Process for purifying fluorine contg. flue-gas for aluminium electrolysis

A purification process, aluminum electrolysis technology, applied in the direction of chemical instruments and methods, dispersed particle separation, separation method, etc., can solve the problems of aluminum electrolytic tank flue gas pollution, short process purification efficiency, etc., to improve the efficiency of collecting alumina, equipment Reliable operation, ensuring the effect of mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

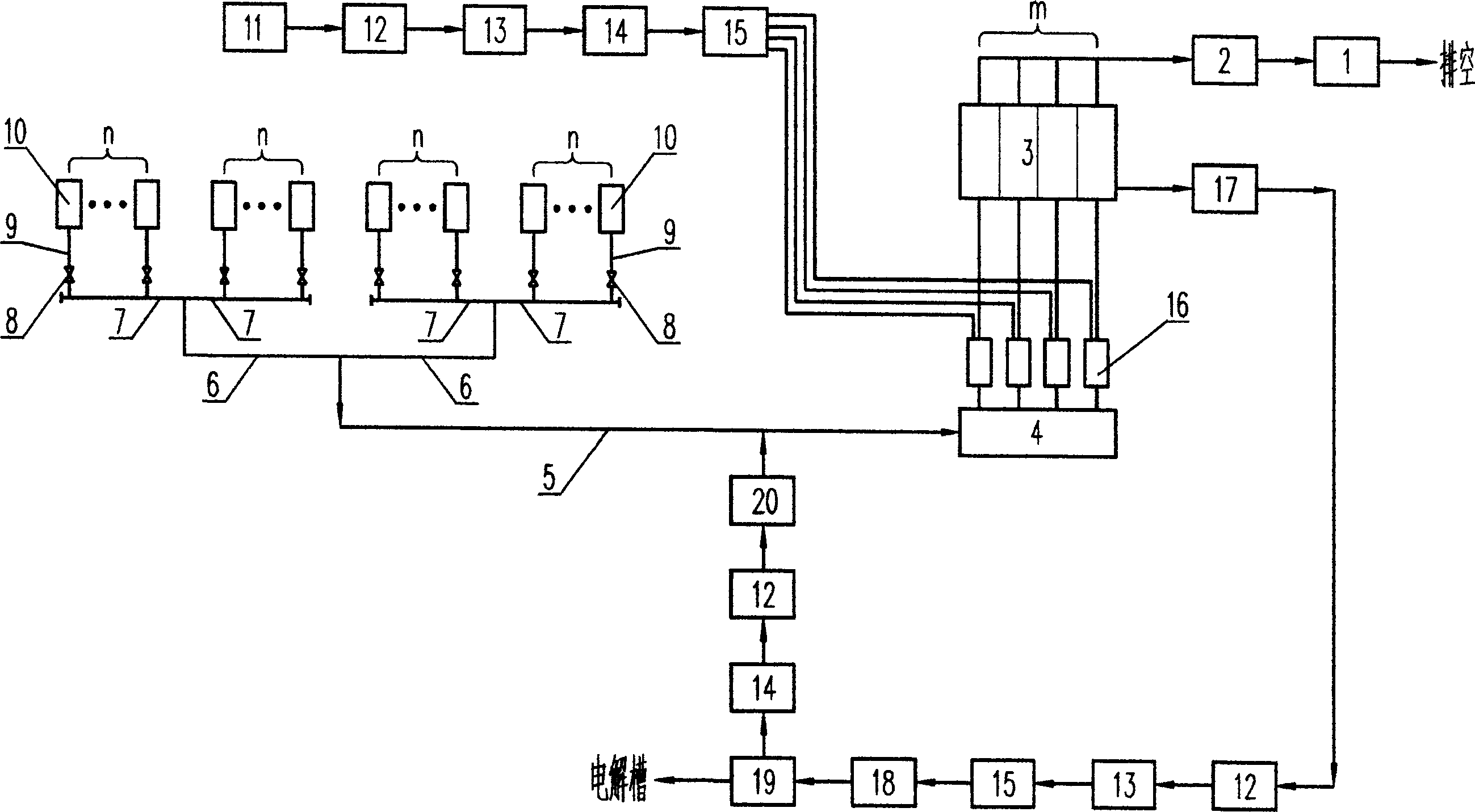

[0022] Embodiments of the present invention: as attached figure 1 Shown, the exhaust fan 2 that adopts in the present invention, pneumatic chute 12, measuring device 14 etc. all can adopt the finished product that sells on the market; Ash device 17, material distribution box 15, claw-shaped feeding device 20, sealing box 13, air lifter 18, etc. can be ordered according to the technical conditions of actual use, and are made by professional manufacturers.

[0023] When performing flue gas purification treatment, all electrolytic cells 10 are sealed with small movable cover plates and upper cover plates, and the flue gas in the cells is connected to the system through the gas collecting hood and the upper connecting branch pipe. The smoke exhaust branch pipe of each electrolytic cell 10 9 are all connected to the outdoor overhead horizontal smoke exhaust sub-dry pipe 7, the smoke exhaust sub-dry pipe 7 converges to the smoke exhaust main pipe 6, and then the smoke exhaust main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com