Patents

Literature

63results about How to "Reduce shaft diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

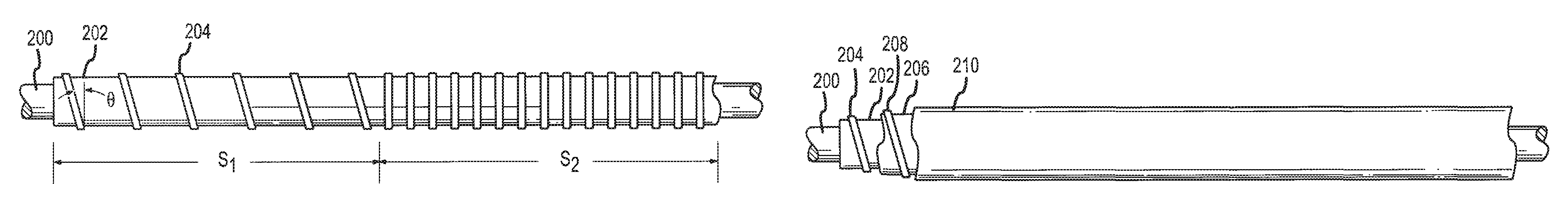

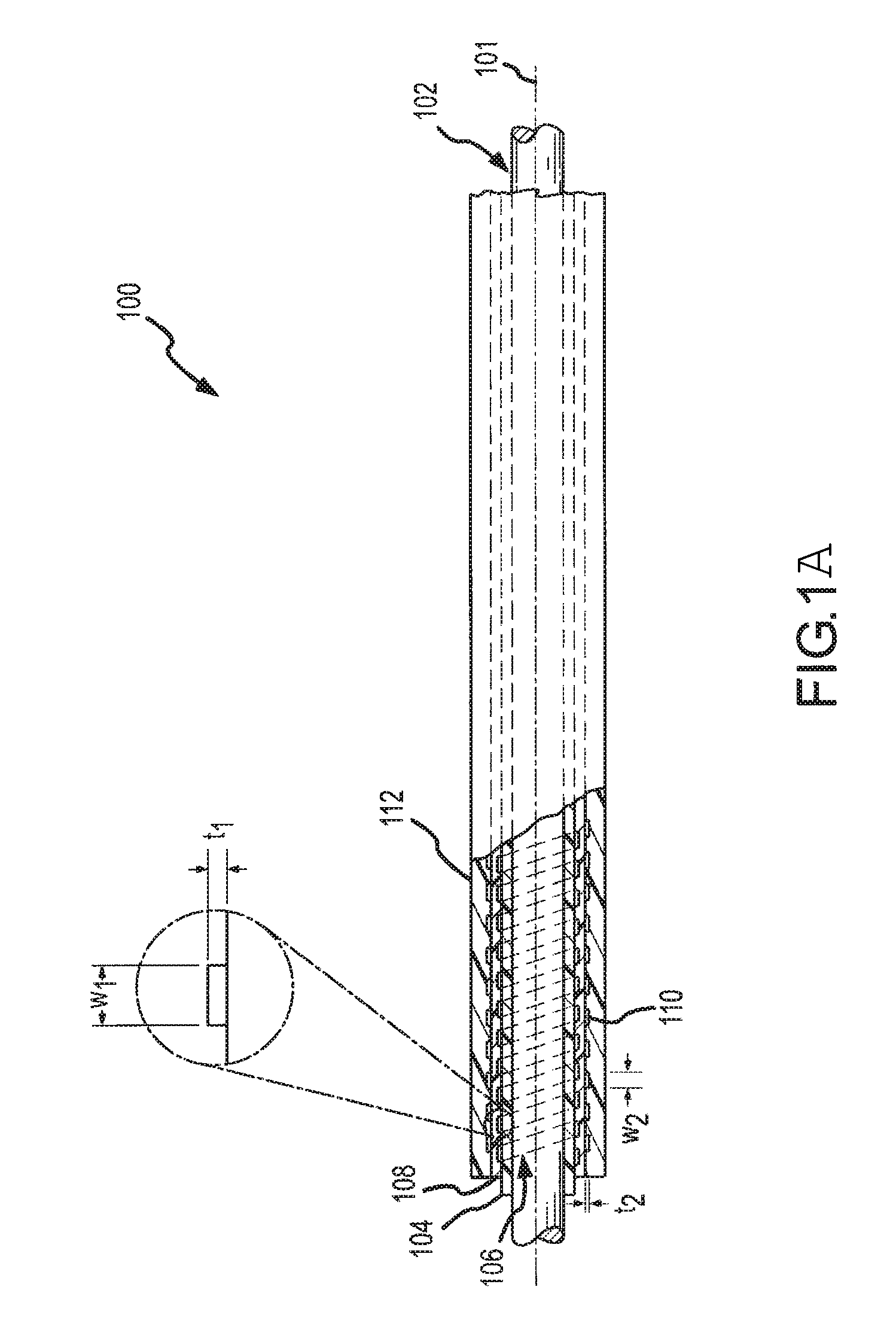

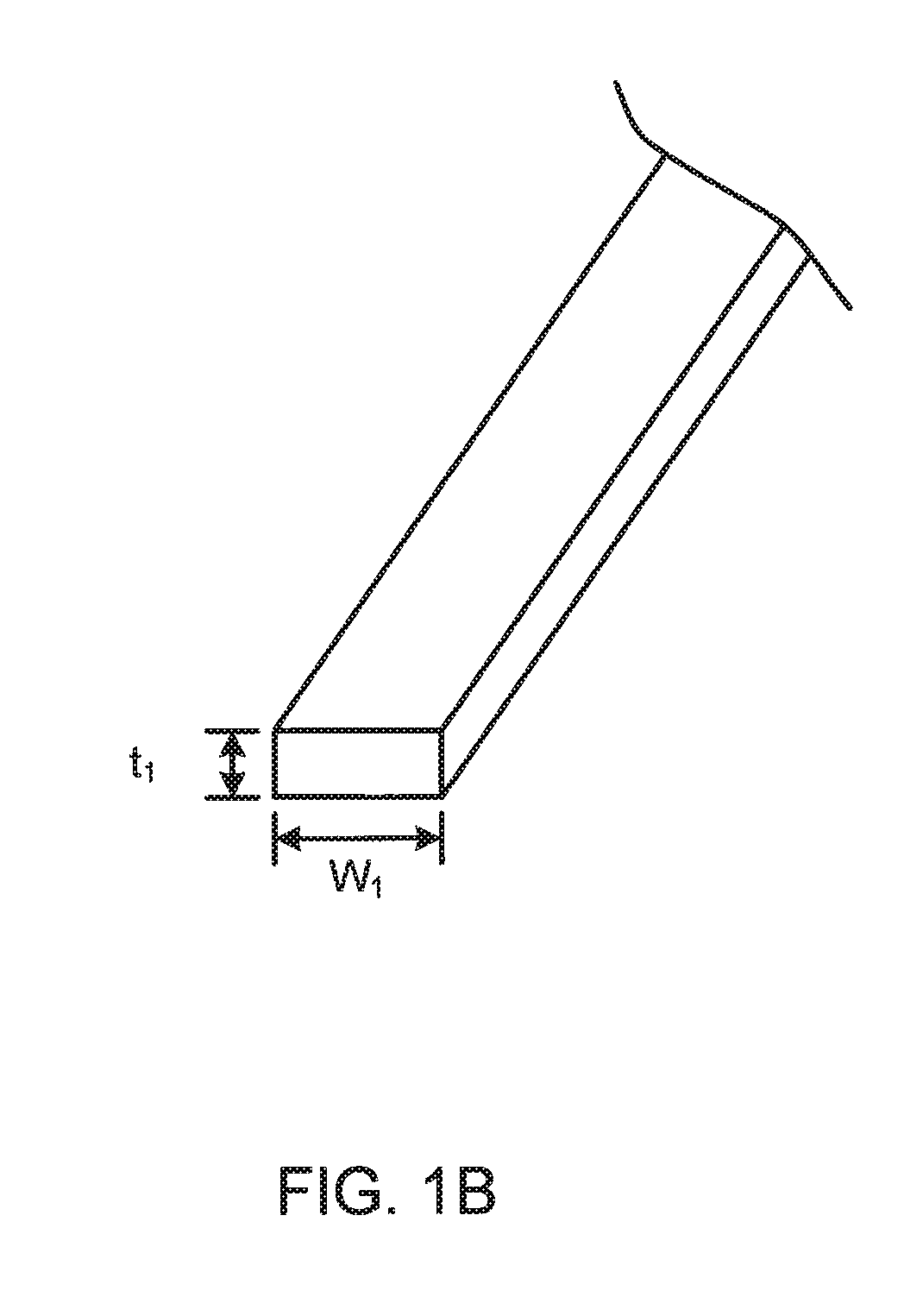

Dual braided shaft

ActiveUS20080161762A1Simple designReduce shaft diameterCatheterIntravenous devicesEngineeringMechanical engineering

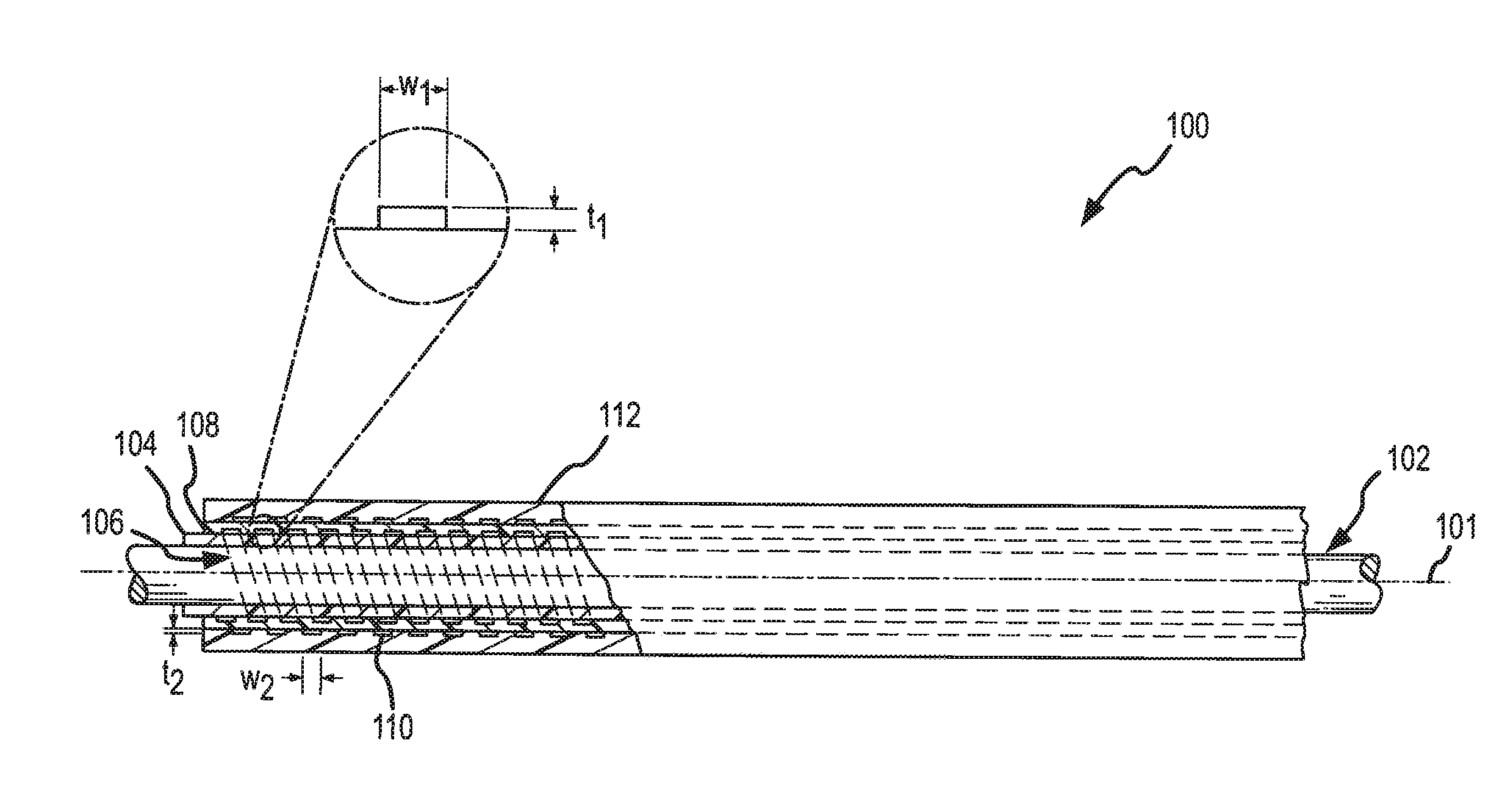

A dual braided catheter shaft includes a flat wire forming the inner braid, thereby potentially allowing for reduced radial thickness of the shaft. In one embodiment, the shaft (100) includes an inner polymer jacket (104), an inner braid (106) formed on the inner jacket (104), an intermediate jacket (108) formed over the inner braid (106), an outer braid (110) formed on the intermediate jacket (108) and an outer jacket (112) formed on the outer braid (110). A preferred construction process involves extruding polymer material directly onto each of the inner and outer braids (106 and 110) so that little or no air gaps remain between the polymer material and the braids (106 and 110). The braiding parameters of the inner and outer braids (106 and 110) can be varied along the length of the catheter to provide varying mechanical properties.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

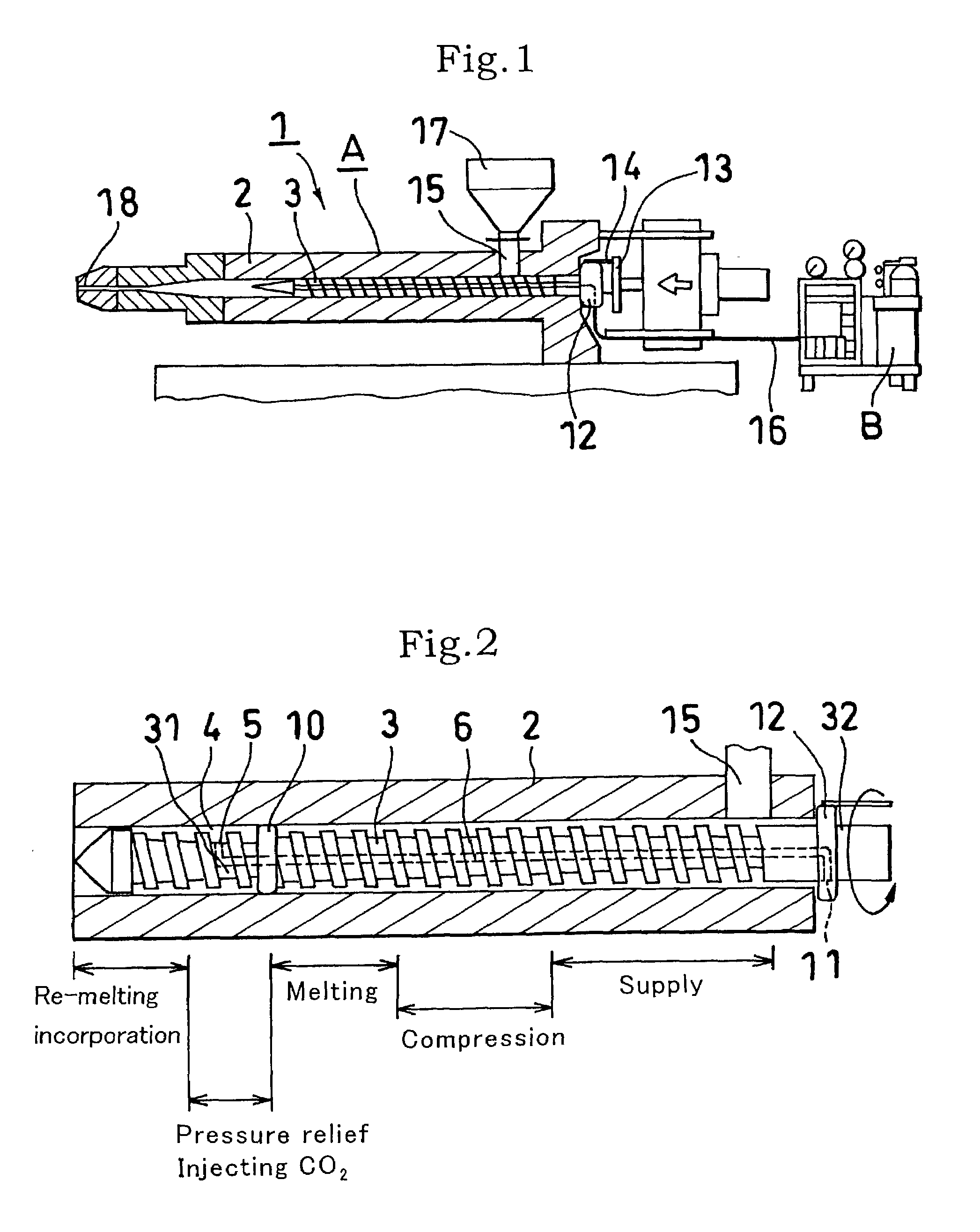

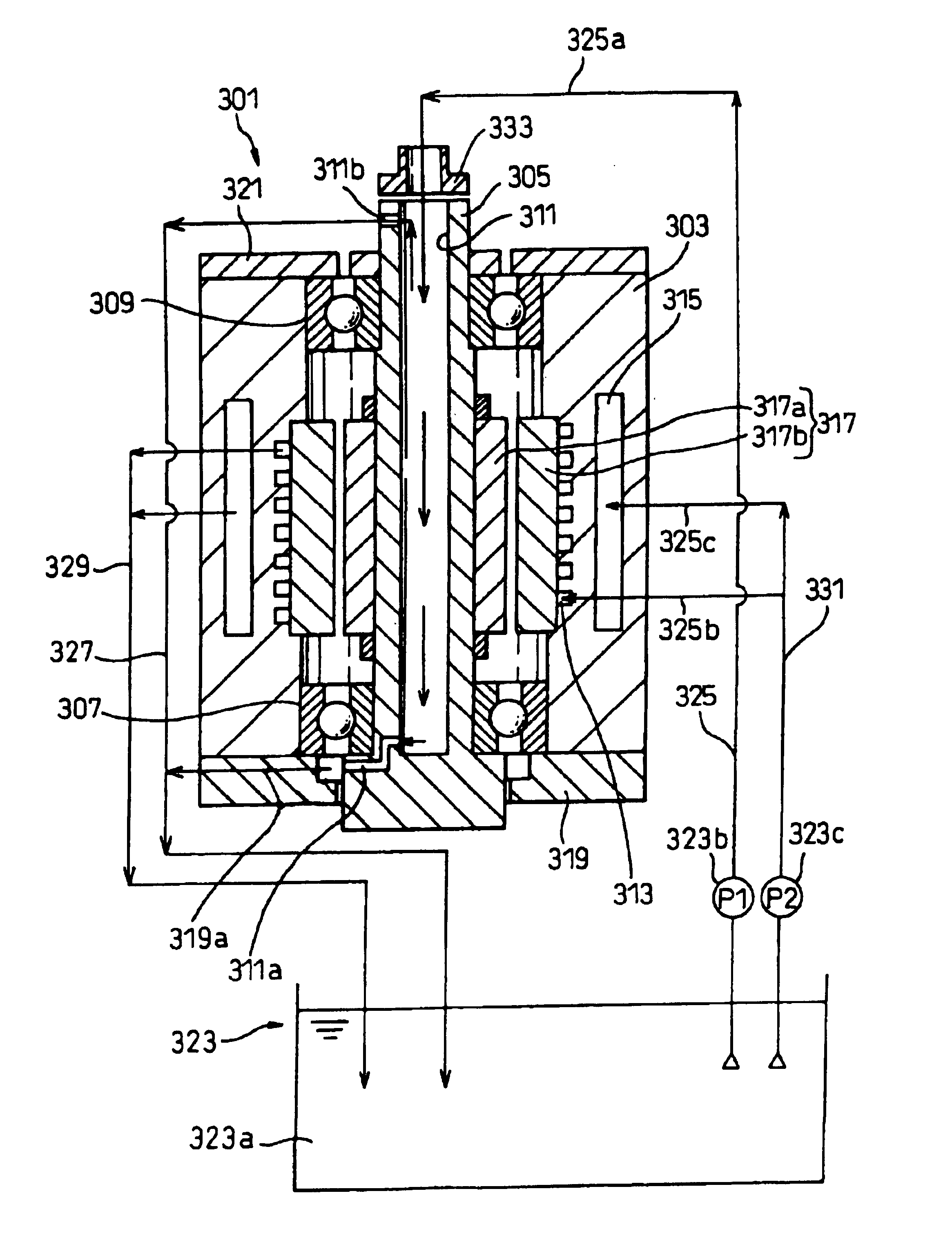

Injection molding process and injection molding apparatus for thermoplastic resin molded articles

InactiveUS6949208B1Efficient meltingIncrease pitchRotary stirring mixersFrozen sweetsFoaming agentReactive gas

Owner:SEKISUI CHEM CO LTD

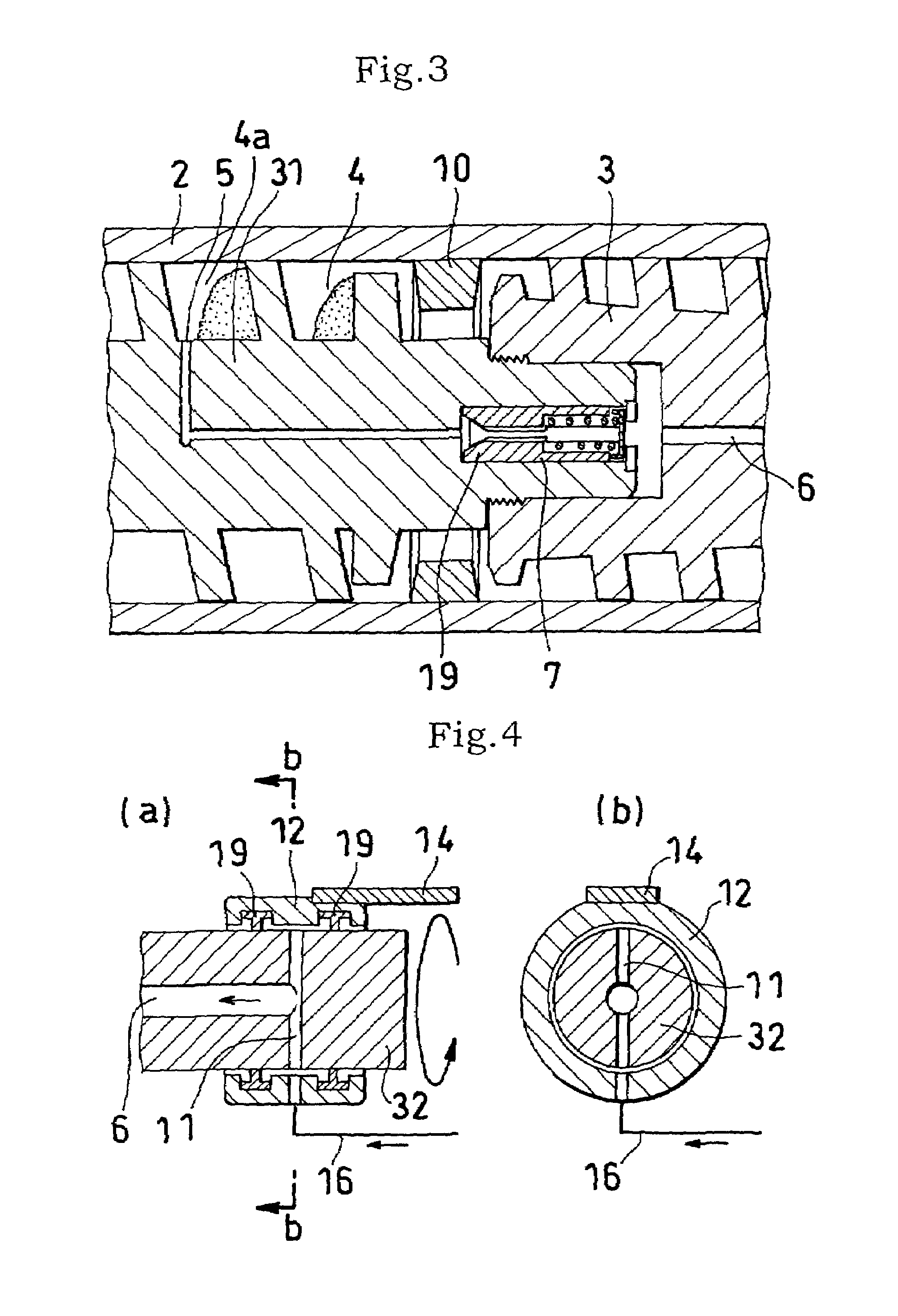

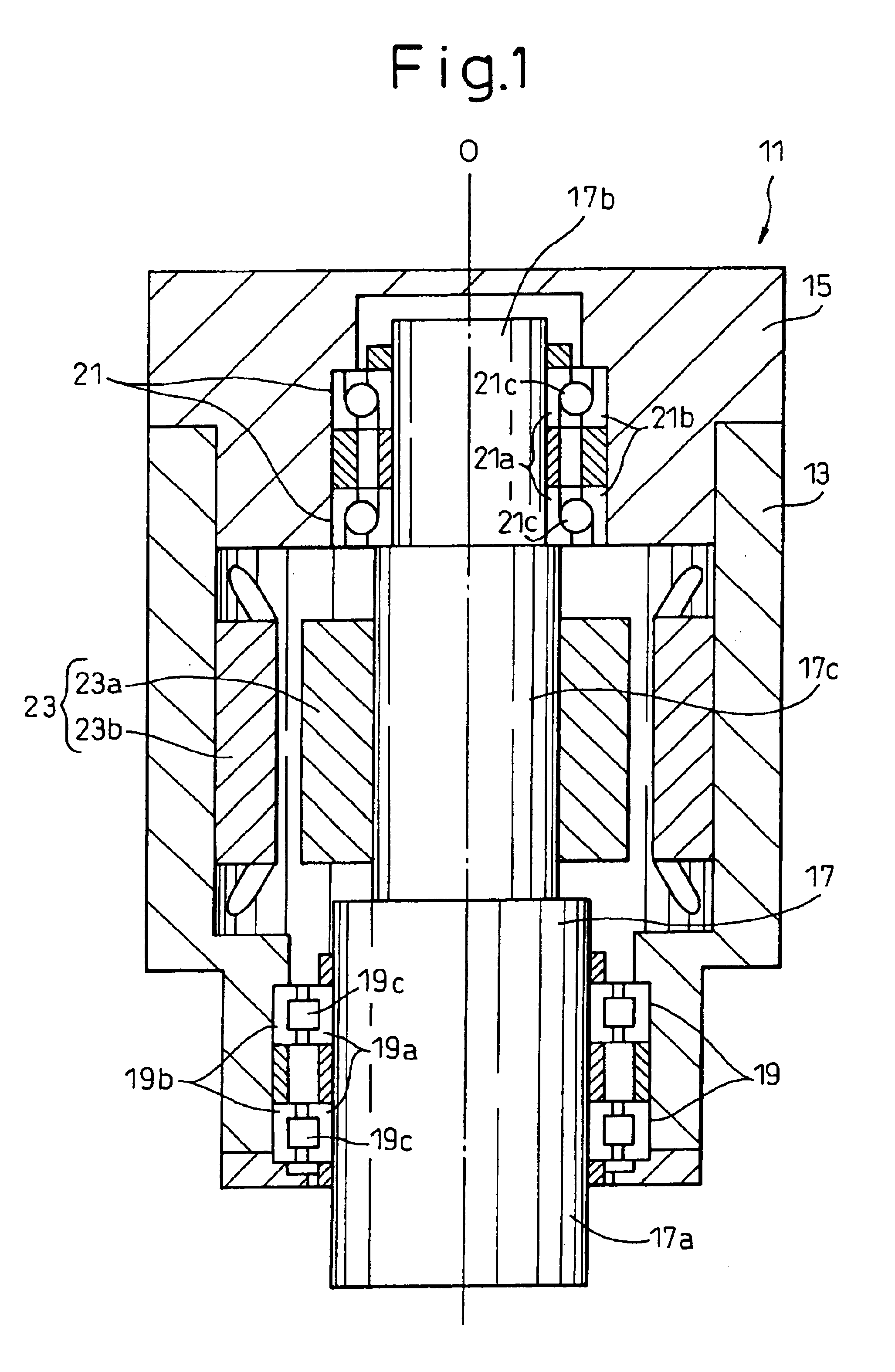

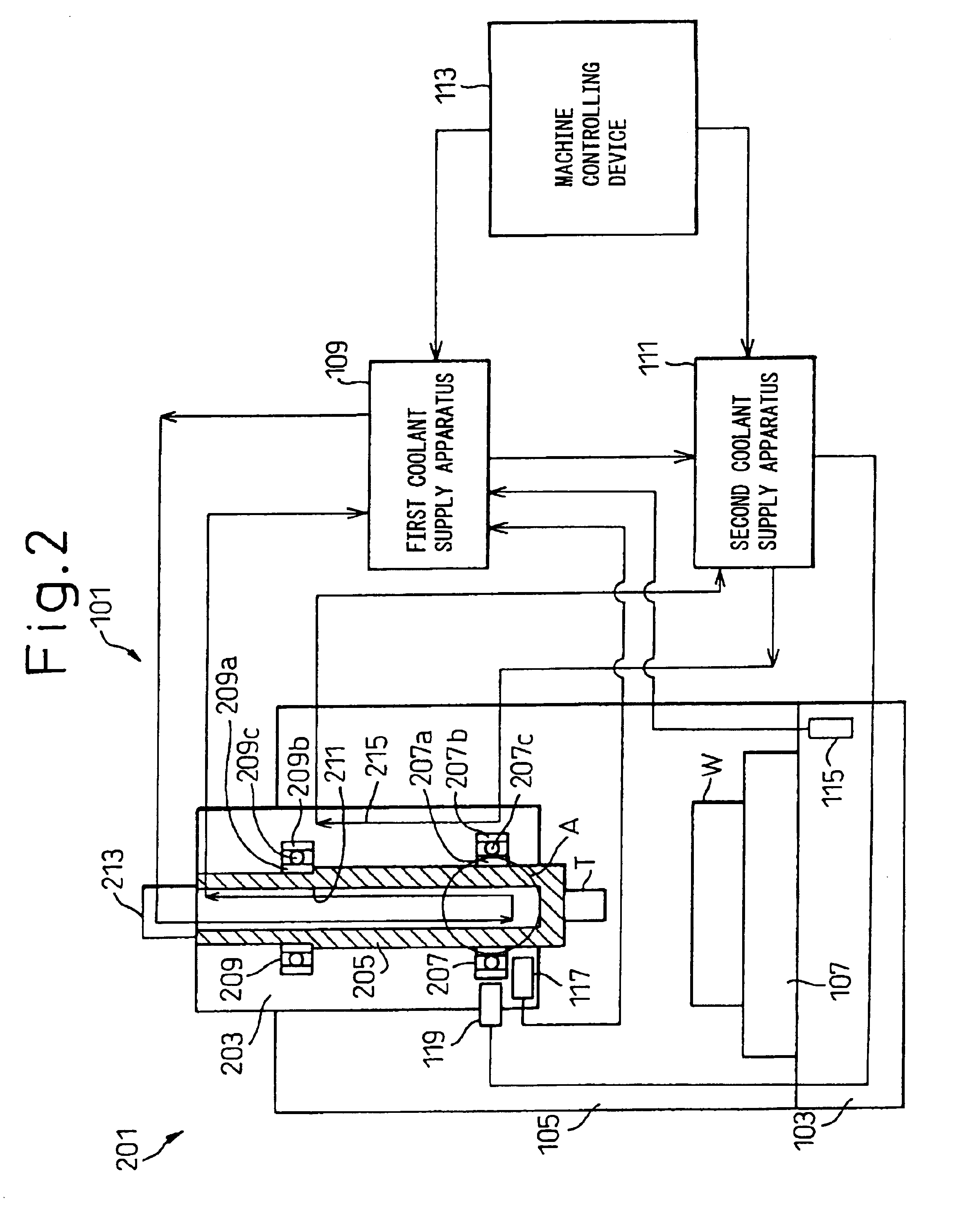

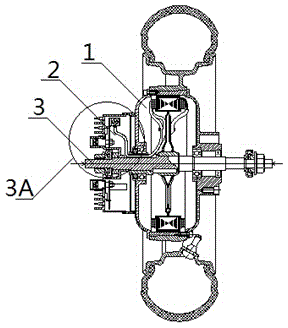

Rotating shaft apparatus

InactiveUS6913390B2Ensures rigidityLow heat generationCrankshaftsRolling contact bearingsBall bearingEngineering

A shaft 17 defines a front end portion 17a having a larger diameter and an opposite tail end portion 17b having a smaller diameter, the shaft 17 being rotatably supported by the housing 13 through a radial bearing 19 and a pair of angular ball bearings 21 at the front side large diameter portion 17a and the small diameter portion 17b, respectively.

Owner:MAKINO MILLING MASCH CO LTD

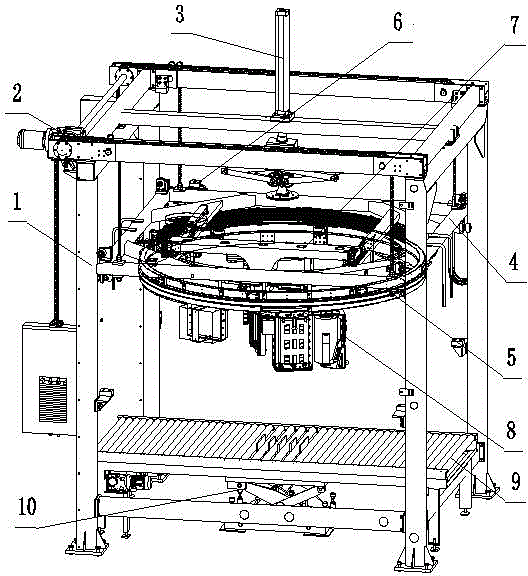

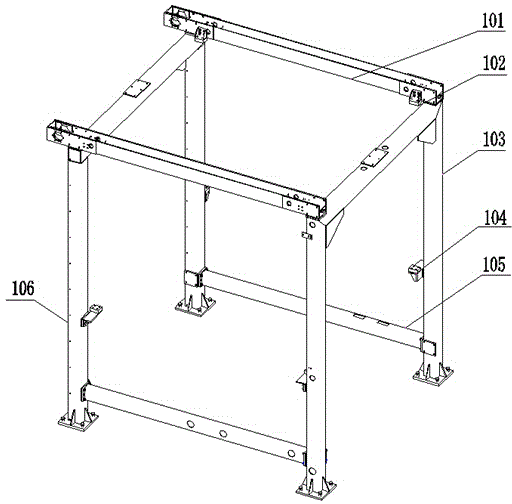

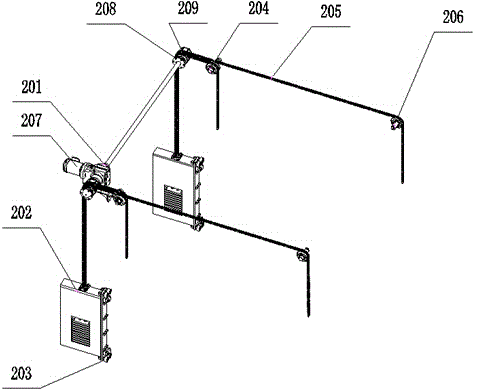

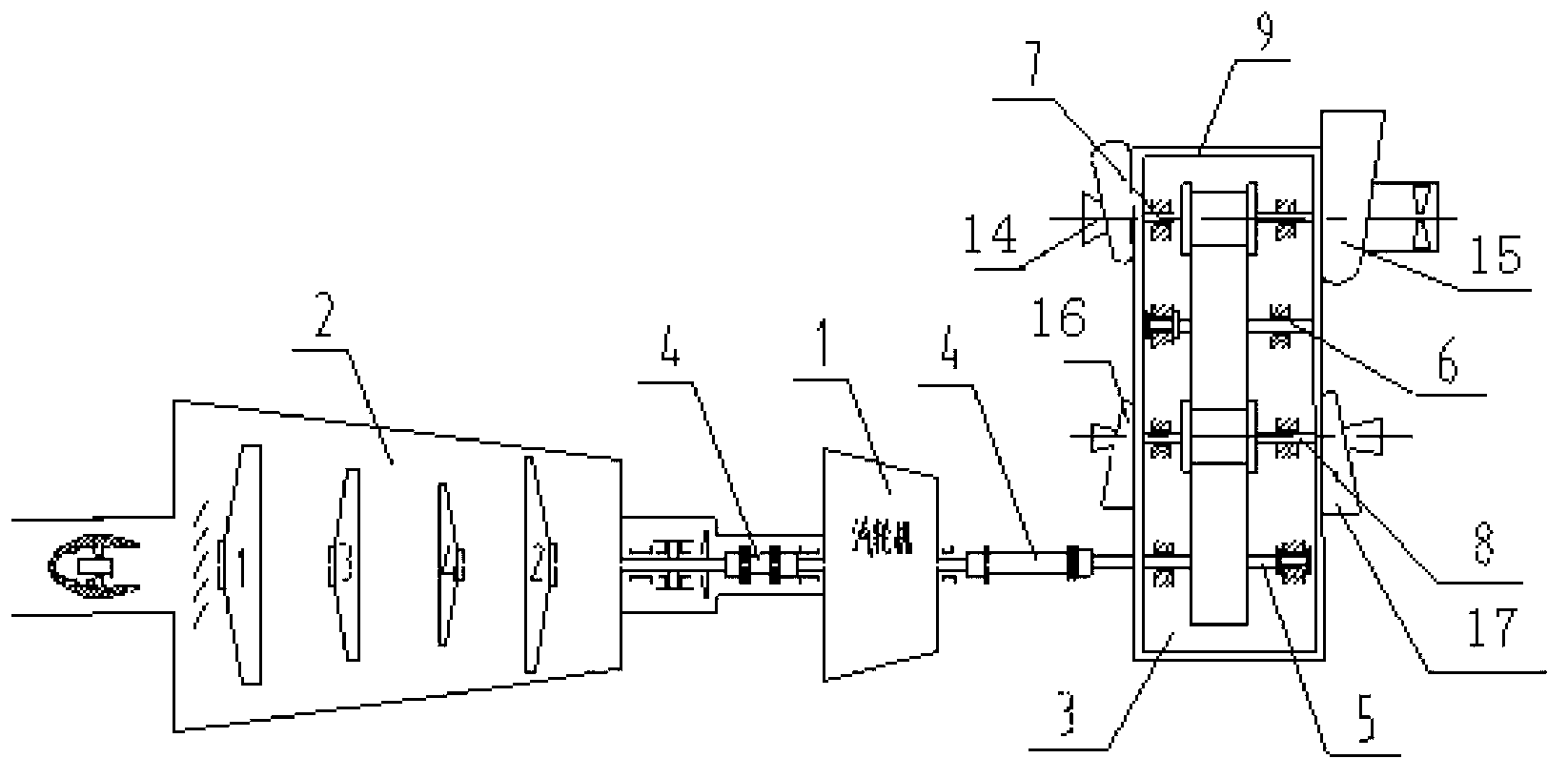

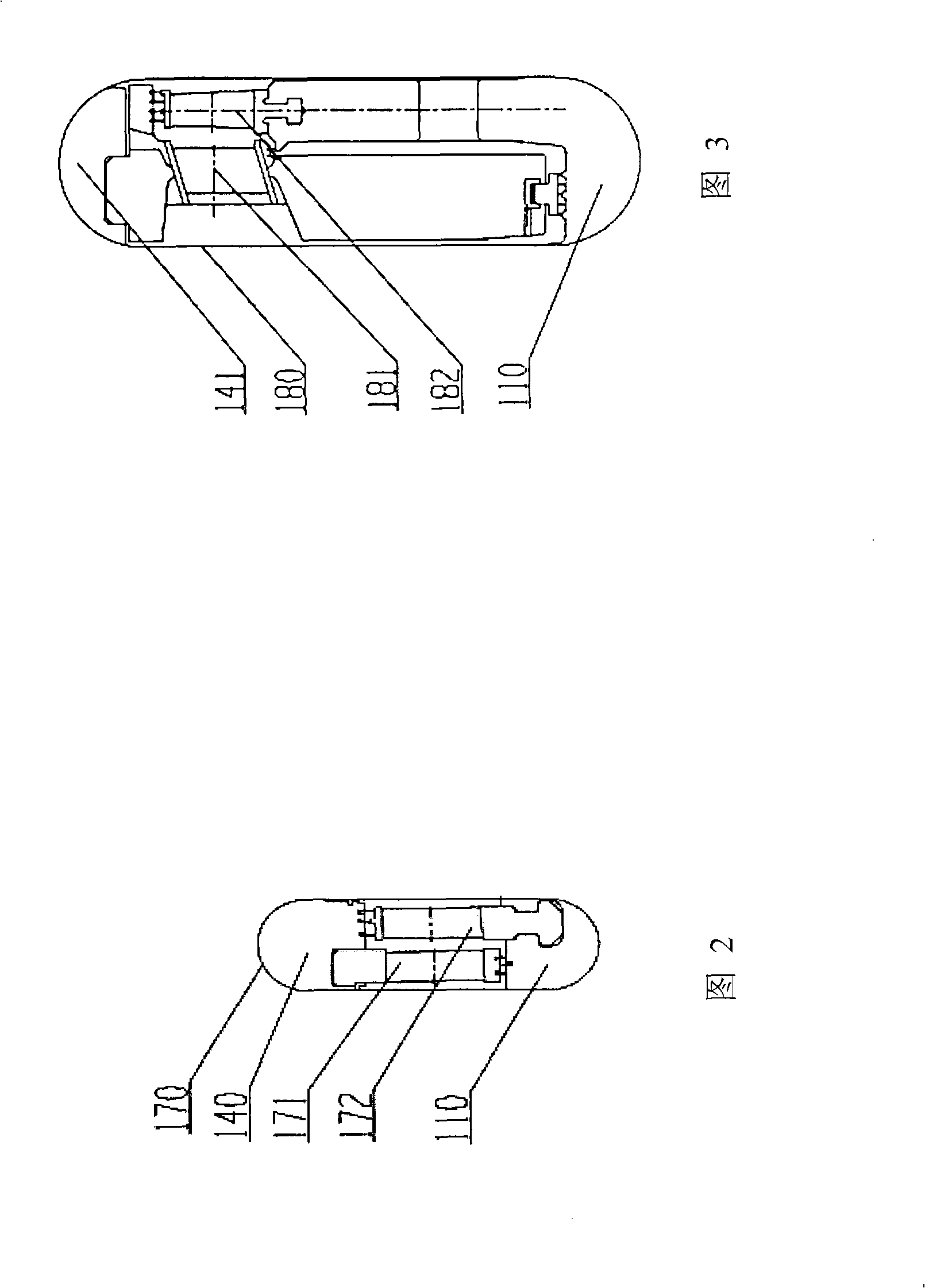

Full-automatic vertical PE (Poly Ethylene) film packaging machine

ActiveCN104401522AOptimize structureReduce shaft diameterWrapping material feeding apparatusWeb rotation wrappingElectric machineryAutomatic control

The invention discloses a full-automatic vertical PE (Poly Ethylene) film packaging machine, which comprises a main machine frame, a lifting device, a downward pressing device, a travelling device, a revolving device, a driving device, a film clamping device, a film frame device, a roller conveyor, a jacking device, an automatic control system, a pneumatic system and a hydraulic system. A driving shaft of the lifting device is supported by four pivots and driven by a built-in motor; due to the film frame device, a film can be pre-stretched to 250%, so that material consumption can be reduced; by means of the suspension installing manner of the film clamping device, film tails cannot be generated while packaging; power and communication signals are obtained in a closed 8-pole sliding contact line by adopting double electric brushes, so that the signals cannot be lost in the operation process; in addition, in the event of lifting a material to package, the upper head face and the lower head face of the material are wrapped to a certain extent with the help of the tension of the film.

Owner:中轻长泰(长沙)智能科技股份有限公司

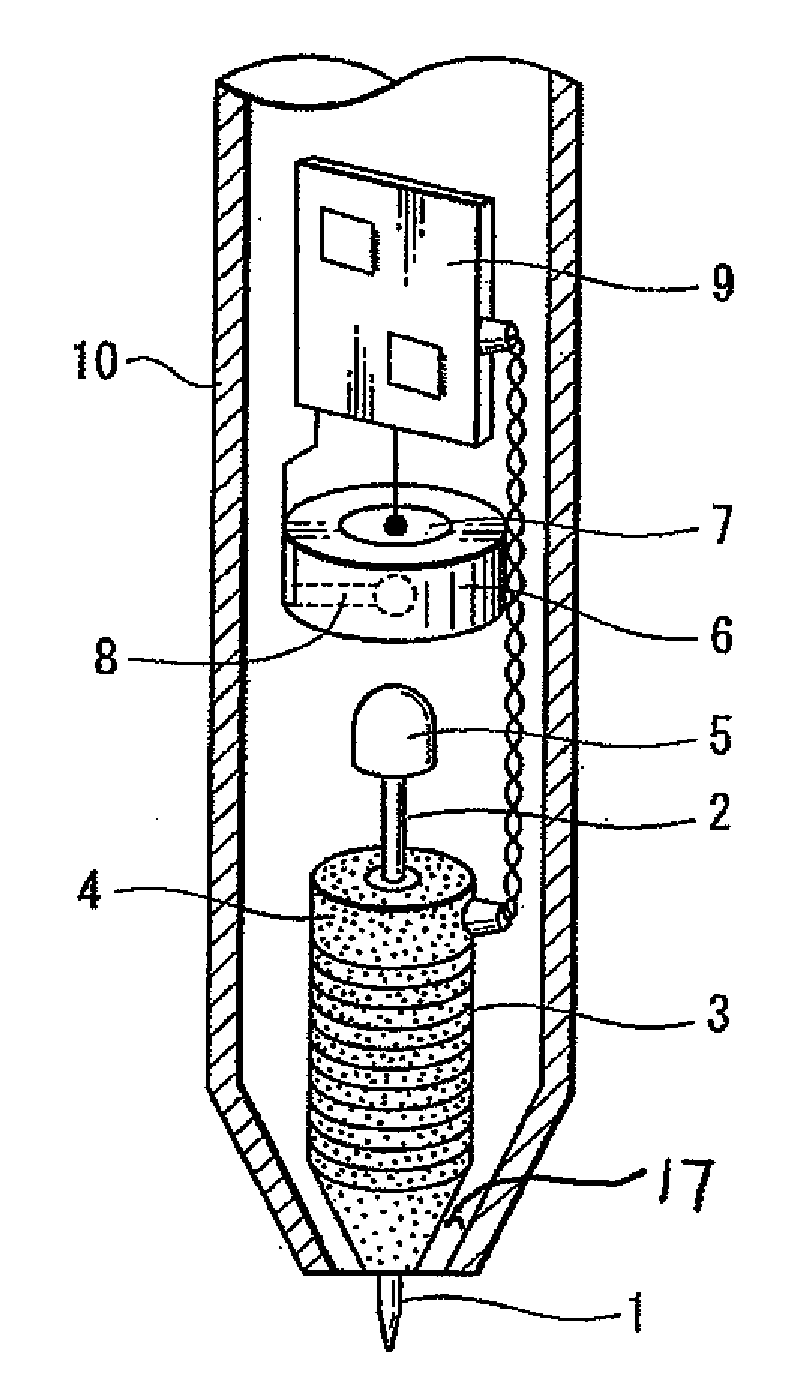

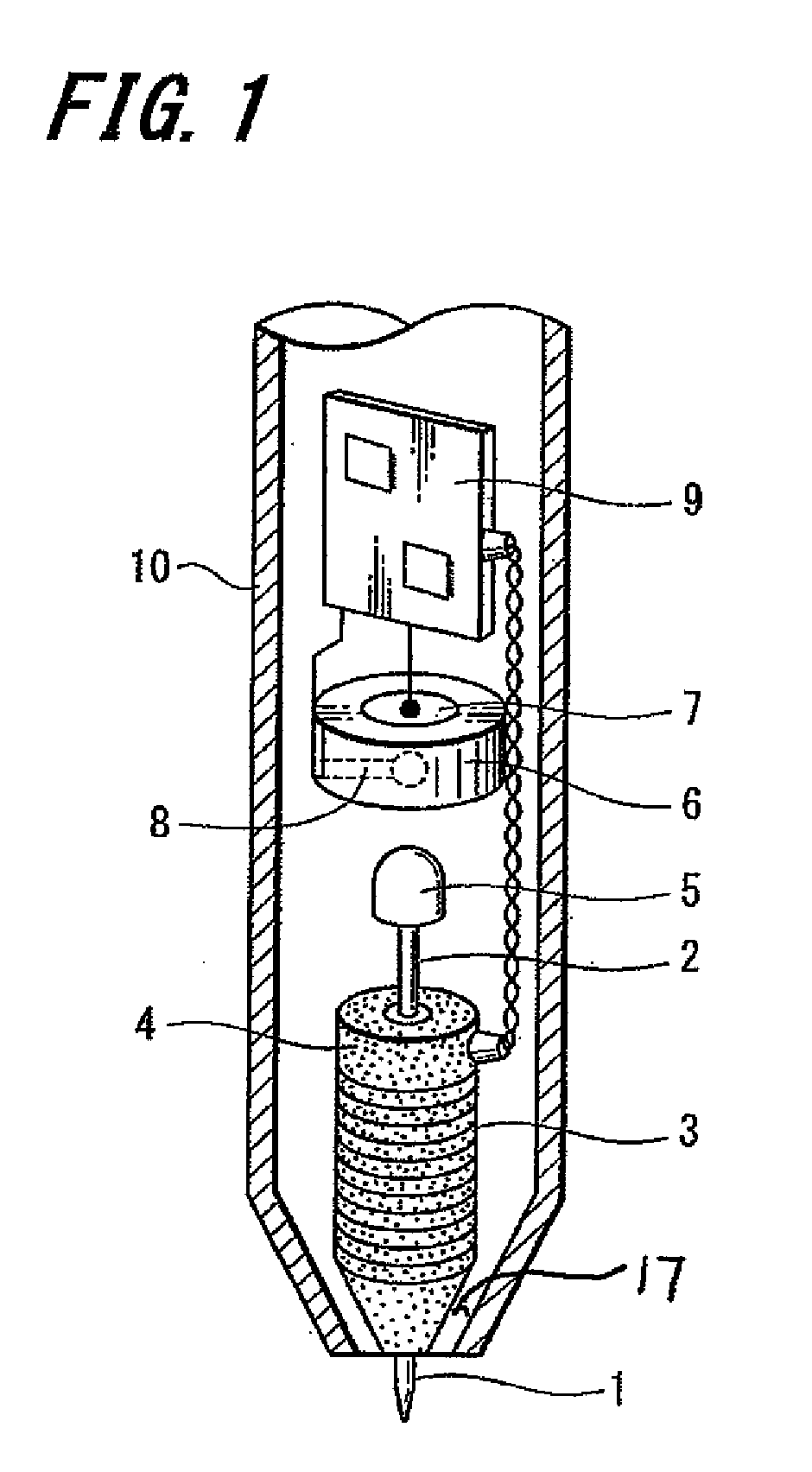

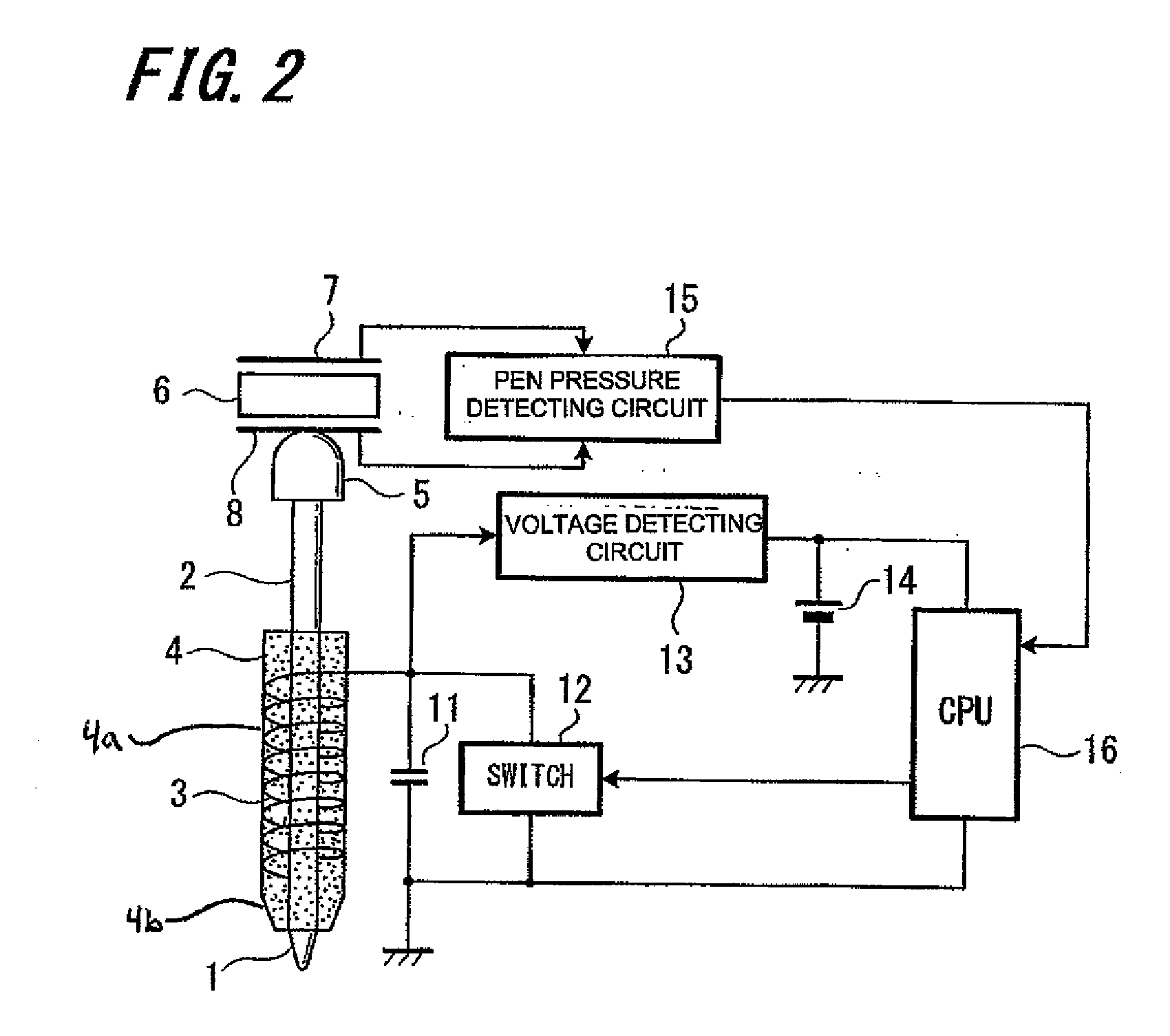

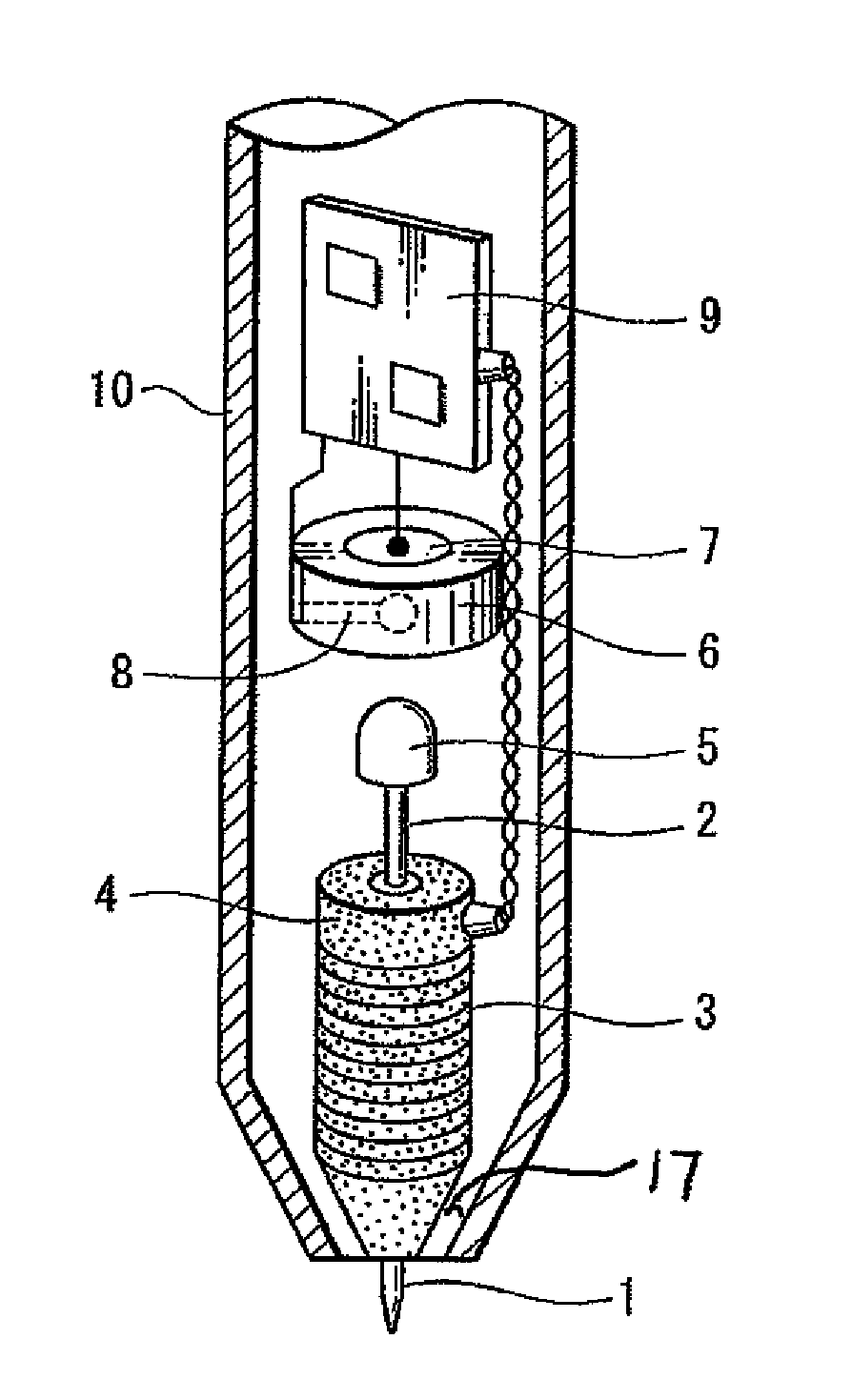

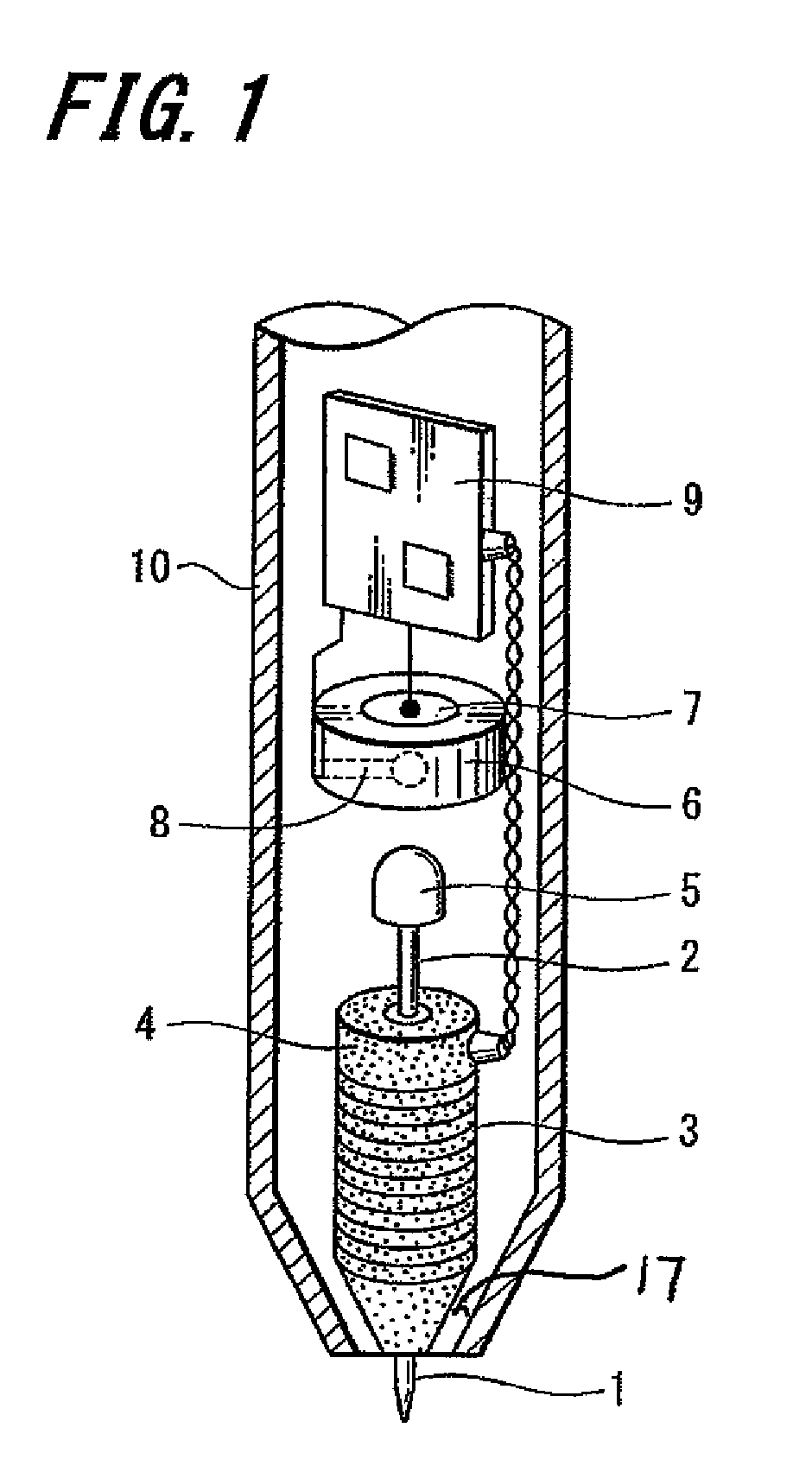

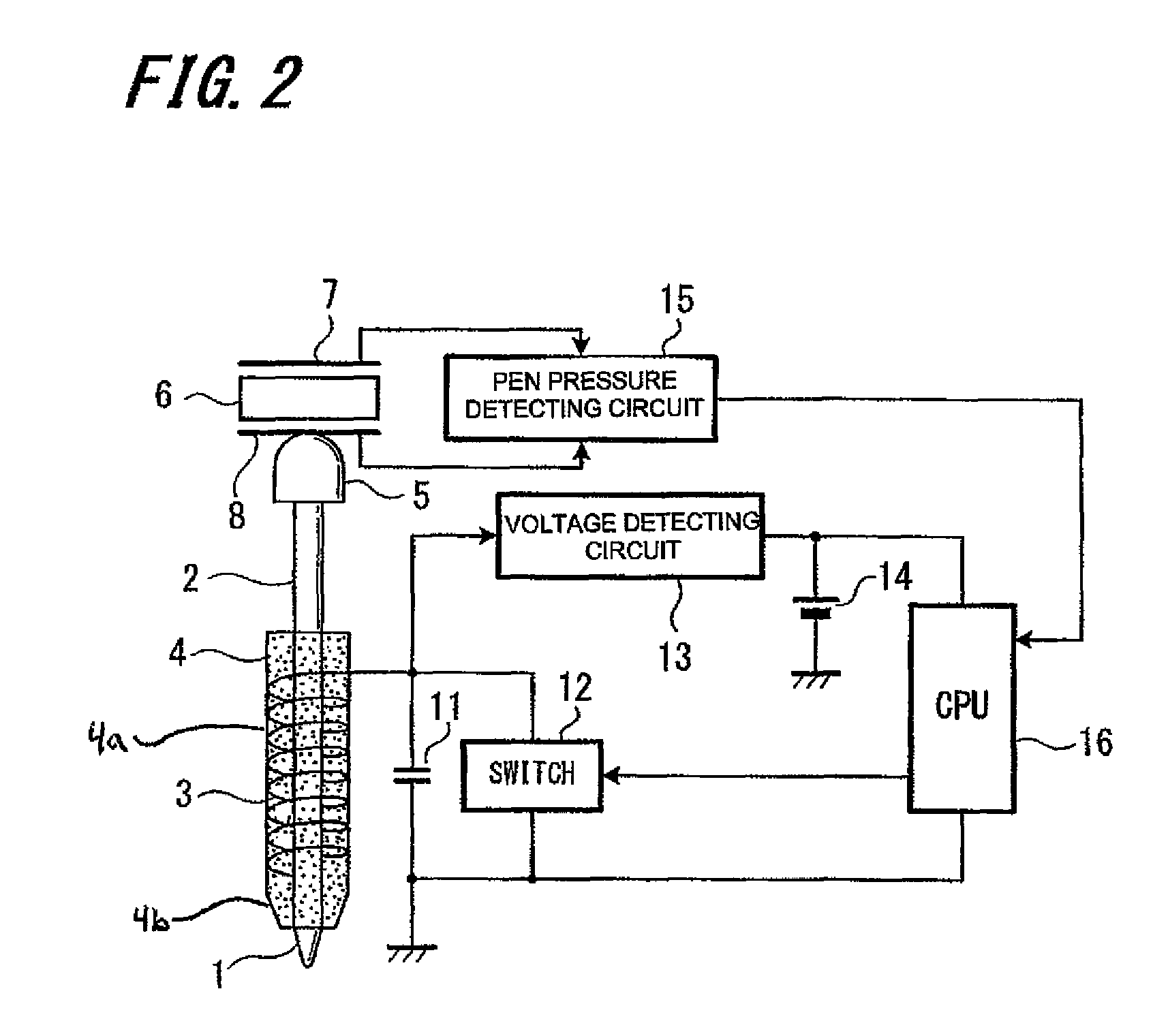

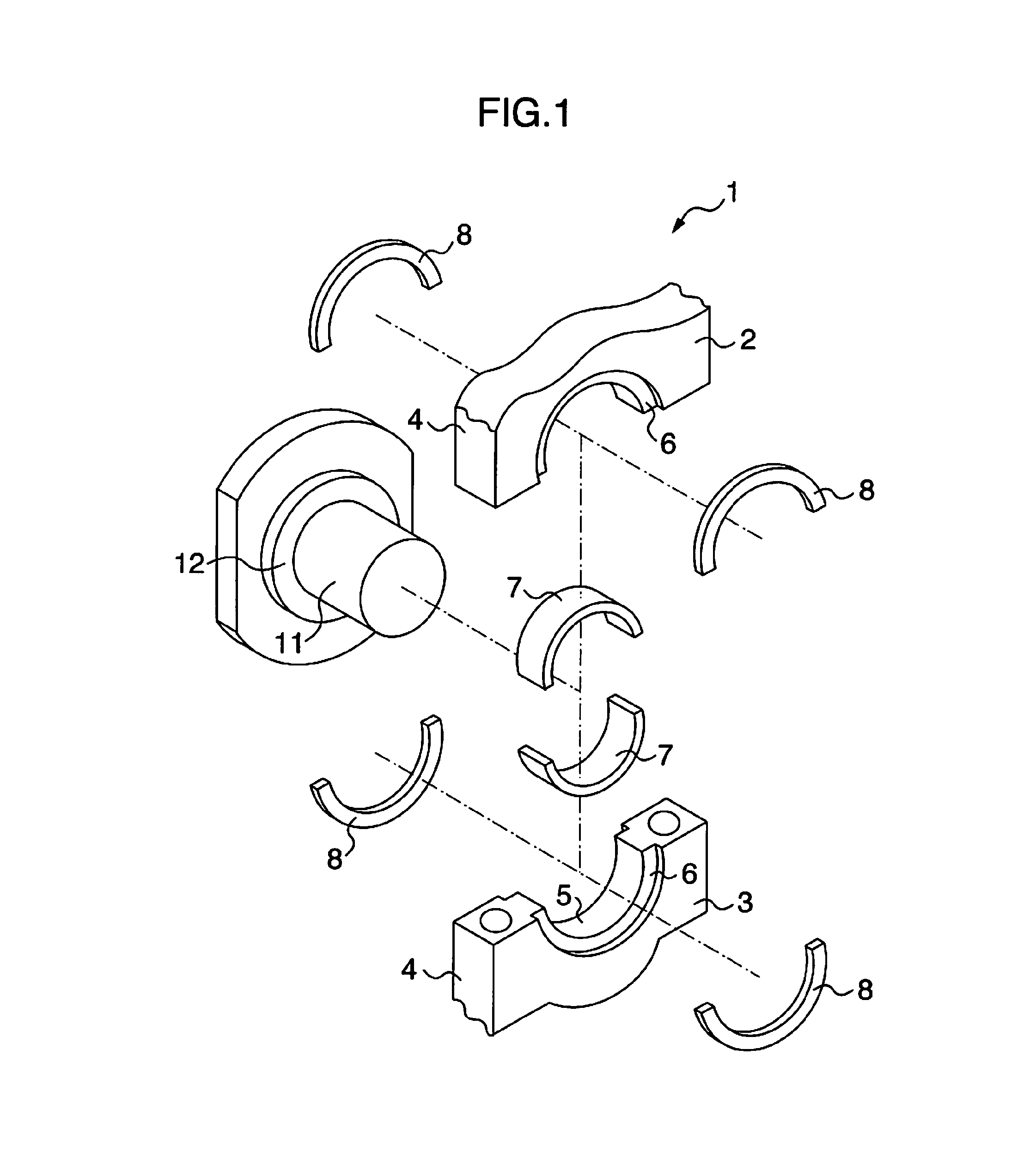

Position indicator

ActiveUS20080180092A1Improve seismic performanceReduce damage rateAnalogue/digital conversionElectric signal transmission systemsMetal powderDigital converter

A position indicator for use with a digitizer is provided. The position indicator generates a response to an alternating field received from the digitizer. The position indicator includes a core formed of a composition including a soft magnetic metal powder mixed with a resin binder, and at least one coil provided around the core configured to generate the response to the alternating field based on the alternating field received from the digitizer.

Owner:WACOM CO LTD

Dual braided catheter shaft

A dual braided catheter shaft includes a flat wire forming the inner braid, thereby potentially allowing for reduced radial thickness of the shaft. In one embodiment, the shaft (100) includes an inner polymer jacket (104), an inner braid (106) formed on the inner jacket (104), an intermediate jacket (108) formed over the inner braid (106), an outer braid (110) formed on the intermediate jacket (108) and an outer jacket (112) formed on the outer braid (110). A preferred construction process involves extruding polymer material directly onto each of the inner and outer braids (106 and 110) so that little or no air gaps remain between the polymer material and the braids (106 and 110). The braiding parameters of the inner and outer braids (106 and 110) can be varied along the length of the catheter to provide varying mechanical properties.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

Position indicator

ActiveUS8674967B2Improve seismic performanceReduce damage rateCapacitor with electrode distance variationInductances/transformers/magnets manufactureEngineeringDigital converter

A position indicator for use with a digitizer is provided. The position indicator generates a response to an alternating field received from the digitizer. The position indicator includes a core formed of a composition including a soft magnetic metal powder mixed with a resin binder, and at least one coil provided around the core configured to generate the response to the alternating field based on the alternating field received from the digitizer.

Owner:WACOM CO LTD

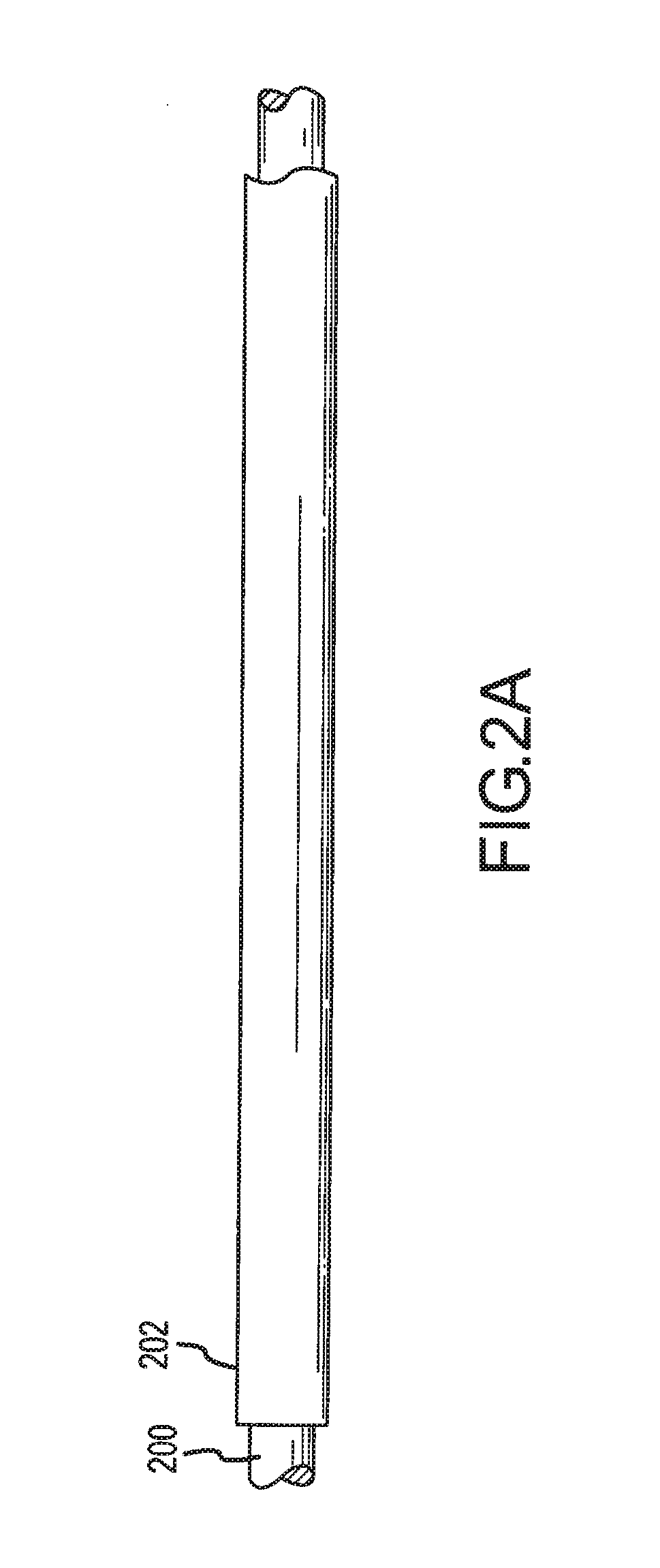

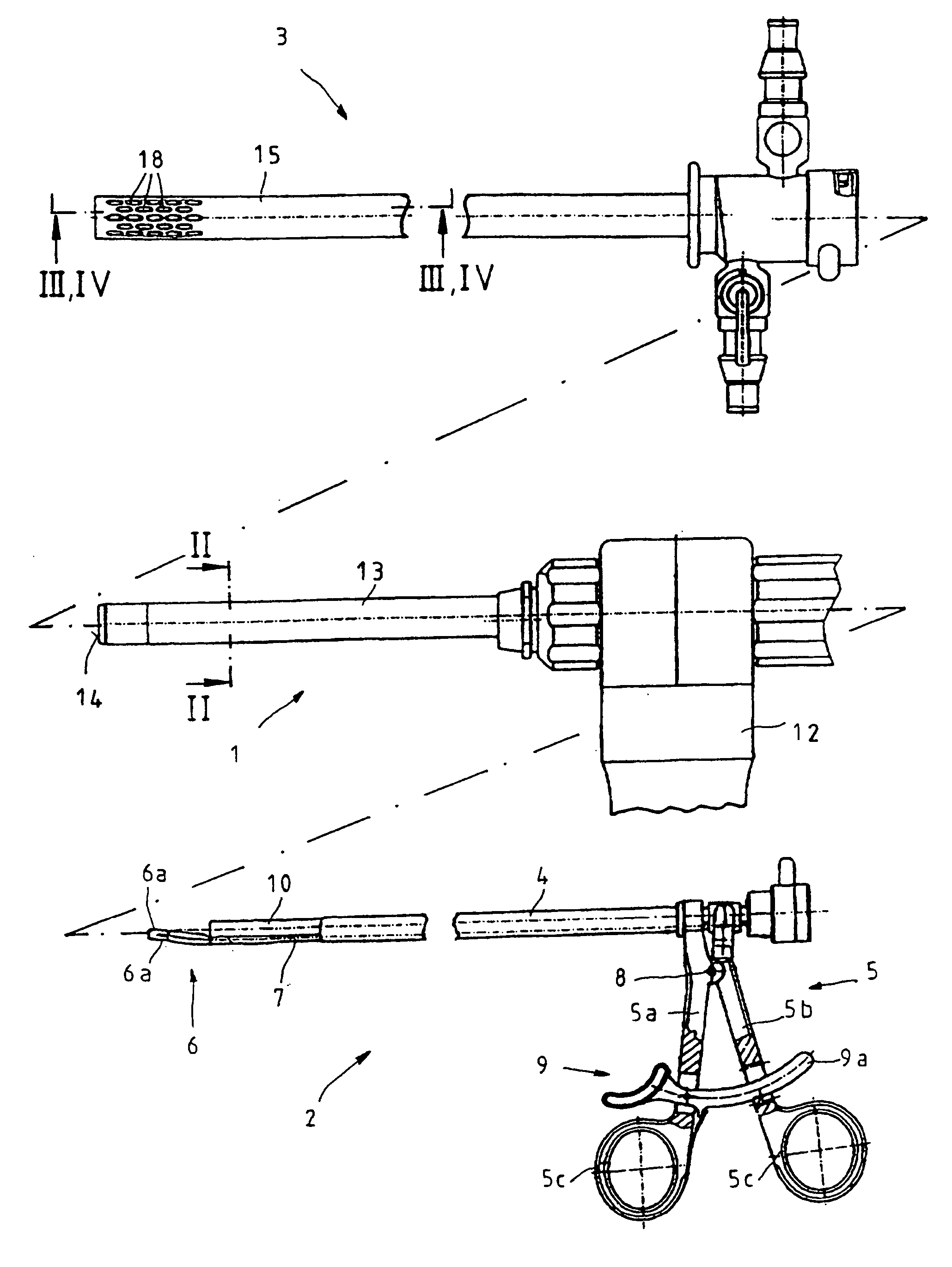

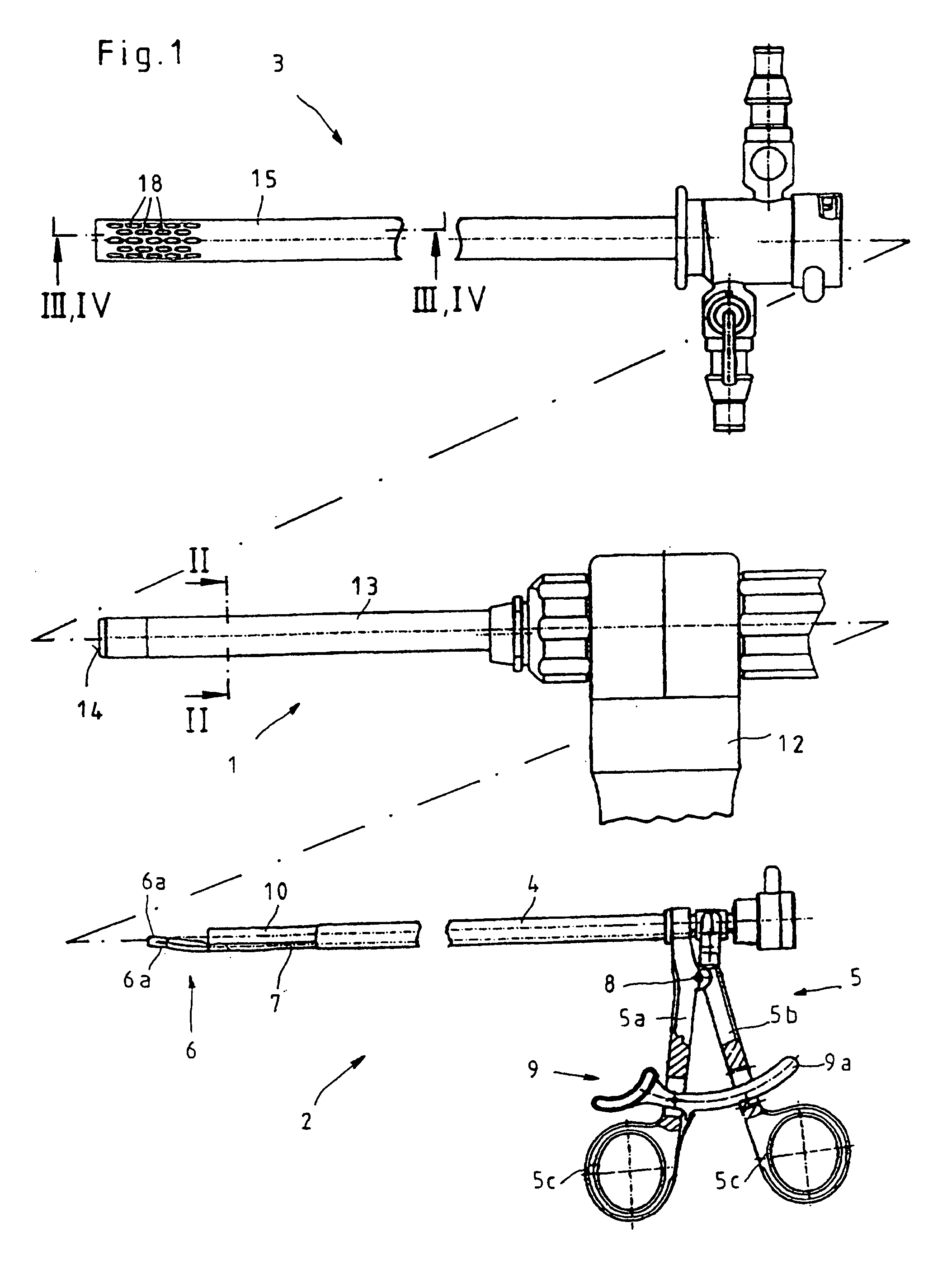

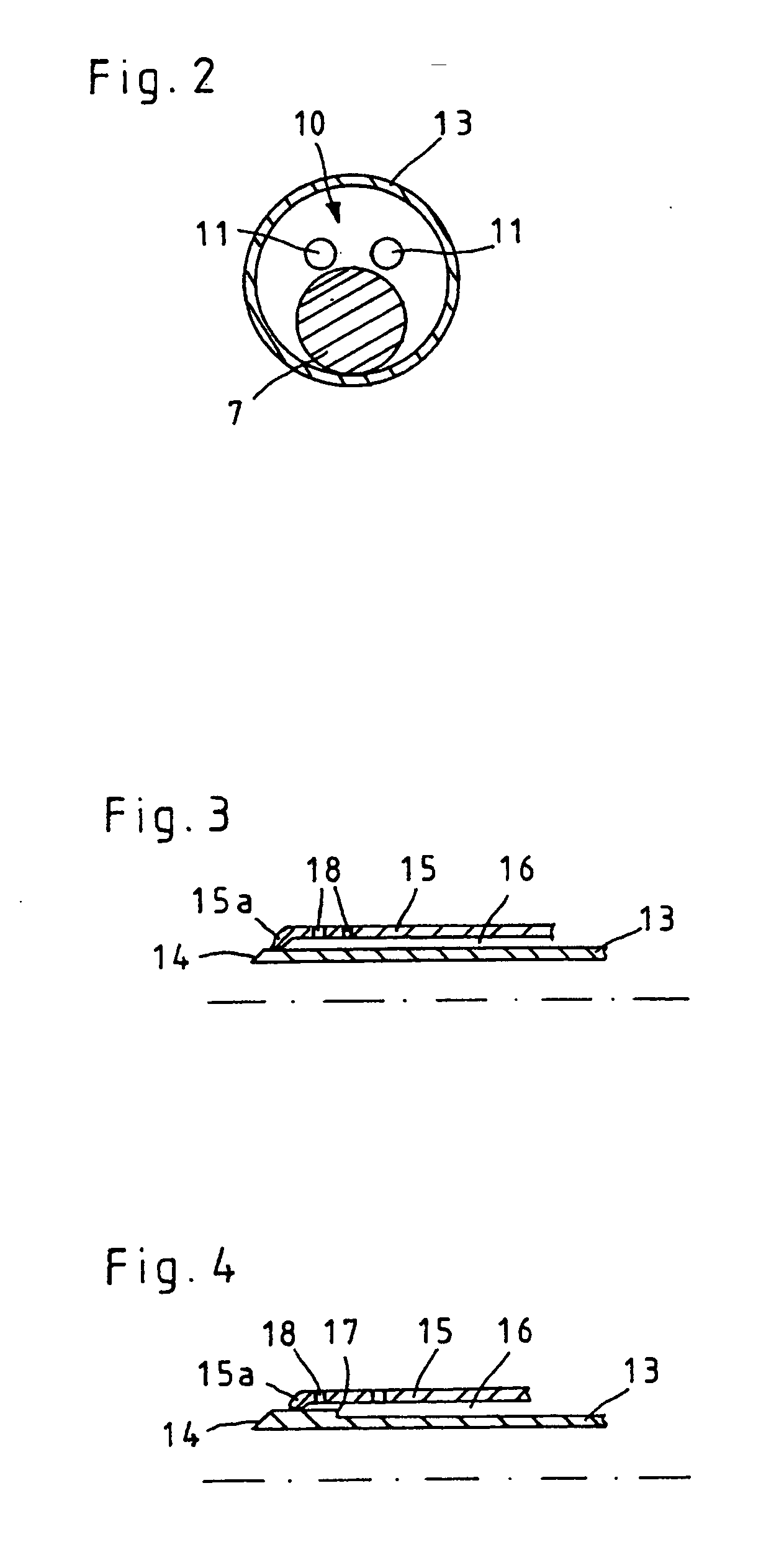

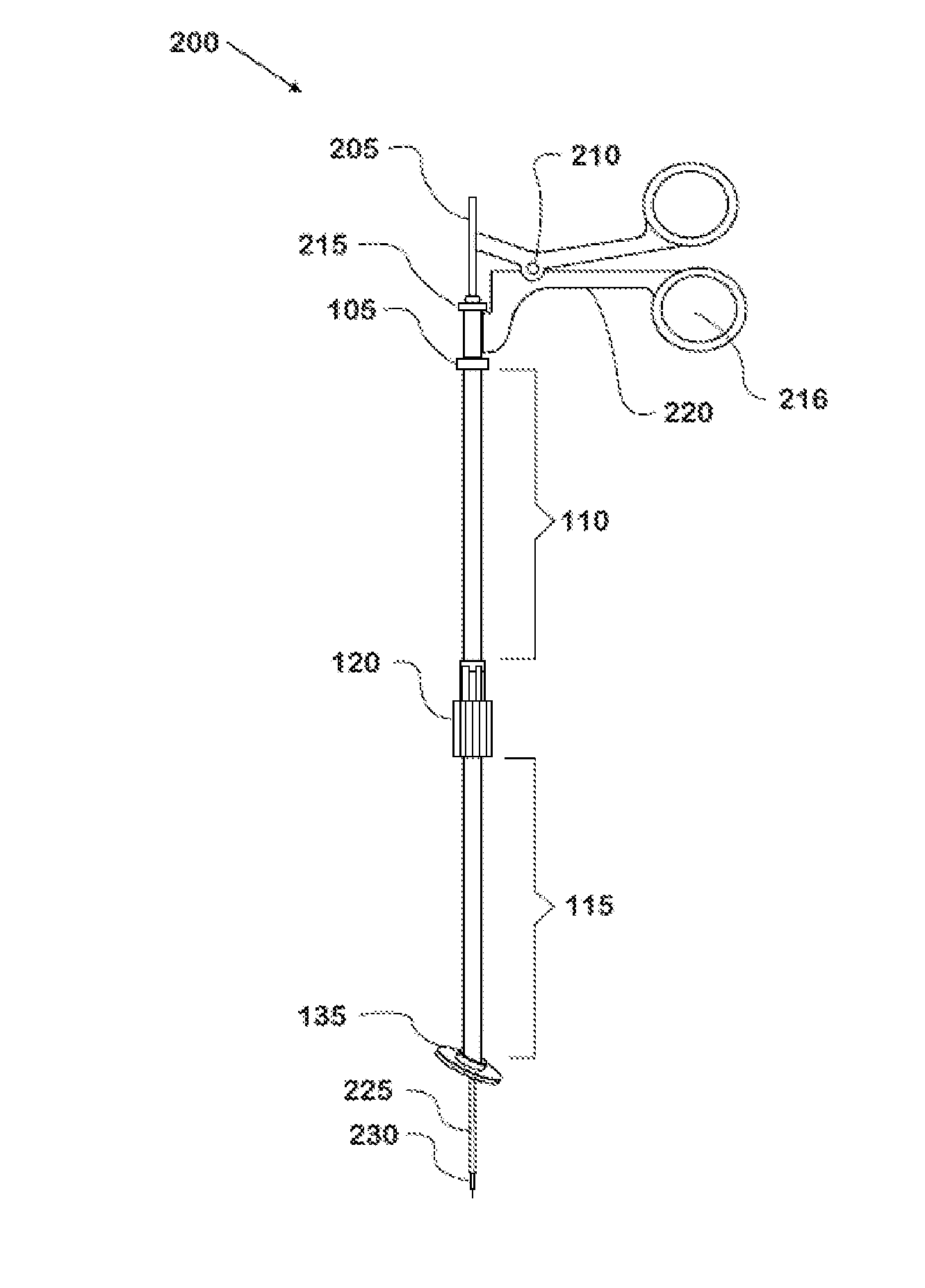

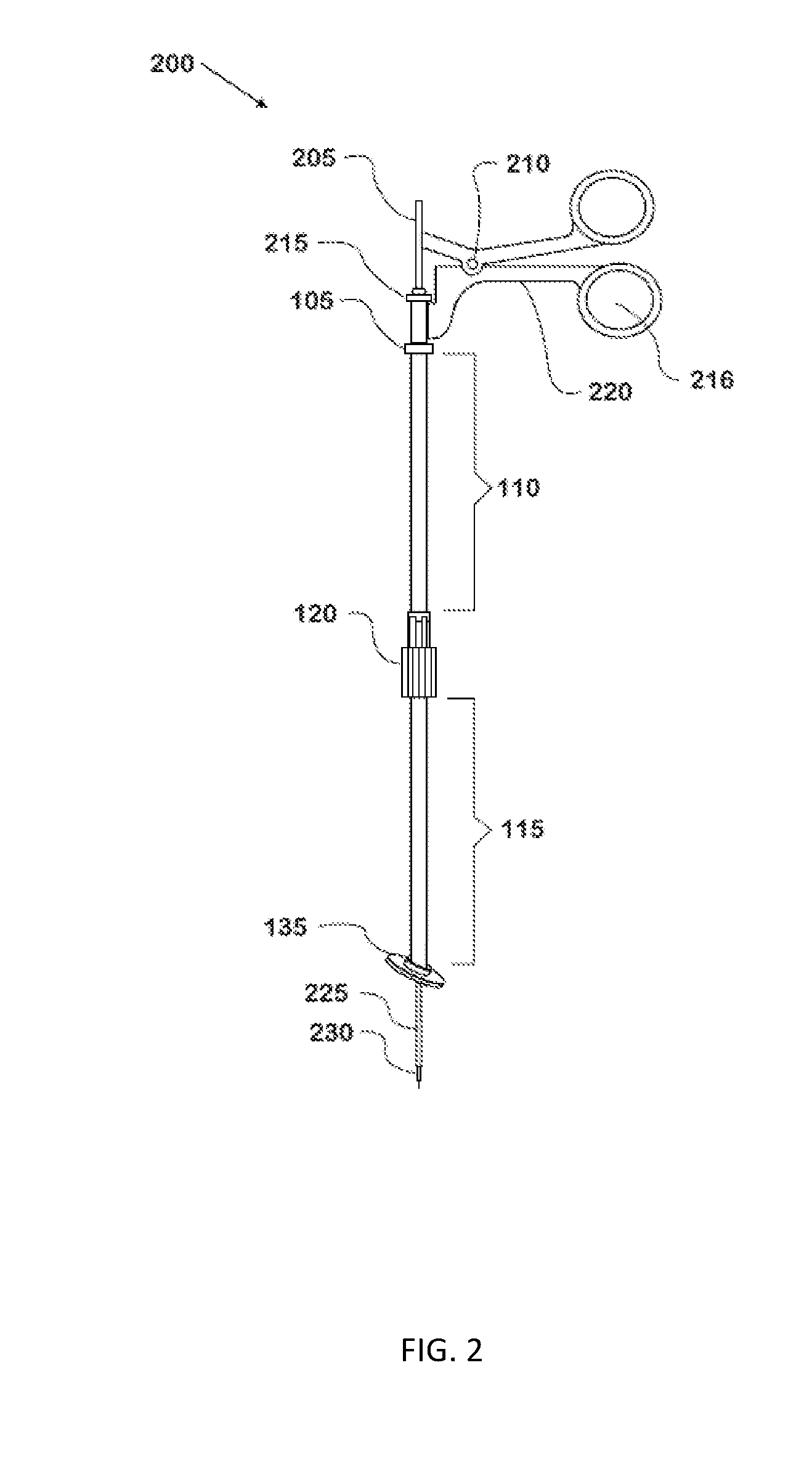

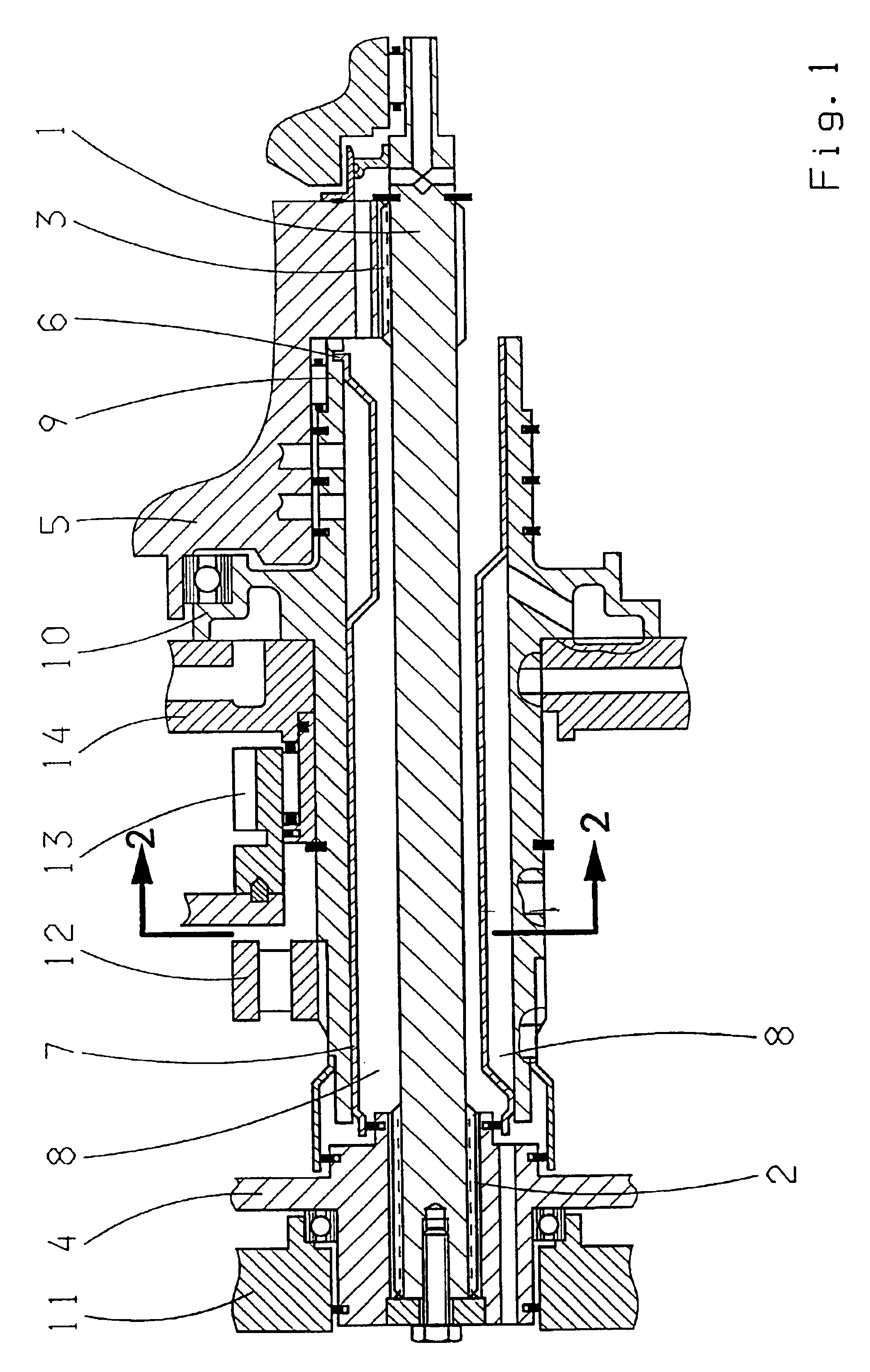

Surgical instrument system

The invention relates to a surgical instrument system encompassing a morcellator with a hollow shaft on whose distal end a cutting blade is configured, as well as a gripping instrument with a shaft on whose distal end a tool consisting of at least two jaw members and on whose proximal end a handle consisting of at least two gripping members is configured to activate the tool, in such a way that the gripping instrument can be inserted into the hollow shaft of the morcellator so that it can slide in the longitudinal direction of the morcellator shaft. To ensure versatile application along with simple structure, it is proposed with the invention that the morcellator with the insertable gripping instrument can be inserted into a hollow shaft of an additional medical instrument, in particular a resectoscope, and that an additional irrigation and / or suction canal is configured between the shaft of the morcellator and the inside of the hollow shaft of the additional medical instrument.

Owner:KARL STORZ GMBH & CO KG

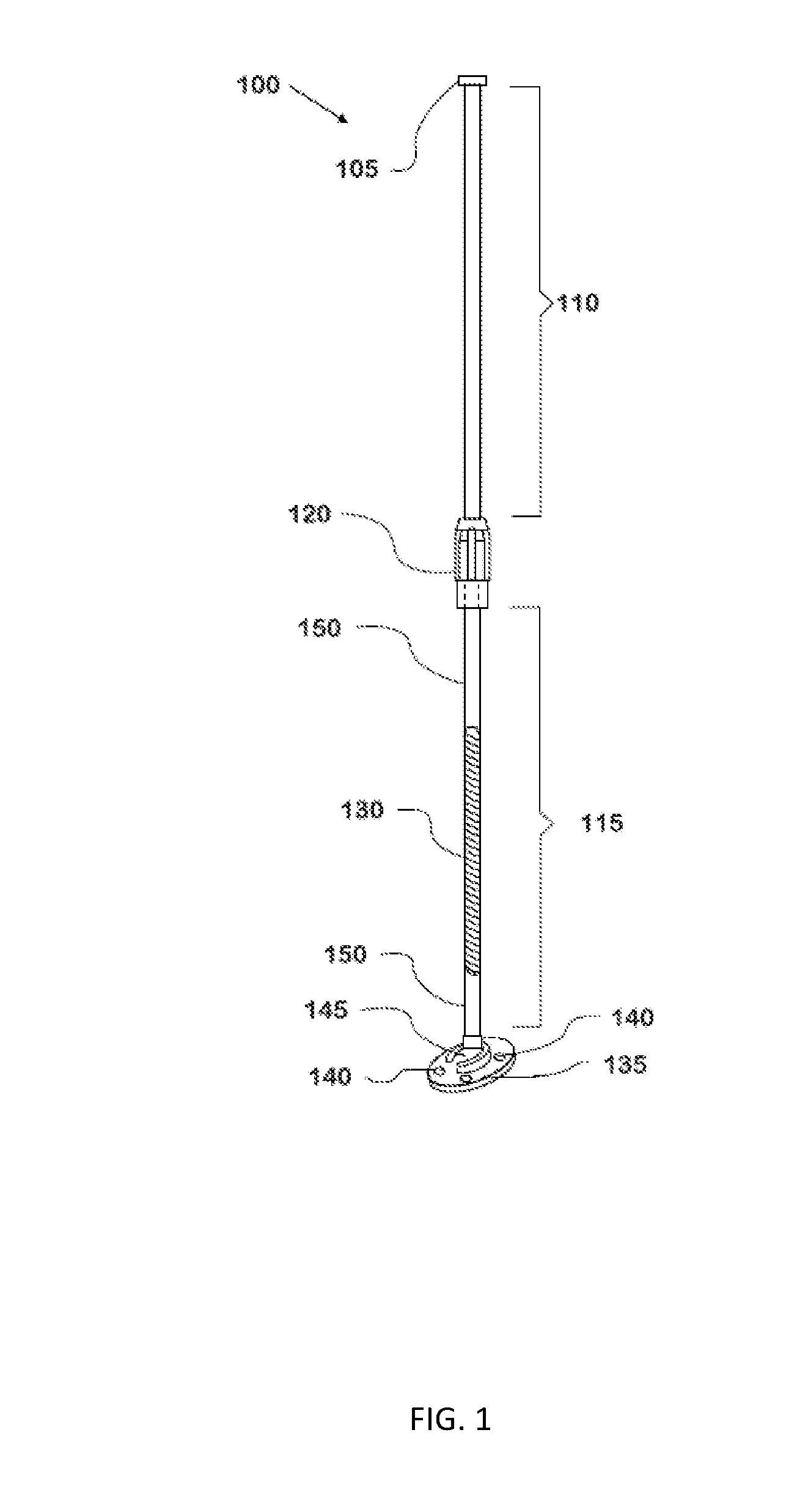

Instrument sleeve strengthening device

ActiveUS20160256036A1Function increaseHigh strengthSurgical needlesLaproscopesLess invasive surgeryEngineering

The present invention is directed towards surgical devices and a method used in minimally invasive surgery whereby a device is incorporated into or onto an instrument to strengthen its shaft and improve its functionality in minimally invasive surgery. The primary goal of the invention is to increase the strength and rigidity of an instrument by using a specially designed sleeve that strengthens the instrument, thereby reducing its ability to bend and increasing its load carrying capacity. The invention will provide a system that gives extra strength and rigidity to small instrument shafts, so that surgeons can still safely and reliably perform their procedures, but can also use incisions that are as small as possible.

Owner:NEW WAVE ENDO-SURGICAL CORP

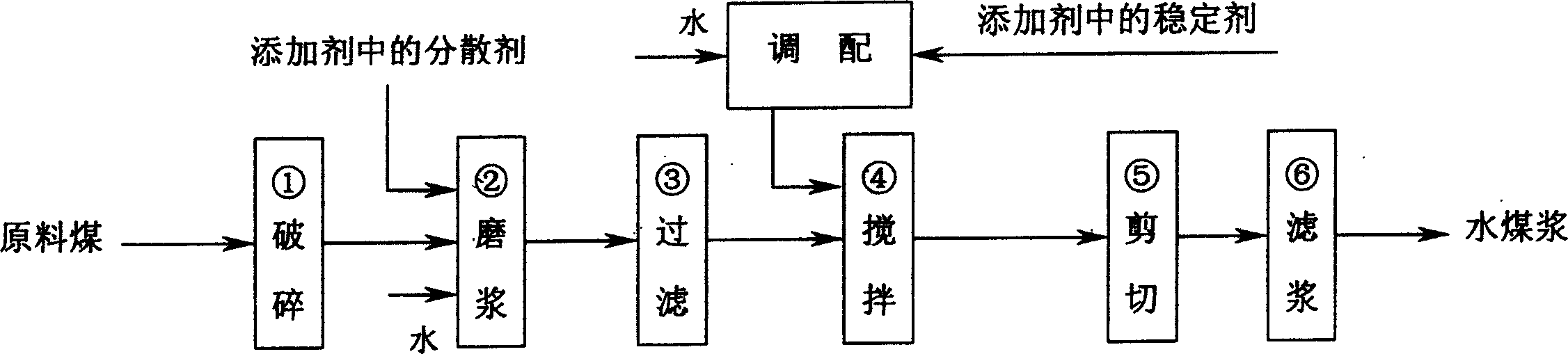

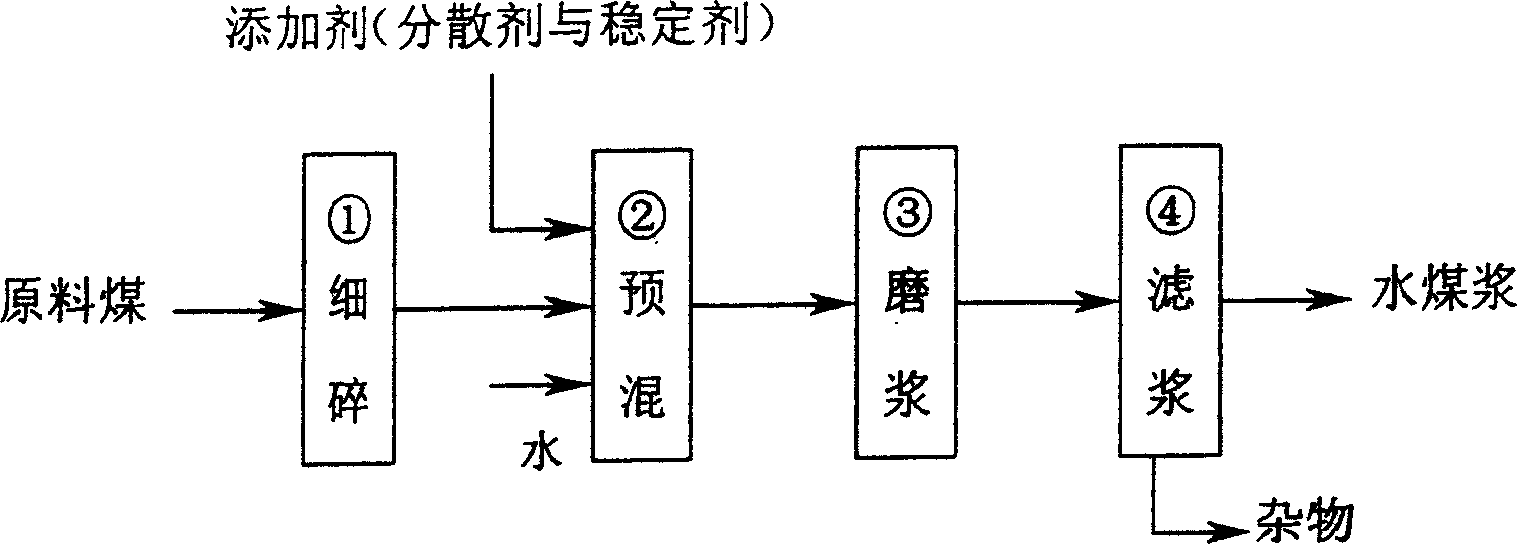

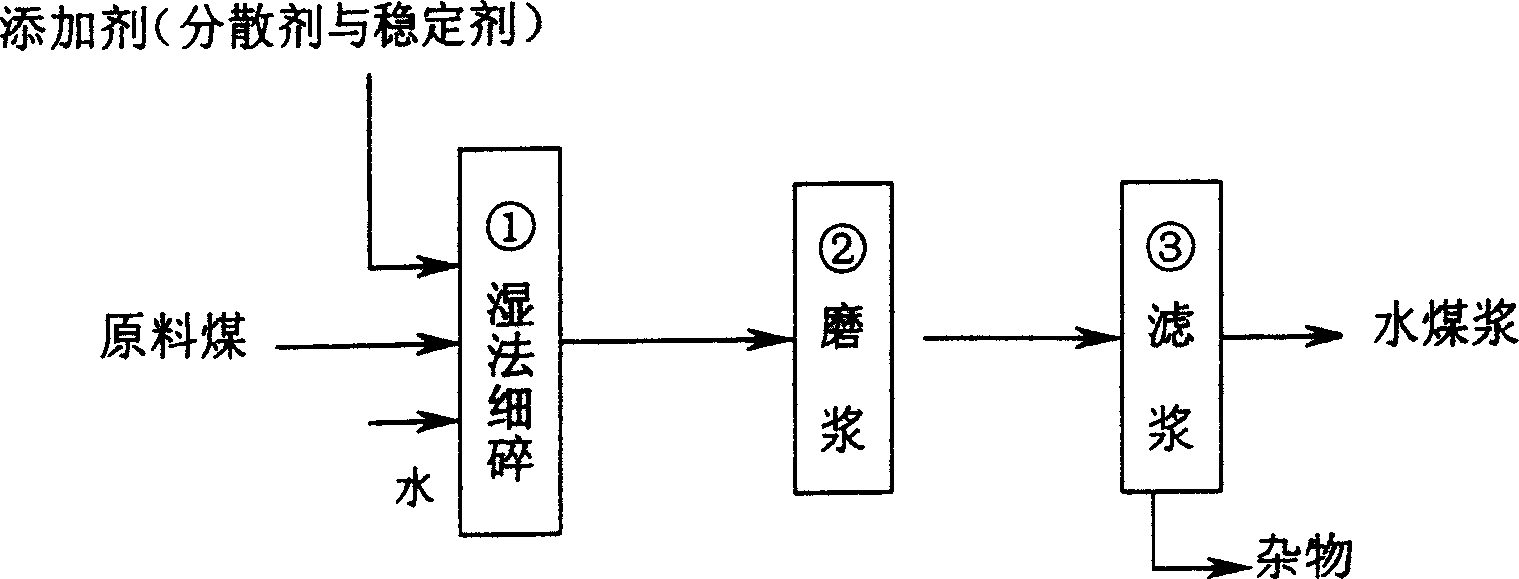

Preparation process of high producing rate, energy-saving water coal paste

InactiveCN1597878ASmall granularityAvoid efficiencyLiquid carbonaceous fuelsLump/pulverulent fuel preparationCoal waterFilling rate

The invention is a high-productivity energy-saving coal water fuel preparing method, relating to the ore wet-milling field, including the steps of finely crushing, premixing, pulp-milling and pulp-filtering, where the finely crushing step further reduces the particle size of raw material coal, the premixing step mixes raw material coal, coal water fuel additive and water together into a uniform strongly self-flowing pulp, the pulp-milling step has strong milling effect because of the increased filling rate of a miller, and the pulp-filtering step adopts centrifugal pulp filtering, so as to make the coal water fuel high-productivity and energy-saving.

Owner:北京柯林斯达能源技术开发有限公司

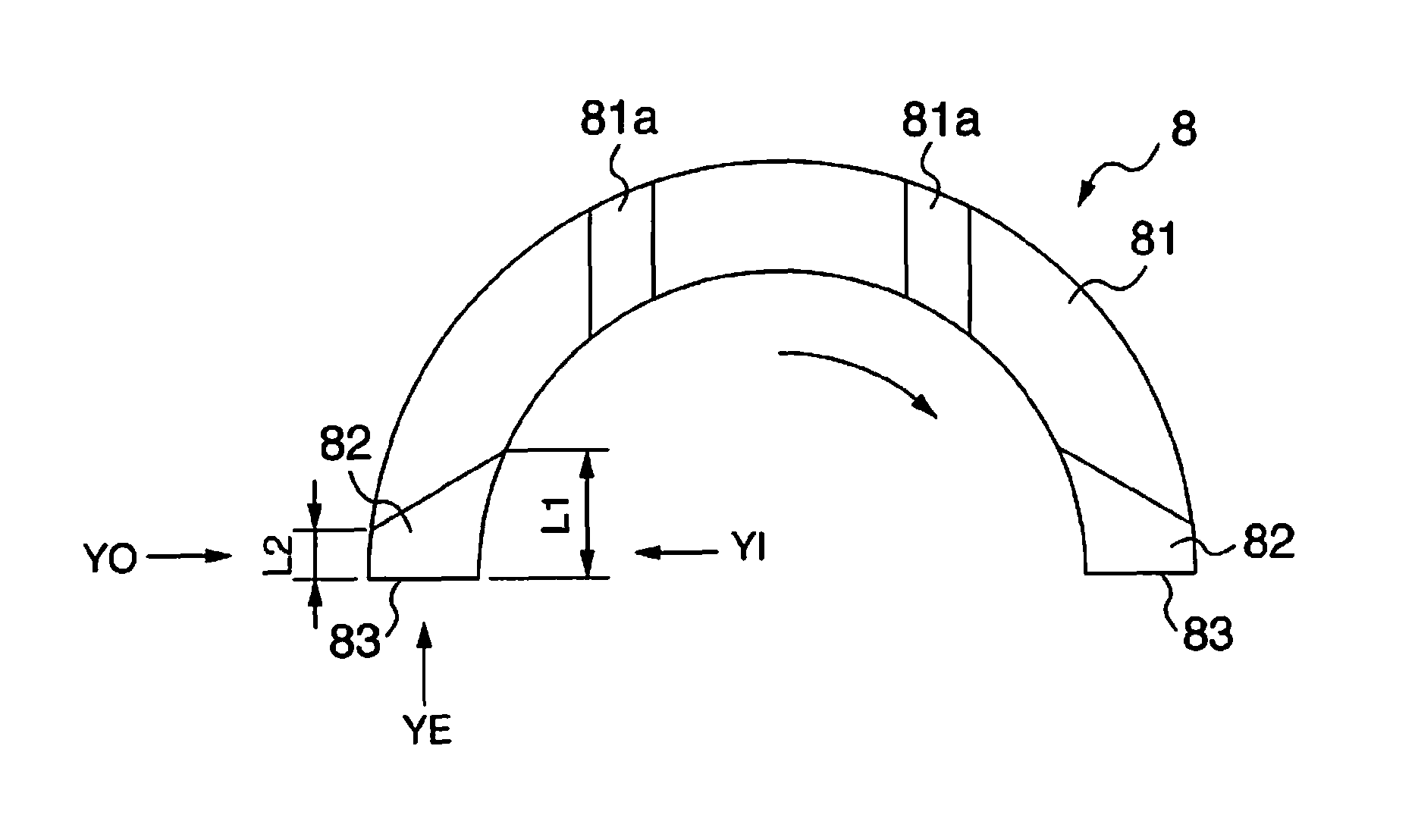

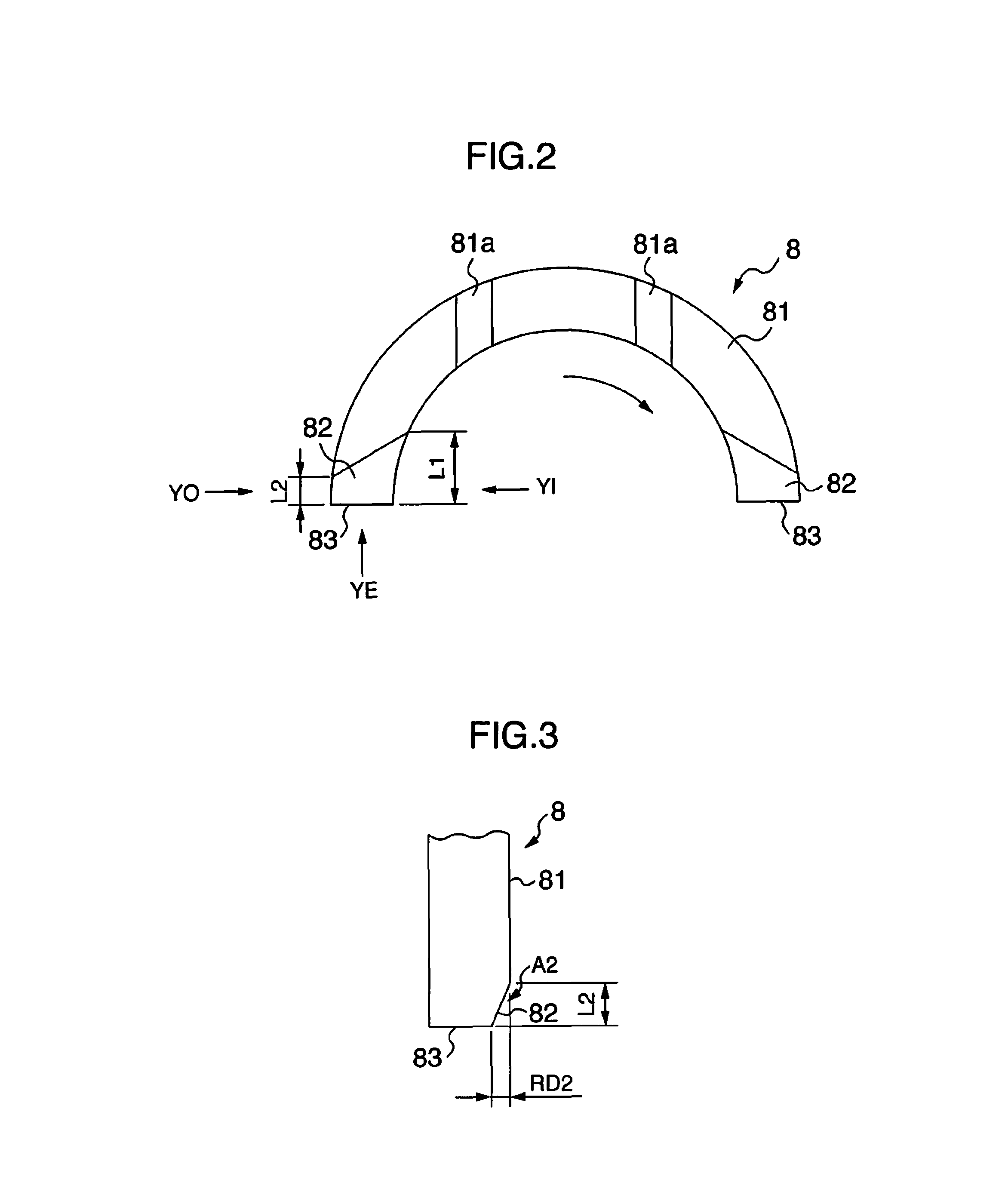

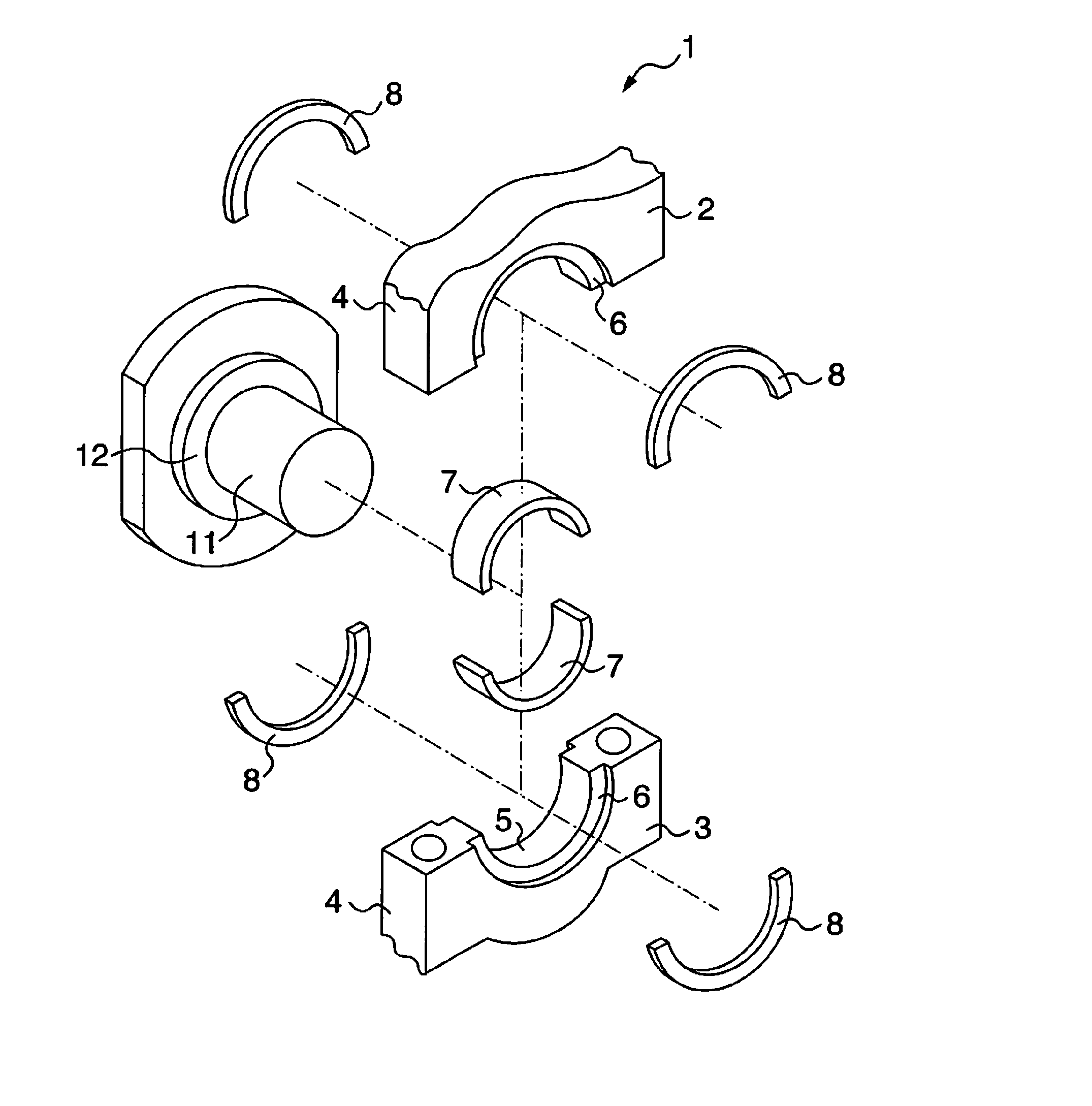

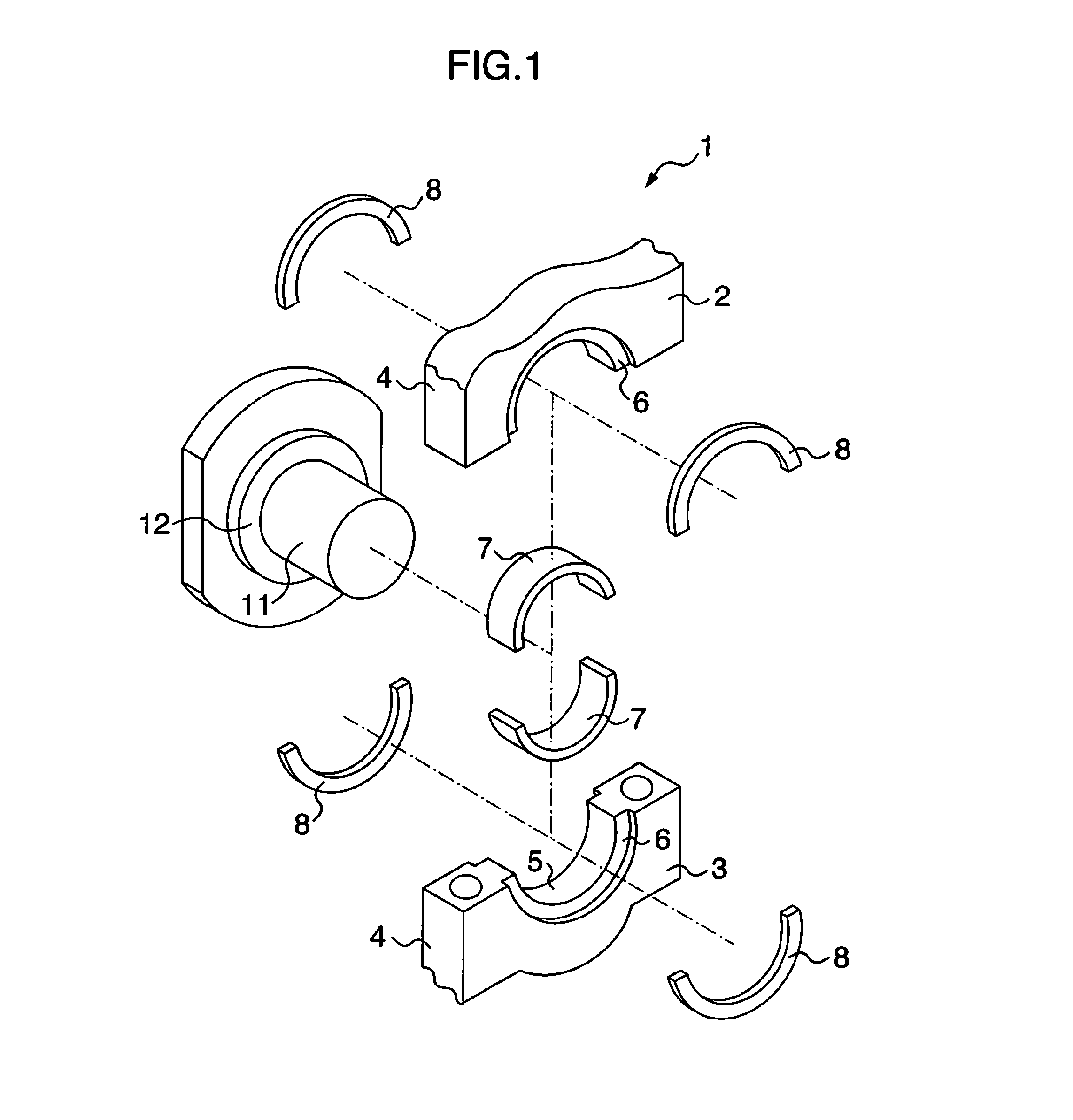

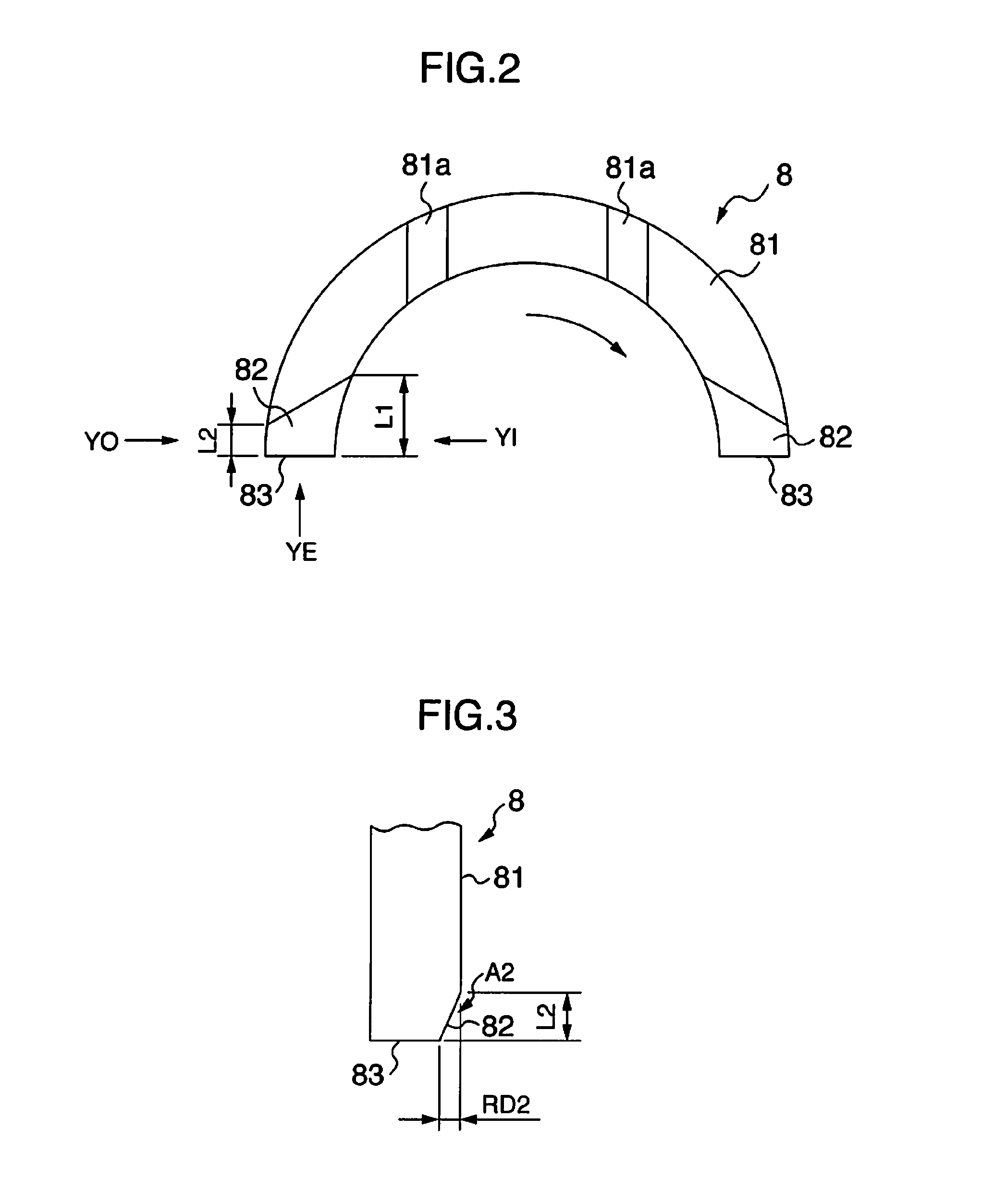

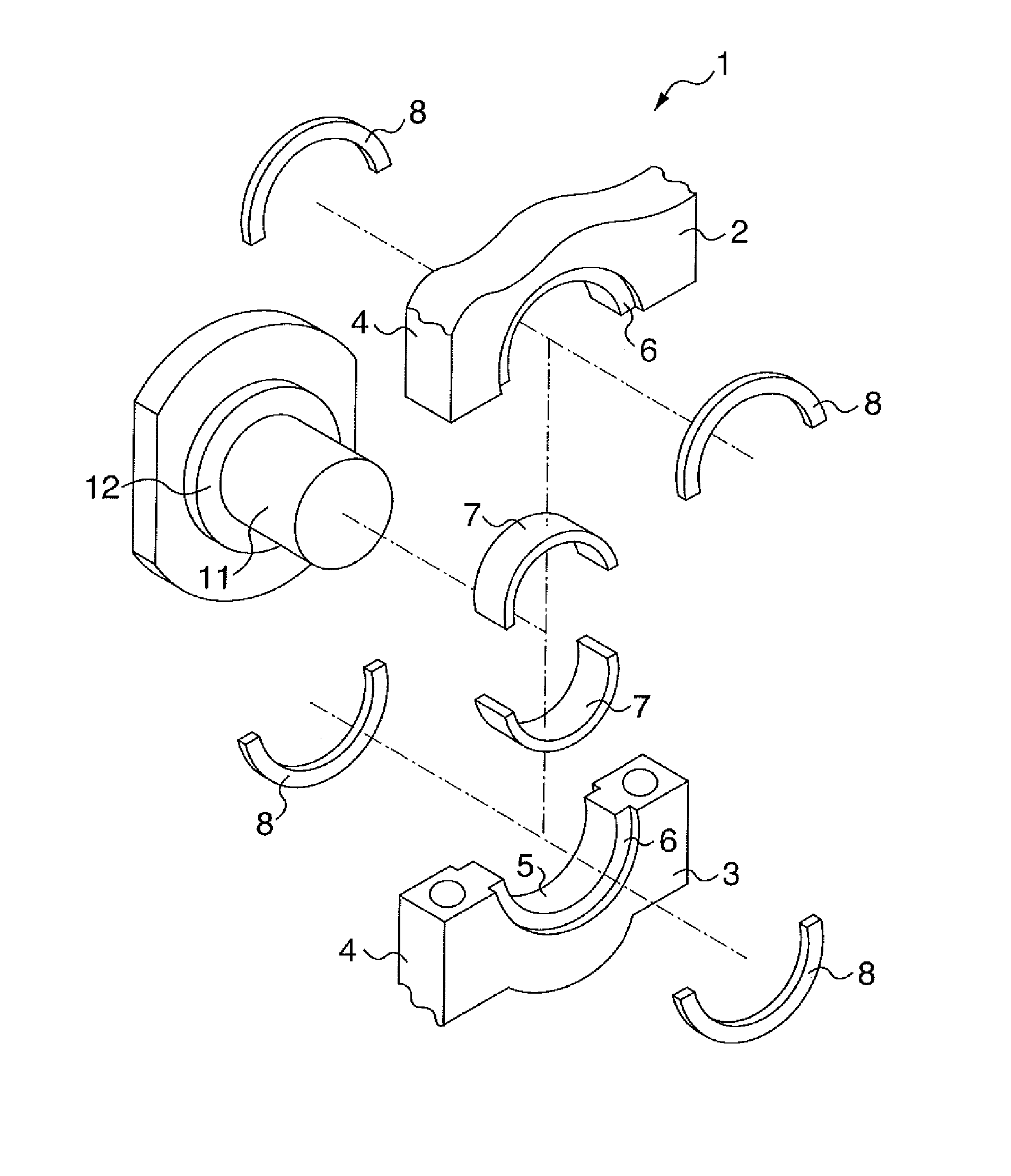

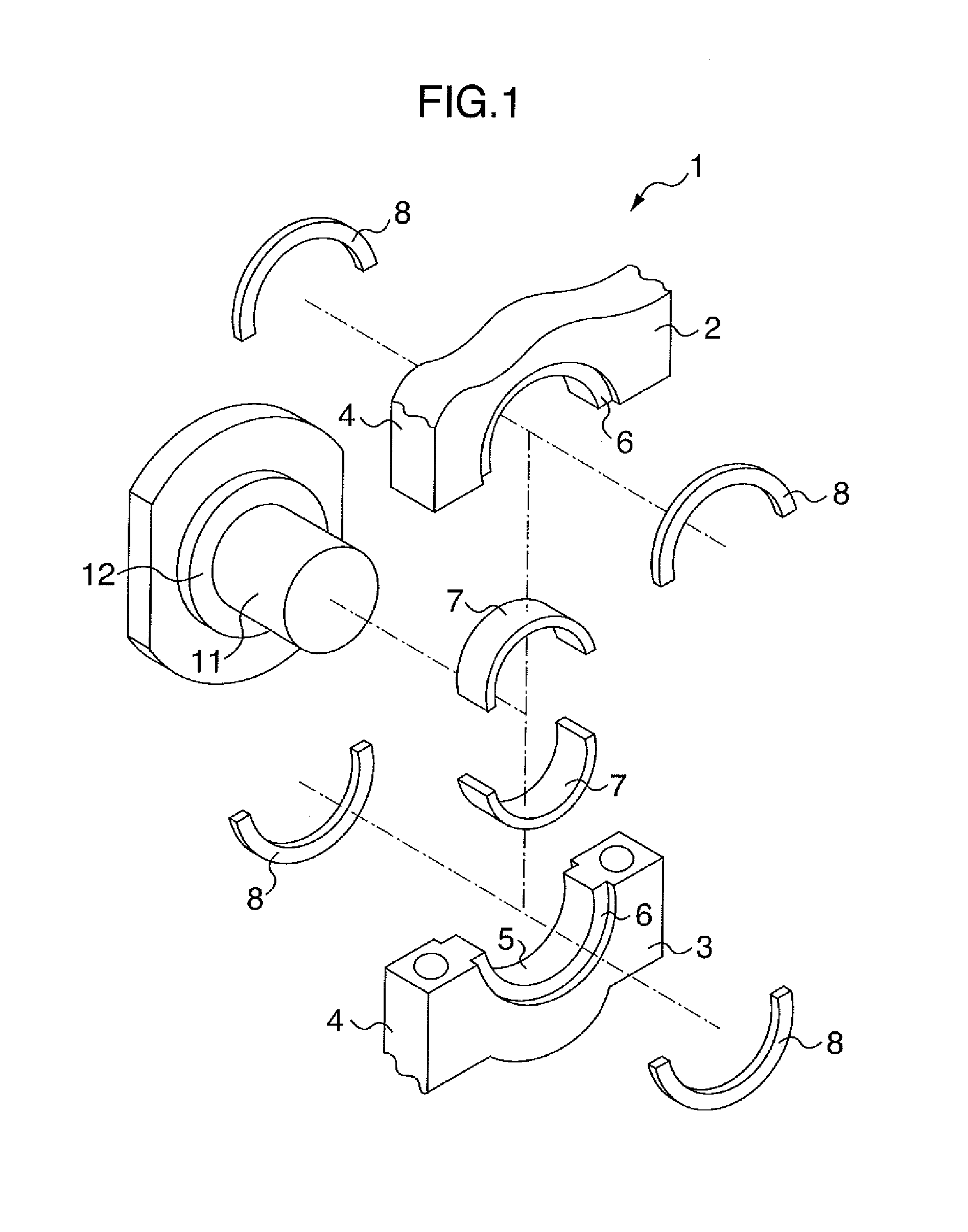

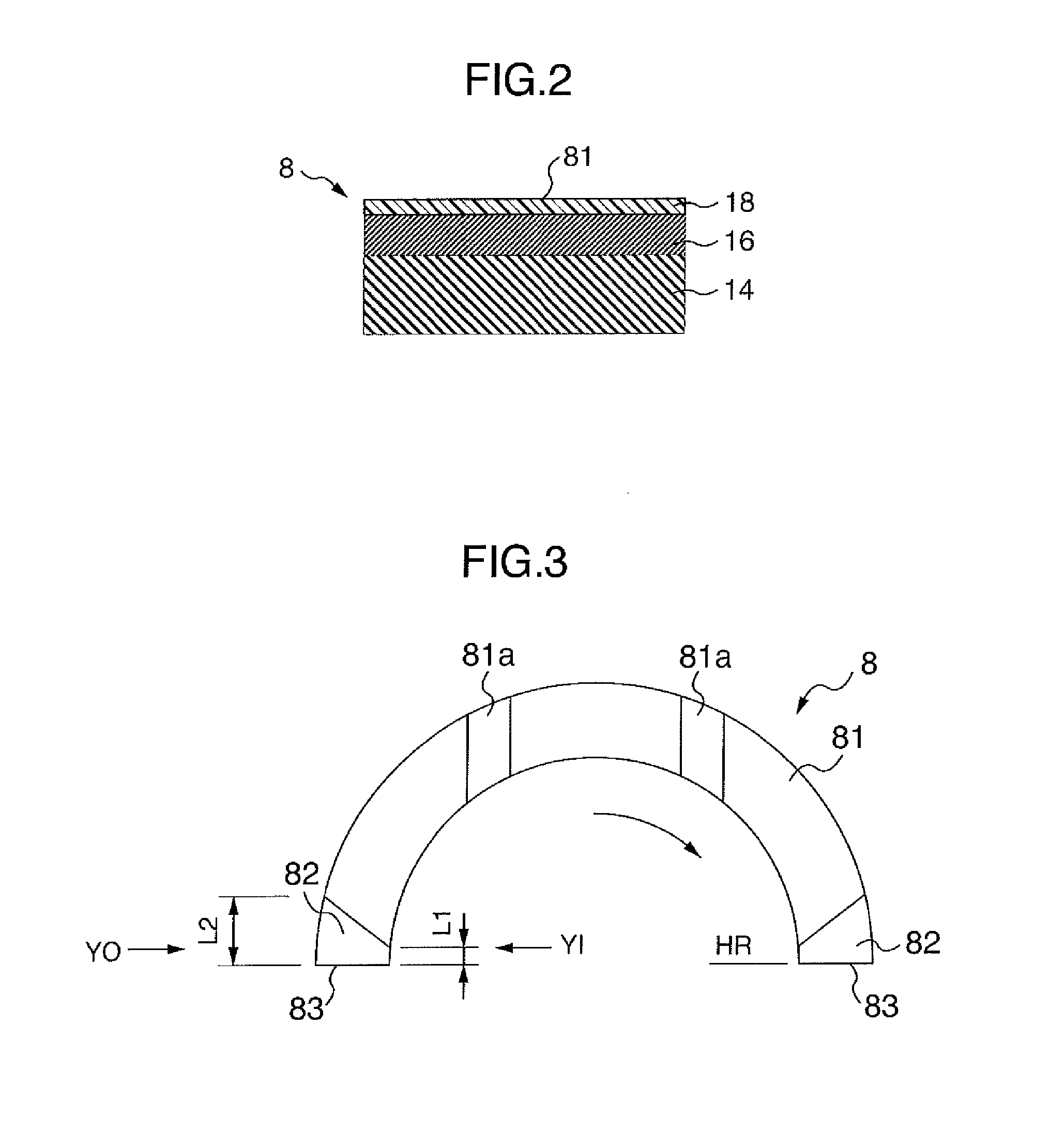

Half thrust bearing and bearing device

ActiveUS9188159B2Reduce rigidityIncrease deflectionCrankshaft bearingsShaftsThrust bearingAxial force

A half thrust bearing having a semicircular ring shape for receiving an axial force of a crankshaft of an internal combustion engine is provided. The half thrust bearing includes thrust reliefs formed adjacently to end surfaces on both sides in a circumferential direction on a slide surface side which receives the axial force so that wall thicknesses become thinner toward the end surfaces. The thrust relief on a rear side in a rotational direction of the crankshaft or both thrust reliefs are formed so that a length of the thrust relief in an inner end portion in a radial direction of the half thrust bearing is longer than a length of the thrust relief in an outer end portion in the radial direction of the half thrust bearing.

Owner:DAIDO METAL CO LTD

Half thrust bearing and bearing device

A half thrust bearing having a semicircular ring shape for receiving an axial force of a crankshaft of an internal combustion engine is provided. The half thrust bearing includes thrust reliefs formed adjacently to end surfaces on both sides in a circumferential direction on a slide surface side which receives the axial force so that wall thicknesses become thinner toward the end surfaces. The thrust relief on a rear side in a rotational direction of the crankshaft or both thrust reliefs are formed so that a length of the thrust relief in an inner end portion in a radial direction of the half thrust bearing is longer than a length of the thrust relief in an outer end portion in the radial direction of the half thrust bearing.

Owner:DAIDO METAL CO LTD

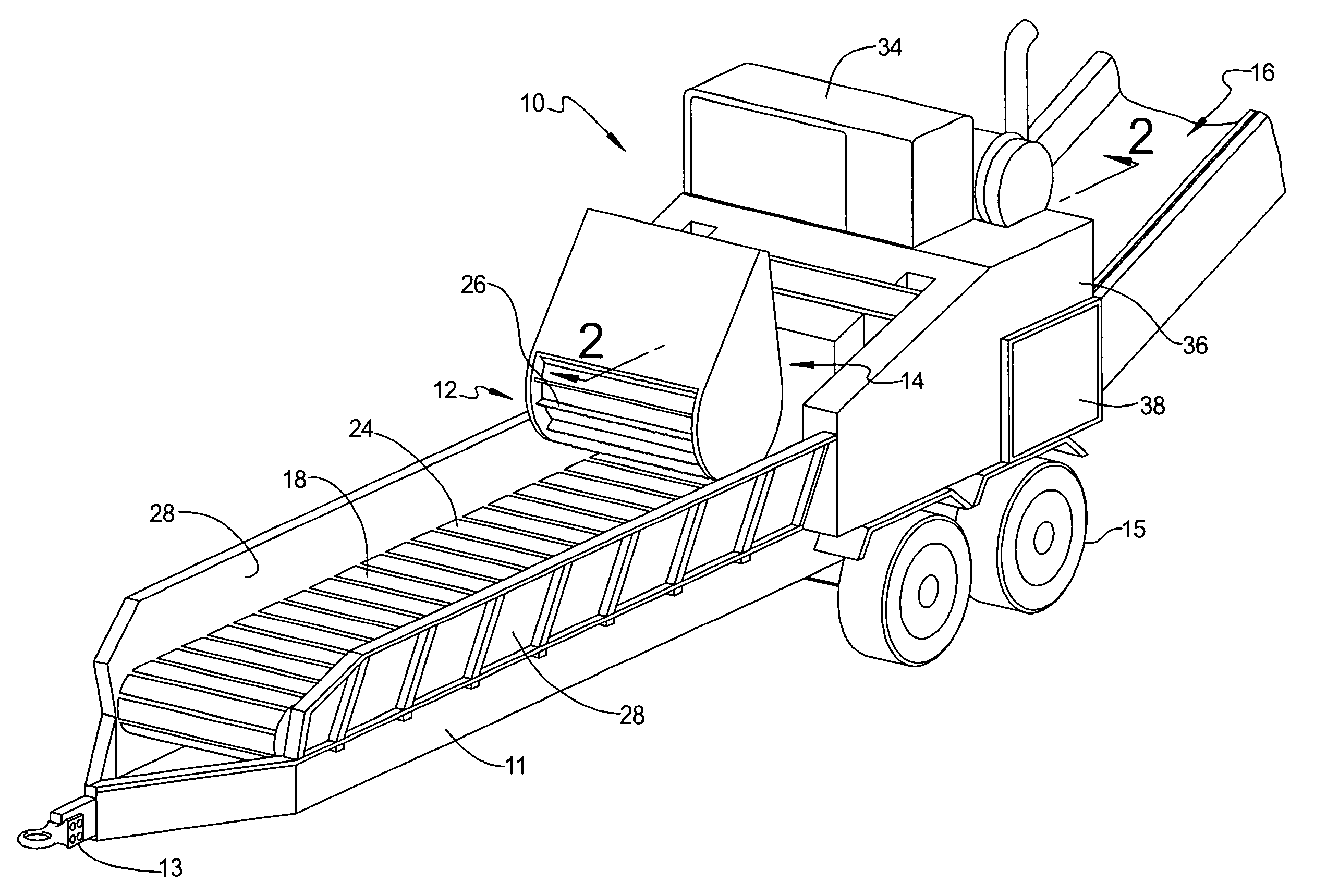

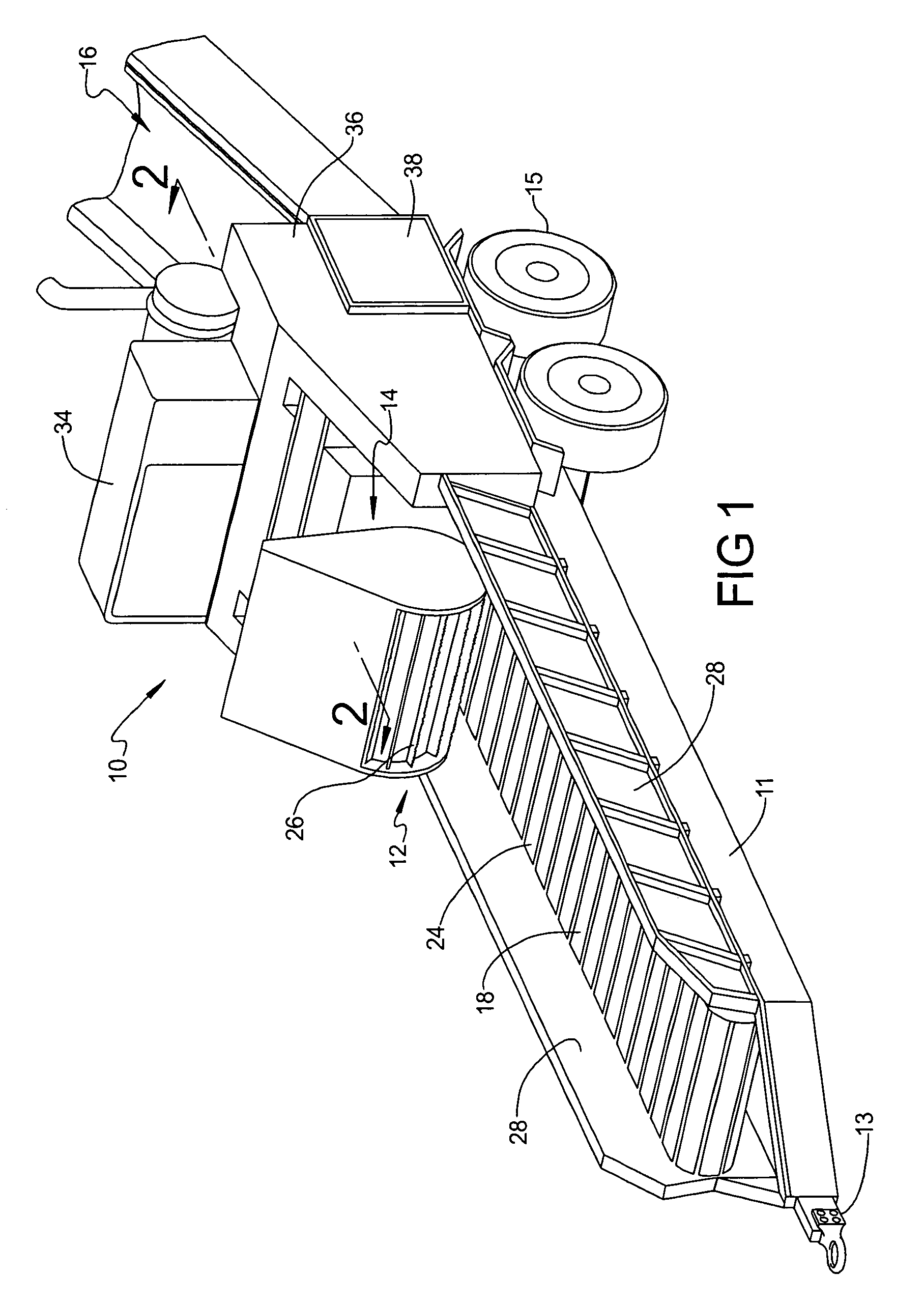

Rotatable assembly for machines

InactiveUS7163166B1Less-detrimental shock and concentrated loadingAvoid concentrated stressSortingGrain treatmentsEngineeringMechanical engineering

A rotatable assembly for a machine includes a rotatable shaft having a longitudinal axis and a rotatable member disposed about the shaft. The rotatable assembly also includes at least one first connecting member operatively mounted to the rotatable member and to the shaft at a first location along the longitudinal axis of the shaft. The rotatable assembly includes at least one second connecting member operatively mounted to the rotatable member and located at a second location spaced from the first location along the longitudinal axis of the shaft. The rotatable assembly further includes a bearing operatively mounted to the shaft, wherein the second connecting member is operatively mounted to the bearing to allow the shaft to twist without permanent deformation when a concentrated load is subjected to the shaft as the rotor is rotated.

Owner:SMORACY

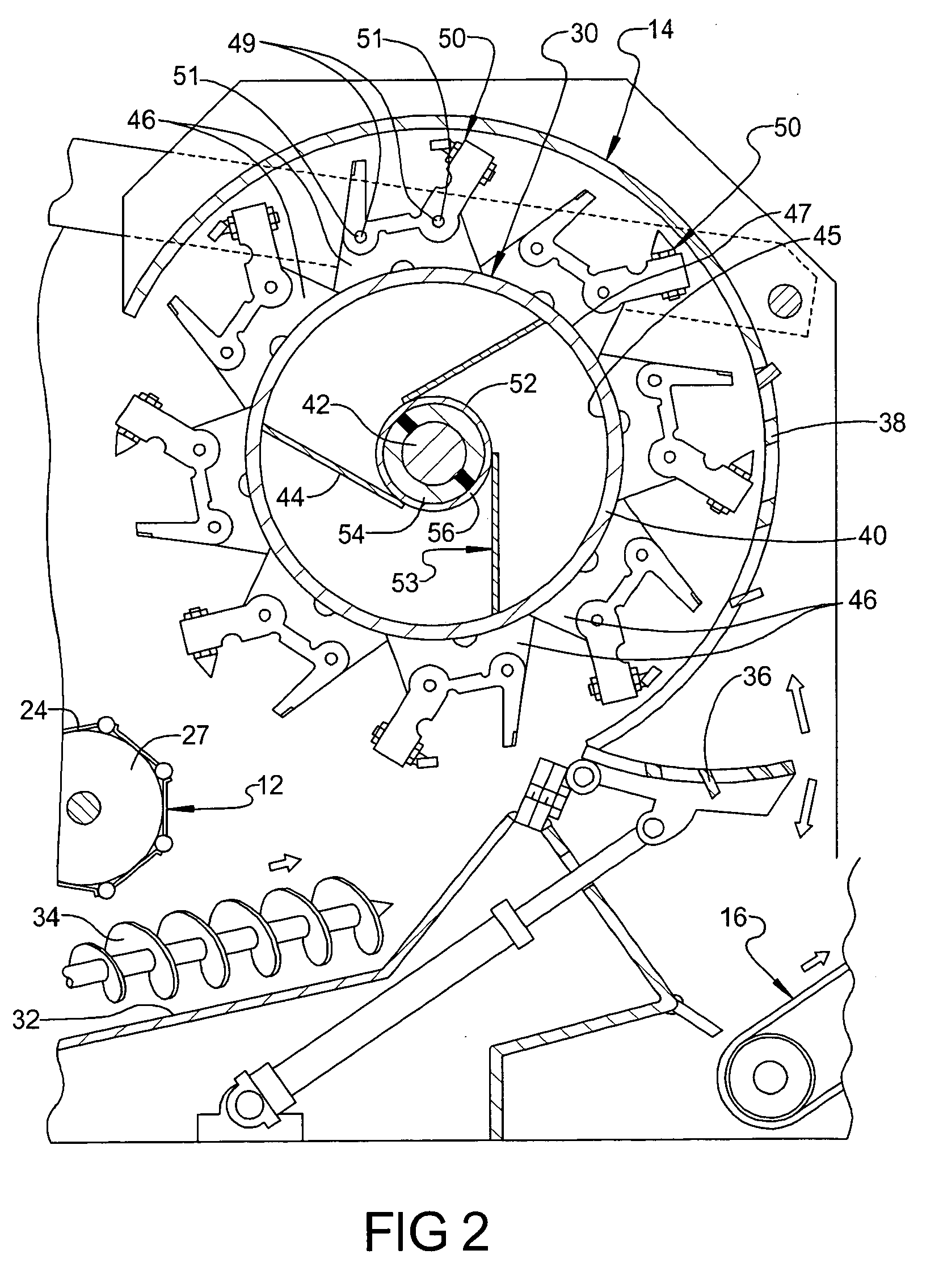

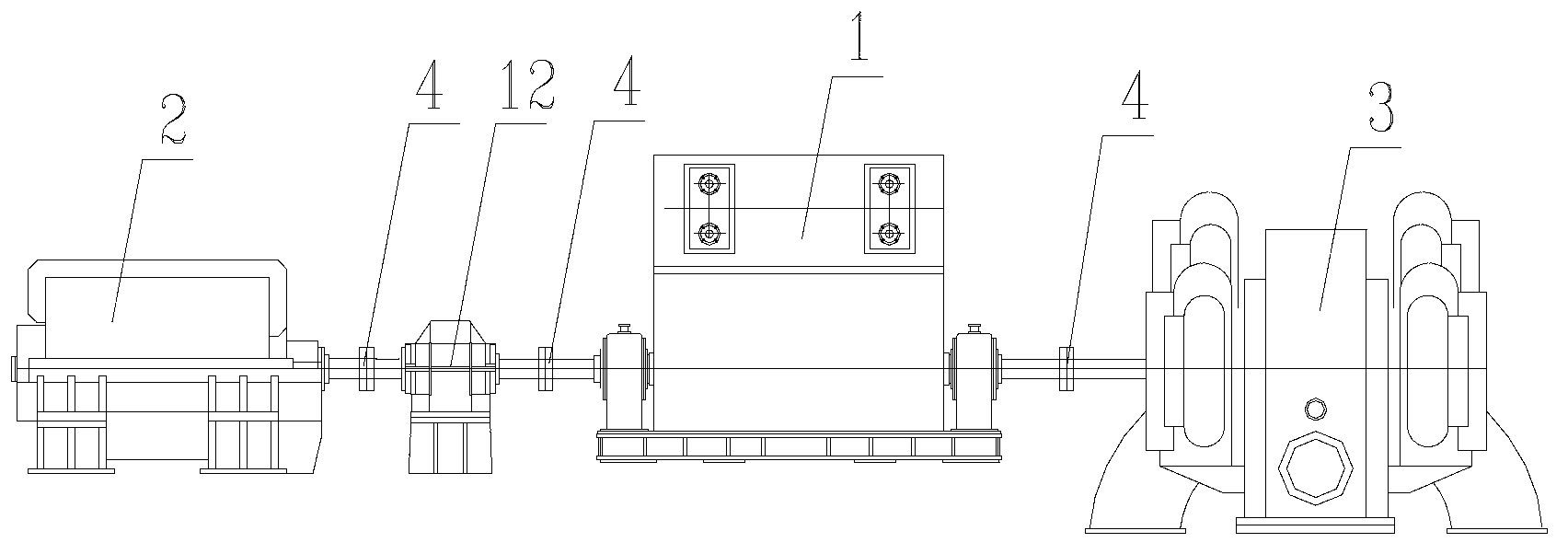

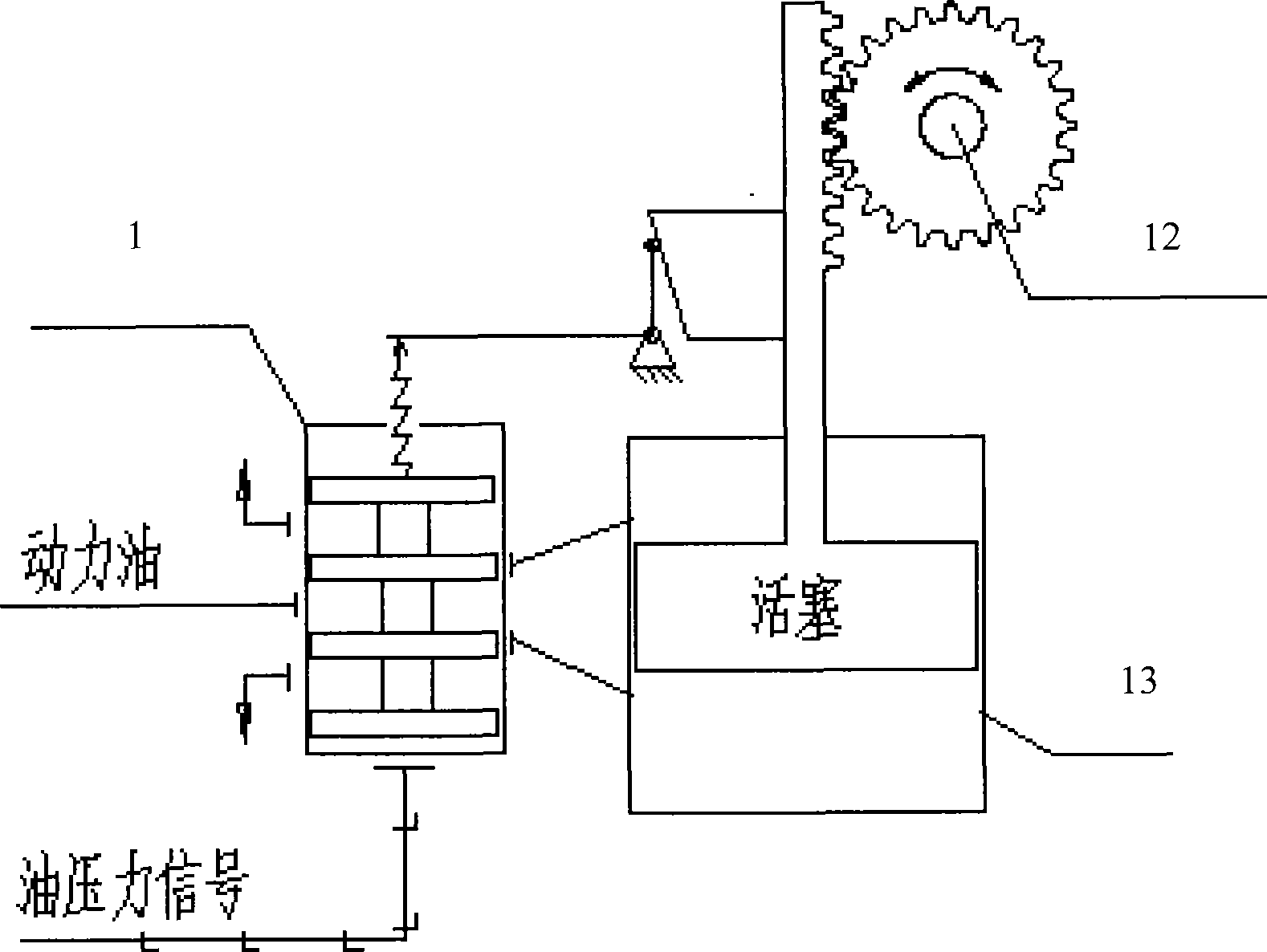

Single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit

ActiveCN102979751ADetermine the numberSingle stage pressure ratio highPump installationsNon-positive displacement fluid enginesProcess systemsCoupling

A single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit comprises a double extended shafts type driving device. A diaphragm coupling which is used for a left extended shaft of the double extended shafts type driving device is directly connected with a single-shaft type low pressure cylinder. The diaphragm coupling which is used for a right extended shaft of the double extended shafts type driving device is connected with a multiple-shaft type high pressure cylinder. Carbon dioxide gas enters into a first stage impeller of the single-shaft type low pressure cylinder, after four stage compression, the carbon dioxide gas flows out through a back outlet pipeline of a fourth stage of the low pressure cylinder and then enters into a first stage impeller of the multiple-shaft type high pressure cylinder. After another four stage compression, the carbon dioxide gas is discharged from a fourth stage impeller of the multiple-shaft type high pressure cylinder 3 and enters into subsequent process system. The single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit can save energy by over 10 % compared with the existing single-shaft plusing multiple-shaft type device and is high in security and stability compared with the multiple-shaft type carbon dioxide gas compressor in foreign.

Owner:西安赛尔机泵成套设备有限责任公司

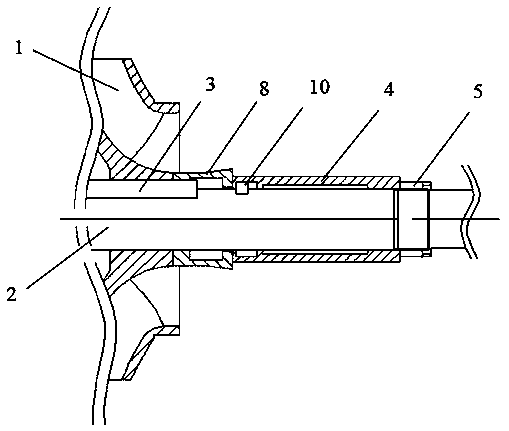

Engines VVT phase machine oil supply duct structure

InactiveCN101158298AHigh strengthSolve the lack of spaceMachines/enginesNon-mechanical valveControl valvesCamshaft

The invention provides an engine VVT phaser oil supply passage structure. An oil trough ring is arranged on the internal wall of a shaft hole of a camshaft of a cylinder cover and a corresponding internal wall of a camshaft cover; the oil trough is communicated with an oil hole of an oil inlet passage or an oil return passage to which the camshaft leads an internal oil chamber and an external oil chamber of the VVT phaser; the oil trough of the cylinder cover is provided with an oil hole communicated with an engine oil control valve; meanwhile, the external wall of the shaft neck of the camshaft is also provided with an oil trough ring; the oil trough is communicated with the oil hole of the oil inlet passage or the oil return passage to which the camshaft leads the internal oil chamber and the external oil chamber of the VVT phaser, and is also communicated with the oil hole leading to the engine oil control valve and arranged at a corresponding position of the cylinder cover. As only one oil trough is arranged on the cylinder cover, the structure reserves sufficient space for the design and installation of the shaft cover of the camshaft; the other oil trough is arranged on the shaft diameter of the camshaft, which is beneficial for reducing the diameter of the shaft, improving the strength of the position of the camshaft and reducing the processing difficulty.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

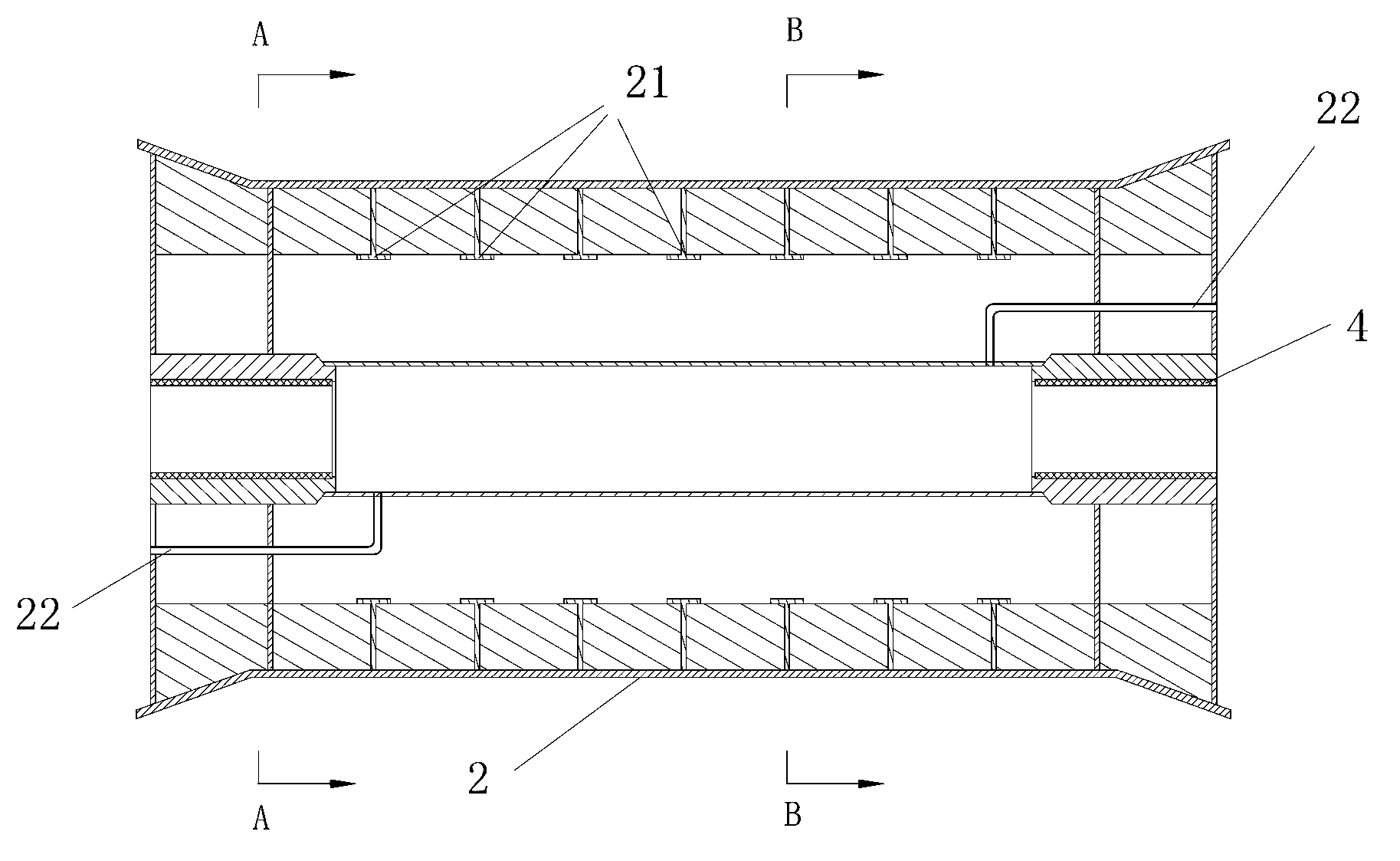

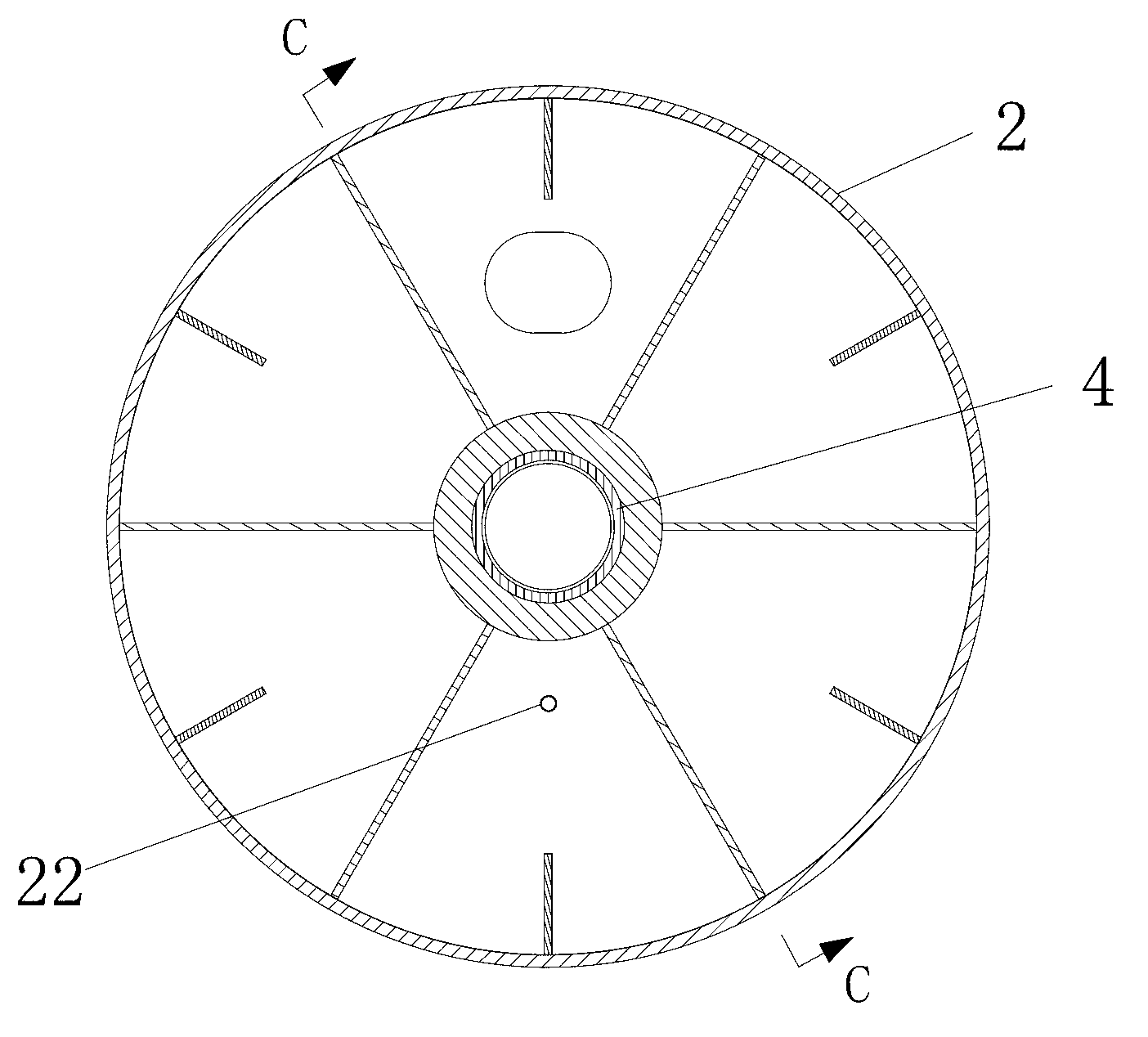

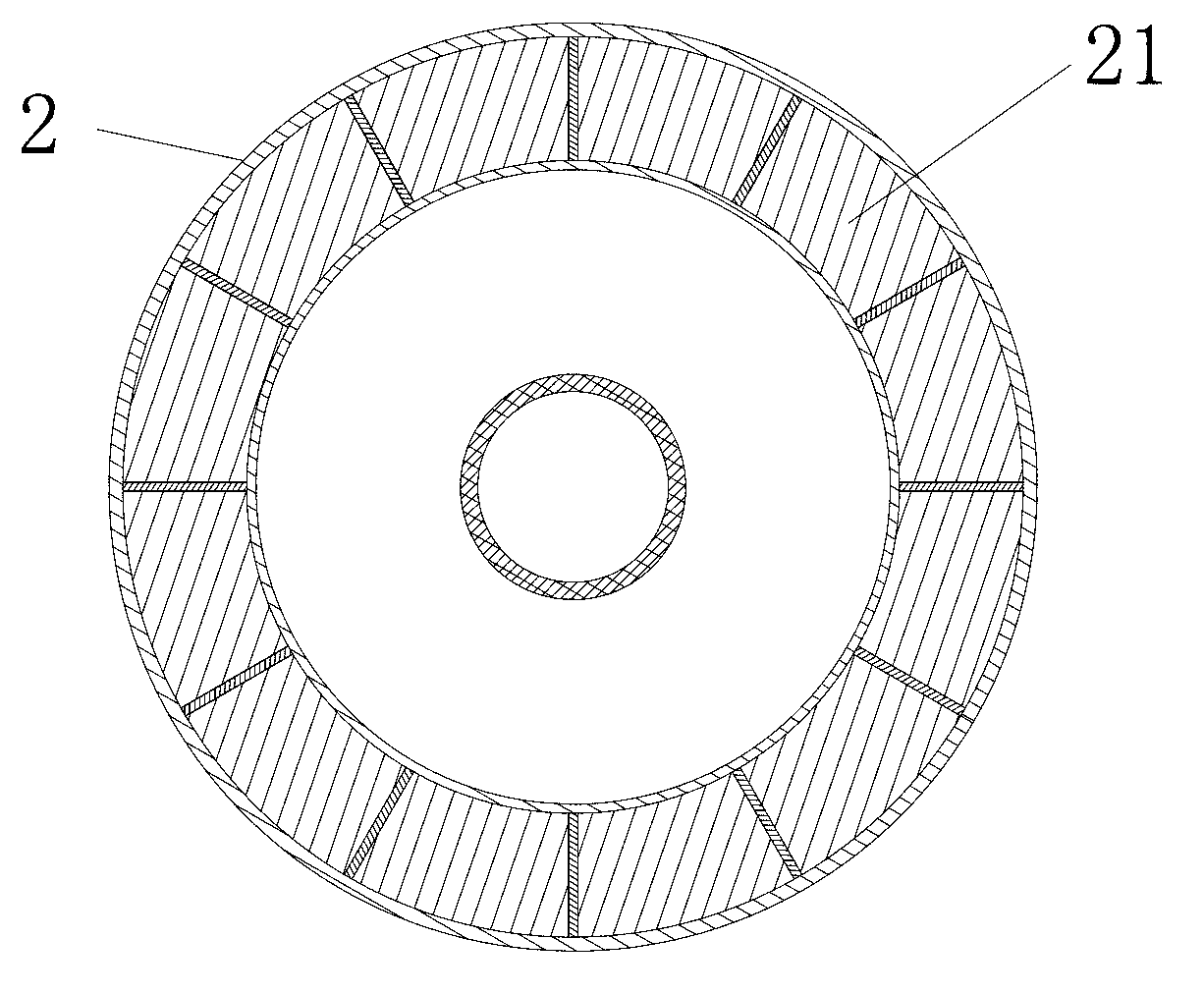

Stern rotary drum

InactiveCN103010406AEasy to installLow installation accuracy requirementsAnchor handling/lashingAnchoring arrangementsEngineeringStern

The invention relates to a stern rotary drum of ships, and in particular to a stern rotary drum, which comprises a shaft body and a drum body arranged on the shaft body through a bearing, wherein the drum body is internally provided with a plurality of horizontal ring-shaped rib plates arranged along the periphery of the shaft body. The stern rotary drum is characterized by also comprising a shaft fork, wherein the shaft body is fixed on the shaft fork. The stern rotary drum is simple in structure, convenient to install, strong in loading capacity and flexible in operation.

Owner:GUANGXIN SHIPBUILDING & HEAVY IND

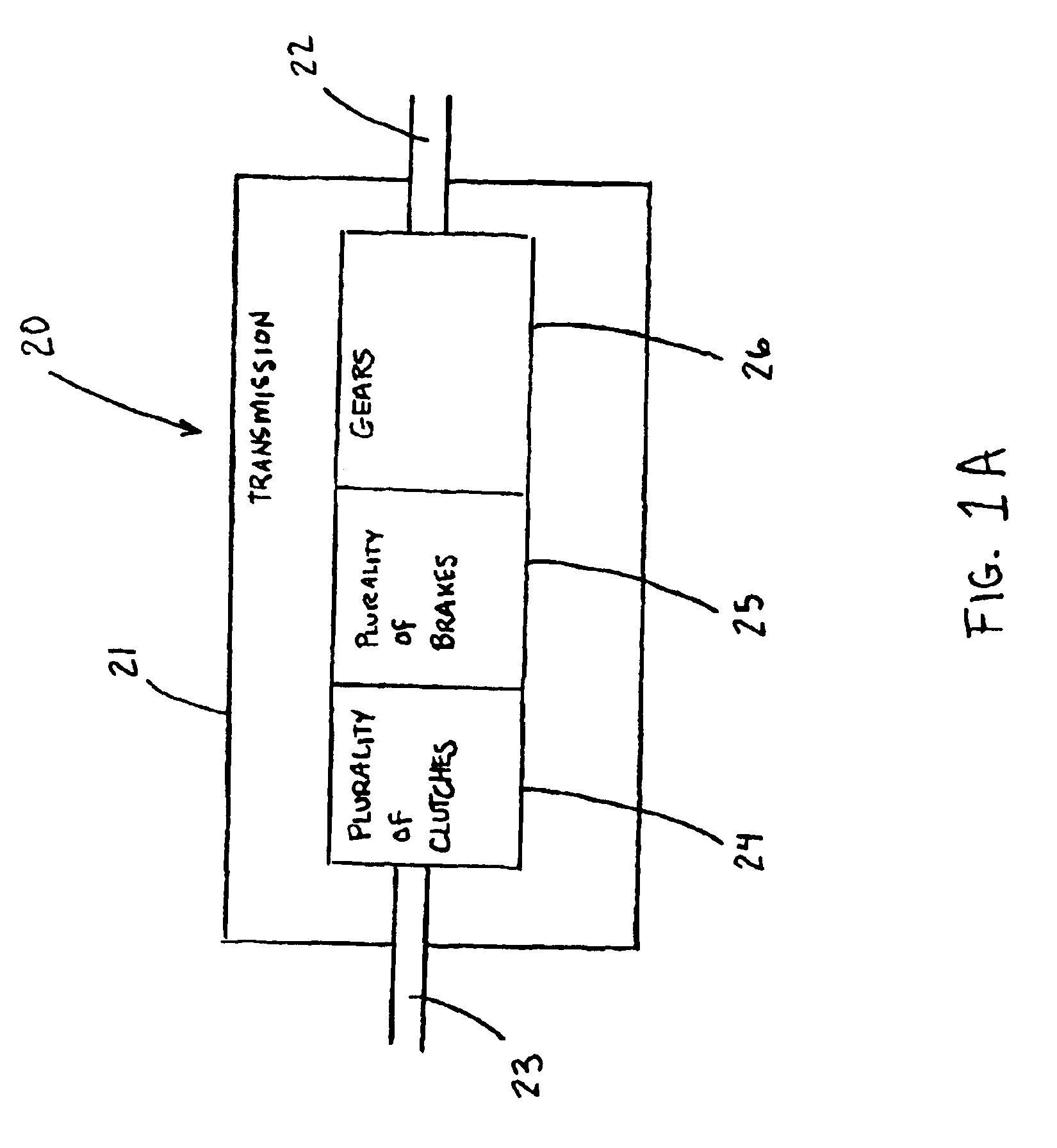

Automatic transmission

InactiveUS6843745B2High strengthLow number of componentsRotary clutchesToothed gearingsAutomatic transmissionEngineering

An automatic transmission for vehicles is equipped with a housing in which a number of clutches and brakes, as well as an input shaft and an output shaft and at least one torque-controlling shaft (1), are positioned. The torque-controlling shaft (1) is equipped with neither a lengthwise bore for the central supply of fluid to the clutches or brakes, nor cross bores and grooves.

Owner:ZF FRIEDRICHSHAFEN AG

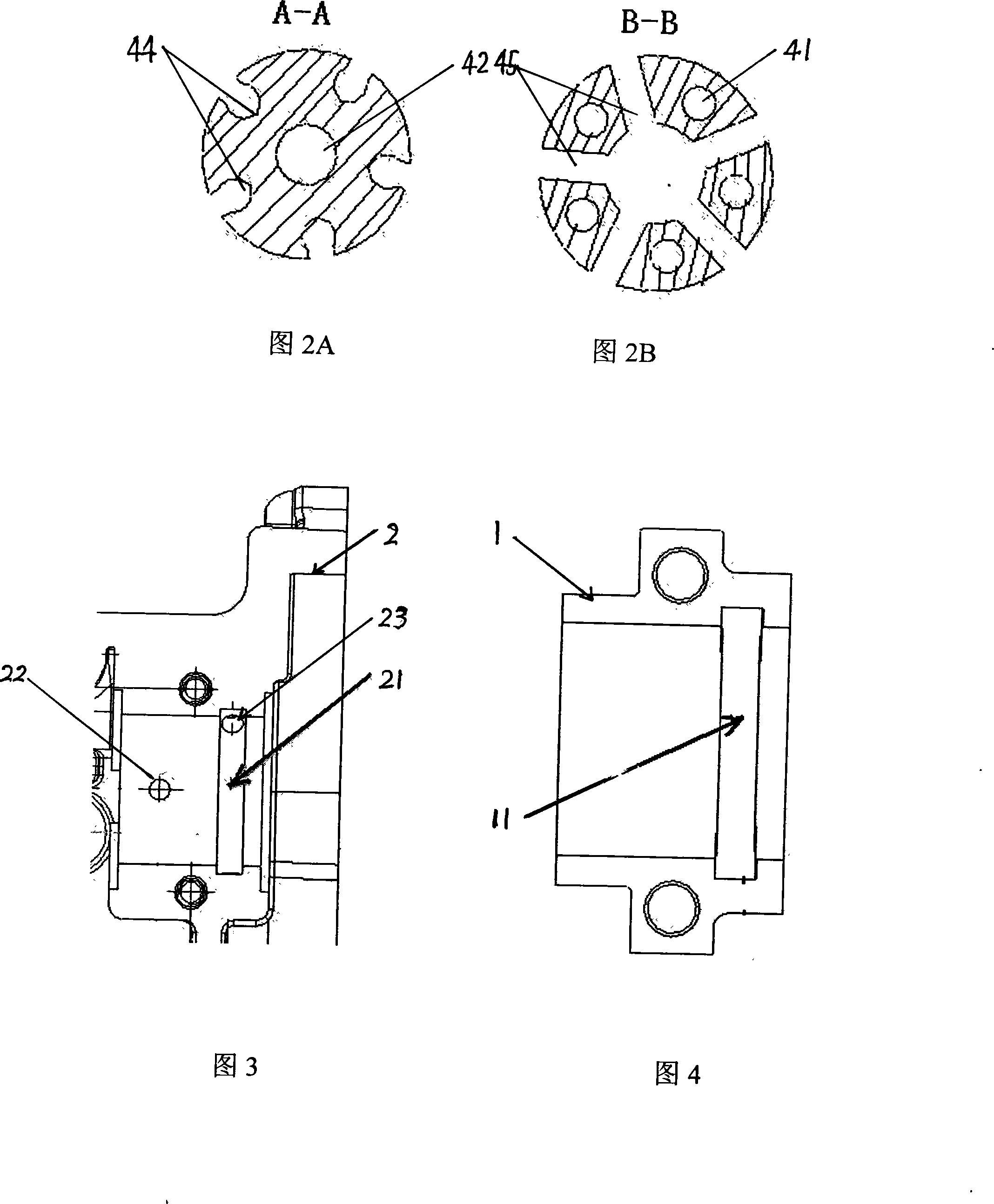

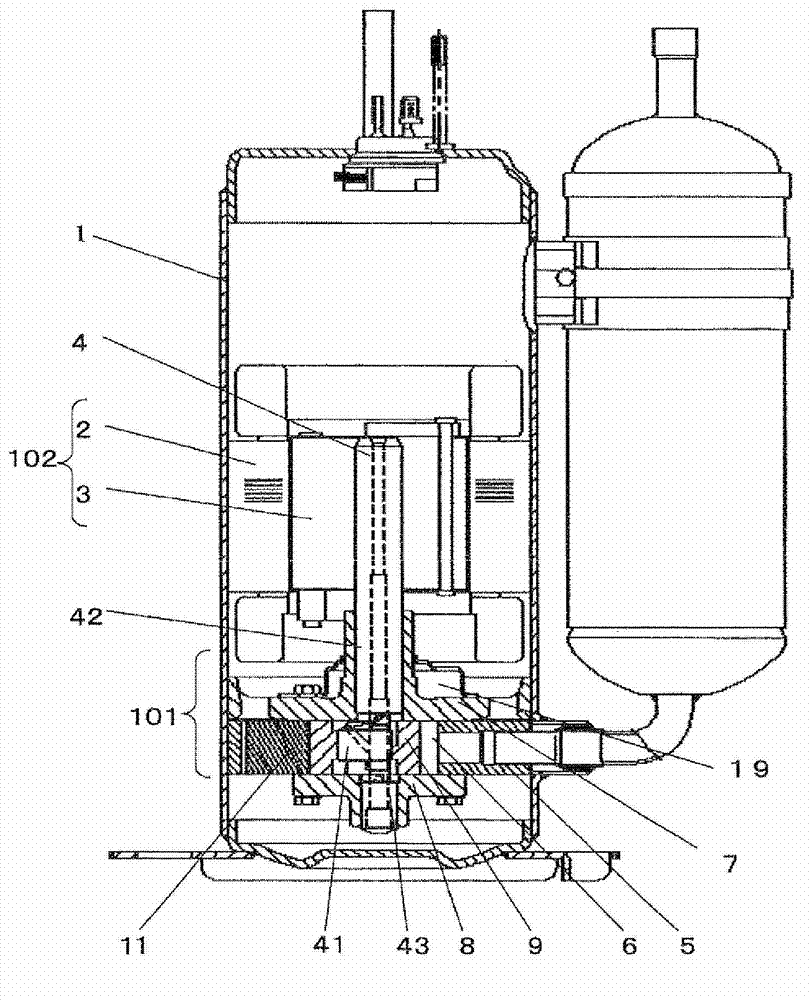

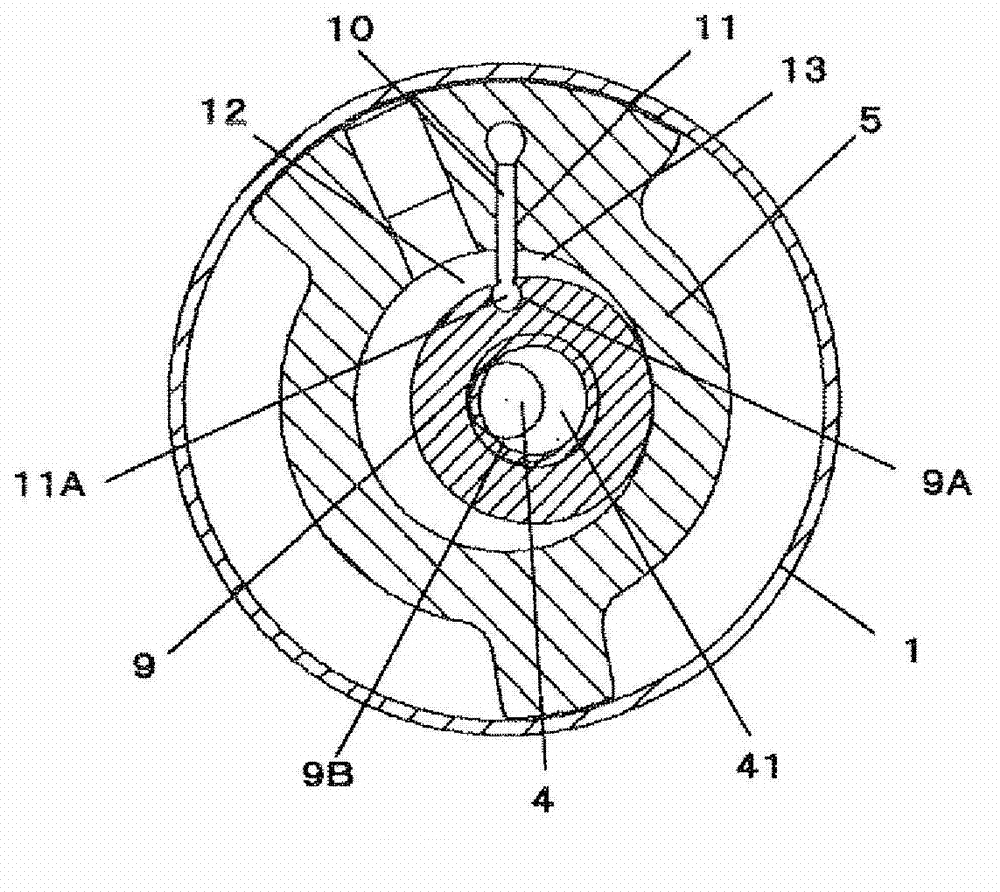

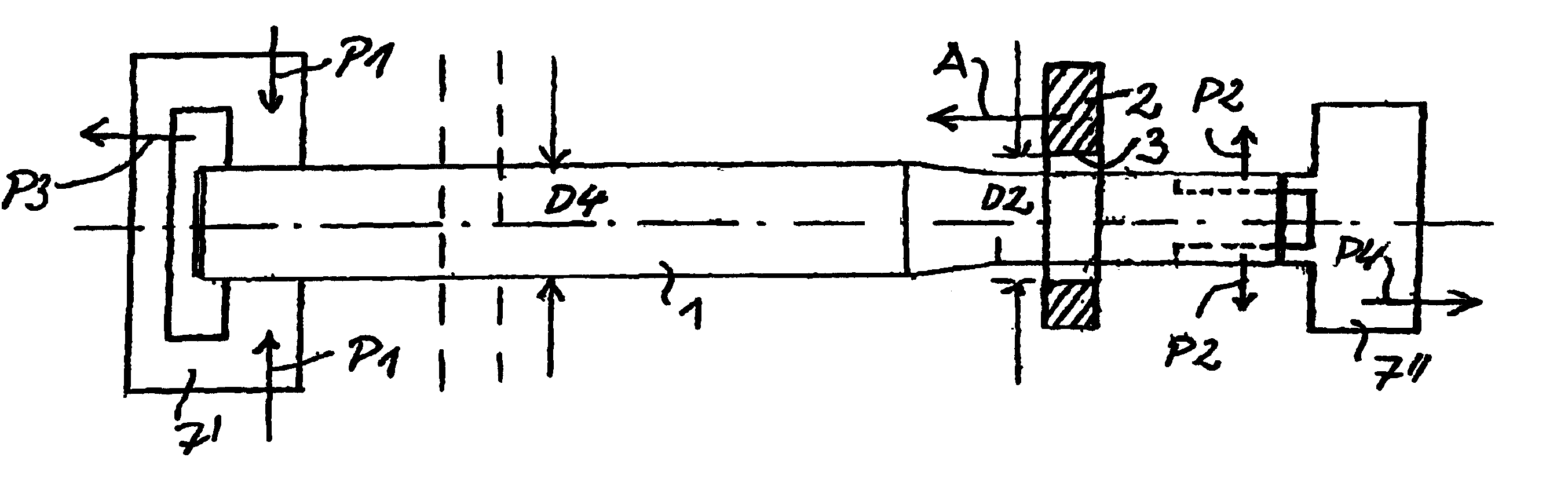

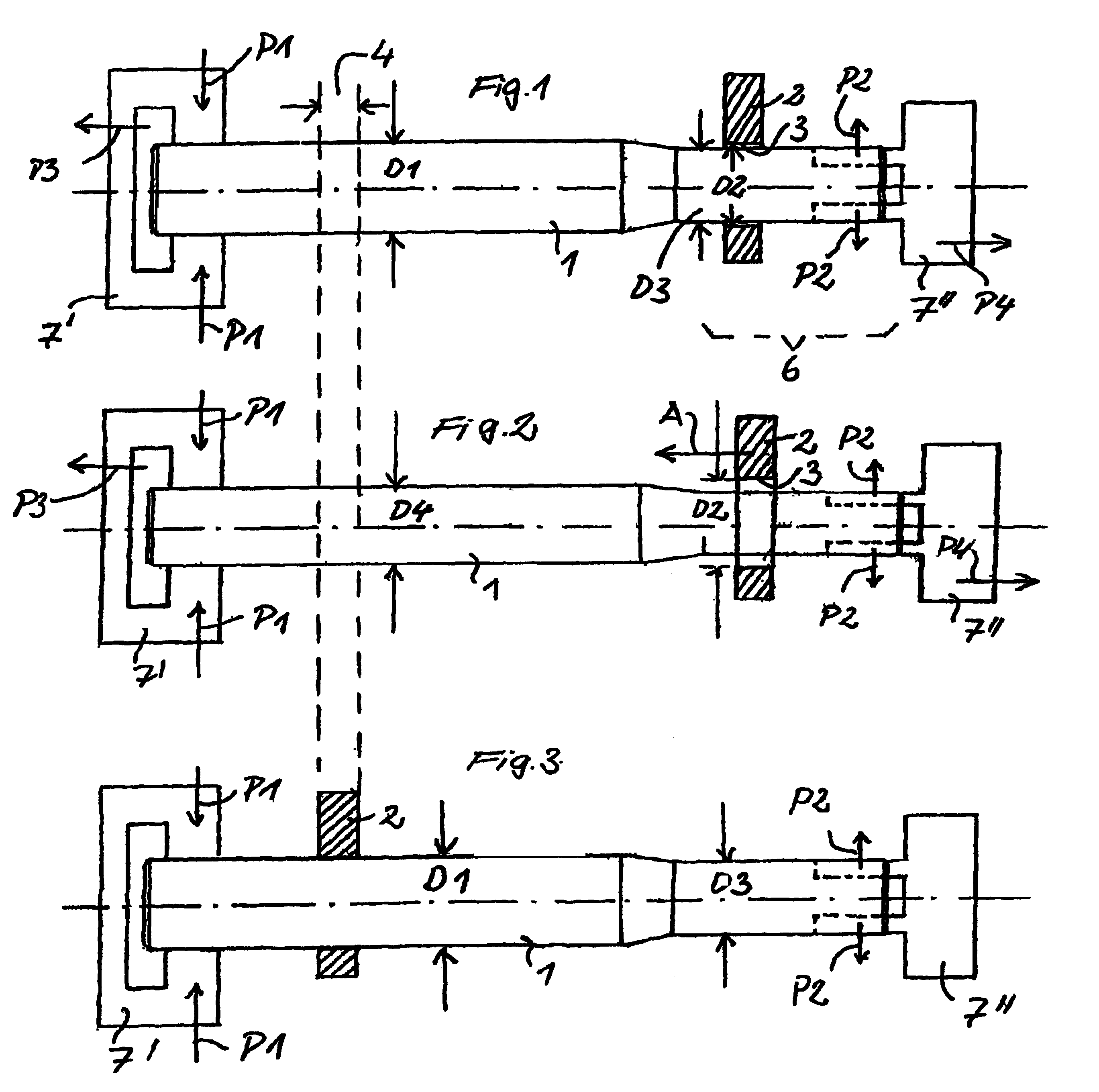

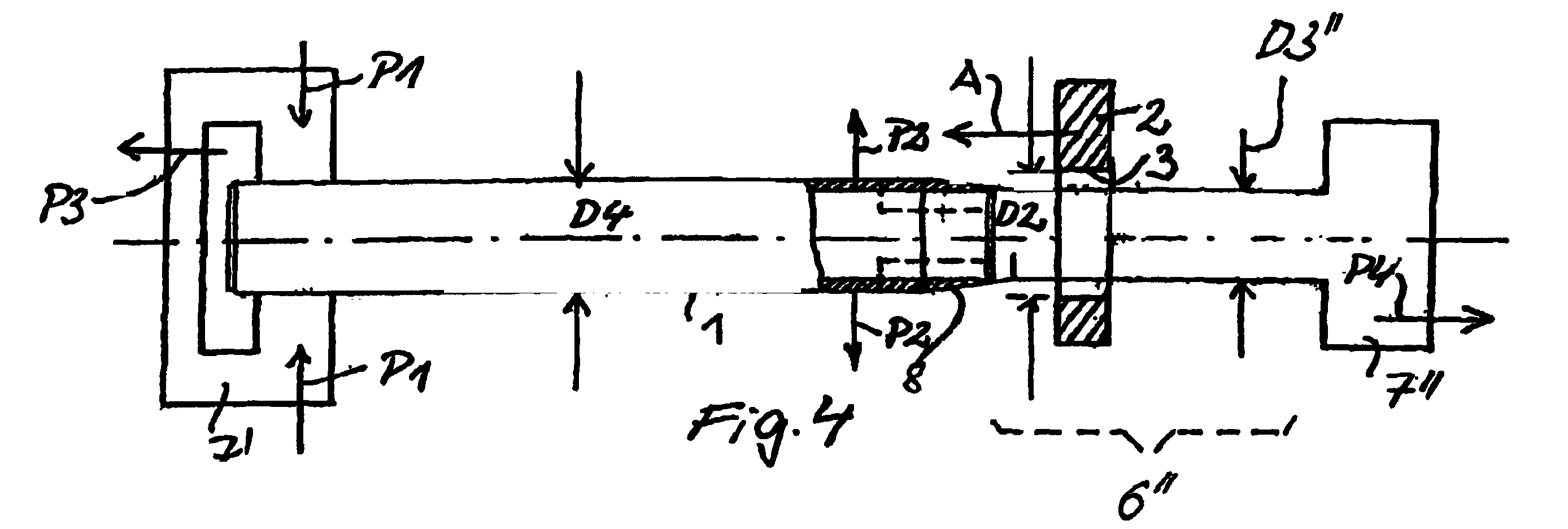

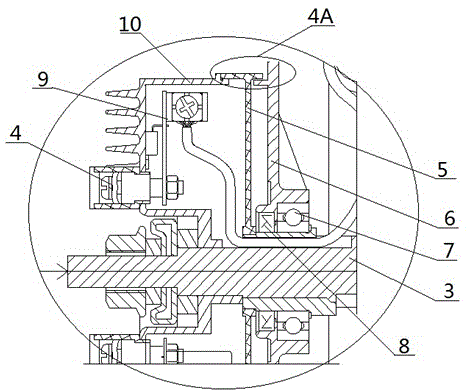

Rotary compressor

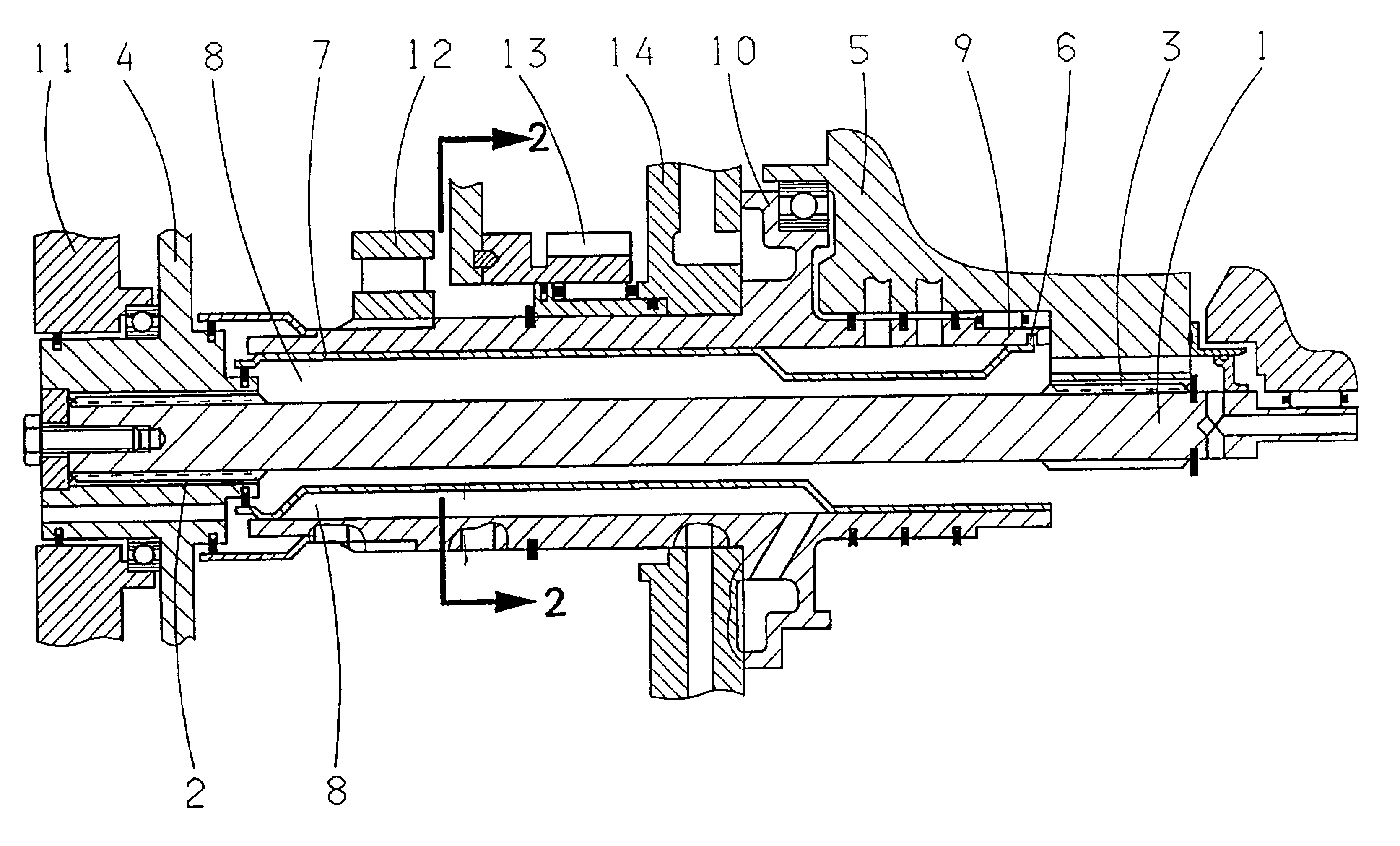

ActiveCN102971537AGuaranteed Strength and ReliabilityReduce shaft diameterRotary piston pumpsRotary piston liquid enginesReciprocating motionPiston

Disclosed is a vane rotary-type rotary compressor wherein the opposite eccentric shaft-side outer peripheral surface of an eccentric portion (41) of a shaft (4) is deviated further inward than the outer peripheral surface of a main shaft portion (42) to be fitted in a main bearing (7) and the outer peripheral surface of a subsidiary shaft portion (43) to be fitted in a subsidiary bearing (8), and clearance means necessary when a piston (9) is assembled with the shaft (4) are provided on the inner peripheral surface of the piston (9) and the eccentric portion (41) of the shaft (4), so that the shaft diameter of the eccentric portion (41) is reduced. Thus, the viscous force of oil applied to the eccentric portion (41) of the shaft (4) and the inner peripheral surface of the piston (9) can be reduced, and the rotational moment around the center of the eccentric portion (41) of the shaft (4), which is applied to the piston (9) in the rotational direction of the shaft (4), can be reduced. Therefore, the sliding loss generated due to the reciprocation of a vane (11) within a vane groove (10) can be reduced.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

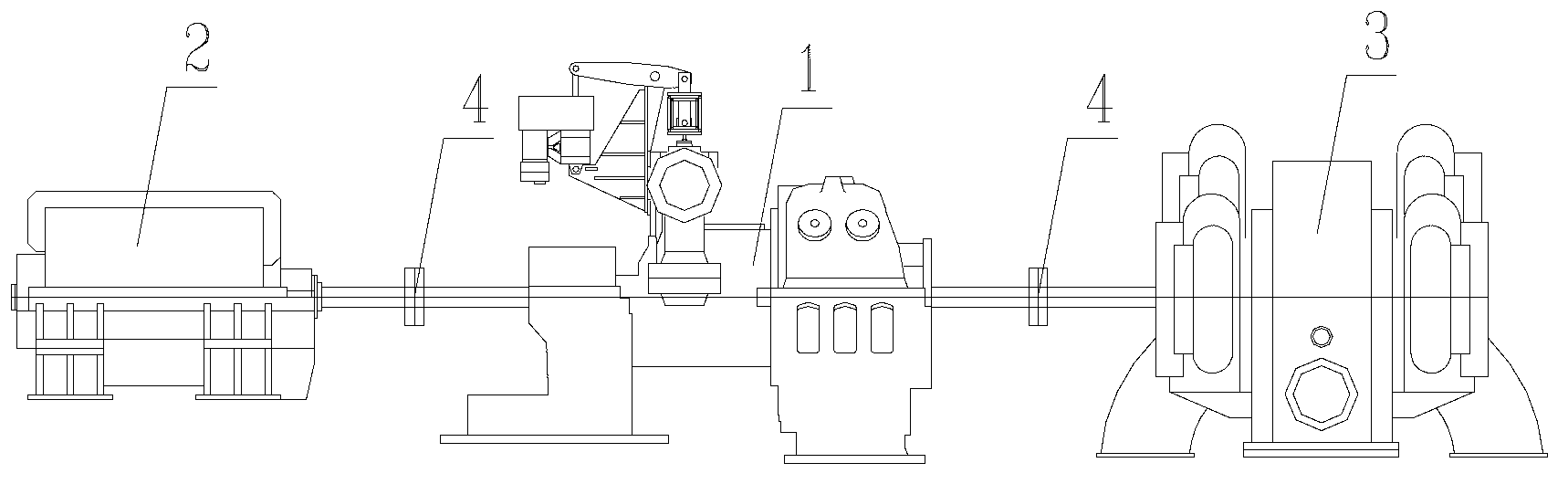

Method for producing a built shaft

InactiveUS7325305B2Diameter of shaftReduce the overall diameterCamsValve arrangementsInterference fitEngineering

A method of producing a built shaft in which at least one part, particularly a cam, is mounted on the shaft, particularly a camshaft, includes inserting the shaft into an opening of the part. Before mounting the part, the shaft is stretched by a stretching and tightening device such that an original diameter in the area of at least one fastening location is reduced to a stretched diameter. The part is slid onto the shaft and up to the fastening location. The stretching and tightening device is then loosened to enable the diameter of the shaft to enlarge once more towards its original diameter. The part is firmly fastened at the fastening location by an interference fit in both an axial and rotationally fixed manner.

Owner:NEUMAYER TEKFOR HLDG GMBH

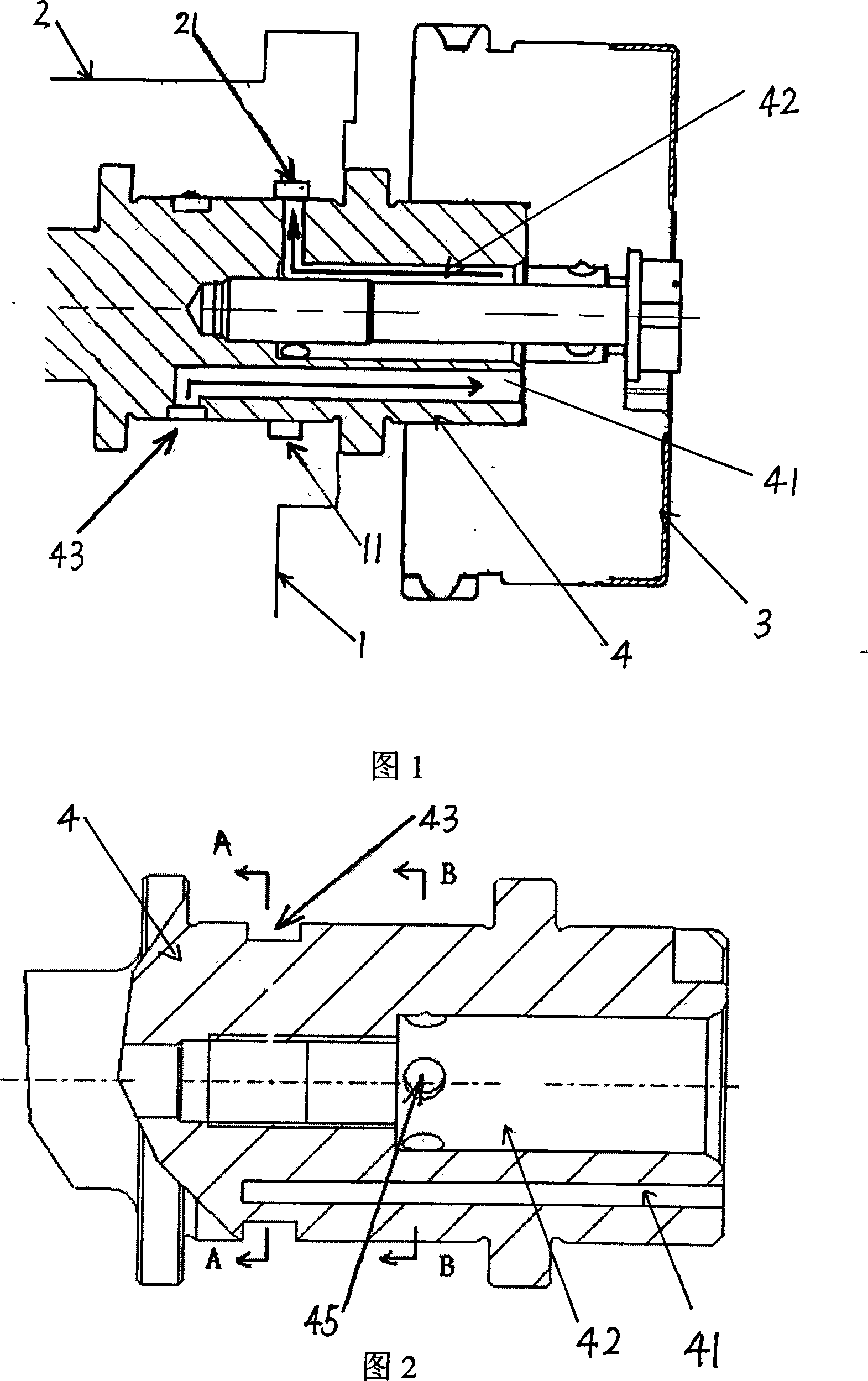

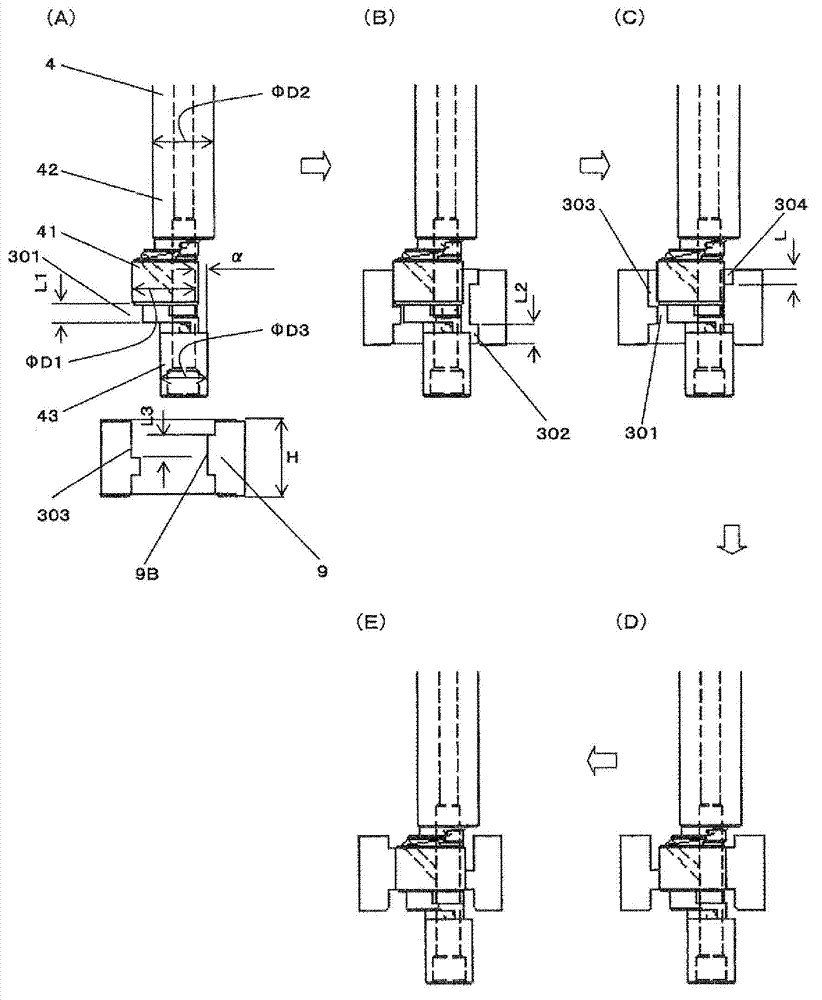

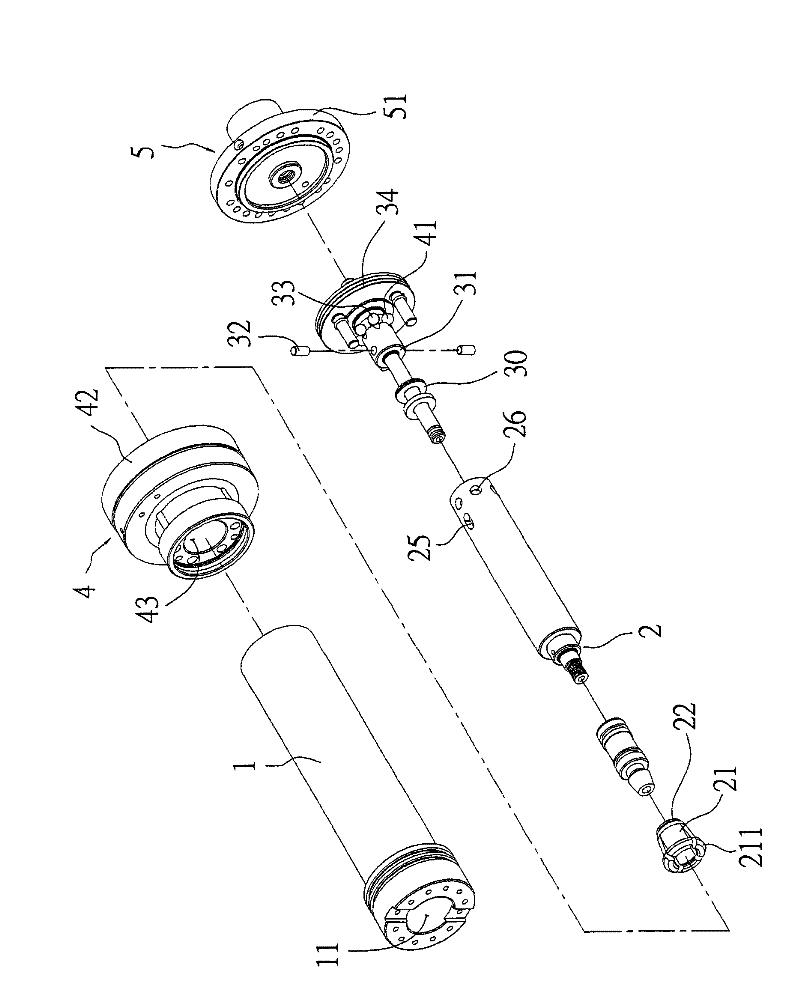

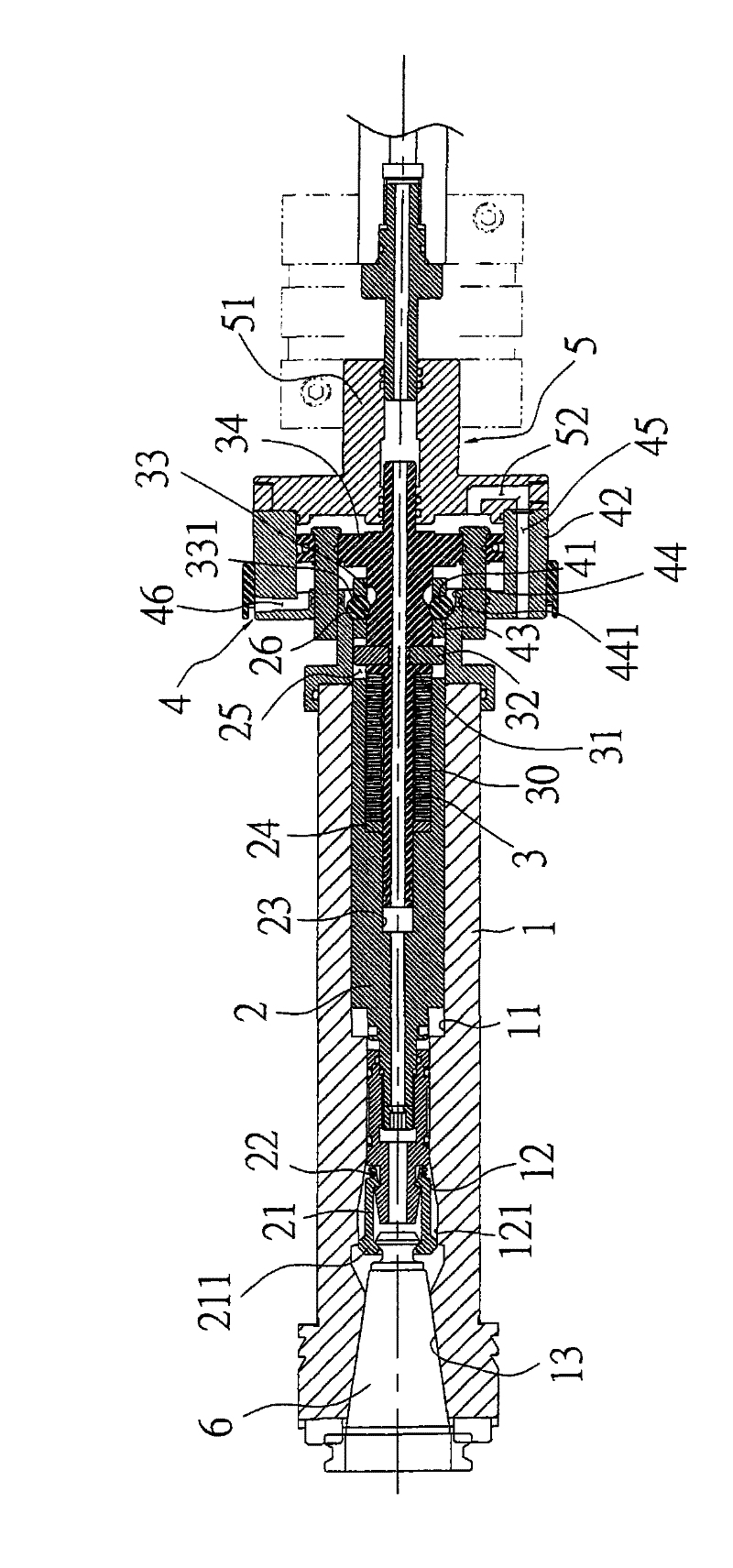

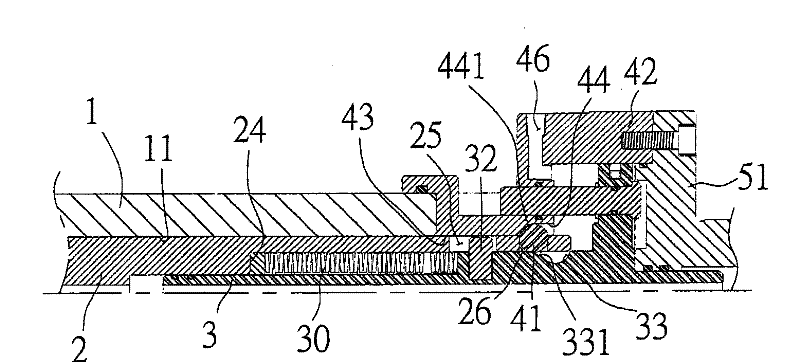

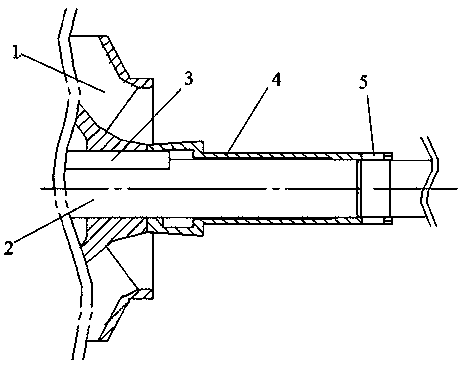

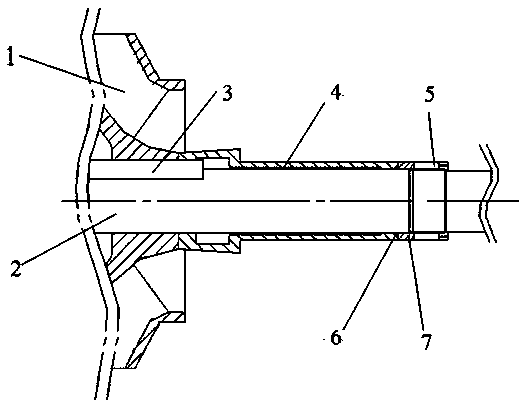

Cutter clamping device

The invention relates to a cutter clamping device. The device is mainly characterized in that a drawbar is arranged in a spindle hole, and a spring set and a push bar are arranged in the draw bar to ensure that the spring set is arranged between the drawbar and the push bar. By using the cutter clamping device of the invention, when the cutter is retracted, the compressed spring set can not directly support and press the spindle hole and damage the bearing covered outside the spindle; and the design of the power intensifier with high amplification factor is utilized to clamp the cutter with the spring set with the least springs and the minimum diameter and the diameter of the spindle is reduced, thus the centrifugal force generated by the rotation of the spindle can be reduced and vibrations can be avoided when the spindle runs so that the condition of inaccurate finished surface can be prevented; and the high-speed actuation of the spindle can be facilitated while the diameter and length of the spindle are reduced.

Owner:FACTORY AUTOMATION TECH CO LTD

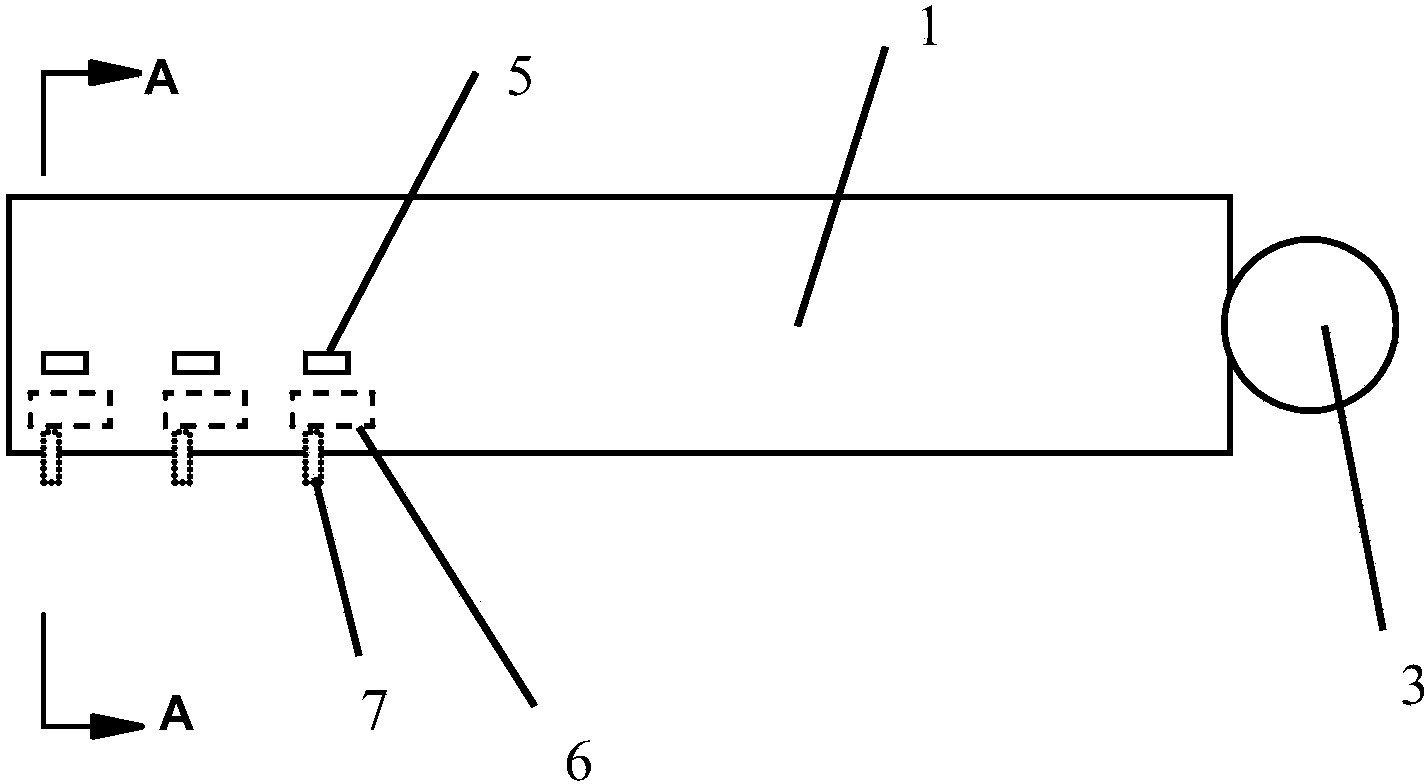

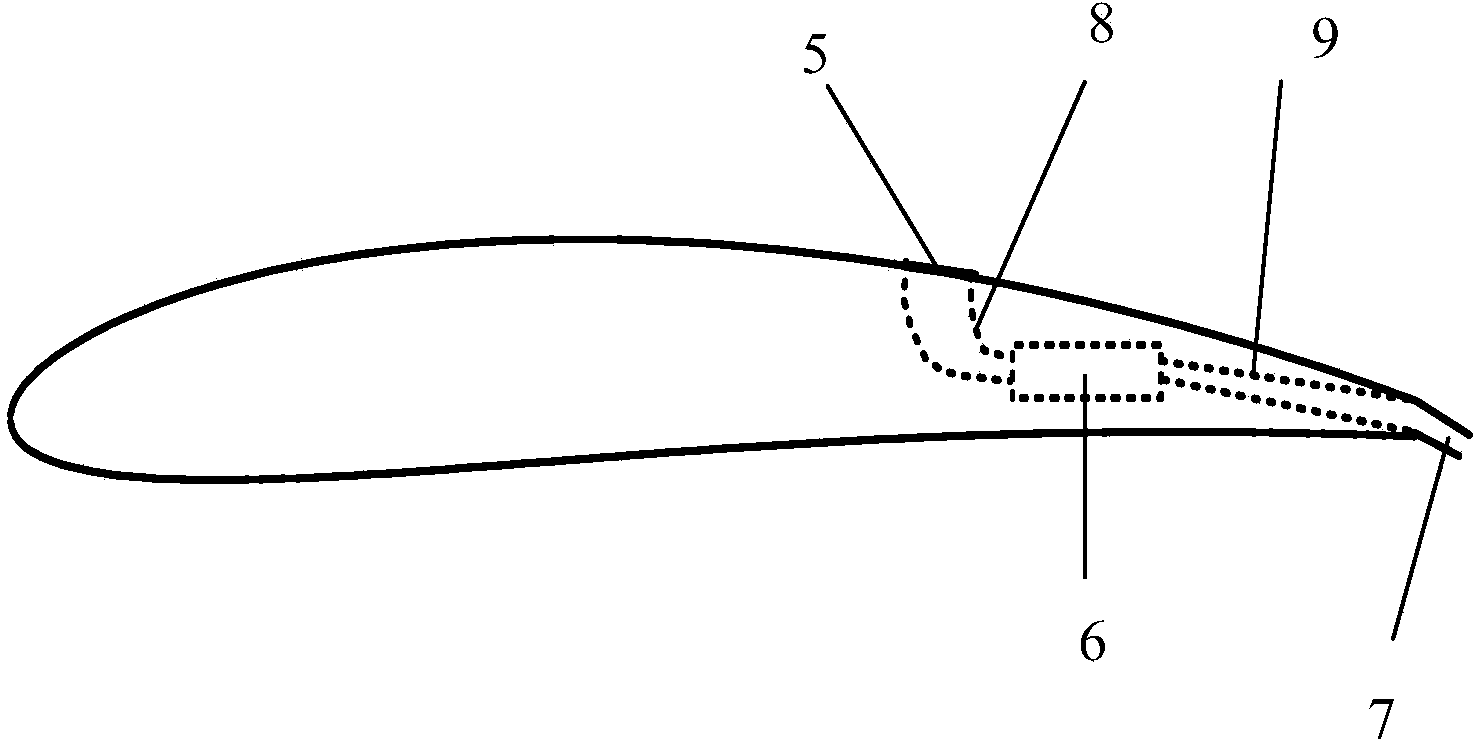

Propeller with trailing edge for air jetting

ActiveCN104029816AImprove aerodynamic efficiencyIncrease lift coefficientRotocraftPropellerTrailing edge

The invention discloses a propeller with a trailing edge for air jetting. The propeller consists of a plurality of air jetting devices, a rotating shaft, a motor and two symmetrical blades, wherein the motor is located at one end of the rotating shaft; the rotating shaft is connected with an output shaft of the motor through a coupling, and the other end of the rotating shaft is fixedly connected with the propeller; the air jetting devices are embedded in the blades at equal intervals, and are located at positions of 60%-95% spanwise length of the blades; two ends of air pumps are respectively and fixedly connected with one ends of front conduits and one ends back conduits, the other ends of the front conduits are communicated with air suction ports in the upper surfaces of the blades, and the other ends of the back conduits are communicated with air jetting ports in the trailing edge. The air jetting devices suck air currents from the air suction ports in the upper surfaces of the blades, the air currents which are accelerated are jetted out of the air jet ports in the trailing edge at a certain angle, and the air jetting direction of the air jet ports can be regulated within 0-90 degrees according to requirements. Counter-acting force which is formed by jetting air currents of the air jetting devices in a rotating plane pushes the propeller to rotate, a torque born by the rotating shaft of the motor is decreased, and the thrust-weight ratio of a propeller system is increased.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

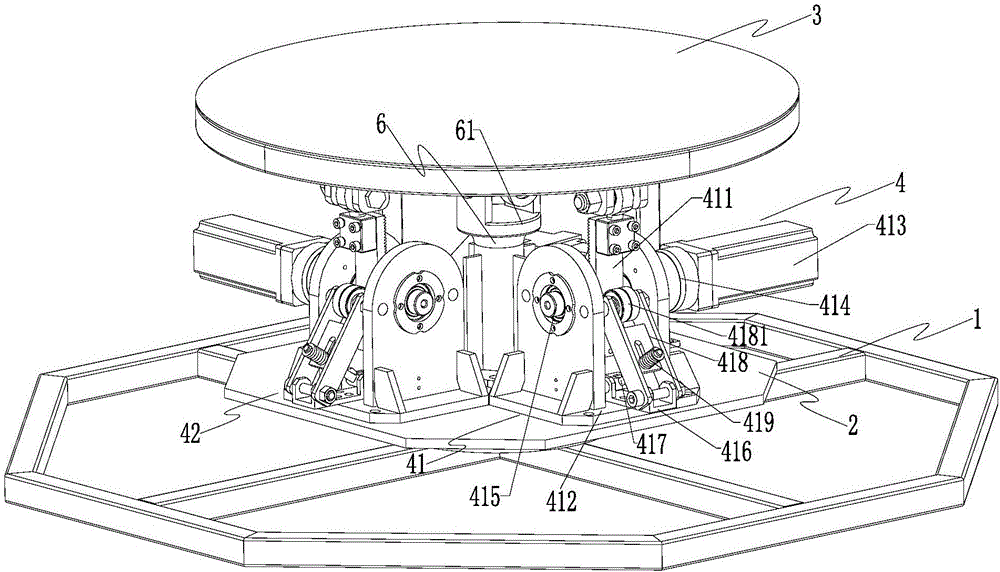

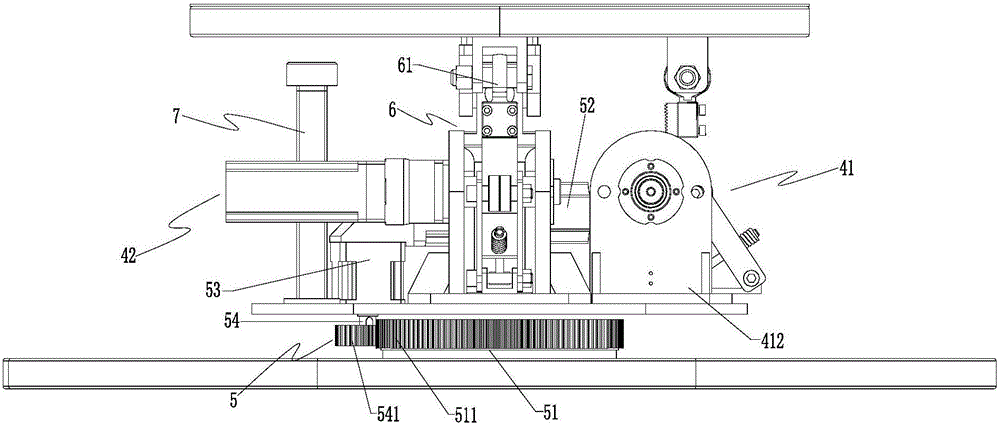

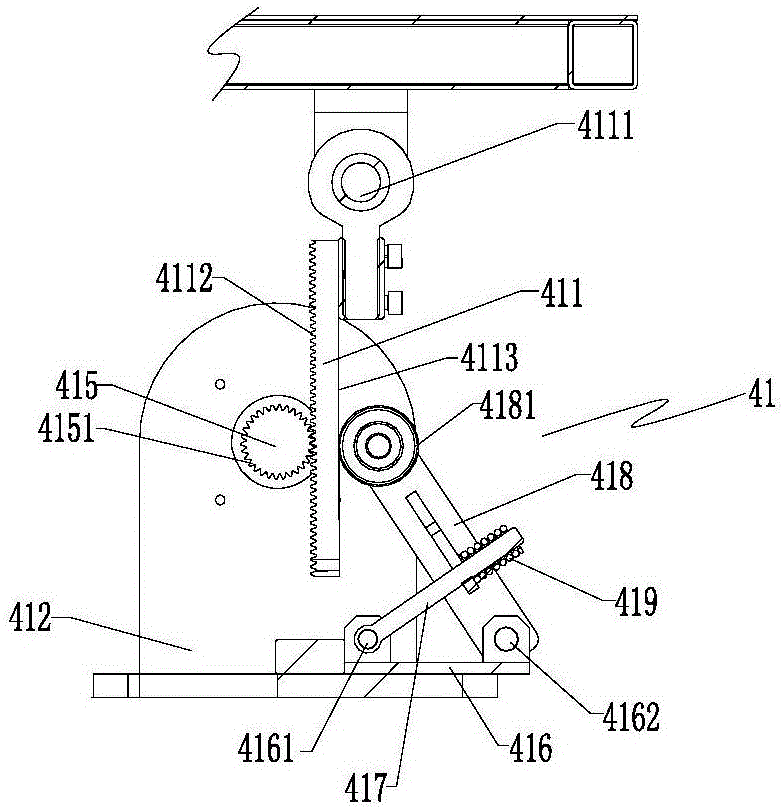

Foot platform structure of game equipment

PendingCN106362404AReduce shaft diameterLittle change in forceAmusementsVideo gamesGear wheelUniversal joint

The invention discloses a foot platform structure of game equipment. The foot platform structure comprises a base, a rotary pedestal arranged above the base, a foot platform arranged above the rotary pedestal and a two-degree-of-freedom rack transmission assembly arranged between the rotary pedestal and the foot platform, wherein the rotary pedestal is rotationally arranged on the base through a rotary component; the foot platform is movably arranged on the rotary pedestal through a universal joint pillar; the two-degree-of-freedom rack transmission assembly comprises a first rack transmission component and a second rack transmission component which have the same structure; and each rack transmission component comprises a rack plate which is movably arranged at the bottom of the foot platform, a servo motor mechanism which is fixedly arranged at the upper part of the rotary pedestal and is in meshing and transmission matching with the corresponding rack plate, and a compaction mechanism which is matched with the corresponding rack plate in a butting-pressing manner and ensures the corresponding rack plate to tend to be in transmission matching with the corresponding servo motor mechanism. According to the foot platform structure, with adoption of a novel rack plate transmission structure, the foot platform structure is simple in structure, convenient to disassemble and assemble, not liable in abrasion, durable and reliable; and in addition, with adoption of a structure mode of supporting a gear shaft by two points, stress of the gear shaft is a torque basically, and thus the diameter of the gear shaft and stress variation on the shaft are small, stress is uniform, and the foot platform structure is safe and stable.

Owner:GUANGZHOU ZHUOYUAN VIRTUAL REALITY TECH CO LTD

Single-cylinder, reaction and impulse turbine

ActiveCN101493016AIncrease the shaft diameterReduce shaft diameterMachines/enginesThree stageLogical part

The invention relates to a technology of single-casing steam turbines; a single-casing, reaction and impulse steam turbine, comprises a horizontally placed cylinder and a rotor in the cylinder; the rotor is supported by bearings in the front and in the back; the cylinder is divided into two logic parts, namely, a high-pressure part and a medium-low pressure part; the high-pressure part is provided with a plurality of reaction stages, therein each comprises a static blade and a movable blade; the static blades of the reaction-type stages are arranged on a high-pressure cylinder; the movable blades are arranged on the rotor; the medium-low pressure part is provided with a plurality of impulse stages, therein each comprises a static blade and a movable blade; the static blades of the impulse stages are arranged on a retaining ring; and the movable blades are arranged on the rotor. The high-pressure part and the medium-low pressure part are in a contraflow configuration. The inventive steam turbine overcomes the problem of insufficient rigidity of rotors with a traditional impulse design and difficult self balancing of impulse force of rotors with the traditional reaction design of single-casing three-stage reheating combined cycle steam turbine of 100MW.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

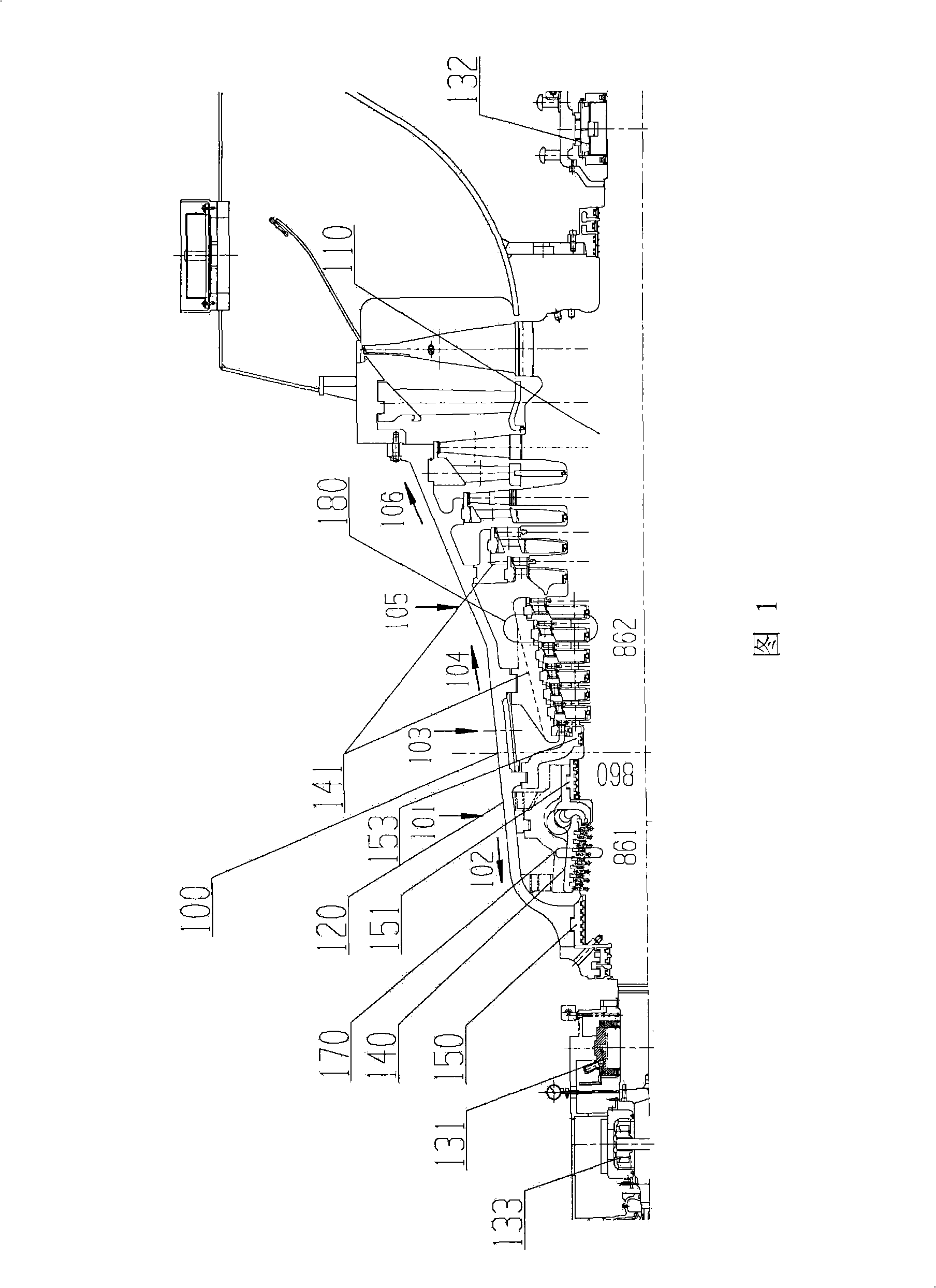

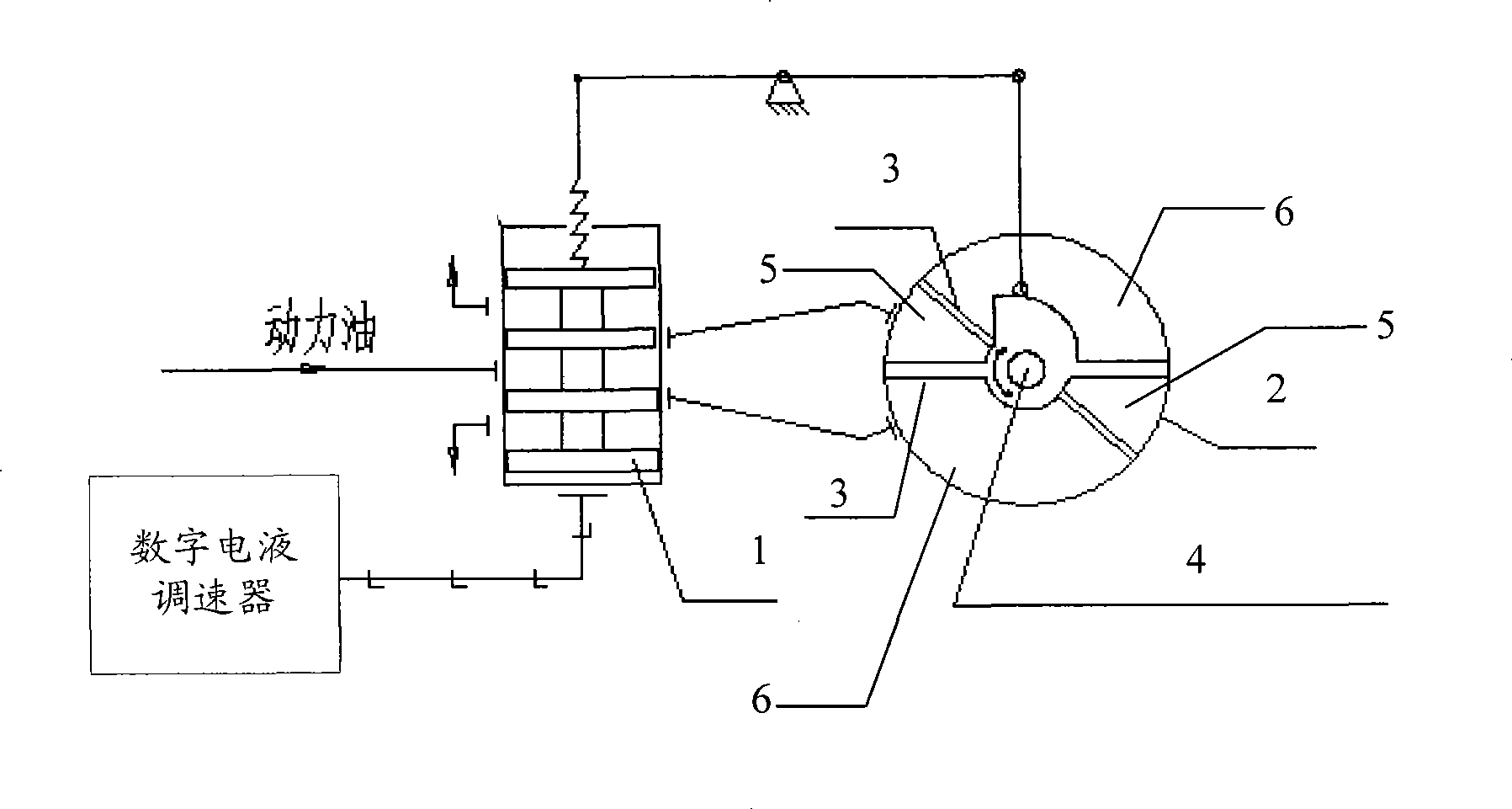

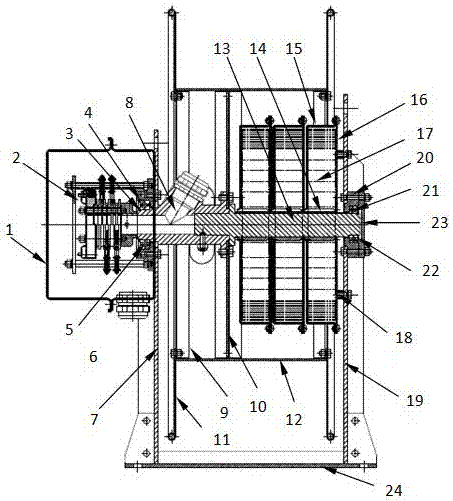

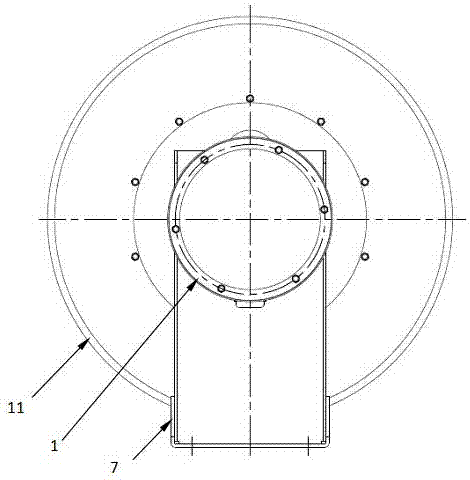

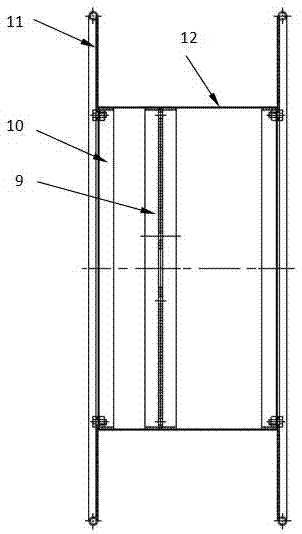

Rotating servo oil motor

ActiveCN101476576AReduce shaft diameterFast transmissionMachines/enginesEngine componentsSpool valveControl signal

The invention discloses a rotary servo oil motor. An oil valve for receiving power oil is connected with a digital electro-hydraulic governor which generates control signals; the oil valve inputs the power oil to corresponding cavities connected in an oil cylinder according to the control signals so as to drive a cam and a rotary valve which are connected with a rotating shaft in the oil cylinder to rotate; the rotary valve drives an adjusting air valve which controls the rotating speed of a steam turbine; and the cam on the rotating shaft is further connected with a restorer which adjusts a slide valve to return to a balance position according to the rotational angle value of the rotating shaft. The rotary servo oil motor performs rotary motion to drive a butterfly adjusting valve to rotate directly without generating additional driving friction force. A servo oil motor shaft can be in rigid connection with a butterfly valve shaft without underdrive. The rotary servo oil motor can reduce the rotating shaft diameter of a rotary butterfly valve so that the drive of a driving mechanism is quick, and the load control of the steam turbine is stable.

Owner:QINGDAO JIENENG STEAM TURBINE GROUP CO LTD

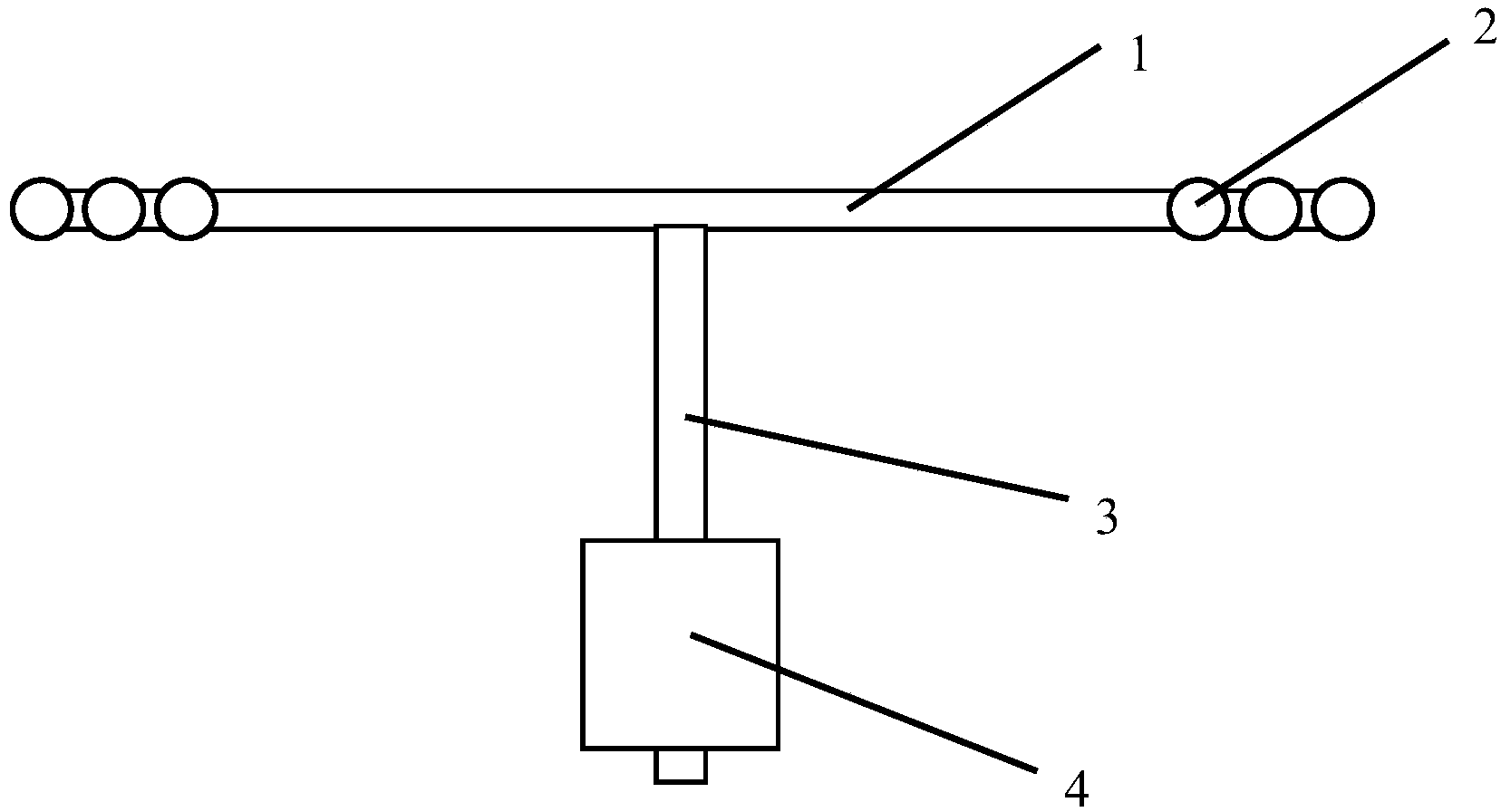

Double-support elastic driving type cable coiling block

The invention discloses a double-support elastic driving type cable coiling block. The double-support elastic driving type cable coiling block comprises an electric fitting half shaft, a spring half shaft, a clockwork spring, a stand and a reel and is characterized in that a center shaft of the double-support elastic driving type cable coiling block comprises the electric fitting half shaft and the spring half shaft, and the electric fitting half shaft is arranged on an electric fitting side support along with an electric fitting side bearing block and a bearing; the spring half shaft is arranged on a spring side support along with a spring side bearing block and a bearing; the electric fitting half shaft and the spring half shaft are in rigidity connection; the reel is arranged on the center shaft formed through connection of the electric fitting half shaft and the spring half shaft; and the clockwork spring is arranged in the spring half shaft arranged in a coiling block body. Due to adoption of the double supports, the installing stability of the elastic driving type cable coiling block is high; the clockwork spring is arranged in the reel, the axial size is reduced, the installing space is saved, and accordingly the occupied installing space is small; and the reel is assembled and integrated, spot welding combination is adopted between a keel ring and the coiling block body, and accordingly the production cost is low.

Owner:YUEYANG HAIRUN ELECTRIC

Half thrust bearing and bearing device using the same

ActiveUS20170009809A1Reduce weightReduce rigidityCasingsCrankshaft bearingsThrust bearingEngineering

The present invention provides a half thrust bearing in a semicircular ring shape for receiving an axial force of the crankshaft of the internal combustion engine, that include a back metal layer, a bearing alloy layer and a resin slide layer, or a bearing alloy layer and a resin slide layer. The resin slide layer constitutes a slide surface receiving the axial force, and the half thrust bearing includes thrust reliefs formed on a side receiving the axial force and adjacent to both circumferential end portions thereof so that a wall thickness of the half thrust bearing becomes thinner toward the circumferential end portions. At least the thrust relief on a rear side in a rotational direction of the crankshaft has a thrust relief length which becomes larger toward an outer end portion from an inner end portion in a radial direction of the half thrust bearing.

Owner:DAIDO METAL CO LTD

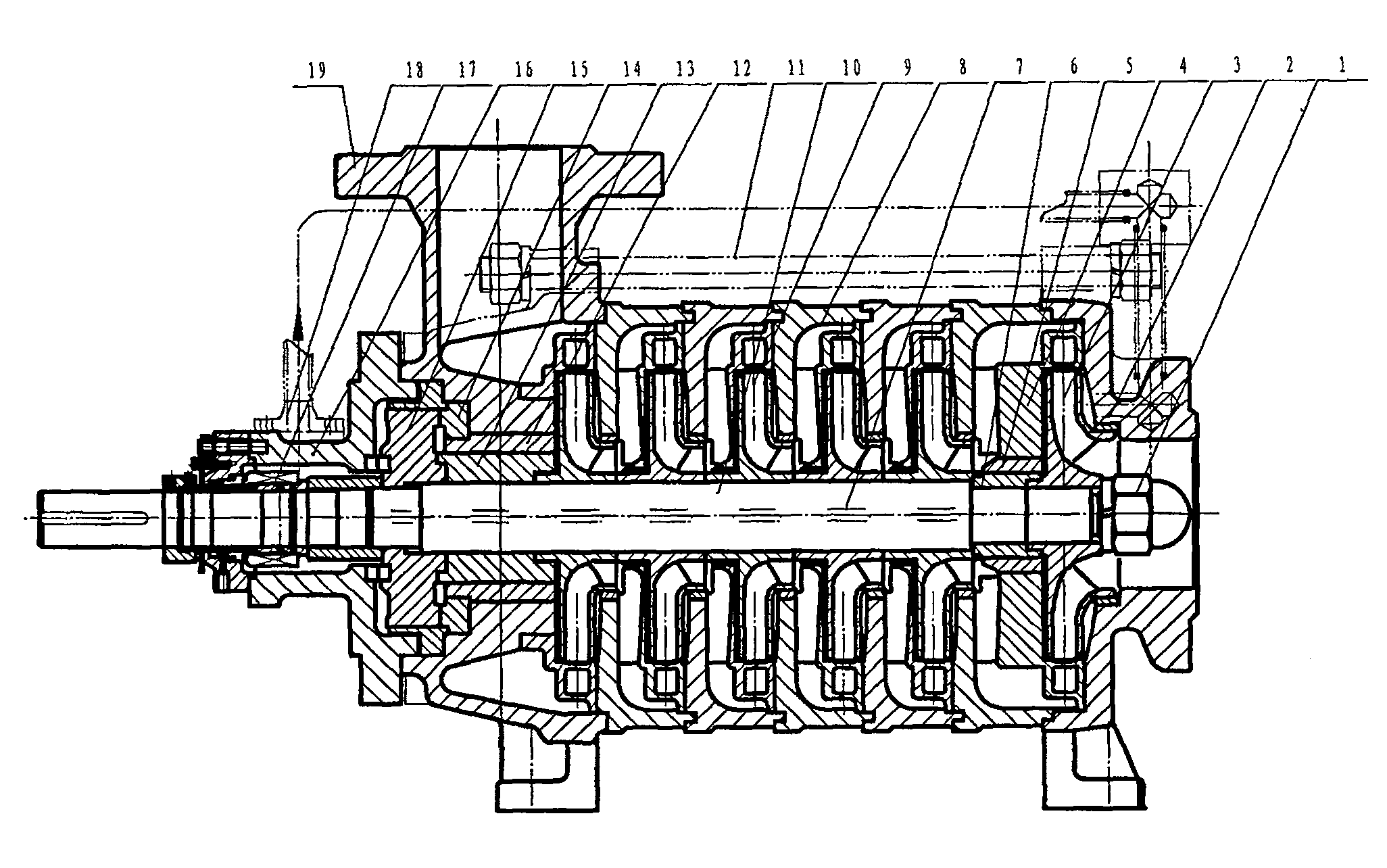

Efficient high-pressure horizontal multi-stage centrifugal pump

InactiveCN100572821CImprove efficiencyImprove performancePump componentsPump installationsCavitationHydraulic pump

Owner:JIANGSU UNIV

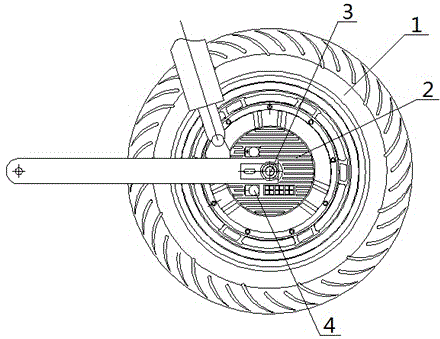

Controller-integration-based wheel hub motor of electric car

InactiveCN104979967AImprove efficiencyReduce distanceStructural associationSupports/enclosures/casingsElectricityCopper wire

The invention relates to a controller-integration-based wheel hub motor of an electric car. The motor comprises a main motor body, a controller, and a main shaft; and the controller is installed on the main shaft. A labyrinth ring II is arranged at a motor side cover of the outer side of the main motor body; a labyrinth ring I is arranged at the position where a controller housing I and the motor side cover are connected; and because of the labyrinth ring II arranged at the motor side cover, the two labyrinth rings form a labyrinth structure. A U-shaped binding post is arranged at an internal circuit board of the controller; and a waterproof binding post electrified with heavy currents is arranged at the controller housing, wherein the waterproof binding post is used for connecting a battery input wire. The controller-integration-based wheel hub motor has the following beneficial effects: the distance between the motor and the controller is small, the motor efficiency is high, the outgoing line is short, and the cost is saved; with the combined shaft sleeve, the shaft diameter can be reduced; because slots passing through holes are formed in the shaft and the shaft sleeve, the outgoing line of the motor is led out directly by a winding copper wire, thereby reducing the wiring process and wiring terminals and saving the outgoing line; the heat radiation condition of the controller is improved and the motor reliability is enhanced; and the electricity leakage risk is reduced.

Owner:上海德愚新能源科技有限公司

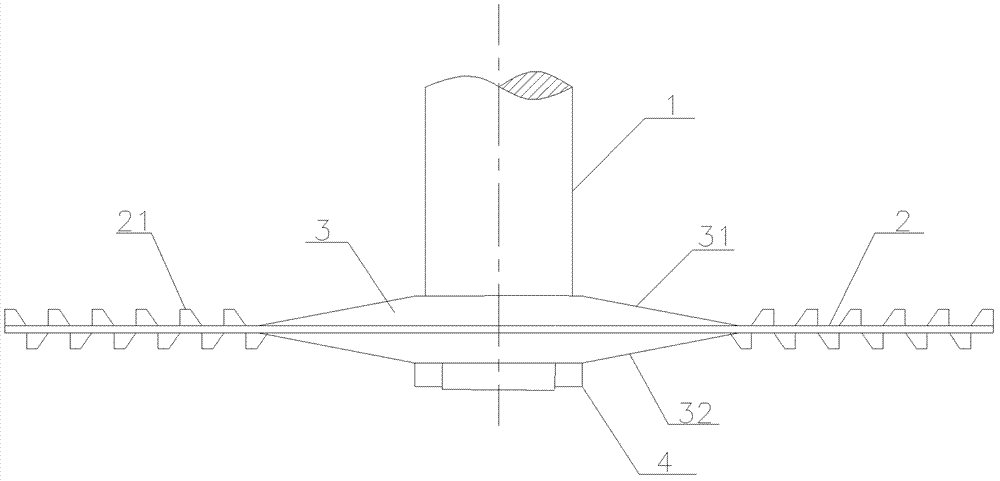

Toothed disk turbine-type stirring device

InactiveCN102895904AEffective mass reductionReduce weightRotary stirring mixersTransportation and packagingCircular discEngineering

The invention relates to a stirring device, and especially relates to a toothed disk turbine-type stirring device. The toothed disk turbine-type stirring device comprises a shaft sleeve and a dispersing disk. The shaft sleeve is connected with the dispersing disk through butterfly pressure plates. There are two butterfly pressure plates, which are a first butterfly pressure plate and a second butterfly pressure plate from top to bottom. The first butterfly pressure plate is positioned on the upper part of the dispersing plate, and the second butterfly pressure plate is positioned on the blower part of the dispersing plate. A round nut used for fixing the shaft sleeve is arranged on the lower part of the second butterfly pressure plate. According to the invention, the clamping-type butterfly pressure plates are used for fixing the dispersing plate and the shaft sleeve, and welding is not needed. With the pre-tightening force between the two butterfly pressure plates, the dispersing plate can be firmly clamped, and two planes can be completely flattened. The two butterfly pressure plates has butterfly shapes and light weights, such that the effective mass of the stirring device at the end of a stirring shaft is reduced, critical rotation speed is improved, shaft diameter is reduced, and cost is reduced.

Owner:江苏华东明茂机械有限公司

Pump shaft sleeve

The invention provides a pump shaft sleeve. The pump shaft sleeve comprises an impeller spacer sleeve, an O-shaped sealing ring, a shaft sleeve body, an L-shaped key and a shaft sleeve nut. The tail end of the impeller spacer sleeve is provided with a plane. The front end of the shaft sleeve is not provided with a key groove but is provided with a 45-degree chamfer. The O-shaped sealing ring is mounted in a triangular area formed between the outer circle of a pump shaft, the plane of the tail end of the impeller spacer sleeve and the 45-degree chamfer of the front end of the shaft sleeve body.The tail end of the shaft sleeve body is provided with a notch. The L-shaped key has two sides, one side is mounted in a key groove of the pump shaft, and the other side is mounted in the notch of the tail end of the shaft sleeve body. The shaft sleeve nut is axially located on the pump shaft. The shaft sleeve can be machined from a thick-wall steel tube without casting. According to the pump shaft sleeve locating structure, the O-shaped sealing ring can be mounted at the front end of the shaft sleeve to prevent medium leakage without increasing the length of the pump shaft. Before the shaftsleeve nut is tightened, an impeller, the impeller spacer sleeve, the O-shaped sealing ring, the shaft sleeve body and the L-shaped key all can move on the pump shaft in the axial direction to achievethe axial position regulating function.

Owner:HUNAN MECHANICAL & ELECTRICAL POLYTECHNIC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com