Rotating servo oil motor

A servo oil and motor technology, applied in fluid pressure actuators, engine components, machines/engines, etc., can solve problems such as large shaft diameter, unstable turbine load control, and slow transmission mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

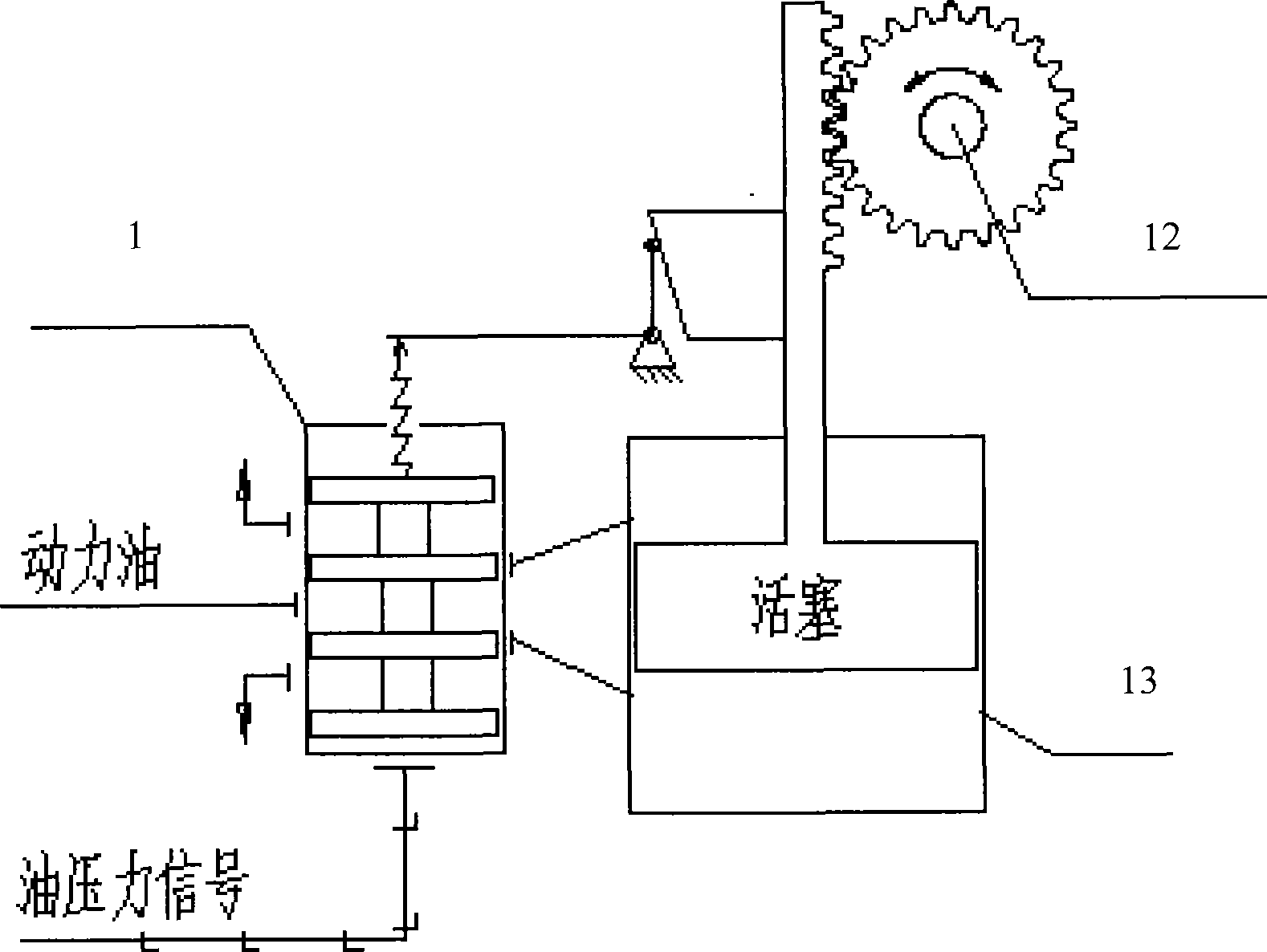

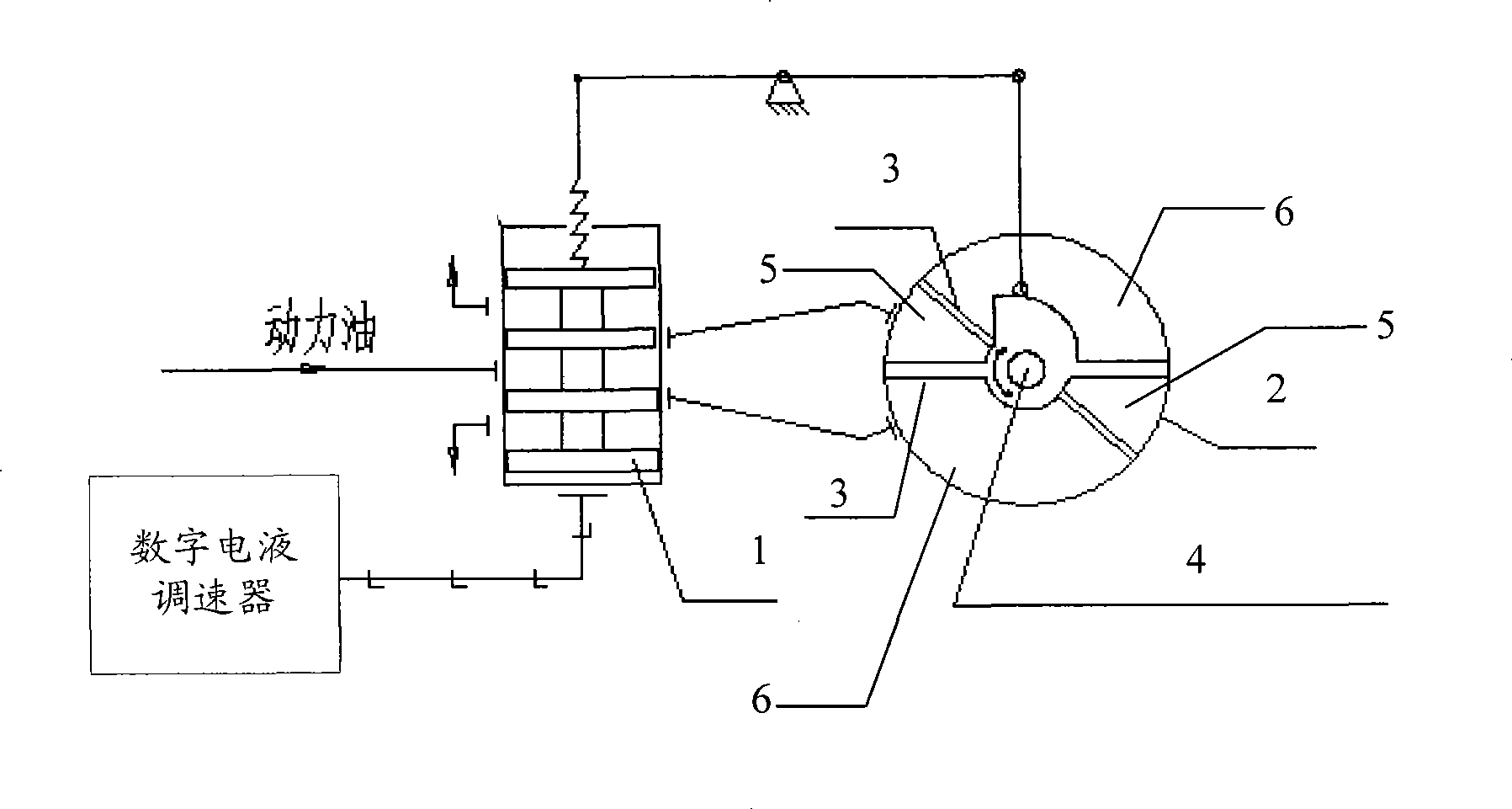

[0012] In order to clearly illustrate the technical solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

[0013] see figure 1 , the rotary servo oil motor includes: the oil valve 1 receiving the power oil is connected to the digital electro-hydraulic governor that generates the control signal, the oil valve 1 inputs the power oil into the corresponding chambers in the connected oil cylinder 2 according to the control signal, and drives The cam and the rotating flap connected to the rotating shaft 4 in the oil cylinder 2 rotate, and the rotating flap rotates to adjust the air valve to control the speed and load of the turbine.

[0014] The DEH control signal generated by the digital electro-hydraulic governor enters the bottom of the slide valve 1, pushing the slide valve 1 to move up or down, and the power oil with high pressure and large flow enters the chamber 5 or chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com