System and method for liquefying natural gas through multi-component refrigerant cycle refrigeration

A liquefied natural gas and refrigerant circulation technology, applied in the field of natural gas liquefaction, can solve the problems of high operation and maintenance requirements, high cost, large system area, etc., and achieve the effect of compact structure, high speed and small area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

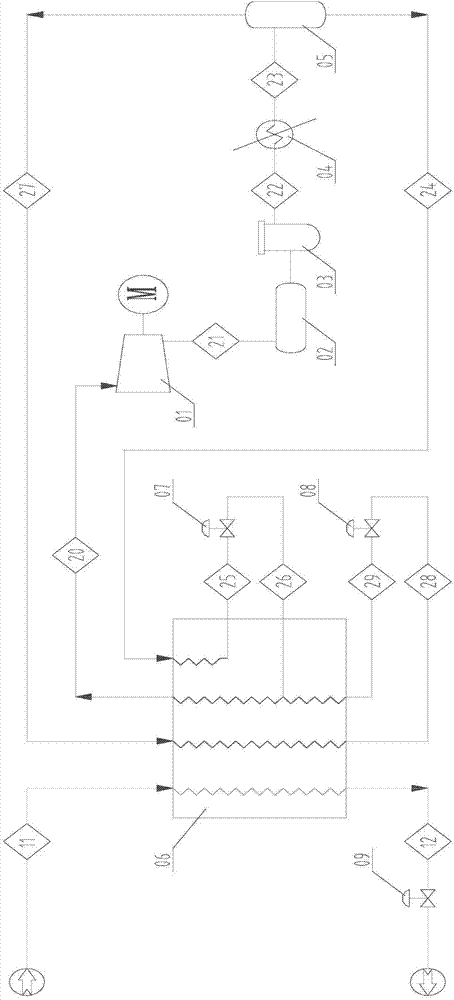

[0082] use as figure 1 The shown multi-component refrigerant cycle refrigeration system for liquefied natural gas, the multi-component refrigerant is composed of 10wt% nitrogen, 23wt% methane, 35wt% ethylene, 15wt% propane and 17wt% isopentane, and the raw natural gas does not contain heavy hydrocarbons , and the processing capacity is 5×10 4 N m 3 / d.

[0083] The multi-component refrigerant is pressurized through the oil-injected screw compressor to obtain a multi-component refrigerant containing oil after pressurization, the pressure reaches 3.2MPa, and the temperature is 115°C; among them, the oil-injected screw compressor is lubricated with micro-oil , the amount of oil entering the compressor is 1.7L / min, the inlet pressure of the compressor is 0.2MPa, the outlet pressure is 3.2MPa, the inlet temperature is 10°C-45°C, and the outlet temperature is 115°C; the cycle of multi-component refrigerant The flow rate is 5200Nm 3 / h;

[0084] The pressurized oil-containing mu...

Embodiment 2

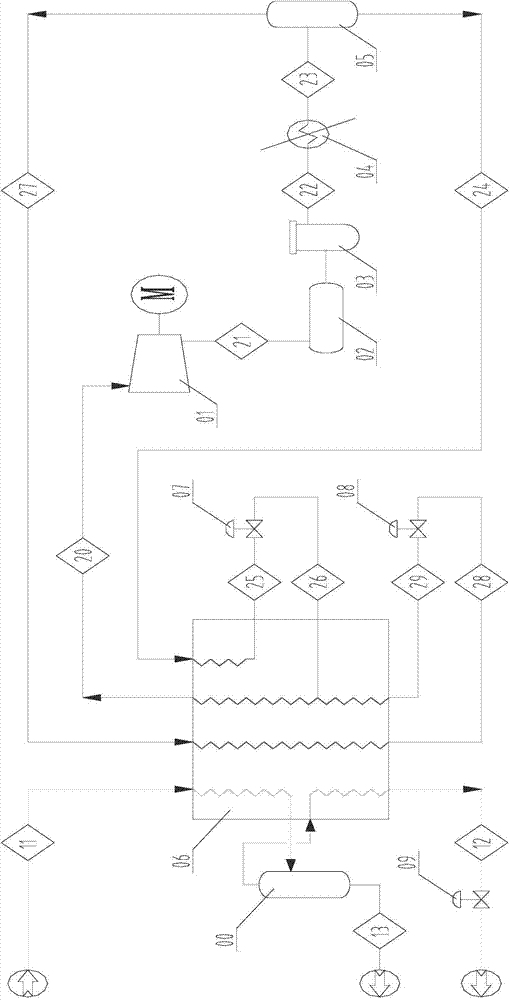

[0091] use as figure 2 The shown multi-component refrigerant cycle refrigeration system for liquefied natural gas, the multi-component refrigerant is composed of 10wt% nitrogen, 25wt% methane, 37wt% ethylene, 13wt% propane and 15wt% isopentane, and the raw natural gas contains a small amount of heavy hydrocarbons (C 6+ wt%: 0.02~0.09), and the processing capacity is 5×10 4 N m 3 / d.

[0092] The multi-component refrigerant is pressurized through an oil-injected screw compressor to obtain a multi-component refrigerant containing oil after pressurization, with a pressure of 3.5 MPa and a temperature of 120°C; among them, the oil-injected screw compressor is lubricated with minimal oil , the amount of oil entering the compressor is 1.7L / min, the inlet pressure of the compressor is 0.2MPa, the outlet pressure is 3.5MPa, the inlet temperature is 10°C-45°C, and the outlet temperature is 120°C; the cycle of multi-component refrigerant The flow rate is 5200Nm 3 / h;

[0093] The...

Embodiment 3

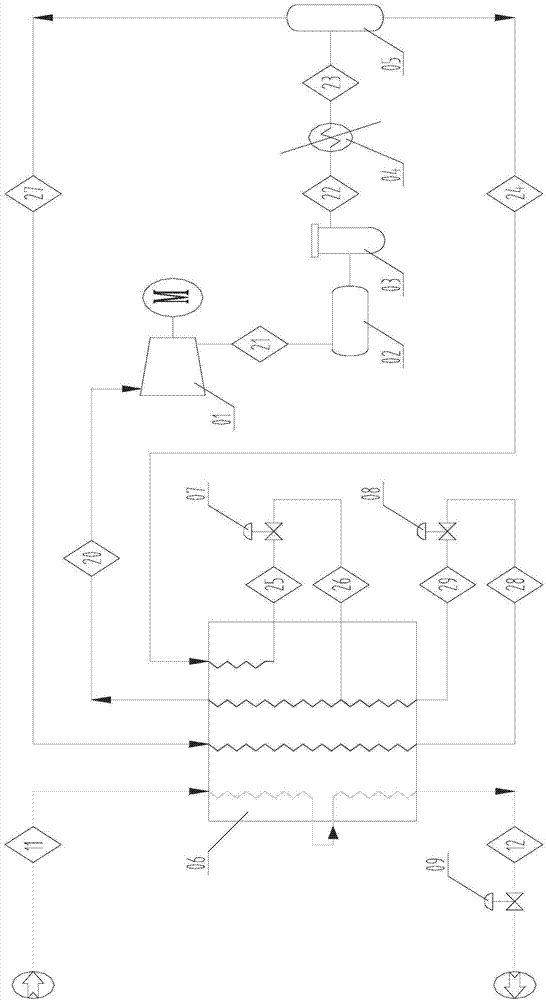

[0100] use as image 3 The shown multi-component refrigerant circulation refrigeration system for liquefied natural gas, multi-component refrigerant is composed of 10wt% nitrogen, 23wt% methane, 35wt% ethylene, 15wt% propane and 17wt% isopentane, raw natural gas contains variable weight Hydrocarbons, and the processing capacity is 5×10 4 N m 3 / d.

[0101] The multi-component refrigerant is pressurized through the oil-injected screw compressor to obtain a multi-component refrigerant containing oil after pressurization, the pressure reaches 3.2MPa, and the temperature is 115°C; among them, the oil-injected screw compressor is lubricated with micro-oil , the amount of oil entering the compressor is 1.7L / min, the inlet pressure of the compressor is 0.2MPa, the outlet pressure is 3.2MPa, the inlet temperature is 10°C-45°C, and the outlet temperature is 115°C; the cycle of multi-component refrigerant The flow rate is 5200Nm 3 / h;

[0102] The pressurized oil-containing multi-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com