Single-shaft plusing multiple-shaft type carbon dioxide gas centrifugal compressor unit

A carbon dioxide, compressor unit technology, applied in mechanical equipment, non-variable-capacity pumps, machines/engines, etc., can solve problems such as high gear pitch speed, waste of energy, and reduced operational reliability, and achieve a high single-stage pressure ratio. , The effect of improving stage efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings.

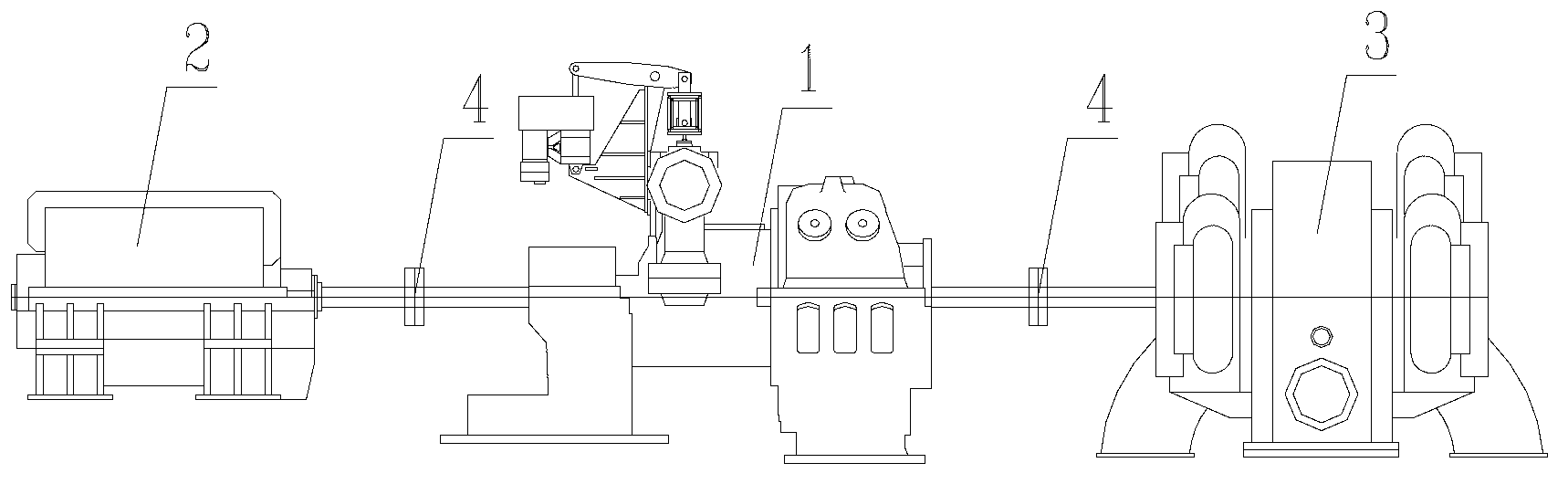

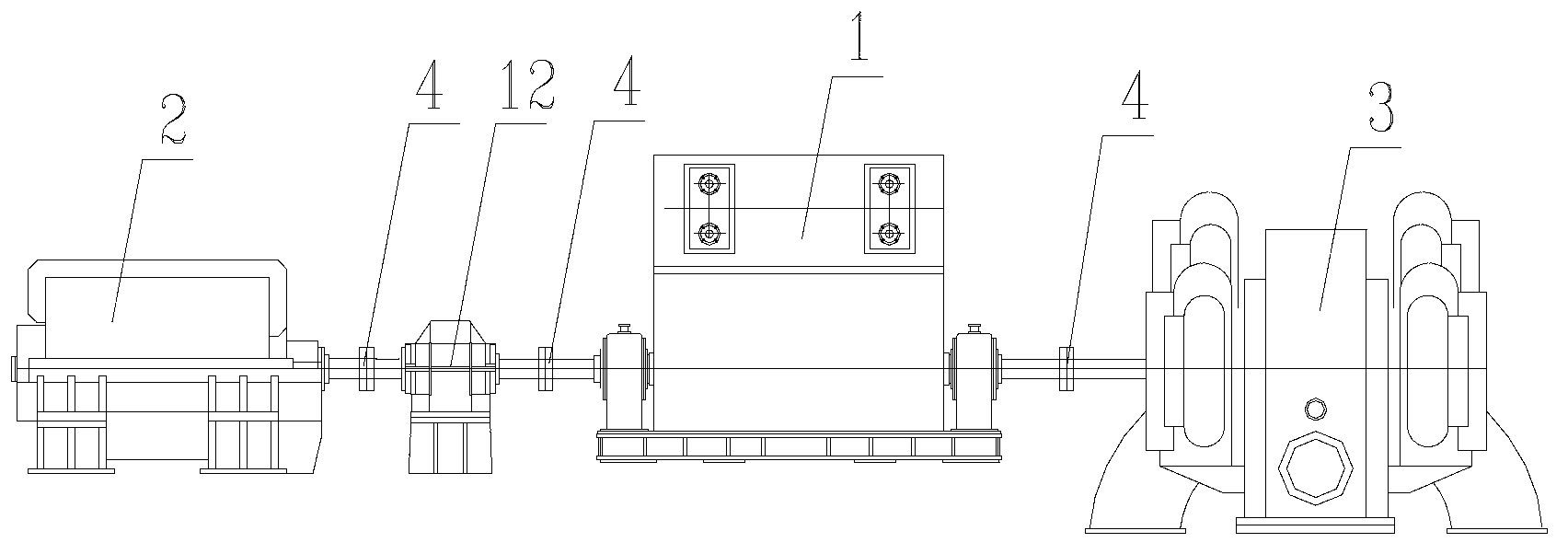

[0055] refer to figure 1 , a single-shaft + multi-shaft carbon dioxide centrifugal compressor unit, including a double-shaft driving device 1, the double-shaft driving device 1 is a steam turbine, and the left shaft of the double-shaft driving device 1 uses a diaphragm coupling The device 4 is directly connected with the single-shaft low-pressure cylinder 2, and the right output shaft of the double-shaft drive device 1 is connected with the multi-shaft high-pressure cylinder 3 with the diaphragm coupling 4;

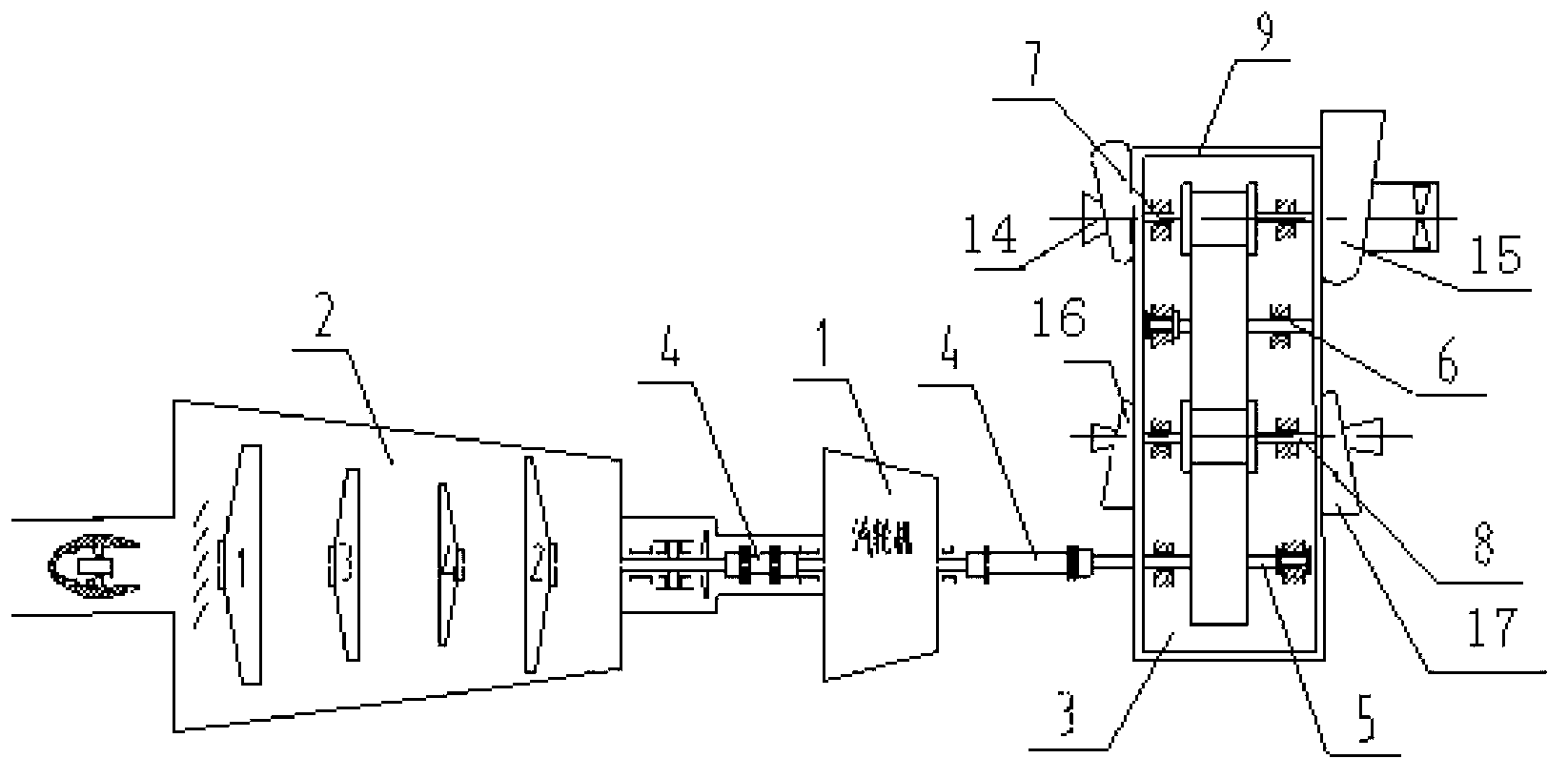

[0056] refer to figure 2 , the steam turbine 1 is directly connected to the first pinion shaft 5 directly below the multi-shaft high-pressure cylinder 3 through the coupling 4, the first pinion shaft 5 meshes with the bull gear 6, drives the bull gear 6, and the bull gear 6 is connected to the gearbox 9 The second pinion shaft 7 on both horizontal sides meshe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com