Novel convenient casting device for experiment

An experimental and convenient technology, applied in ingot workshops, casting workshops, casting equipment, etc., can solve the problems of high production costs, large floor space, troublesome processing, etc., achieve low replacement frequency, eliminate surface pores, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

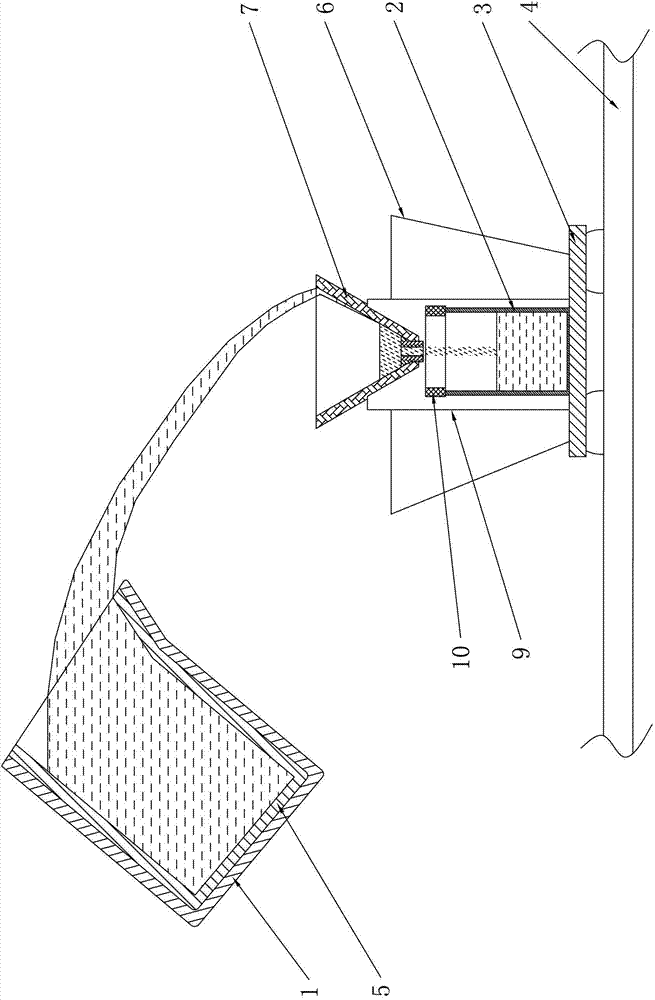

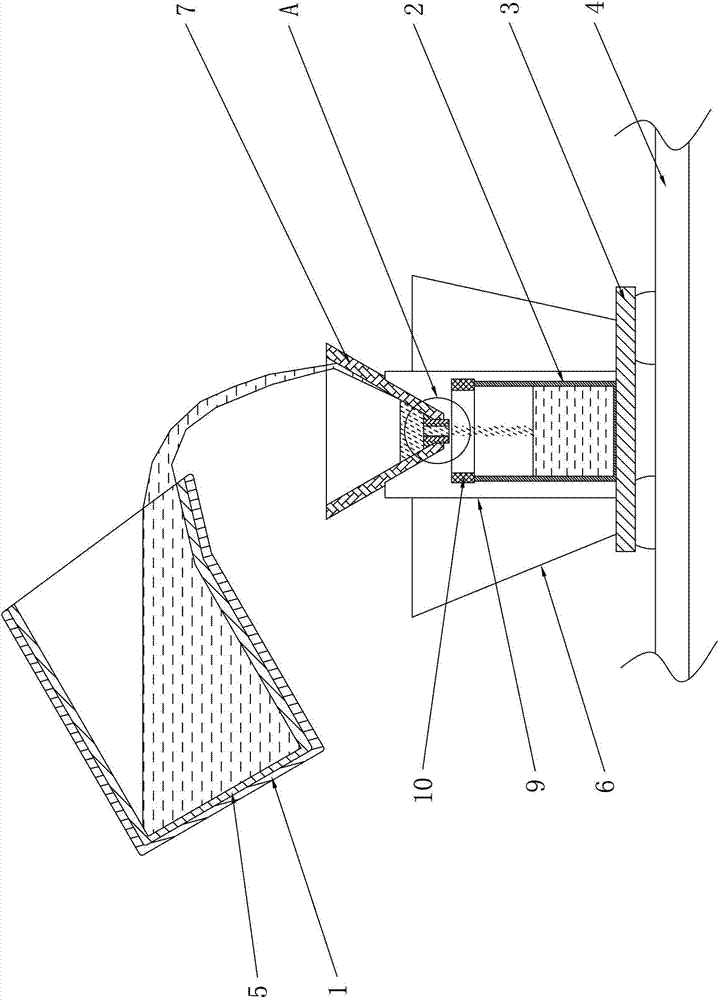

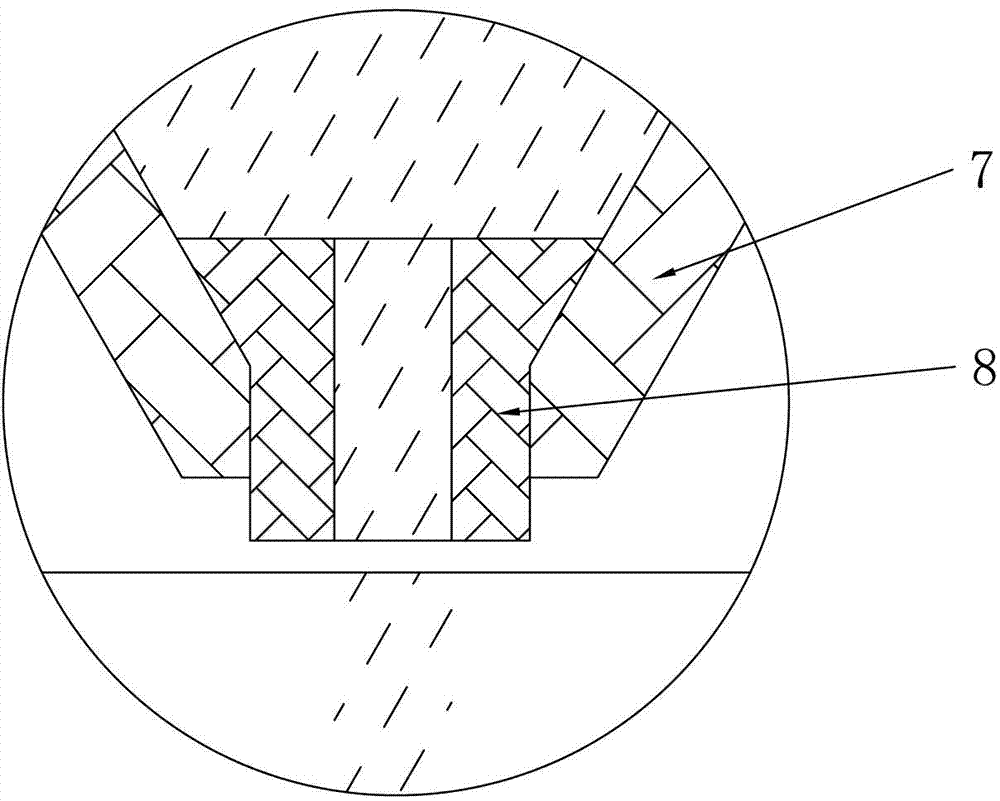

[0031] Implementation mode one: if Figures 1 to 3 As shown, the present invention's novel experimental convenient casting device includes a furnace body 1, a casting mold 2, a mobile trolley 3 and a guide rail 4. The furnace body 1 is a tiltable induction furnace, and a hand-operated furnace tilting device is adopted. The pouring angle of the body 1 is 0°~110°, and its maximum inclination angle is 110°, which can completely empty the melt in the furnace body 1. The furnace body 1 has a built-in flat-bottomed graphite crucible 5, and the built-in flat-bottomed crucible 5 effectively The volume of the crucible 5 is increased, so that the melting efficiency can be improved; the above-mentioned casting mold 2 is arranged on the mobile trolley 3, the above-mentioned guide rail 4 is mainly composed of two parallel angle steels laid on the flat ground, and the above-mentioned mobile trolley 3 is arranged on the guide rail 4, The bottom of the moving trolley 3 is provided with four m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com