Exhaust manifold assembly

An exhaust manifold and assembly technology, which is applied in the field of engine exhaust manifold assembly structure, can solve the problems of unfavorable three-way catalytic converter conversion efficiency durability, unfavorable exhaust manifold structure compactness, three-way catalytic converter stroke Long and other problems, to achieve the effect of being conducive to the layout of the space structure, reducing the interference of air pressure pulses, and reducing the loading space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

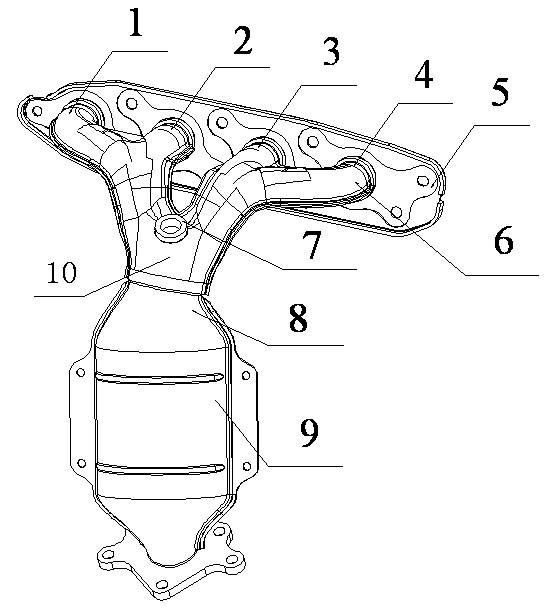

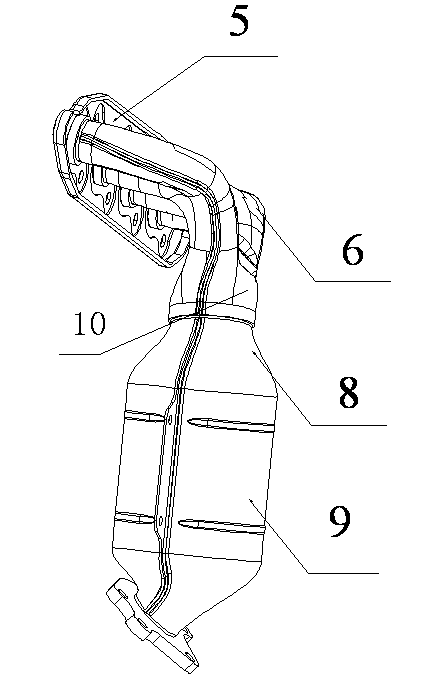

[0016] Such as figure 1 , figure 2 As shown, the exhaust manifold assembly includes an exhaust air passage 6 and a three-way catalytic converter 9 connected to the exhaust air passage 6. One end of the exhaust air passage 6 is a branch air passage and is respectively connected to the cylinder head through the flange plate 5. The exhaust port is connected, and the adjacent branch air channels merge into a "Y" branch along the airflow direction, and the adjacent branch air channels that merge into a "Y" branch correspond to non-adjacent working cylinders, and each "Y" branch The main exhaust air passage 10 is connected with the inlet port 8 of the three-way catalytic converter 9 and merges with the exhaust main air passage 10 at the other end of the exhaust air passage 6 .

[0017] After the piston in one cylinder works and exhausts, the piston in the second cylinder immediately performs work and exhausts, and then the piston in the third cylinder performs work and exhausts. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com