Automatic tool changing motion arm for CNC (Computer Numerical Control) machining center

A technology of automatic tool change and machining center, applied in the field of manipulator arm, it can solve the problems of inflexible action, slow tool change speed and low intelligence, and achieve the effect of flexible action, fast tool change and high intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

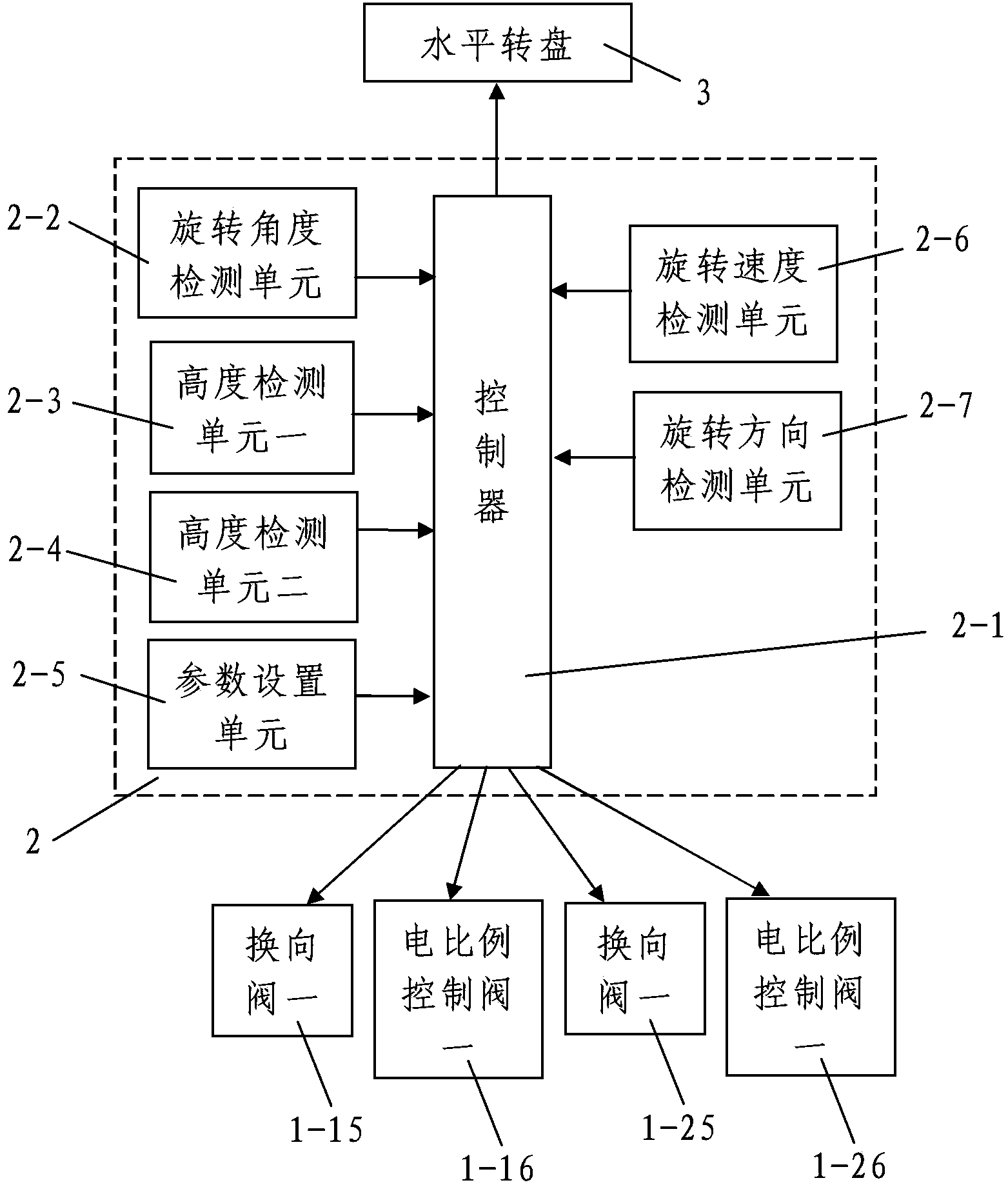

[0025] like figure 1 As shown, the present invention includes two tool changing arms with the same structure and size and an operation control system 2 for automatically controlling the two operating arms. The rear ends of the two tool changing arms are all mounted on a horizontal turntable 3, the horizontal turntable 3 is located between the tool magazine of the CNC machining center and the spindle of the machine tool. The two tool changing arms are operating arm 1 and operating arm 2 respectively; the operating arm 1 includes rear arm 1 and forearm 1 which can swing up and down vertically under the drive of hydraulic cylinder 1, and the rear arm One and the forearm one are connected in a hinged manner, the cylinder rear part of the hydraulic cylinder one is fixed on the rear arm one and the front end of the hydraulic telescopic rod is fixed on the forearm one; the operating arm two includes the rear arm two and Driven by the hydraulic cylinder 2, the forearm 2 can swing up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com