Replacing method of blast furnace shell and water wall

A blast furnace shell and replacement method technology, which is applied in the direction of cooling devices, internal forms, inspection devices, etc., can solve the problems of affecting the utilization efficiency of blast furnaces, rapid replacement of blast furnace shells and water-cooled walls, and long maintenance and construction time, etc., to achieve saving Effects of machinery use and labor costs, shortened maintenance and construction time, and efficient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

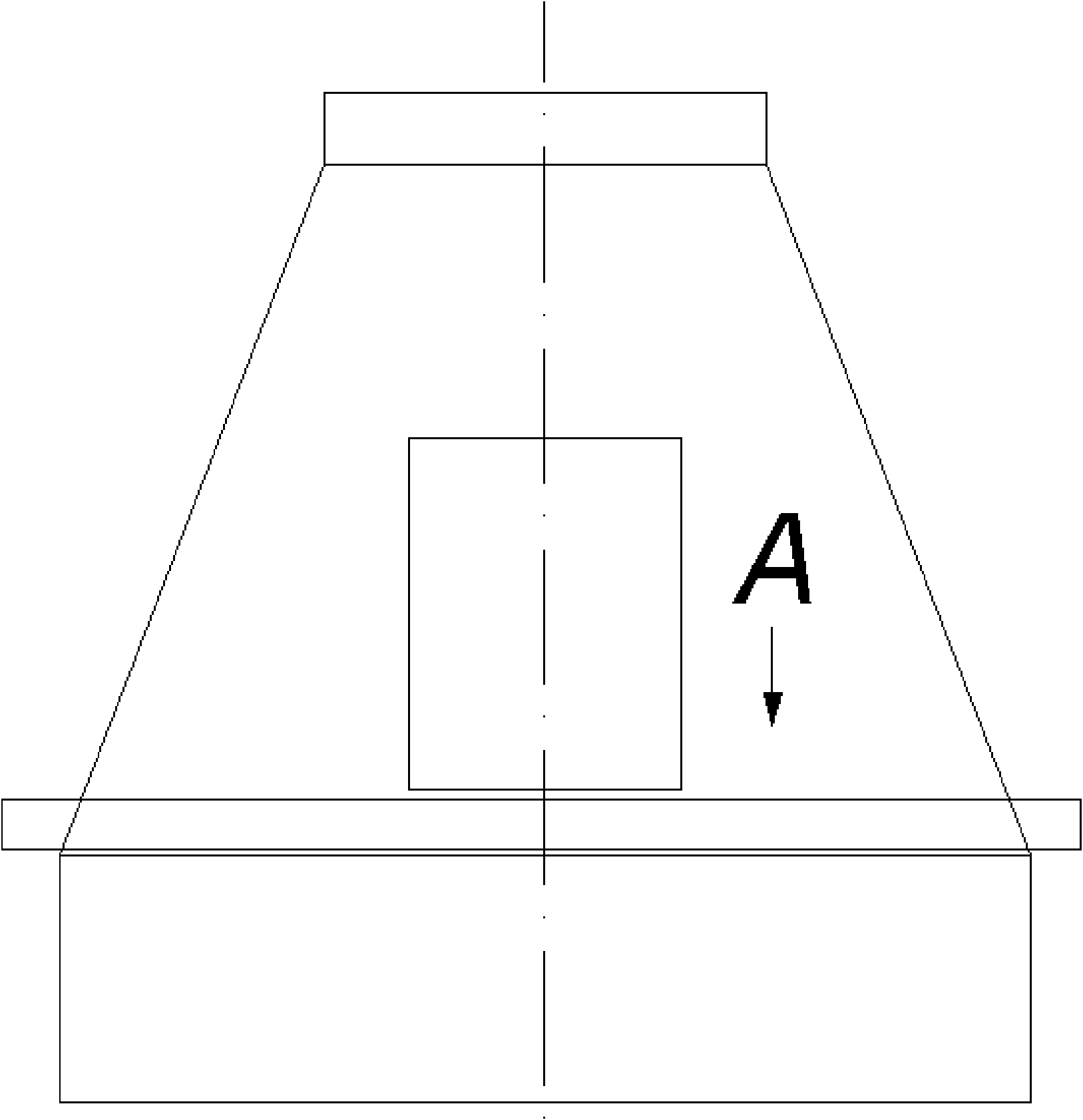

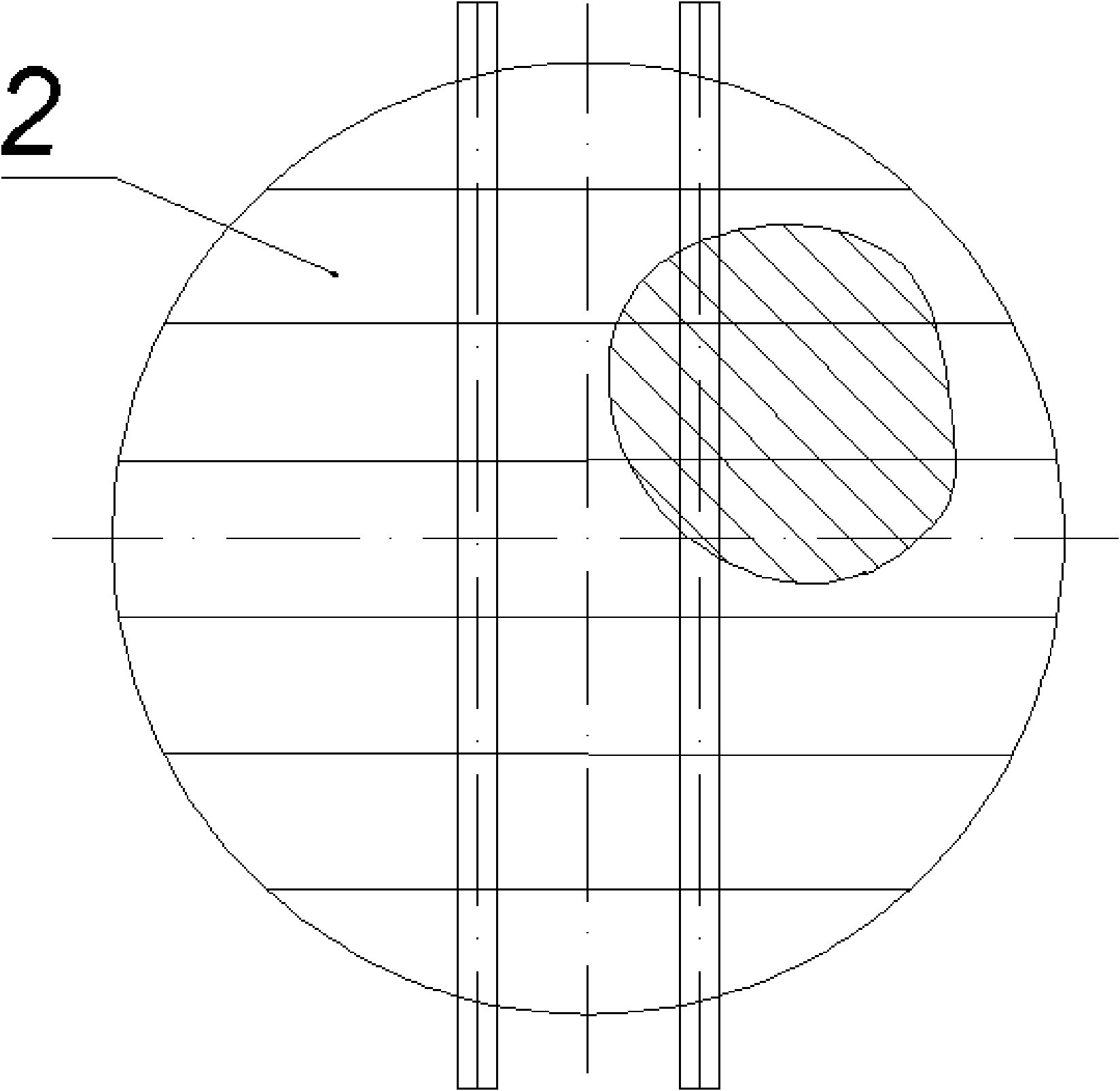

[0019] Such as Figure 1 to Figure 7 Shown, the replacement method of blast furnace shell of the present invention and water wall, comprises the steps:

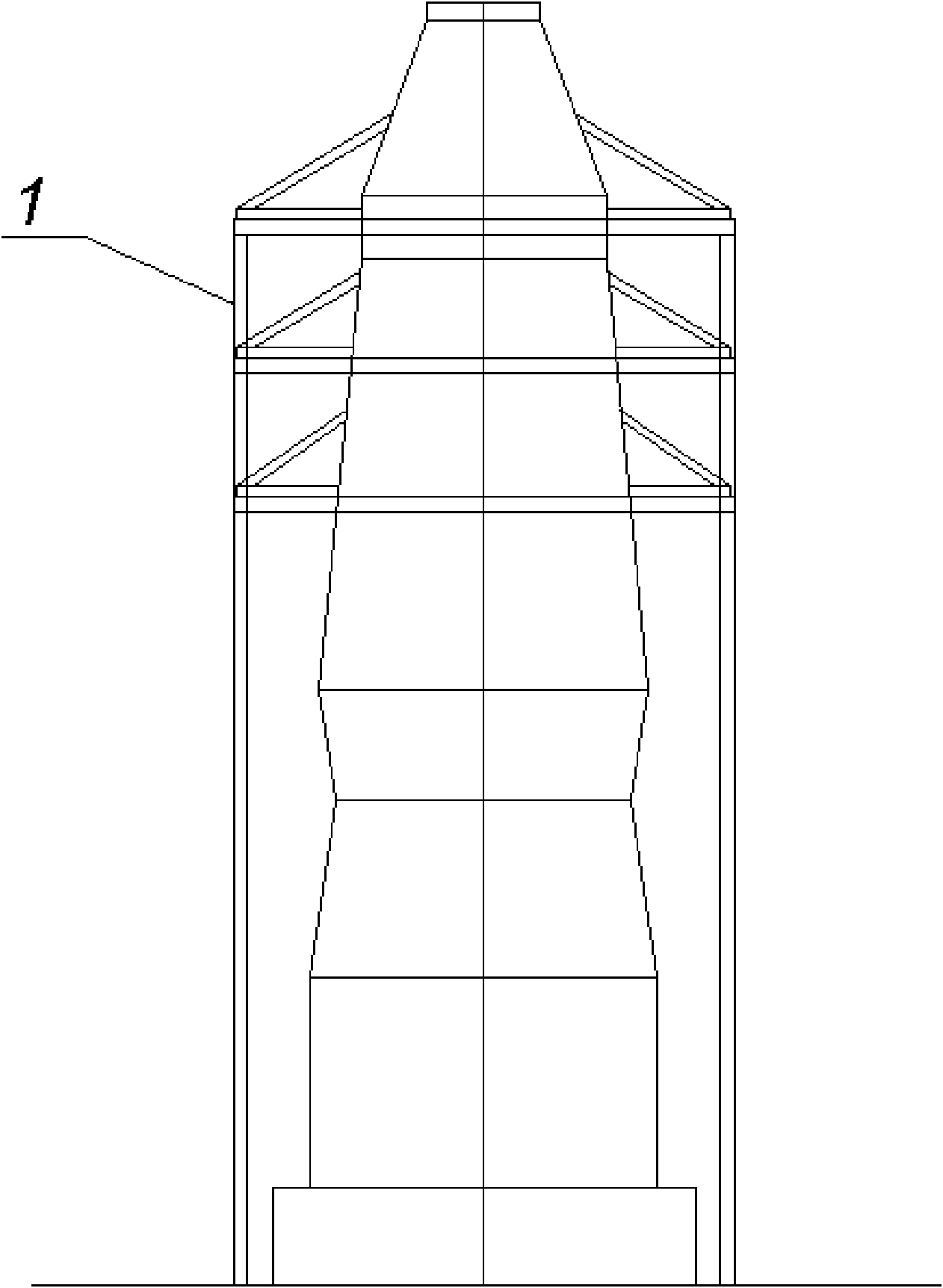

[0020] 1) A support frame 1 is provided around the furnace body to prevent the furnace shell from sinking or tilting. The support frame 1 forms an integral body with the furnace body, which can ensure that when the blast furnace bosh and the furnace shell at the furnace waist are partially removed, the weight of the upper part of the blast furnace is transferred to the support frame 1, thereby preventing the furnace shell from sinking or tilting, and ensuring The overall stability of the blast furnace when shell and water-cooled wall eliminates potential safety hazards.

[0021] 2) Cut the furnace shell that needs to be replaced, and remove the cut furnace shell together with the water wall connected to it. During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com