Modularized pulse aeration apparatus, standard aeration system module and filtration system

An aeration device and pulse-type technology, applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, membrane technology, etc., can solve problems such as gas channel blockage, membrane fouling, and backflow blockage of gas source input ports, etc., to achieve Avoid the effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

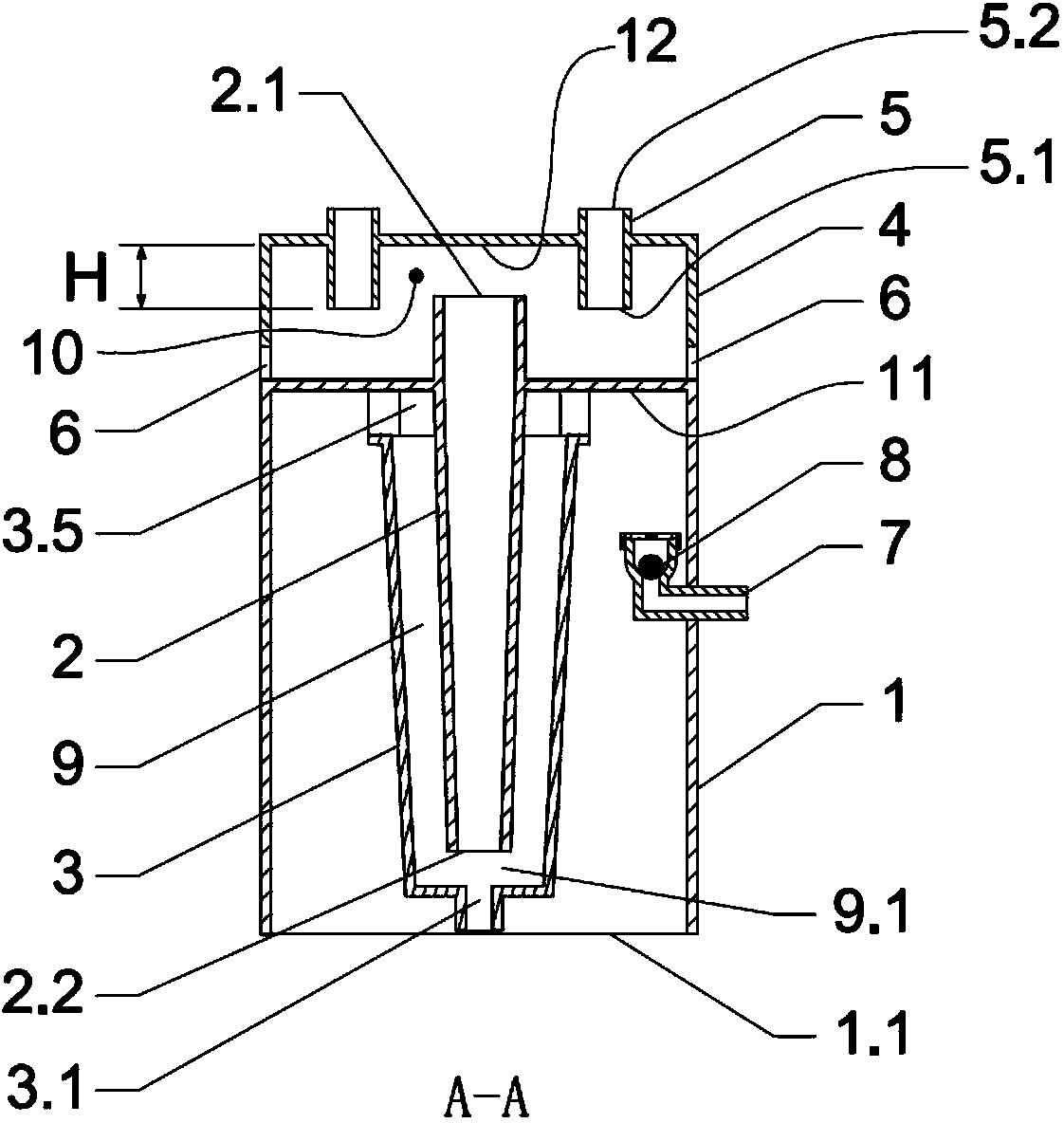

[0065] Embodiment one is a preferred modular pulse aeration device, such as figure 1 shown.

[0066] When the modular pulse aeration device is working, the main step-by-step state of a pulse release air flow cycle is shown as follows: Figure 5A , 5B , 5C, and 5D. The modular pulse aerator is submerged in liquid 40 . The gas fairing 4 is above the top plate 11 of the main housing, and the side wall bottom of the gas fairing 4 has a through hole 6, and the through hole 6 is used as the discharge port of the settled suspended matter in the gas fairing 4, so as to avoid forming a blockage. The upper port 5.2 of the diffuser 5 is flush with or higher than the top plate 12 of the gas fairing, and the highest point of the through hole 6 is lower than the lower port 5.1 of the diffuser 5, so that the airflow is prevented from escaping from the through hole 6 by forming a liquid seal. The height of the upper port 2.1 of the through-hole guide pipe 2 is flush with or higher than th...

Embodiment 2

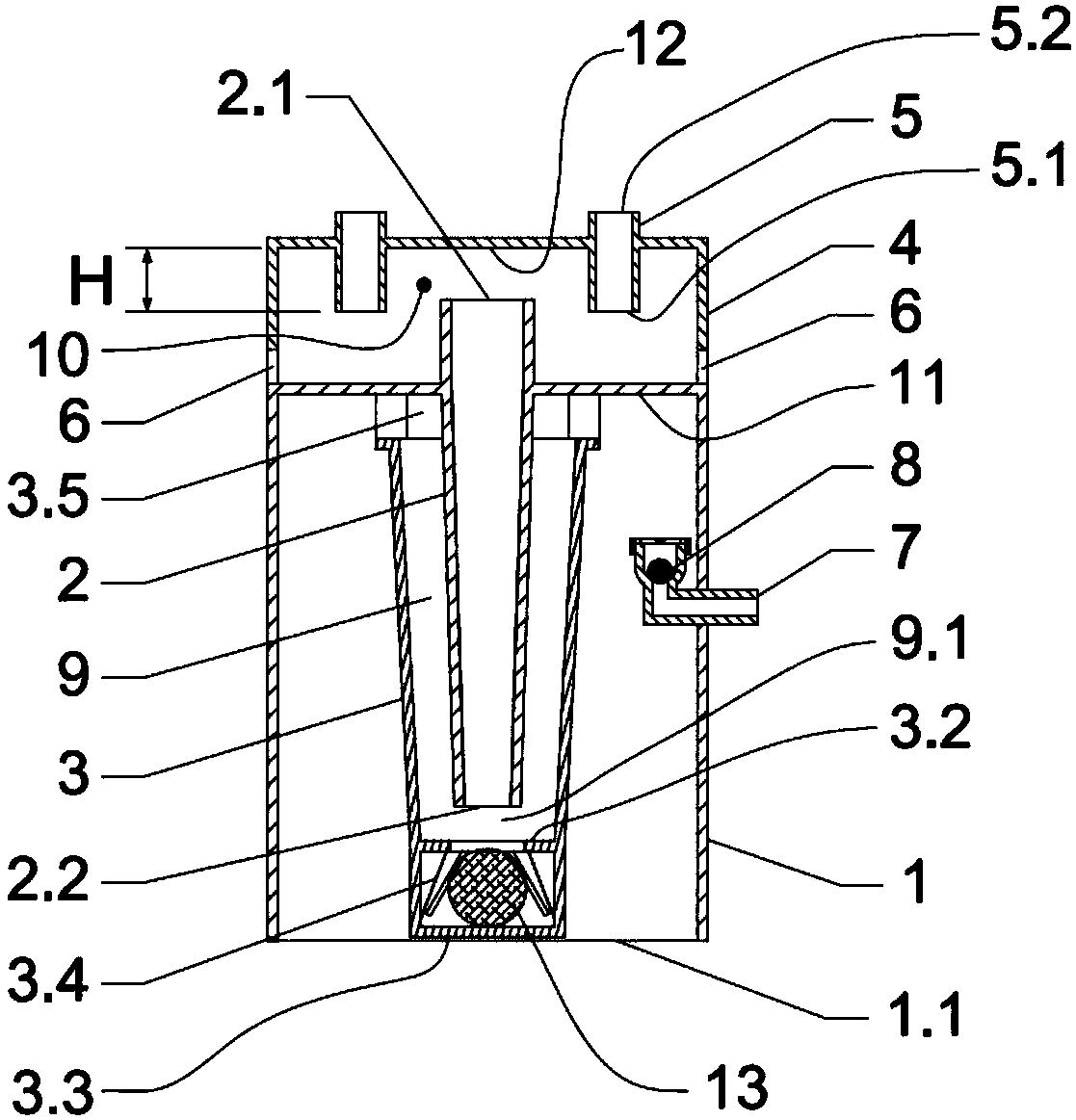

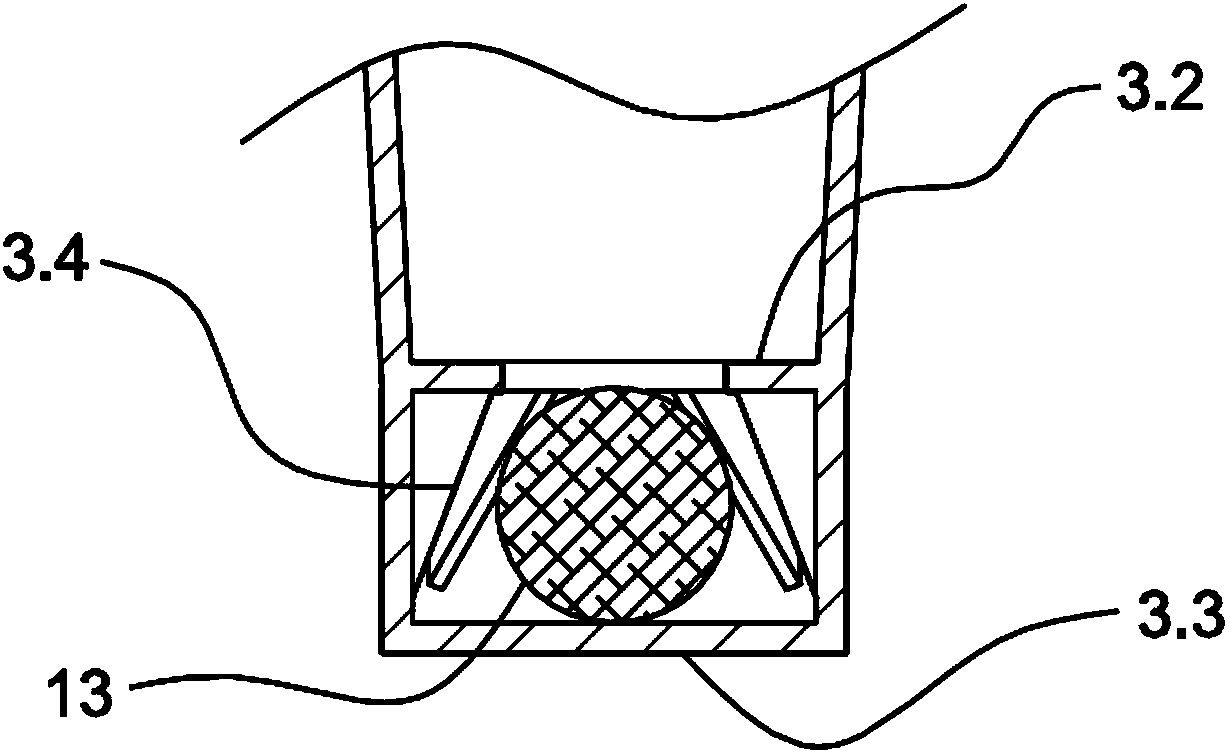

[0071] Embodiment two is another preferred modular pulse aeration device, such as figure 2 shown.

[0072] The gas fairing 4 is above the top plate 11 of the main housing, and the side wall bottom of the gas fairing 4 has a through hole 6, and the through hole 6 is used as the discharge port of the settled suspended matter in the gas fairing 4, so as to avoid forming a blockage. The upper port 5.2 of the diffuser 5 is flush with or higher than the top plate 12 of the gas fairing, and the highest point of the through hole 6 is lower than the lower port 5.1 of the diffuser 5, so that the airflow is prevented from escaping from the through hole 6 by forming a liquid seal. The height of the upper port 2.1 of the through-hole guide pipe 2 is flush with or higher than the lower port 5.1 of the diffuser 5, and a gap is formed between the lower port 5.1 of the diffuser 5 and the upper top plate 12 of the gas fairing. The stagnant air chamber 10 in the height range H will be filled wit...

Embodiment 3

[0077] Embodiment three is another preferred modular pulse aeration device, such as Figure 4 shown.

[0078] The gas fairing 4 is above the top plate 11 of the main housing, and the side wall bottom of the gas fairing 4 has a through hole 6, and the through hole 6 is used as the discharge port of the settled suspended matter in the gas fairing 4, so as to avoid forming a blockage. The upper port 5.2 of the diffuser 5 is flush with or higher than the top plate 12 of the gas fairing, and the highest point of the through hole 6 is lower than the lower port 5.1 of the diffuser 5, so that the airflow is prevented from escaping from the through hole 6 by forming a liquid seal. The height of the upper port 2.1 of the through-hole guide pipe 2 is flush with or higher than the lower port 5.1 of the diffuser 5, and a gap is formed between the lower port 5.1 of the diffuser 5 and the upper top plate 12 of the gas fairing. The stagnant air chamber 10 in the height range H will be filled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com