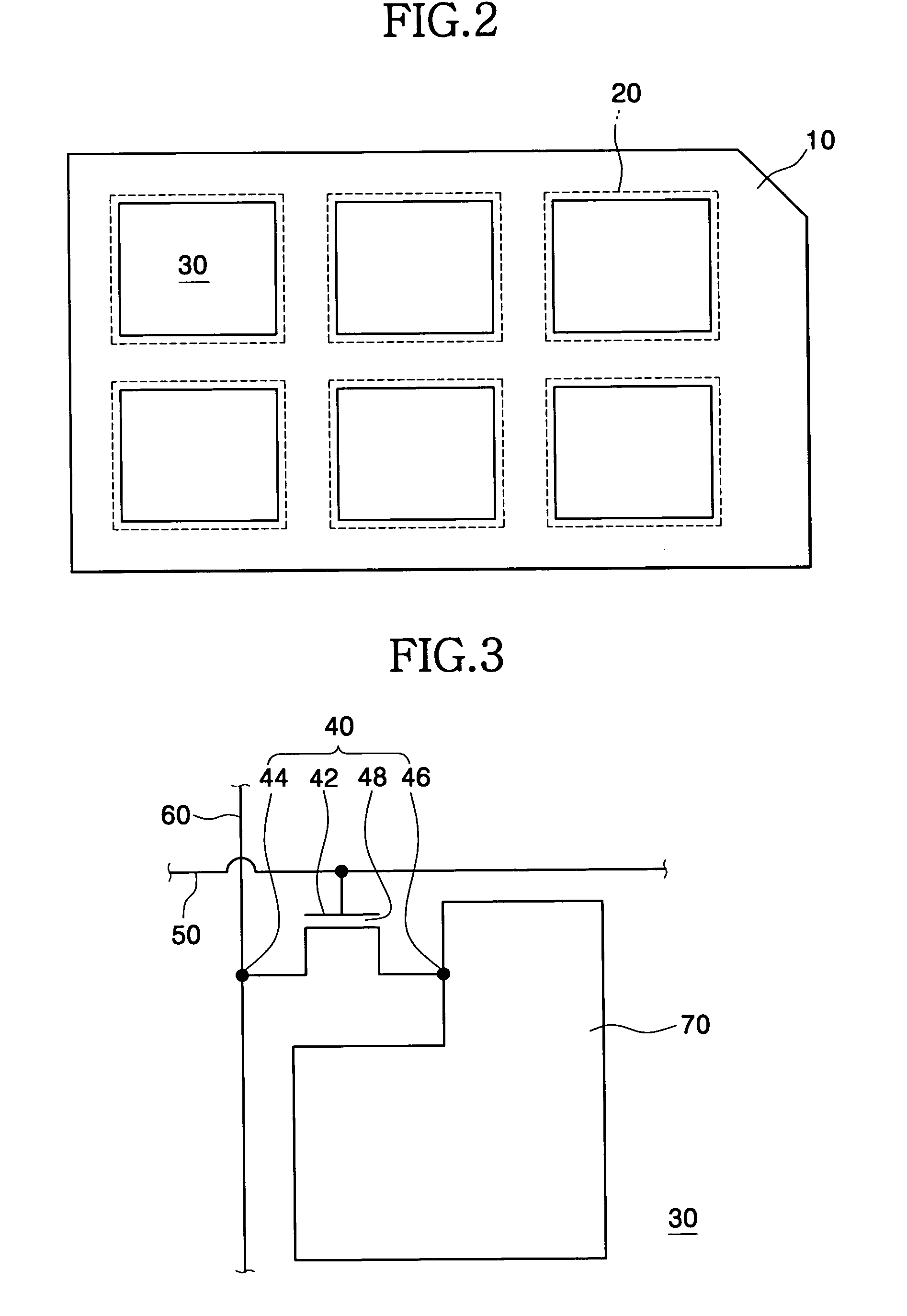

Liquid drop discharge method and discharge device; electro optical device, method of manufacture thereof, and device for manufacture thereof; color filter method of manufacture thereof, and device for manufacturing thereof; and device for incorporating backing, method of manufacturing thereof, and device for manufacture thereof

InactiveUS6837568B2Simple compositionImprove manufacturing productivityInking apparatusSolid-state devicesColor gelLight filter

A liquid drop discharge device provides a head unit 420 which discharges filter element material relative to each of various colors of color filters. The head unit 420 is composed of an ink jet heads which are arranged on one end of a print substrate plate having a shape of rectangular card and head devices 433 which are arranged on the other end of the print substrate plate comprising connectors 441. The head devices 433 are aligned in two rows, as two groups, in a staggered arrangement so that a portion on which the connectors 441 are aligned in one of the two rows does not face to the same portion of the other in the two rows and protrudes outside of the print substrate plate. The head unit 420 discharges the filter element material onto predetermined portions in a superimposing manner while shifting along a direction which intersects to a direction along which the head devices 433 are arranged.

Owner:KATEEVA

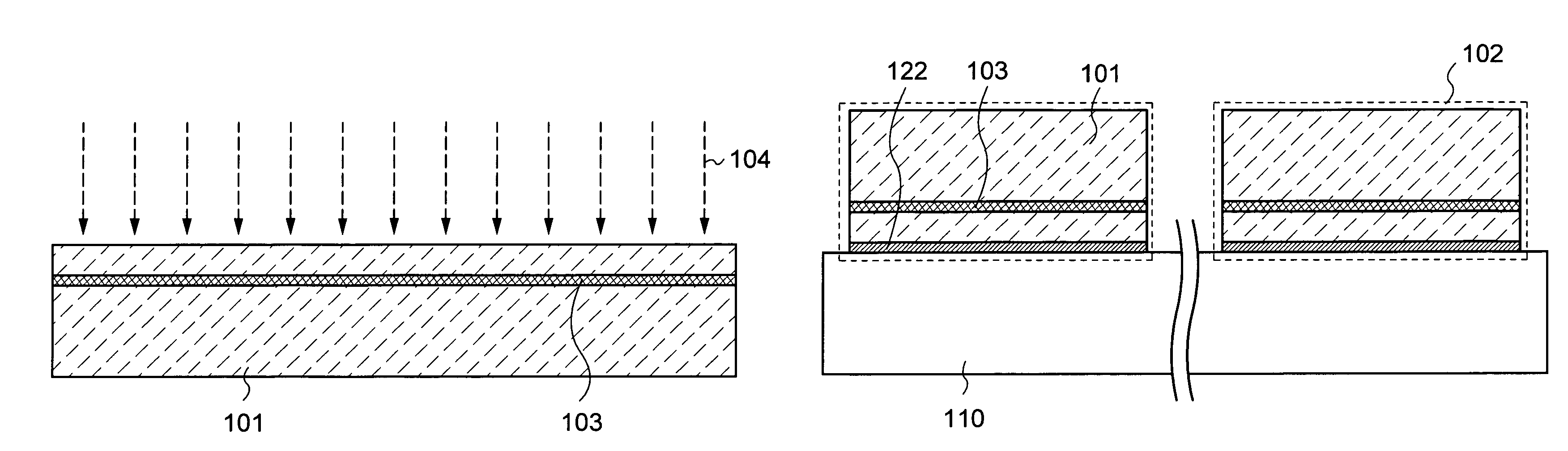

Display device, method for manufacturing display device, and SOI substrate

InactiveUS20080254560A1Improve productivityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingProduction rateDisplay device

A manufacturing method is provided which achieves an SOI substrate with a large area and can improve productivity of manufacture of a display device using the SOI substrate. A plurality of single-crystalline semiconductor layers are bonded to a substrate having an insulating surface, and a circuit including a transistor is formed using the single-crystalline semiconductor layers, so that a display device is manufactured. Single-crystalline semiconductor layers separated from a single-crystalline semiconductor substrate are applied to the plurality of single-crystalline semiconductor layers. Each of the single-crystalline semiconductor layers has a size corresponding to one display panel (panel size).

Owner:SEMICON ENERGY LAB CO LTD

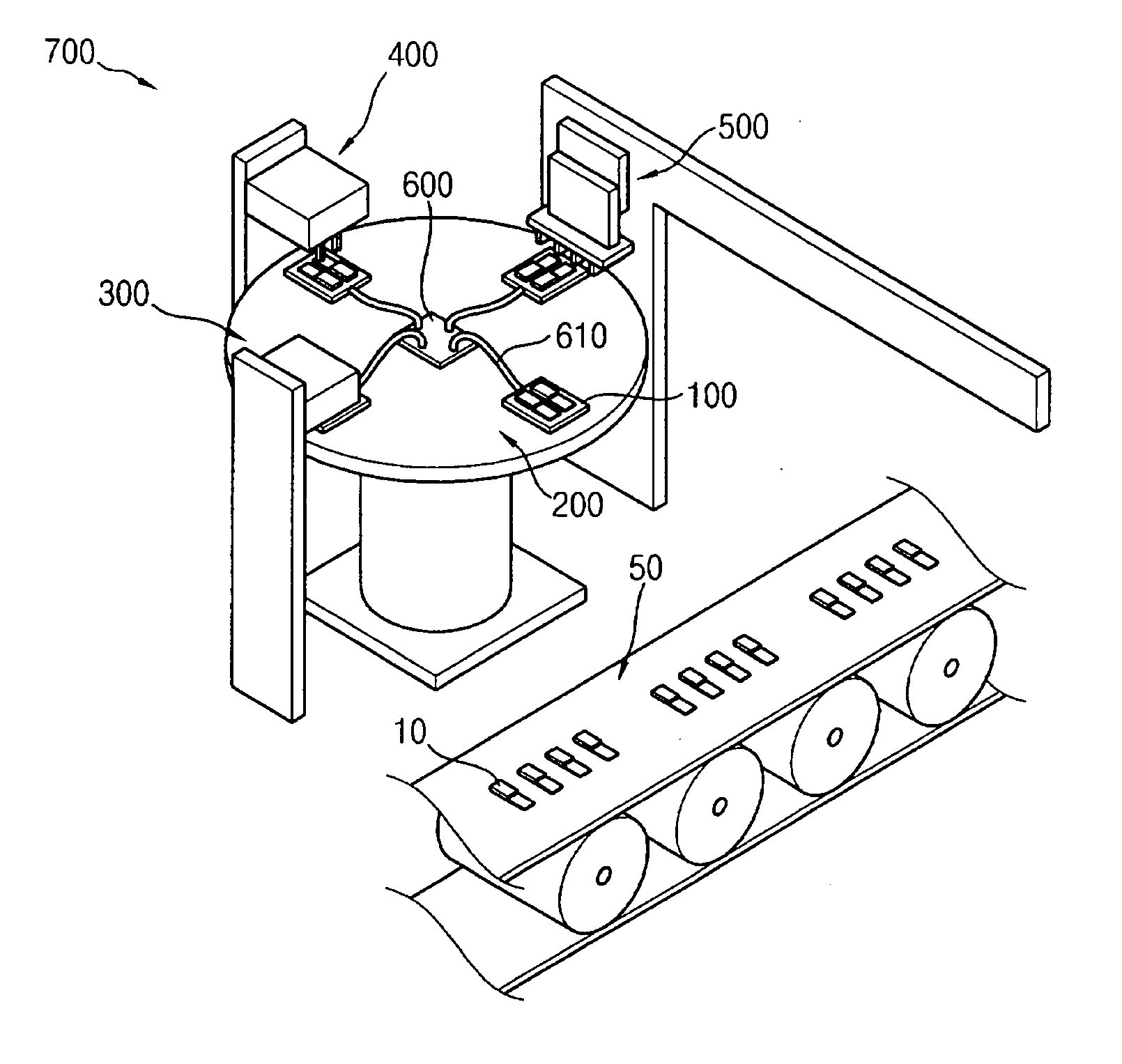

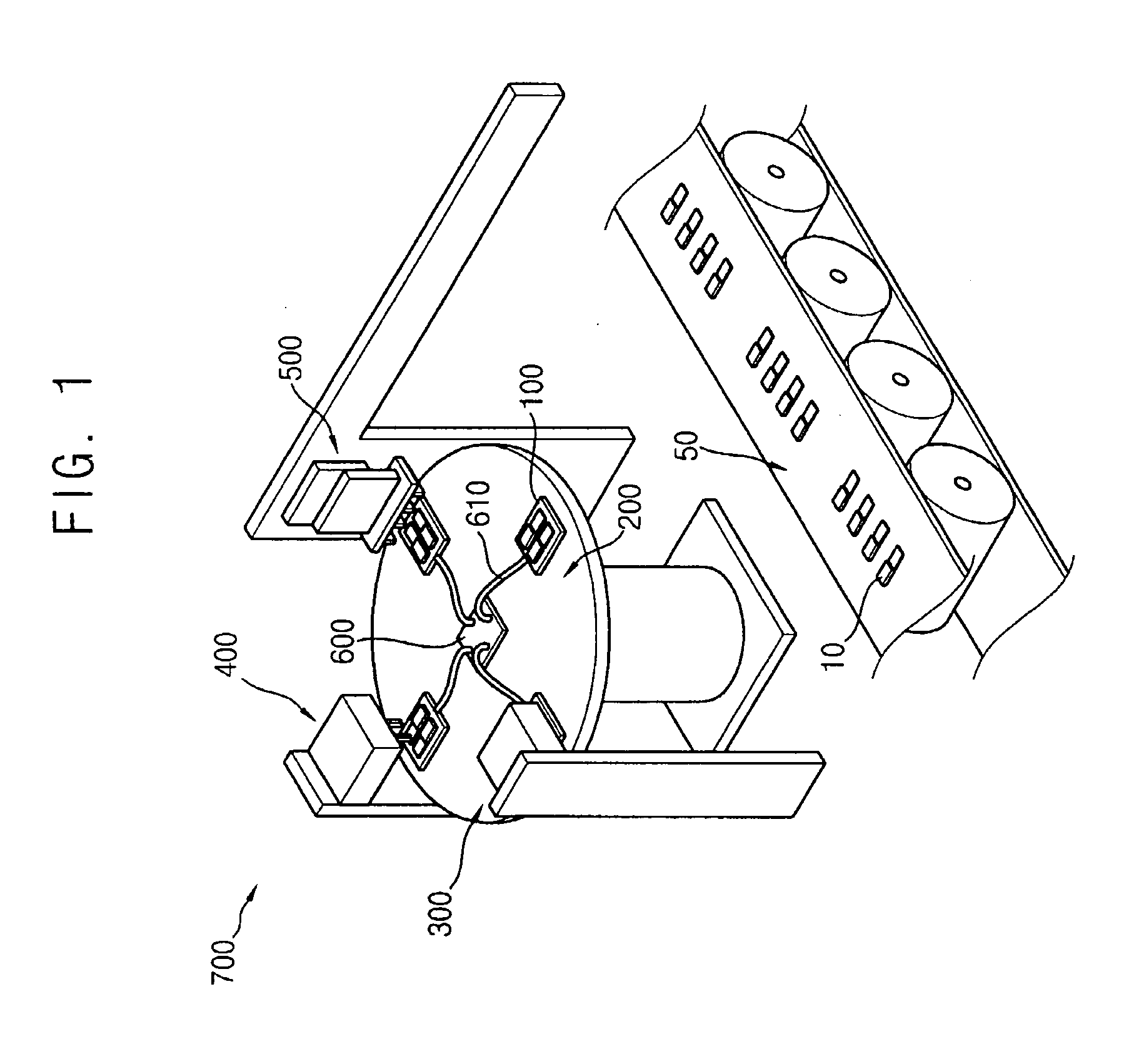

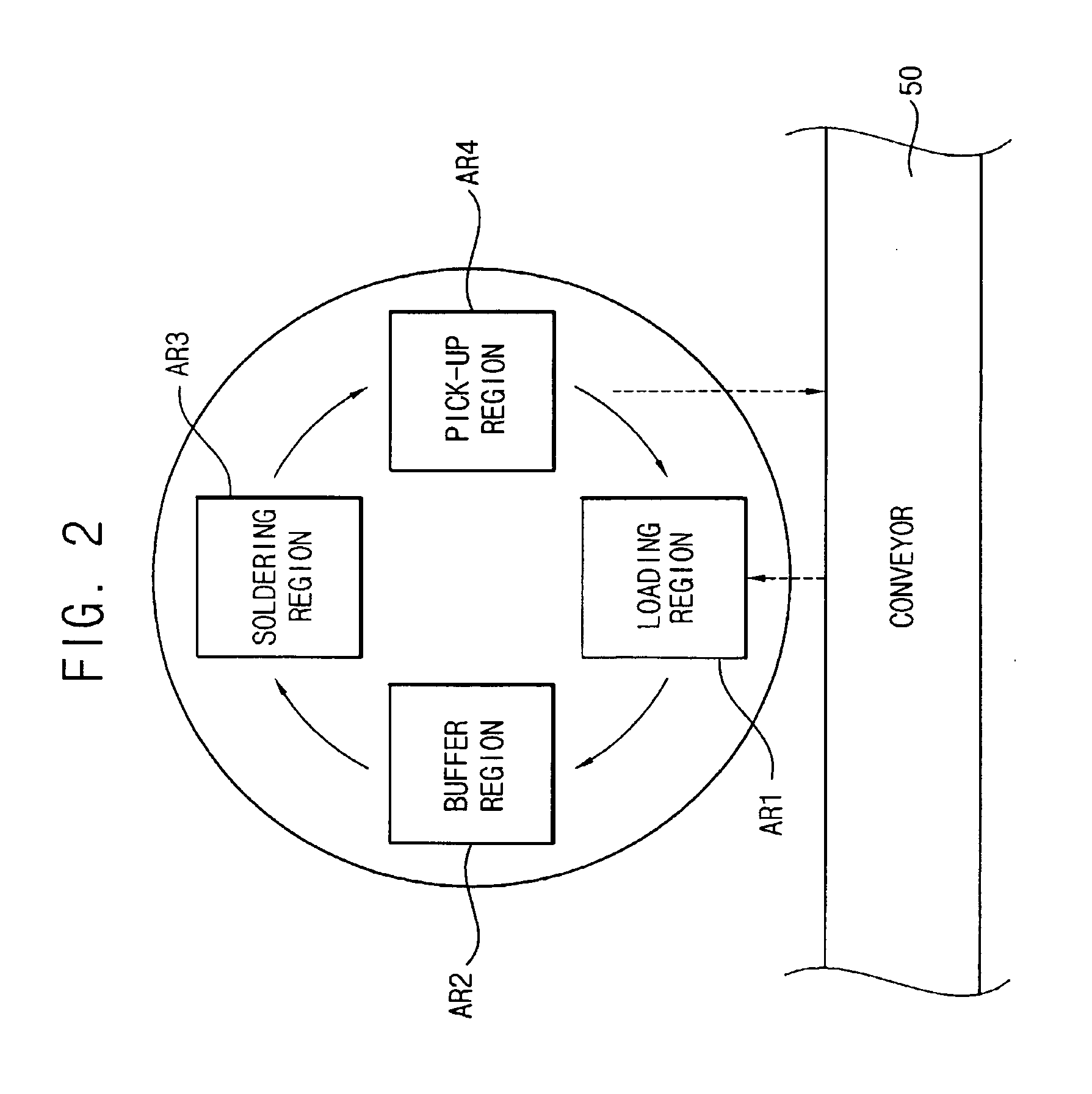

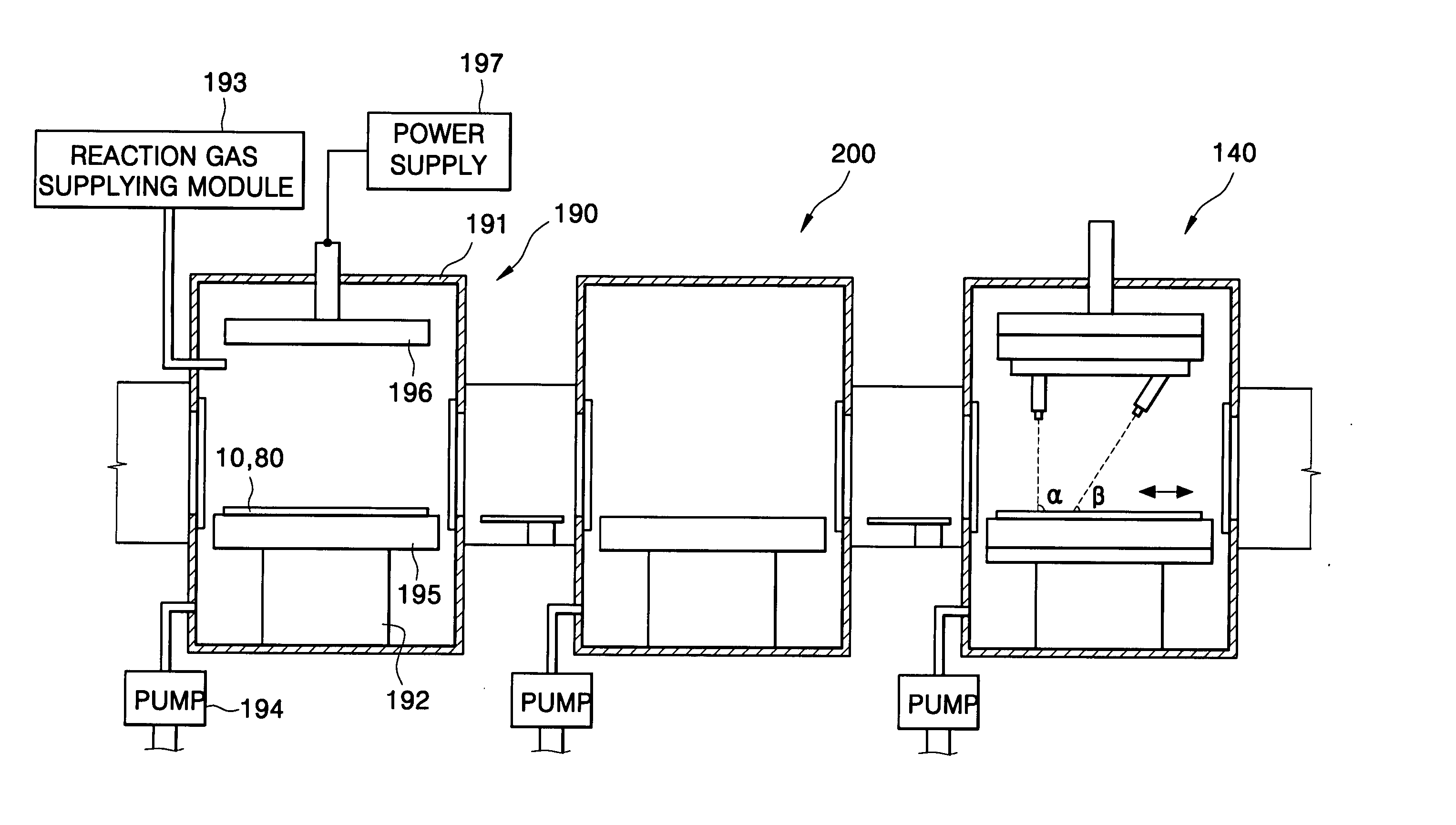

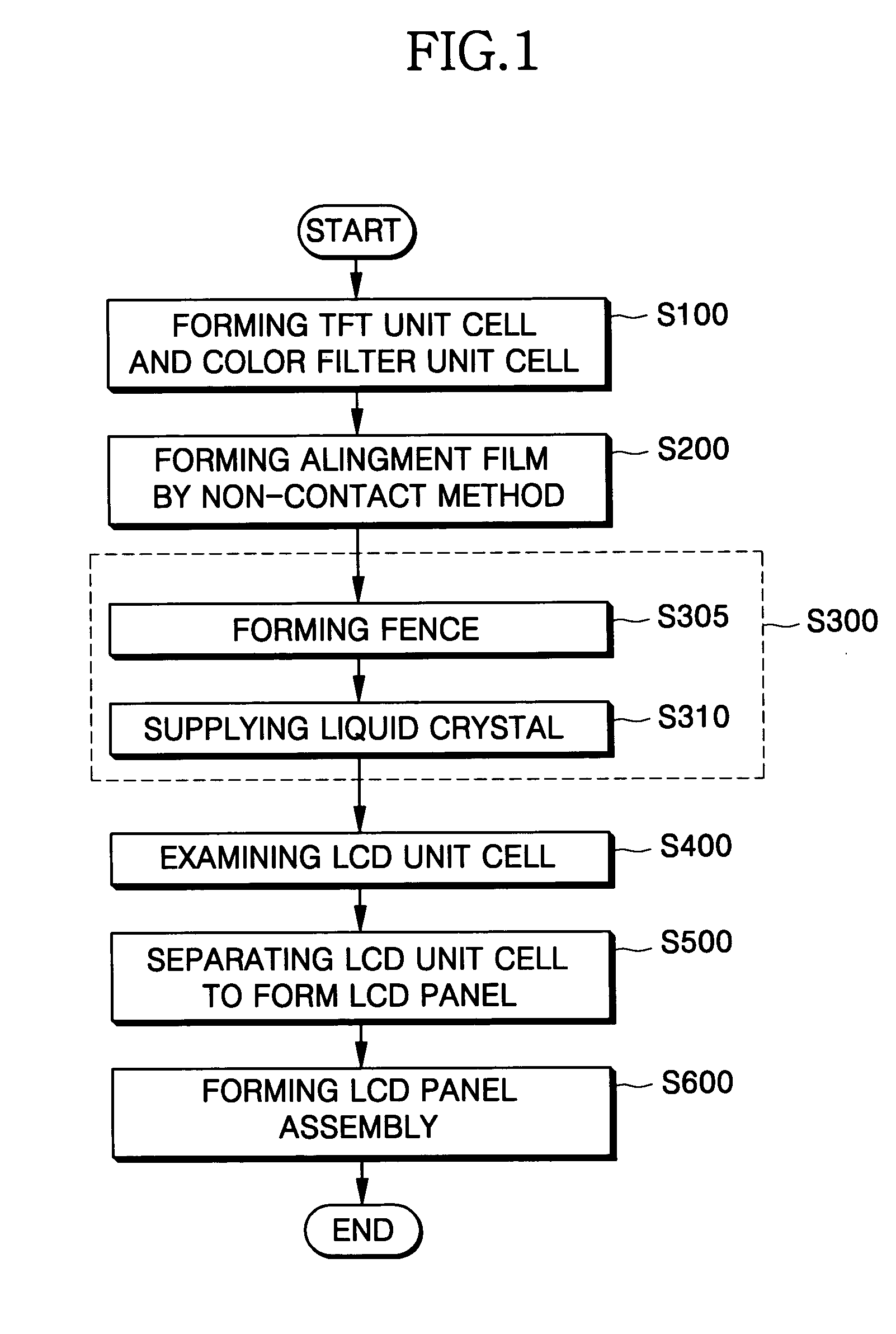

Soldering driving elements in LCD panels

InactiveUS20070157464A1Improve display panel manufacturing productivityReduce potentially harmful exposurePrinted circuit assemblingSemiconductor/solid-state device detailsProduction rateRadial position

An apparatus and method for soldering an LED driving element to an LCD panel includes a panel holding unit, a rotating unit and a soldering unit. The panel holding unit holds the display panel. The rotating unit supports the panel holding unit at initial radial and angular positions relative to a center of rotation of the rotating unit and rotates the holding unit in a horizontal plane about the center of rotation to selected angular positions relative thereto. The soldering unit is disposed above the rotating unit at the initial radial position and at a first angular position relative to initial angular position of the holding unit, and is operable to solder the driving element of the display panel held by the panel holding unit when the rotating unit rotates the panel holding unit to the first angular position. The apparatus and method provide improved display panel productivity.

Owner:SAMSUNG ELECTRONICS CO LTD

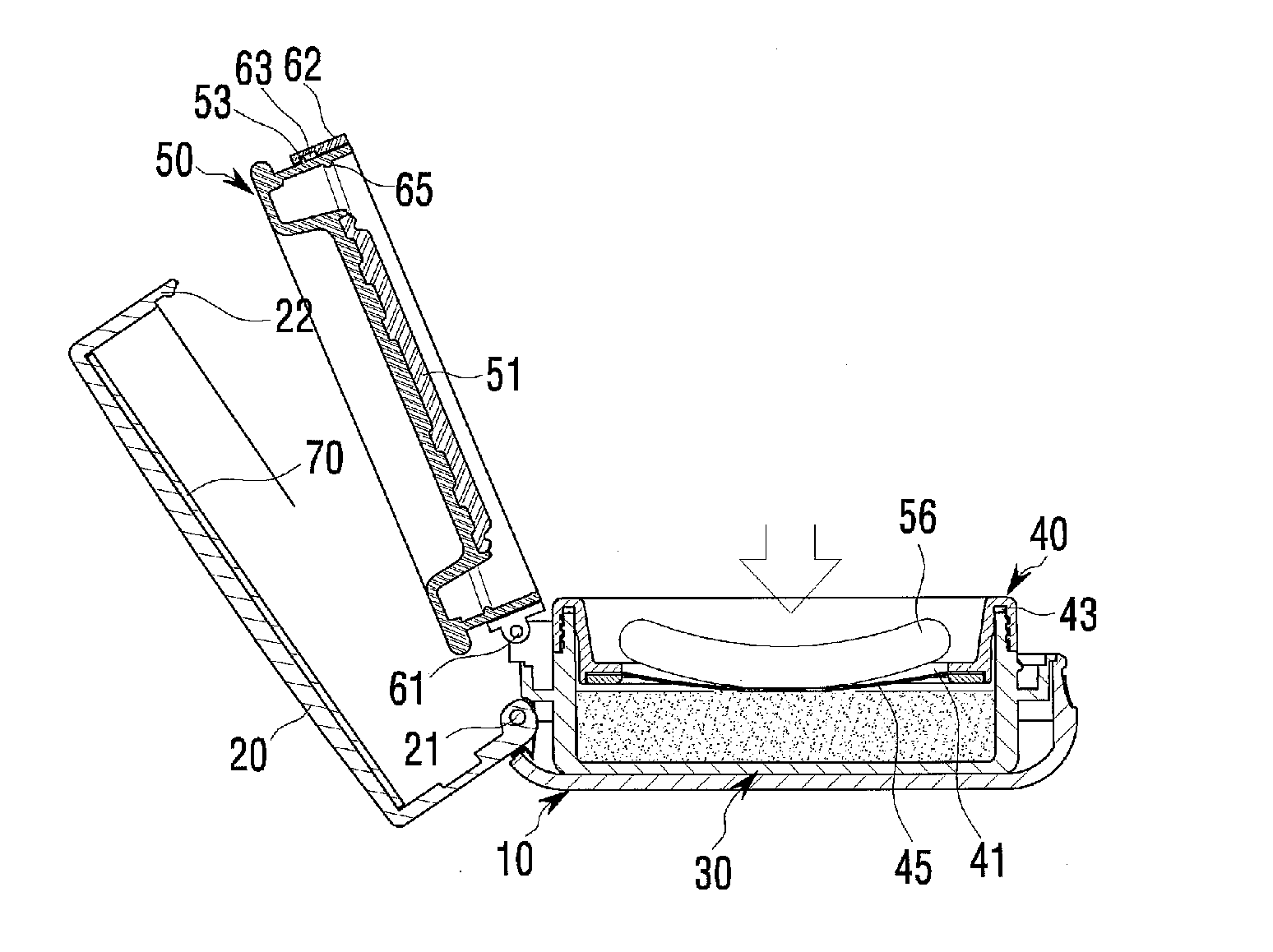

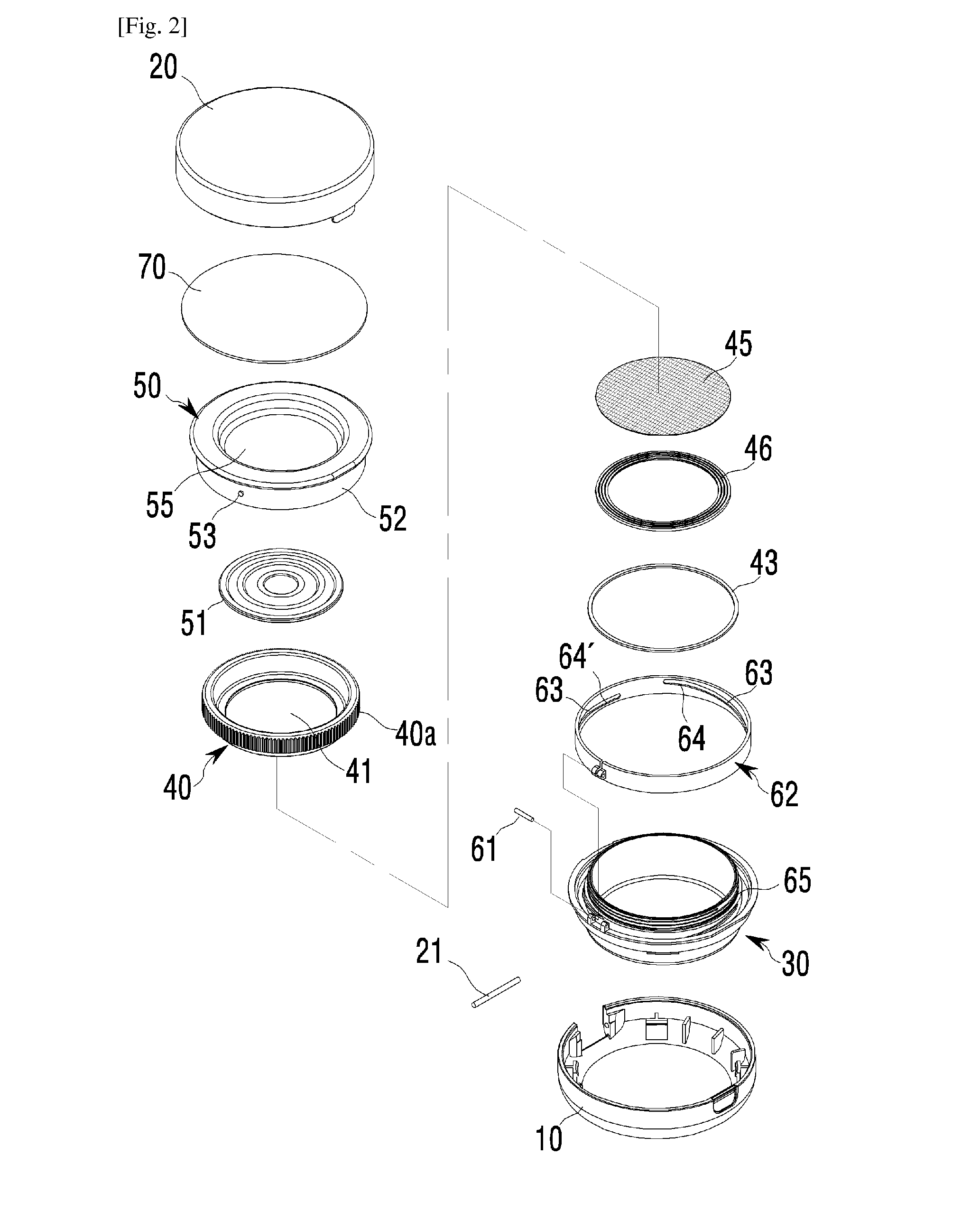

Compact type of airtight cosmetic container

ActiveUS20150320174A1Improve sealingAvoid changePackaging toiletriesPackaging cosmeticsEvaporationBiomedical engineering

Disclosed herein is a compact type of airtight cosmetic container. A shoulder cap (40) to which a mesh is coupled and a puff storage cap (50) which stores a puff are successively placed onto and coupled to a medial body (30) which contains a cosmetic therein. The shoulder cap and the puff storage cap can be airtightly coupled to the medial body by a sealing member (51) provided under the puff storage cap and a sealing ring (43) provided in the lower surface of the shoulder cap. A pressurizing means pressurizes the puff storage cap onto the medial body such that the sealing member and the sealing ring are compressed, whereby the sealability of the cosmetic container can be enhanced so that leakage of powder or a cosmetic change attributable to water evaporation can be reliably prevented.

Owner:CTK

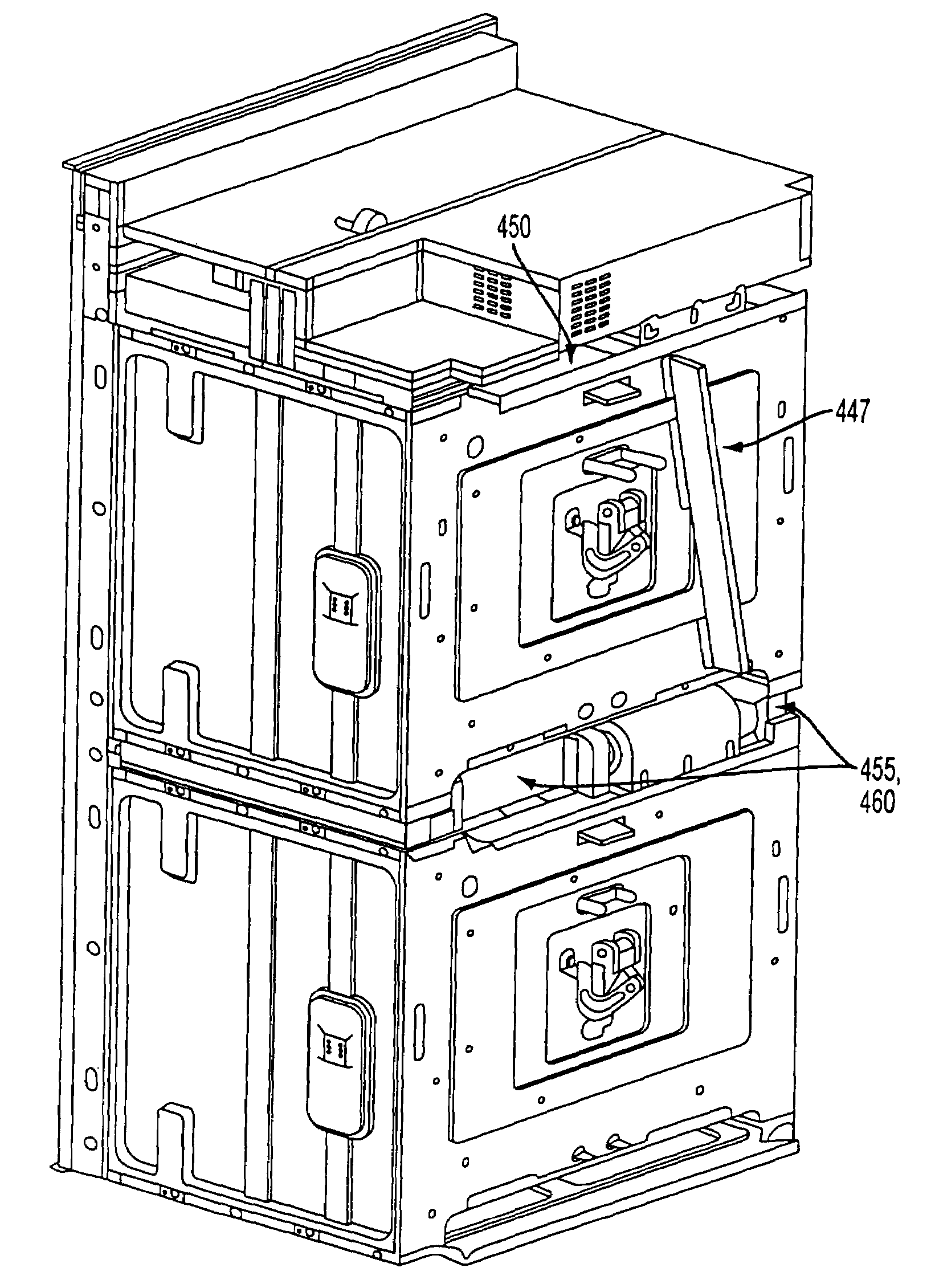

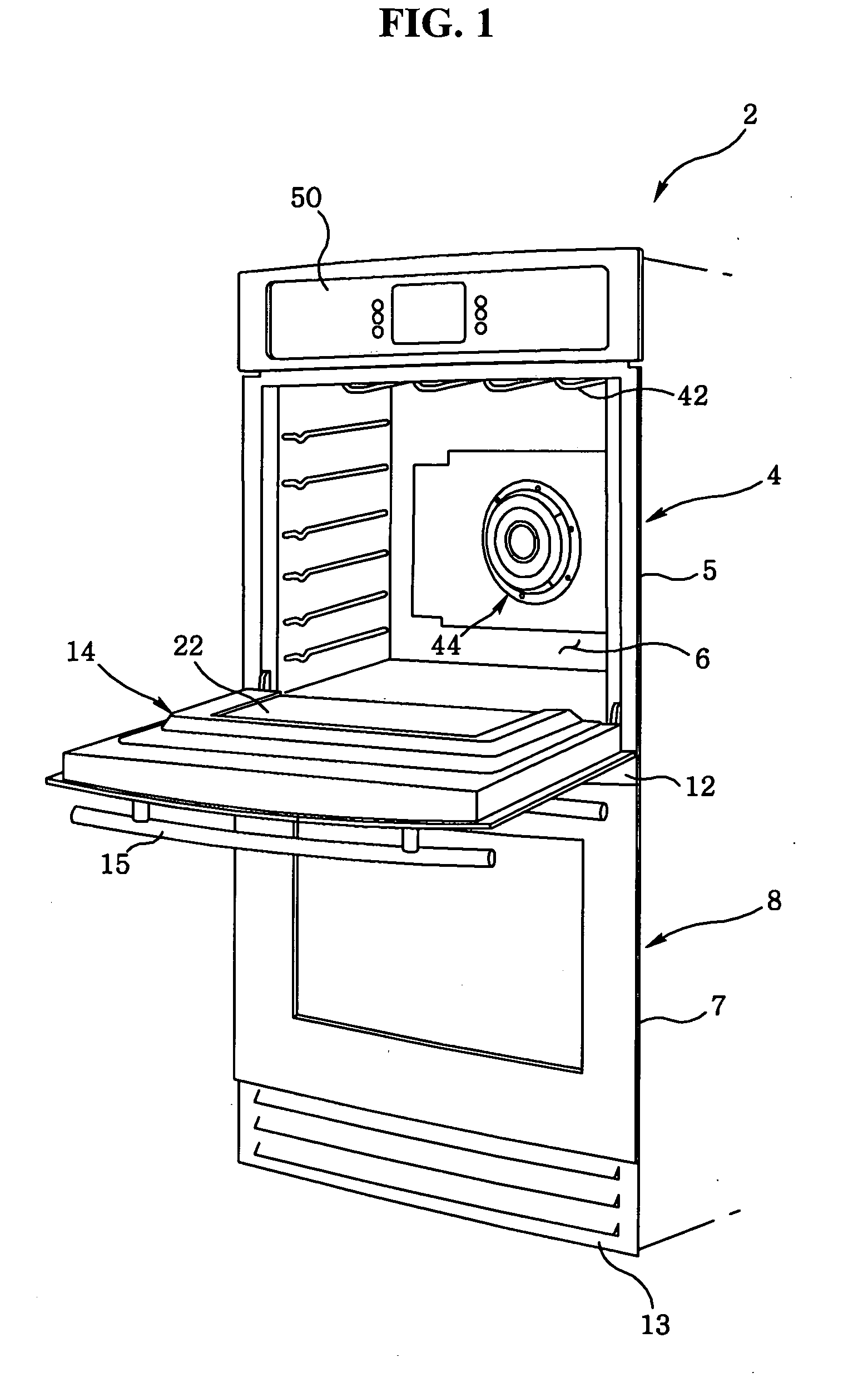

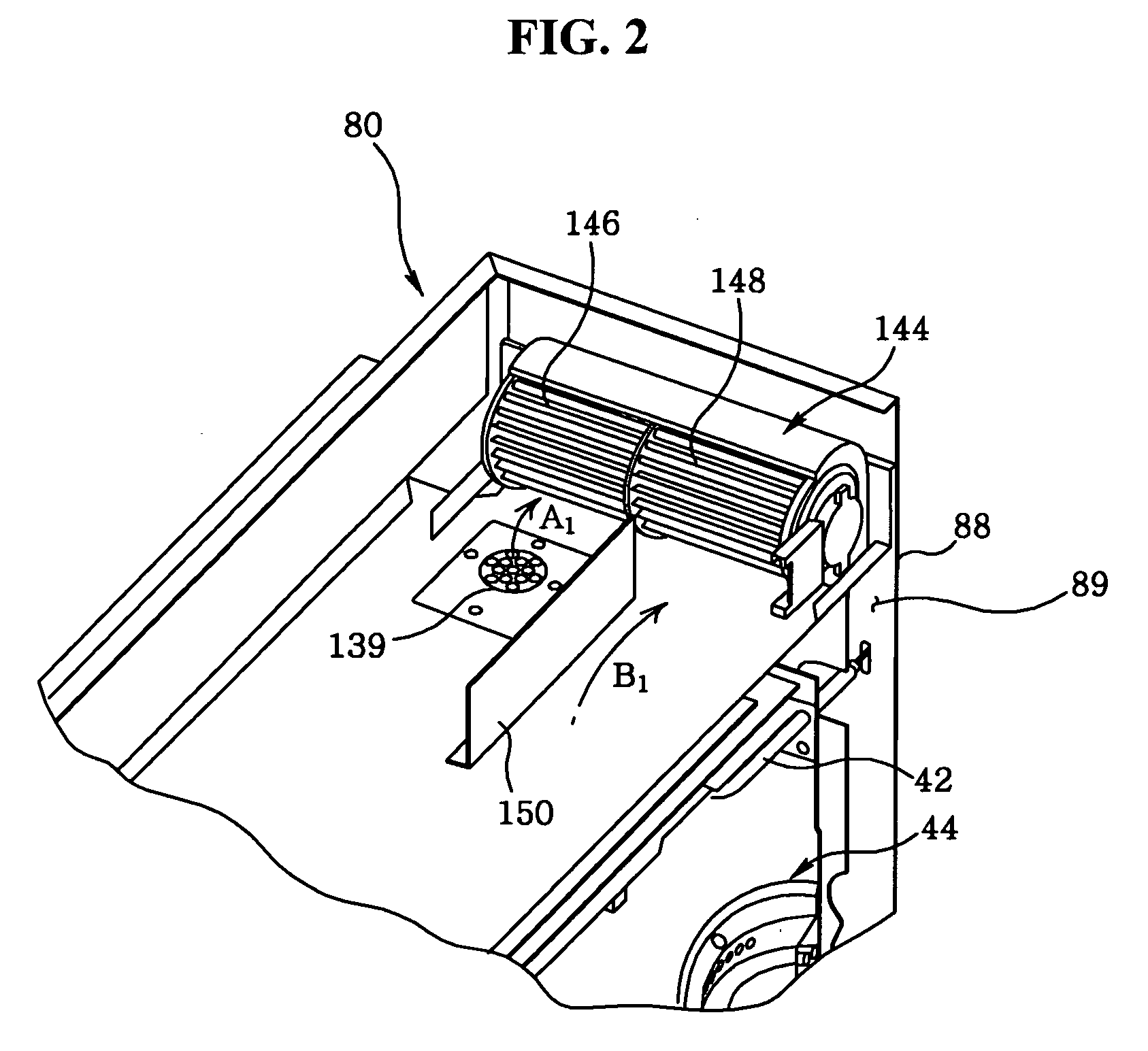

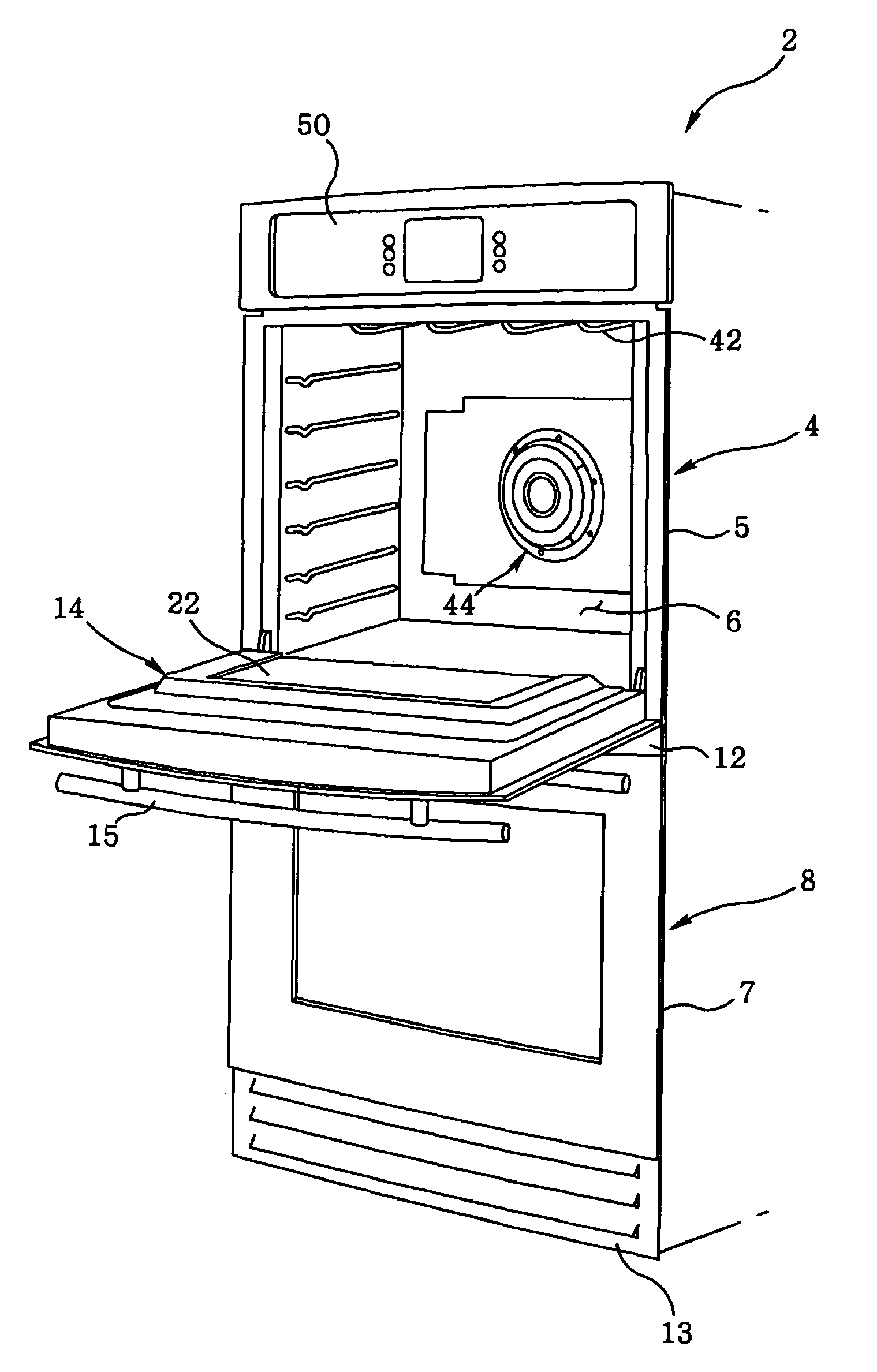

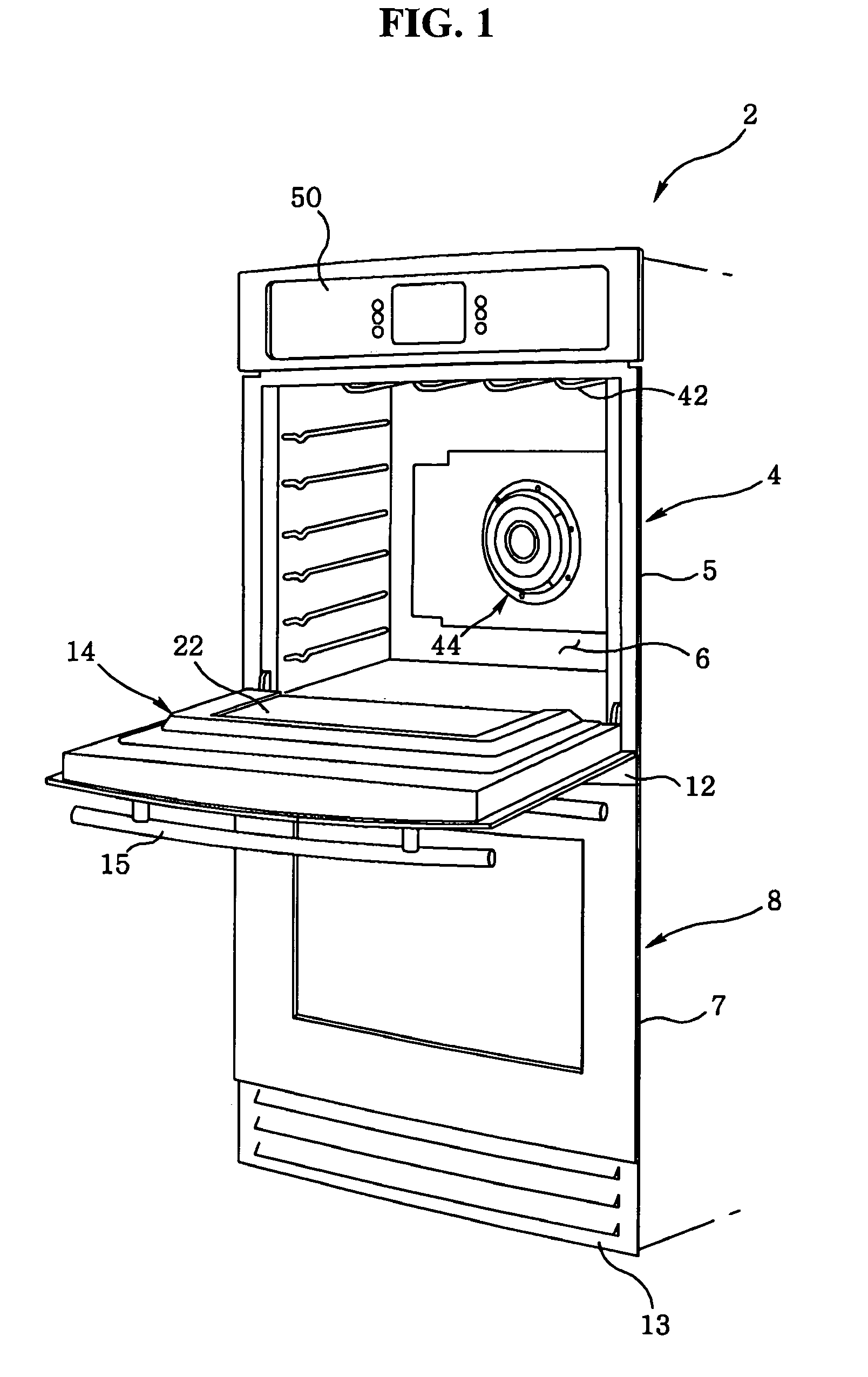

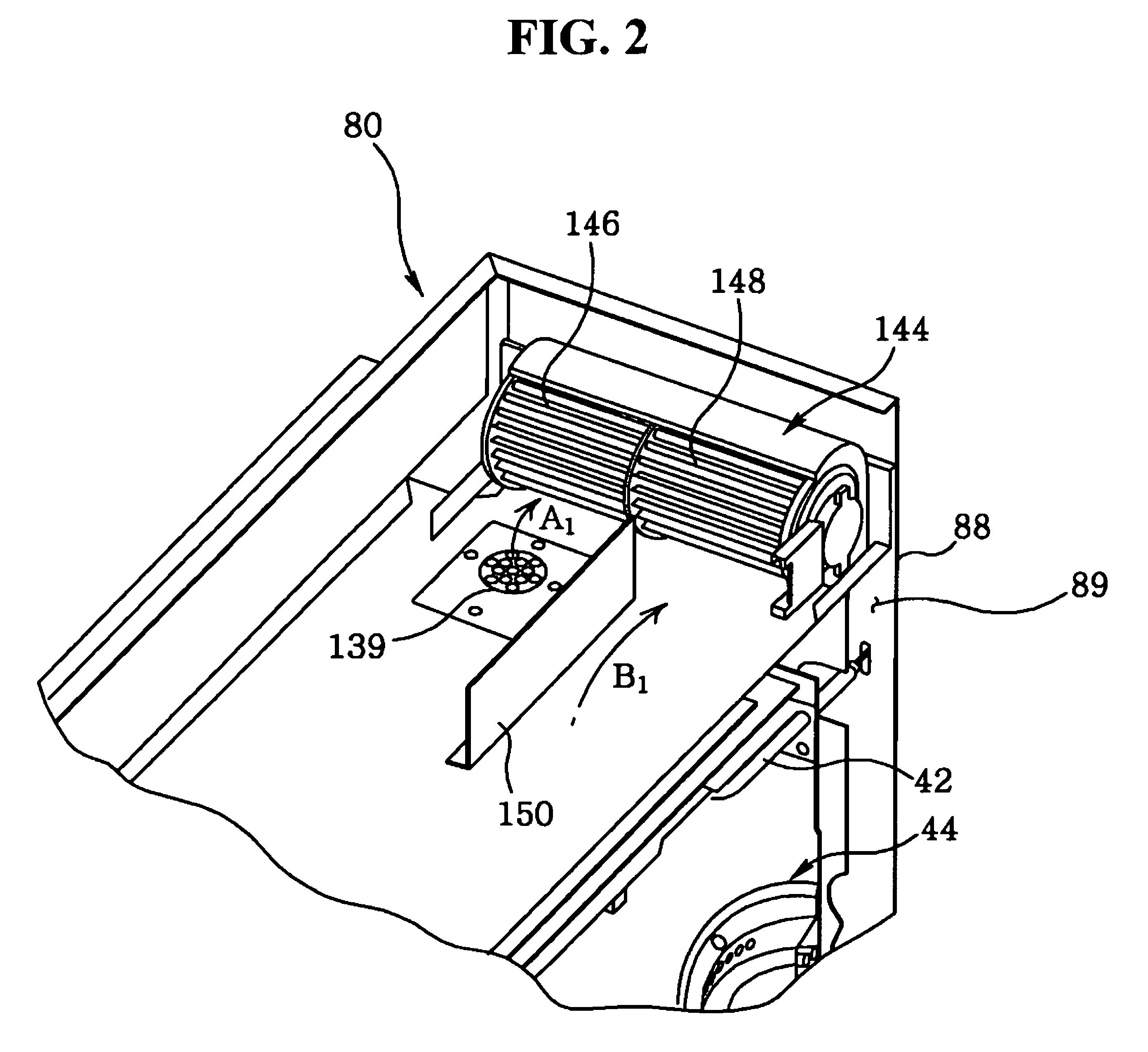

Cooling and exhaust system of dual electric oven

ActiveUS20090050130A1Manufacturing process is complicatedIncreased manufacturing timeDomestic stoves or rangesElectrical heating fuelElectricityProduction rate

A cooling and exhaust system of a dual oven has upper and lower ovens, in which, in one aspect, an installation structure of a cooling fan and an exhaust structure provided for respectively cooling and exhausting the upper and lower ovens may be integrated into a simplified structure having common components to increase the manufacturing productivity. In another aspect, fans provided at the upper and lower ovens may be independently controlled to operate at different speeds according to a desired operation to maximize the cooling efficiency.

Owner:LG ELECTRONICS INC

Cooling and exhaust system of dual electric oven

ActiveUS8584663B2Complicated processingExtension of timeSelf-cleaning stoves/rangesElectric heatingProduction rateElectricity

A cooling and exhaust system of a dual oven has upper and lower ovens, in which, in one aspect, an installation structure of a cooling fan and an exhaust structure provided for respectively cooling and exhausting the upper and lower ovens may be integrated into a simplified structure having common components to increase the manufacturing productivity. In another aspect, fans provided at the upper and lower ovens may be independently controlled to operate at different speeds according to a desired operation to maximize the cooling efficiency.

Owner:LG ELECTRONICS INC

Apparatus for attaching polarizing plate

InactiveUS6848488B2Shorten the timeImprove manufacturing productivityMechanical working/deformationLamination ancillary operationsLiquid-crystal displayPolarizer

The apparatus of attaching a polarizing plate includes a base body, a first cutting out module, a first protection sheet strip module and a first polarizing plate attaching module. The first cutting out module cuts out a first polarizing plate from a first mother polarizing plate. The first cutting out module is disposed on the base body. The first protection sheet strip module strips a first protection sheet from the first polarizing plate. The first polarizing plate is stripped off the first protection sheet to be a first stripped polarizing plate. The first protection sheet strip module is disposed on the base body. The first polarizing plate attaching module attaches the first stripped polarizing plate to a first face of a liquid crystal display unit cell of an assembled substrate. The first polarizing plate attaching module is disposed on the base body.

Owner:SAMSUNG DISPLAY CO LTD

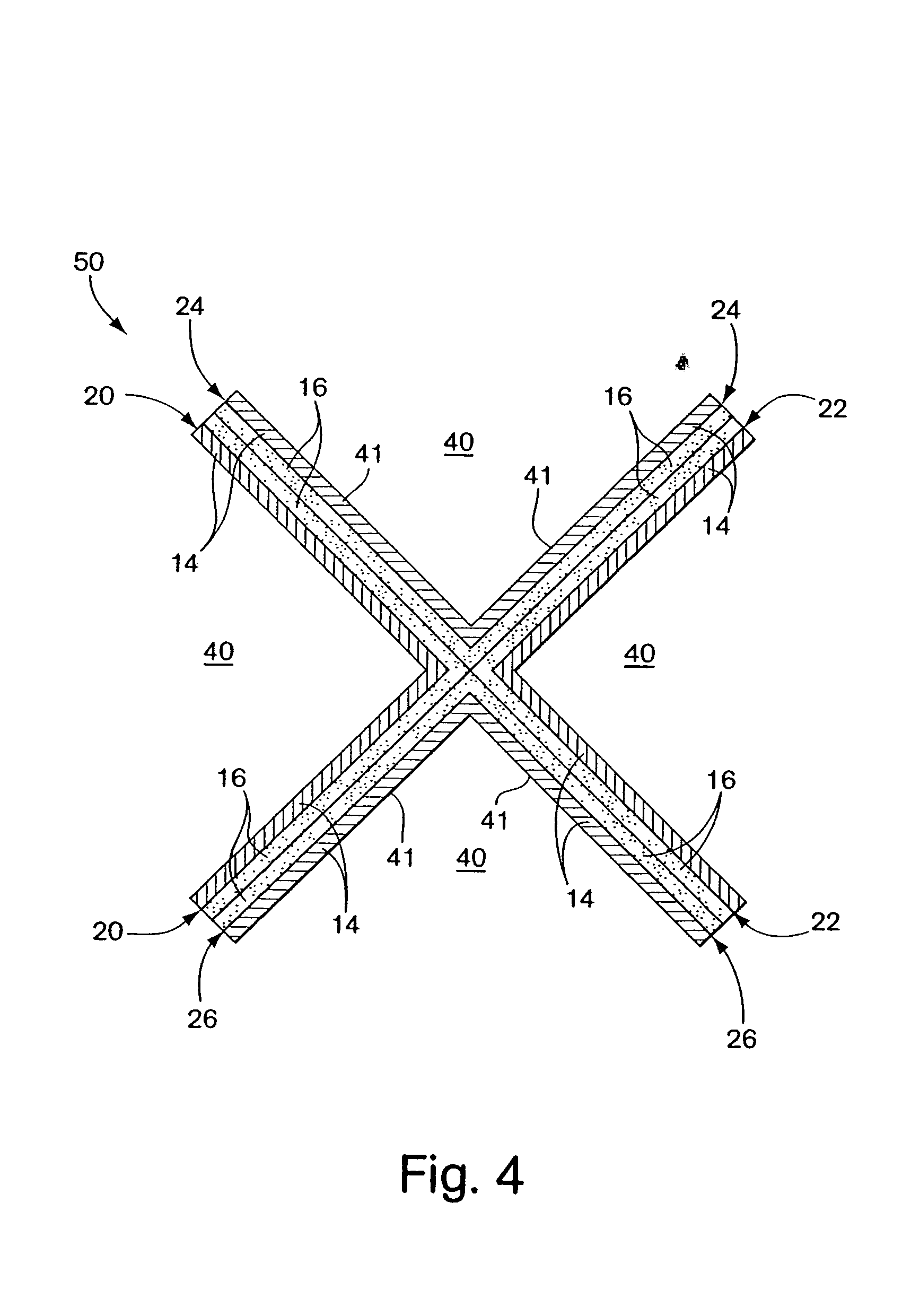

Multifolded composite tape for use in cable manufacture and methods for making same

InactiveUS6974913B2Improve isolationGood data transmissionFlat/ribbon cablesInsulated conductorsElectrical conductorCrosstalk

The invention provides a composite wrapping and shielding tape for use in cable manufacture. Embodiments of the composite tape comprise a single tape configuration to separate and shield individual pairs of insulated conductors housed within a cable such as a high-speed data communications cable. The single tape configurations of the invention are multifolded and assembled from foil / film laminates to form a plurality of longitudinal channels or grooves to accommodate one or more pairs of insulated conductors and a variety of cable designs. During cable manufacture, one or more pairs of insulated conductors is wrapped within a continuous shield provided by each longitudinal channel or groove, thereby separating and shielding each pair of insulated conductors and, hence, isolating or at least substantially reducing crosstalk between pairs of insulated conductors contained within the cable. The invention also provides methods for making a multifolded composite tape. The invention further provides a communications cable comprising a multifolded composite tape to separate and shield insulated conductors.

Owner:NEPTCO +1

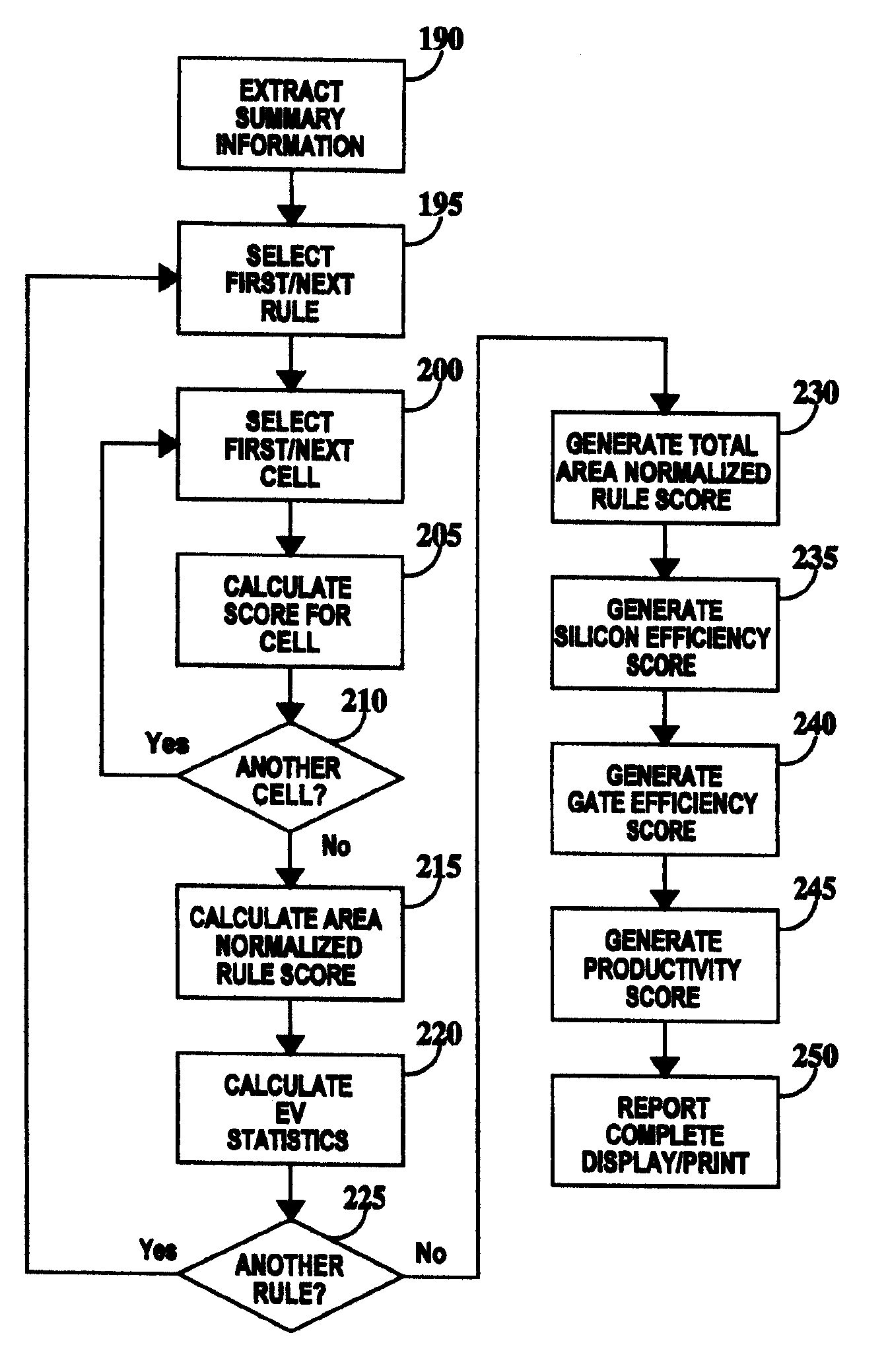

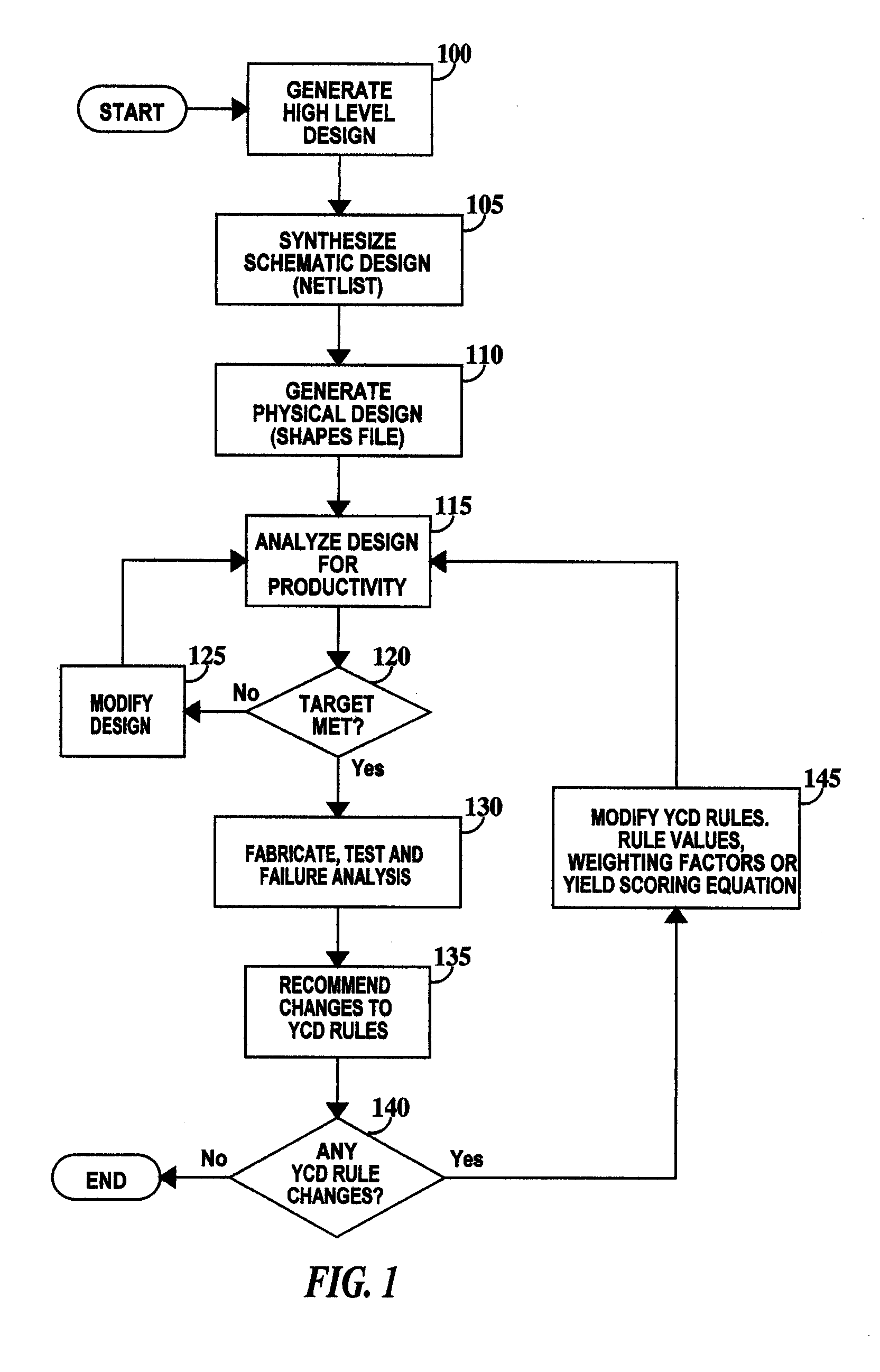

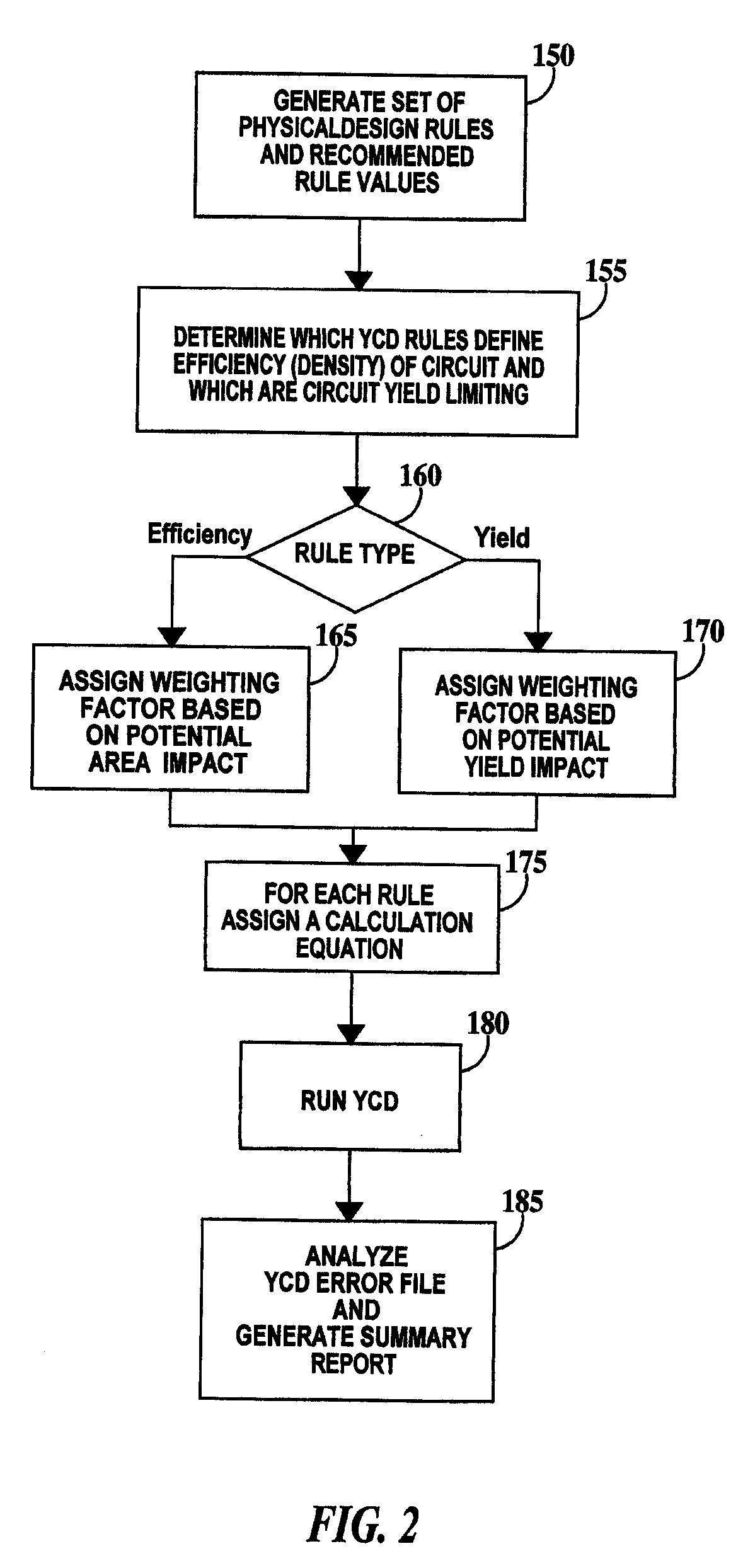

Method and system for improving integrated circuit manufacturing productivity

InactiveUS7076749B2Improve manufacturing productivityComputer aided designTotal factory controlProduction rateIntegrated circuit manufacturing

Owner:IBM CORP

Semiconductor sensor

InactiveUS7373835B2Improve manufacturing productivityFluid pressure measurement by electric/magnetic elementsSolid-state devicesProduction rateElectrical conductor

A semiconductor sensor for improving manufacturing productivity. Opposing electrodes, or a diaphragm electrode and a fixed electrode, form an electrostatic capacity sensing semiconductor microphone on a microphone chip. A through electrode is formed on the microphone chip by a conductor extending between the upper and lower surfaces of the semiconductor substrate. The through electrode directly and electrically connects a MEMS configuration formed by the diaphragm electrode to the wiring of a printed wiring board without using wire bonding.

Owner:SANYO ELECTRIC CO LTD

Guarded cover sheet for LCD polarizers and method of making the same

InactiveUS7662456B2Improve flatnessEasy to manufactureAutomatic/semiautomatic turning machinesTailstocks/centresEngineeringPolymer thin films

The invention generally relates to polymer films used as protective cover sheets for polarizer plates, their manufacture, and to a method for producing polarizing plates employing such polymer films. More particularly, the invention provides a guarded cover sheet composite comprising a temporary carrier substrate having a first cover sheet comprising a first low birefringence film on one side and a second cover sheet comprising a second low birefringence film on the other side.

Owner:EASTMAN KODAK CO

Semiconductor device with stacked chips and method for manufacturing thereof

InactiveUS7605019B2Improve manufacturing productivitySemiconductor/solid-state device detailsSolid-state devicesContact padEngineering

A semiconductor device includes a first semiconductor device and a second semiconductor device. Through-holes in the second semiconductor device extend from an upper side of the second semiconductor device adjacent contact pads to a bottom side of the second device. Tower contact bumps are electrically connected to contact pads of the first semiconductor device. The second semiconductor device is arranged adjacent the first semiconductor device so that the tower contact bumps are disposed within the through-holes and are electrically connected with contact pads of the second semiconductor device.

Owner:POLARIS INNOVATIONS LTD

Display device, method for manufacturing display device, and SOI substrate

InactiveUS8048728B2Improve productivityImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingProduction rateDisplay device

A manufacturing method is provided which achieves an SOI substrate with a large area and can improve productivity of manufacture of a display device using the SOI substrate. A plurality of single-crystalline semiconductor layers are bonded to a substrate having an insulating surface, and a circuit including a transistor is formed using the single-crystalline semiconductor layers, so that a display device is manufactured. Single-crystalline semiconductor layers separated from a single-crystalline semiconductor substrate are applied to the plurality of single-crystalline semiconductor layers. Each of the single-crystalline semiconductor layers has a size corresponding to one display panel (panel size).

Owner:SEMICON ENERGY LAB CO LTD

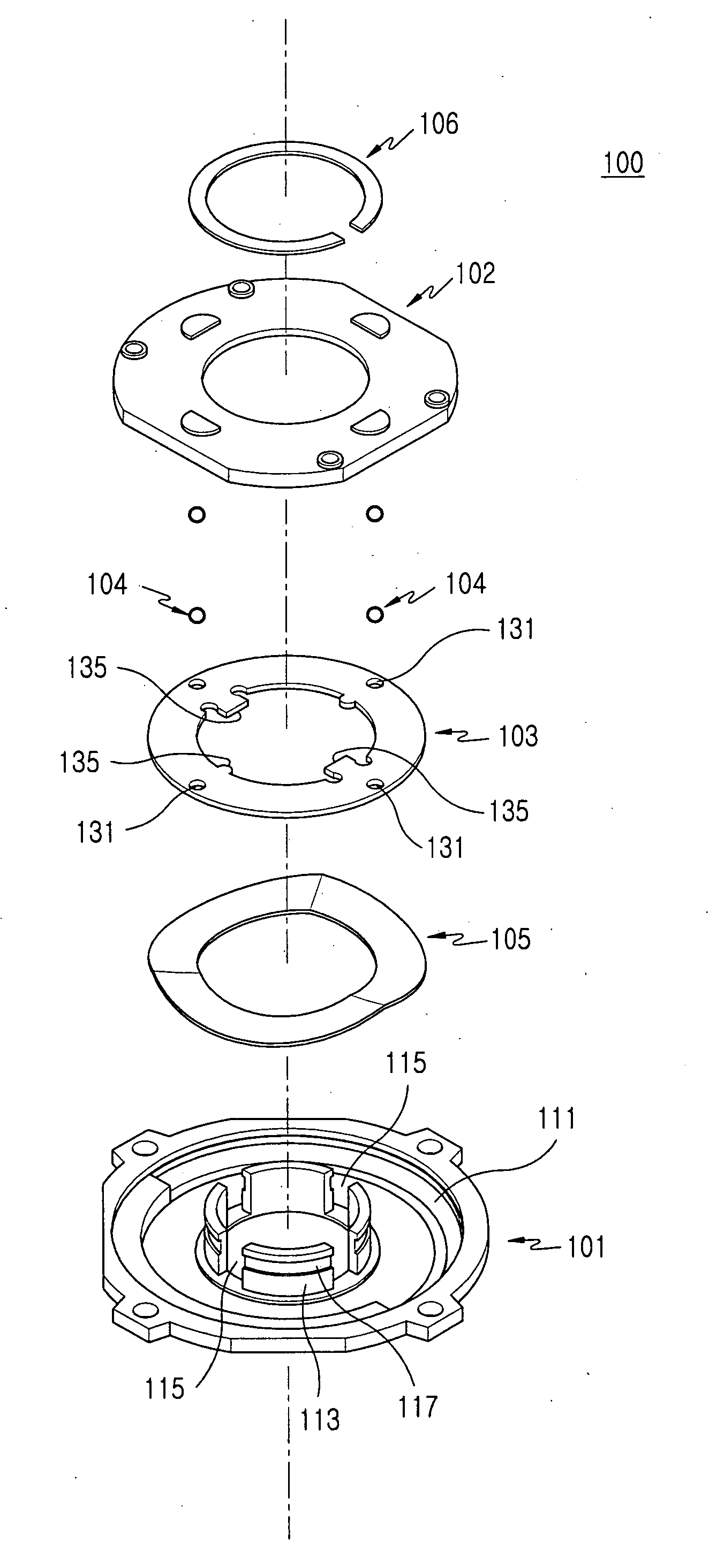

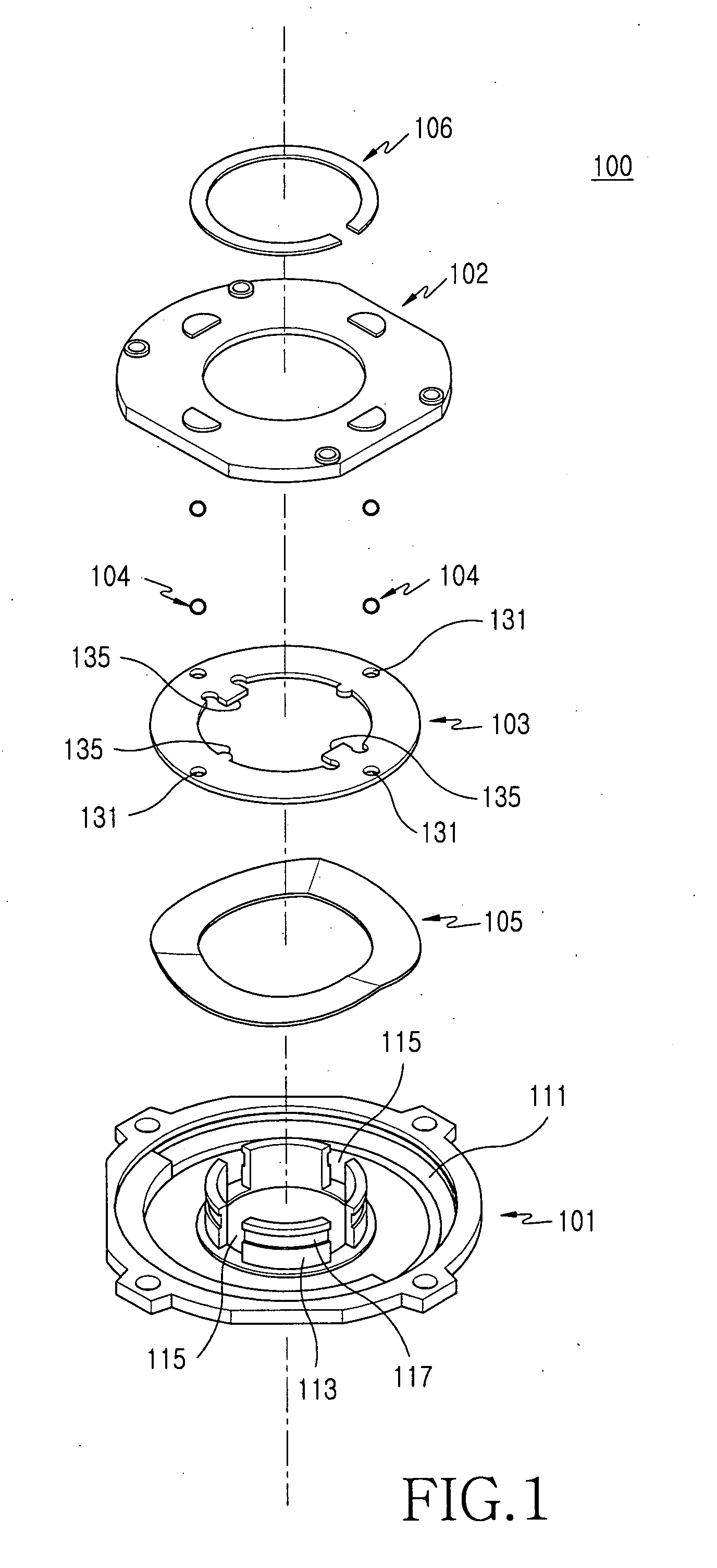

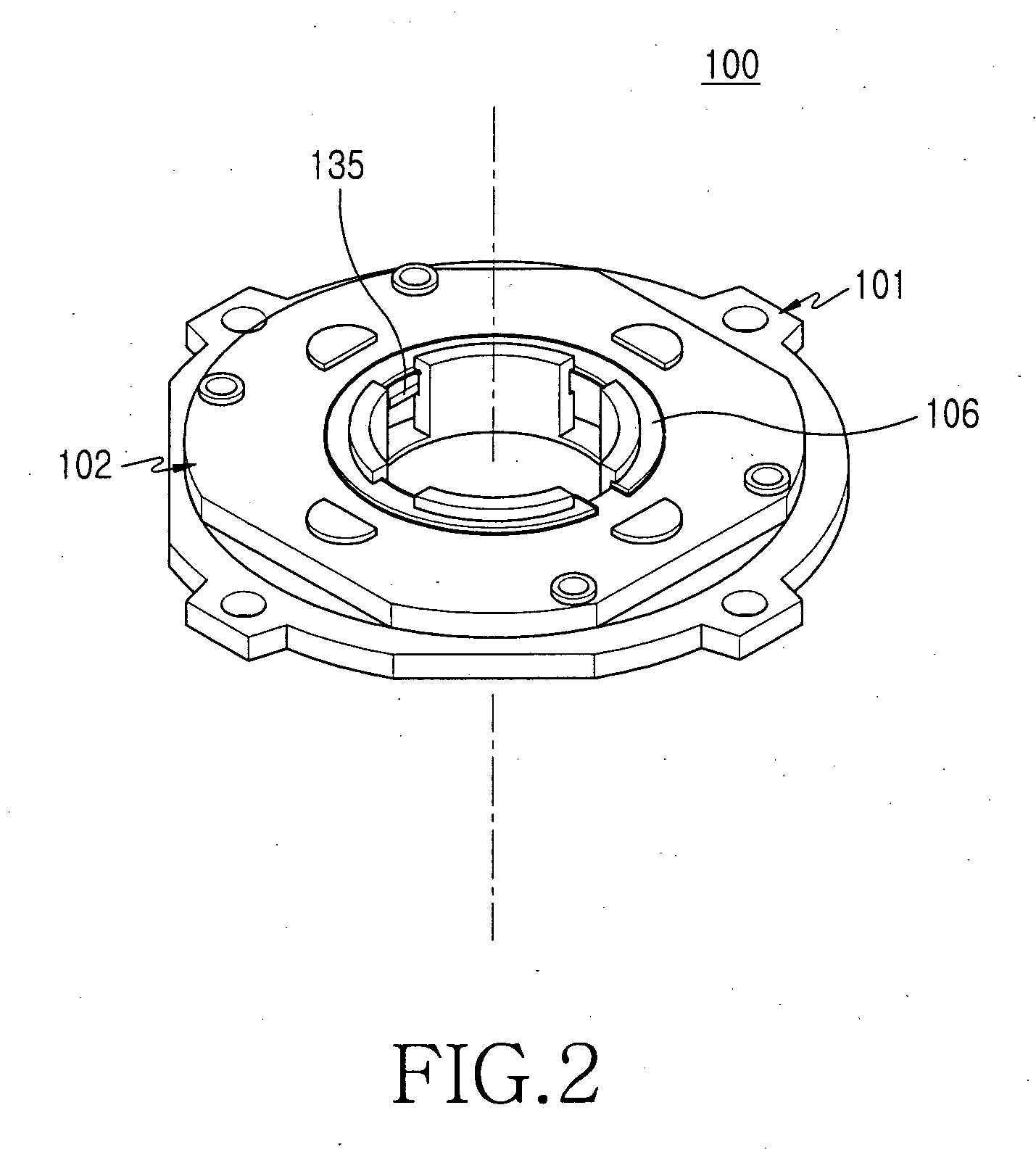

Swing hinge device for portable terminal and portable terminal having the same

InactiveUS20070119024A1Improve portabilitySmall sizeWing fastenersDetails for portable computersMechanical engineeringHinge angle

A hinge device for a portable terminal includes a first hinge base, a second hinge base, and an elastic member. The first hinge base has a receiving groove on a surface thereof. The second hinge base is rotatably coupled to the first hinge base and has stopper ribs which extend from a surface of the second hinge base and are arranged along a circumferential direction. The elastic member is received in the receiving groove of the first hinge base and presses against an outer peripheral surface of the stopper ribs as the second hinge base rotates with respect to the first hinge base. The hinge device has a reduced number of parts so as to allow easy assembly of the hinge device, thereby improving manufacturing productivity. Further, the structure with the elastic member that presses the stopper rib minimizes the size of the portable terminal and improves the portability of the portable terminal.

Owner:SAMSUNG ELECTRONICS CO LTD

Apparatus for attaching polarizing plate

ActiveUS20040108075A1Shorten the timeImprove manufacturing productivityMechanical working/deformationLamination ancillary operationsLiquid-crystal displayPolarizer

The apparatus of attaching a polarizing plate includes a base body, a first cutting out module, a first protection sheet strip module and a first polarizing plate attaching module. The first cutting out module cuts out a first polarizing plate from a first mother polarizing plate. The first cutting out module is disposed on the base body. The first protection sheet strip module strips a first protection sheet from the first polarizing plate. The first polarizing plate is stripped off the first protection sheet to be a first stripped polarizing plate. The first protection sheet strip module is disposed on the base body. The first polarizing plate attaching module attaches the first stripped polarizing plate to a first face of a liquid crystal display unit cell of an assembled substrate. The first polarizing plate attaching module is disposed on the base body.

Owner:SAMSUNG DISPLAY CO LTD

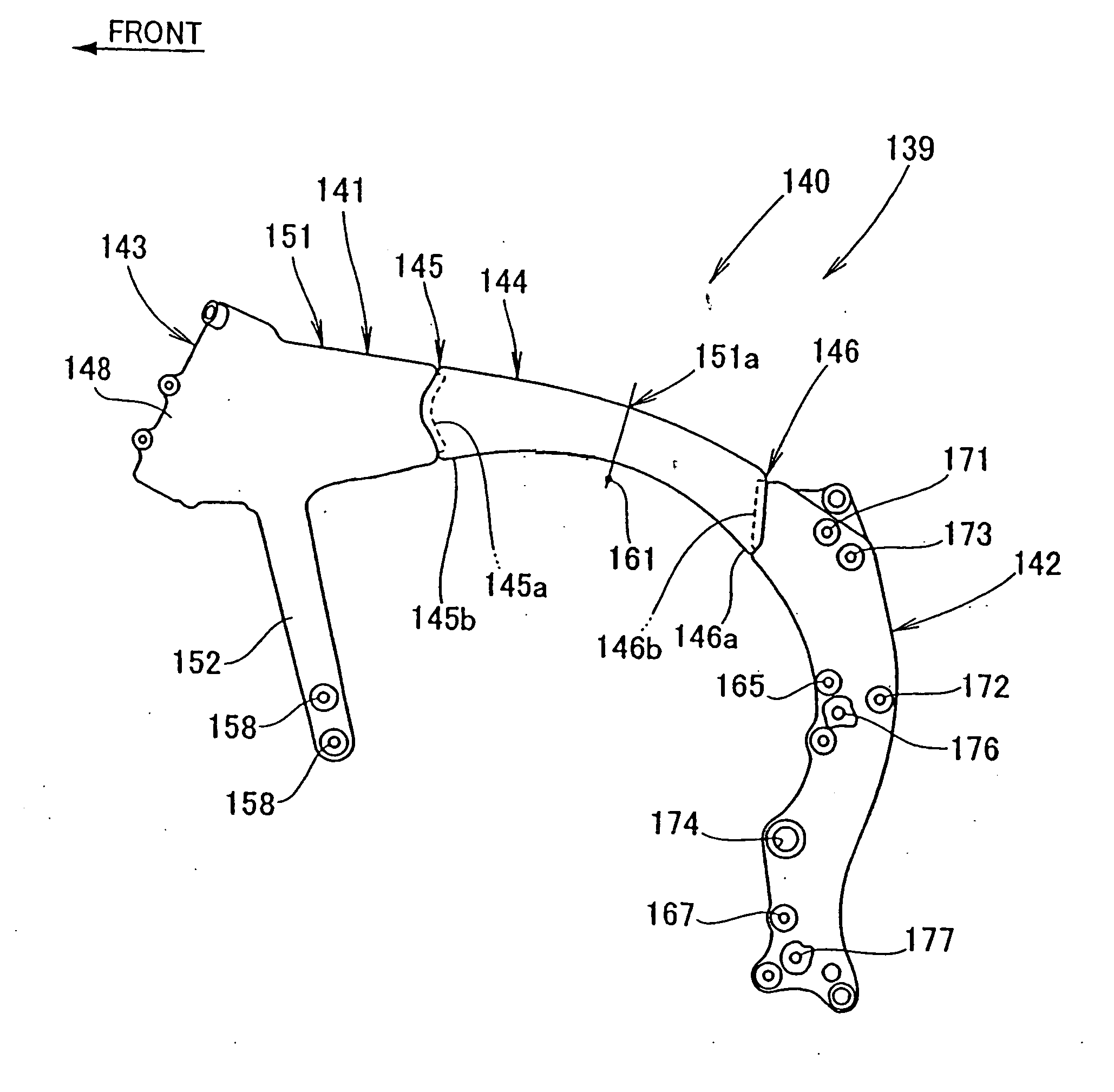

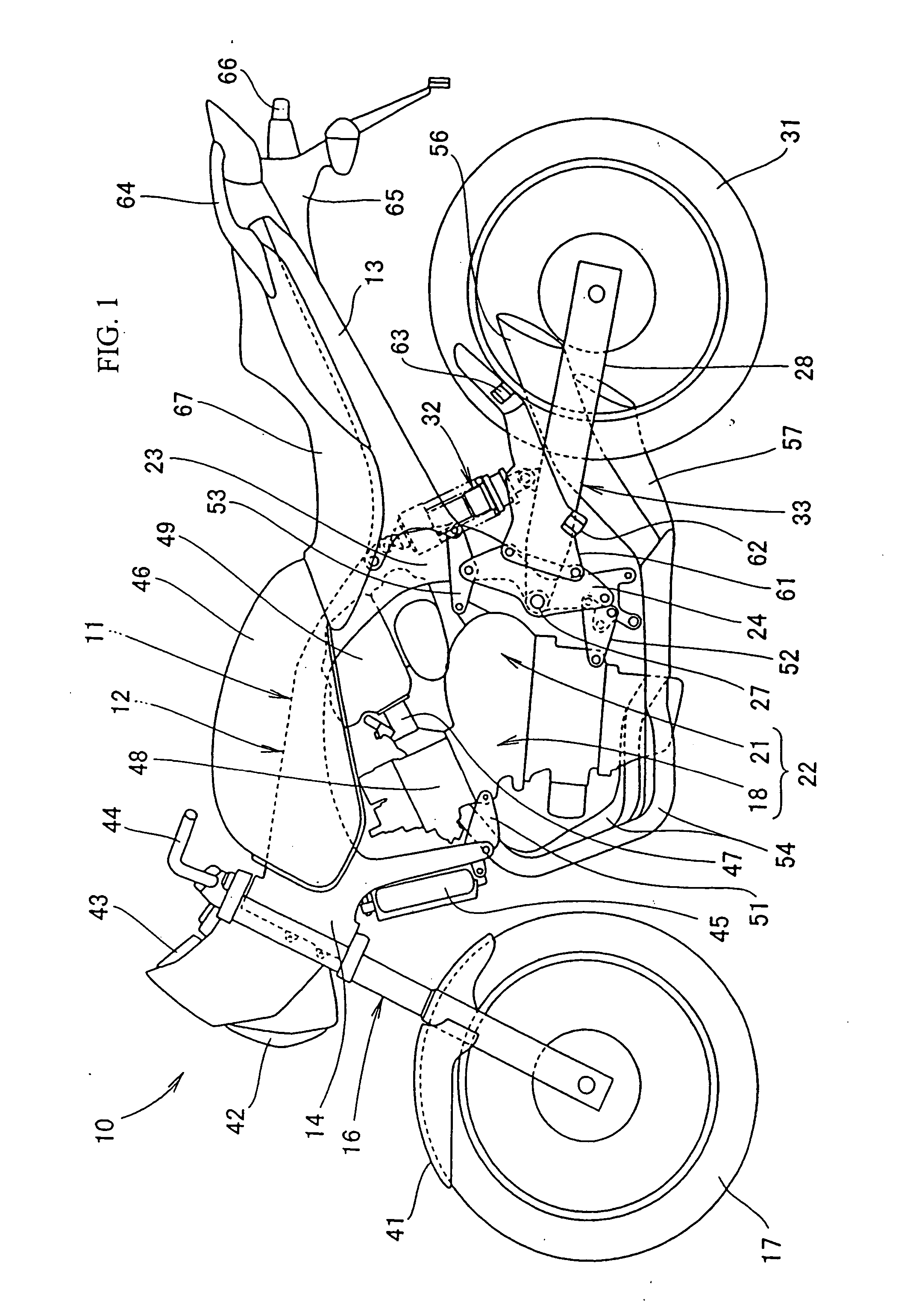

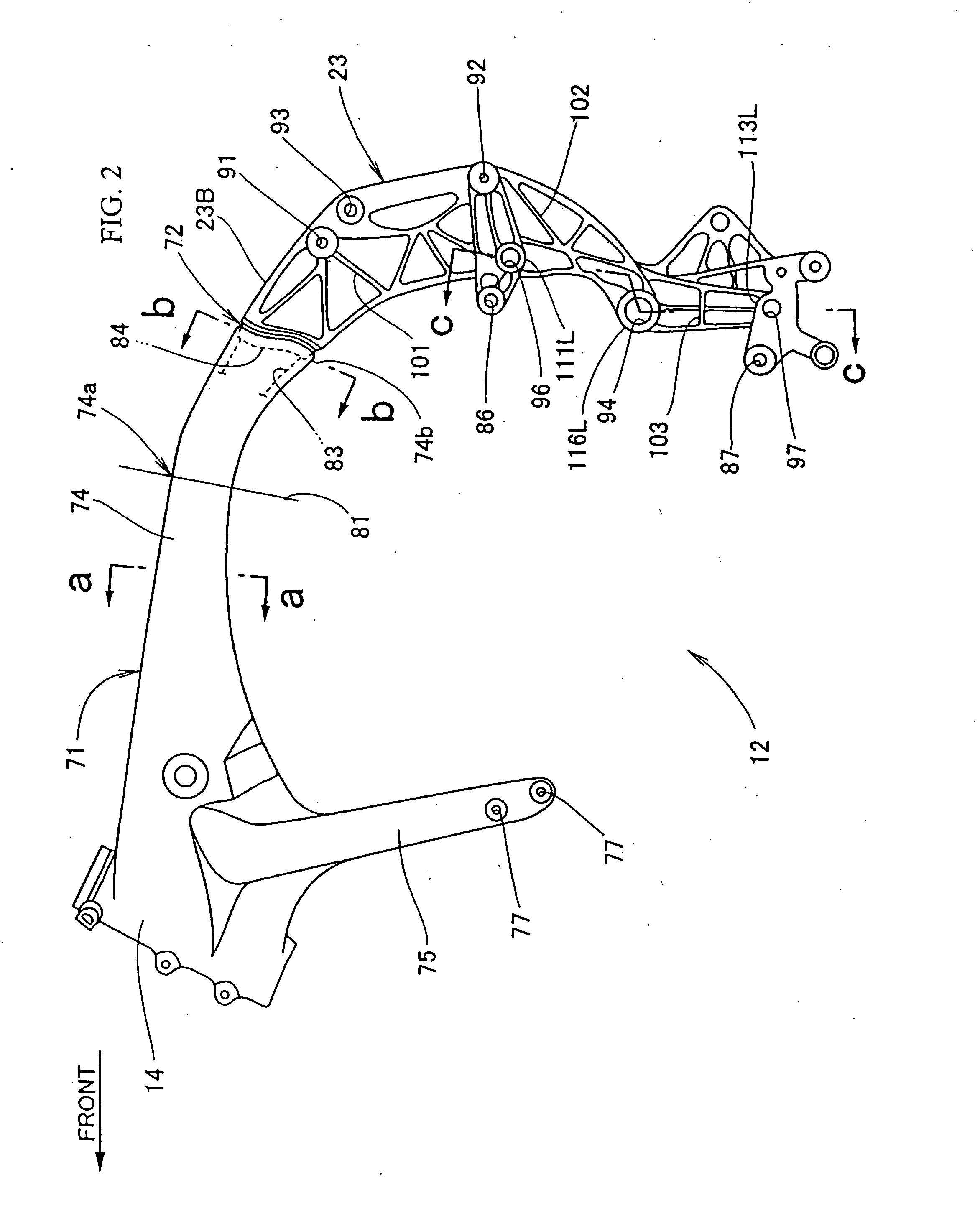

Frame assembly for a motorcycle

ActiveUS20060197304A1Improve manufacturing productivityReduce weld lengthPassenger cyclesChildren cyclesVehicle frameCoupling

A motorcycle body frame includes a main frame including a head pipe for supporting a front suspension at the front end thereof, a single leading frame portion extending rearwardly from the head pipe, and a rear frame portion for supporting a rear wheel suspension. The rear frame portion extends substantially downwardly from a rear part of the leading frame portion. The main frame, cast from an aluminum alloy, includes two component parts arranged front-to-rear. For example, a front frame portion is provided, and a rear frame portion is fixed to the rear side of the front frame portion. The leading frame portion has a small section portion, where the main frame is smallest in sectional area, disposed substantially centrally in the longitudinal direction thereof. The two component parts of the frame are joined at a coupling portion of the main frame situated in back of the small section portion.

Owner:HONDA MOTOR CO LTD

Method of forming thin film for improved productivity

ActiveUS7232492B2Extended maintenance periodImprove manufacturing productivityElectrostatic cleaningSemiconductor/solid-state device manufacturingProduction rateStress relief

There is provided a method of forming a thin film for providing improved fabrication productivity. The method includes introducing a semiconductor substrate into a process chamber. A process thin film is formed on the semiconductor substrate, in which a chamber coating layer is formed on inner walls of the process chamber while the process thin film is formed. The semiconductor substrate is removed from the process chamber. A stress relief layer is formed on the chamber coating layer. After all of the above operations are repeatedly performed at least one time, an in-situ cleaning is performed on the chamber coating layer and the stress relief layer, which are alternately formed in stack on the inner walls of the process chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

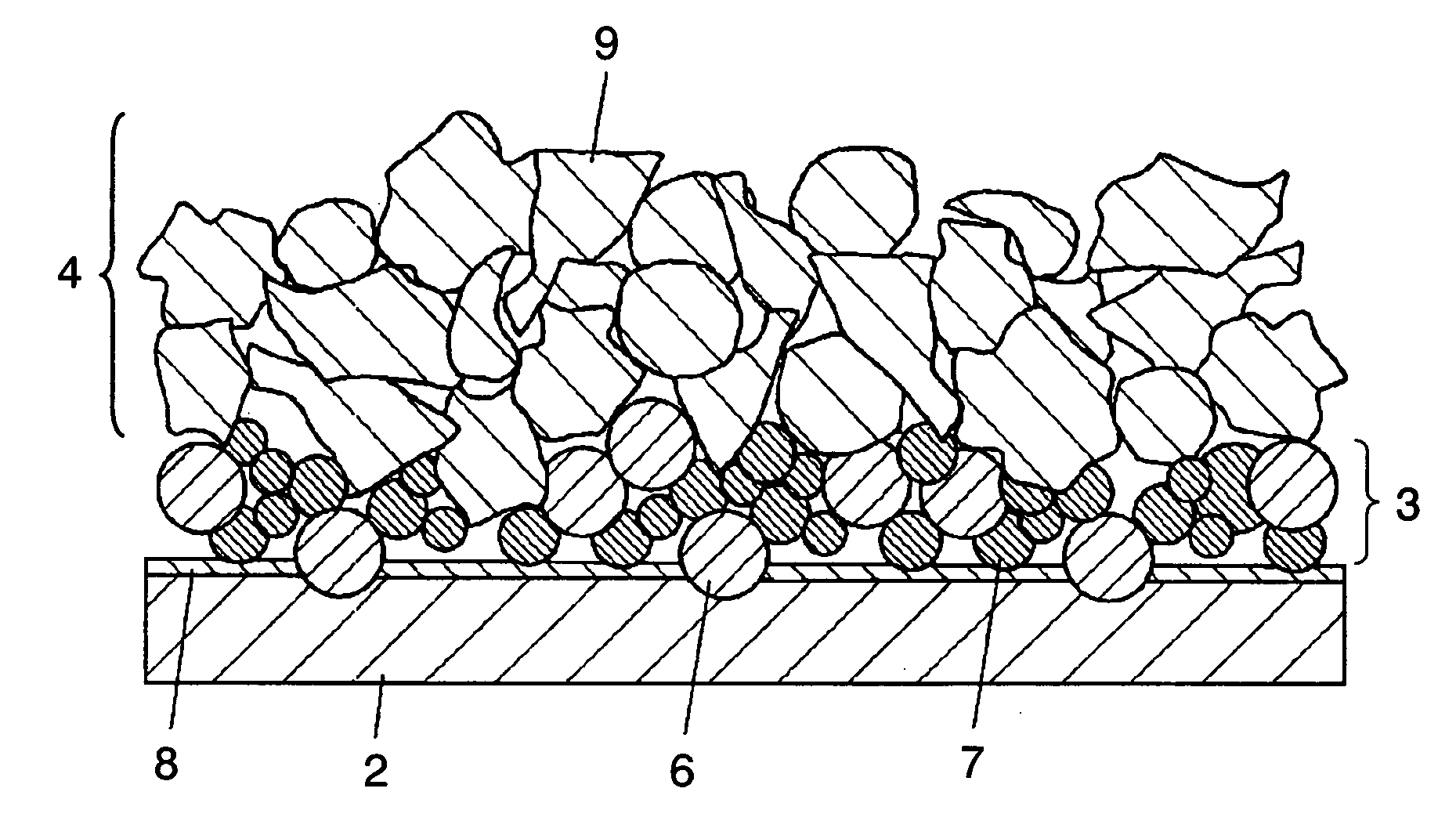

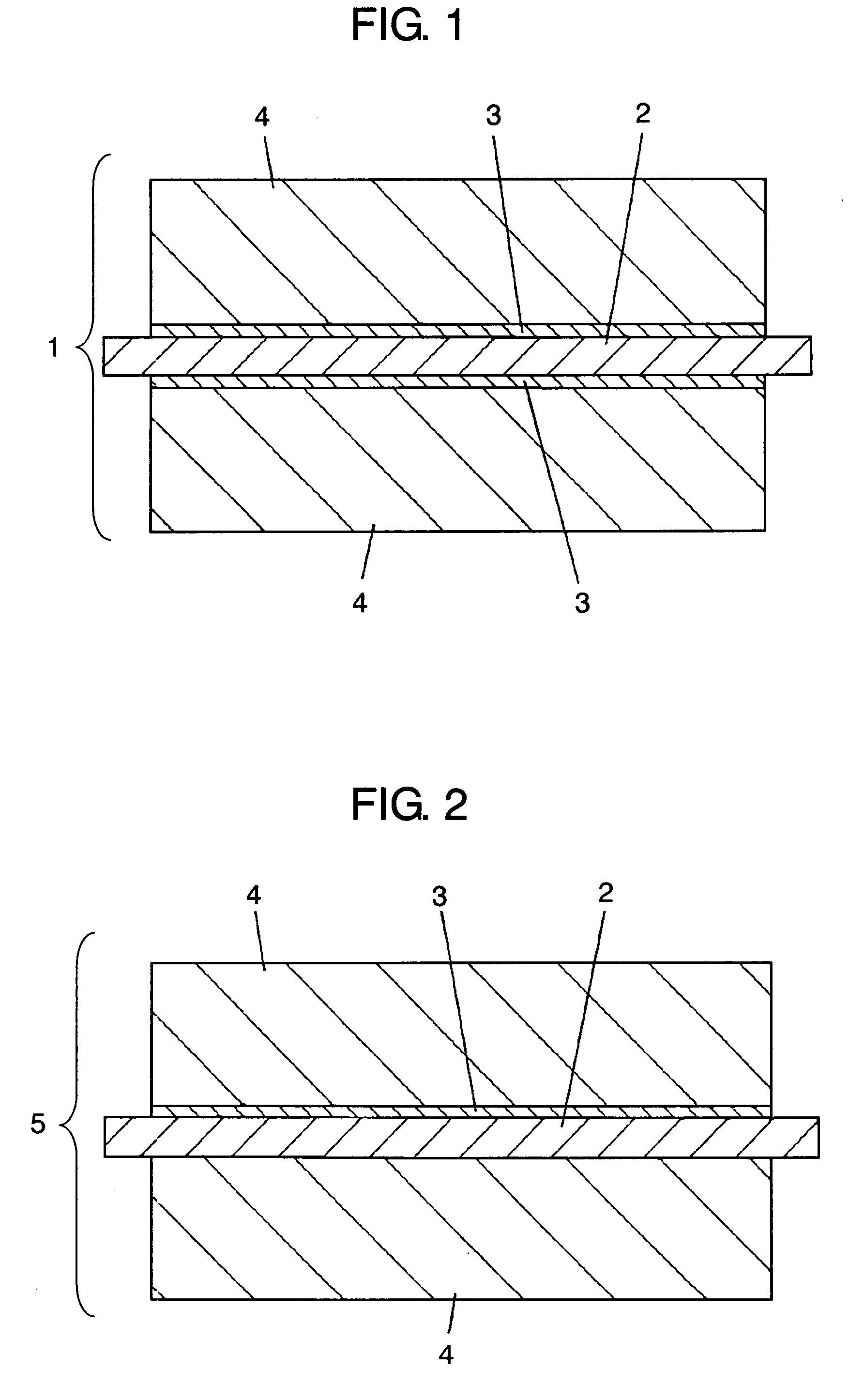

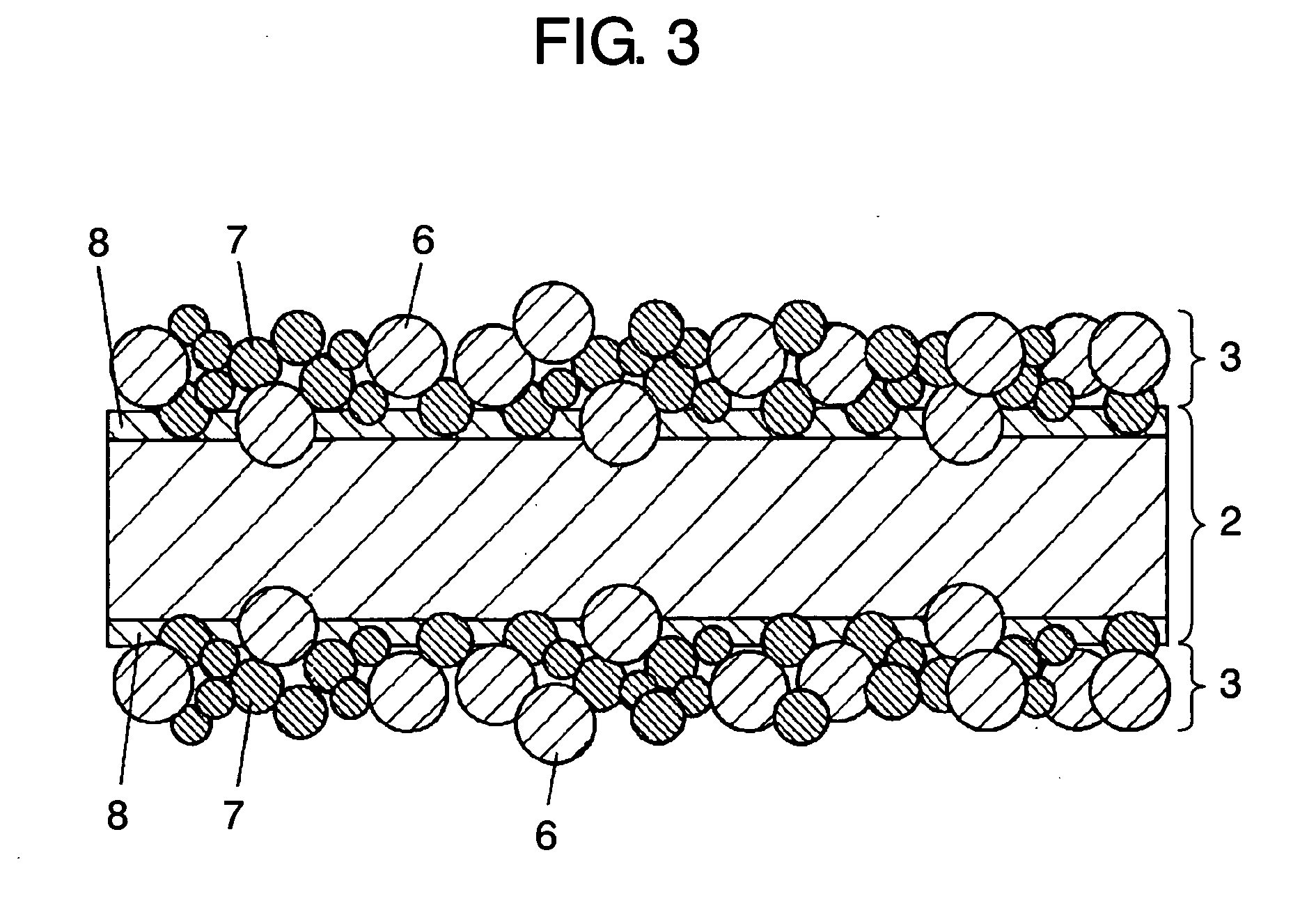

Polarizable Electrode Member, Process for Producing the Same, and Electrochemical Capacitor Utilizing the Member

ActiveUS20070247788A1Lower internal resistanceImprove reliabilityNon-insulated conductorsHybrid capacitor electrodesPolyvinyl alcoholElectrochemistry

A polarized electrode for use in an electrochemical capacitor, in which electrode includes a current collector made of a metal plain foil, an anchor coat layer formed at least on one of the surfaces of the current collector, and an electrode layer formed on either the anchor coat layer or the current collector. The anchor coat layer contains a conductive carbon and a binder. The conductive carbon is graphitized carbon black. The binder contains at least one selected from the group consisting of an ammonium salt of carboxymethylcellulose, a rubber polymer, polytetrafluoroethylene, polyvinyl alcohol, polyvinyl pyrrolidone, alternating copolymer of isobutylene-maleic anhydride. With this configuration, a polarized electrode can be made thinner, and an electrode layer can be formed directly on the anchor coat layer. Furthermore, it can ensure sufficient coupling strength between the current collector and the electrode layer, and increase the energy density and the power density realizing a reduced resistance.

Owner:PANASONIC CORP

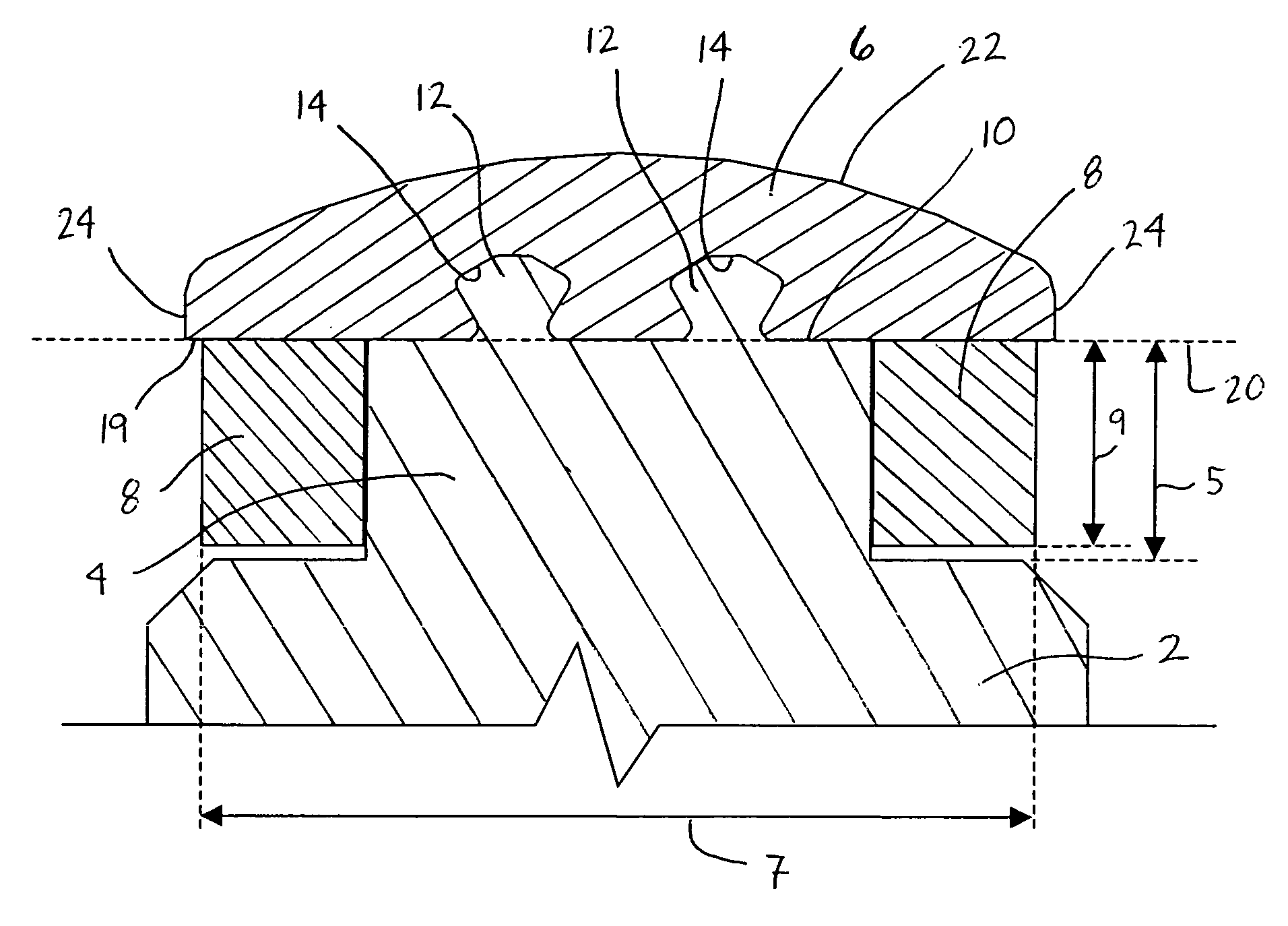

Pole body and pole tip connections used with rotating machines

InactiveUS20050253476A1Reduce loadEasy maintenanceMagnetic circuit stationary partsSalient polesEngineeringMechanical engineering

Owner:TECO WESTINGHOUSE MOTOR

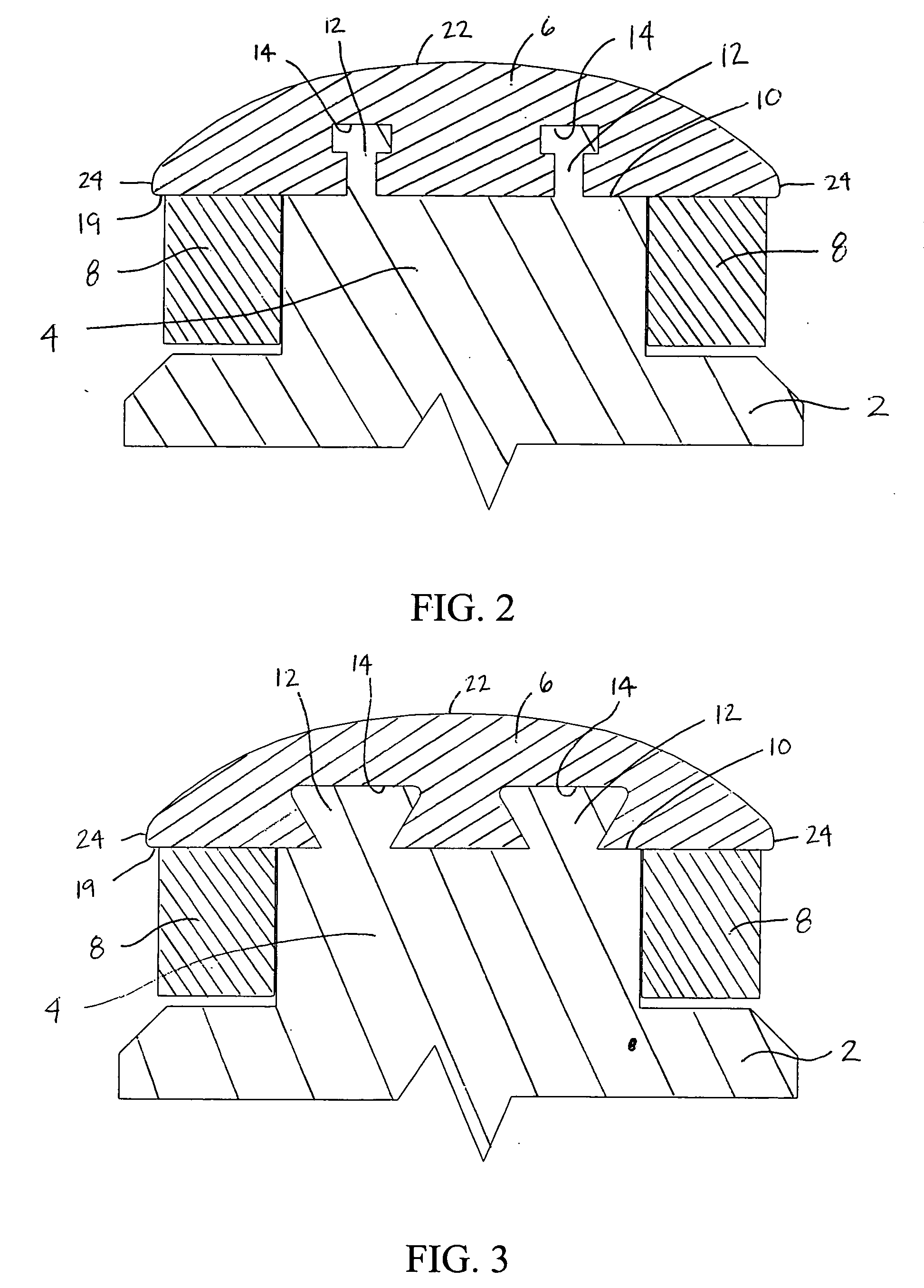

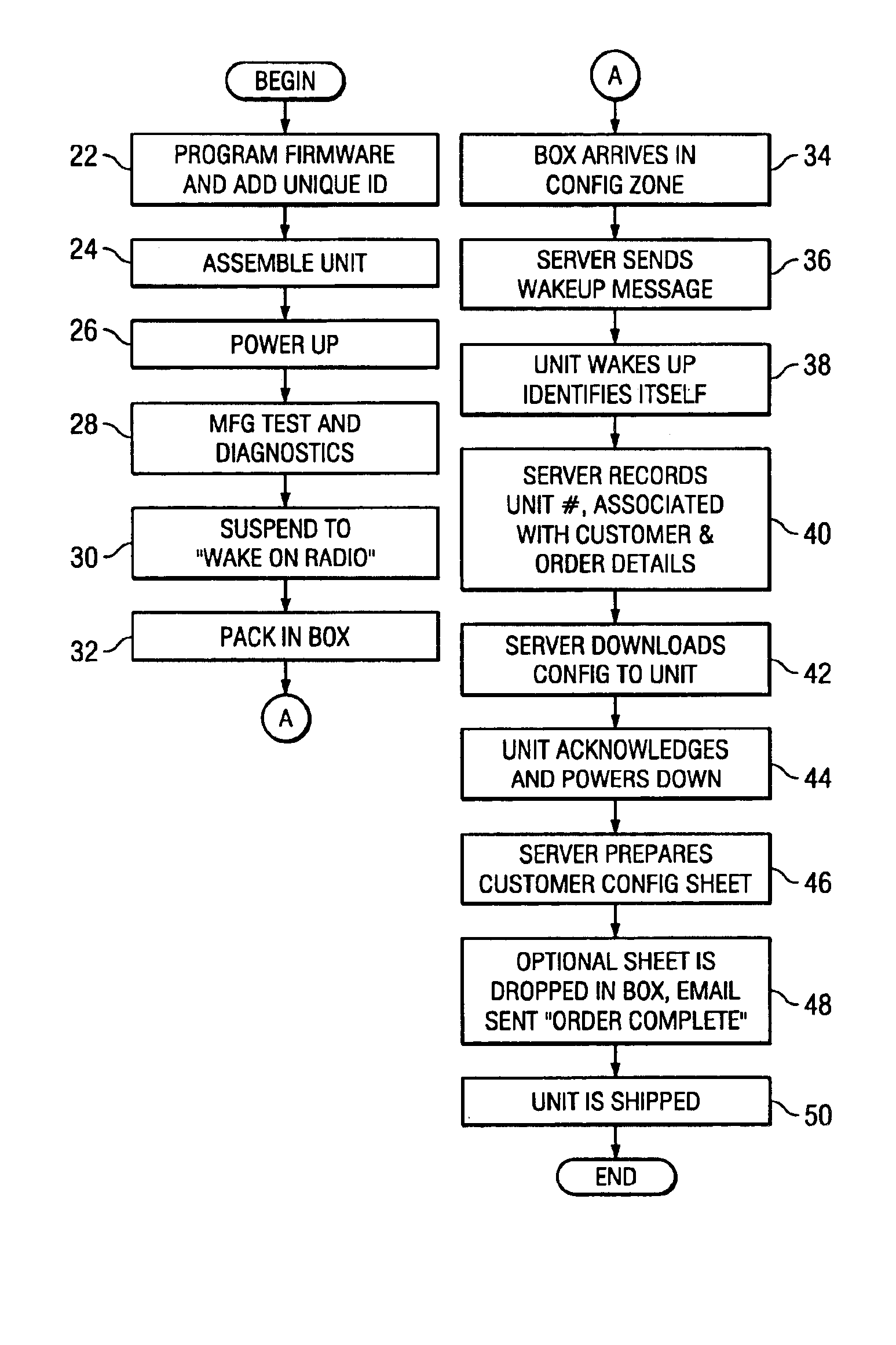

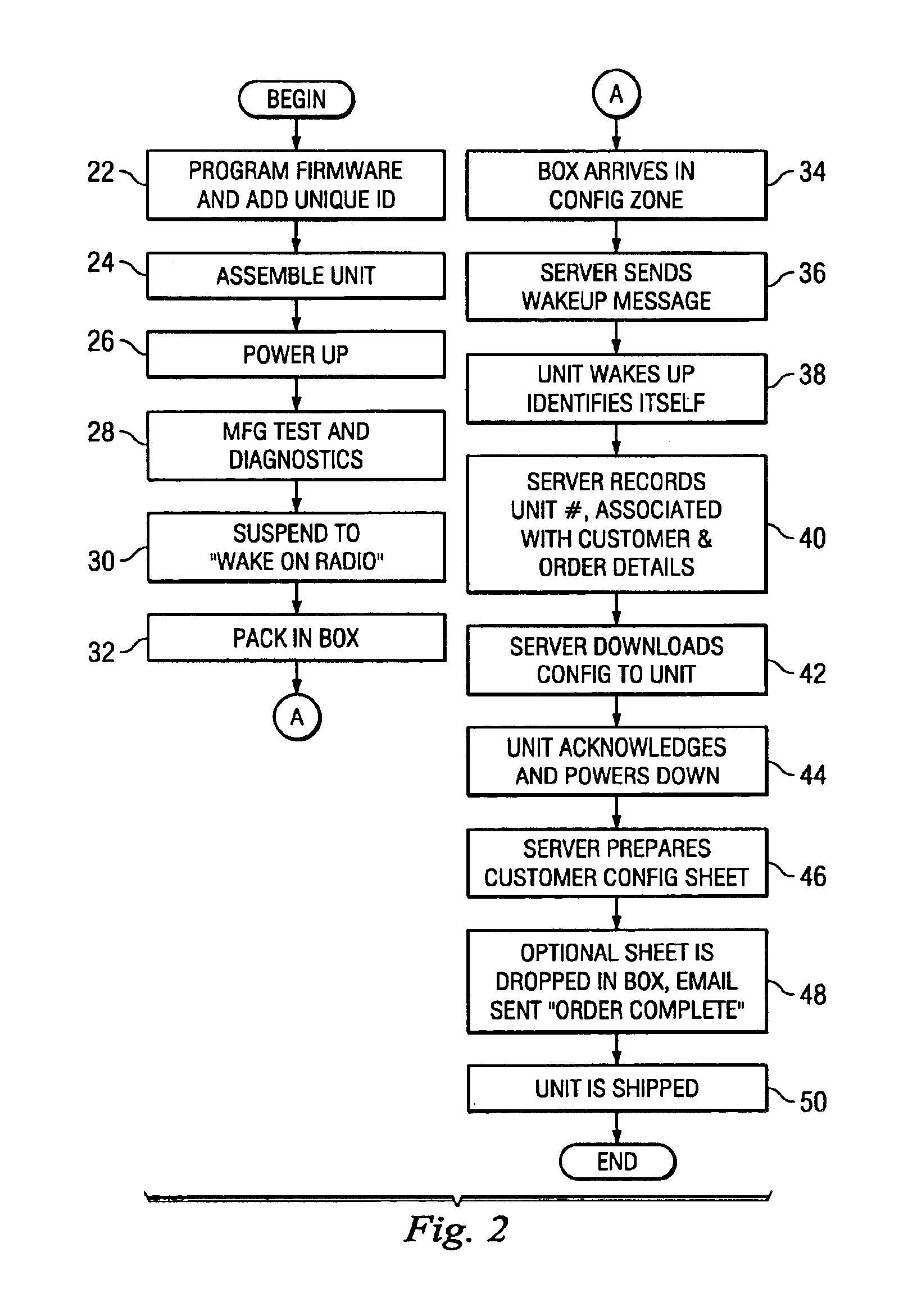

Method and system for manufacturing and servicing a computing product with the assistance of a wireless communication subsystem attached to a peripheral port

InactiveUS6865436B2Improve manufacturing productivityManufacturing process for the computing product is further automatedTotal factory controlSpecial data processing applicationsServices computingEngineering

A wireless access subsystem is first attached to a peripheral port of a computing product. The computing product is further assembled with other components and goes through various testing processes while being tracked and monitored by a manufacturing control server through wireless communications with the wireless access subsystem. The wireless access subsystem has a separate power supplier incorporated therein and operates independently from the computing product.

Owner:DELL PROD LP

Semiconductor device having a gate insulating film structure including an insulating film containing metal, silicon and oxygen and manufacturing method thereof

InactiveUS7306994B2Improve manufacturing productivityReduce interface state densityTransistorSolid-state devicesOxygenAmorphous metal

Claimed and disclosed is a semiconductor device including a transistor having a gate insulating film structure containing nitrogen or fluorine in a compound, such as metal silicate, containing metal, silicon and oxygen, a gate insulating film structure having a laminated structure of an amorphous metal oxide film and metal silicate film, or a gate insulating film structure having a first gate insulating film including an oxide film of a first metal element and a second gate insulating film including a metal silicate film of a second metal element.

Owner:HEAD TECHNOLOGY GMBH LTD +1

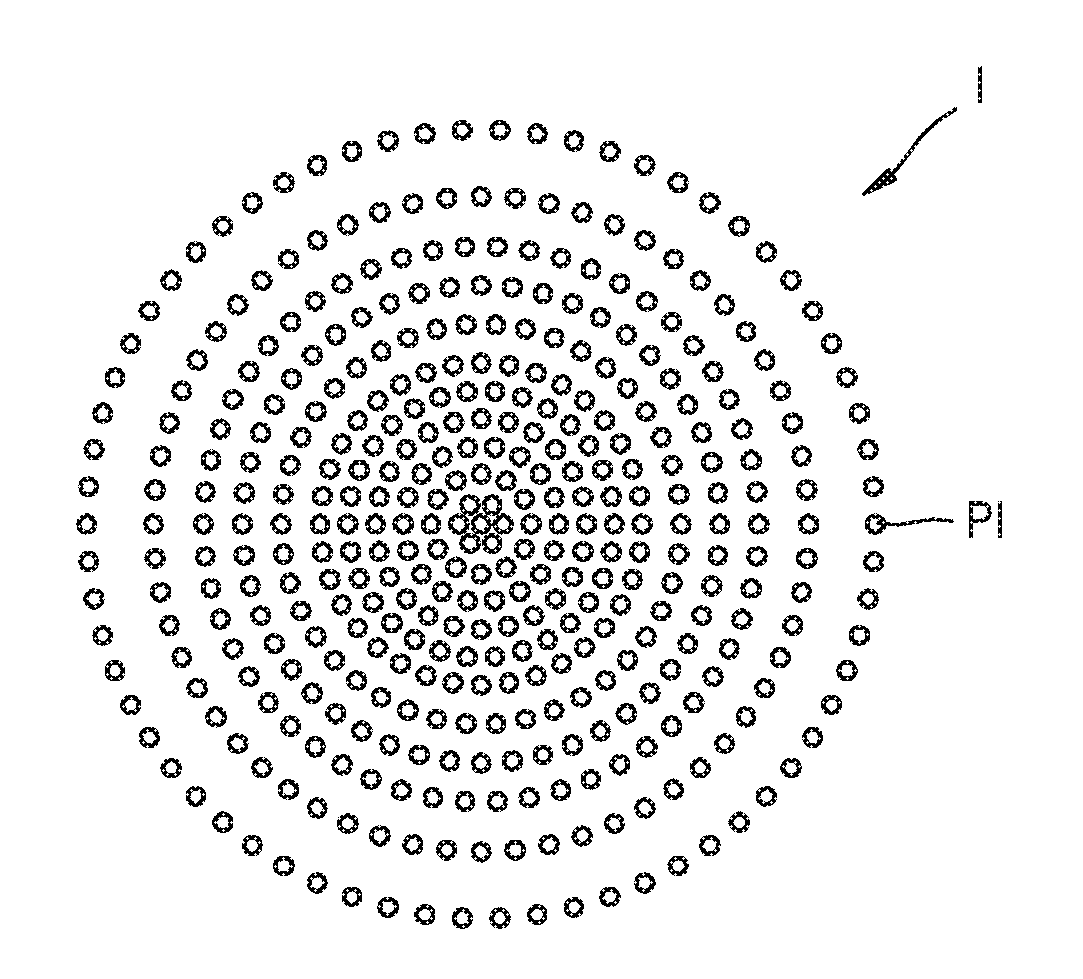

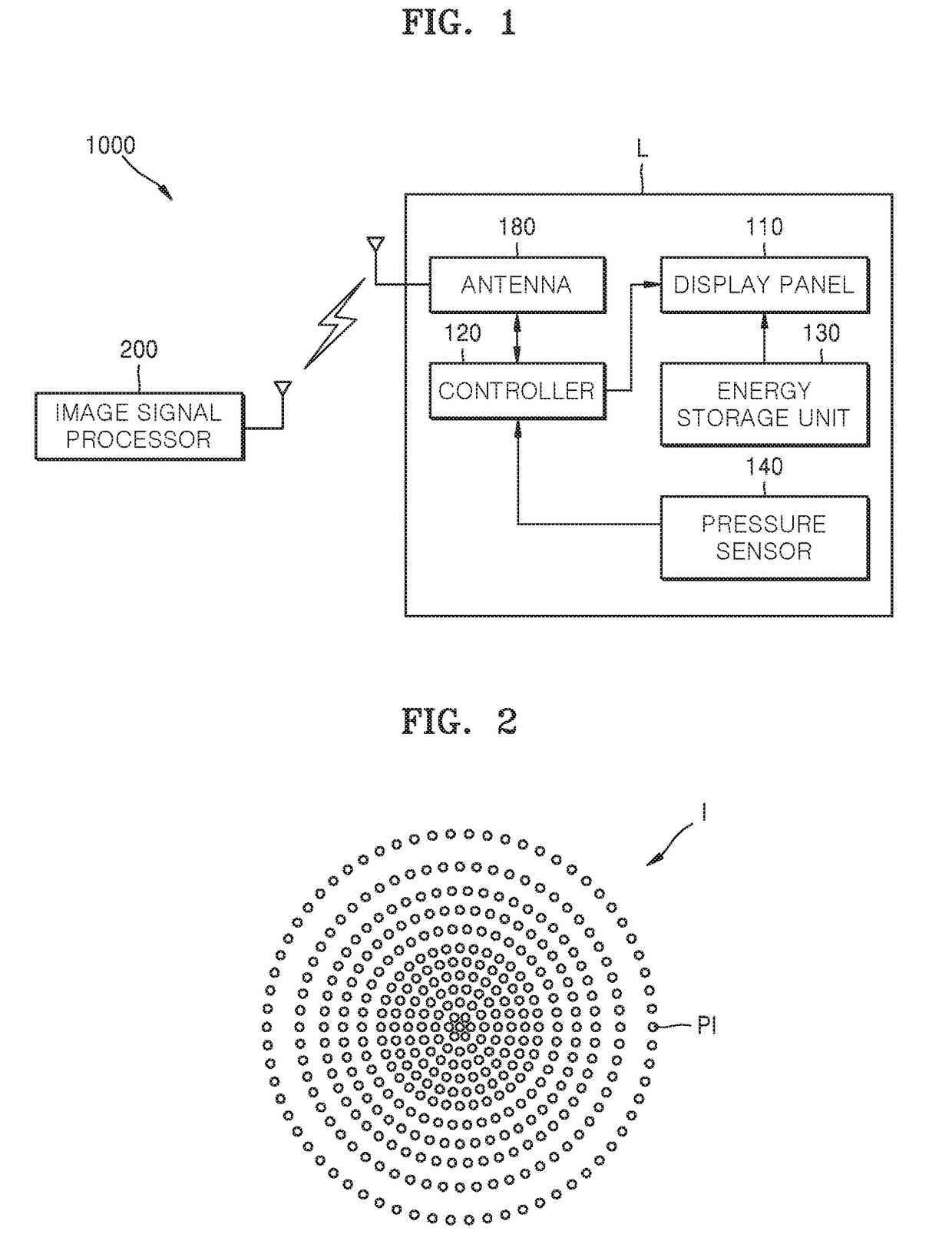

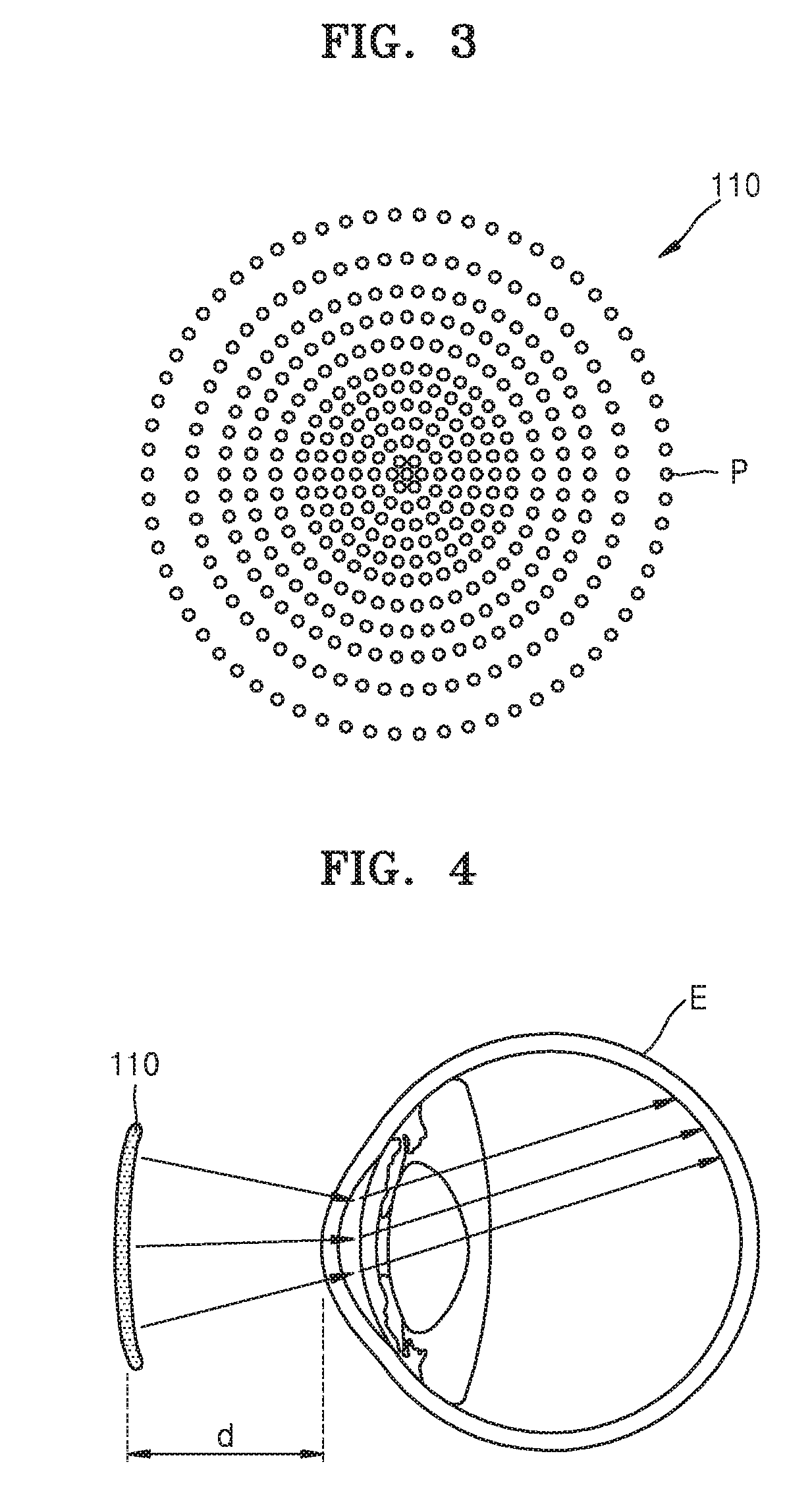

Image display device and method using unidirectional beam

ActiveUS20170116897A1Easy to implementReduce the number of pixelsInput/output for user-computer interactionGeometric image transformationImage resolutionControl signal

An image display device includes an eye wearable lens; a display panel embedded inside the eye wearable lens or arranged on a surface of the eye wearable lens, the display panel comprising an array of a plurality of optical elements for forming an image to be projected onto a retina, wherein a resolution of the image formed by the plurality of optical elements is higher on a central portion of the retina than on a peripheral portion of the retina; and an image signal processor for generating an image signal according to image information which is to be displayed on the display panel and for generating a control signal for controlling each of the plurality of optical elements to be turned on / off according to the image signal.

Owner:SAMSUNG ELECTRONICS CO LTD

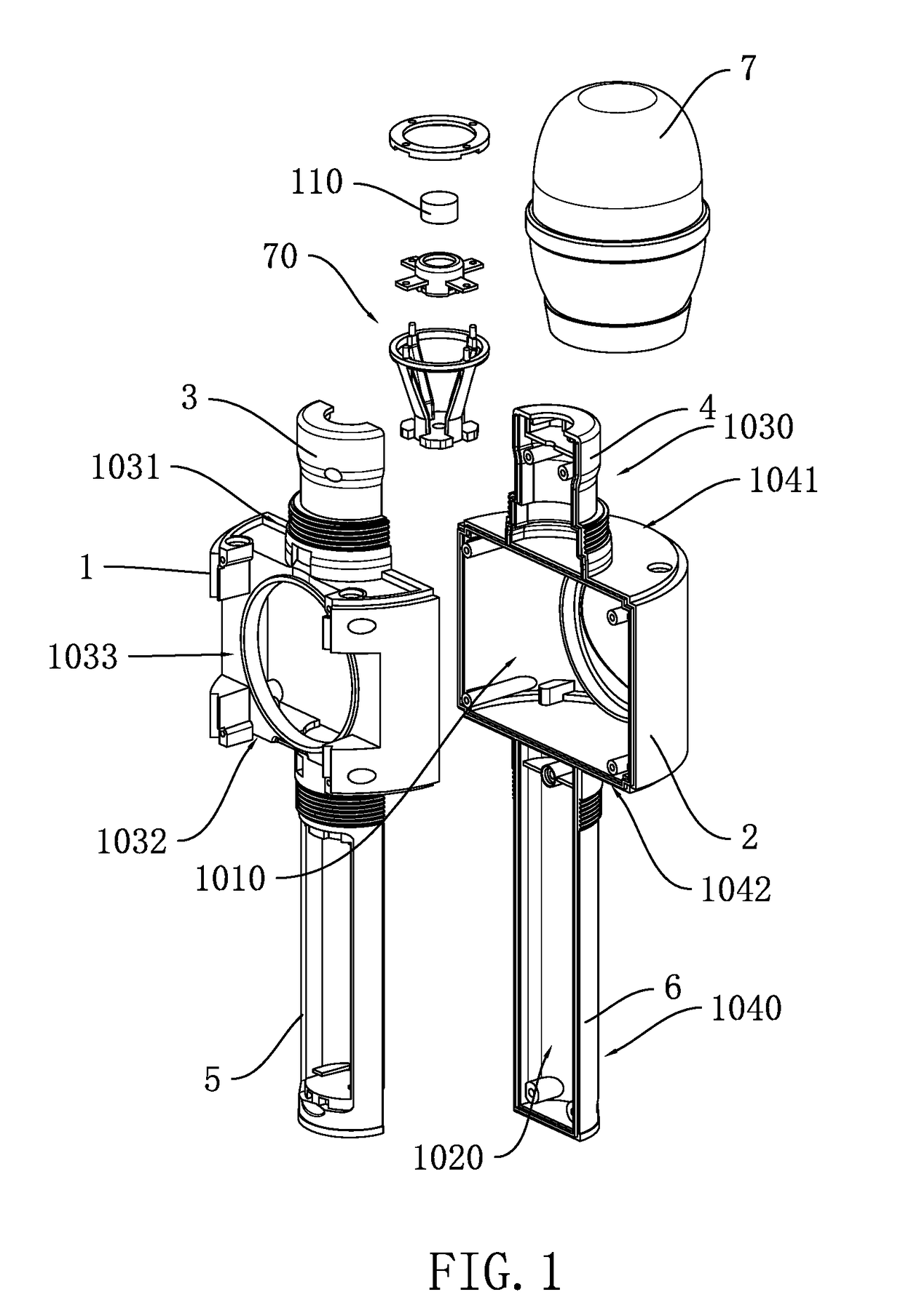

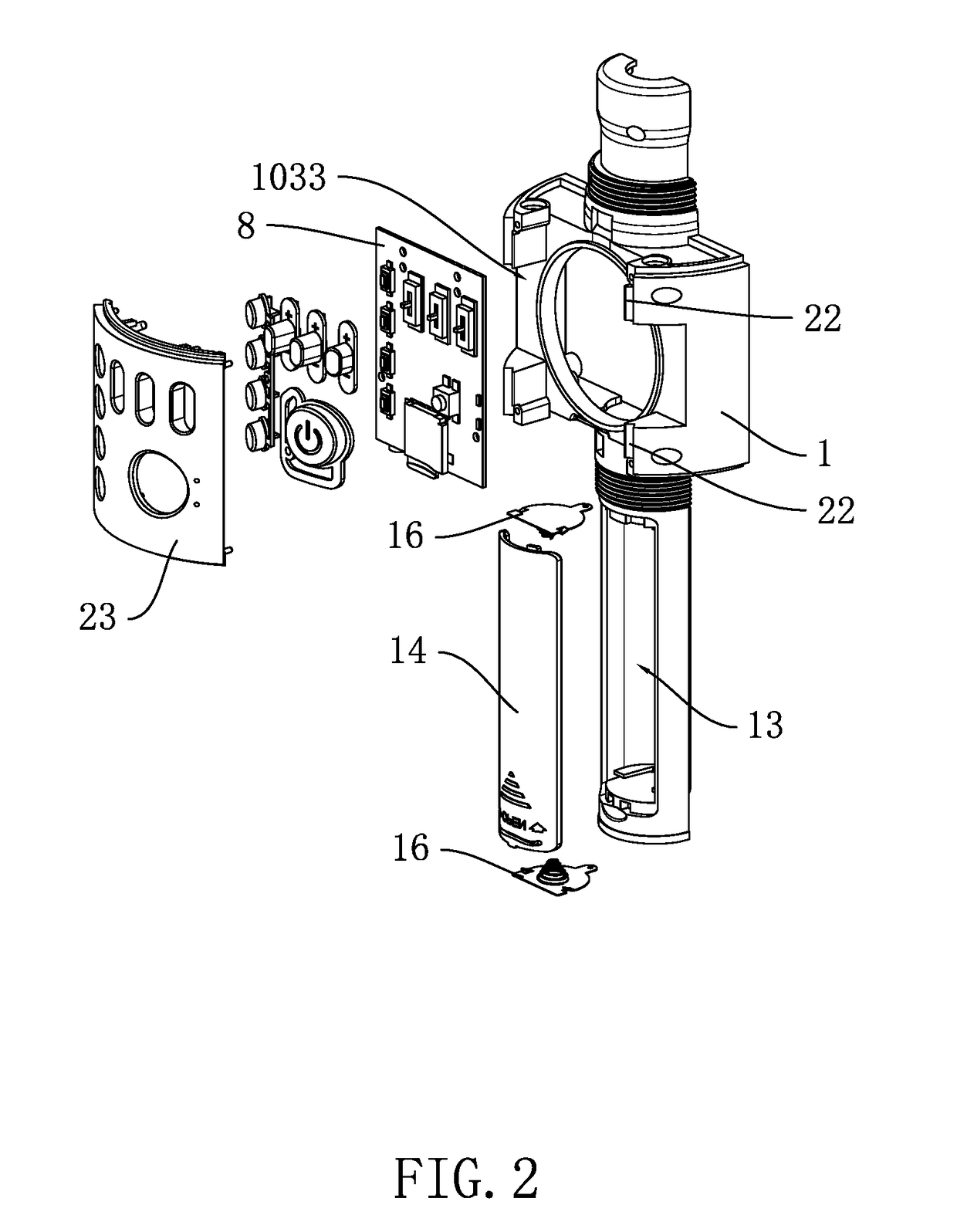

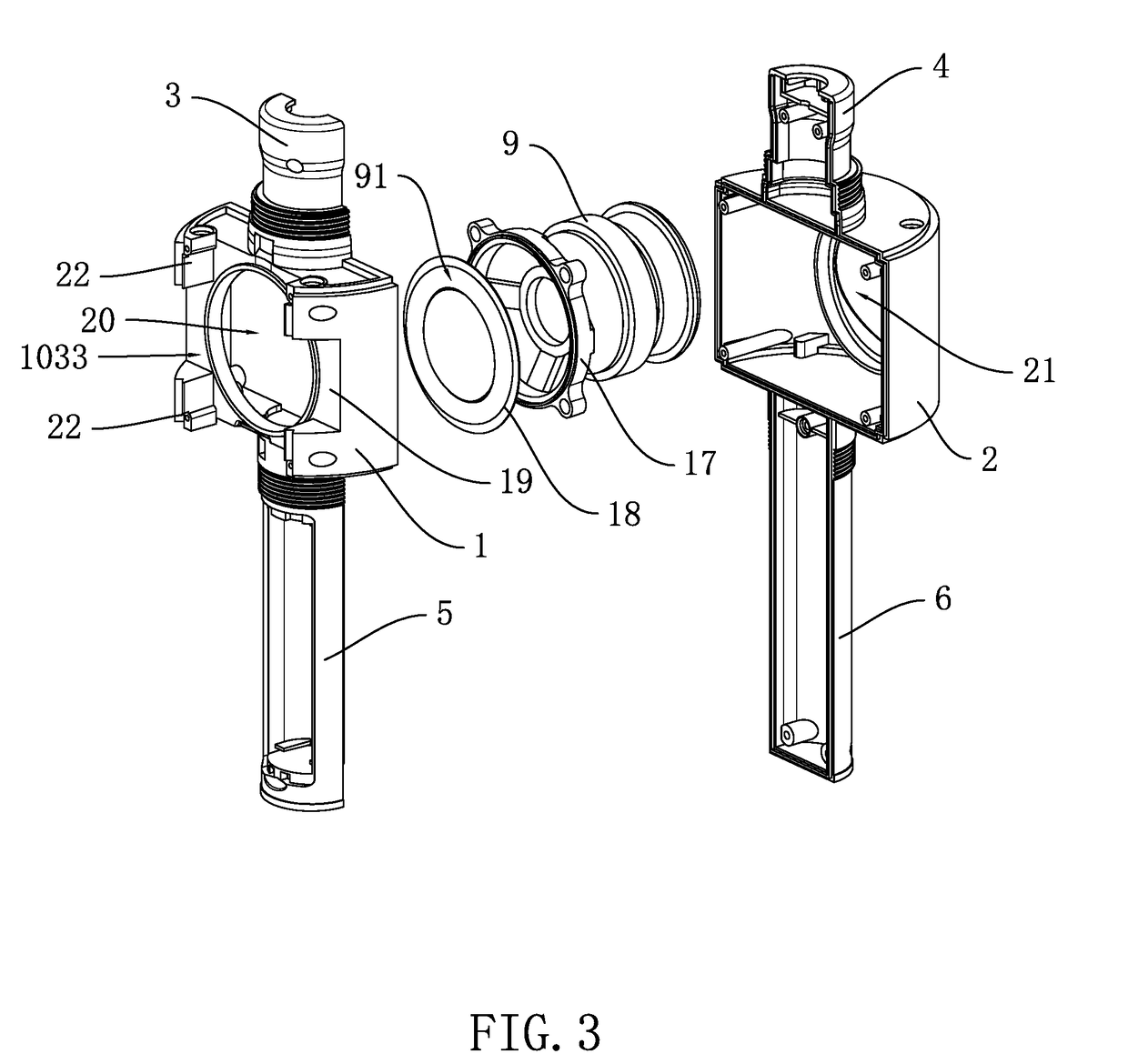

Microphone with Integrated Sound Box

ActiveUS20190069060A1Enhance utilization rateEnhance aesthetical appearanceLoudspeakersMicrophone structural associationLoudspeakerMicrophone

A microphone with integrated speaker which includes a front casing with a front connecting portion and a front handle portion having a battery opening; a rear casing with a rear connecting portion and a rear handle portion connected to the front casing to form a first cavity with a cylindrical connecting portion and a cylindrical handle portion with a second cavity; a metallic net cover coupled with the cylindrical connecting portion; a vocal pickup support arrangement provided inside the metallic net cover between the front connecting portion and the rear connecting portion in which a vocal pickup unit is provided; a speaker positioned inside the first cavity; a pair of electrode plates positioned inside the second cavity; a circuit board affixed on the front casing; a battery cover detachably connected to the front handle portion; and an aluminum alloy handle covers the cylindrical handle portion.

Owner:SHENZHEN HUA SIRUI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com