High-chamber annular ventilation vertical preheater

A vertical preheater and preheater technology, applied in lime production and other directions, can solve the problems of equipment structure, unbalanced volume matching, inability to make full use of energy, insufficient material preheating time, etc., and achieve good preheating effect. , The effect of the improvement of the body structure and the increase of the overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

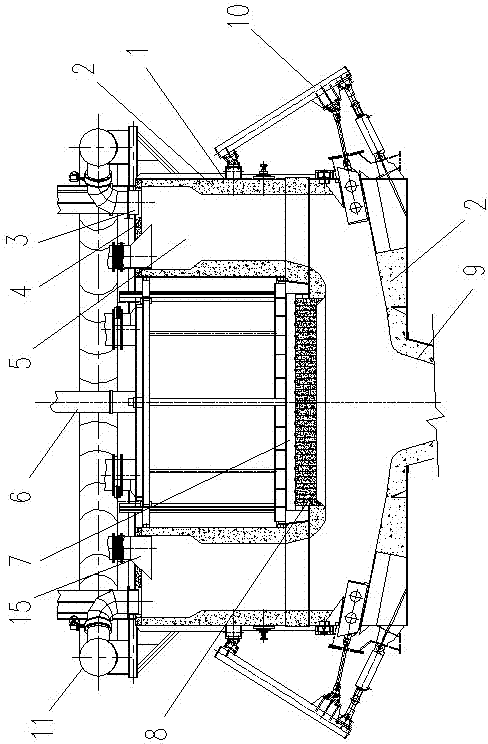

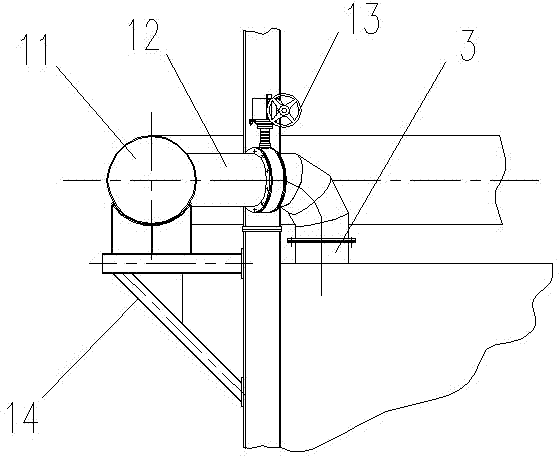

[0013] The present invention comprises a shell 1, a preheater upper cover plate 4 is arranged on the upper opening of the shell 1, a discharge chute 9 is arranged at the outlet below the shell 1, and a plurality of annularly distributed The preheating chamber cavity 5, the inner wall of the preheating chamber cavity 5 is provided with a refractory masonry layer 2, and this embodiment takes 6 preheating chamber cavities as an example. The height of the preheating chamber cavity 5 is 3000mm-4500mm, which is 3800mm in this embodiment. On the shell 1, a hydraulic pushing system 10 is provided symmetrically corresponding to the discharge hopper 9 and each preheating chamber cavity 5. On the upper cover plate 4 of the preheater, a feeding pipe 15 communicating with the top of the preheating chamber cavity 5 is arranged, and a hanging brick frame 7 is arranged in the middle part of the shell 1, and the top of the hanging brick frame 7 is arranged on the supporting column of the prehea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com