Patents

Literature

112results about How to "Uniform exhaust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

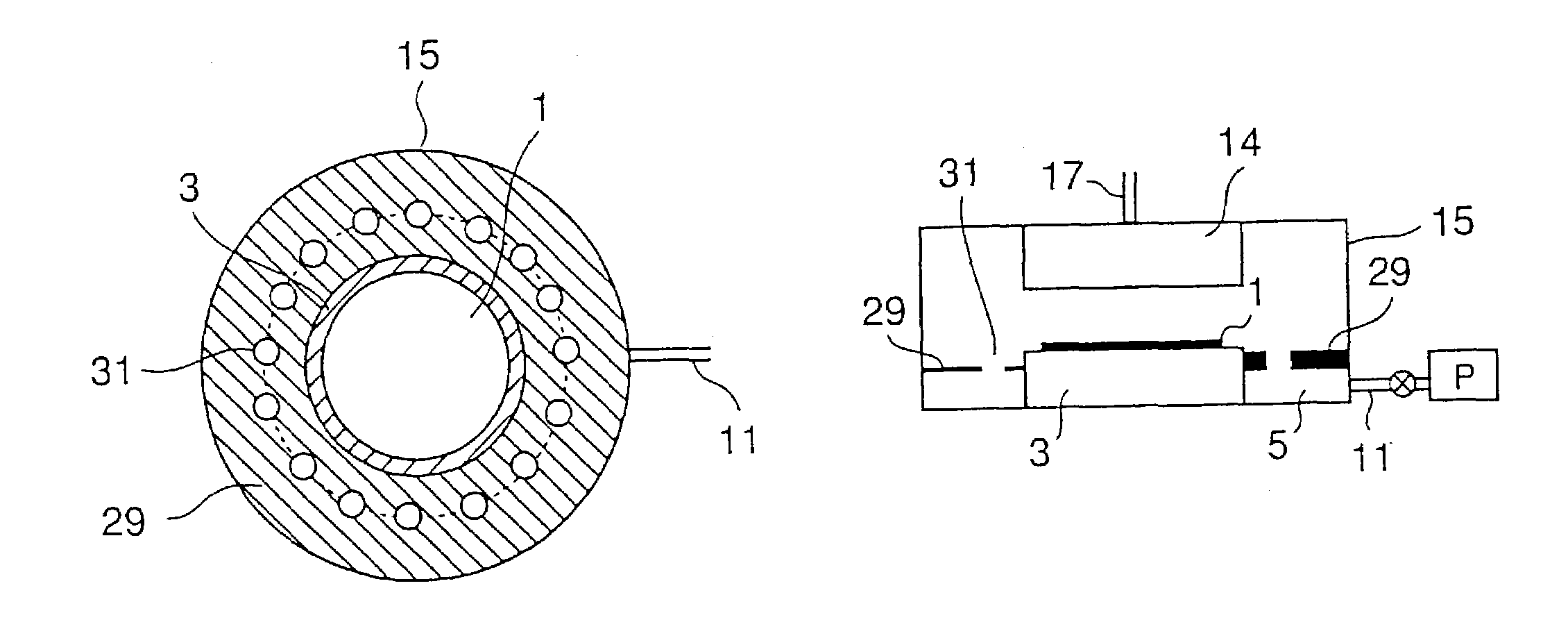

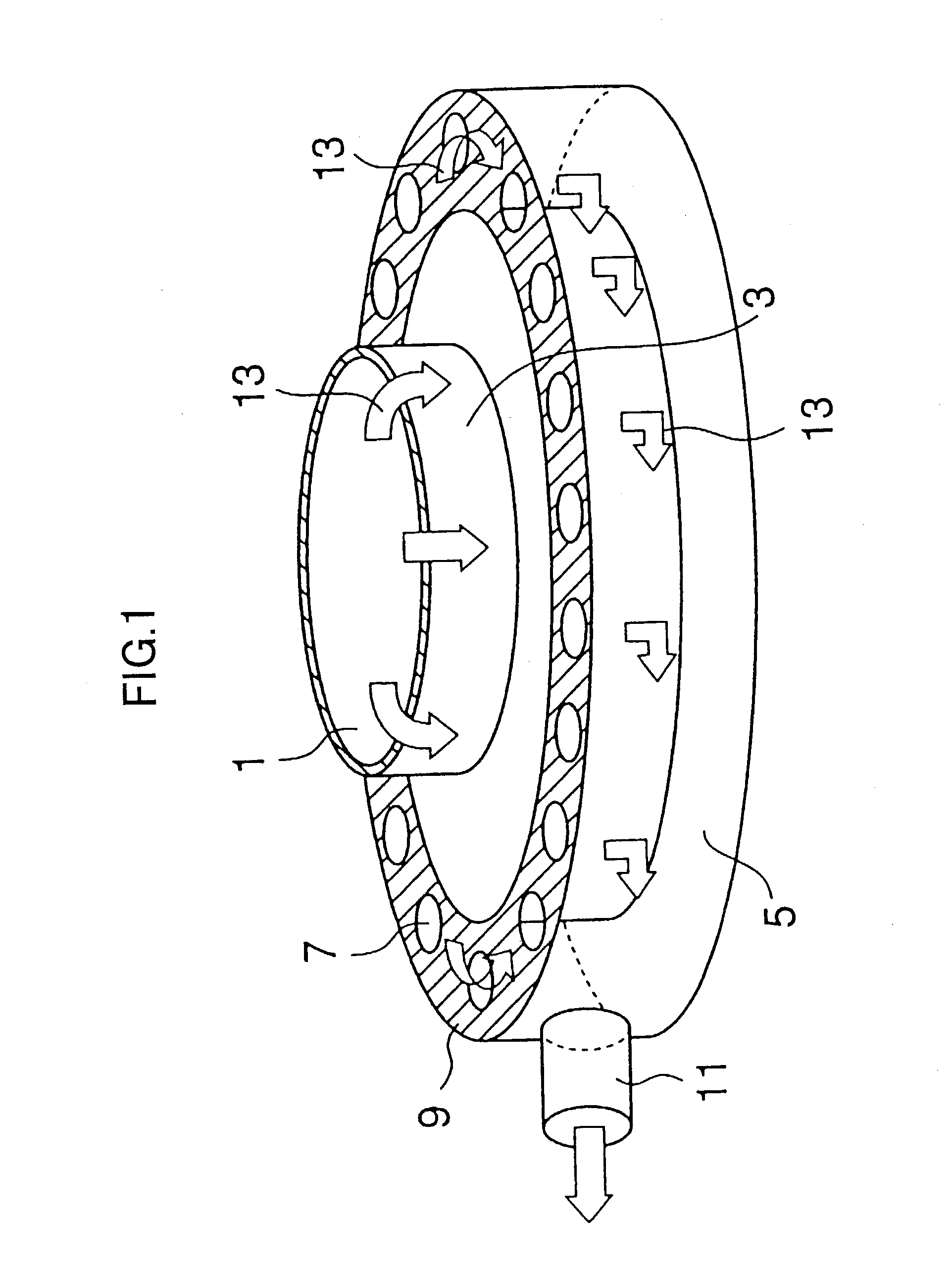

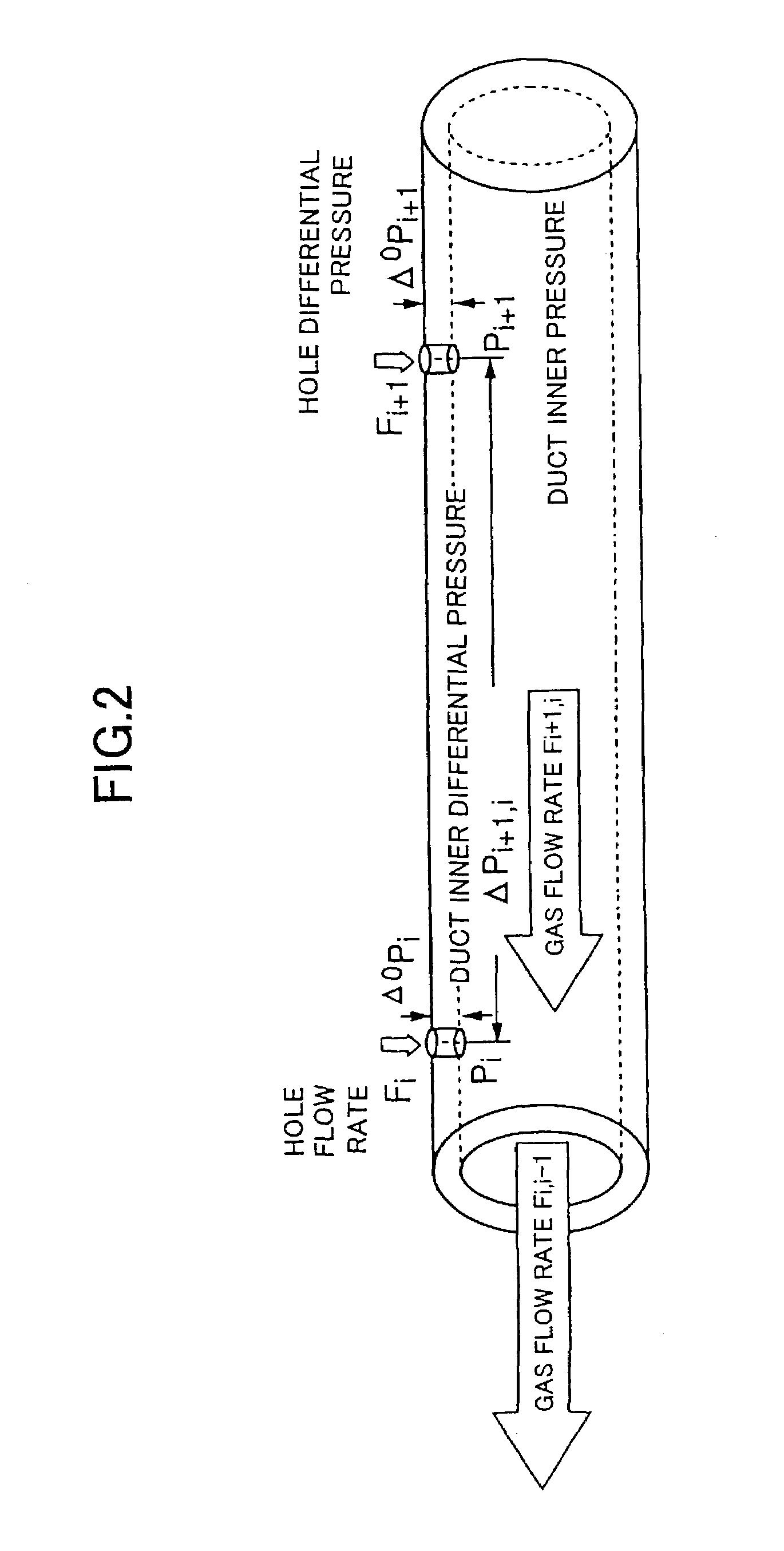

Baffle plate, apparatus for producing the same, method of producing the same, and gas processing apparatus containing baffle plate

InactiveUS7648610B2Uniform exhaustElectric discharge tubesSemiconductor/solid-state device manufacturingChemical treatmentProduct gas

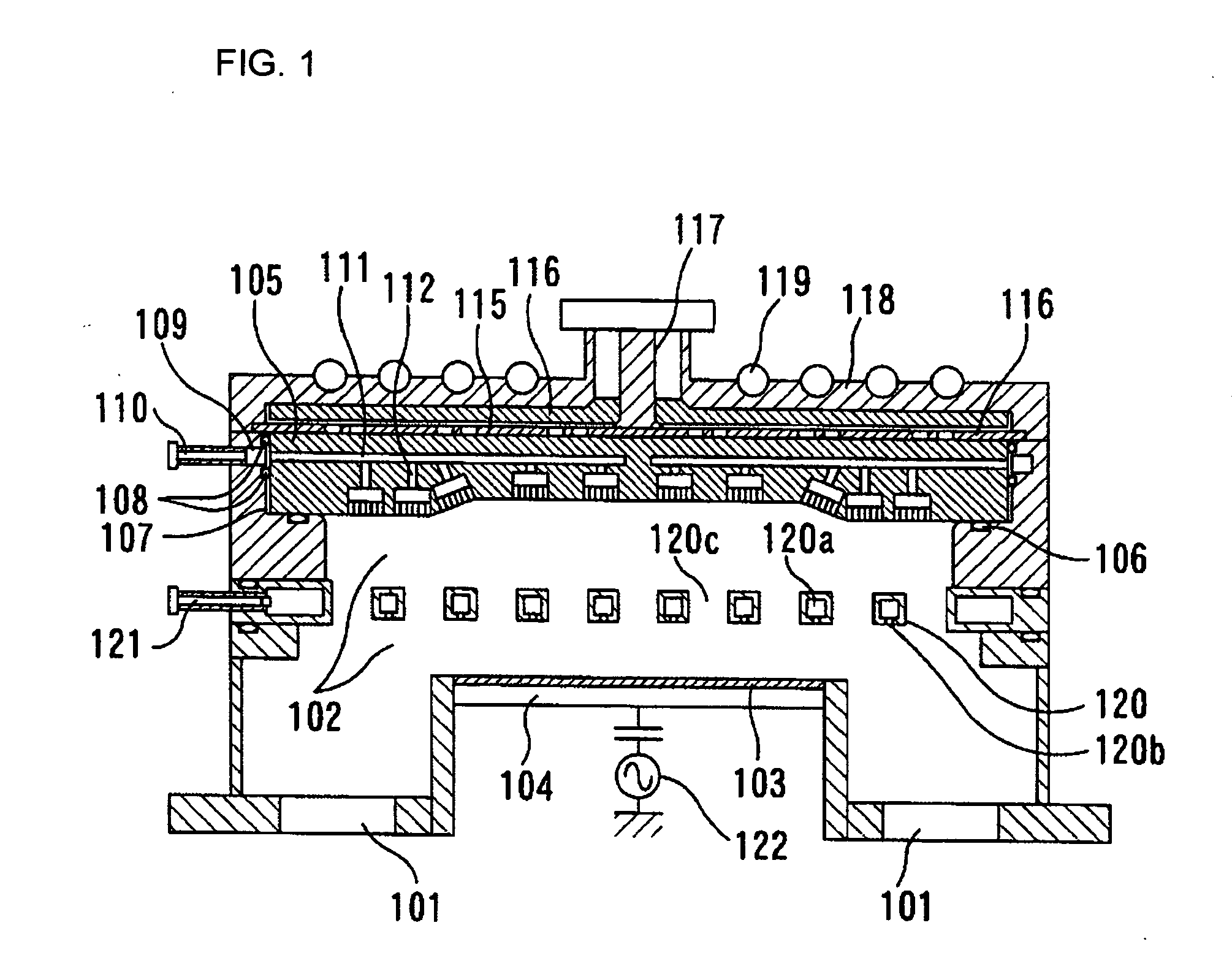

The present invention provides a gas process apparatus that realizes uniform exhaust without depending on process conditions, a gas process chamber that constitutes the gas process apparatus, a baffle plate mounted on the gas process chamber, a method of producing the baffle plate, and an apparatus for producing the baffle plate. The baffle plate of the present invention serves as a partition between a process space in which a chemical process is carried out with a supplied gas, and a duct that is adjacent to the process space and functions to discharge exhaust gas generated as a result of the chemical process. In accordance with the difference between the pressures on both sides of the baffle plate, which difference varies depending on the location on the baffle plate, the baffle holes are disposed on a plurality of locations on the baffle plate.

Owner:TOKYO ELECTRON LTD

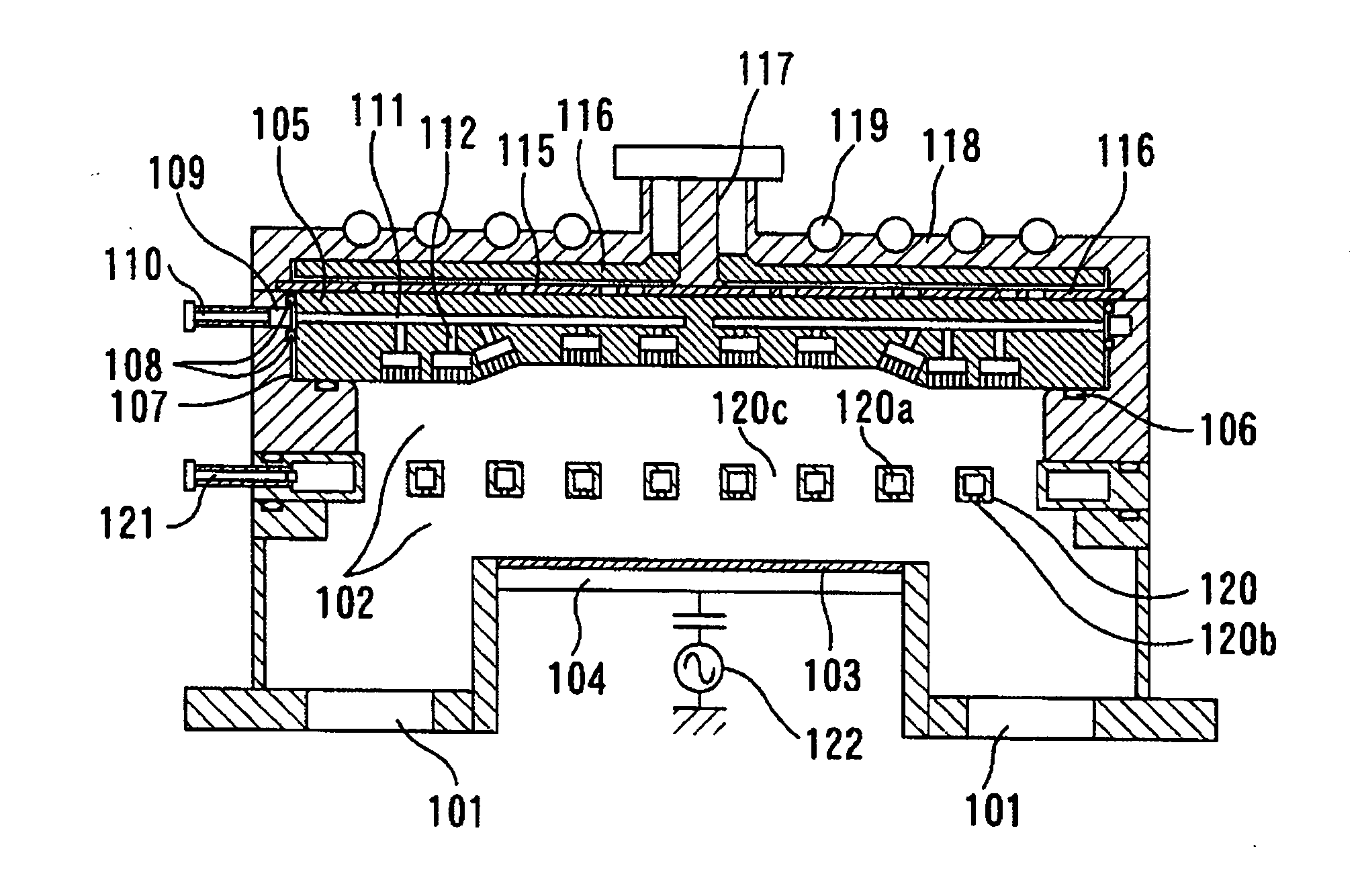

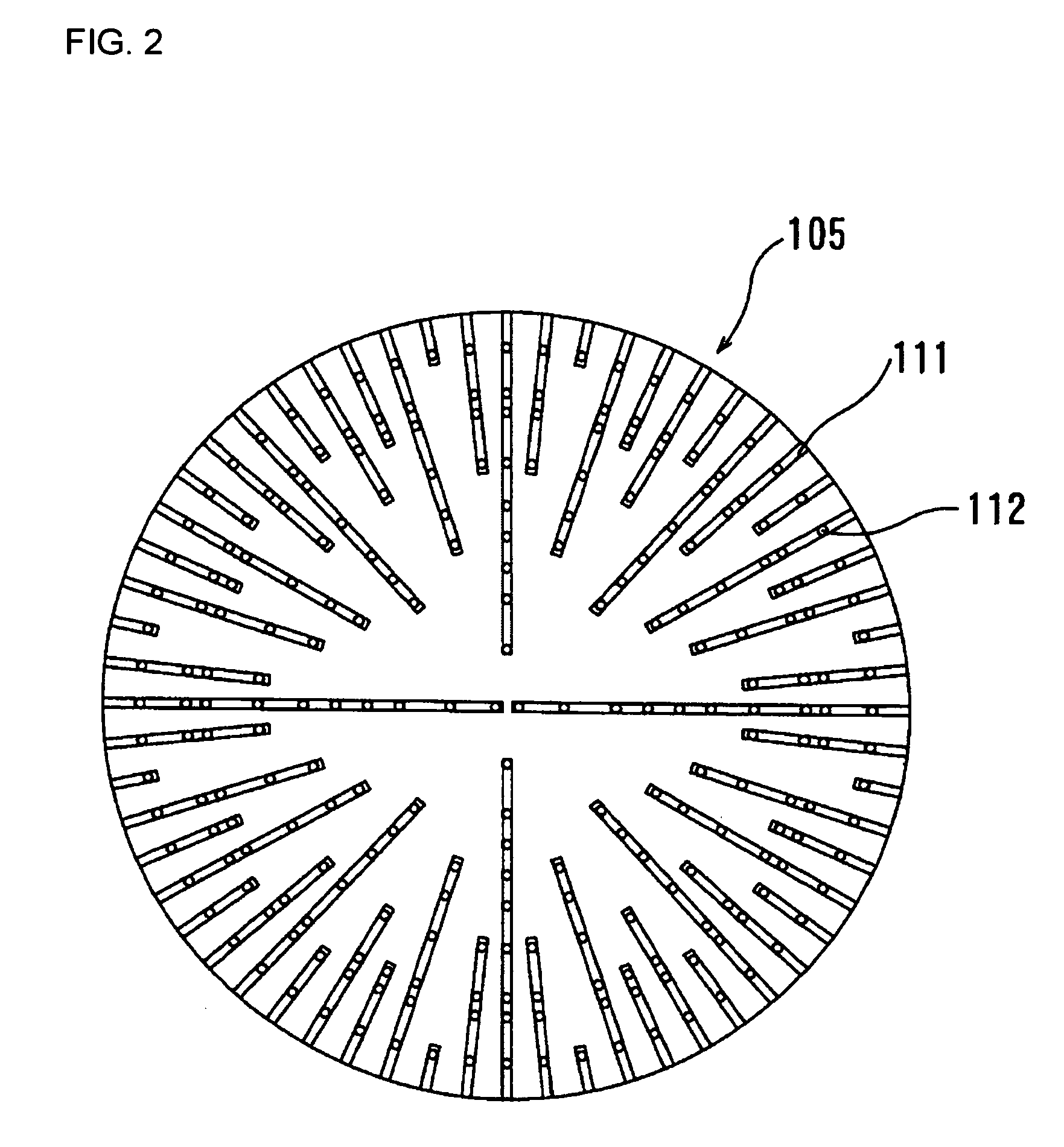

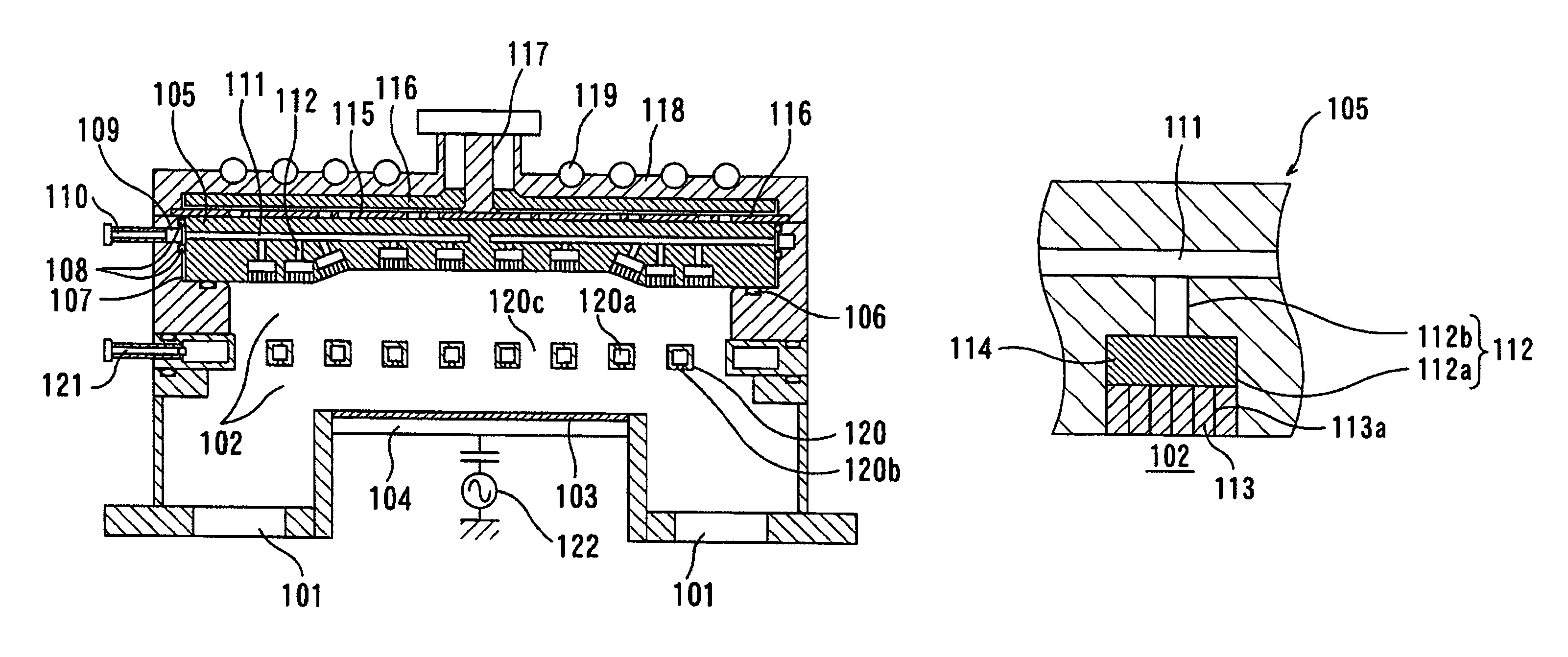

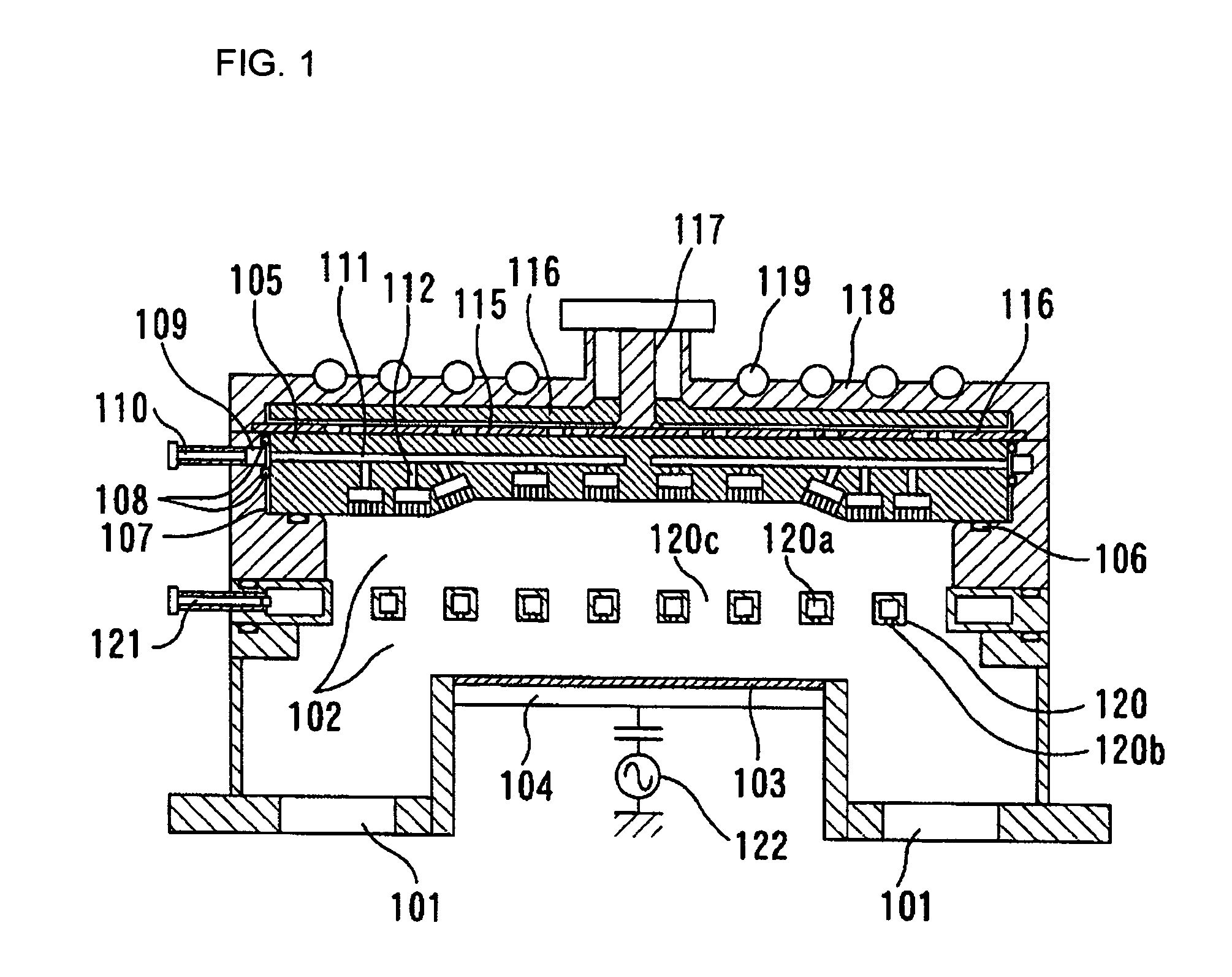

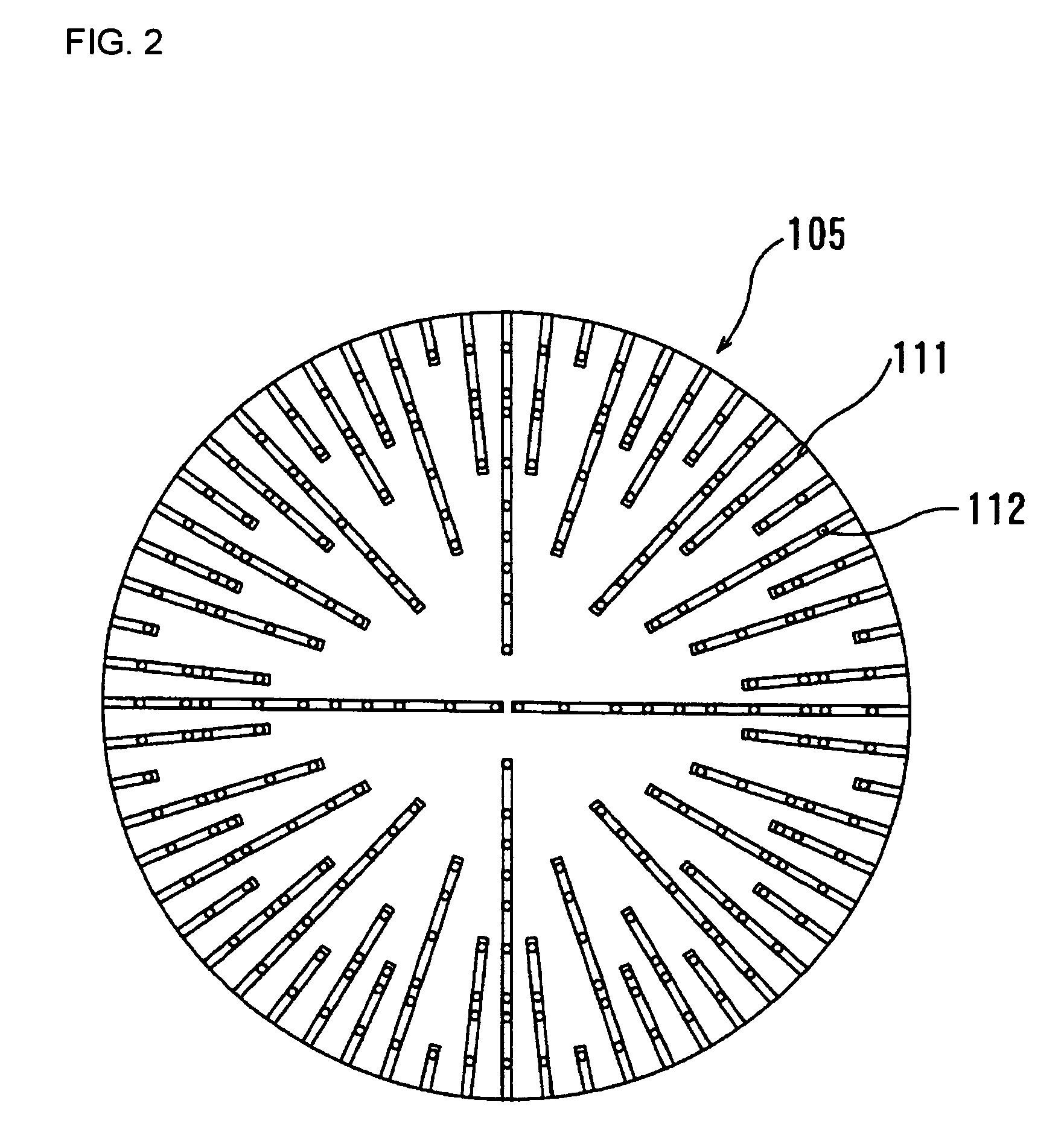

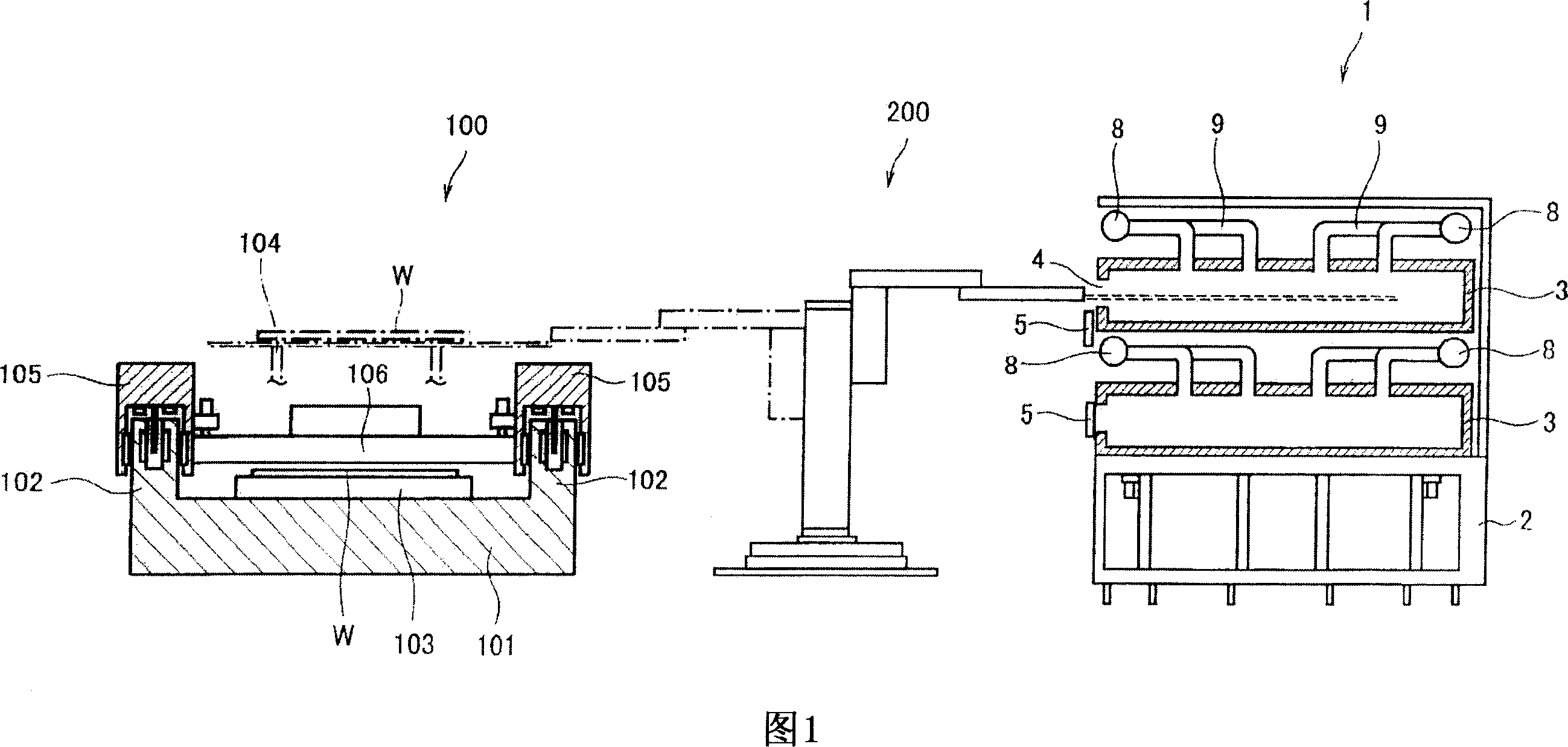

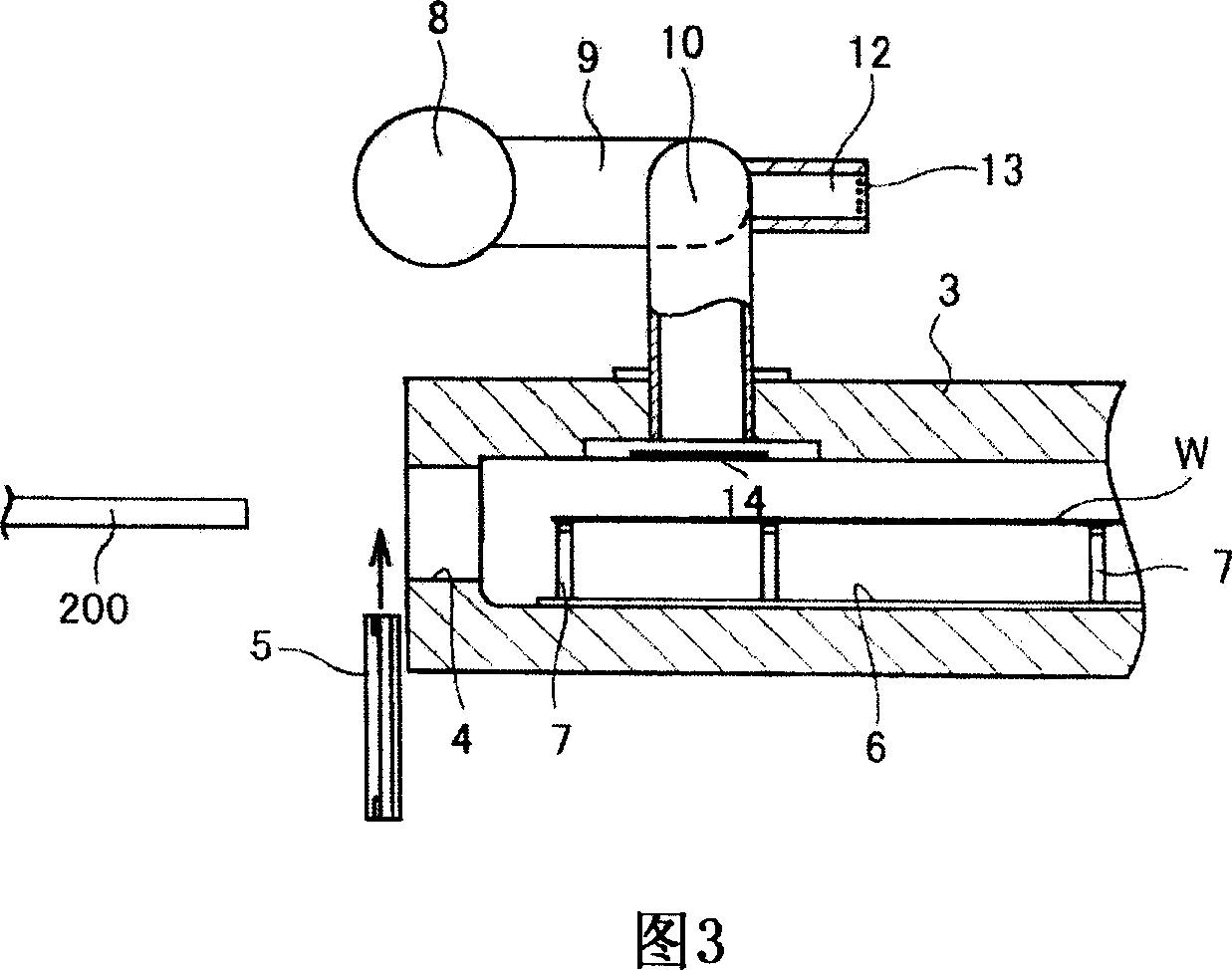

Shower Plate, Method for Manufacturing the Shower Plate, Plasma Processing Apparatus using the Shower Plate, Plasma Processing Method and Electronic Device Manufacturing Method

InactiveUS20100230387A1Low efficiencyPrevent backflowElectric discharge tubesDecorative surface effectsGas passingPore diameter

Occurrence of a back-flow of plasma or ignition of gas for plasma excitation in a longitudinal hole portion can be prevented more completely, and a shower plate in which efficient plasma excitation is possible is provided. In shower plate 105, which is arranged in processing chamber 102 of a plasma processing apparatus and discharges gas for plasma excitation into processing chamber, porous-gas passing body 114 having a pore that communicates in the gas flow direction is fixed onto longitudinal hole 112 used as a discharging path of gas for plasma excitation. The pore diameter of a narrow path in a gas flowing path formed of a pore, which communicates to porous-gas passing body 114, is 10 μm or lower.

Owner:TOKYO ELECTRON LTD +1

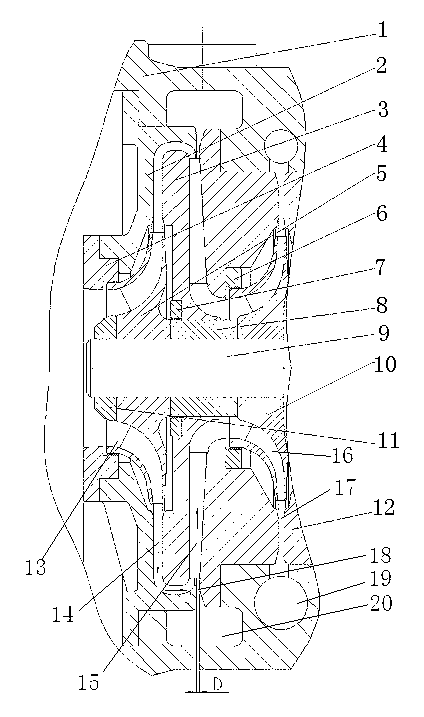

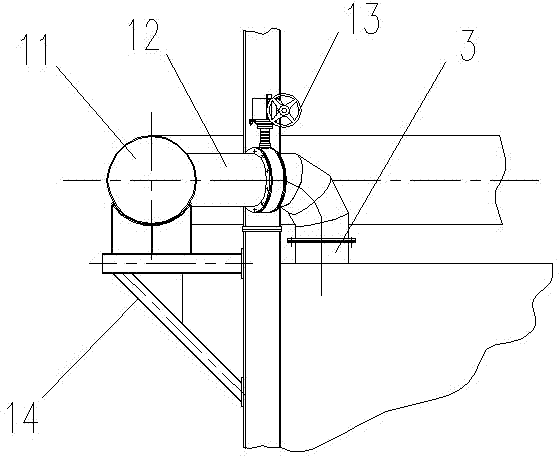

Novel interstage air supplementing device of multi-stage compression centrifugal type refrigeration compressor

InactiveCN103016409APlay the role of ejectionImprove uniformityPump componentsRadial flow pumpsRefrigeration compressorImpeller

The invention discloses a novel interstage air supplementing device of a multi-stage compression centrifugal type refrigeration compressor. The air supplementing device is characterized in that a second-stage exhaust volute (19) is arranged in a casing (1); a first-stage suction guiding ring (11), a first-stage impeller (5), a second-stage impeller (10) and an impeller distance ring (8) are arranged on a transmission shaft (9); a second-stage suction passage (15) is arranged in an interstage baffle (3); a first-stage exhaust passage (14) is formed between a first-stage diffuser (2) and the interstage baffle (3) in the casing (1); a second-stage exhaust passage (17) is formed between the interstage baffle (3) and the second-stage impeller (10); the casing (1), the first-stage diffuser (2) and the interstage baffle (3) commonly form an air supplementing and supplying passage (20); a straight slot section (18) is formed between the first-stage diffuser (2) and the interstage baffle (3); and an inter-stage sealing ring (7), a first-stage wheel cover sealing (4) and a second-stage wheel cover sealing (6) are arranged. By the device, the interstage air can uniformly enter a reflux apparatus of the compressor; the efficiency of the compressor is improved; and the airflow noise of the compressor is reduced.

Owner:烟台蓝德空调工业有限责任公司

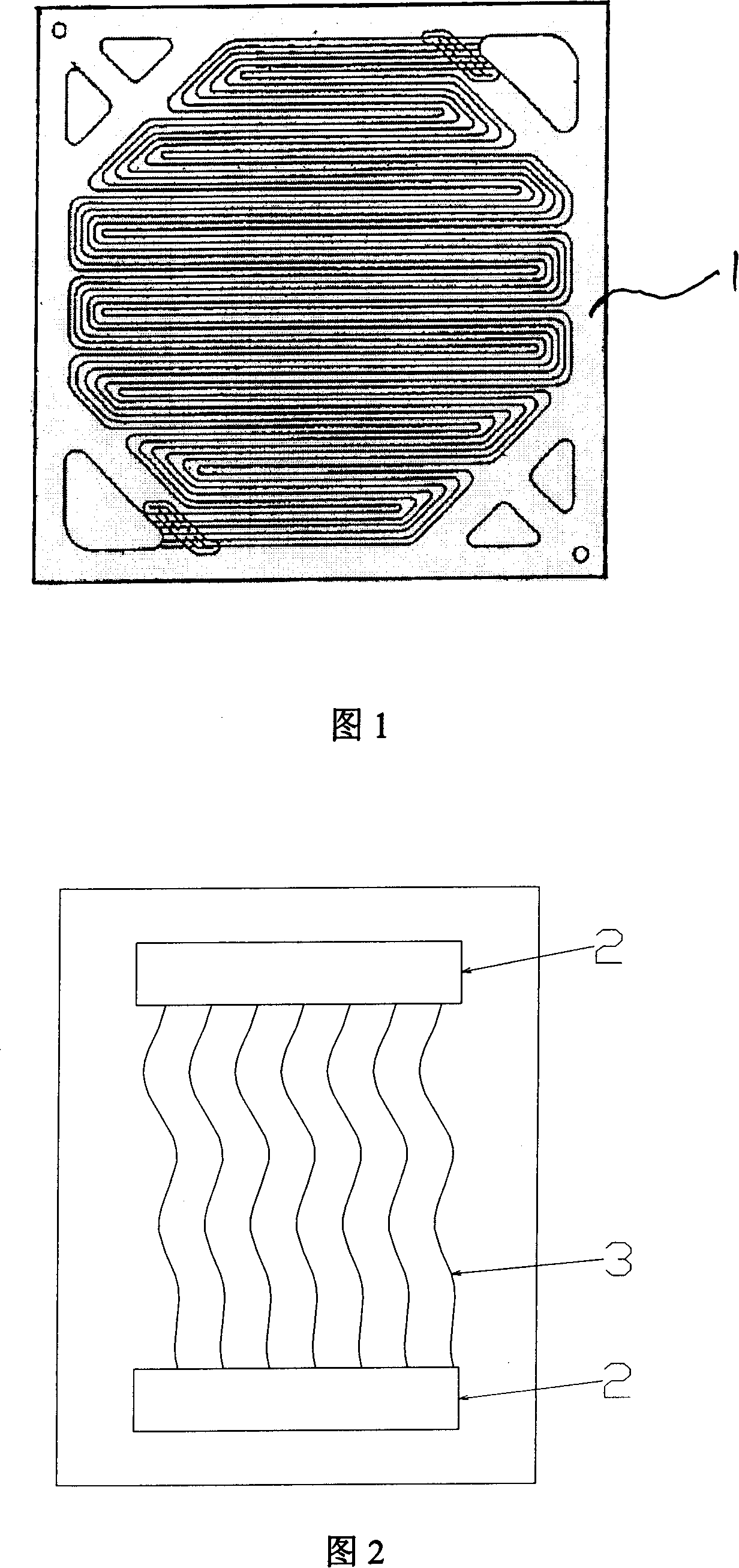

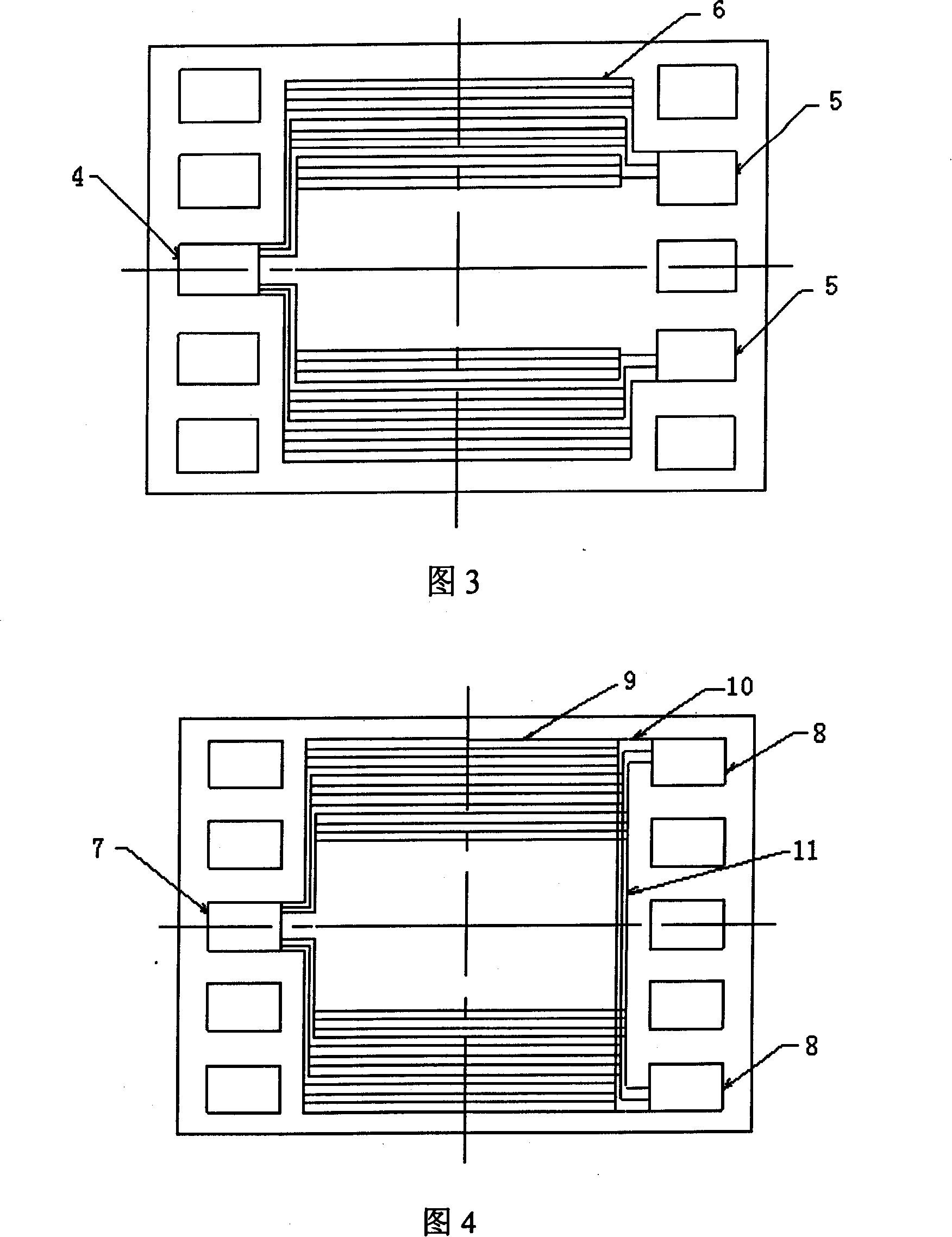

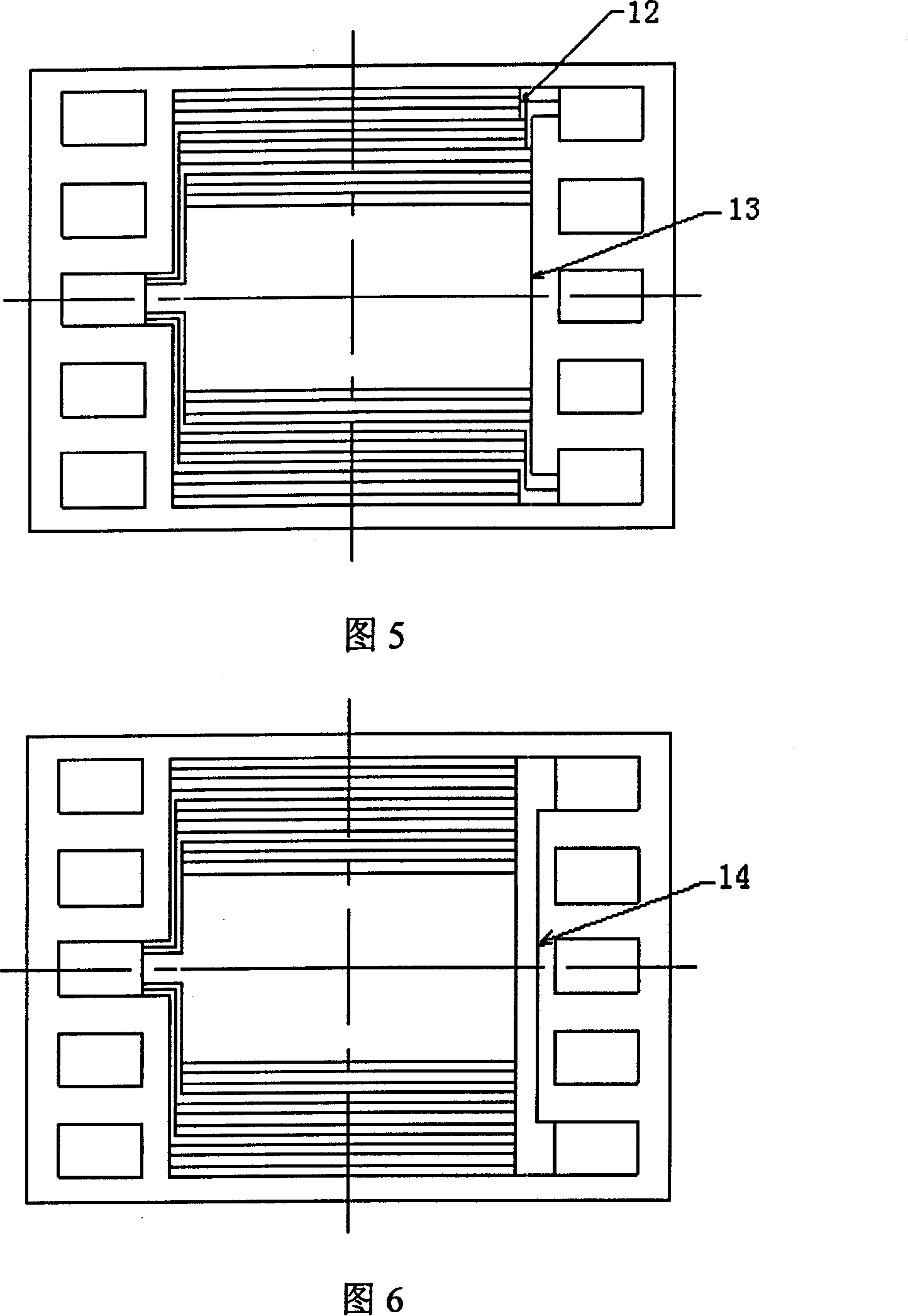

A fuel battery flow guiding polarized plate without water blockage

The invention relates to fuel battery guiding board which is not easy to stop water, the guiding board is guiding two-way board, said guiding two-way board comprises positive air guiding groove, negative hydrogen guiding groove, middle cooling flow interlayer, said flow hole which air or hydrogen in and out is single hole for in, two or more hole for out, guiding groove and connecting groove which connects guiding groove are set between flow hole for air or hydrogen, the guiding groove and connecting groove are all designed to direct flow groove or nearly direct flow groove; said flow hole for cooling liquid is single hole or double holes or more holes for in, two holes or more holes for out, guiding groove and connecting groove which connects guiding groove are set between flow hole for cooling liquid, the guiding groove and connecting groove are all designed to direct flow groove or nearly direct flow groove. Comparing with current technique, the invention can make liquid flow on liquid field evenly, freely; jam of guiding groove can be avoided.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

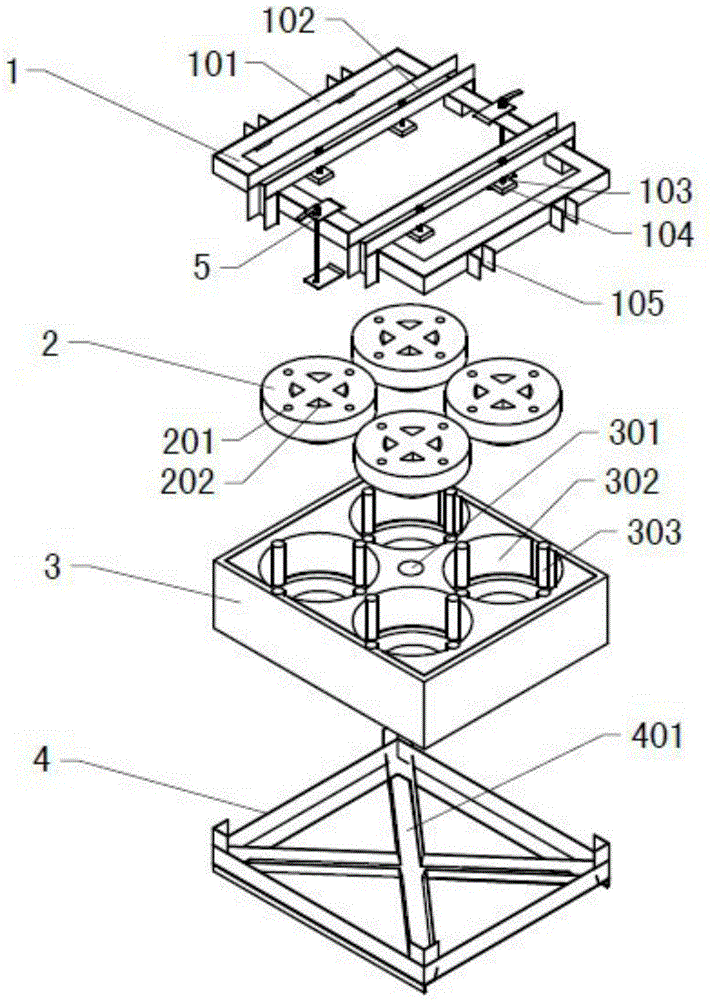

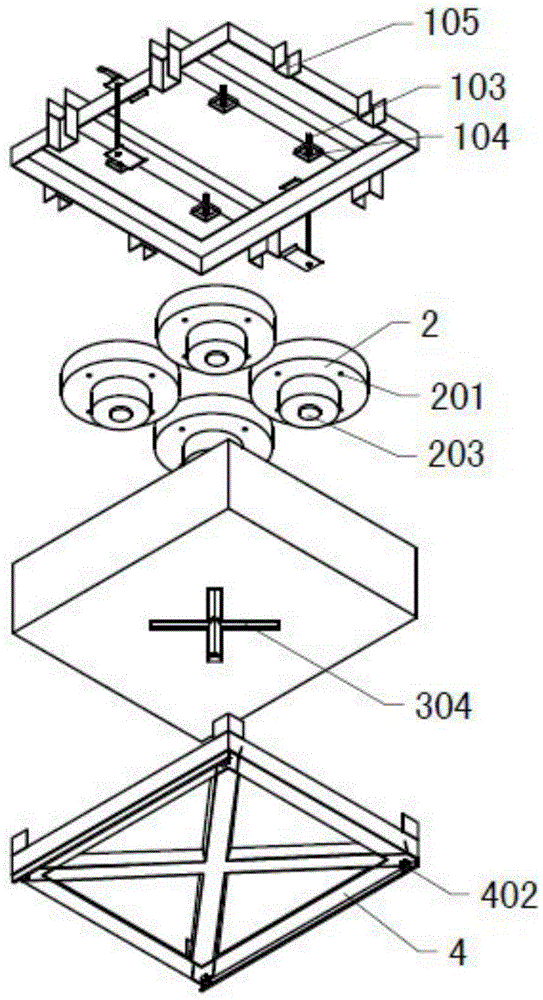

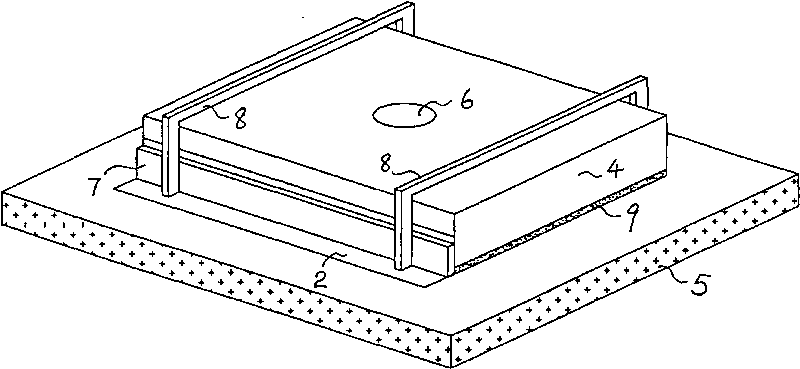

Modularized pulse aeration apparatus, standard aeration system module and filtration system

ActiveCN104084049AAvoid cloggingEvenly aeratedSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisAirflowStreamflow

The invention provides a modularized pulse aeration apparatus. After a small flow of airflow is continuously input, and a pulse aeration effect generating large bubbles by instantly uniformly releasing a large flow of airflow can be realized, so the aeration cleaning effect of a membrane is improved, and the energy consumption of equipment is reduced. The apparatus can avoid aeration failure caused by obstruction. The invention also provides a standard aeration system module. The standard aeration system module comprises one or more modularized pulse aeration apparatuses, and the release of airflows with different frequencies and different flows by any positions and number of the modularized pulse aeration apparatuses can be realized in the standard aeration system module according to practical use demands to reach different aeration intensities in order to improve the aeration cleaning effect of the membrane and reduce the energy consumption of the equipment. The invention further provides a filtration system. The filtration system can be an external shell membrane filtration system or a submerged membrane filtration system, and comprises one or more standard aeration system modules.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

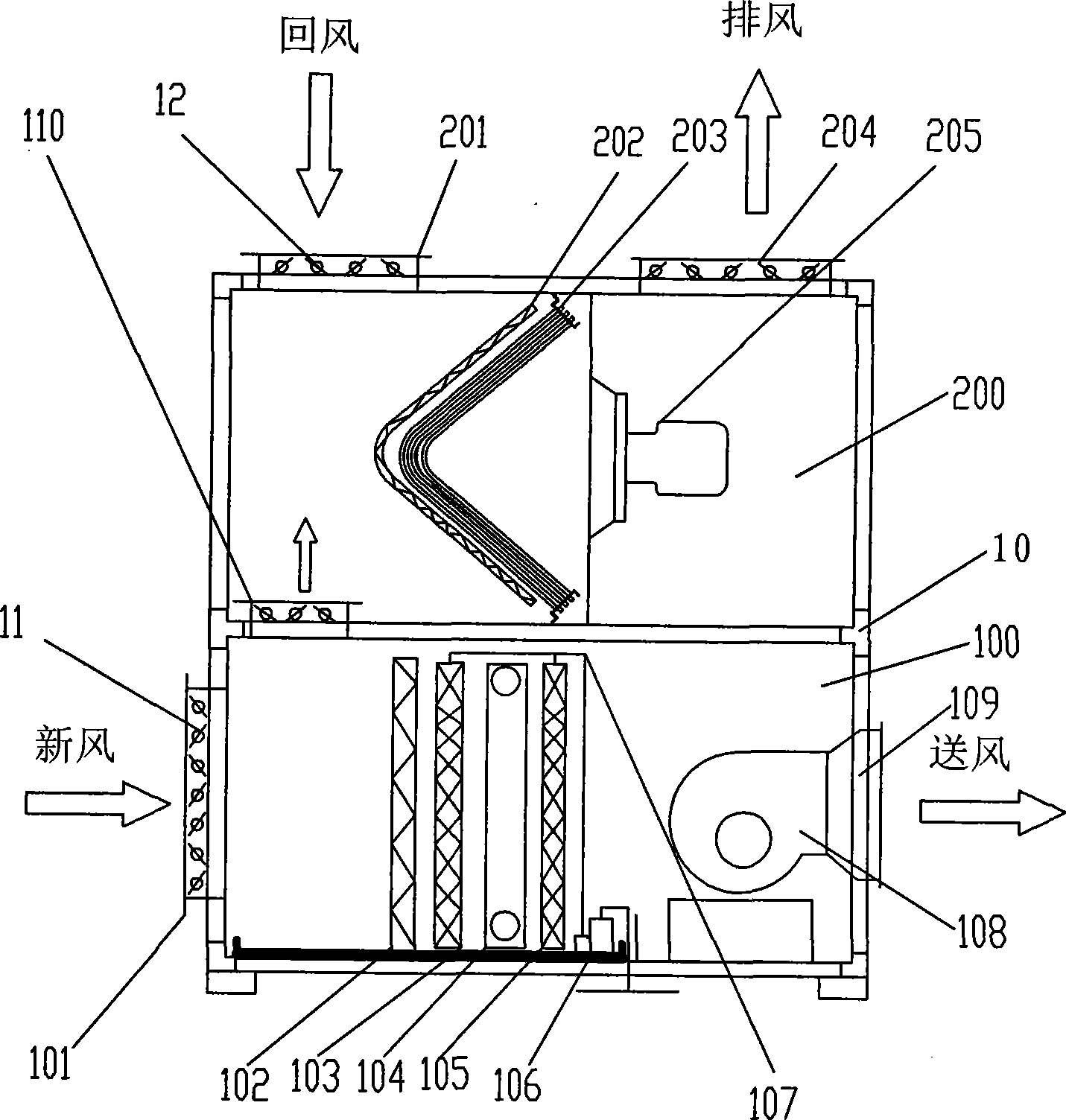

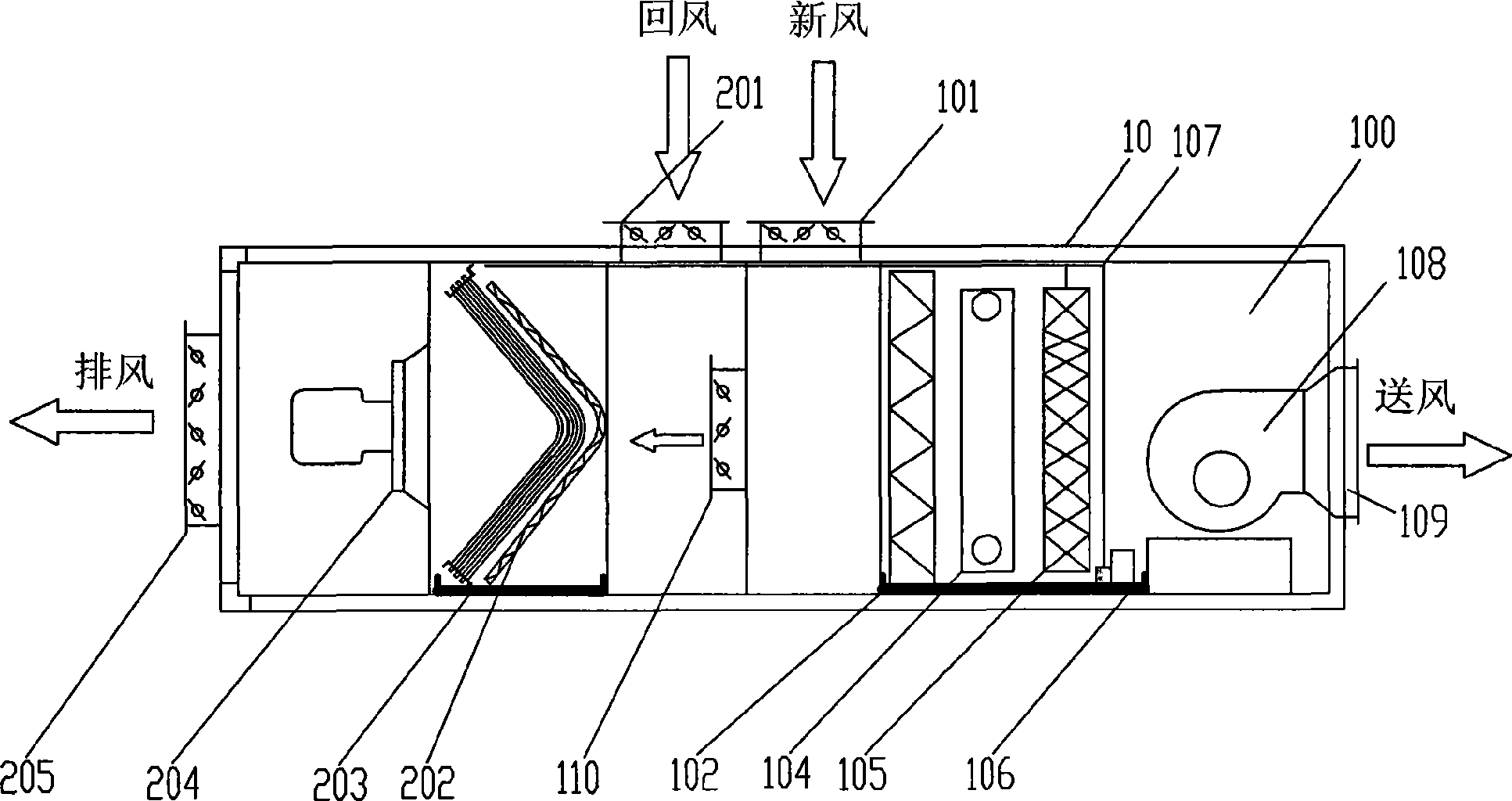

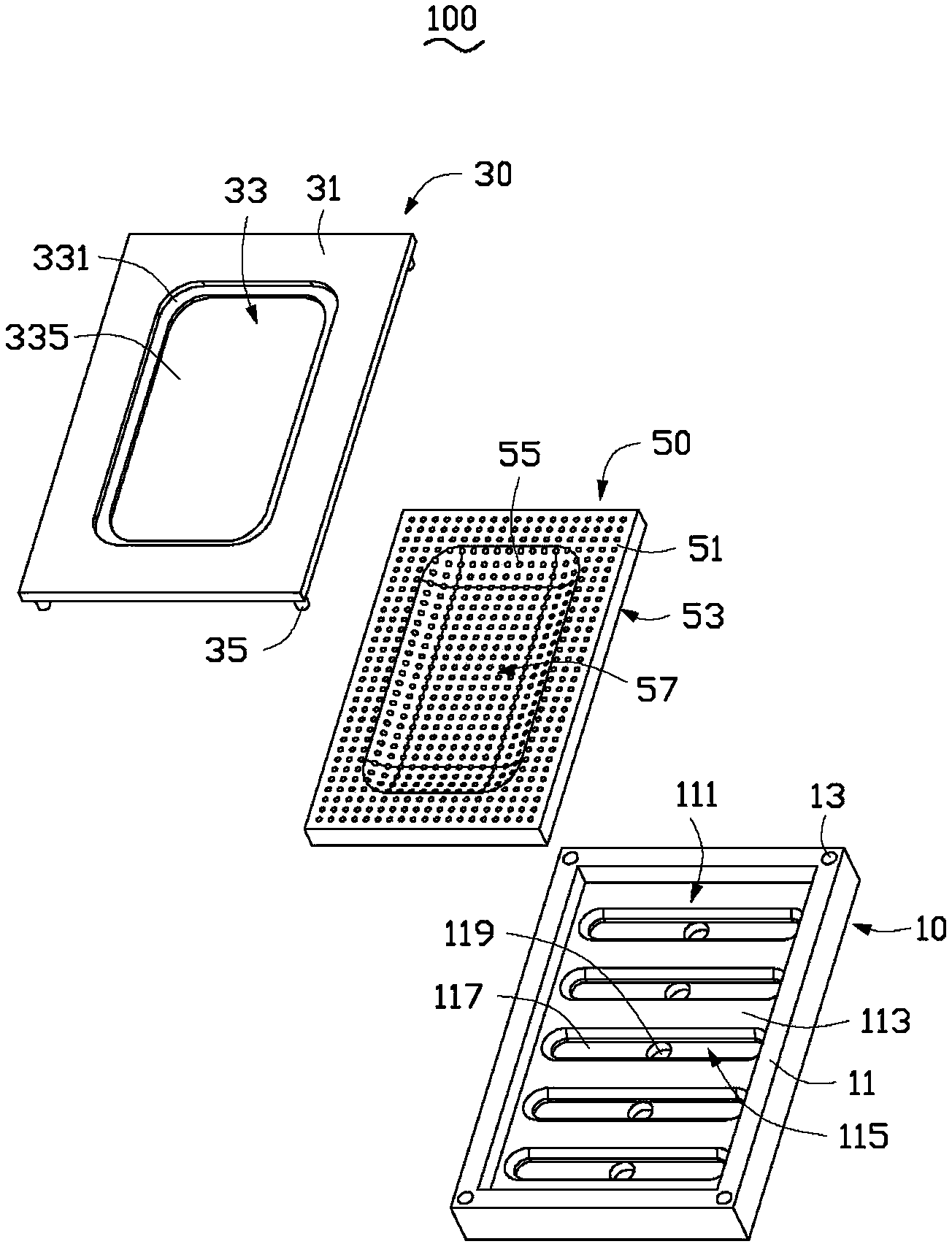

Integration full fresh air conditioner

ActiveCN101363647AGood heat exchange effectReduce air conditioning energy consumptionLighting and heating apparatusAir conditioning systemsIndoor airEvaporator

The invention provides an integrated all-fresh air conditioner which comprises a housing, a fresh air inlet for introducing fresh air, electrical elements such as a compressor, etc., a condenser, an evaporator, a water tank, a pipeline system of all parts, a blower arranged at the rear part of the evaporator, an air outlet communicated with the blower, a return air inlet for absorbing indoor air, a condensate fan arranged at the rear part of the condenser, and an air outlet communicated with the condensing fan; wherein, a chemical filter and a fresh-air pre-cooled film are arranged at the front part of the evaporator, and a humidification film is arranged at the rear part of the evaporator, and a filter is arranged at the front part of the condenser. The integrated all-fresh air conditioner is designed into a whole body, and is condensed by the return air in an air conditioned room and the precooled fresh air, which can realize all-fresh-air effect while saving energy.

Owner:江苏国莱特空调设备有限公司

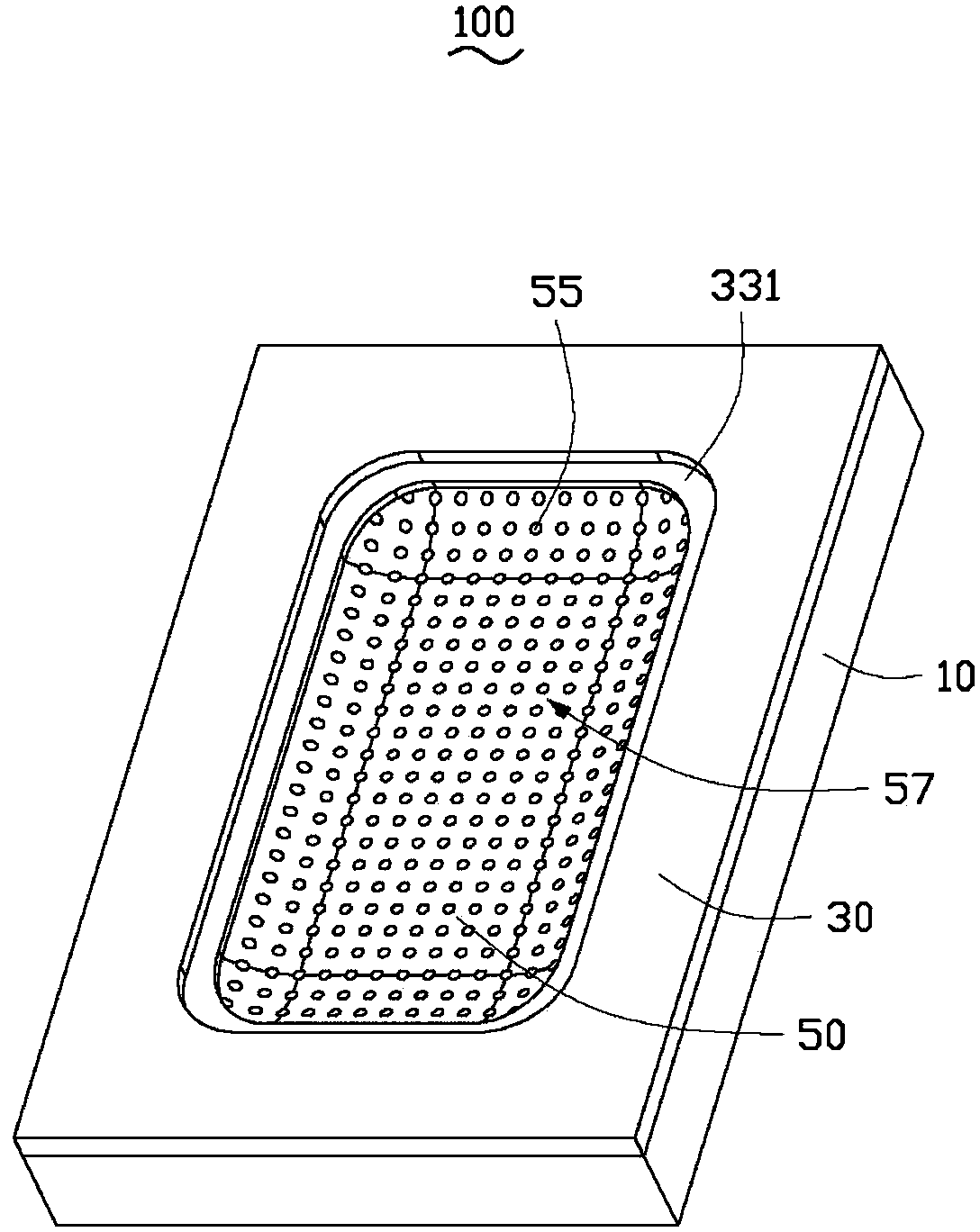

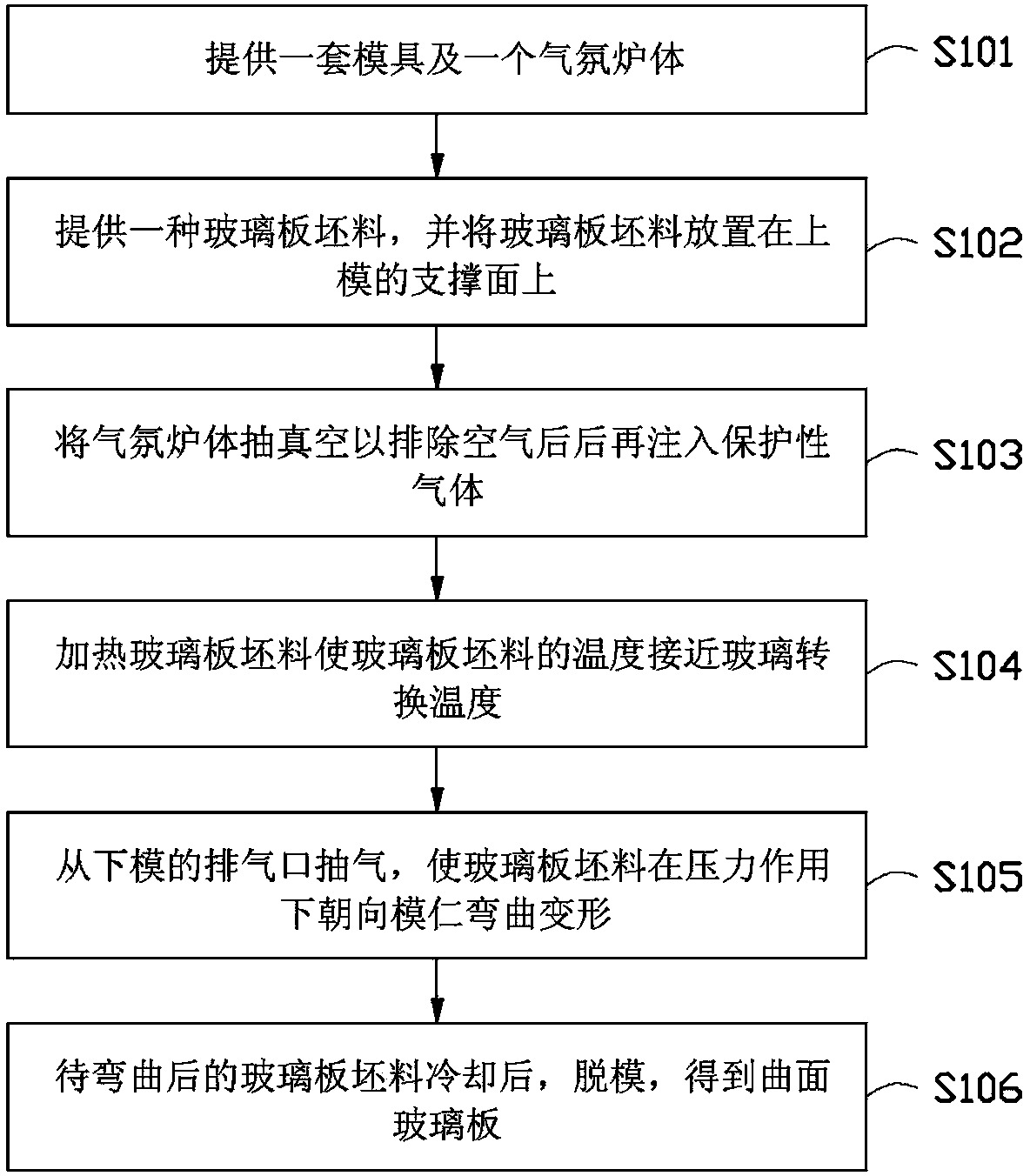

Curved glass moulding method and die adopted by the method

ActiveCN104071970AImprove surface qualitySmall inner concave surface roughnessGlass reforming apparatusCeramicwareGlass formingMaterials science

Owner:富联精密电子(郑州)有限公司

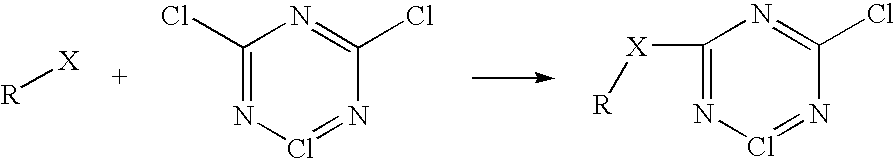

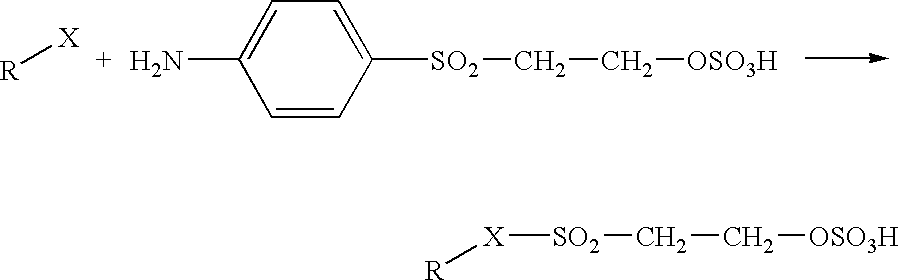

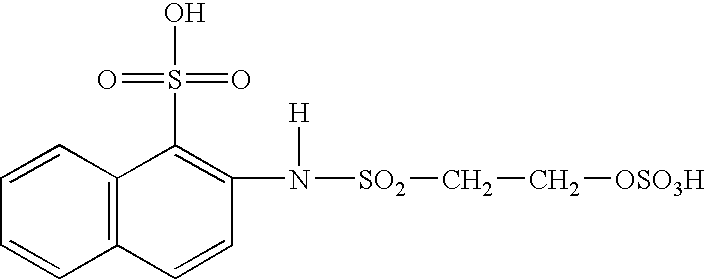

Method for providing protective treatment to nylon fibers

InactiveUS6719810B1Increased durabilityIncreased longevityMonocomponent protein artificial filamentReactive dyesResistDisperse dye

Owner:KELLY DAVID R +2

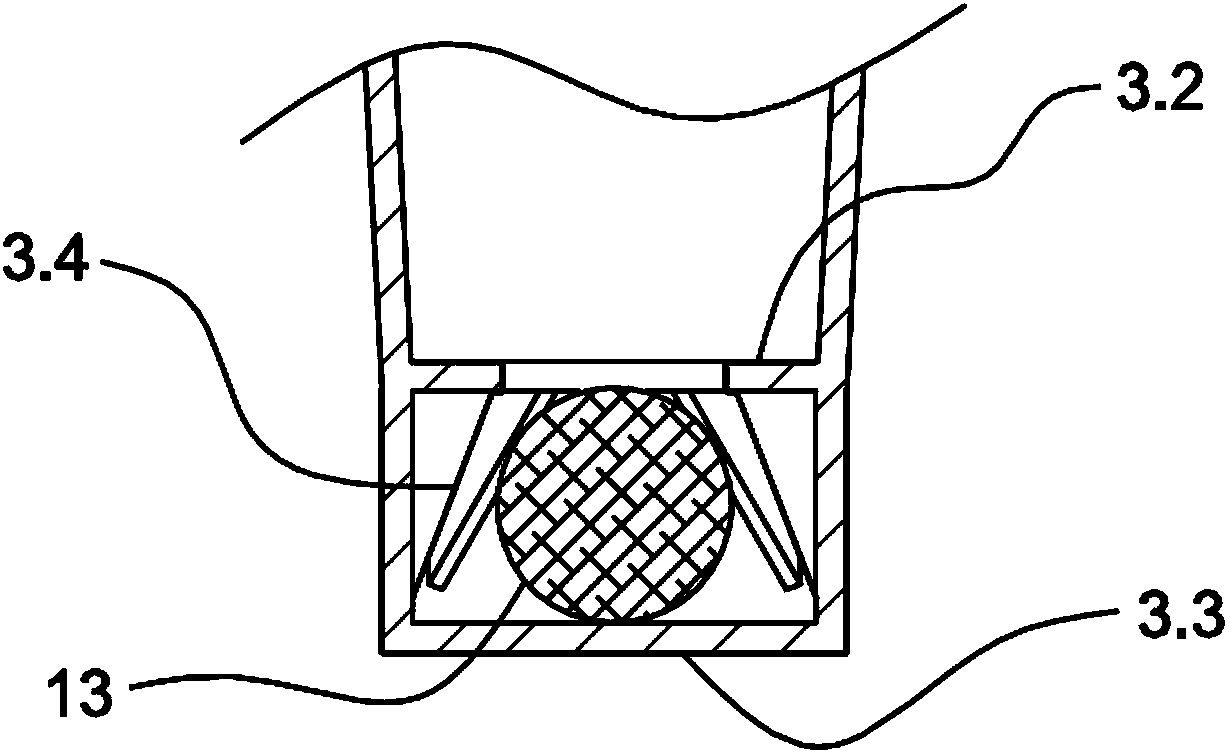

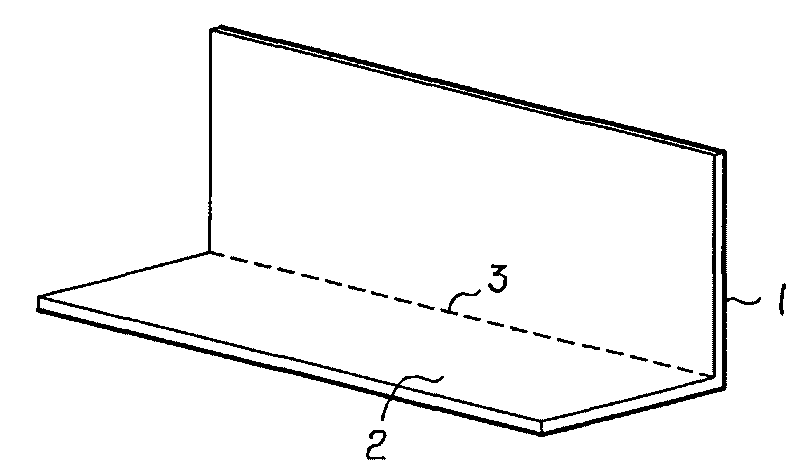

Rubber base and manufacturing method thereof

ActiveCN1831363AGuaranteed heightUniform exhaustBridge structural detailsShock absorbersEngineeringAtmosphere

The invention relates to a rubber bracket and the manufacturing method thereof, where the rubber bracket is of a cuboid, or cylinder or other geometrical shape formed of multiple layers of elastic rubber and multiple layers of reinforced steel plates by in turn laminating and sulfuration, the vertical side surface of the rubber bracket has a protective rubber layer with 1-1500 uniformly distributed small bumps, the shape of the bump is a cylinder, or cuboid or circular truncated cone or their combined body, and the manufacturing method comprises the steps of stock preparing, mould processing, mould splicing, mould assembling, vulcanizing, demoulding, etc, where a side mould has N air and glue discharge holes and the shape of the side mould is that one end is big and the other end is small, where the big end is located at the inner wall of the side mould and the small end is externally made with glue discharge groove connected with the atmosphere, the air and glue discharge can be performed on the side surface of the mould, and the air discharge is uniform to make upper and lower covers tightly contact with the side mould, and the rubber bracket has good planeness, accurate height but no inclined plates in the steel plates.

Owner:柳州东方工程橡胶制品有限公司

Shower plate, method for manufacturing the shower plate, plasma processing apparatus using the shower plate, plasma processing method and electronic device manufacturing method

InactiveUS8372200B2Low efficiencyPrevent backflowElectric discharge tubesSemiconductor/solid-state device manufacturingGas passingPore diameter

Owner:TOKYO ELECTRON LTD +1

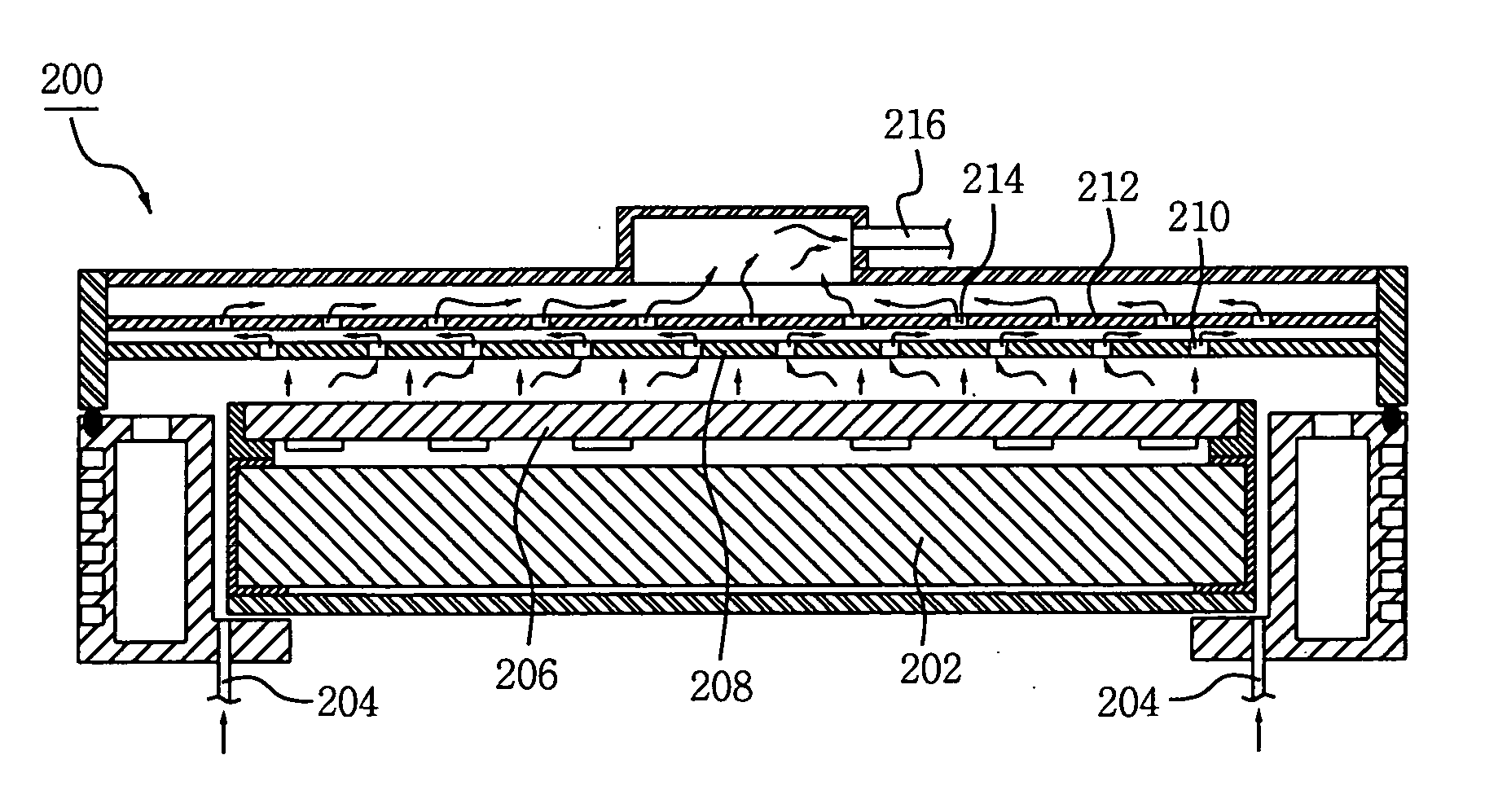

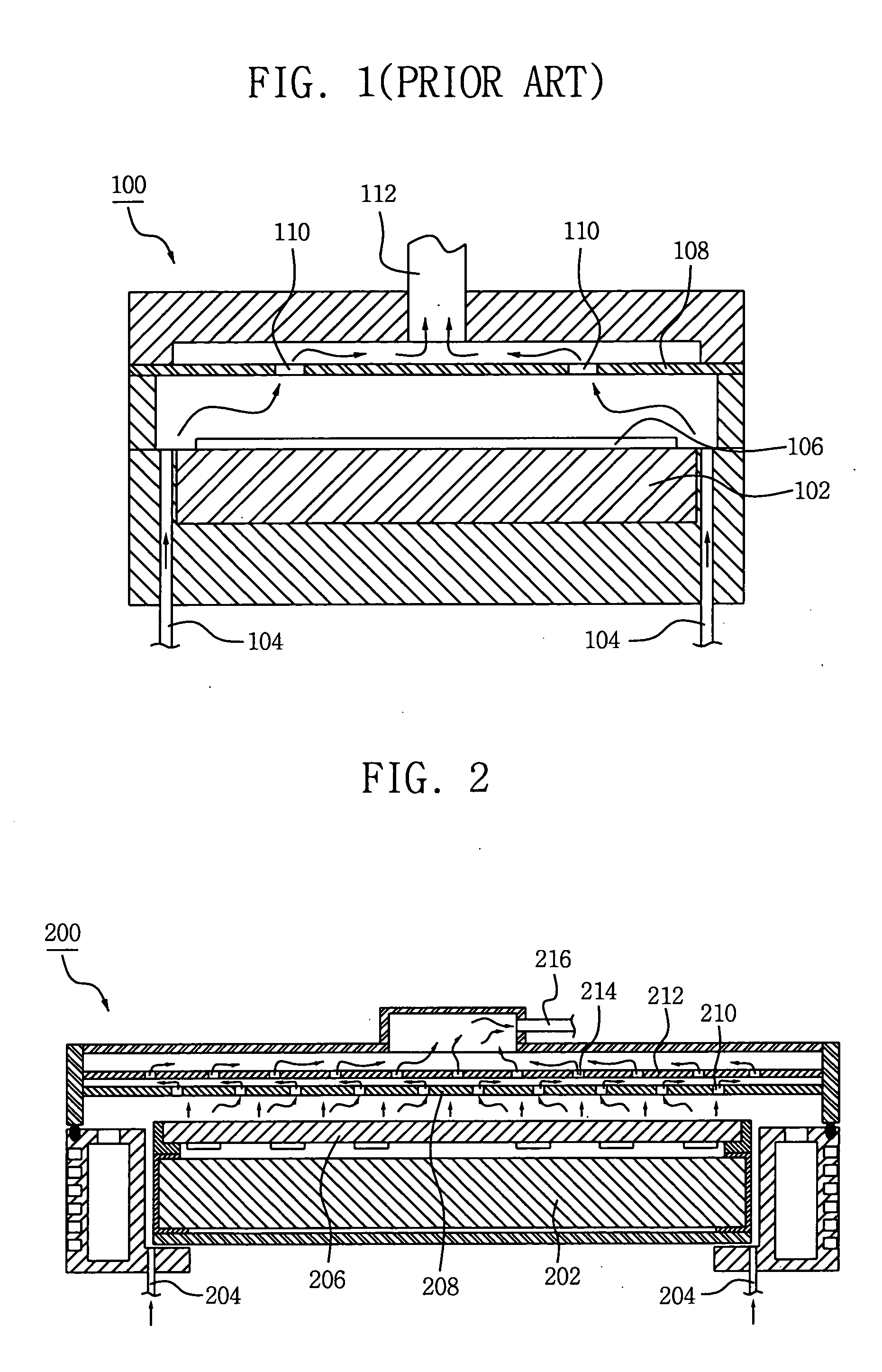

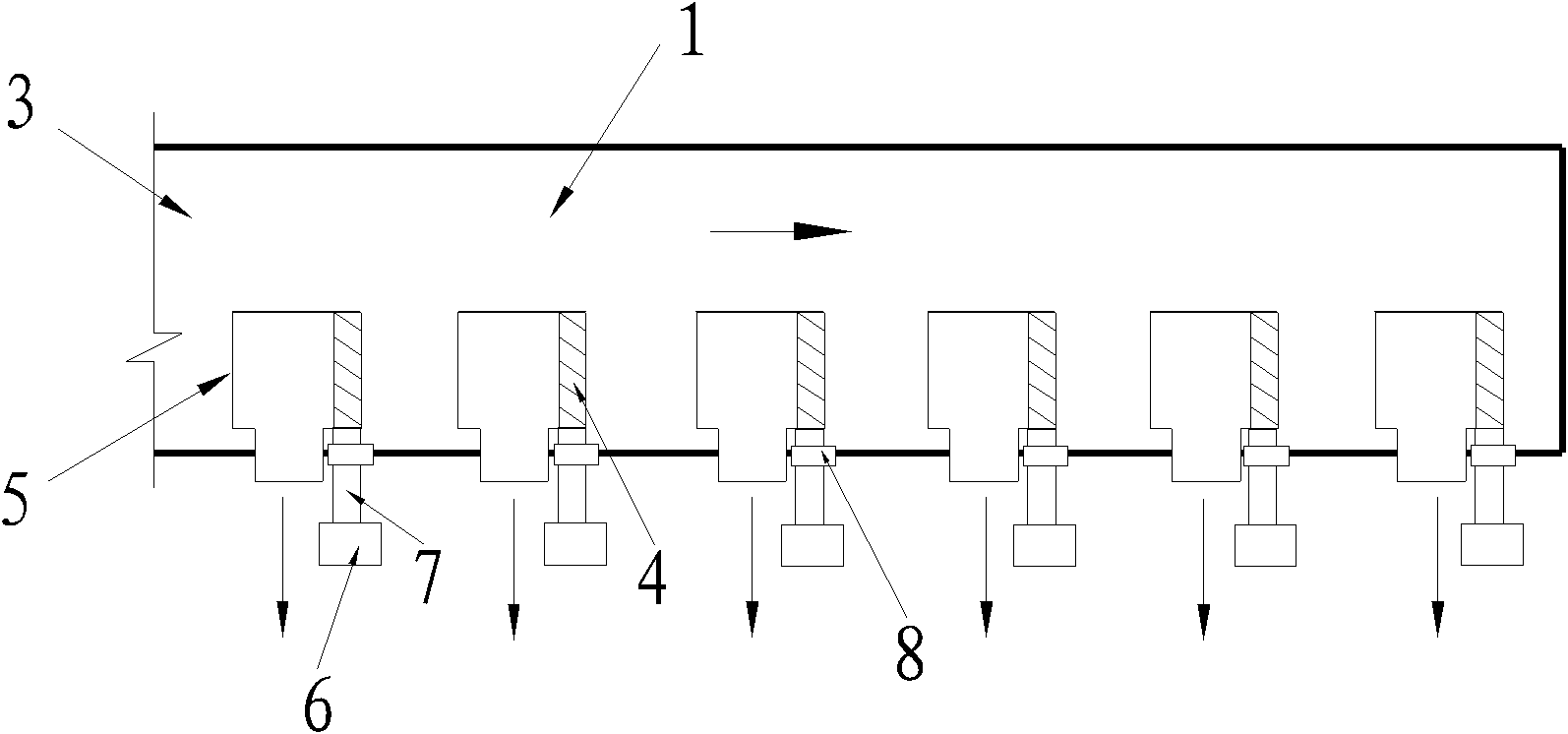

Bake apparatus for use in spin-coating equipment

InactiveUS20050244759A1Uniform exhaustDrying solid materials with heatMuffle furnacesSemiconductorSpin coating

Bake apparatus for use in baking a substrate, such as a semiconductor wafer, includes a chamber, a hot plate installed within the chamber, and first and second buffer plates for uniformly dispersing hot gas. The hot plate is configured to support the semiconductor wafer. The gas is injected into the chamber through an air passageway and is exhausted through an air exhaust opening. The first buffer plate is disposed within an upper part of the chamber so as to uniformly disperse the gas within the chamber. The second buffer plate is disposed above the first buffer plate. The first and second buffer plates each have a number of discharge holes by which the gas is uniformly discharged from the chamber to the exhaust opening.

Owner:SAMSUNG ELECTRONICS CO LTD

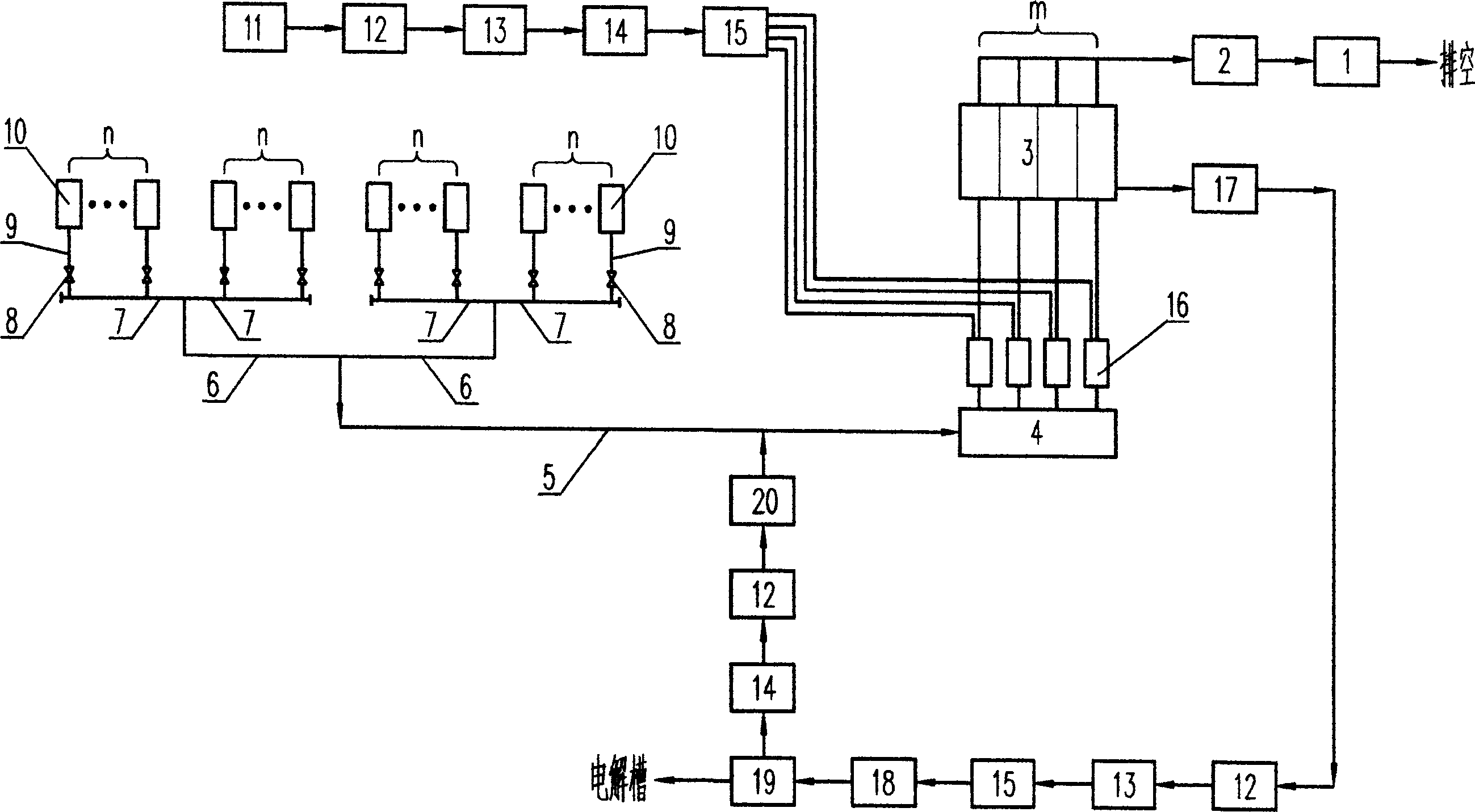

Process for purifying fluorine contg. flue-gas for aluminium electrolysis

ActiveCN1831201AUniform exhaustImprove mixing uniformityDispersed particle separationAluminium electrolysisEngineering

The invention discloses a purify technology of aluminum electrolyzing FI contained smoke that makes the smoke from electrolyzing FI passing through smoke evacuation branch pipe, smoke evacuation secondary main pipe, smoke evacuation main pipe and smoke evacuation total pipe spraying to impulse purifying filterer. Before coming into the filterer, the two steps material feeding would be taken and take adsorption reaction, and taking filtering and separating in the filterer. One section of the separated alumina containing FI could be used as the raw material to make electrolytic tank, and some would be return to the total pipe to mix with hydrogen fluoride. The purified smoke would be sent to air. The invention has short process, high efficiency, low power consumption, high reliable, no secondary pollution, etc.

Owner:GUIYANG AL-MG DESIGN & RES INST

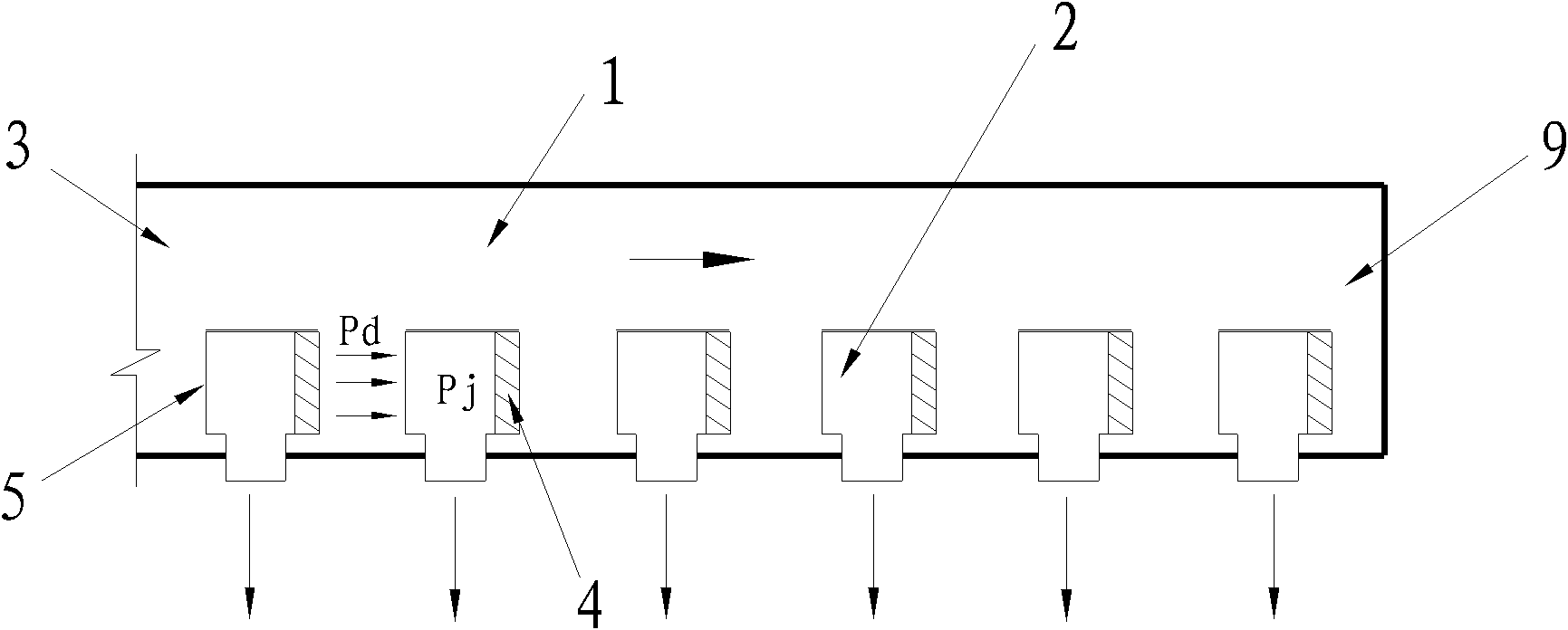

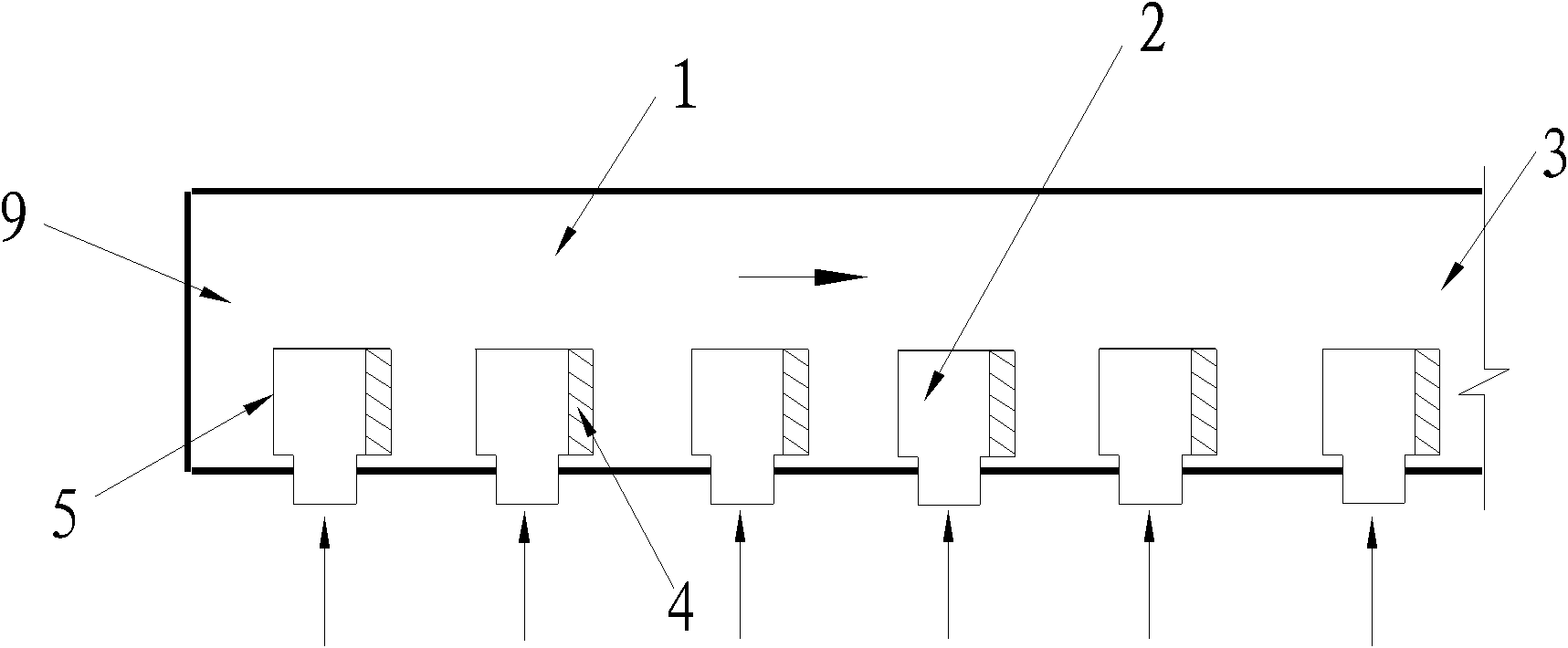

Flow-equalizing ventilation device

ActiveCN101818932AEasy to adjustPrevent leakageDucting arrangementsSpace heating and ventilation safety systemsEngineeringStreamflow

The invention discloses a flow-equalizing ventilation device, which is characterized by simple and convenient operation. The flow-equalizing ventilation device comprises a plurality of air openings arranged on a ventilation pipeline, wherein the ventilation pipeline comprises an opened end and a closed end, one air opening closest to the closed end of the ventilation pipeline belongs to the first group, other air gaps belong to the second group, windward sections of all the air openings are parallel to the section of the ventilation pipeline, a flow limiting device is arranged at least on each air opening in the second group and is specifically arranged on the other end corresponding to the end of the windward section; and the number of the opened flow limiting devices of the air openings arranged on the ventilation pipeline sequentially increases or decreases as the distance from the flow limiting devices to the farthest position of the closed end of the ventilation pipeline decreases gradually. The quantity and speed of airflows can be adjusted by adjusting the number of the opened flow limiting devices so as to realize uniform air supply and uniform air discharge, and simultaneously, the flow-equalizing ventilation device with simple and convenient operation can realize uniform air supply and discharge via simple adjusting and flow limiting devices.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Method and device for preventing moisture condensation of roof of textile workshop

InactiveCN101818550AImprove anti-condensation effectSolve condensationDucting arrangementsSpace heating and ventilation safety systemsAutomatic controlRelative humidity

The invention discloses a method and a device for preventing moisture condensation of a roof of a textile workshop. The method comprises the following steps of: using an exhausting and dehumidifying fan in winter: starting the exhausting and dehumidifying fan when the air humidity of the roof reaches the highest limit value of the given relative humidity through an exhausting and dehumidifying pipe net fixed at the lower surface of the roof of the textile workshop, and extracting the humid air around the lower surface of the roof. The device comprises the exhausting and dehumidifying pipe net at the lower surface of the roof of the textile workshop, a humidity sensor, the exhausting and dehumidifying fan and an anti-fogging automatic control circuit; the exhausting and dehumidifying pipe net consists of at least one exhausting and dehumidifying main pipe and a certain quantity of exhausting and dehumidifying branch pipes arranged by a certain regular way; the two sides of each exhausting and dehumidifying branch pipe are at least respectively provided with a row of exhausting and dehumidifying holes or seams arranged uniformly. The invention has good effect of preventing moisture condensation, low cost of application, simple structure and convenient use; and the operation fee is only 4% of the traditional method. The invention can save energy and reduce the power consumption, has good environmental-friendly performance and provides great economic benefits and social benefits in the textile industry.

Owner:郑州宏大纺纱新技术咨询有限公司

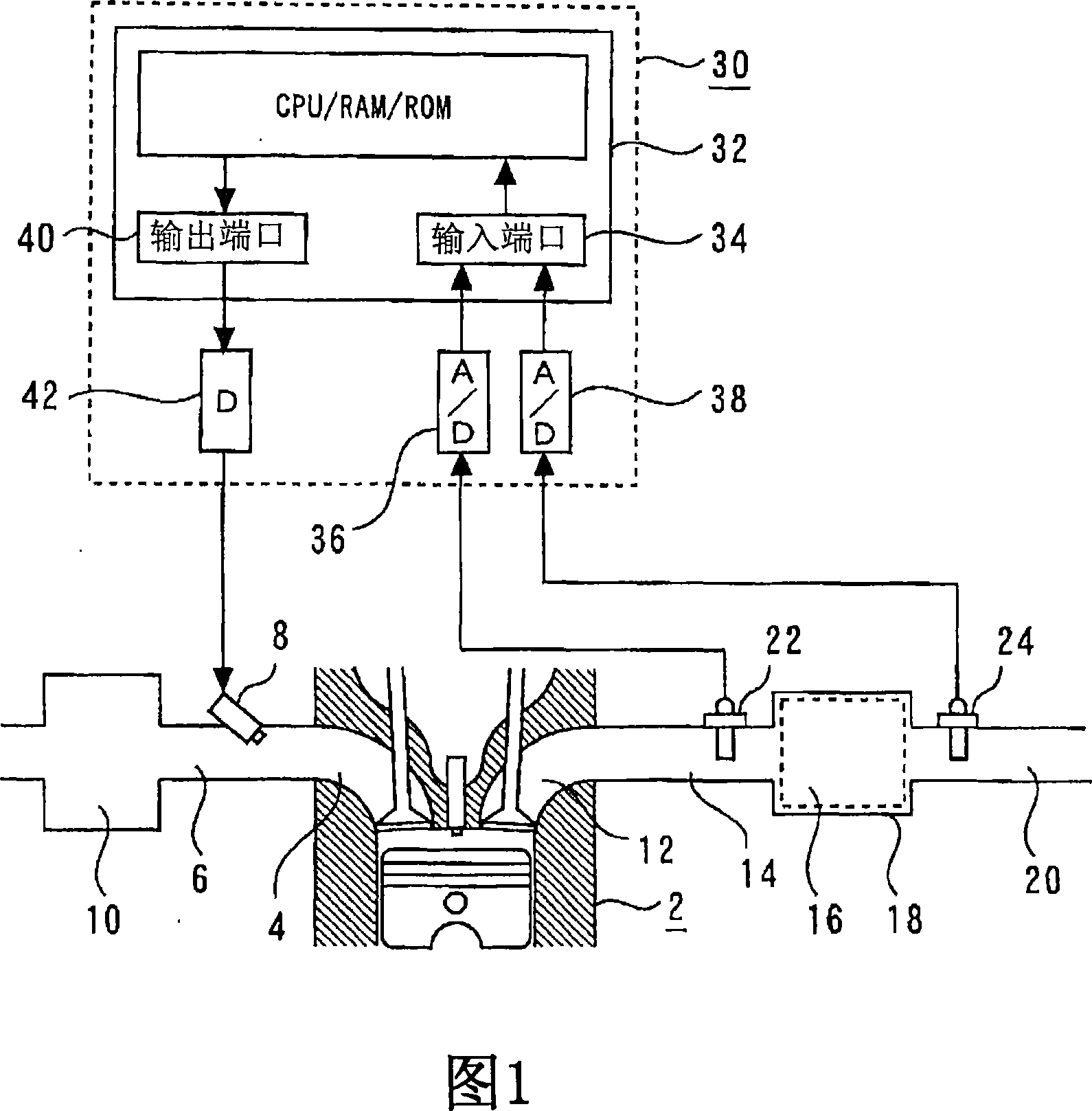

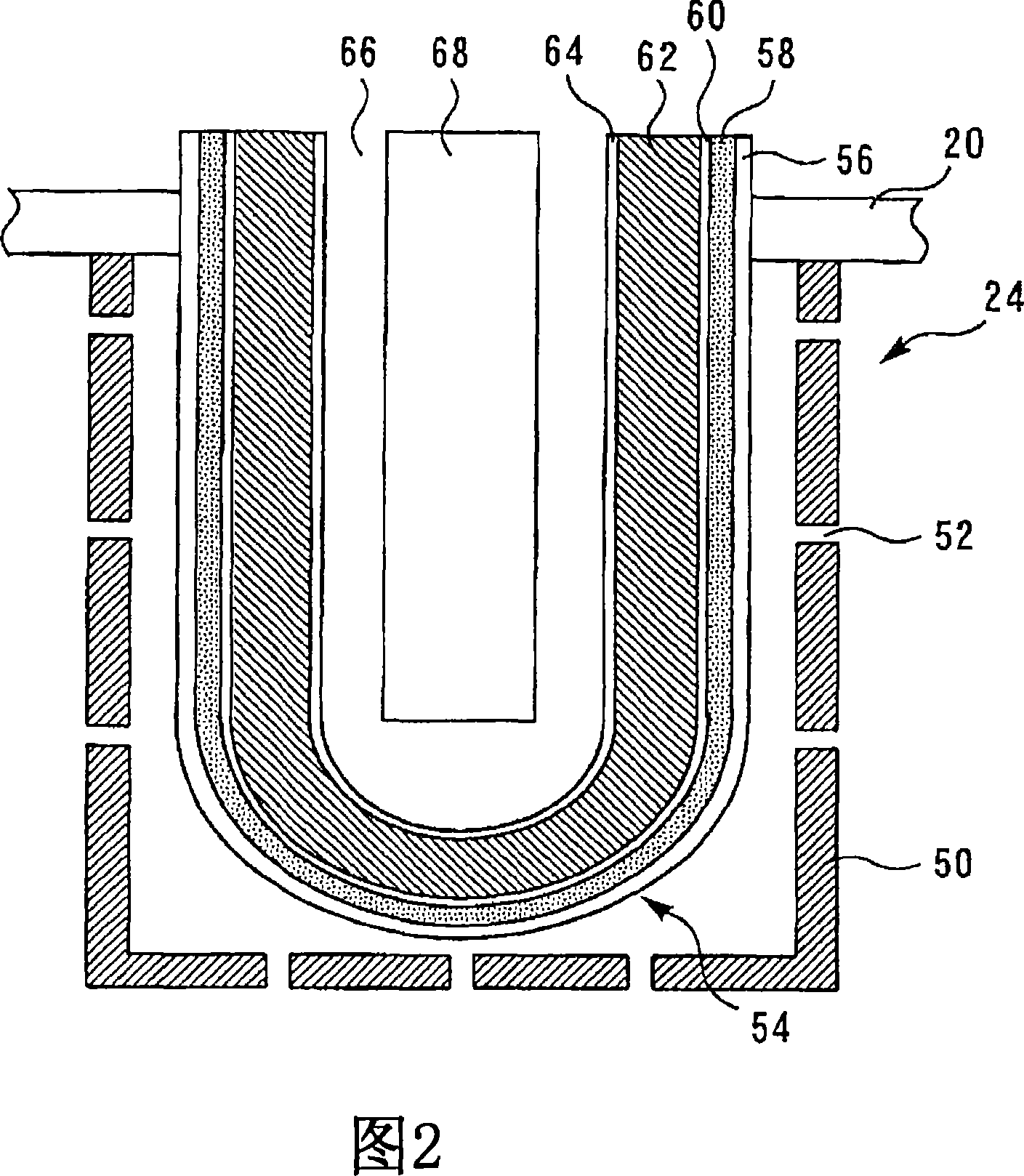

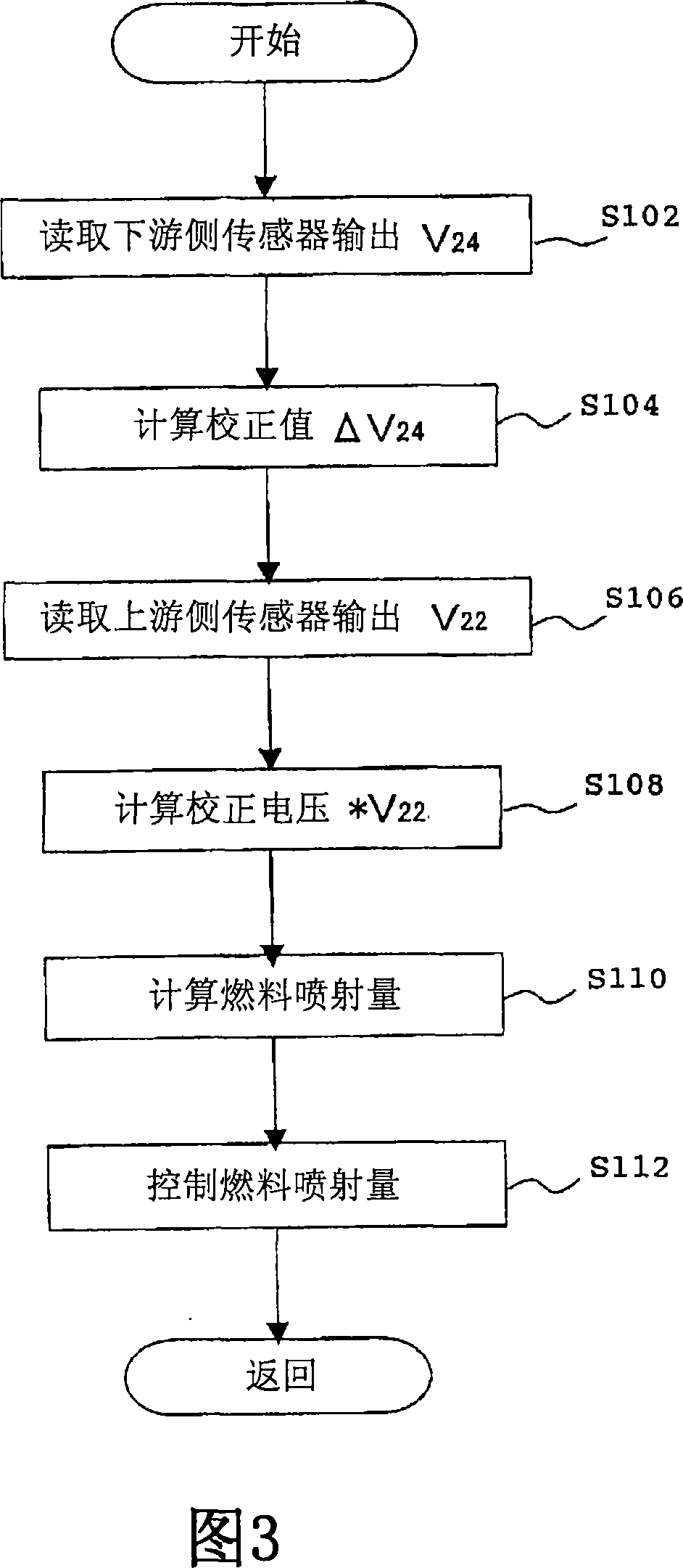

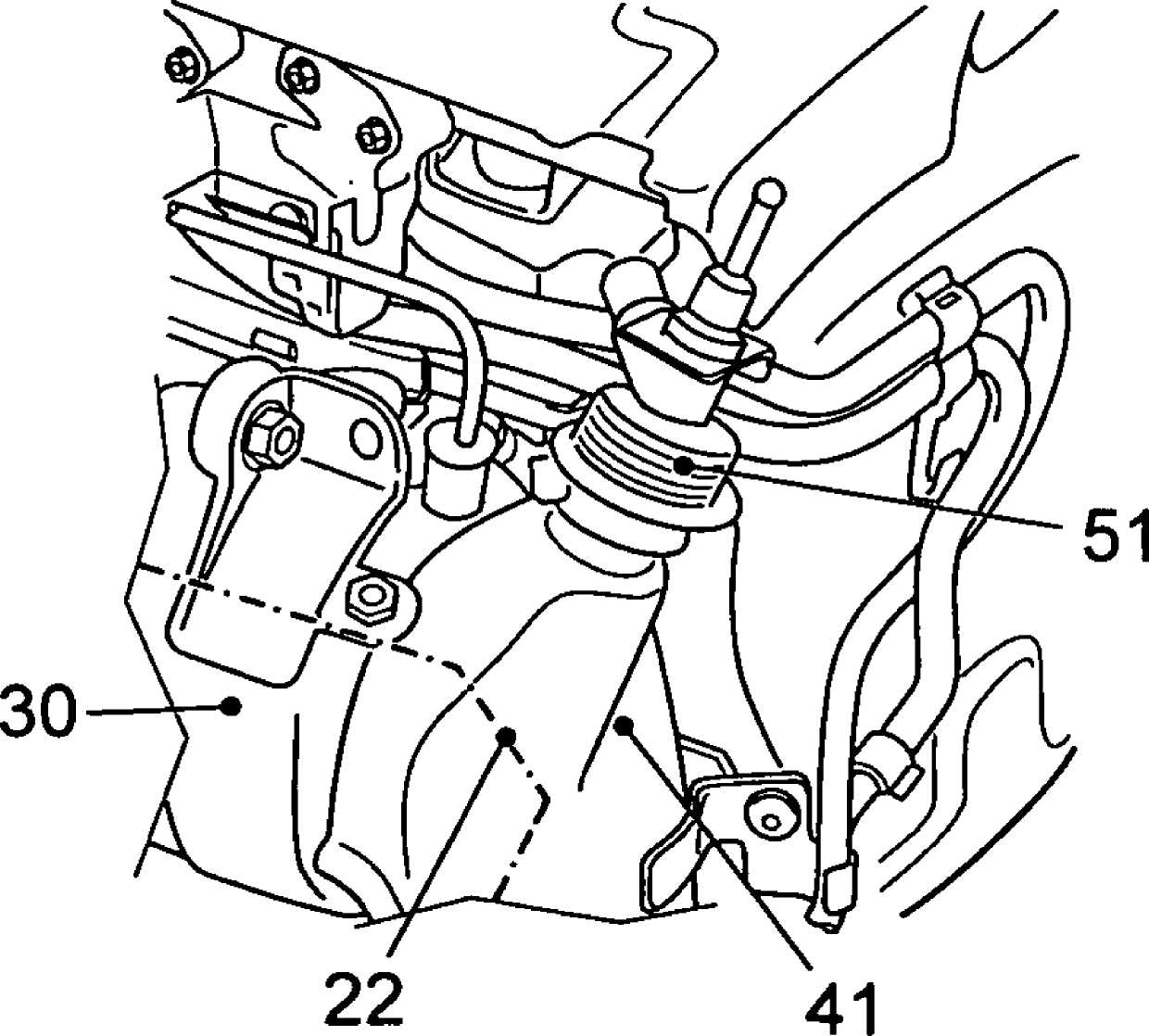

Oxygen sensor and air/fuel ratio control system

InactiveCN101091112AUniform exhaustImprove output accuracyElectrical controlMaterial analysis by electric/magnetic meansControl systemOxygen sensor

In the oxygen sensor, the correct output can also be obtained for the low-concentration exhaust gas downstream of the three-way catalyst. The reference gas side electrode of the reference gas as the oxygen concentration reference; the electrolyte disposed between the exhaust side electrode and the reference gas side electrode, further, has a lowering unit on the surface side of the exhaust side electrode, so that the lead-in exhaust side electrode The amount of exhaust gas flowing to the outside of the oxygen sensor is relative to the amount of exhaust gas flowing to the outside of the oxygen sensor, and the amount of exhaust gas that is less than that introduced into the electrode of the air-fuel ratio sensor is relative to the amount of exhaust gas flowing to the outside of the air-fuel ratio sensor.

Owner:TOYOTA JIDOSHA KK

Automobile brake disc casting die and technology

ActiveCN105562602AImprove work efficiencySolve the problem of error-prone boxesFoundry mouldsFoundry coresImpurityMaterials science

The invention discloses an automobile brake disc casting die and technology. A sand mold is fixed between an upper tool and a lower tool and comprises upper sand mold bodies and a lower sand mold body. A plurality of cavities are formed in the upper side of the lower sand mold body. The upper sand mold bodies are fixed in the cavities. The upper tool is provided with an upper sand mold fixing mechanism used for downwards pressing the upper sand mold bodies. A molten iron channel communicating with the bottoms of the cavities is formed in the bottom of the lower sand mold body. A molten iron channel bottom tray for sealing the molten iron channel is arranged on the lower tool. Exhaust gaps are formed between the circumferences of the upper portions of the upper sand mold bodies and the cavities. Molten iron is directly poured into the molten iron channel through a sprue gate in the middle of the lower sand mold body and then enters the cavities from bottom to top, the molten iron flows from bottom to top at a constant speed, and air and some impurities in the cavities are directly discharged upwards through the exhaust gaps. The casting die has the beneficial effects that the casting yield is increased, the casting cost is reduced, and the labor intensity is lowered.

Owner:杨合军

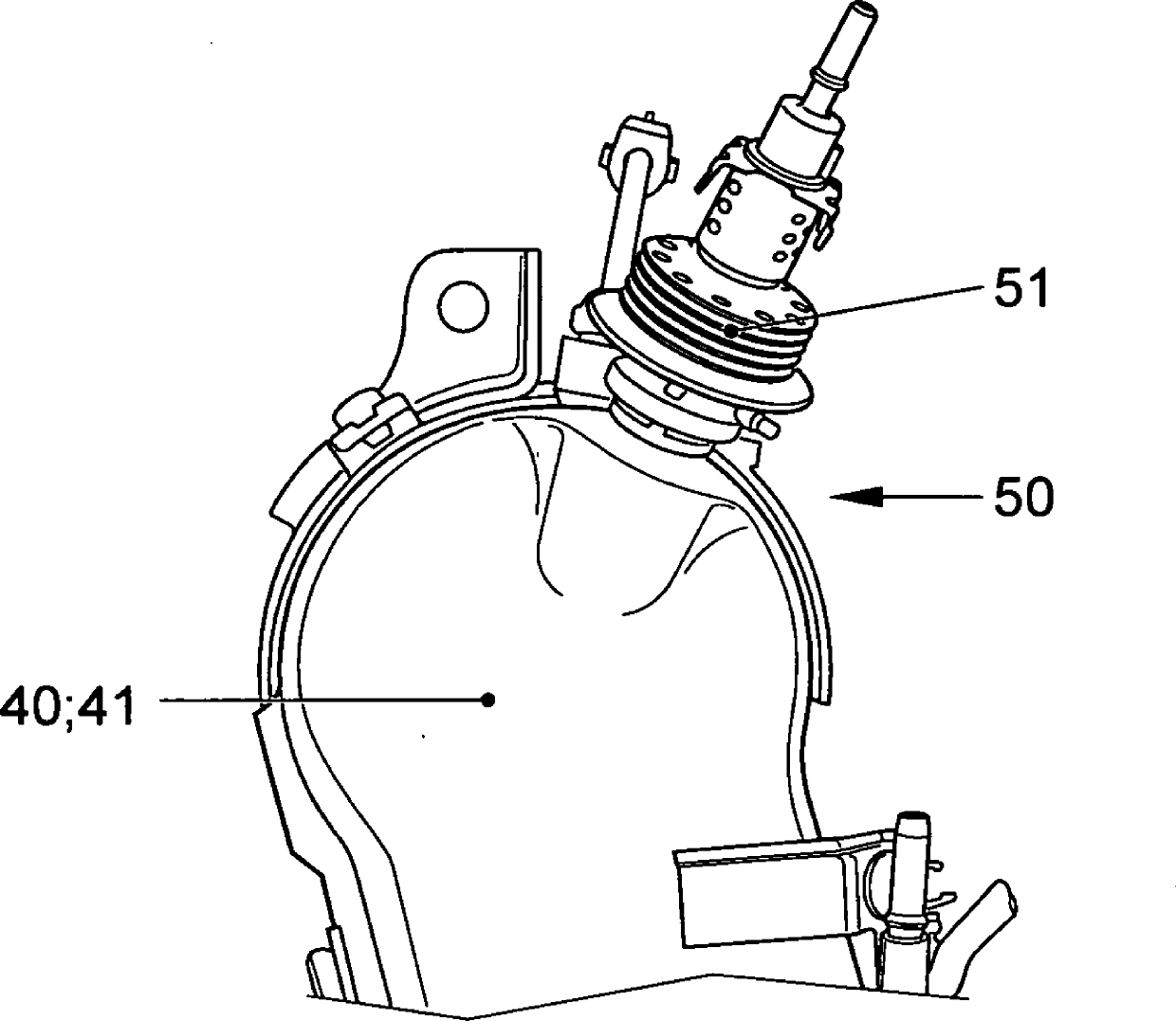

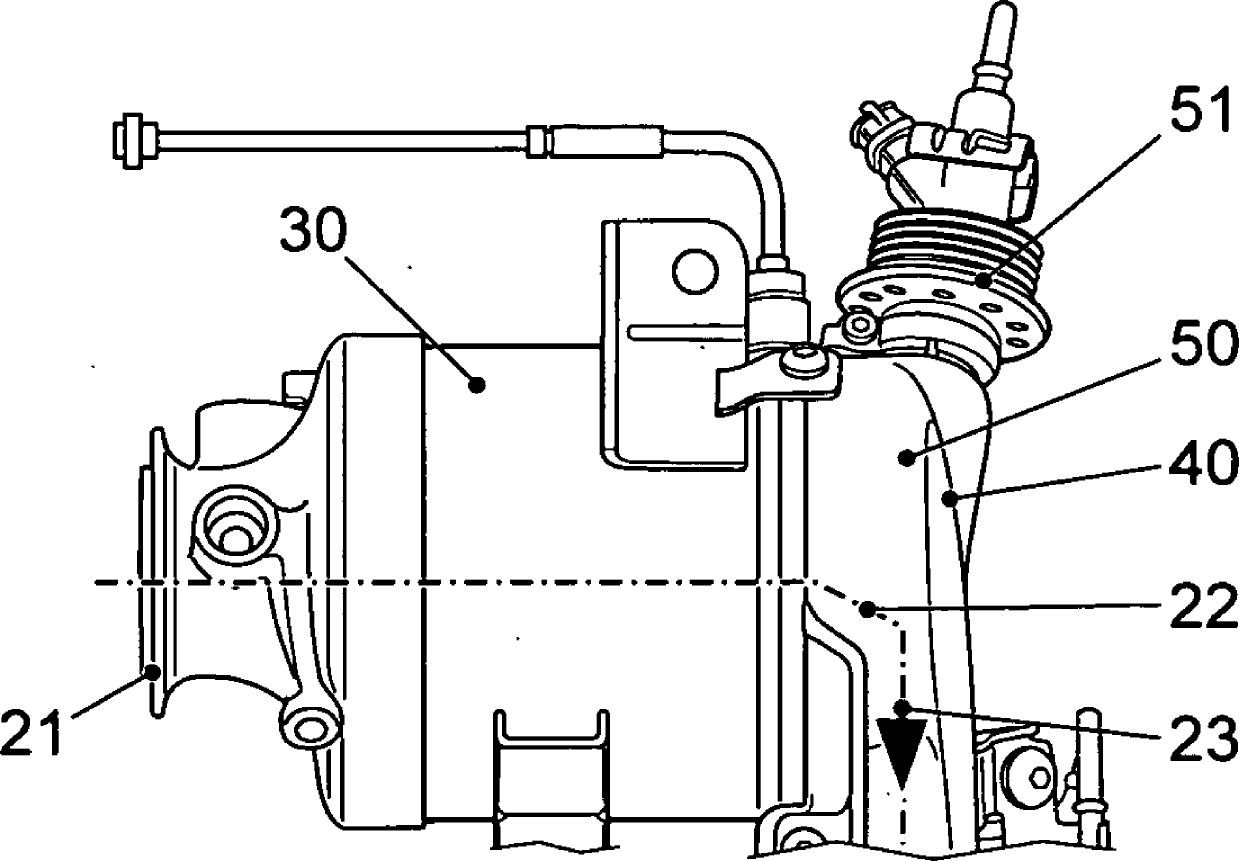

Exhaust gas treatment device, method for processing exhaust gas, and motor vehicle

ActiveCN103748332AImprove efficiencyReduce displacementInternal combustion piston enginesNon-fuel substance addition to fuelCombustionProcess engineering

The invention relates to an exhaust gas treatment device for processing exhaust gas from a combustion unit, in particular a diesel engine. Furthermore, the invention relates to a method for processing exhaust gas from a combustion unit by selective catalytic reaction, and to a motor vehicle, in which the method according to the invention is implemented or which includes the exhaust gas treatment device according to the invention. According to the invention, the exhaust gas treatment device comprises an exhaust gas system and an oxidation catalyst, a reduction catalyst for selective catalytic reduction and a particle filter arranged therein, wherein the oxidation catalyst is arranged upstream of the reduction catalyst and the reduction catalyst is arranged upstream of the particle filter. The reduction catalyst (50) is arranged in the exhaust gas system (20) so far upstream in the exhaust gas flow direction (23) that the heat of the exhaust gas passing through the reduction catalyst (50) is sufficient to bring the reduction catalyst (50) to operating temperature.

Owner:VOLKSWAGEN AG

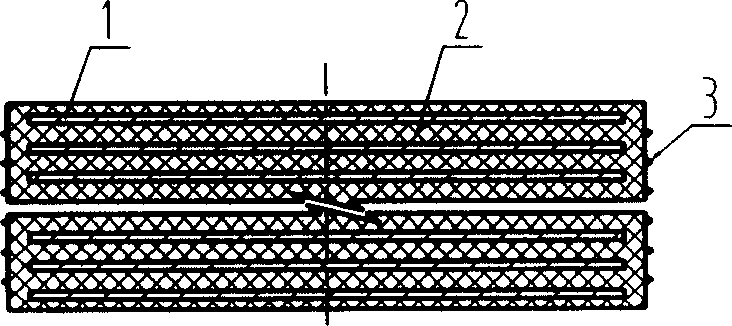

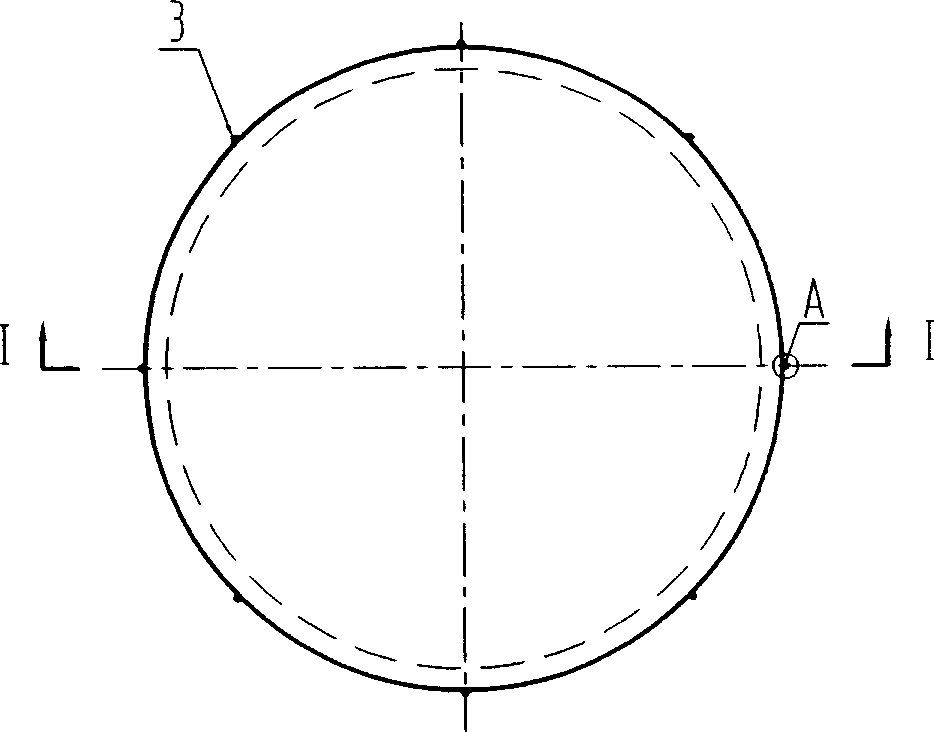

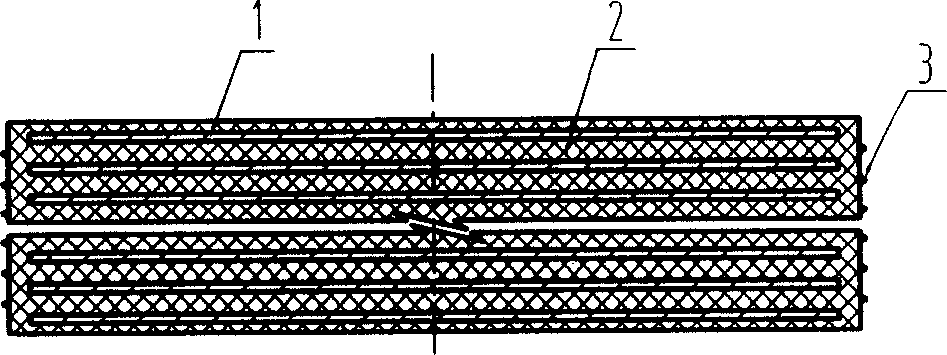

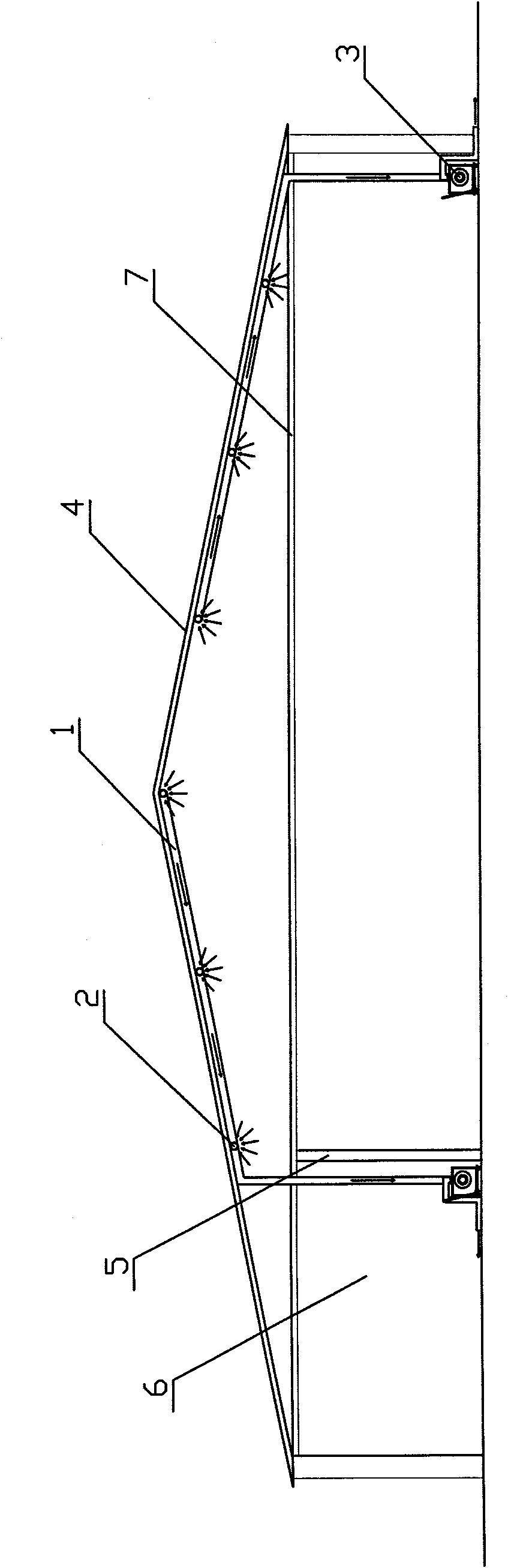

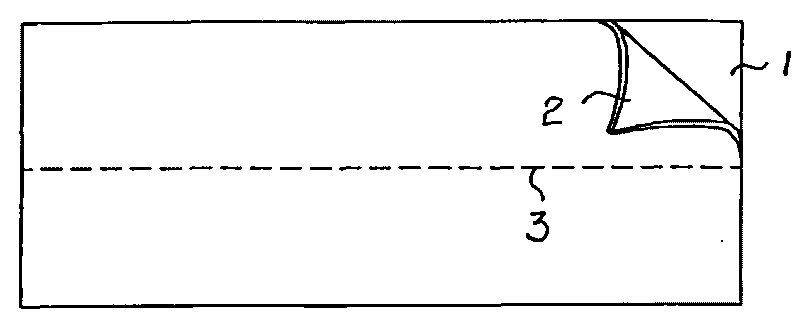

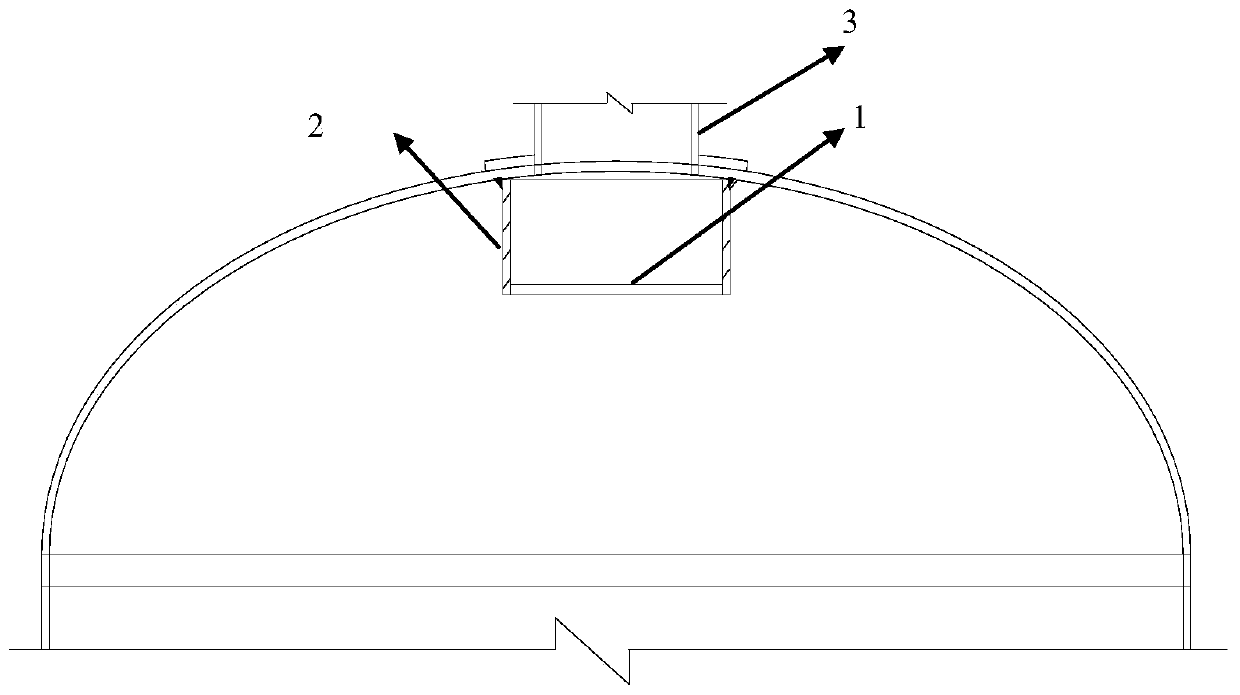

Edge bonding belt special for grouting for high-speed railway II type track board

ActiveCN101696559AImprove breathabilityImprove sealingRailway track constructionEngineeringWaste material

The invention relates to an edge bonding belt special for grouting for a high-speed railway II type track board, which is used for sealing mortar between the high-speed railway II type track board and a concrete base board. The edge bonding belt is characterized by comprising at least one waterproof venting layer (1) at the inner side and at least one sealing venting layer (2) at the outer side, wherein the waterproof venting layer (1) is jointed with the sealing venting layer (2). The edge bonding belt special for grouting for a high-speed railway II type track board has good venting performance and sealing performance. When in use, the edge bonding belt is fixed on the edge of the II type track board through a clamping board and a clamp so as to seal a gap between the track board and the base board; after the bedding mortar is solidified, the edge bonding belt can be taken down, thus the edge bonding belt is convenient to use, is used at any time along with sealing and filling, has low cost, saves time and labor, is beneficial to construction organization and arrangement and overcomes the defects of large quantity of building waste materials generated by using mortar for bonding edges, and the like. Except for effectively sealing the mortar, the edge bonding belt has good sealing performance and venting performance so as to guarantee the high filling degree of the bedding mortar.

Owner:JIANGSU DINGTAI ENG MATERIAL

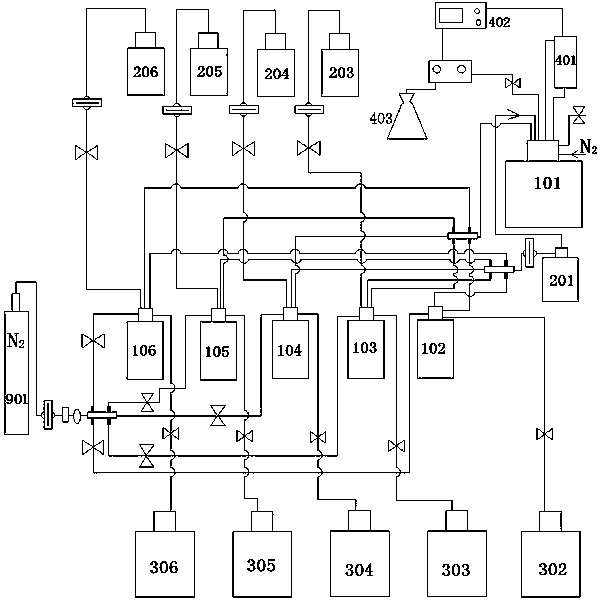

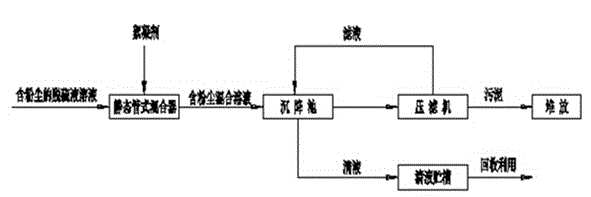

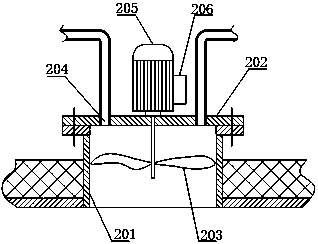

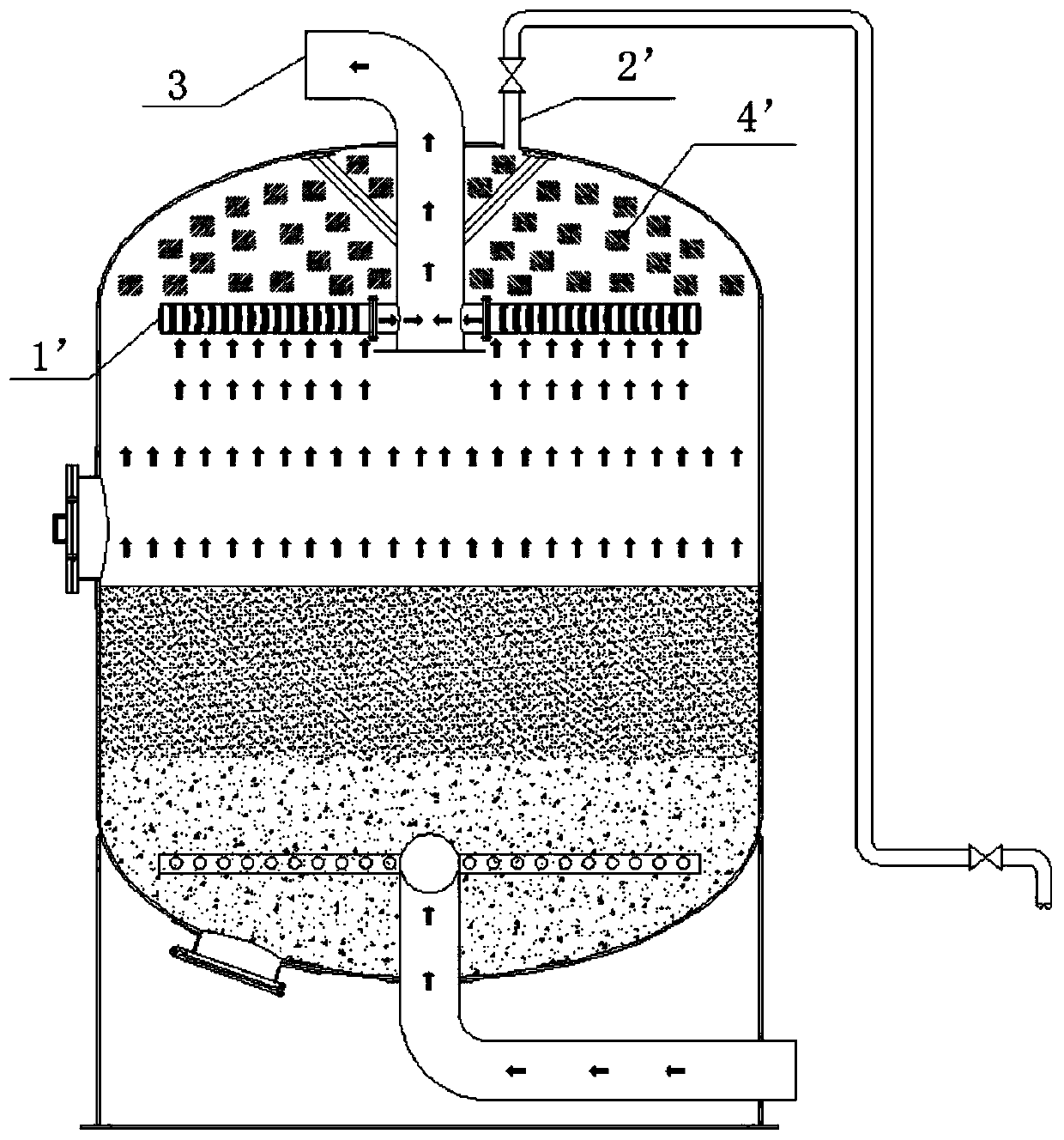

Fermentation system for simulating colonic environment and simulated fermentation method of system

ActiveCN110734843ASimulate the realImprove parallelismBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention relates to a fermentation system for simulating a colonic environment and a simulated fermentation method of the system and belongs to the fields of bionics, human physiology, microbiology and organic chemistry. The fermentation system comprises an intestinal flora colonization system, a pH control system, a gas path system, a flow rate control system and a temperature and stirring control system. A fermentation method for simulating a colonic environment is characterized by comprising the three main work contents: control parameter setting, intestinal flora colonization and simulated fermentation. By using the fermentation system for simulating the colon of a human body and a simulated experiment method based on the system, the fermentation process for simulating parts of microorganisms in the colon of the human body under an in-vitro condition is realized. The fermentation system is realistic in simulation and has good parallelity, stability and repeatability.

Owner:CHENGUANG BIOTECH GRP CO LTD

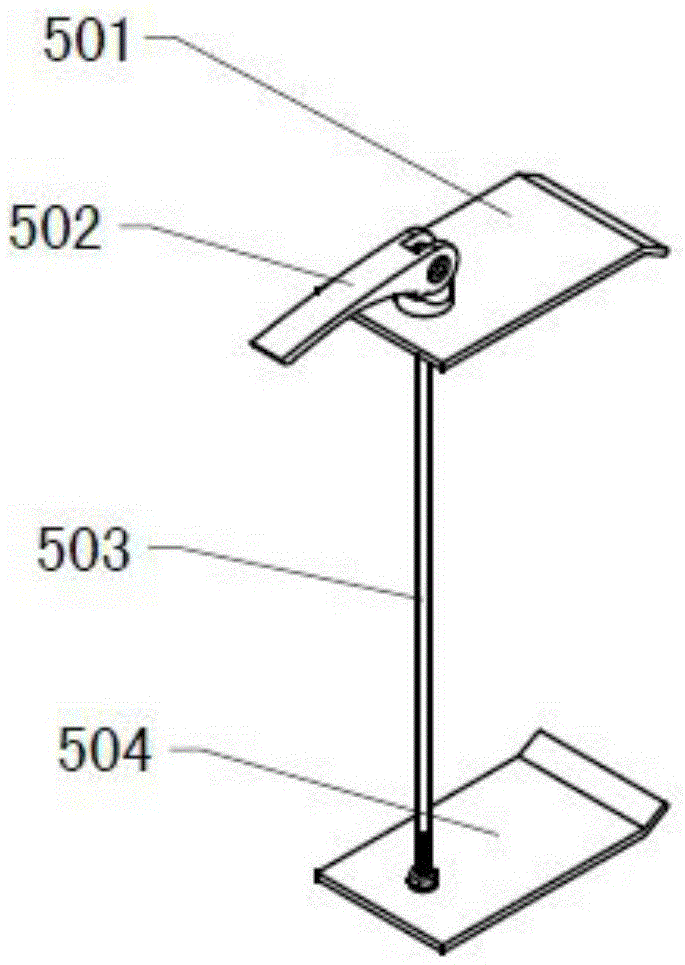

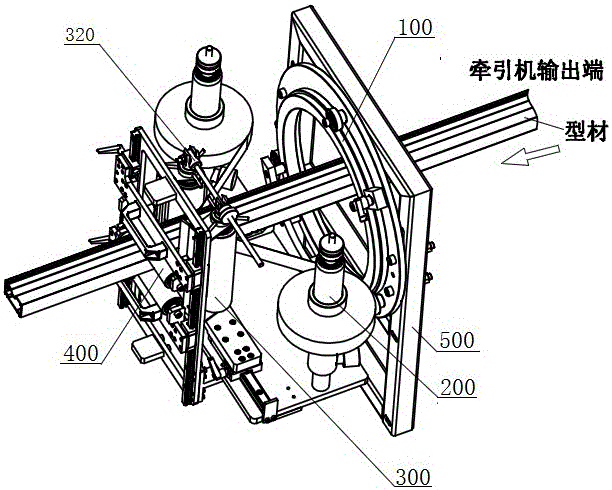

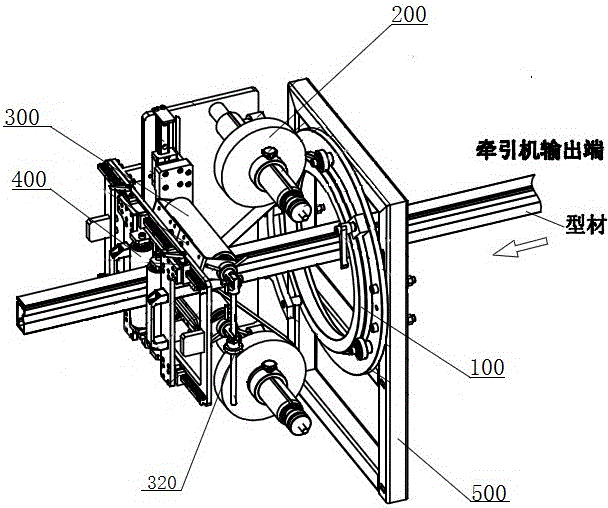

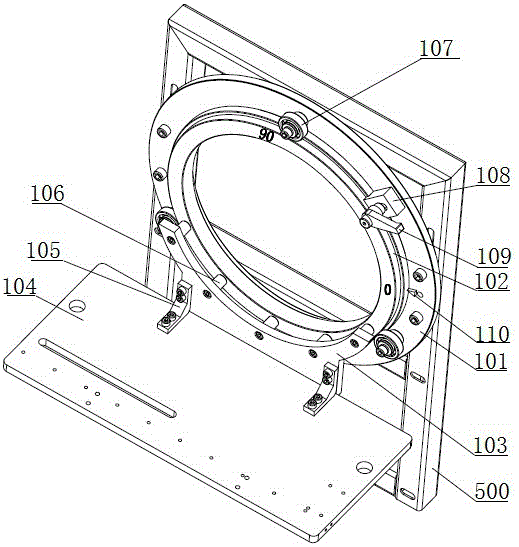

Automatic online film pasting machine for profiles

InactiveCN105857713AEasy to switchGuaranteed vertical pressurePackagingEngineeringElectrical and Electronics engineering

The invention discloses an automatic online film pasting machine for profiles. The automatic online film pasting machine for the profiles is installed at the output end of a traction machine, and comprises a supporting frame, and the supporting frame is installed at the output end of the traction machine and used for allowing the profiles to penetrate through. A discharging device, a pressure roller device and a limiting roller device are fixed to the supporting frame. The automatic online film pasting machine for the profiles further comprises a rotating device which is fixed to one side of the supporting frame. The discharging device, the pressure roller device and the limiting roller device are arranged on the rotating device and sequentially distributed in the profile forwarding direction, and the discharging device, the pressure roller device and the limiting roller device are driven to rotate at the same time through rotation of the rotating device. The horizontal film pasting mode or the vertical film pasting mode can be achieved through switching according to actual needs, and the whole process is stable, reliable, and easy and convenient to implement.

Owner:HESHAN LESSO IND DEV

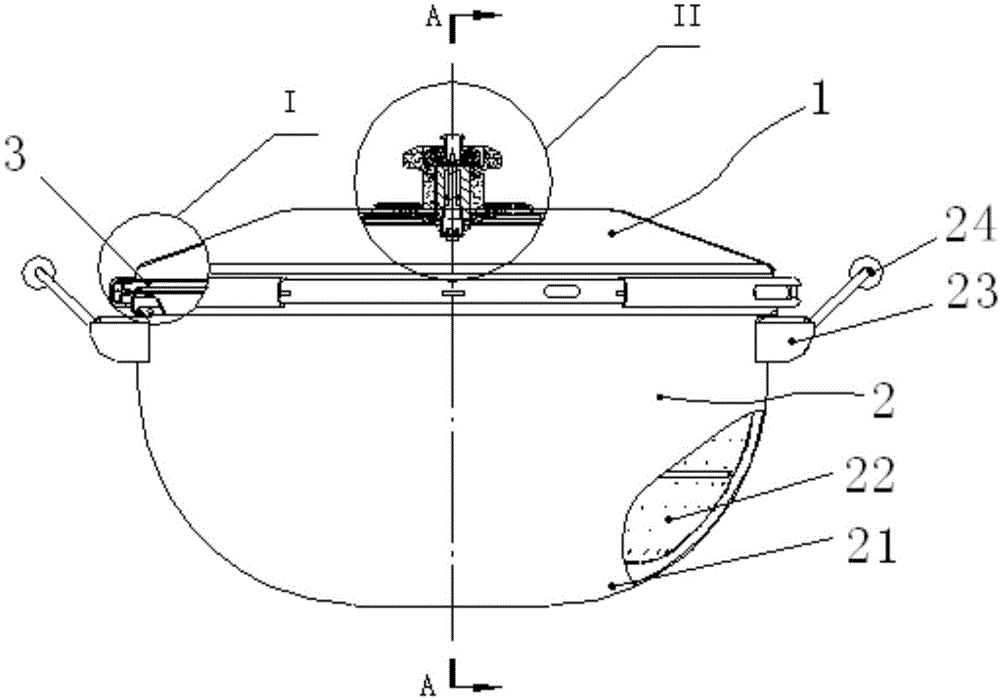

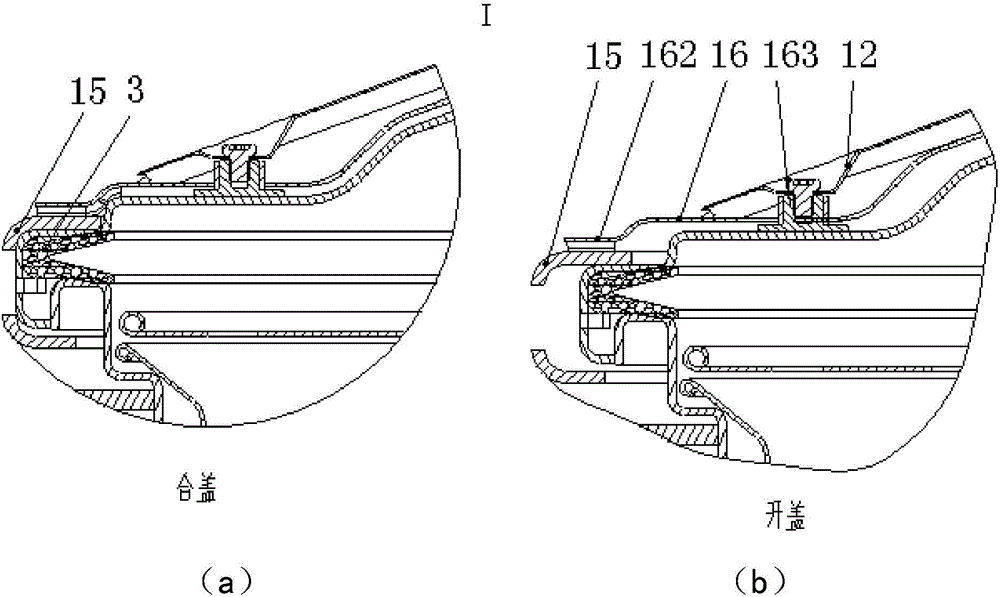

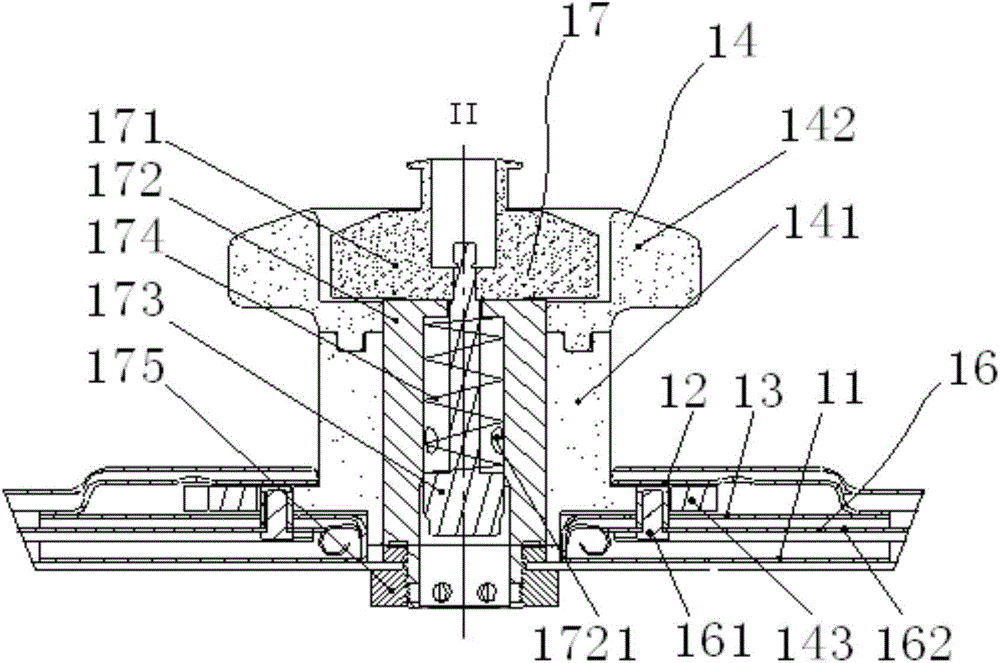

Multifunctional cooking pot

The invention relates to a multifunctional cooking pot. The multifunctional cooking pot comprises a pressure pot cover, a pot body and a seal ring arranged between the pressure pot cover and the pot body. The pressure pot cover comprises a fixing board, a cover board, a pressing board, a handle, a plurality of buckles and a plurality of transmission mechanisms used for connecting the buckles and the handle. A shell of the pressure pot cover is formed by the fixing board and the cover board. The pressing board is arranged between the fixing board and the cover board. The handle comprises a cam base and a handheld portion connected to the upper portion of the cam base. The lower portion of the cam base penetrates through the cover board and the pressing board and is rotationally connected to the fixing board. A plurality of lugs extending outwards are arranged on the portion, between the cover board and the pressing board, of the cam base in the circumference direction and an arc through groove is formed in each lug; the buckles are arranged at the edge of the fixing board in the circumference direction and connected with the handle through the transmission mechanisms located between the pressing board and the fixing board; each transmission mechanism comprises a sliding shaft, a sliding sheet and a guide post.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

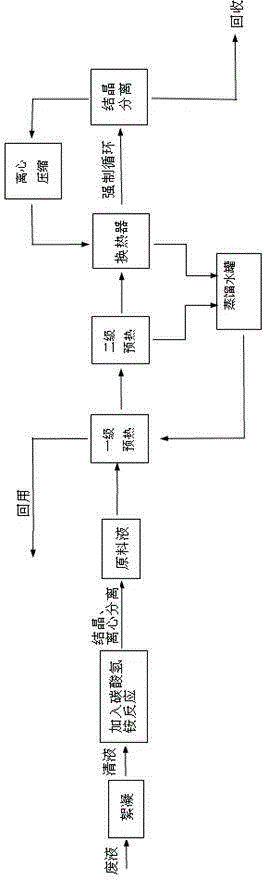

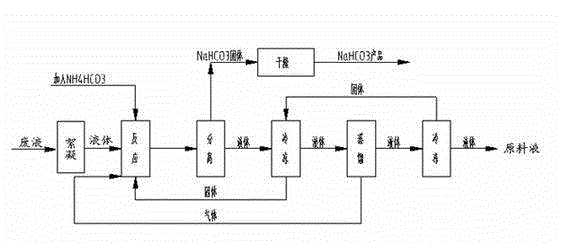

Process for preparing ammonium salt by recycling waste liquid generated by purifying flue gas

ActiveCN104445275AReduce consumptionSave raw steamAmmonium nitratesAmmonium sulfatesFlue gasSupersaturation

The invention provides a process for preparing ammonium salt by recycling waste liquid generated by purifying flue gas. The process is characterized by comprising the following steps of flocculating waste liquid generated by the wet purification of the flue gas to obtain a clear liquid, feeding the clear liquid to a reactor to react with ammonium bicarbonate, after the reaction is completed, carrying out solid-liquid separation on a material liquid, cooling and crystallizing the liquid to obtain a clear liquid as a raw material liquid, pumping the raw material liquid into a pre-heater, feeding the preheated raw material liquid into a heat exchanger, heating the preheated raw material by virtue of shell pass steam in a tube pass of the heat exchanger to raise the temperature, feeding the raw material liquid into a crystallization separator under the pushing action of a forced circulation pump, flashing in the crystallization separator, crystallizing the raw material liquid due to supersaturation to obtain ammonium salt crystals for recycling; and compressing secondary steam generated by flashing by virtue of a compressor as a heat source and feeding the compressed secondary steam into the shell pass of the heat exchanger.

Owner:CHENGDU HUAXITANG INVESTMENT

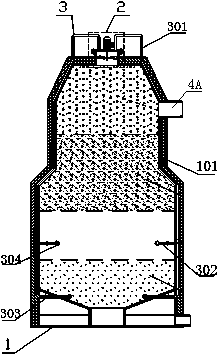

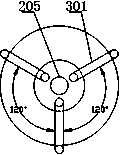

Pressurizing reverse-flow type organic garbage gasification furnace

PendingCN108117889AFast dryingHigh calorific valueGasification processes detailsCombustible gas productionCombustionHydrogen

The invention relates to the technical field of garbage treatment devices and provides a pressurizing reverse-flow type organic garbage gasification furnace. The pressurizing reverse-flow type organicgarbage gasification furnace comprises a gasification furnace body, a smoke refluxing device, a porous gas fetching device and an umbrella-type heat guiding device, and also comprises a smoke refluxing and cooling device. The gas refluxing and cooling device is arranged on t he top of the gasification furnace body, so that the drying speed of the garbage is accelerated, more carbon monoxide and hydrogen are generated, and the heat value of gasified gas is improved effectively. In addition, a plurality of gas fetching pipes are also arranged, so that gas is uniformly distributed in the furnacebody, and purity of discharged gas is prevented from being affected as the generated gas is left in the gasification furnace. The umbrella-type heat guiding device is arranged above the hearth of thegasification furnace, so that the temperature of a combustion layer can be kept in a high-temperature state. By refluxing the smoke in the organic garbage gasification furnace to a cooling and dehydrating device to remove water vapor in the smoke, the combustion value of the smoke is increased effectively.

Owner:玉溪市圣力环保科技有限公司

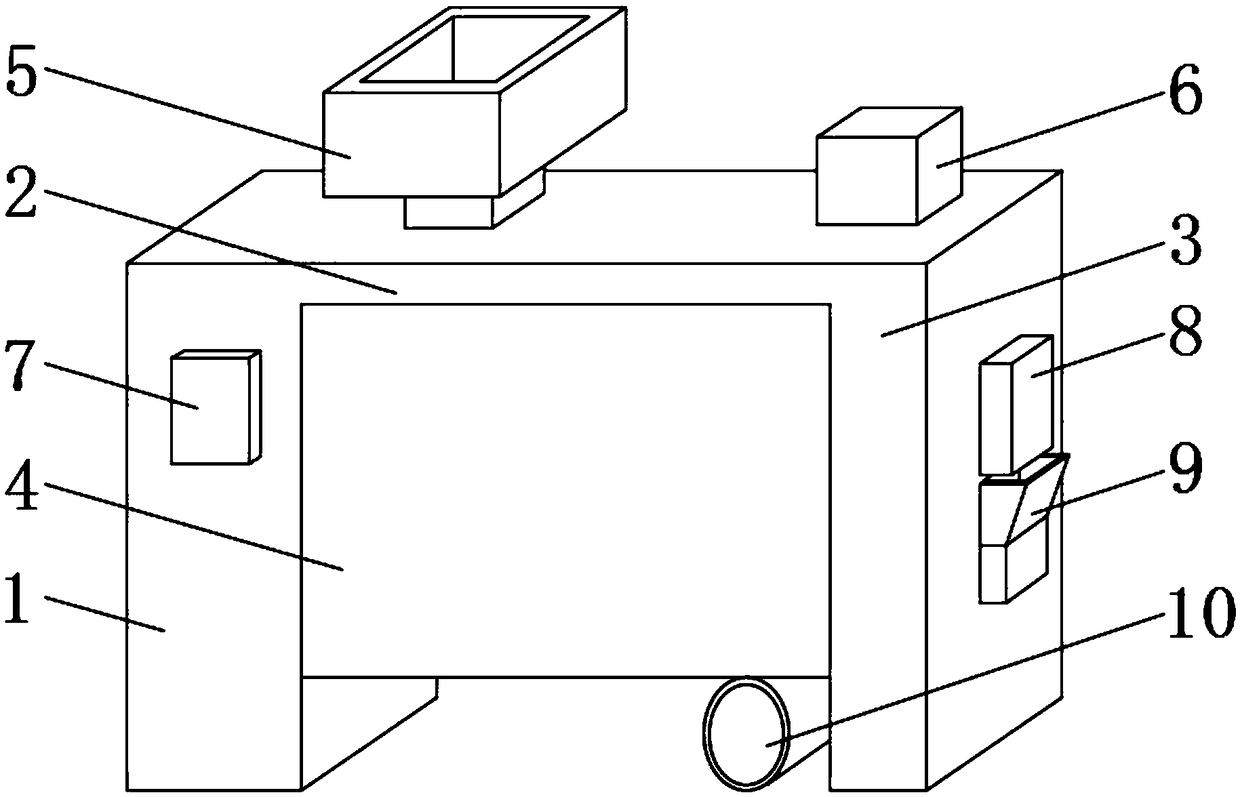

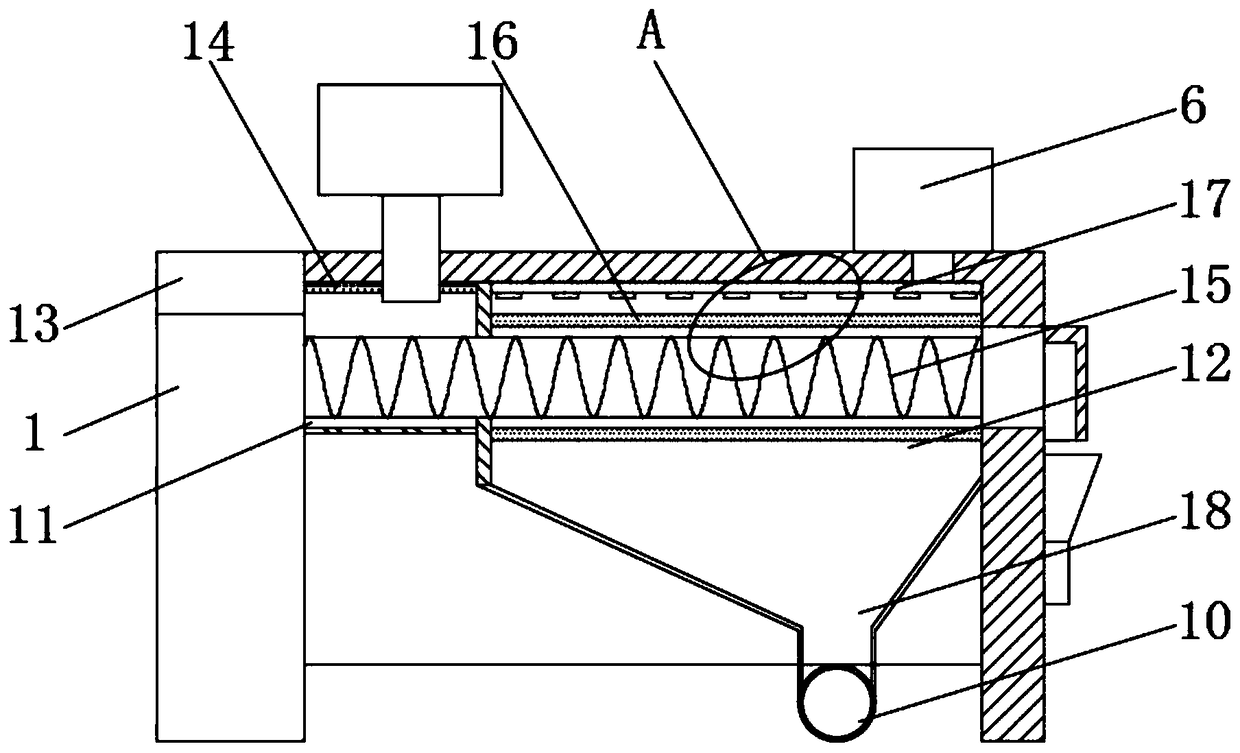

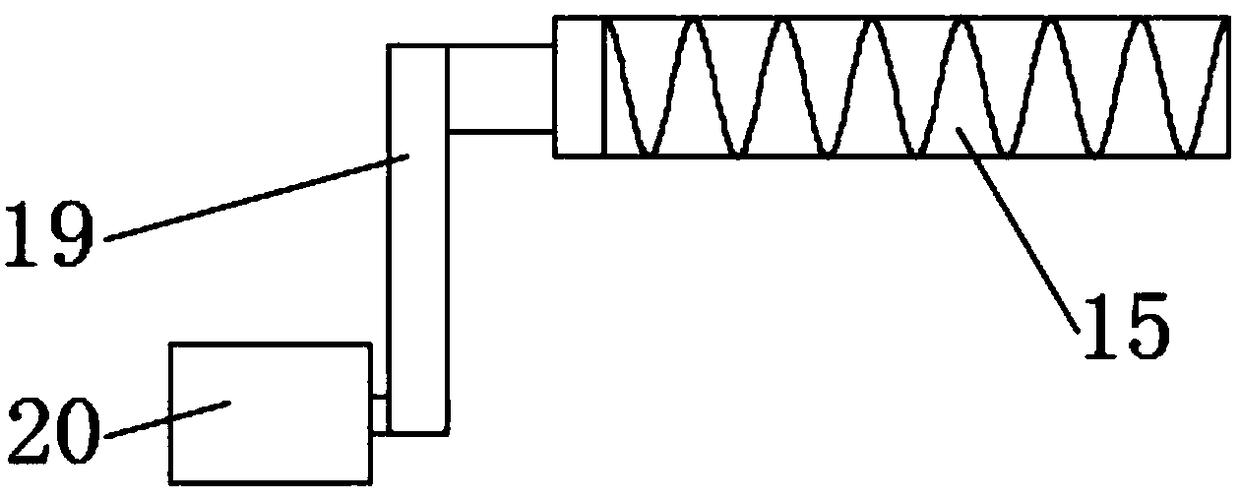

Rice polishing device

InactiveCN109482258APromote wettingImprove the finishGrain huskingGrain polishingAgricultural engineeringBran

The invention discloses a rice polishing device. The rice polishing device comprises a body box and a top plate fixedly arranged at the upper end of the body box. A bottom box is fixedly arranged at one end of the bottom of the top plate. A feeding chamber and a polishing chamber are fixedly arranged at the bottom end of the top plate. According to the rice polishing device, water can be evenly sprayed to rice entering the feeding chamber, rice wetting is convenient, rice bran can be better thoroughly removed through grinding, the smooth finish and polishing uniformity of rice are improved, crushed rice is reduced, uniform exhausting can be conducted on the polishing chamber, bran powder generated due to polishing can be blown out of a polishing pipe, falls into a material receiving chamber and is discharged through a bran powder discharging pipe. Meanwhile, the rice obtained after polishing is dried, a front cover arranged at the front end can be convenient to mount and dismount, detection and maintenance can be conducted on the inner feeding chamber and the polishing chamber, the material receiving chamber can be conveniently cleaned, inner cleanliness is kept, pipeline blockageis avoided, and better usage prospects are brought.

Owner:颍上县皖润米业有限公司

Novel convenient casting device for experiment

The invention discloses a novel convenient casting device for experiment, which is characterized by comprising a furnace body, a casting mould, a mobile trolley and a guide rail. The furnace body is a dumping electric induction furnace, a flat graphite crucible is arranged in the furnace body, the dumping angle of the furnace body is 0-110 degrees, the casting mould is arranged on the mobile trolley, the guide rail is an angle iron guide rail, the mobile trolley is arranged on the guide rail, a support frame is arranged on the mobile trolley, the casting mould is located in the support frame, a funnel made of graphite is arranged on the support frame, the funnel is located above the casting mould, a funnel plug is arranged in the funnel, and a through hole is formed in the funnel plug. The novel convenient casting device is wide in ingot casting production size and weight range, and is very suitable for material research and development; less scrap is generated in fusion casting production; capacity of the crucible is increased, and yield is high; and the novel convenient casting device is simple, easy to use, low in graphite change frequency, labor-saving, material-saving and cost-saving, convenient to operate, safe, simple and efficient, and high in casting quality.

Owner:NINGBO SHENGFA COPPER IND

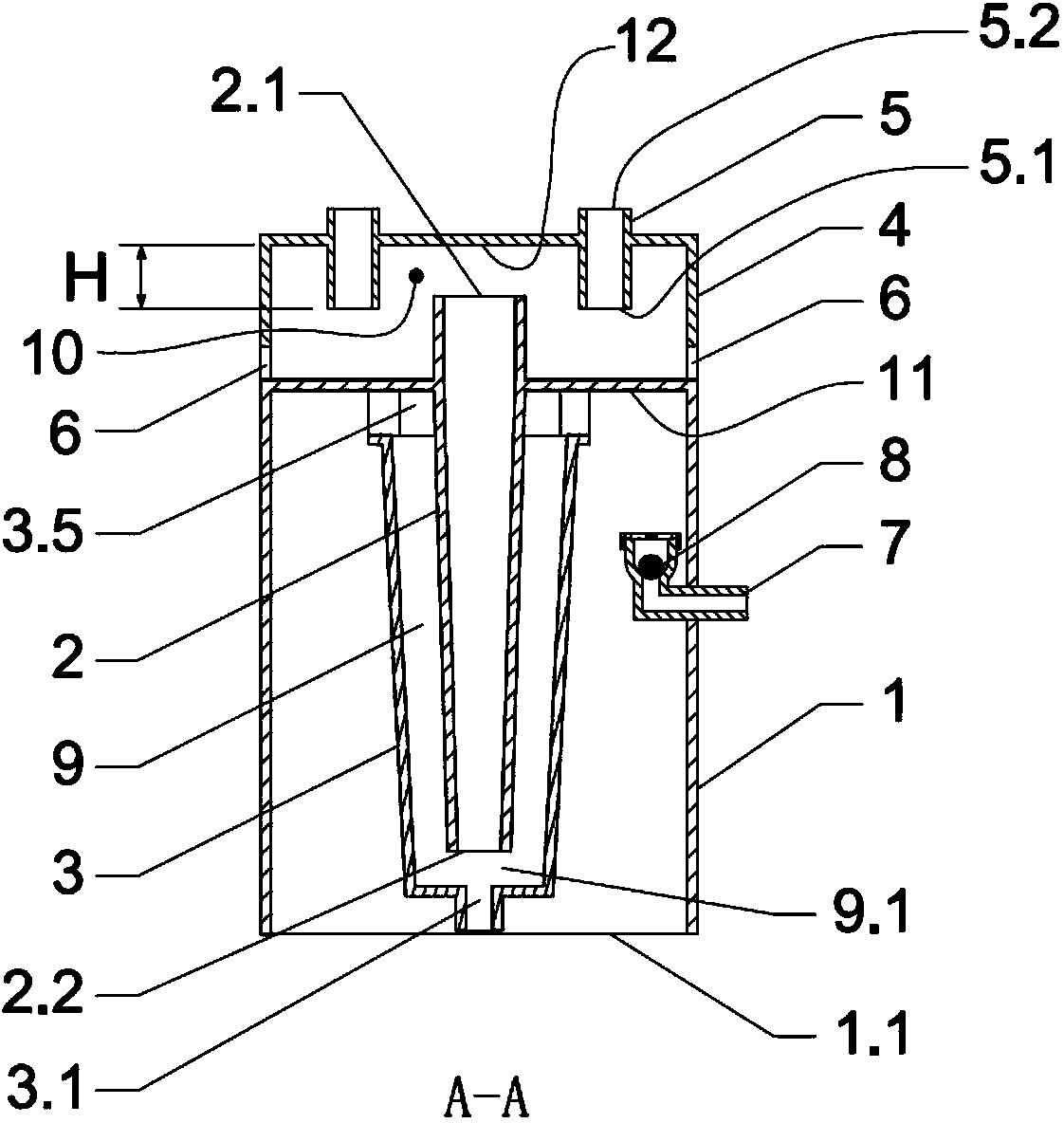

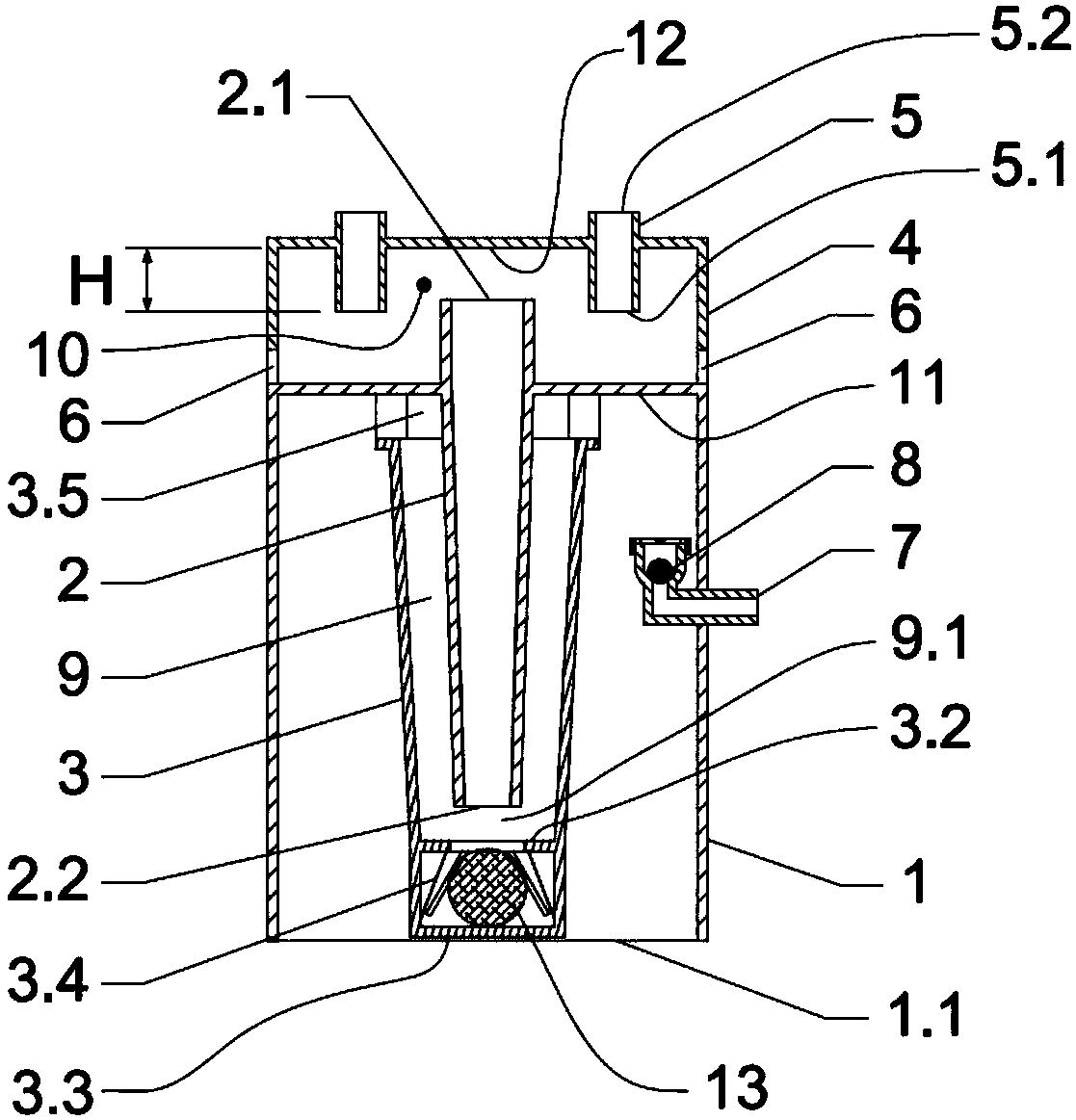

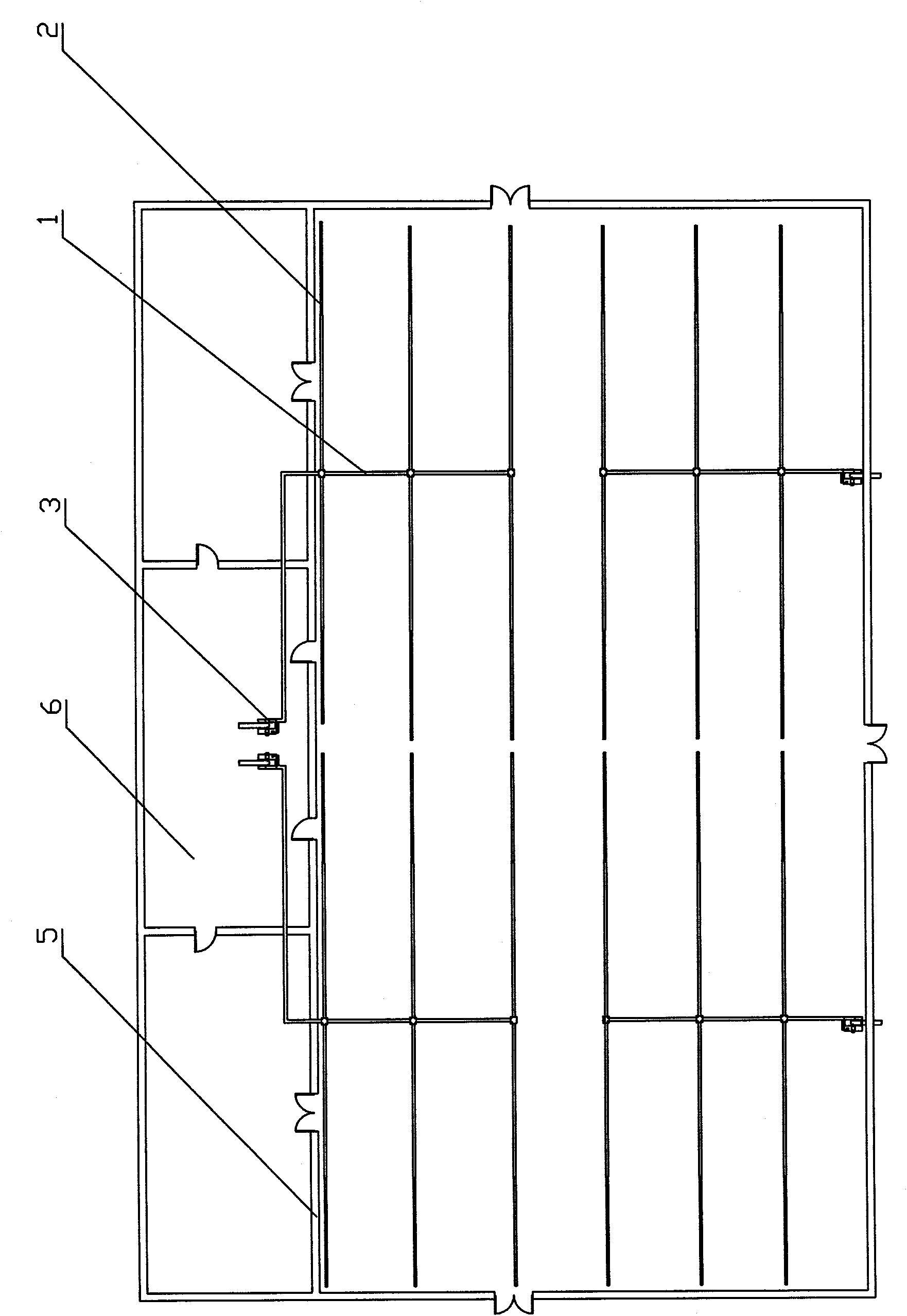

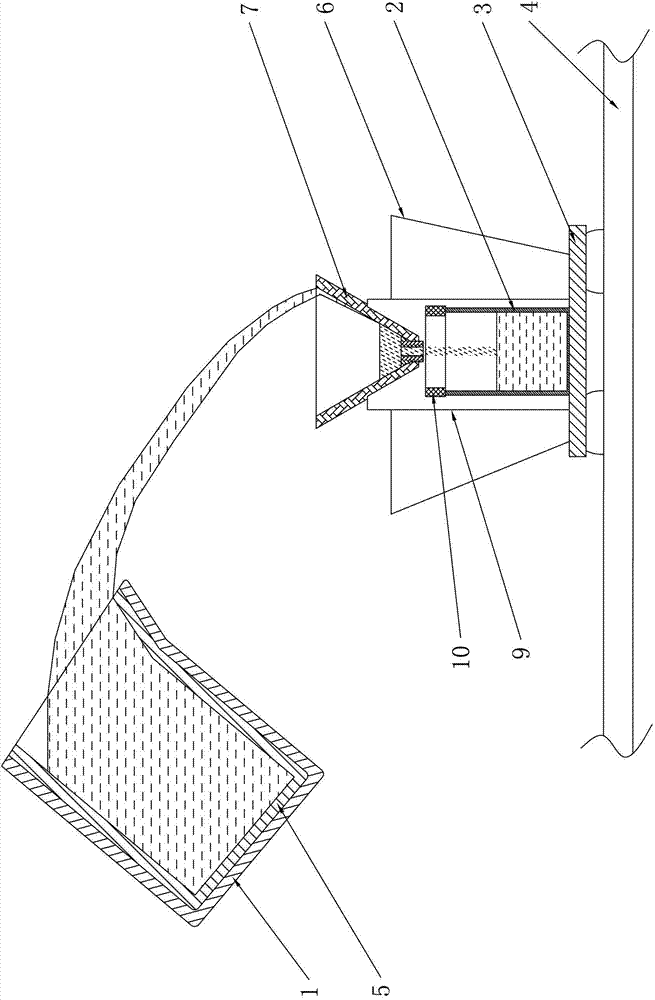

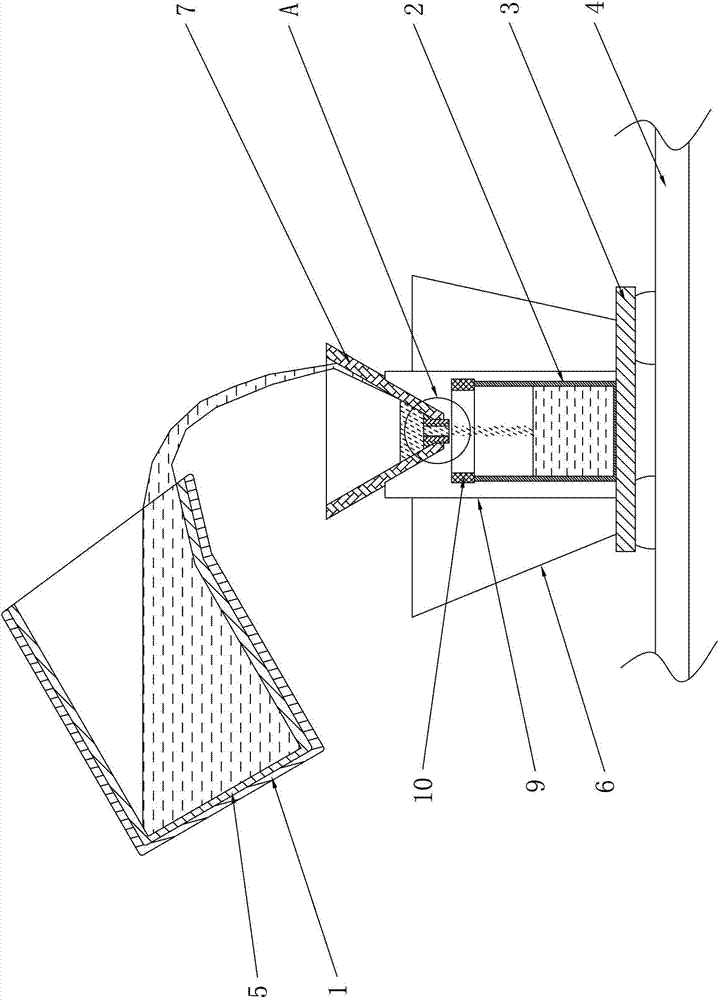

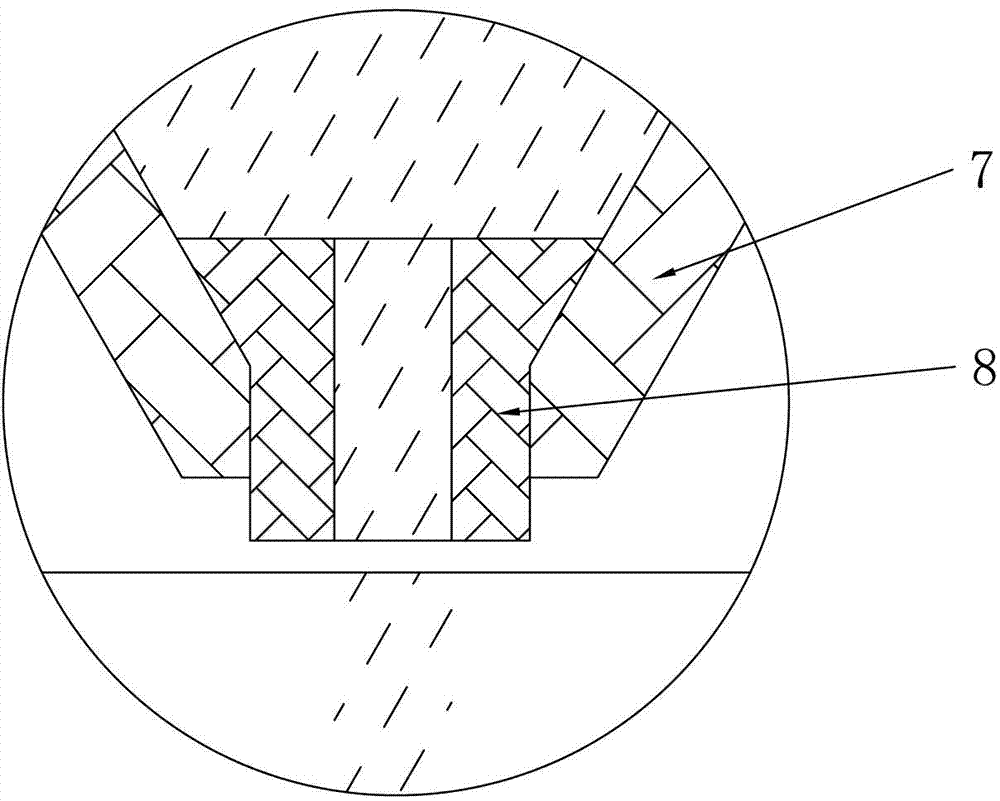

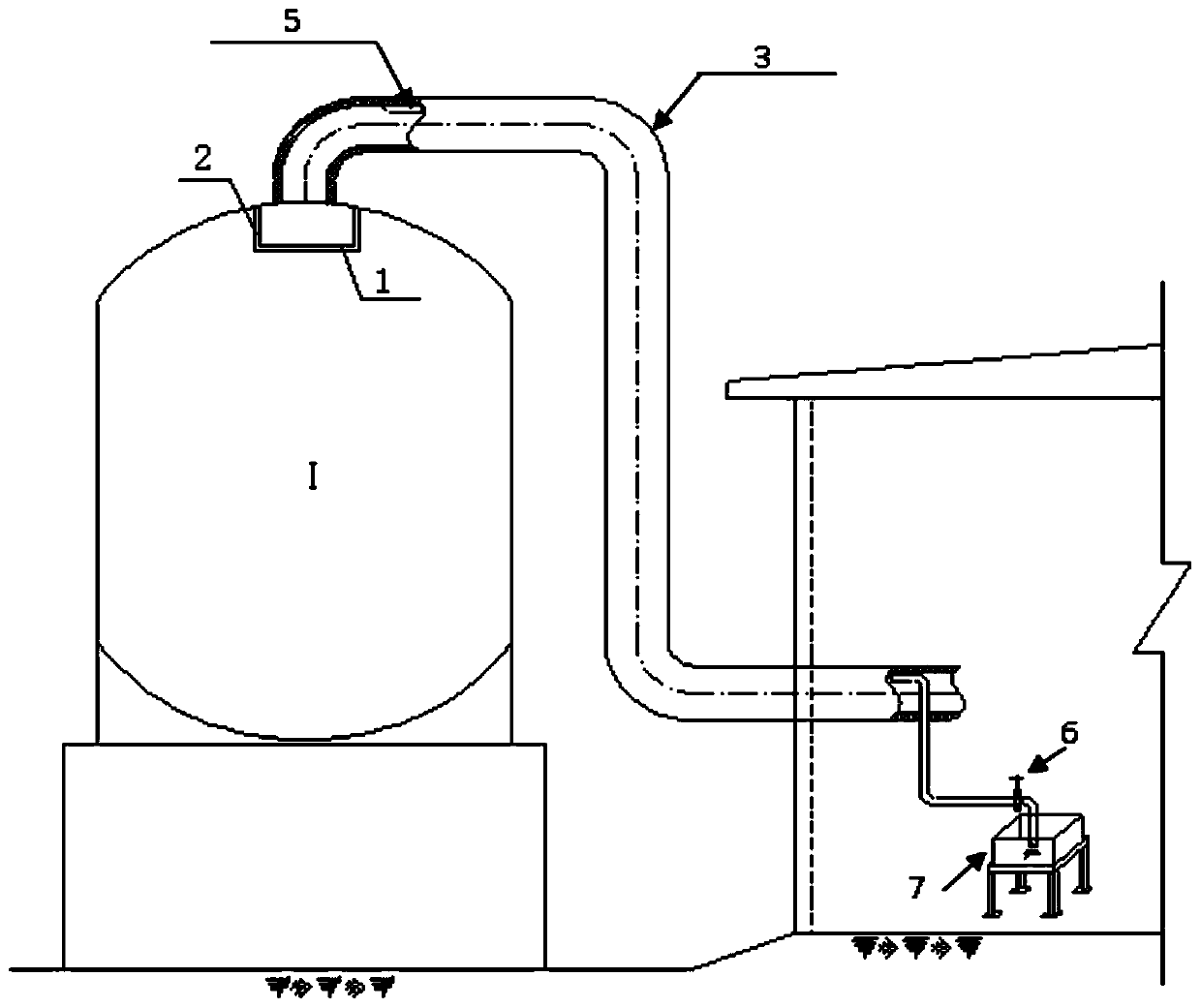

Water distribution and exhaust device for pressure filtration tank, pressure filtration tank and water distribution and exhaust method

PendingCN110694314ASimple structureReduce manufacturing costWaste water treatment from quariesTreatment involving filtrationFiltrationOil field

The invention discloses a water distribution and exhaust device for a pressure filtration tank, the pressure filtration tank and a water distribution and exhaust method. The water distribution and exhaust device comprises a water distribution structure and an exhaust structure; the water distribution structure is arranged at the top end of the interior of a pressure filtering tank, and is composedof a bottom blocking plate and side blocking plates; a cylinder with an upper opening and a lower opening is formed by the side blocking plates; a plurality of through holes are uniformly distributedin the surface of the cylinder; the bottom blocking plate is arranged at the bottoms of the side blocking plates, and a container with an upper opening and a sealed bottom is formed by the bottom blocking plate and the side blocking plates; the upper opening of the side blocking plates and an top end opening of the pressure filtering tank are in sealing connection, and is communicated with a filtering inlet water dry pipe arranged at the top end opening of the pressure filtering tank. The water distribution and exhaust device is low in manufacturing cost; no blockage is caused, no pressure build-up is induced, no dead water area is formed, uniform water distribution is achieved, thorough exhaust is achieved, no freezing during operation in winter is caused, the treatment efficiency of oilfield pressure filter tanks is improved, and the service life is prolonged.

Owner:DAQING OILFIELD CO LTD +1

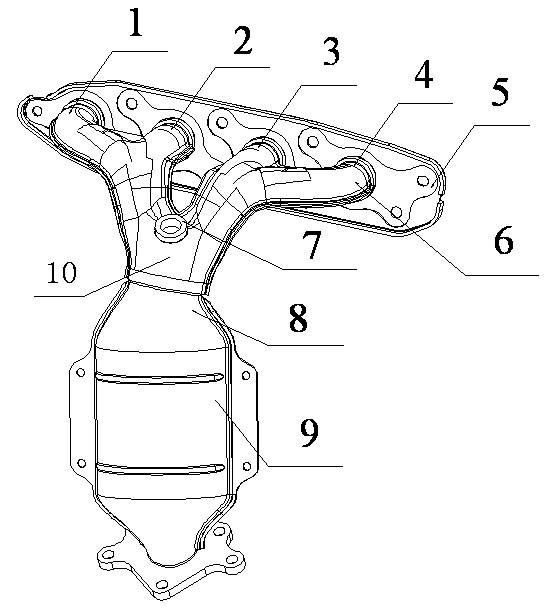

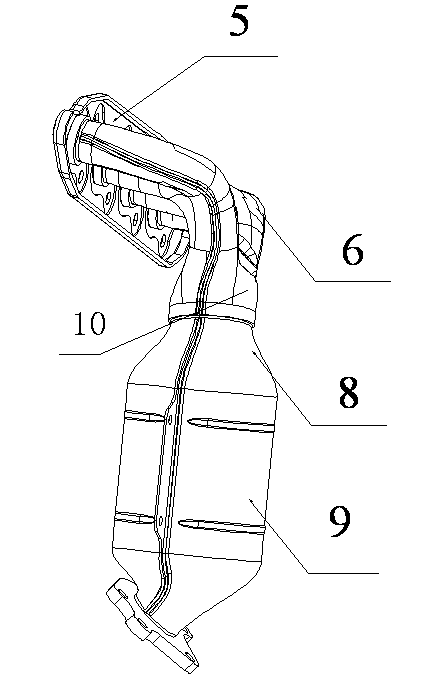

Exhaust manifold assembly

InactiveCN103375240AImprove conversion efficiencyIncreased durabilityExhaust apparatusSilencing apparatusEngineeringAtmospheric pressure

The invention discloses an exhaust manifold assembly structure which is symmetrical and compact in structure. By the aid of the exhaust manifold assembly symmetrical in structure, tail gas entering a three-way catalyst is ensured to be even, and air pressure impulse interference is reduced. Sub-branch manifolds connecting with every cylinder cover exhaust port are preferably converged to form 'Y'-shaped branches, and the 'Y'-shaped branches are converged at the position of a main exhaust manifold of the exhaust manifold, so that the exhaust manifold assembly is ensured to be shorter and more compact in structure, stroke length of the exhaust manifold assembly is shortened, and high converting efficiency and good durability of the three-way catalyst can be guaranteed.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

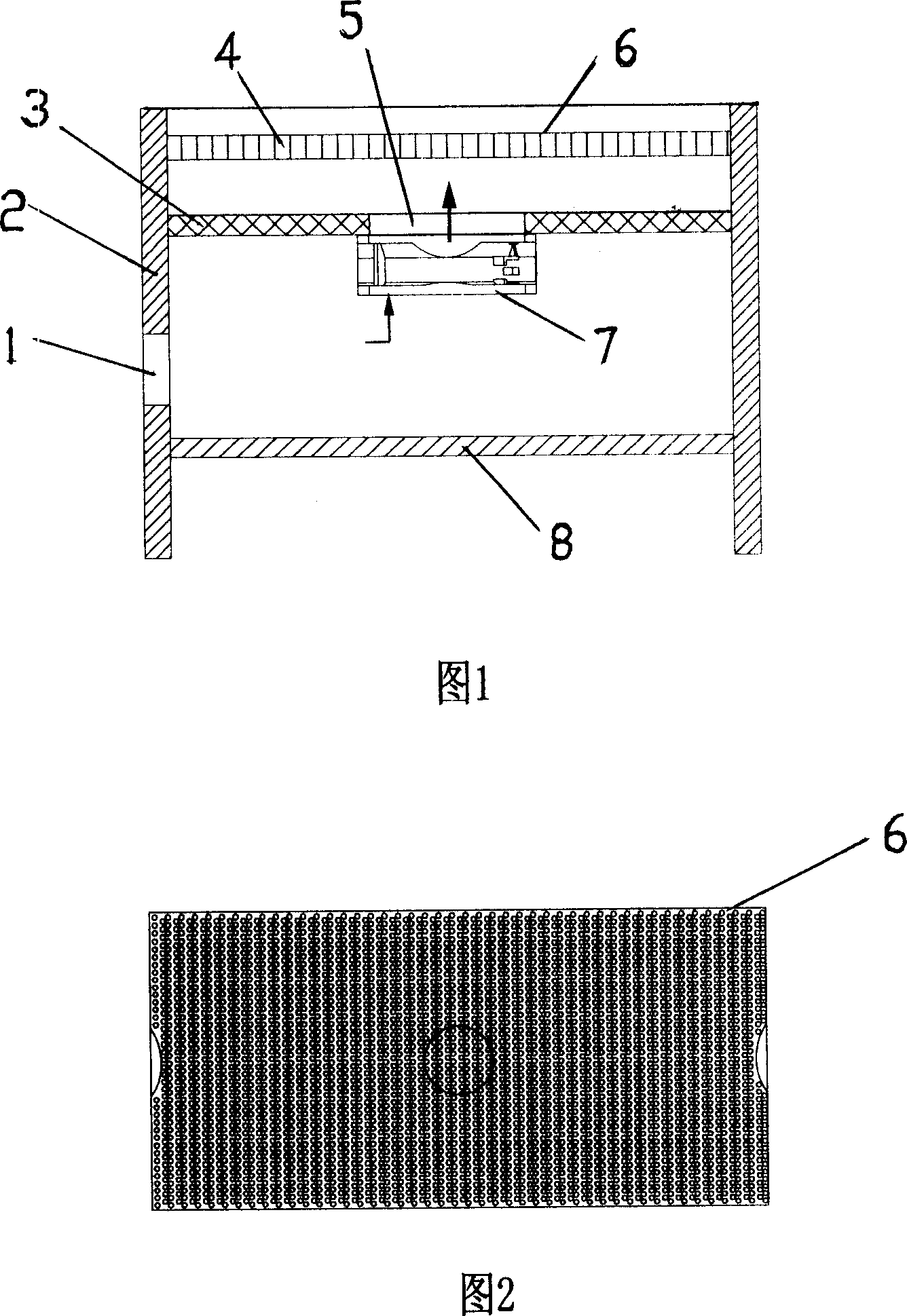

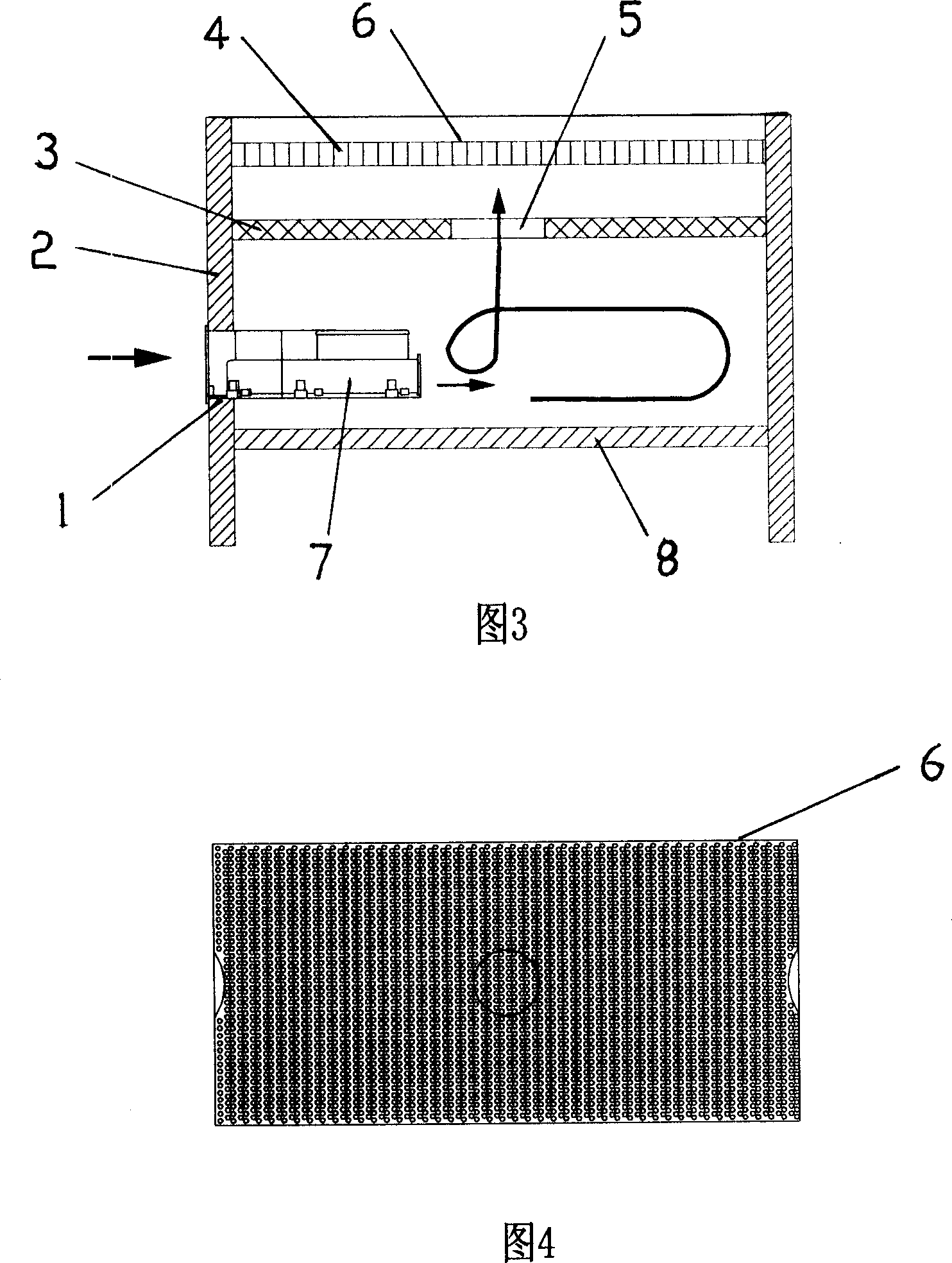

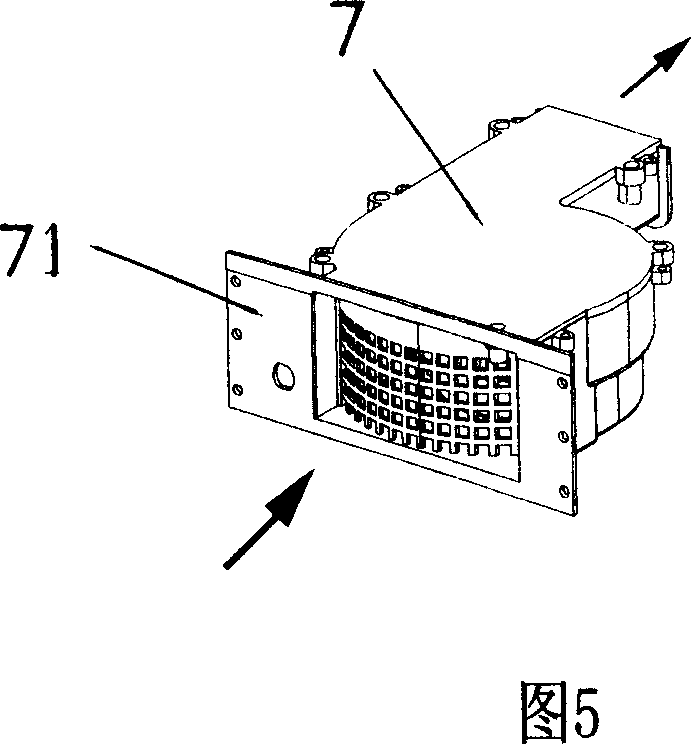

Table air hokey aide air-feeding method and table air hokey

The invention relates to a method for feeding wind beside air ball table, and relative air ball table, wherein it comprises that: it uses beside feeding method; the table is formed by table panel, middle plate, low panel and side panel, to form sealed space; the wind only is discharged at the porous of table panel; the side panel has wind inlet; the middle plate has ventilating outlets; the fan is mounted on the wind inlet; the airflow is guided via the ventilating outlet uniformly into the space between table panel and middle plate to be discharged via porous.

Owner:SHENZHEN S&T MOTOR CO LTD

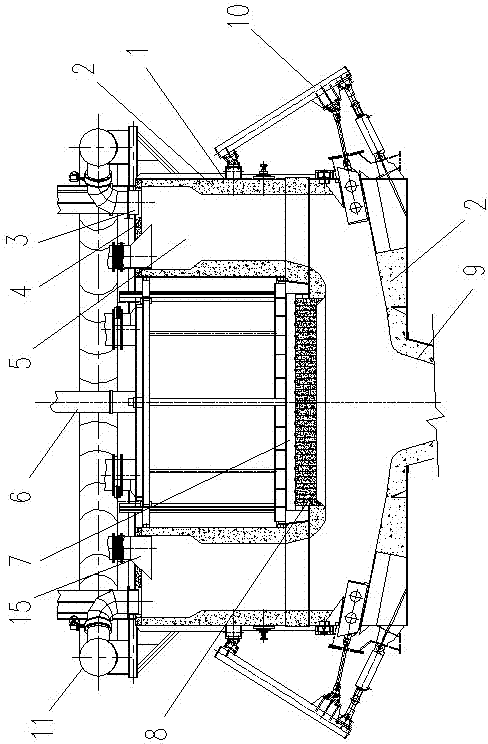

High-chamber annular ventilation vertical preheater

The invention discloses a high-chamber annular ventilation vertical preheater. The preheater is reasonable in structure and neat in layout, a ventilation system is uniform in exhaust, energy sources can be fully utilized, and the productivity of the preheater can be improved. The preheater comprises a shell and an upper preheater cover plate, wherein a discharging sliding bucket is arranged at a lower outlet of the shell. The preheater is characterized in that a plurality of annularly distributed preheating chamber cavities are formed in the inner periphery of the shell; the preheating chamber cavities are 3000 to 4500mm high; hydraulic pushing systems are symmetrically arranged at positions corresponding to the discharging sliding bucket on the shell; discharging pipes communicated with the preheating chamber cavities are arranged on the upper preheater cover plate; preheater support upright posts are uniformly distributed around the shell; a hoisting brick frame is arranged on the inner middle part of the shell; refractory hoisting bricks are arranged on the lower surface of the hoisting brick frame; a ventilation duct bracket is arranged on the preheater support upright posts; an annular ventilation duct is arranged on the ventilation duct bracket; the preheating chamber cavities are communicated with the annular ventilation duct through ventilation duct joints and preheating chamber air outlet pipes connected with the ventilation duct joints; air outlet pipe adjusting valves are arranged on the preheating chamber air outlet pipes.

Owner:CHAOYANG HEAVY MASCH CO LTD

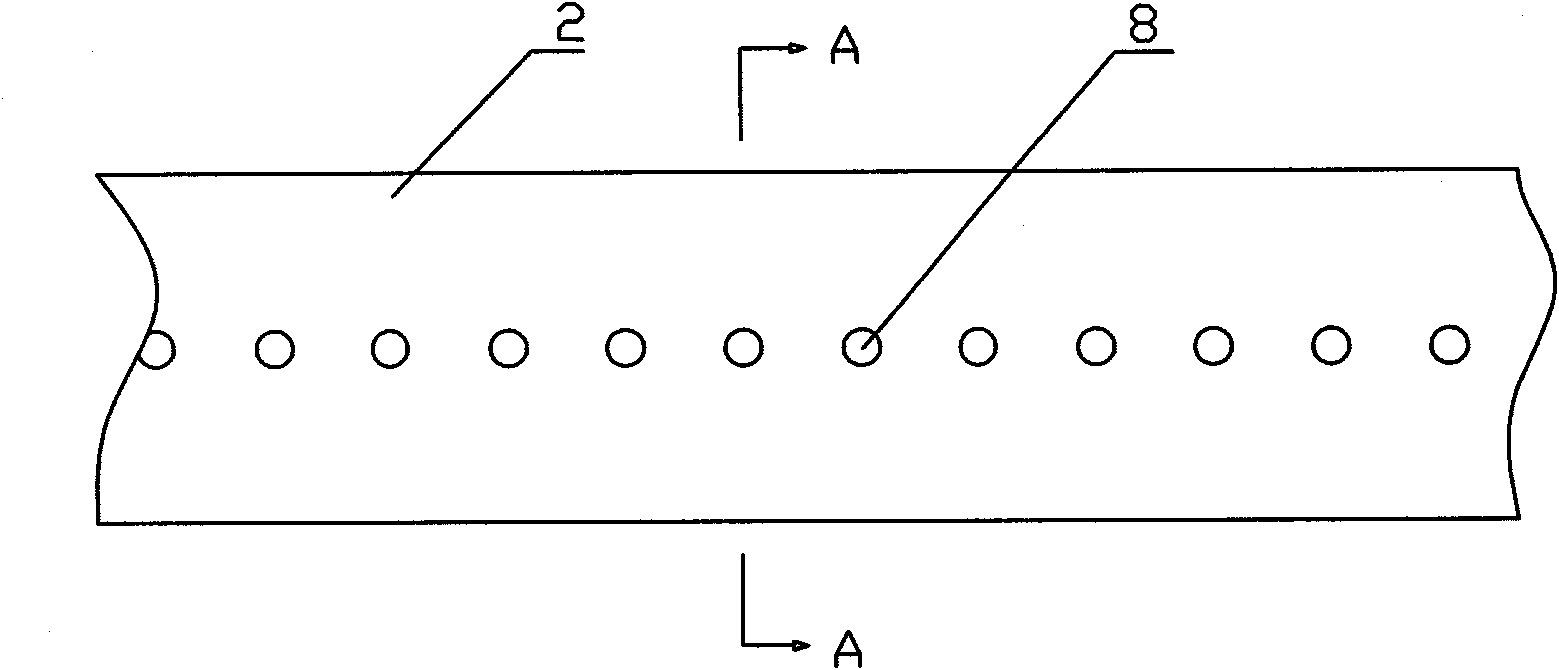

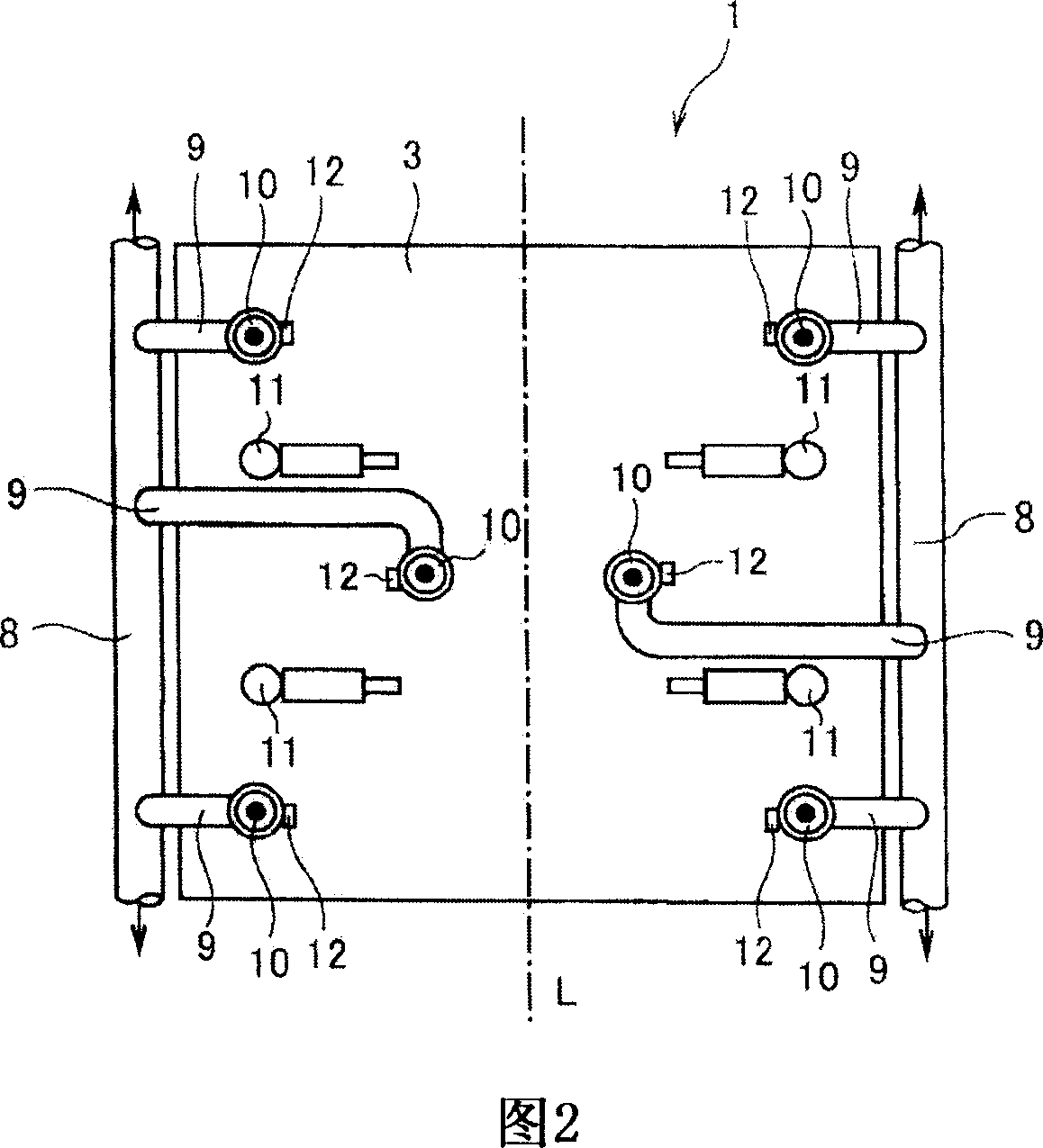

Decompression processing device

InactiveCN1958172AUniform exhaustUniform film thicknessDrying solid materials without heatVacuum evaporation coatingMechanical engineering

Disclosed is a decompression processing device for forming uniform envelope on large scale glass substrate. Auxiliary exhaust ducts (9) branching from primary exhaust duct (8, 8) extend along the upper surface of a case body (3), suction parts (10) having opening to decompression processing space in the case body (3) are mounted at front end of each auxiliary exhaust ducts (9). The suction parts (10) are arranged at a position symmetric in both sides of the axes as reference in overlook observation. The suction parts (10) are arranged in such positions that even vacuum is drawn in the decompression processing space within a short time, temperature non-uniformity can be prevented.

Owner:TOKYO OHKA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com