Efficient high-pressure horizontal multi-stage centrifugal pump

A centrifugal pump and high-pressure technology, applied in the field of centrifugal pumps, can solve problems such as low efficiency, difficult maintenance, complex structure, etc., and achieve the effects of compact overall structure, improved cavitation performance, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

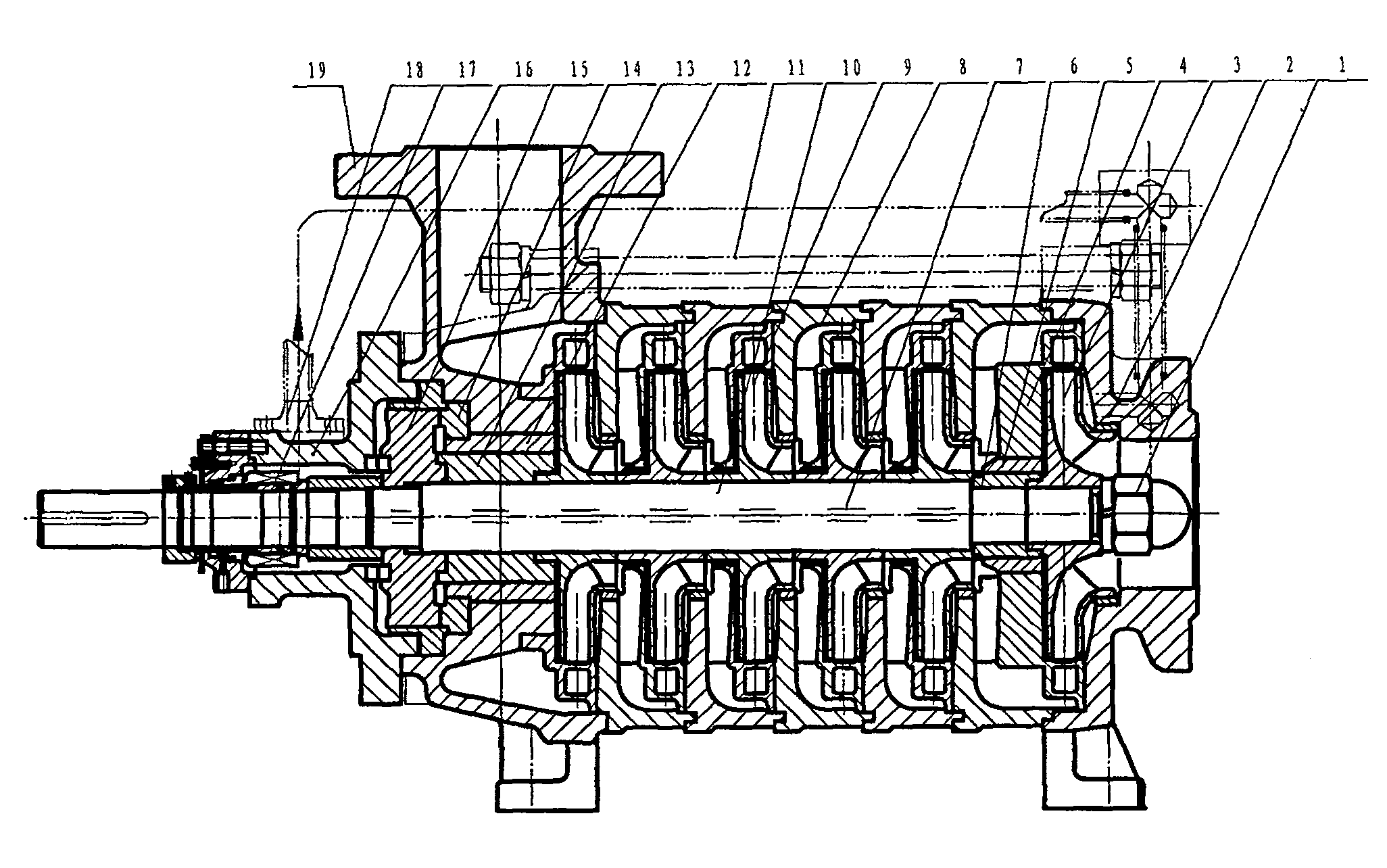

[0007] The present invention is used as a high-pressure pump (2 sets, flow rate 220m 3 / h, lift 600m, single-stage lift 100m, six-stage pump), such as figure 1 As shown, it is composed of water inlet and outlet parts, hydraulic parts for energy conversion, axial force automatic balance device, support parts, mechanical seal parts and couplings.

[0008] The water inlet and outlet components include: a water inlet section 2 and a water outlet section composition 19 . It mainly plays the role of water inlet guide and outlet water collection.

[0009] The hydraulic components for energy conversion include: primary impeller 3 , guide vane 4 , middle section 8 , and secondary impeller 9 . The first-stage impeller 3 and the secondary impeller 9 function to convert energy, so that the transported liquid can obtain energy; the guide vane 4 collects the liquid, converts kinetic energy into pressure energy, and introduces the liquid into the next-stage impeller or the outlet section; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com