Multi-redundancy landing gear electric retraction controller

A landing gear and controller technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve the problems of increasing aircraft weight, aircraft bomb weight, low utilization rate of hydraulic actuation energy, and large bomb load weight, etc. Achieve the effect of reducing the probability of being unable to retract, light weight, and high working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

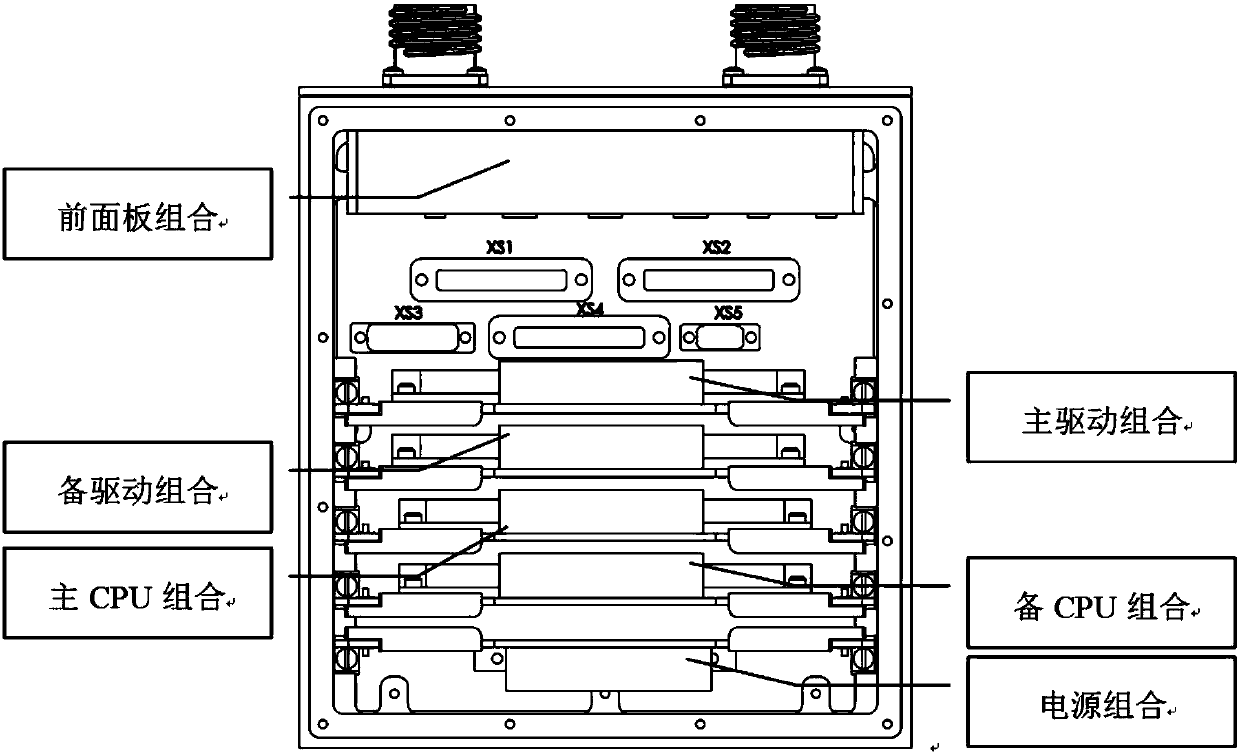

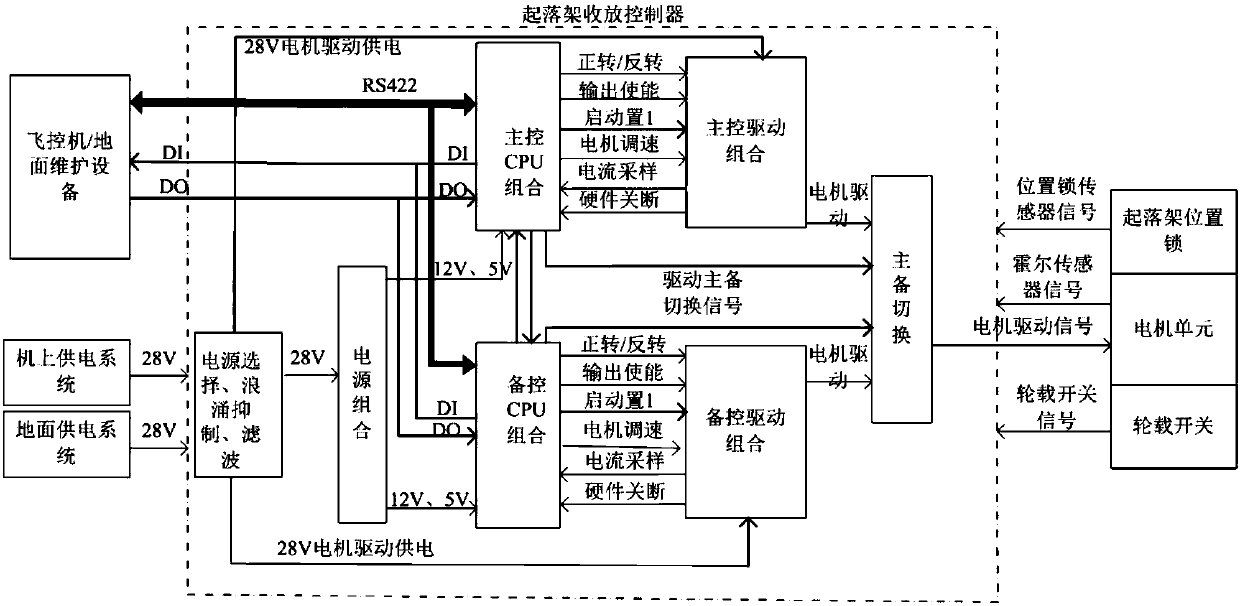

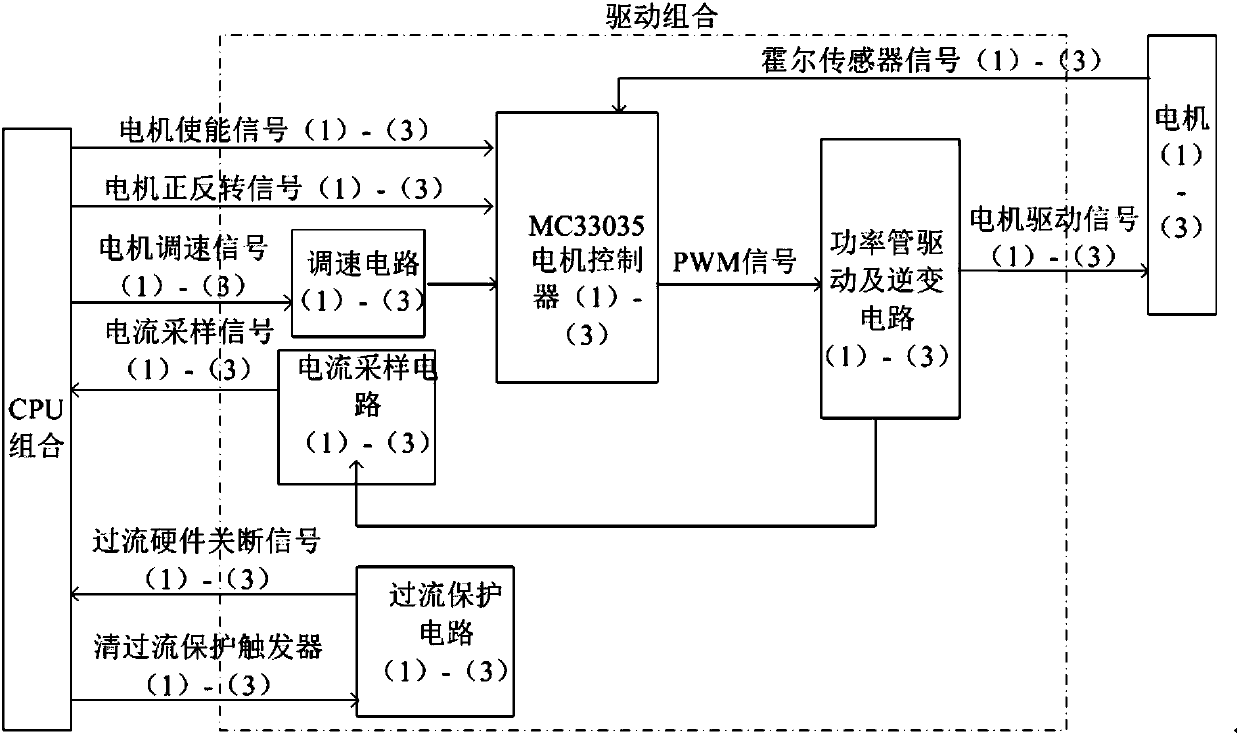

[0019] refer to figure 1 , figure 2 . In the embodiments described below, a multi-redundancy landing gear electric retractable controller is composed of a chassis structure and 6 electronic components. The chassis structure includes a front panel module, a bottom plate combination, and an upper cover plate combination, and the front panel module is used for power supply selection, surge suppression, filtering, and main and standby channel switching. The electronic components include: a main control CPU combination module, a backup control CPU combination module, a main control drive combination module, a backup control drive combination module, a master / standby switching module, a power supply combination module and a motherboard combination module. The power combination module, the main control CPU combination module, the backup control CPU combination module, the main control drive combination module, the backup control drive combination module and the master / standby swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com