Pump shaft sleeve

A technology of pump shaft sleeves and shaft sleeves, which is applied in the field of pump shaft sleeves and pump shaft sleeves for circumferential positioning at the end of the shaft sleeves. It can solve the problems of reducing the strength of the rotor, increasing the length of the pump shaft, and increasing the size of the shaft diameter. Achieve the effect of shortening the length of the pump shaft and enhancing the strength of the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

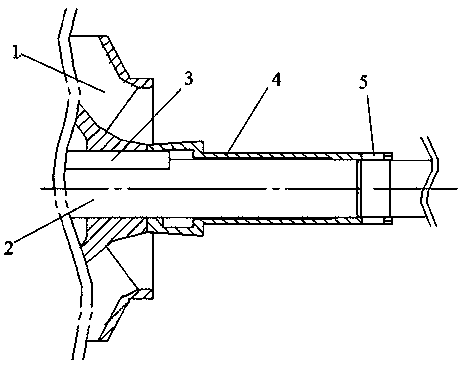

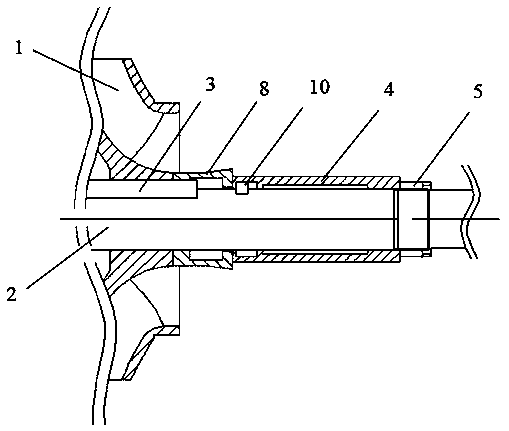

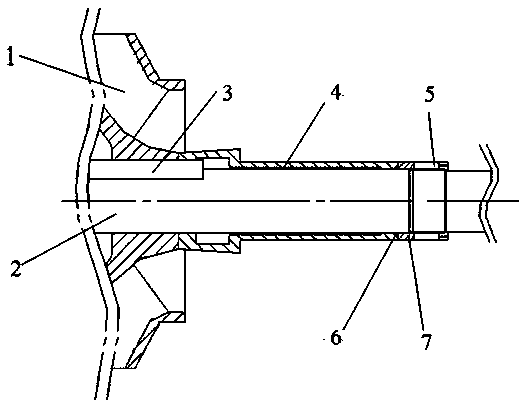

[0015] Pump shaft sleeve, including shaft sleeve 4, shaft sleeve nut 5, "O" type seal ring 6, impeller retainer sleeve 8 and "L" type key 9, after the impeller flat key 3 and impeller 1 are installed on the pump shaft 2, Install the impeller retaining sleeve 8, "O" type seal ring 6, shaft sleeve 4, "L" type key 9 and shaft sleeve nut 5 on the pump shaft in sequence. The tail end of the impeller retaining sleeve 8 is a plane, the front end of the shaft sleeve 4 does not have a keyway, but has a 45° chamfer, and the "O" type seal ring 6 is installed on the outer circle of the pump shaft 2 1. The triangular position between the plane of the tail end of the impeller block sleeve 8 and the 45° chamfer at the front end of the shaft sleeve 4 is used to seal the outward leakage of the medium between the shaft sleeve 4 and the pump shaft 2 . The tail e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com