Disc type tool changer

A disc-type, tool magazine technology, applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of delaying the operation of CNC machine tools, high manufacturing and using costs, and complex structures, and achieves simple structure, low price, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

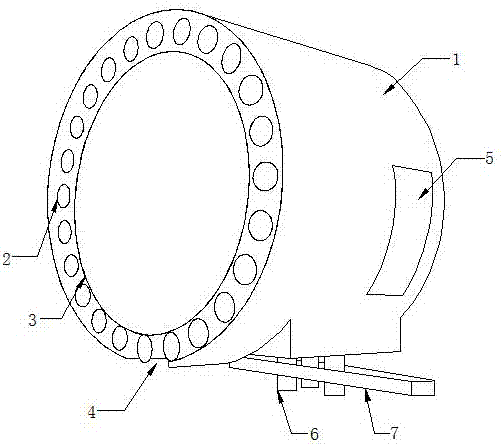

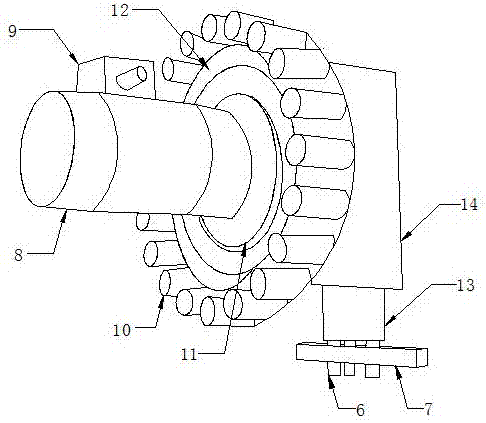

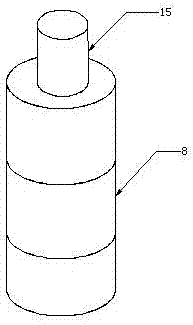

[0017] Such as Figure 1-3 As shown, a disc-type tool magazine includes a motor 8, a rotating shaft 15 is installed on one side of the motor 8, the motor 8 is installed on a mounting plate 11, the rotating shaft 15 is connected to a turntable 12, and a turning tool mounting shaft 10 is installed on the turntable 12. A numerical control device 14 is installed on one side of the turntable 12, and a casing 1 is installed on the outer side of the turntable 12. The bottom of the numerical control device 14 is connected to a support shaft 13, and the bottom of the support shaft 13 is provided with a connecting shaft 6, and the connecting shaft 6 is provided with a fixing plate 7. The shell 1 is provided with a cooling port 5 , and one side of the shell 1 is provided with a knife edge 2 and a top cover 3 .

[0018] The upper end of the motor 8 is equipped with an infrared positioner 9, which can measure the position of the tool, making the tool change faster and more accurate; the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com