Turning machining method of flange bolt as well as positioning and clamping device for same

A flange bolt and clamping device technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problem of unable to meet the dimensional accuracy requirements, achieve good turning accuracy, increase contact area, coaxial good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

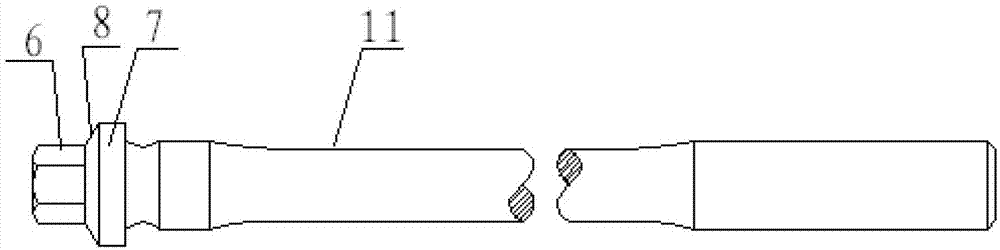

[0026] The present invention will be further described below in conjunction with the accompanying drawings by taking the processing of the ultra-small head hexagon flange slender bolts provided with the waist groove 11 as an example.

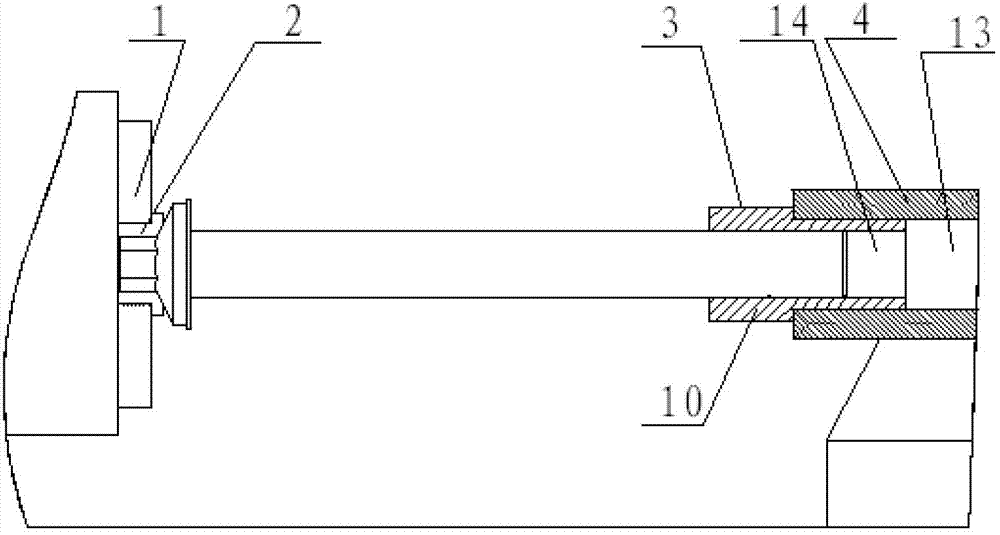

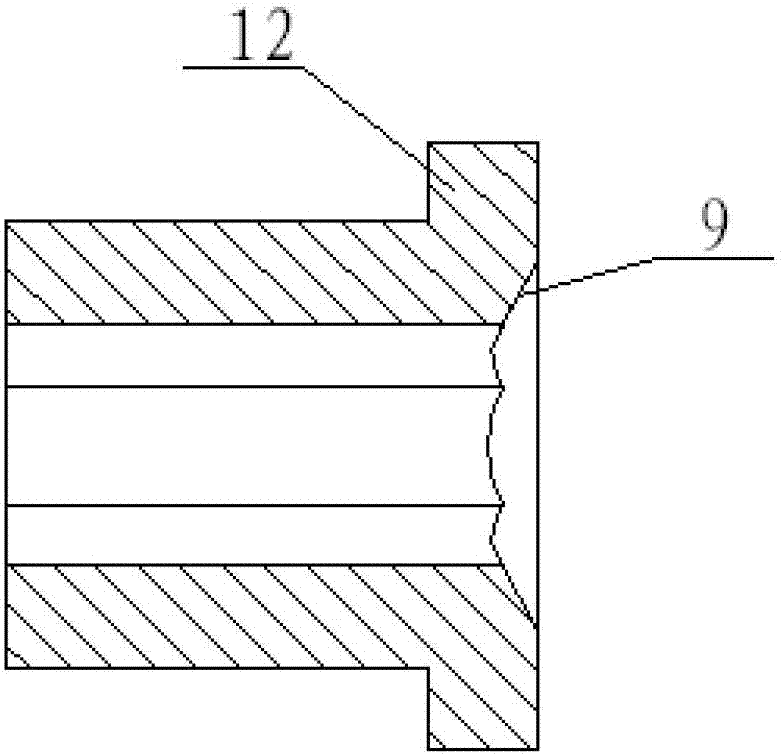

[0027] Such as Figure 1-11 As shown, the positioning device of the present invention is made up of being arranged on the tailstock 4 of the lathe and the tailstock bushing 3 arranged in the tailstock hole 13. match. The bushing inner hole 14 of the tailstock bushing 3 is preferably a straight through hole, which is equal to the diameter of the processed bolt shank. When the bolt shank is inserted into the bushing inner hole 14, the bolt shank and the bushing inner hole 14 are gaps. Mate connection. The tailstock hole 13 can be a straight hole or a tapered hole to match it, and the surface of the tailstock bushing 3 matched with the tailstock hole 13 is a truncated cone or a cylindrical shape. To facilitate the disassembly and assembly of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com