Process for preparing ammonium salt by recycling waste liquid generated by purifying flue gas

A flue gas purification and waste liquid technology, applied in the direction of ammonium nitrate, ammonium sulfate, application, etc., can solve the problem that the secondary steam cannot be used directly, achieve good dust removal effect, small equipment footprint, and reduce occupation The effect of the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

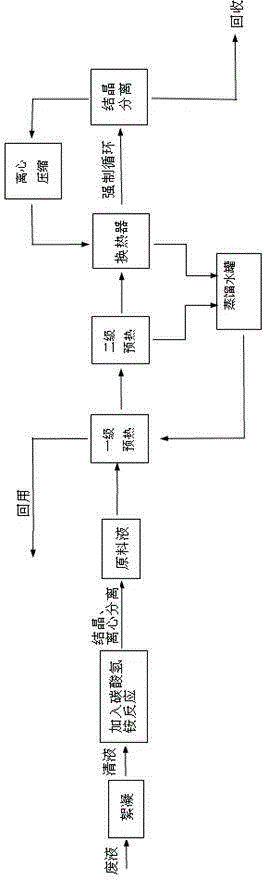

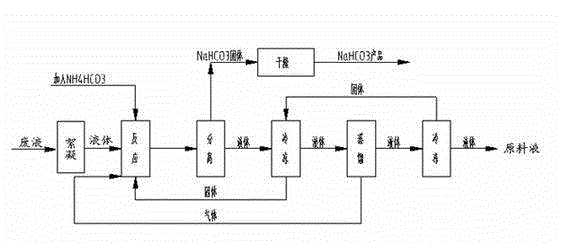

[0060] A process for recovering and utilizing flue gas purification waste liquid to prepare ammonium salts. After flue gas is wet-purified, waste liquid is flocculated, and the clear liquid enters the reactor to react with ammonium bicarbonate. After the reaction is completed, the feed liquid undergoes solid-liquid separation , the clear liquid obtained after liquid cooling and crystallization is used as the raw material liquid, pumped into the preheater, the preheated raw material liquid enters the heat exchanger, and is heated by the shell side steam in the tube side of the heat exchanger, and the temperature of the raw material liquid is Driven by the forced circulation pump, it enters the crystallizer, and flashes in the crystallizer, the raw material liquid is supersaturated and crystallized, and the ammonium salt crystals are recovered; the secondary steam generated by the flash is compressed by the compressor and used as The heat source enters the shell side of the heat ...

Embodiment 2

[0062] The implementation mode of this embodiment is basically the same as embodiment 1, on this basis:

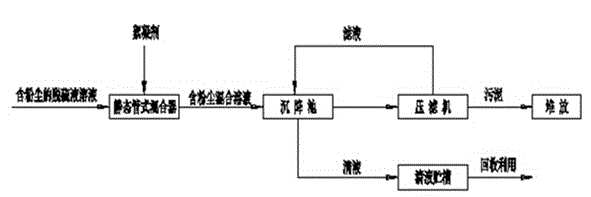

[0063] The flocculation refers to: adding the aqueous solution of the composite flocculant to the desulfurization liquid through a pipeline mixer, the desulfurization liquid is flocculated and clarified in the settling tank, the clear liquid enters the lower regeneration process, and the settled sludge is dehydrated. The filtrate is transported outside, and the filtrate is returned to the settling tank for circulation and clarification.

Embodiment 3

[0065] The implementation mode of this embodiment is basically the same as embodiment 2, on this basis:

[0066] The aqueous flocculant solution is prepared from polyacrylamide and sodium polyacrylamide with a mass ratio of 1:3 to form an aqueous solution with a mass fraction of 0.06%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com