Patents

Literature

127results about How to "Increase unit capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

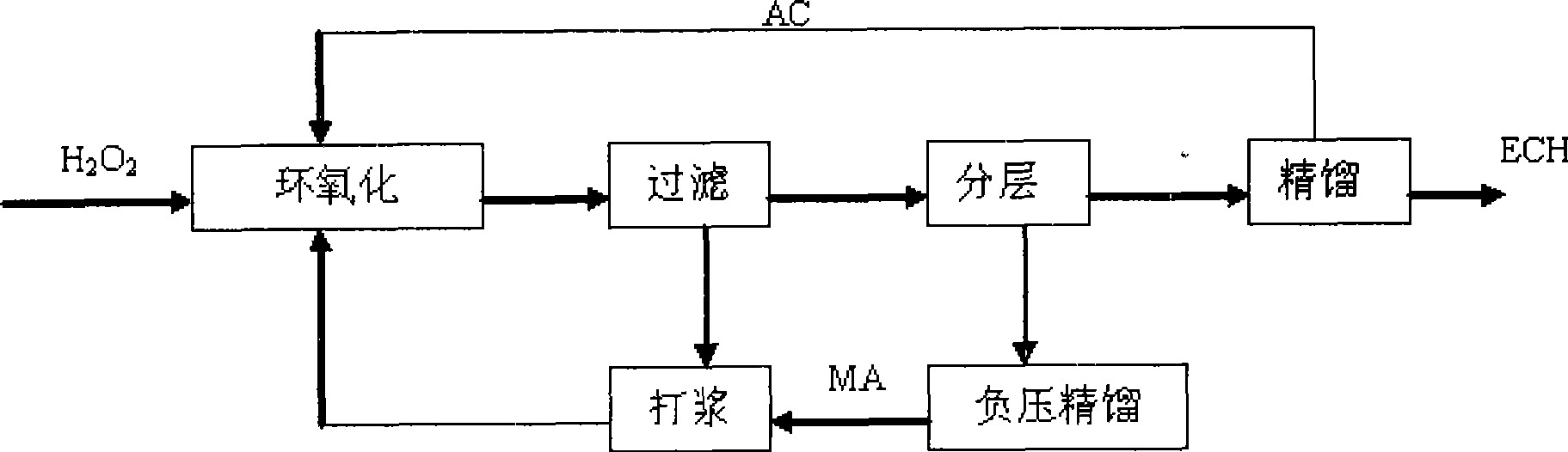

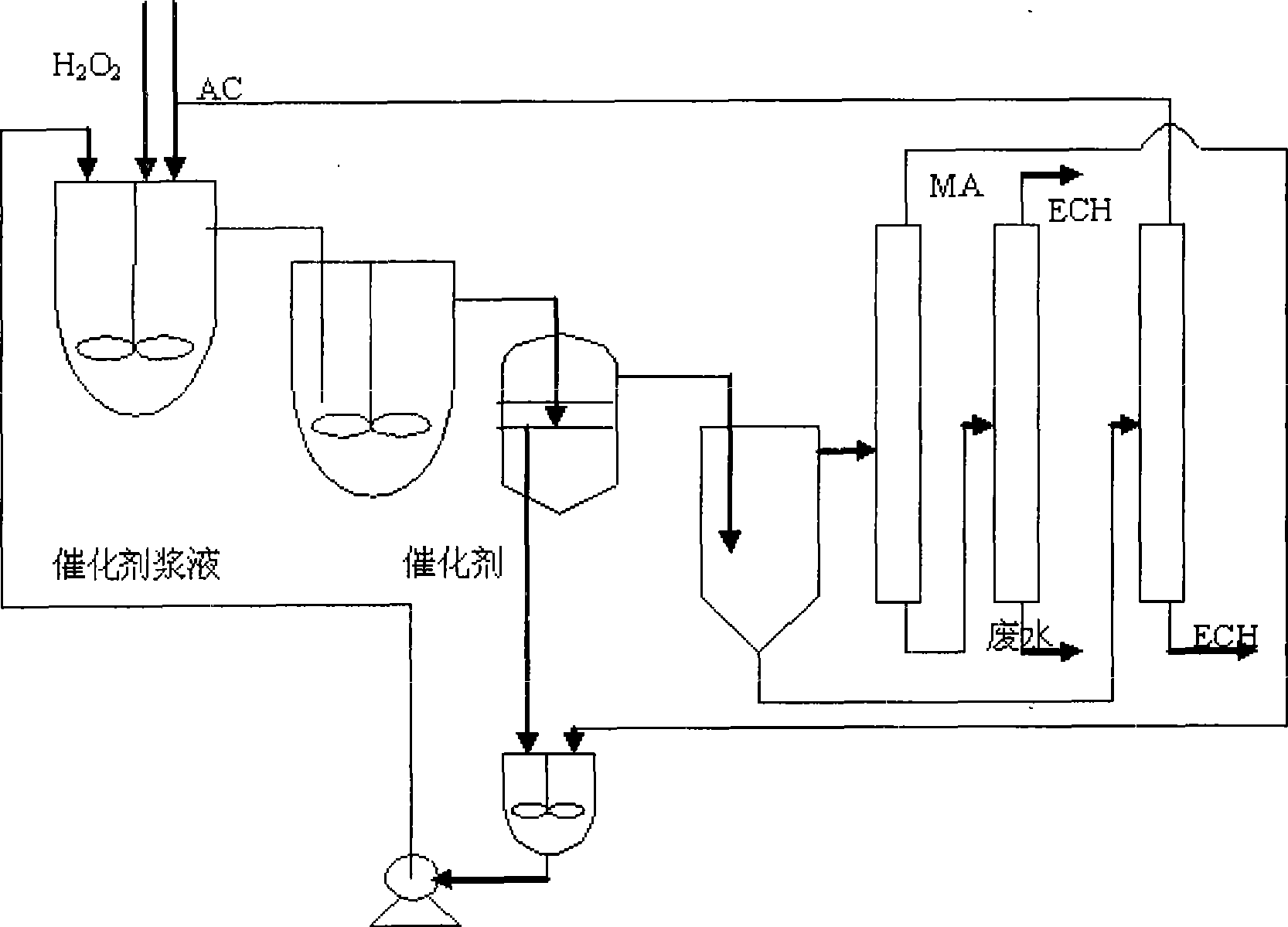

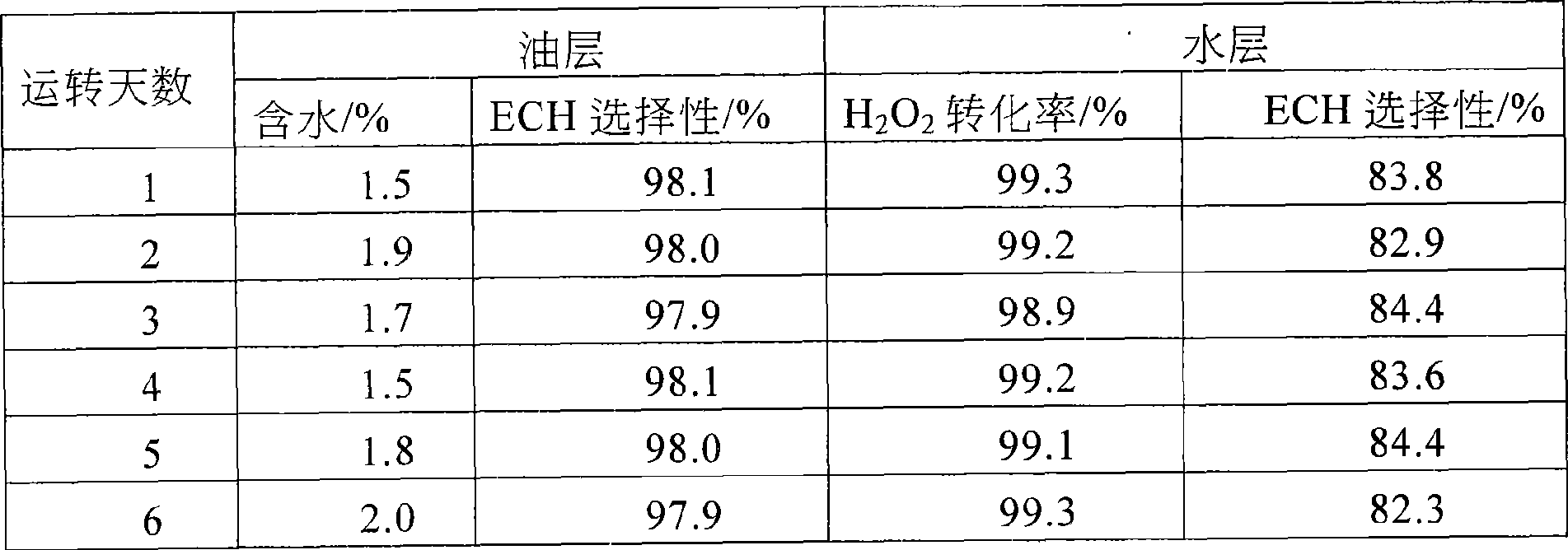

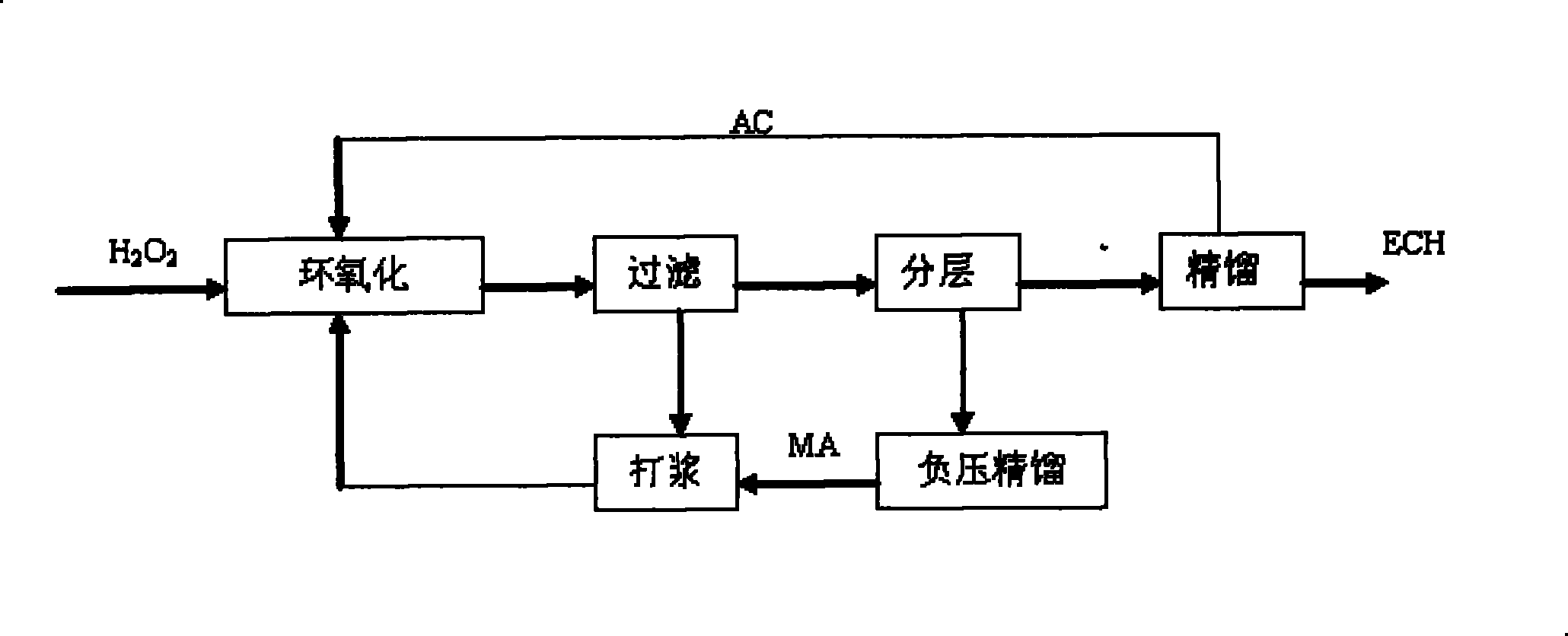

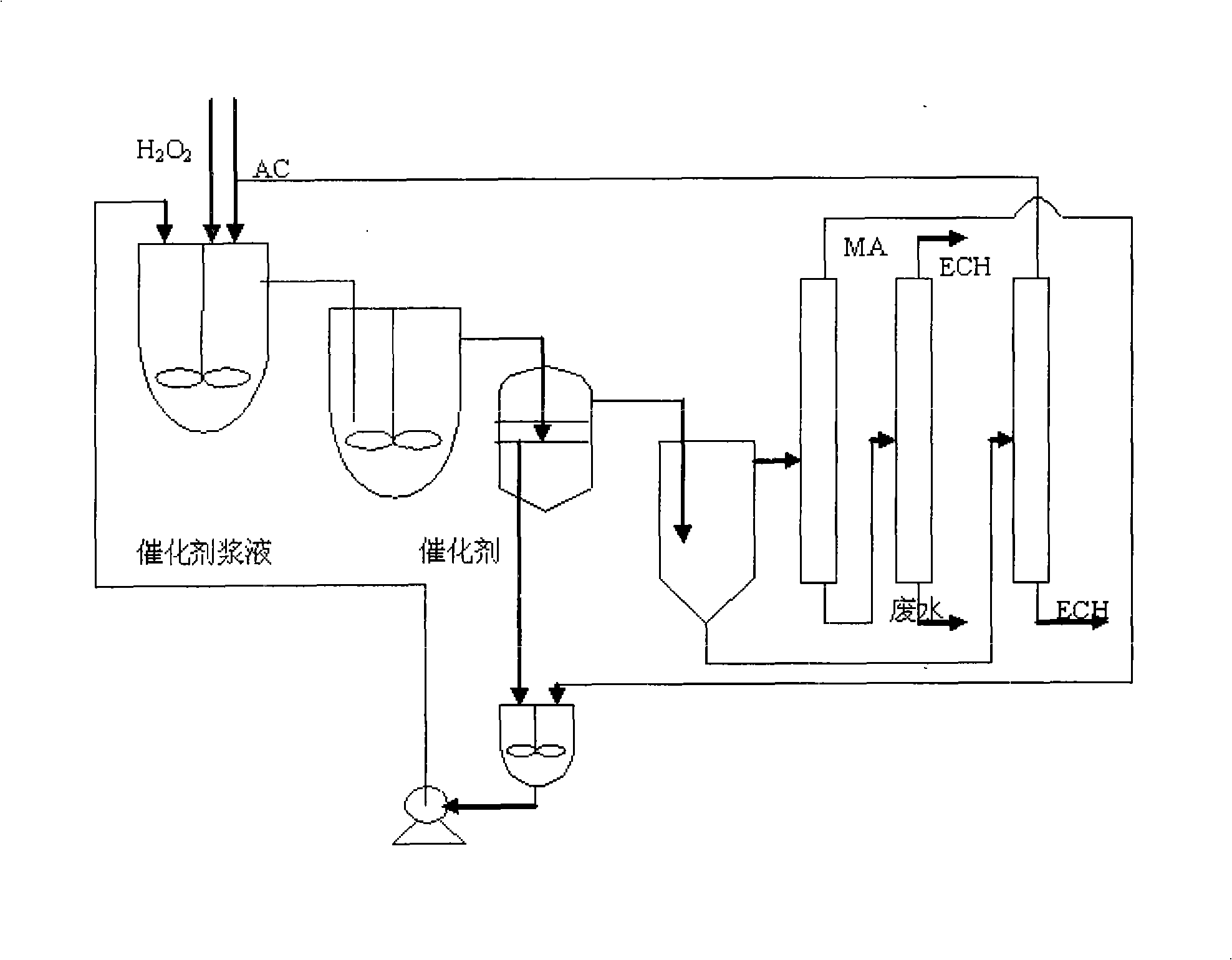

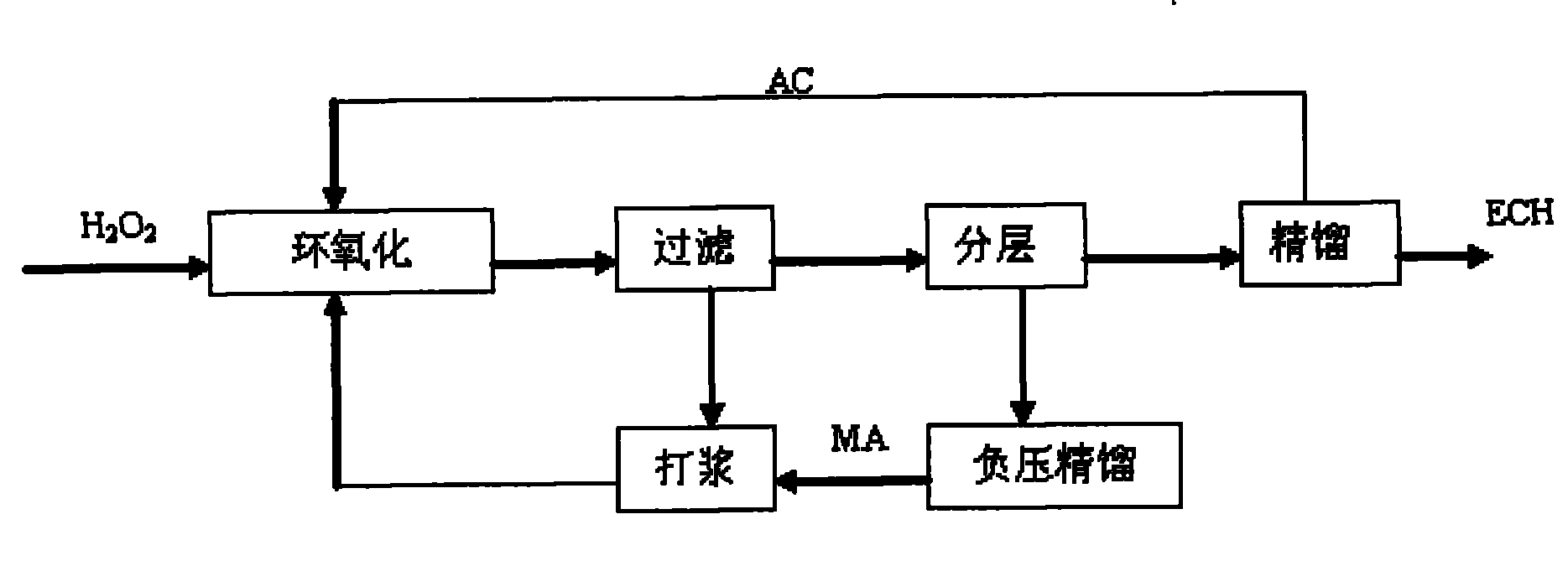

Continuous production method of epoxy chloropropane by hydrogen peroxide process

The invention provides a preparation method of chloroepoxy propane by chloropropene epoxidation. Chloropropene, a solvent and titanium silicalite molecular sieve catalyst fine particles are put in a reaction kettle for reaction at the temperature of 10-80 DEG C. The method is characterized in that the reaction kettle is a single kettle or multistage slurry bed reaction kettles with same or different volumes which are connected in series; the reaction solution needs not to be homogeneous phase, slurry particles of the chloropropene, the solvent and the titanium silicalite molecular sieve catalyst are added to a first stage reaction kettle by a metering pump, hydrogen peroxide is dropwise added to the first stage reaction kettle or each stage of the reaction kettles, the reaction occurs in a weakly acidic condition, materials are subject to oil-water delamination after the reaction to be divided into oil-phase slurry and water-phase slurry; the catalyst is suspended in the water phase, and the oil phase is sent to a rectification tower to separate the chloropropene, the epichlorohydrin and trace methanol; the water phase slurry is filtered, a catalyst filter cake or concentrated slurry is directly beaten by the solvent, and pumped to a first stage epoxidation reaction kettle, the water phase slurry contains the methanol, trace epichlorohydrin and the water which is generated by the reaction and the water which is taken by the hydrogen peroxide, the trace methanol and the epichlorohydrin are separated out by negative pressure rectification, and the recovered methanol is used for preparation of the catalyst slurry. The method has the advantages of simple process, little solvent consumption and high product separation yield, and is available for industrialized production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

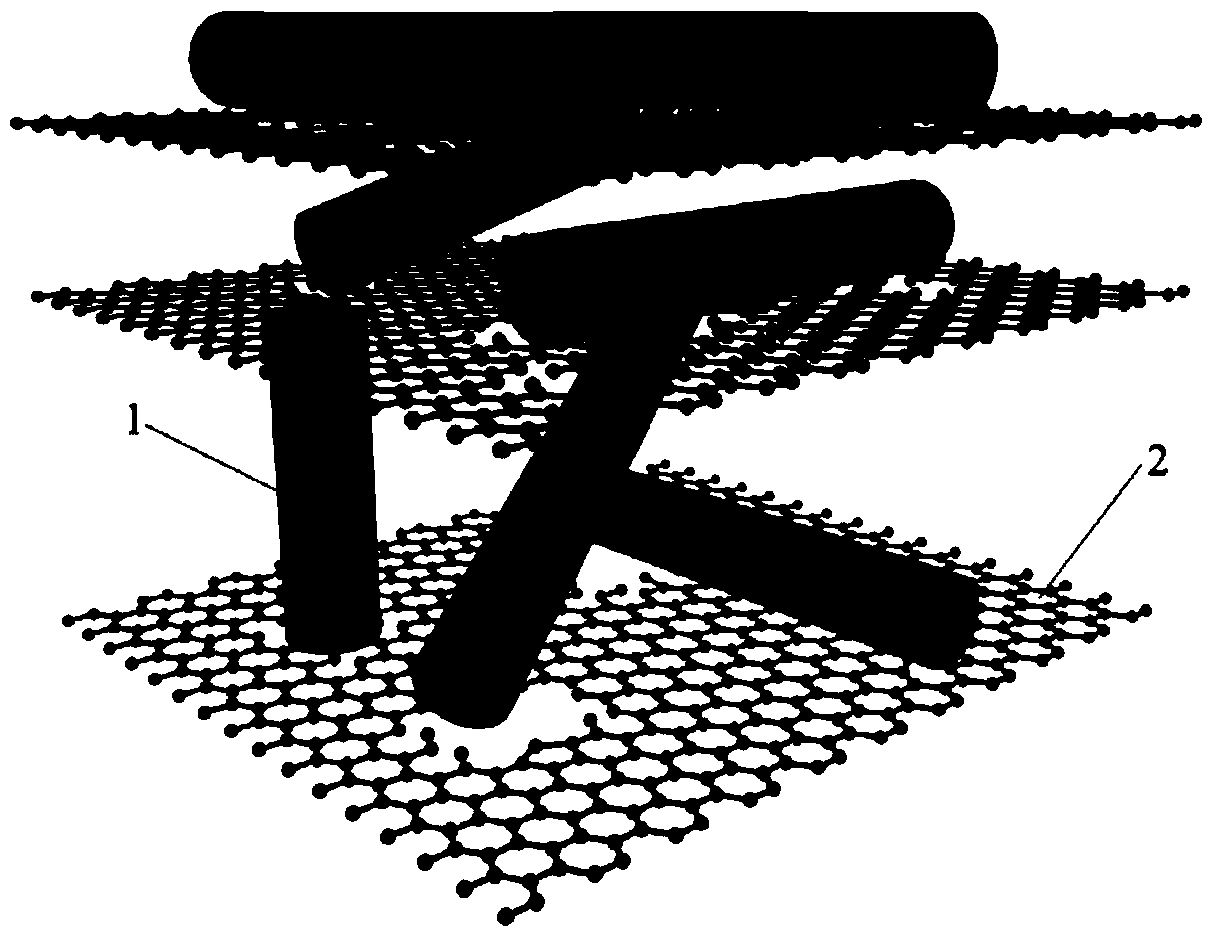

Carbon nanotube-MXene composite three-dimensional porous carbon material and preparation method thereof

ActiveCN109671576AExpand migration spaceHigh yieldMaterial nanotechnologyHybrid capacitor electrodesFreeze-dryingPorous carbon

The invention discloses a preparation method of a carbon nanotube-MXene composite three-dimensional porous carbon material. According to the preparation method of the material, based on the hydrophilic property of the MXene material, the MXene material is dispersed in a carbon nanotube stabilizing solution, and then is added into a PVA water solution to form a uniformly dispersed stable system. The three-dimensional porous composite carbon material is obtained through freeze drying and carbonization. According to the preparation method, a carbon nanotube can be inserted into a two-dimensionallayer structure of MXene, so that sheet agglomeration is prevented. The specific surface area is increased, and the ion migration space is enlarged. The improvement of the unit capacity and the cycling stability is facilitated. The problem that an MXene material and a graphene material are not easy to disperse uniformly is solved. The mesoporous and macroporous composite three-dimensional porous carbon material is prepared. The preparation method is simple, green, environment-friendly, low in cost, high in yield and easy for industrial production.

Owner:四川翔丰华新能源材料有限公司 +1

Multicomponent doping spherical lithium iron phosphate anode material and method of manufacturing the same

ActiveCN101369657AImprove conductivityImprove processing behaviorCell electrodesChemical/physical/physico-chemical processesPhosphateMaterials science

The invention provides a multi-doping spherical ferric phosphate lithium anode material and manufacture method thereof, the chemical formula of the anode material is Li1.03-xMgx / 2Fe1-yTiy / 2PO4-z / 2Fz / C, wherein 0<x<=0.1; 0<y<=0.1; 0 <z<=0.1. The anode material according to the invention comprises high unit capacity (>160mAh / g) and compaction proportion (1.45 to 1.75g / cm3), which efficiently enhance conduction ability thereof with excellent unit capacity. The raw material of the anode material according to the invention uses villaumite to reduce reaction activation energy, increase liquidoid during reaction process in order to control product particle feature to obtain spherical particle and enhance compaction proportion, being beneficial to improve manufacture process of electrode paste, simplify preparation and coating of battery paste and process the plate electrode; by being doped with magnesium, titanium and fluorine in the material structure to form semiconductors, the conduction ability of the material can be improved. The invention has simply process, low costs, being convenient to realize industrial manufacture.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

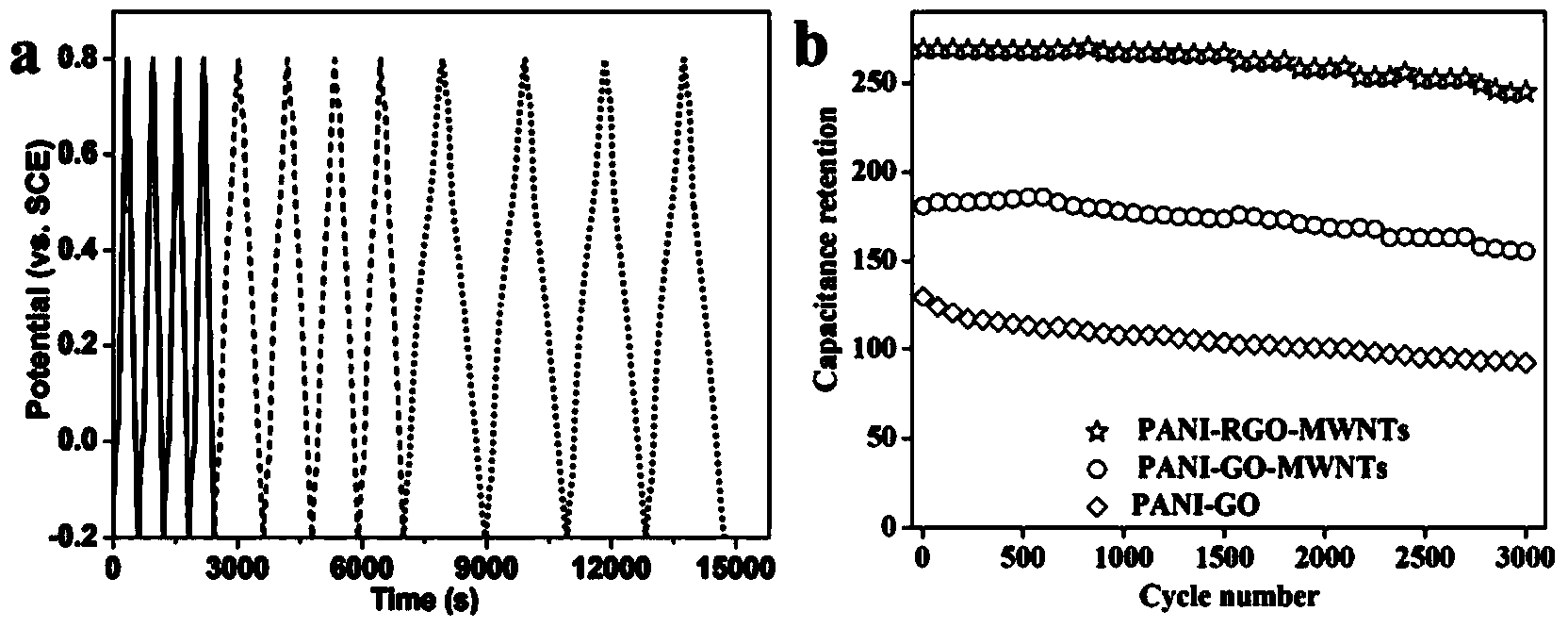

Flexible electrode and preparation method thereof

ActiveCN104078248AIncrease unit capacityGood flexibilityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectronic transmission

The invention discloses a preparation method of a flexible electrode and the flexible electrode obtained through the preparation method. The preparation method comprises the steps of a, manufacturing a carbon nano tube and an grapheme oxide into a homodisperse mixed dispersion agent; b, removing a solvent in the mixed dispersion agent, and obtaining a thin film with a three-dimensional conductive network; c, conducting in-situ polymerization on the three-dimensional conductive network with organic polymer conductive materials to obtain a three-element flexible composite film; d, conducting reduction on the grapheme oxide in the three-element flexible composite film to obtain the flexible electrode. According to the preparation method, firstly, the thin film with the three-dimensional conductive network is formed by the carbon nano tube and the grapheme oxide, and then, the in-situ polymerization is carried out on the three-dimensional network with the organic polymer conductive materials; in the three-dimensional conductive network, the carbon nano tube is inserted into the portion between grapheme sheet layers, so that the interval between the grapheme sheets and the specific surface area of the grapheme sheets are increased, the carbon nano tube also overcomes the defect generated in the oxidation process of grapheme, electronic transmission is facilitated, and the specific capacitance of the flexible electrode is improved.

Owner:未名电池科技(深圳)有限公司

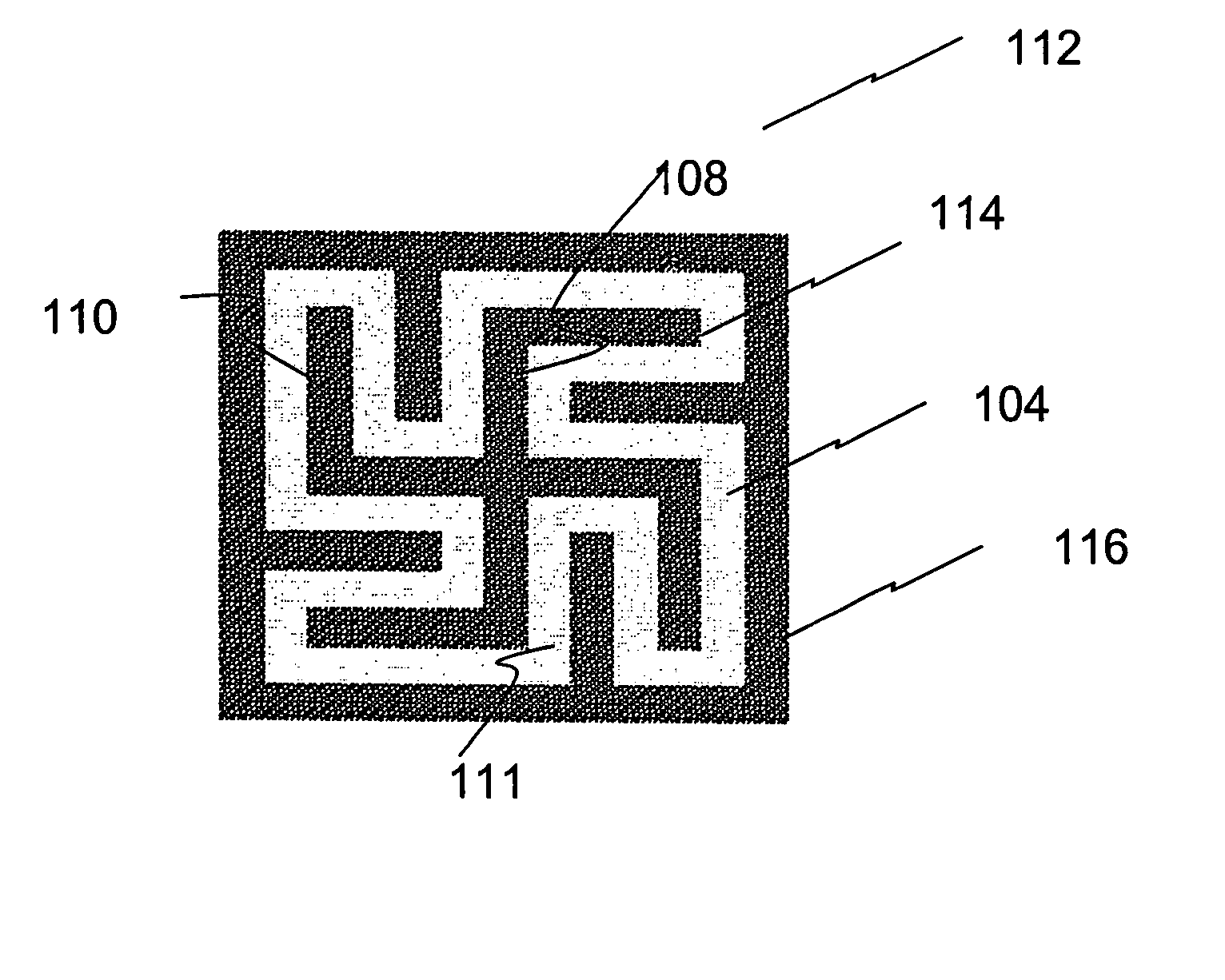

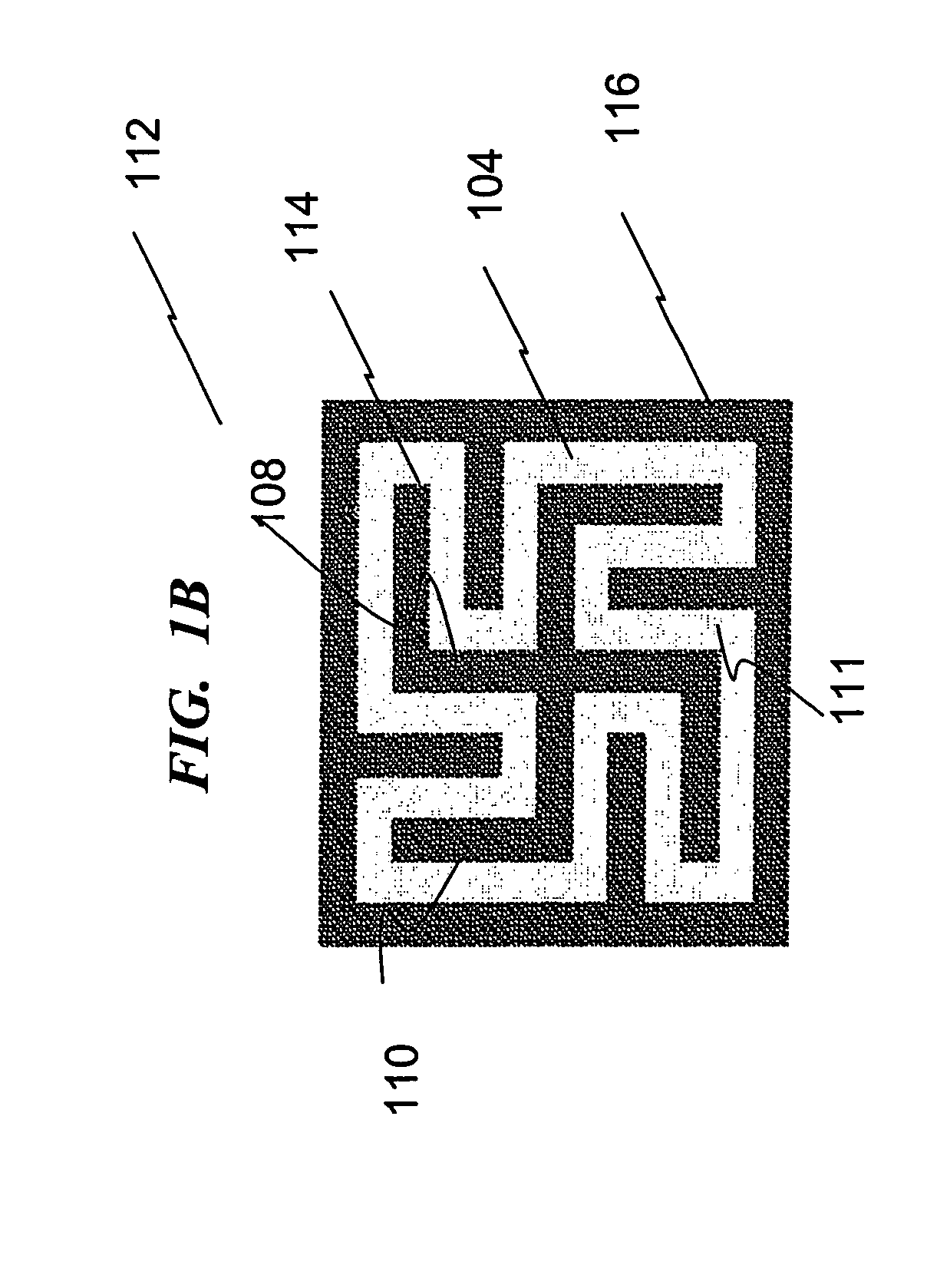

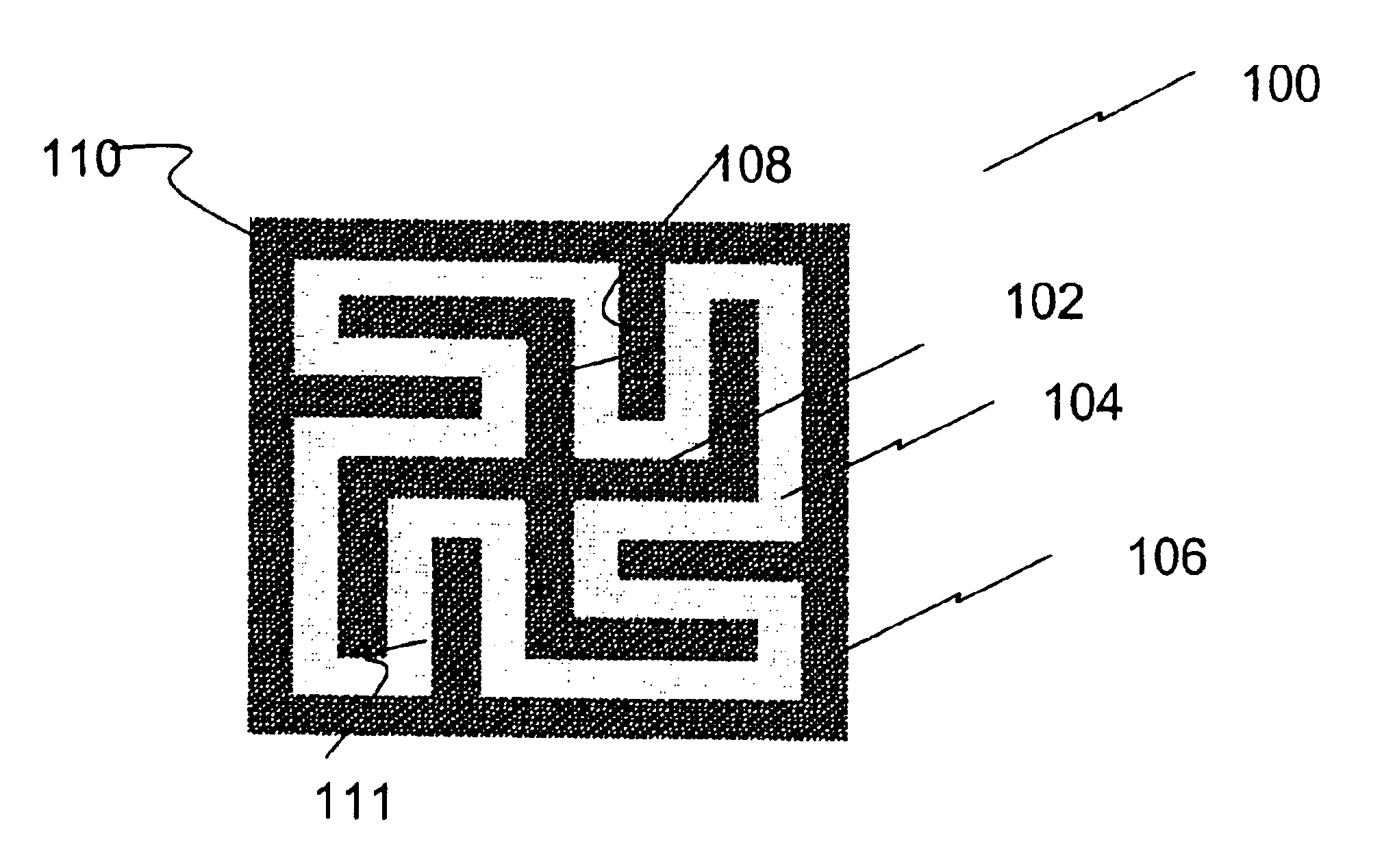

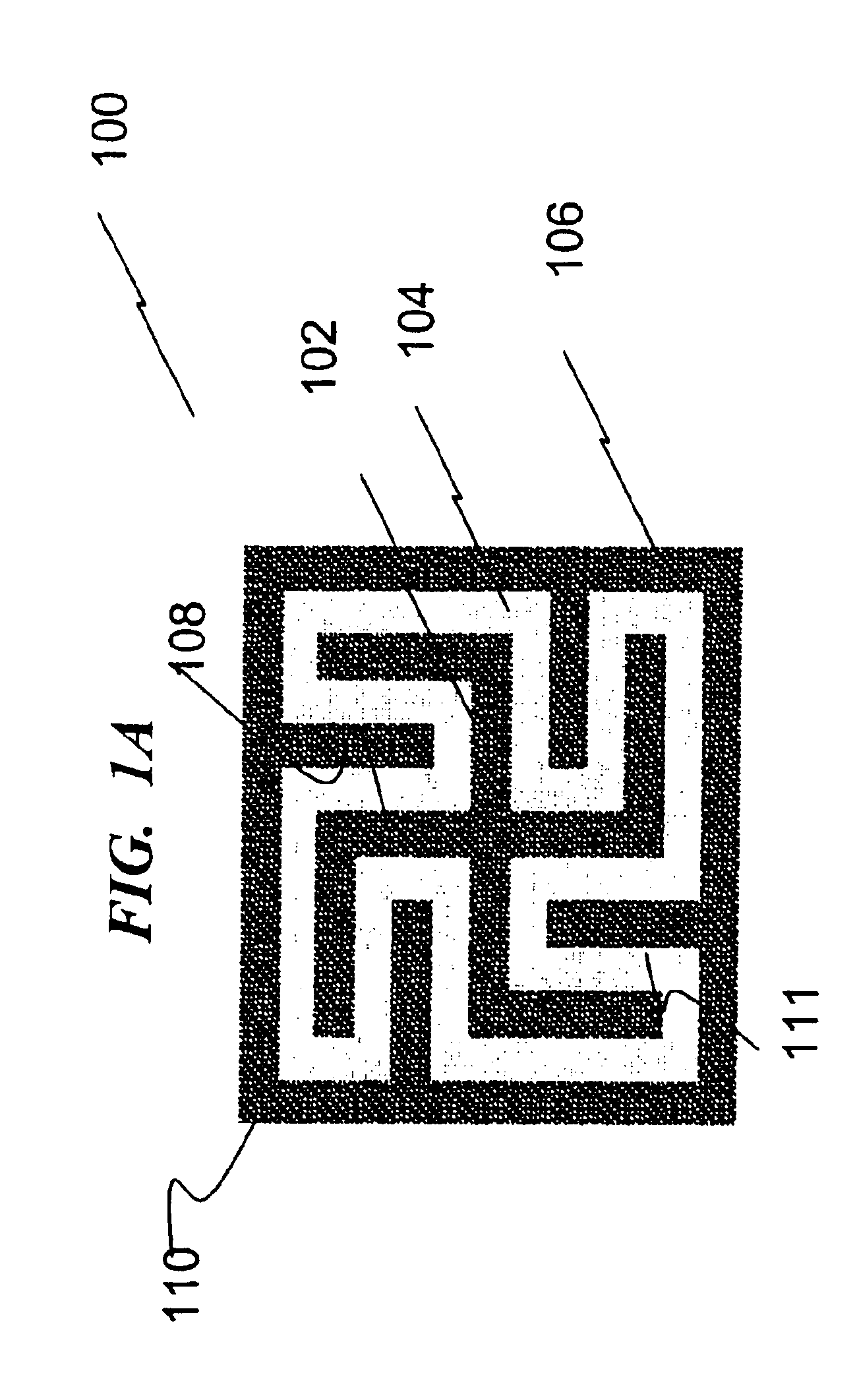

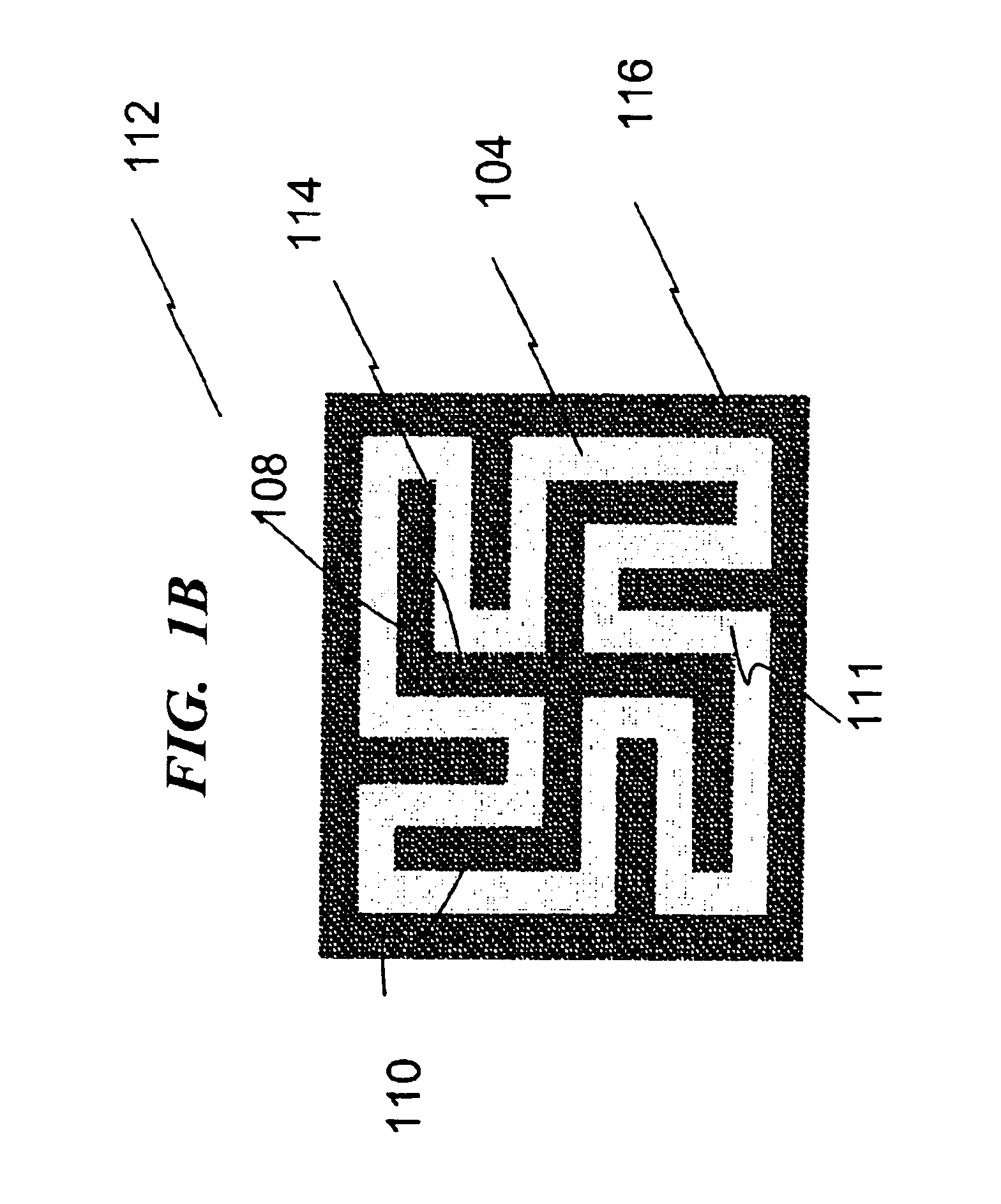

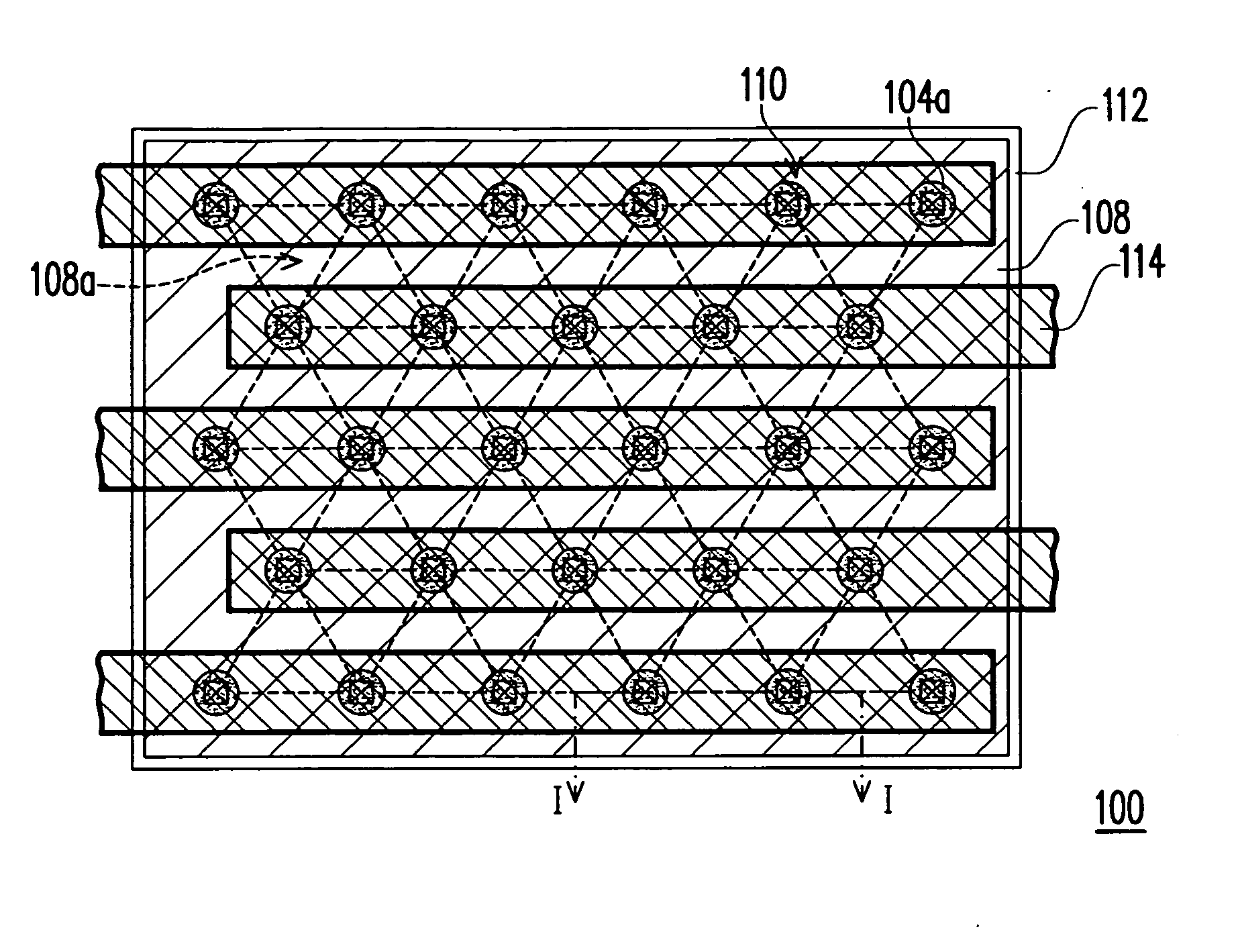

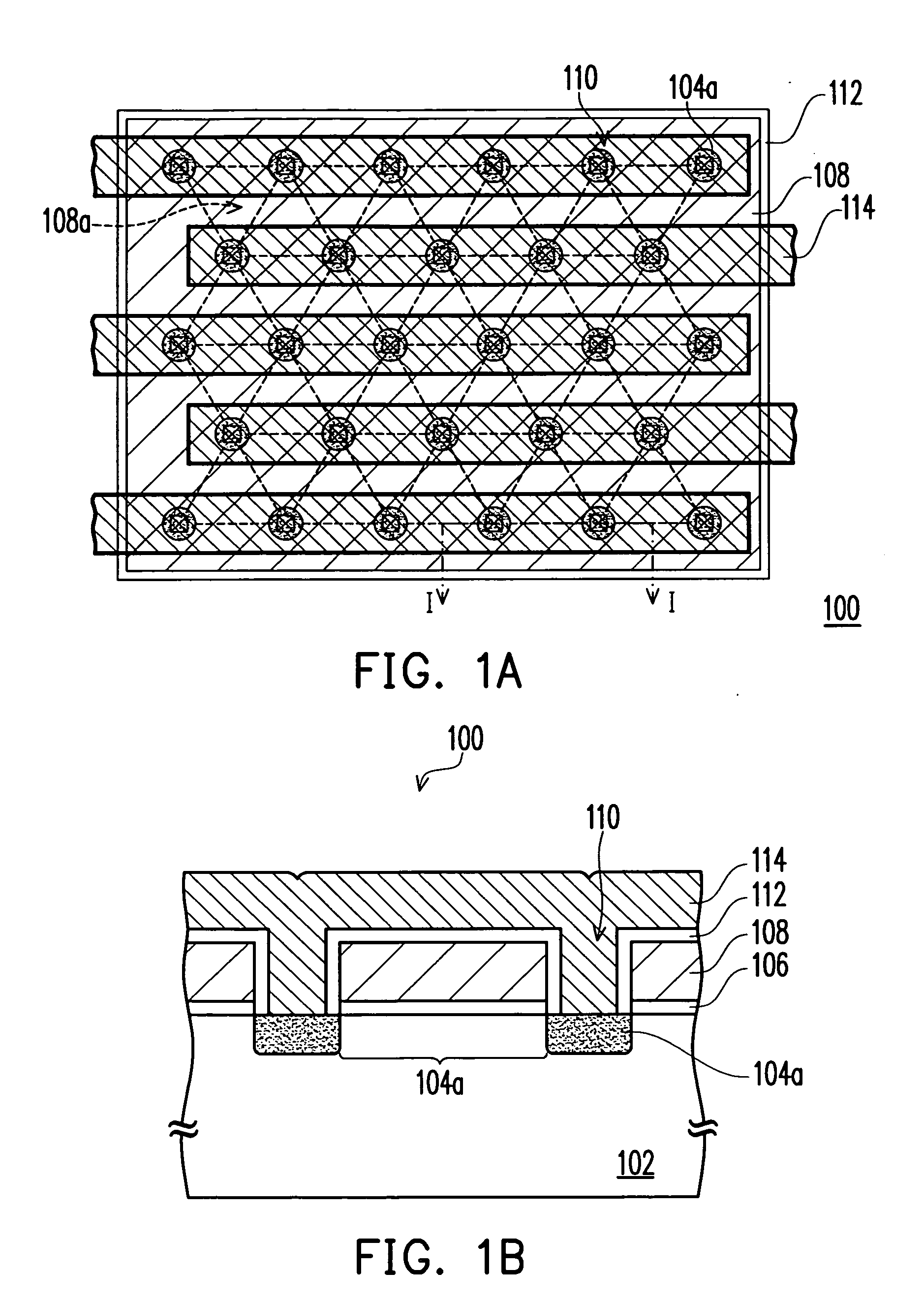

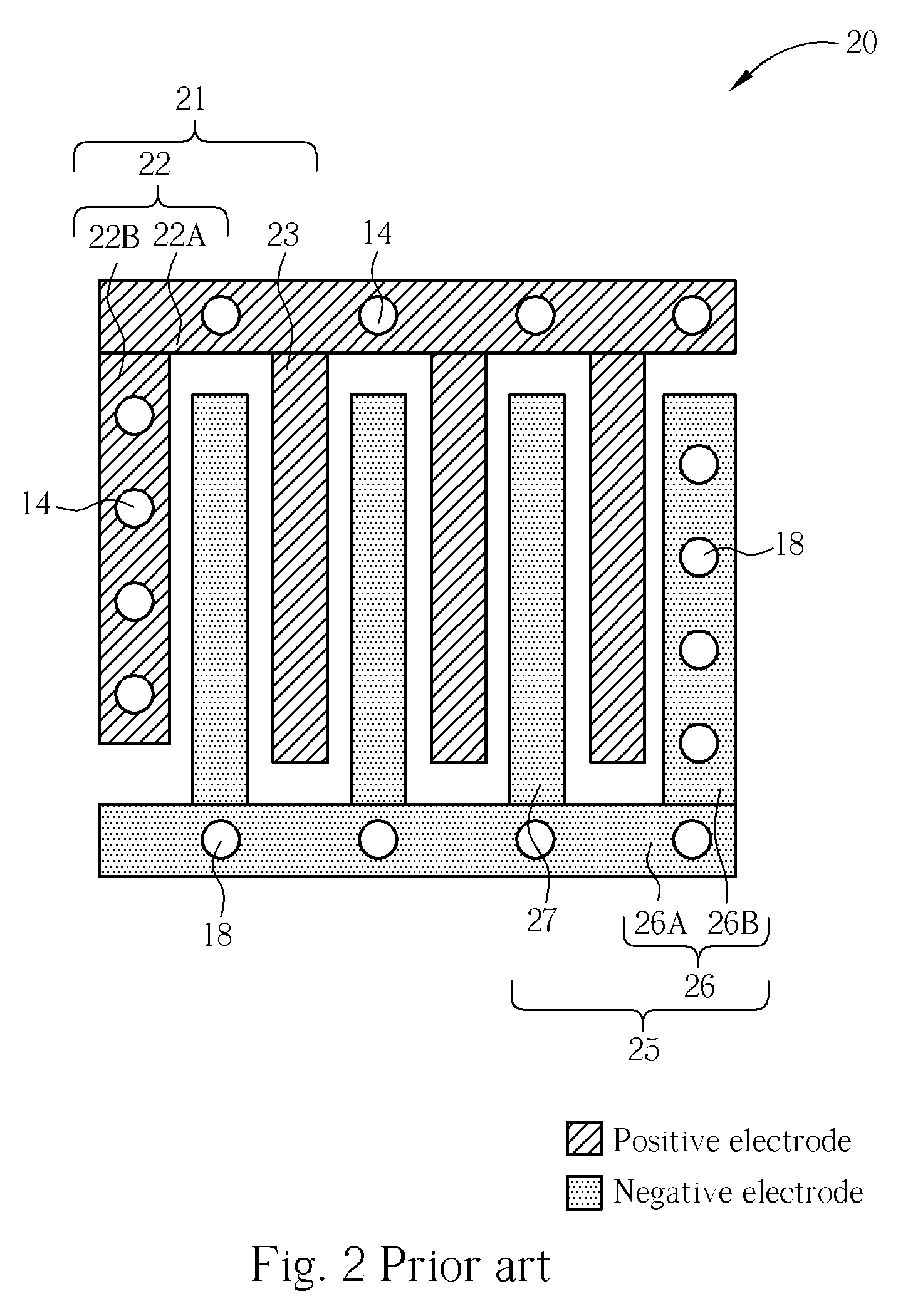

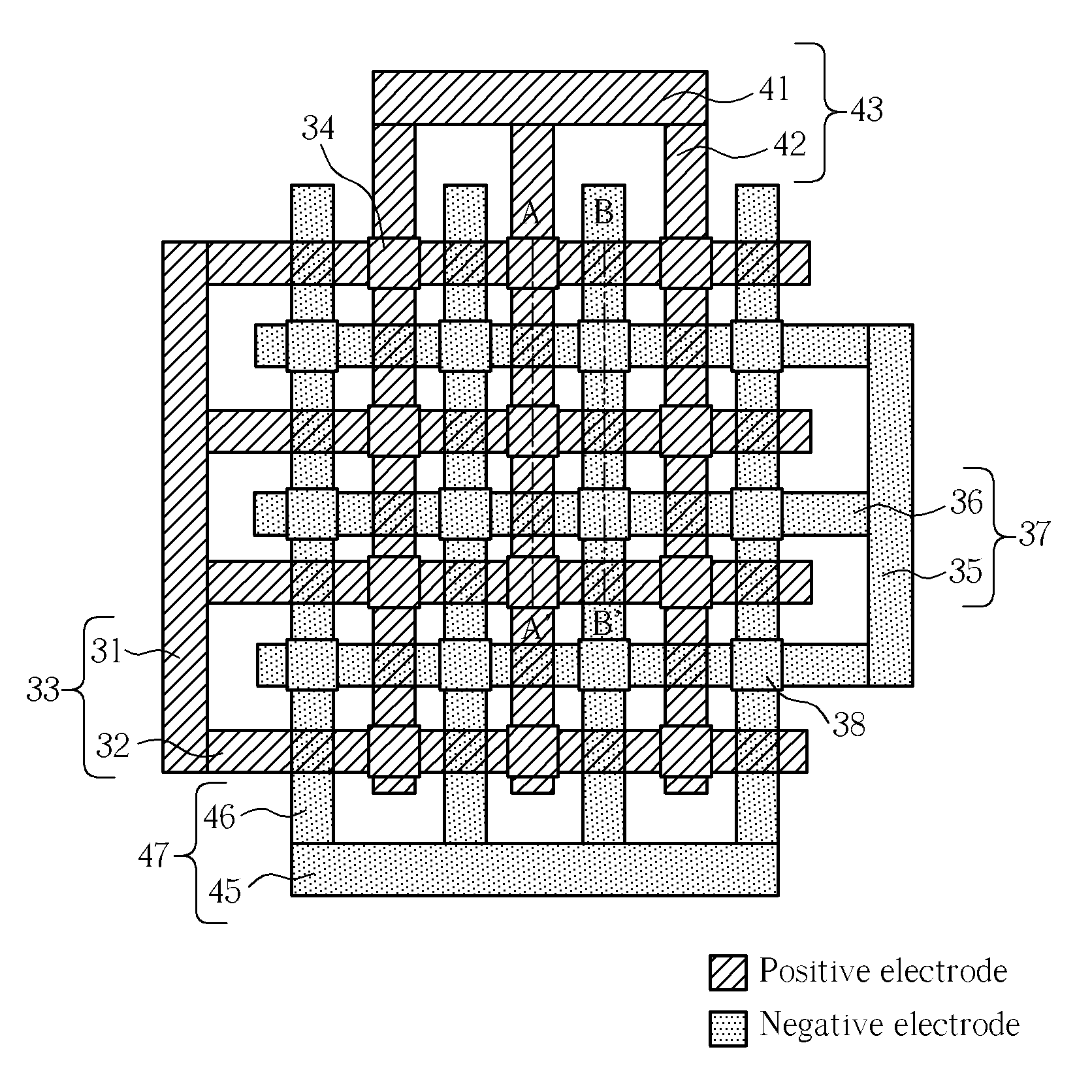

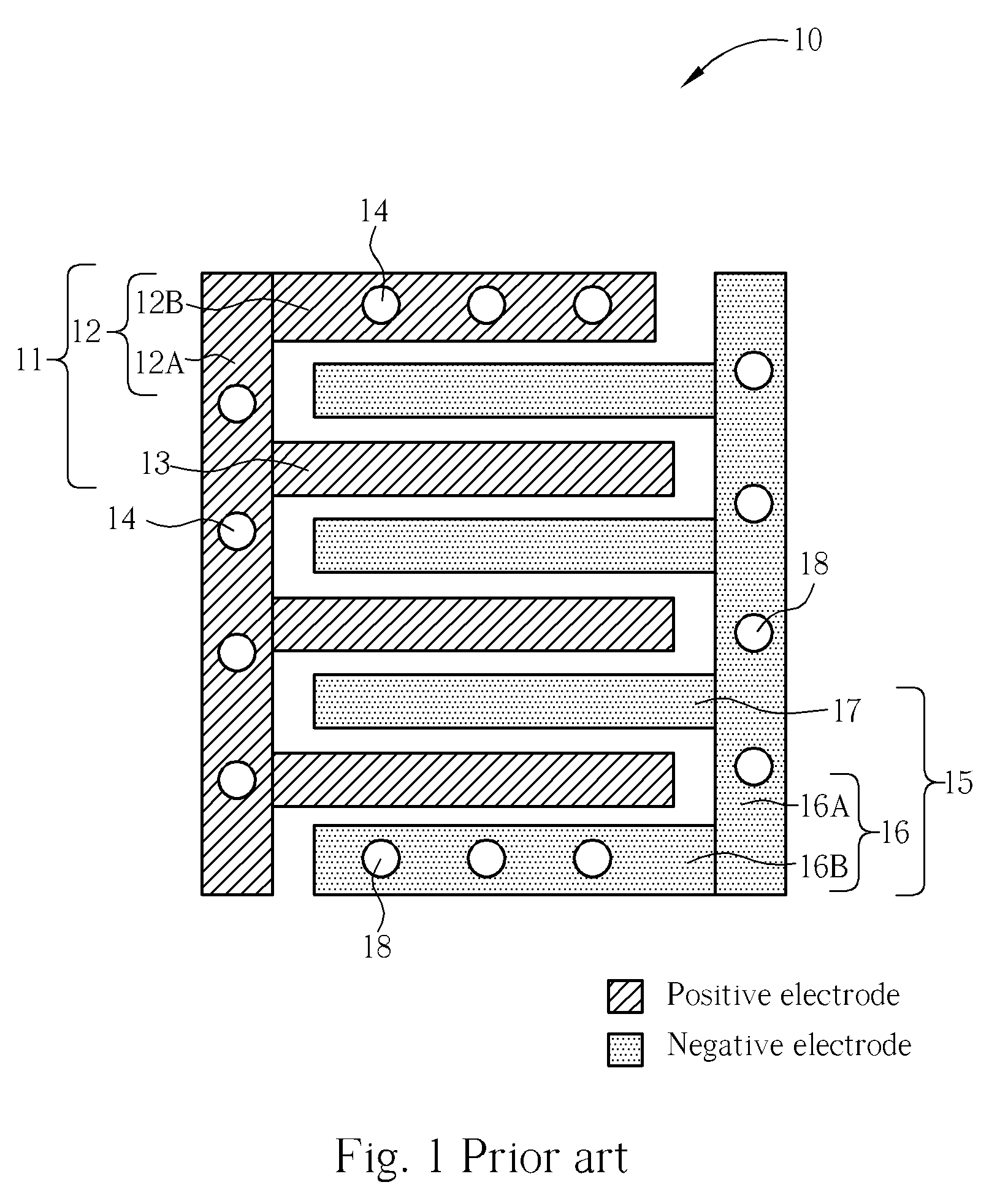

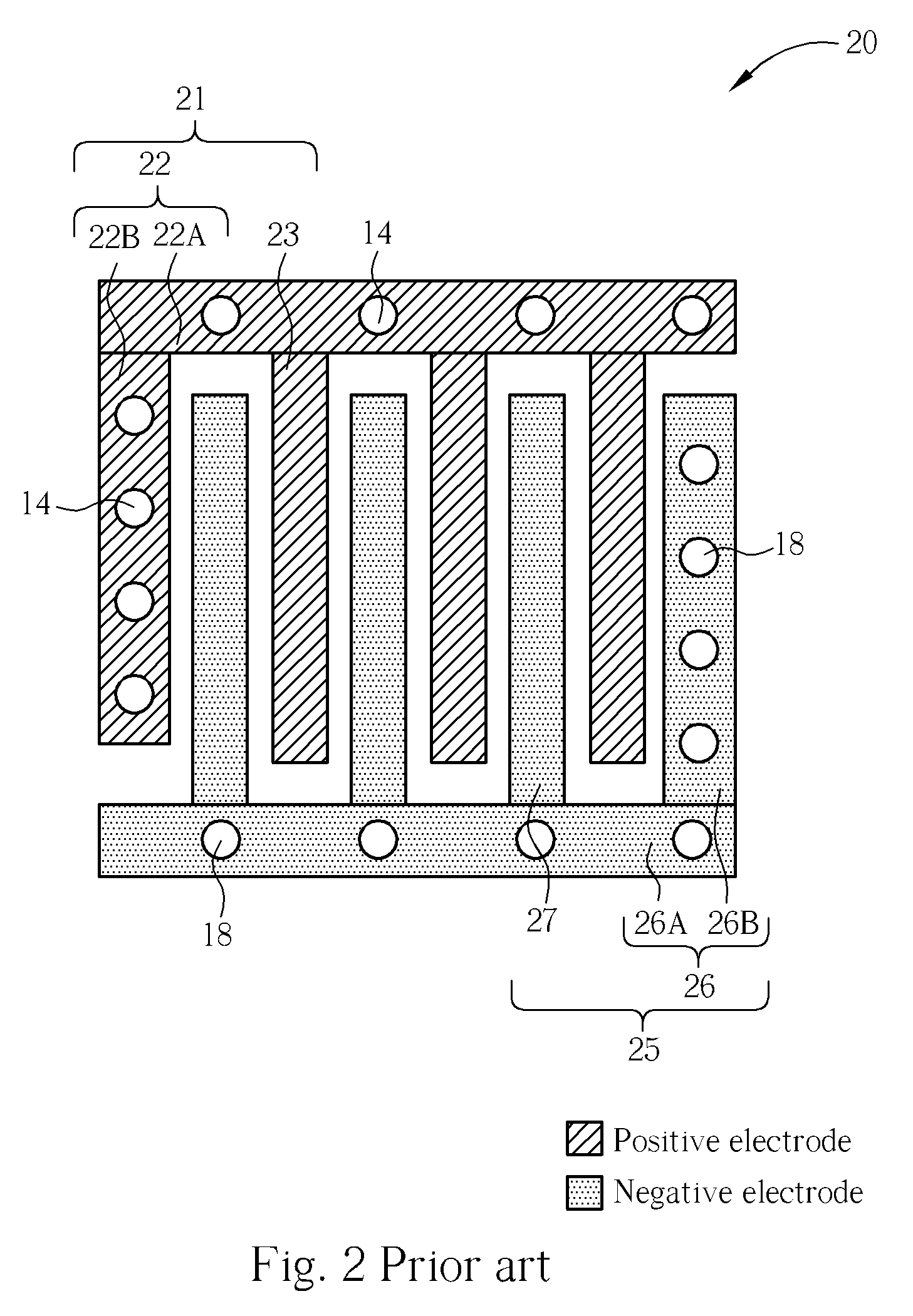

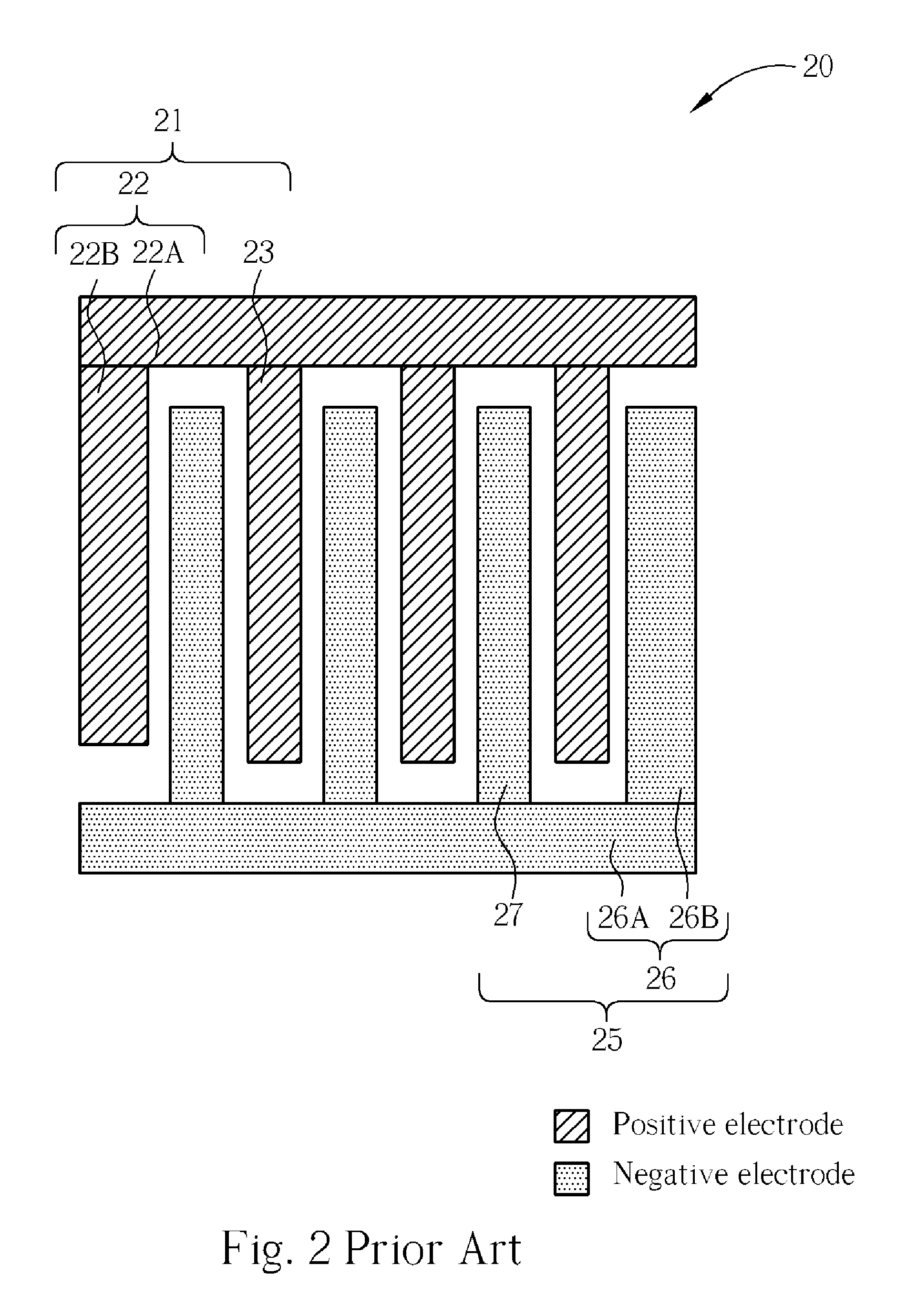

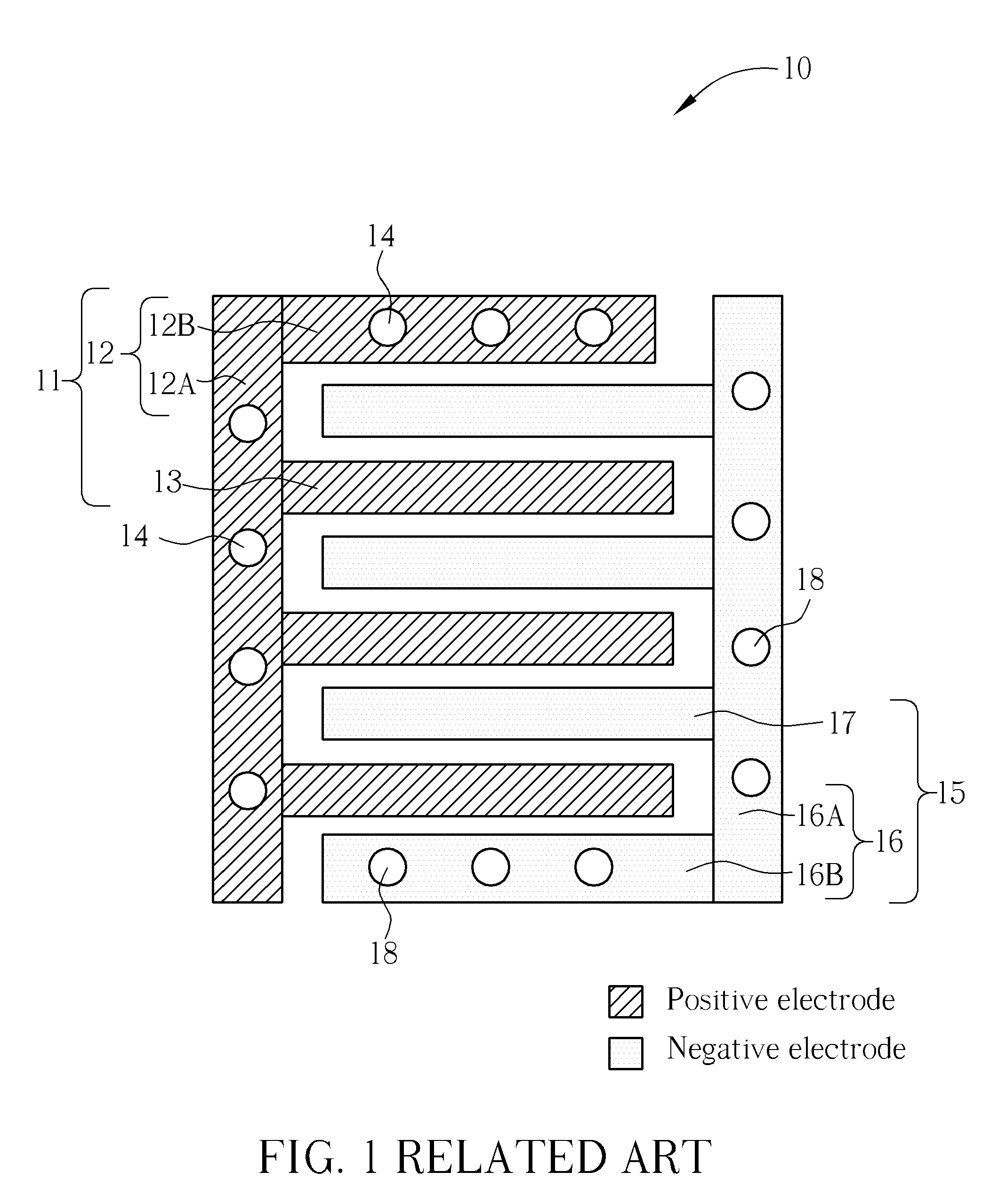

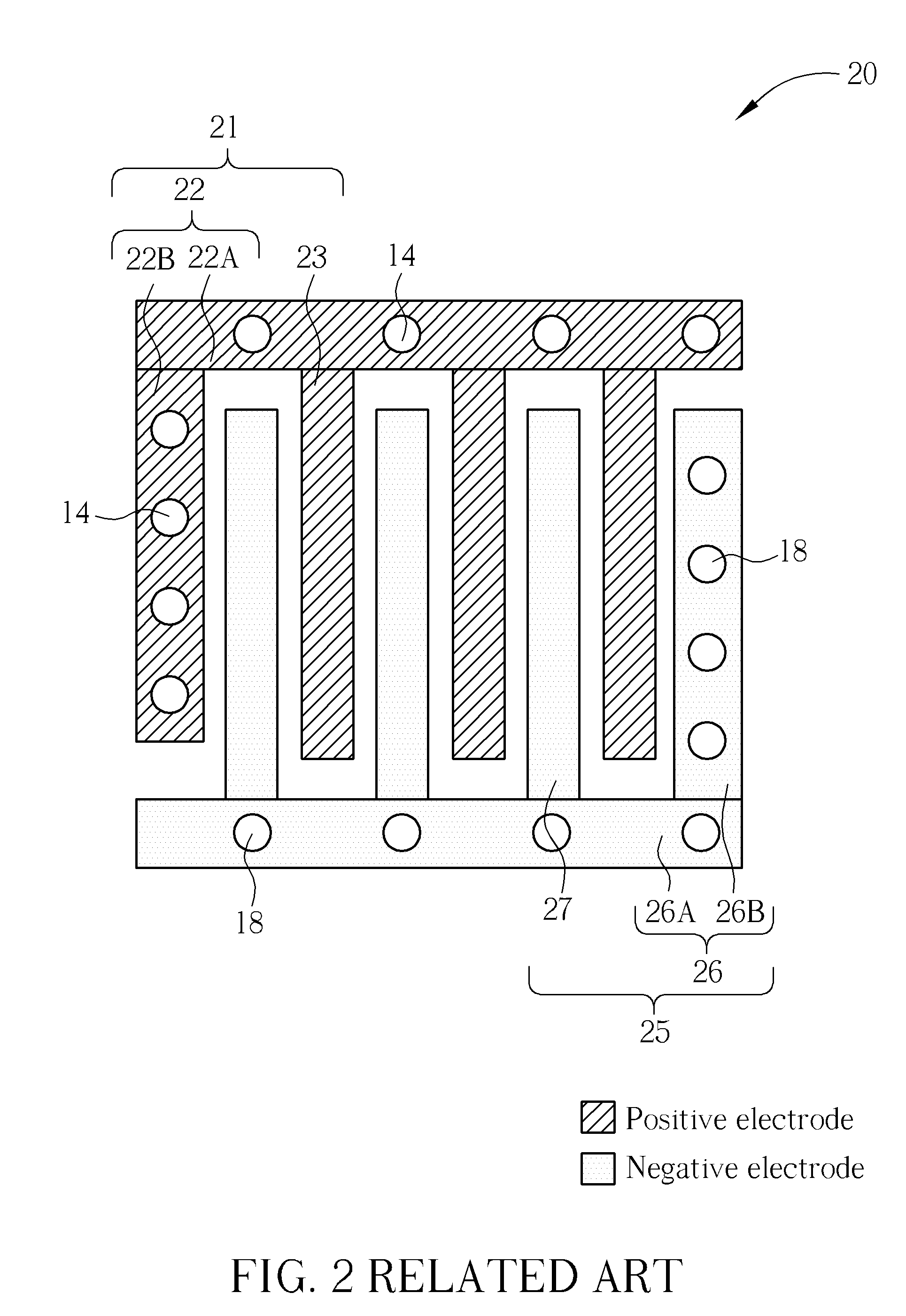

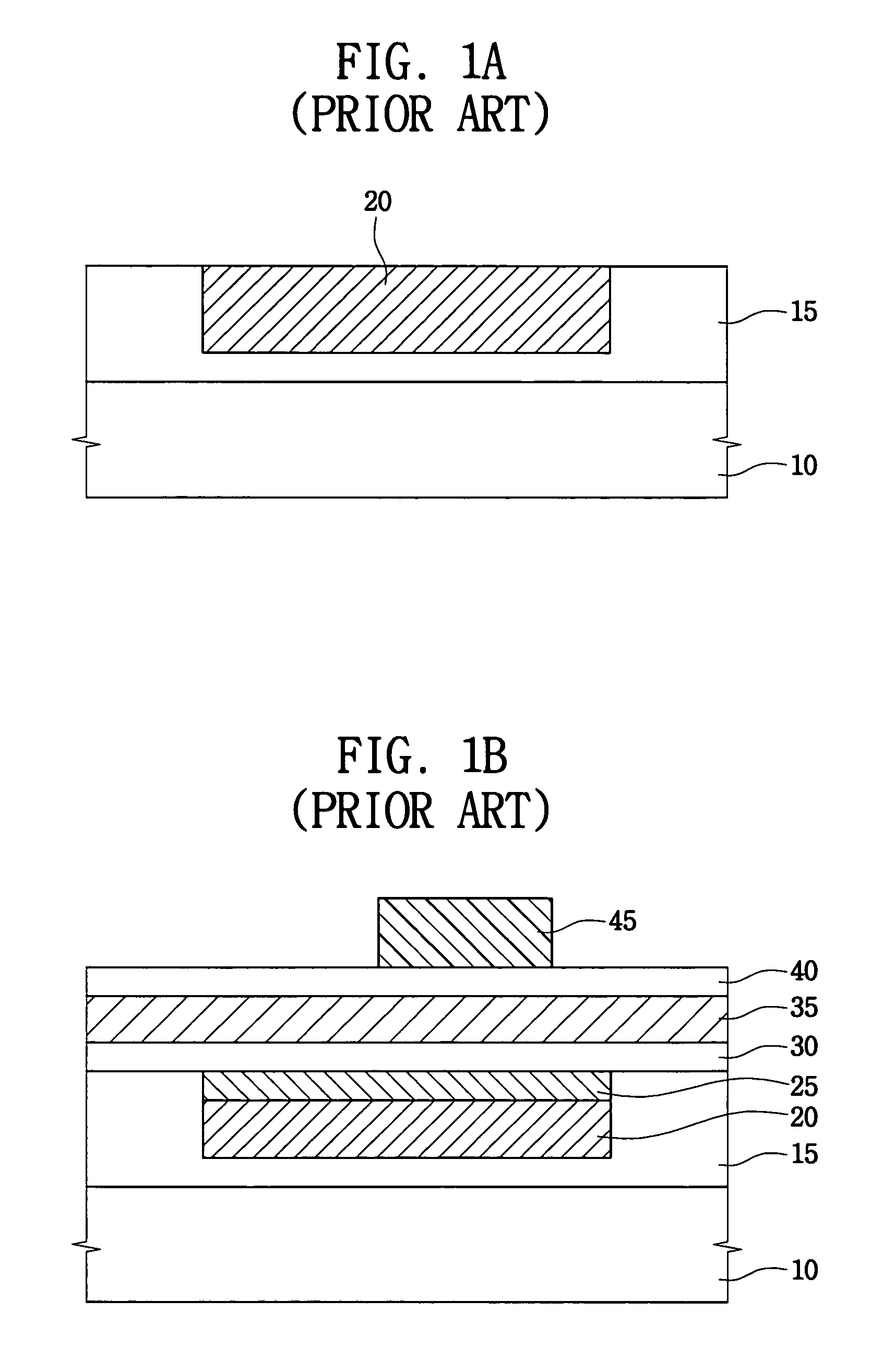

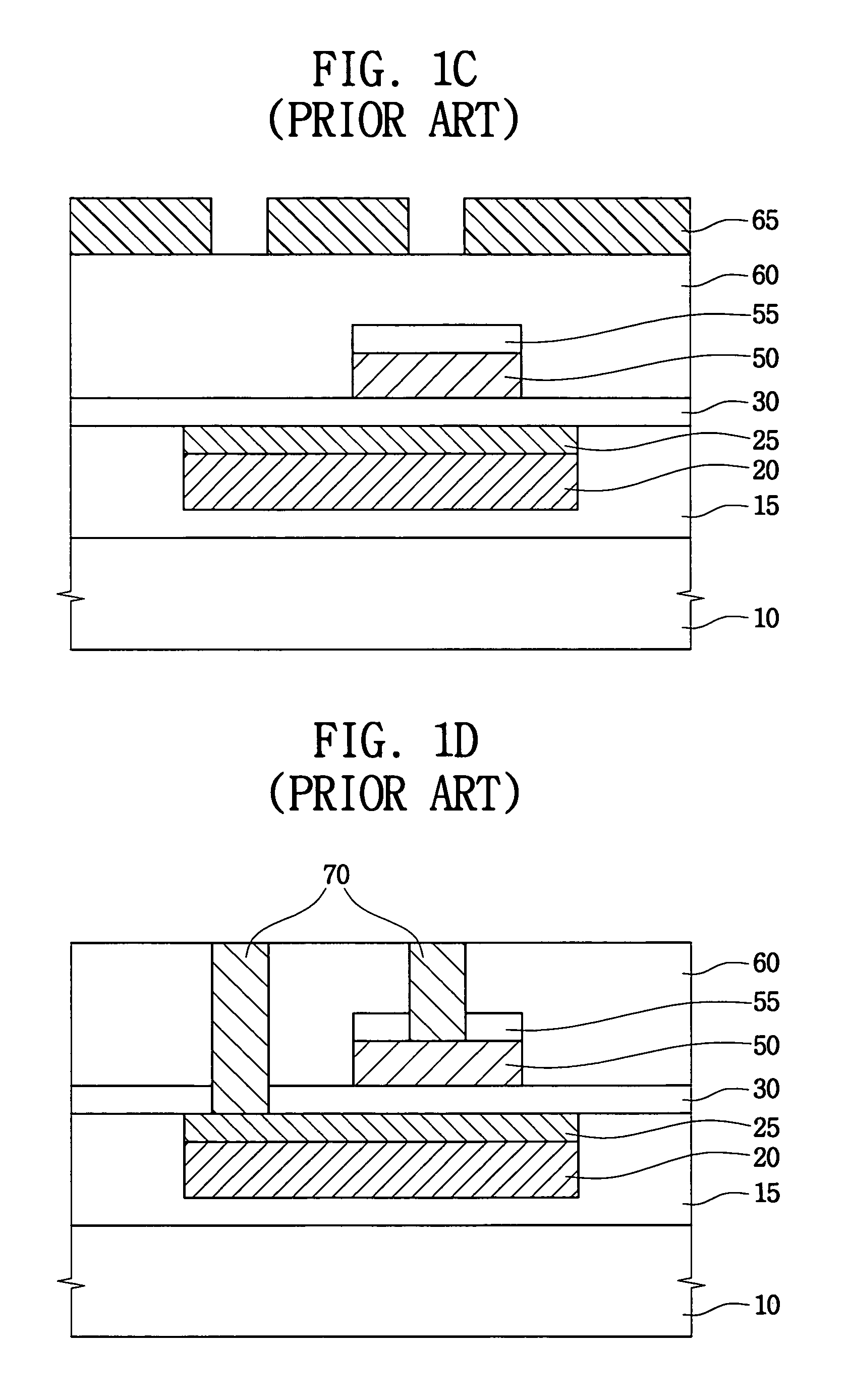

Metal-over-metal devices and the method for manufacturing same

ActiveUS20050077581A1Easy to integrateAdditional processing stepsTransistorSemiconductor/solid-state device detailsFour quadrantsMetal device

A metal-over-metal (MOM) device and the method for manufacturing same is provided. The device has at least one device cell on a first layer comprising a frame piece and a center piece surrounded by the frame piece. The center piece has a cross-shape center portion defining four quadrants of space between the frame and center pieces. The center piece has one or more center fingers each extending from at least one of the four ends thereof within a quadrant. The frame piece also has one or more frame fingers extending therefrom, each being in at least one quadrant and not being overlapped with the center finger in the same quadrant.

Owner:TAIWAN SEMICON MFG CO LTD

Metal-over-metal devices and the method for manufacturing same

ActiveUS6949781B2Easily integrated with aluminum and copper metal processIncrease unit capacityTransistorSemiconductor/solid-state device detailsFour quadrantsMetal device

Owner:TAIWAN SEMICON MFG CO LTD

Method of manufacturing back contact heterojunction single crystalline silicon solar cell

InactiveCN105118870ASimple processIncrease unit capacityFinal product manufacturePhotovoltaic energy generationHeterojunctionChemical plating

The invention provides a method of manufacturing a back contact heterojunction single crystalline silicon solar cell, which belongs to the technical field of solar photovoltaics. The method comprises the following steps: (1) cleaning of single crystalline silicon, removal of a damage layer and etching are carried out; (2) a single crystalline silicon front surface passivation layer is formed, and coating of an anti-reflective layer is carried out; (3) coating of a single crystalline silicon back surface passivation layer is carried out; (4) a mask technology is adopted to form a P-type amorphous silicon pattern through coating of the single crystalline silicon back surface; (5) a mask technology is adopted to form an N-type amorphous silicon pattern through coating of the single crystalline silicon back surface; (6) a mask technology is adopted to form a protection film pattern through coating of the back surface; and (7) a chemical plating plus electroplating technology is adopted to form a contact electrode for a transmitting electrode and a base electrode on the back surface. the method of the invention has the advantages of simple process and low manufacturing cost whether for coating and positioning of a P / N junction or for back electrode manufacturing, and can be applied to mass production of the back contact heterojunction single crystalline silicon solar cells.

Owner:深圳市科纳能薄膜科技有限公司

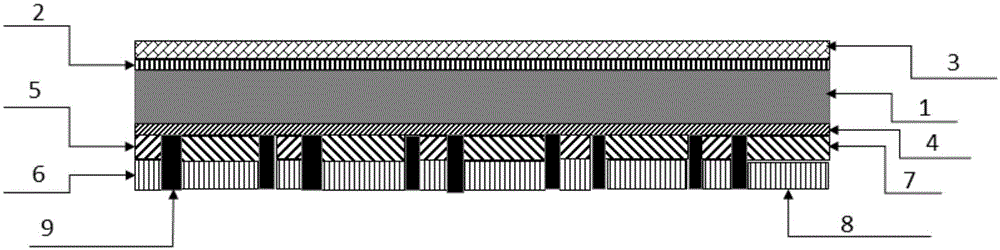

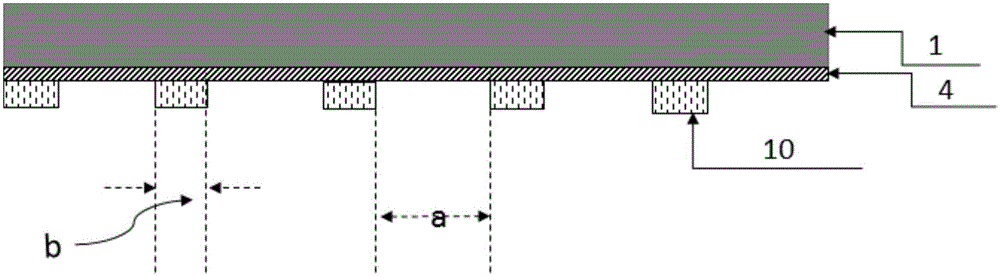

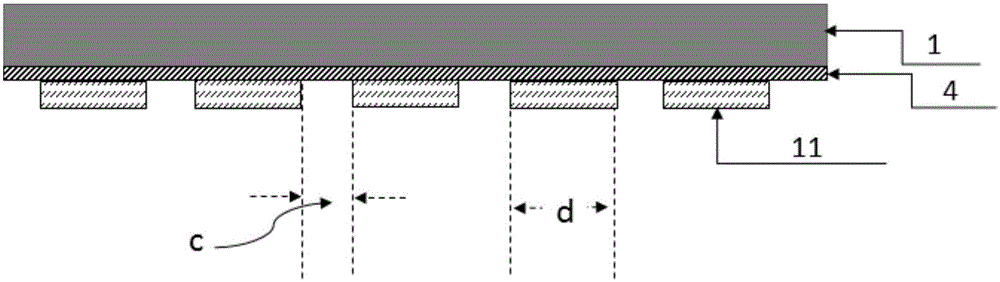

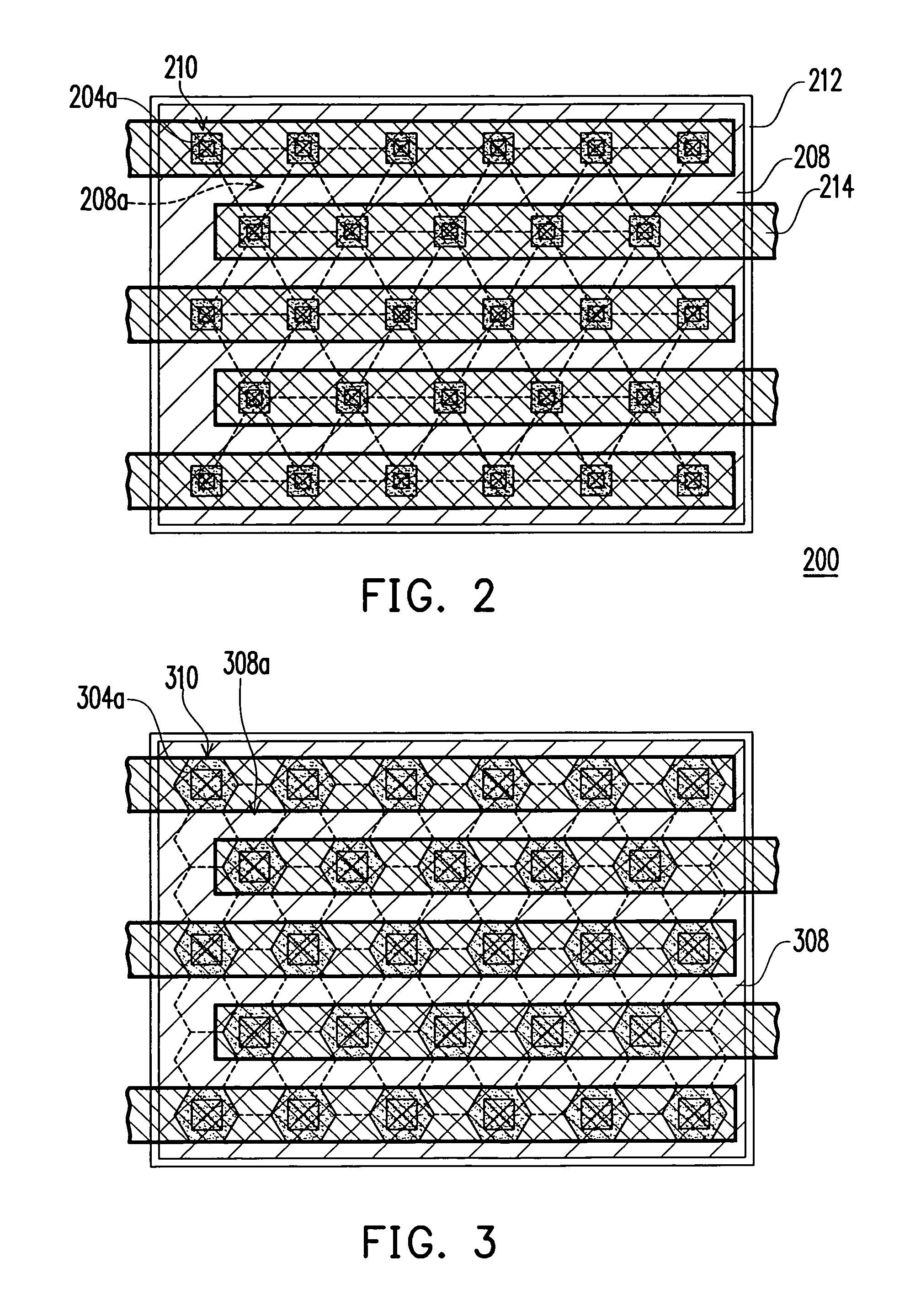

Varactor

ActiveUS20070246801A1Increase unit capacityHigh quality factorSemiconductor devicesElectrode locationDielectric layer

A varactor on a substrate is provided. The varactor comprises a bottom electrode, an upper electrode, a first dielectric layer and a conductive layer. The bottom electrode has several doped regions arranged in the substrate as an array with several rows and several columns, wherein the doped regions in adjacent columns are arranged alternatively. The upper electrode is located over the substrate and the upper electrode is composed of several electrode locations and has several openings, wherein each opening exposes the corresponding doped region. Furthermore, each electrode location is surrounded by three doped regions. The first dielectric layer is located between the substrate and the upper electrode. The conductive layer is located over the upper electrode, wherein the conductive layer and the upper electrode are isolated from each other and the conductive layer and the doped regions are electrically connected to each other.

Owner:UNITED MICROELECTRONICS CORP

Method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup

The invention discloses a method for recovering coin protein sugar dregs and preparing protein nitrogen sources and nitrogen-containing syrup in the production of enzymatic corn starch sugar, comprising the steps of size mixing, liquefying, saccharifying, standing separation, centrifugal separation, proteolysis, concentration, drying, compounding, and the like. In the invention, protein is condensed under the heat flash of liquefying, the protein sugar dregs concentrate and float upwards in saccharifying, the sugar dregs are recovered through the steps of standing separation and centrifugal separation, the sugar dregs are dried into protein, or the sugar dregs are hydrolyzed to prepare protein nitrogen sources, and the nitrogen sources can be compounded with syrup to form nitrogen-containing starch syrup for fermenting. Clarified saccharification liquid after centrifugal separation is decolored, filtered, refined and concentrated, and starch syrup products are obtained. The majority of lentous sugar dregs in the saccharification liquid are removed before the treatment of decoloring and filtering, and the decoloring and filtering performance of the material is better. The use level of active carbon, and the like can be properly reduced, the production capability of filtering equipment is improved, and the frequency of the loading and unloading of filters as well as the consumption of washing waste water and various kinds of loss are greatly reduced.

Owner:广州双桥(重庆)有限公司

Multiple enzyme process of preparing N-containing syrup for fermentation with rice and rice powder

InactiveCN1847403AIncrease the sugar contentReduce formationFermentationGlucose productionSlurryChloride

The present invention discloses multiple enzyme process of preparing N-containing syrup for fermentation with rice and rice powder, and provides one kind of preparing starch syrup with easy fermentation and sufficient nitrogen source content. The multiple enzyme process includes producing rice and rice powder into slurry, adding calcium chloride and liquefied amylase into the slurry for continuous jetting liquefaction to obtain liquefied liquid, adding saccharifying enzyme and lipase for cooperative hydrolysis, adding plant proteinase and / or microbial proteinase for reaction to obtain clear liquid without solid flocculate and particle, filtering the liquid, refining and concentrating to obtain the starch syrup. The prepared starch syrup has controllable saccharide components and relatively high content of alpha-amino nitrogen and other nitrogen containing organic matters, and is suitable for use as the fermentation material for food and biomedicine production.

Owner:SOUTH CHINA UNIV OF TECH +1

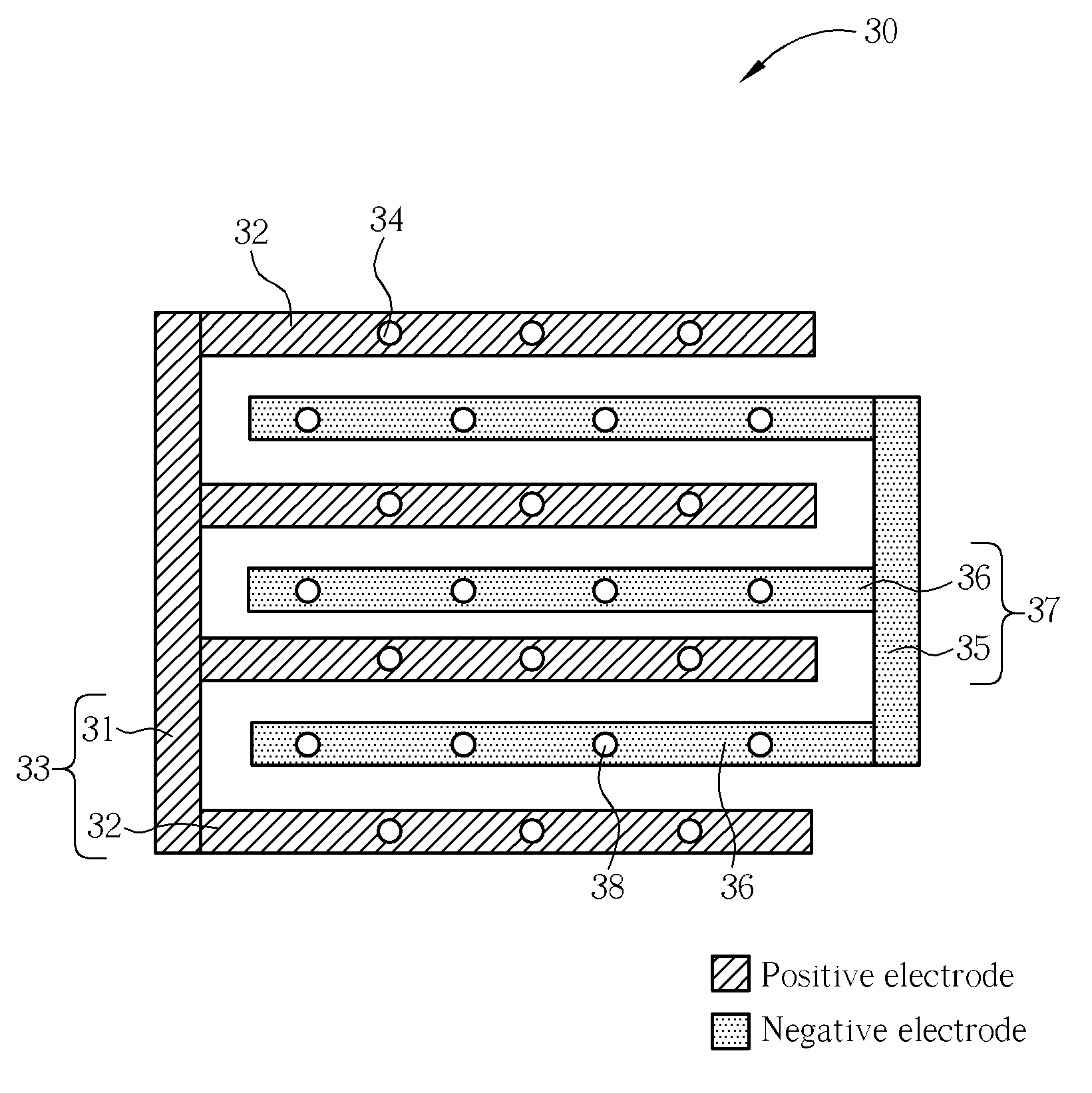

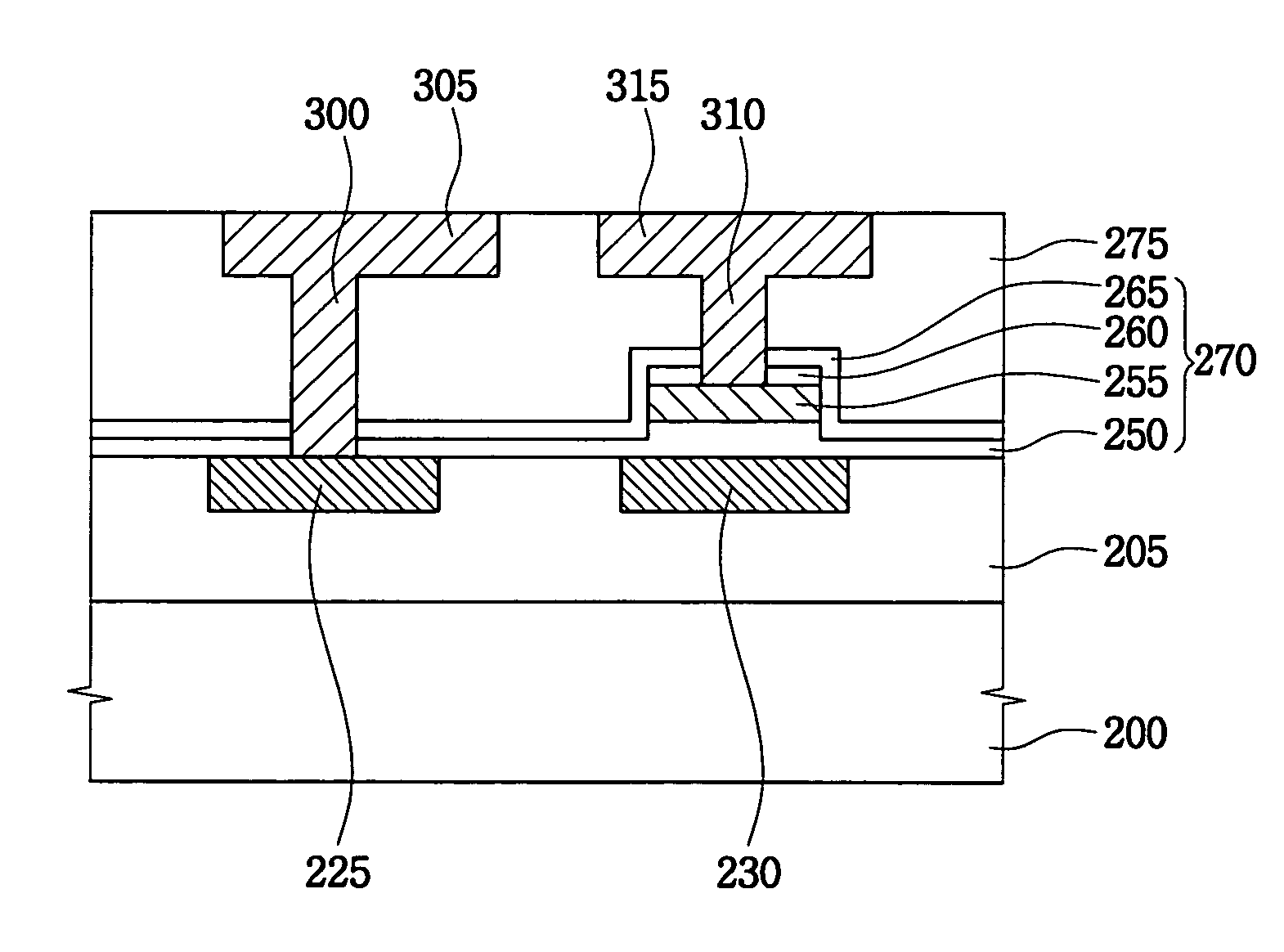

X-Shaped Semiconductor Capacitor Structure

ActiveUS20070291439A1Good capacitance characteristicsIncrease unit capacityTransistorSemiconductor/solid-state device detailsEngineeringSemiconductor

A semiconductor capacitor structure includes a first metal layer, a second metal layer, a first set of via plugs, a second set of via plugs, and a dielectric layer. The first metal layer includes a first portion, a plurality of parallel-arranged second portions, a third portion, and a plurality of parallel-arranged fourth portions. The second metal layer includes a fifth section, a plurality of sixth sections, a seventh section, and a plurality of eighth sections. The first set of via plugs electrically connects the plurality of second sections to the plurality of sixth sections. The second set of via plugs electrically connects the plurality of fourth sections to the plurality of eighth sections.

Owner:REALTEK SEMICON CORP

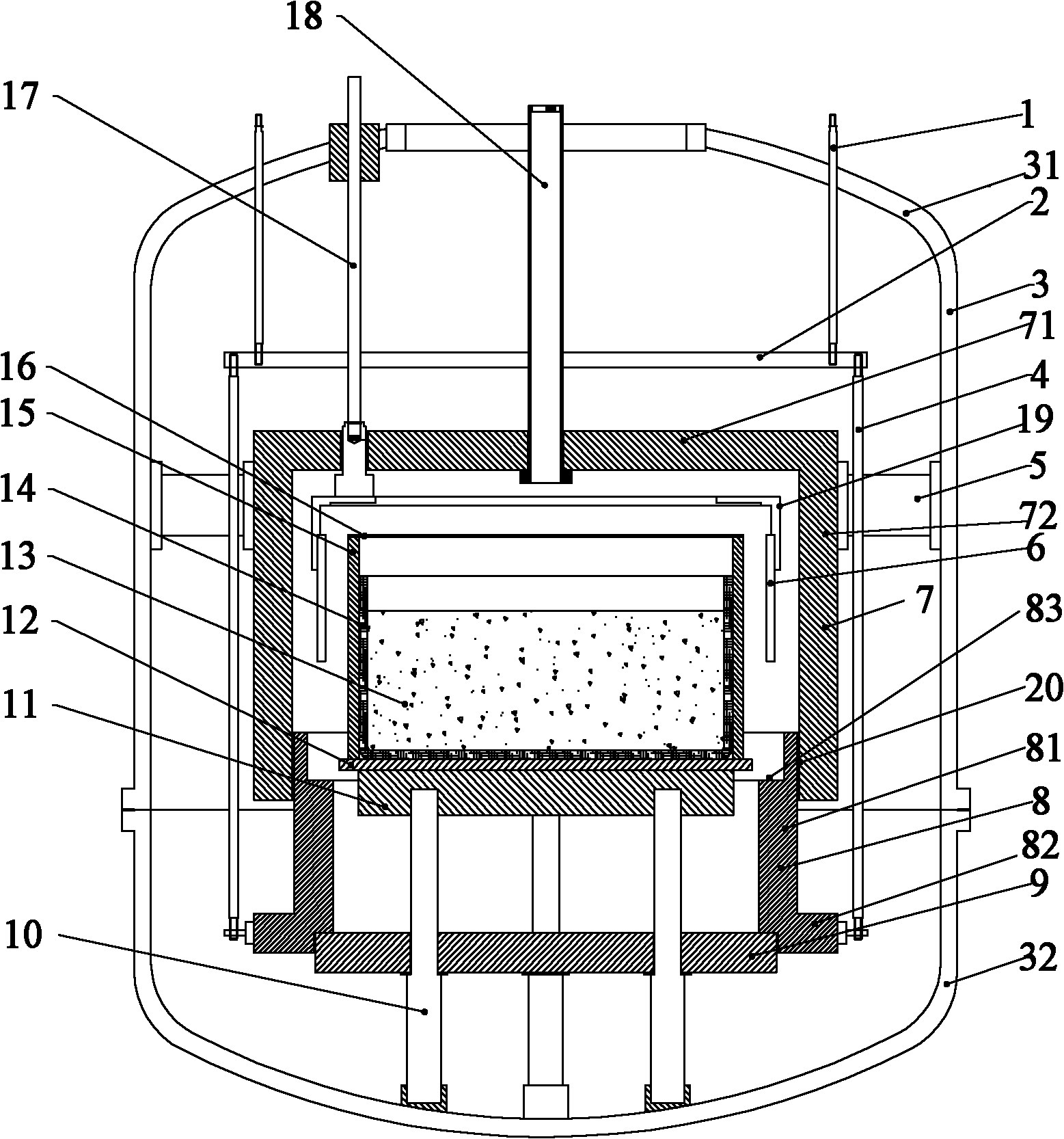

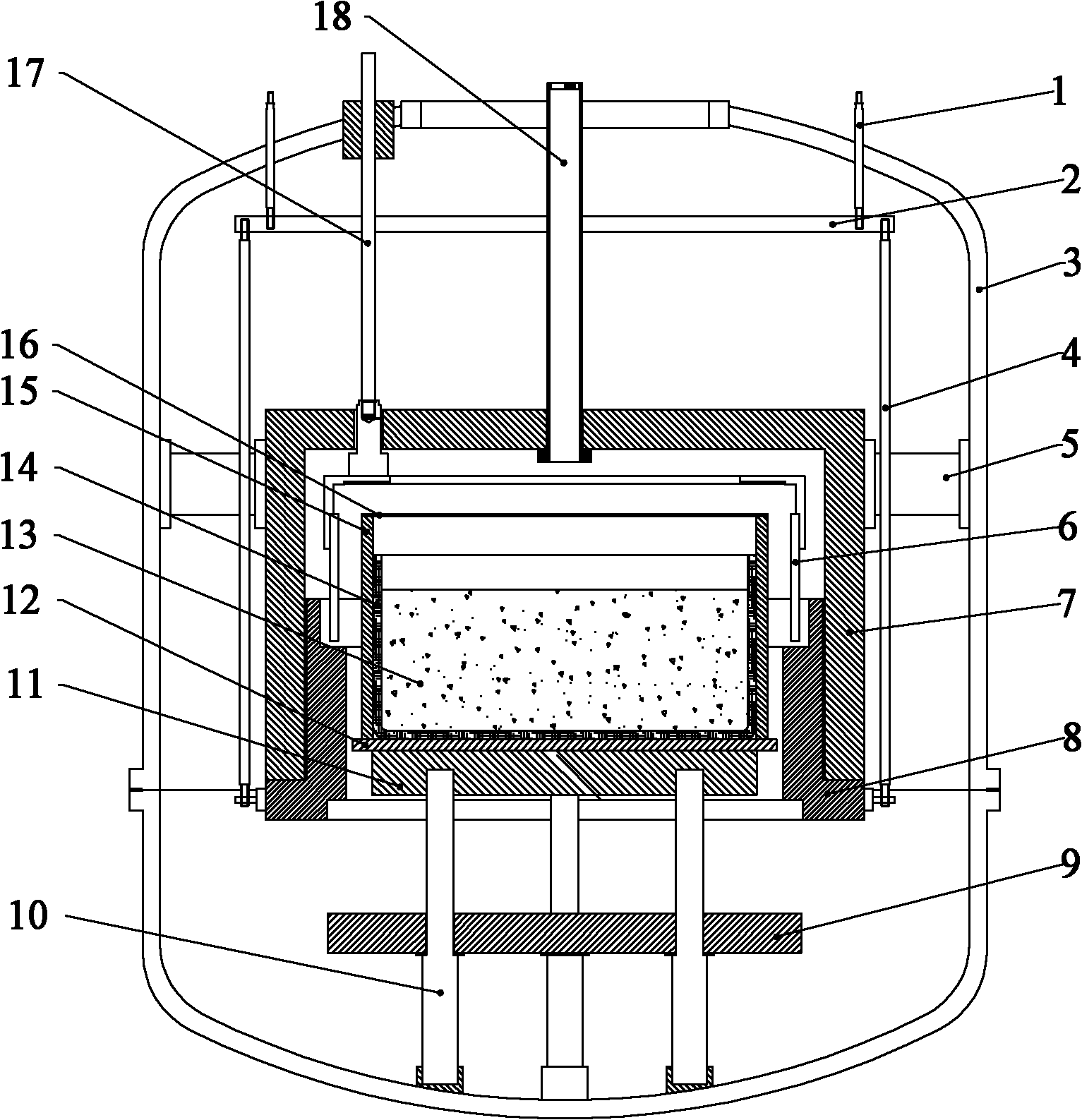

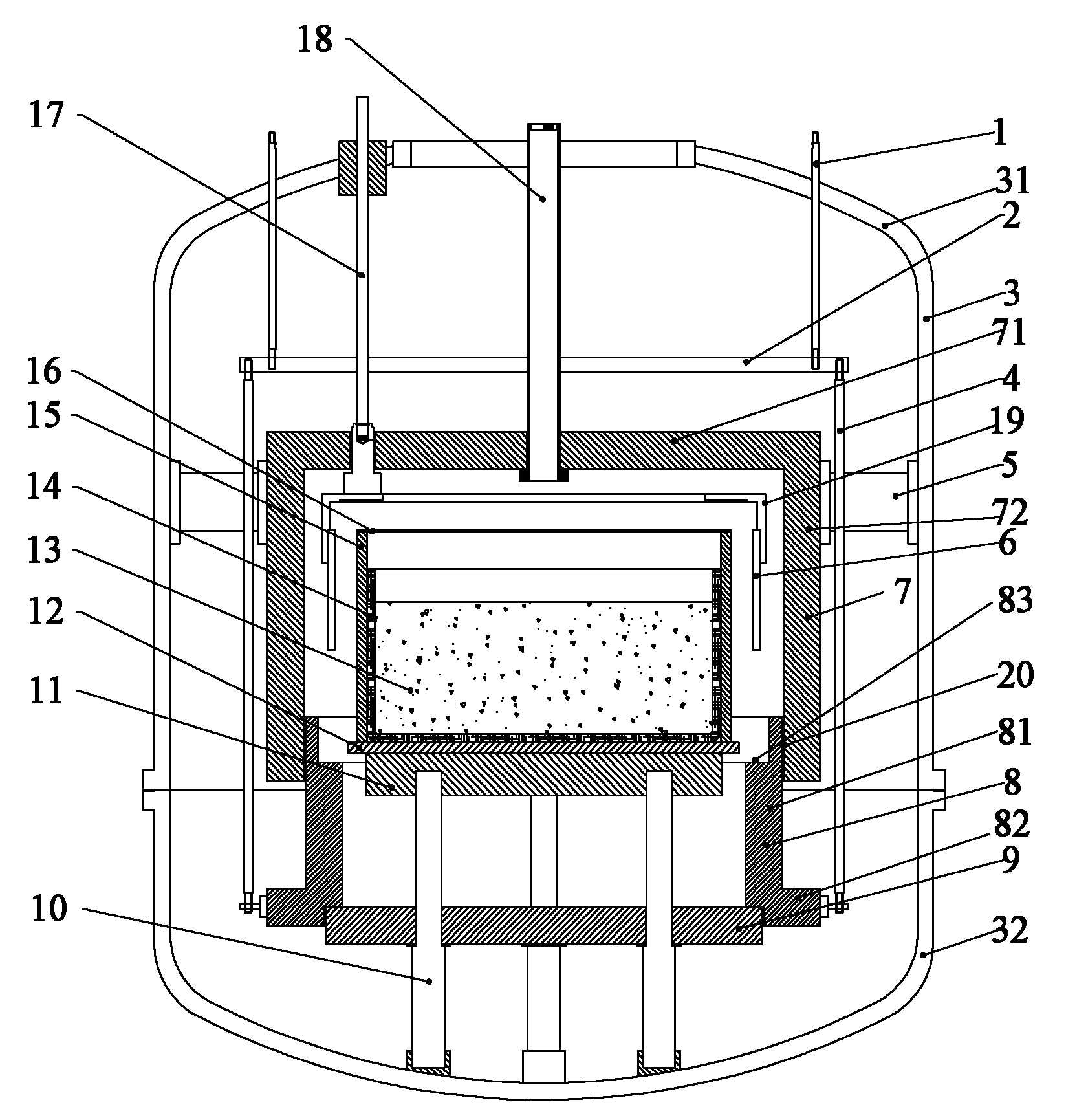

Thermal field structure of polysilicon ingot casting furnace

ActiveCN102162125AQuality improvementReduce energy consumptionPolycrystalline material growthSingle crystal growth detailsThermal insulationPolycrystalline silicon

The invention relates to a thermal field structure of a polysilicon ingot casting furnace, which comprises a furnace body, a thermal-insulation cage body and a crucible, wherein the thermal-insulation cage body is arranged inside the furnace body, the crucible is arranged inside the thermal-insulation cage body, and the thermal-insulation cage body is a sealed thermal field chamber formed by an upper thermal-insulation body, a lower thermal-insulation body and a thermal-insulation baseplate; the upper thermal-insulation body is fixed on the furnace body; the bottom of the lower thermal-insulation body is placed on the thermal-insulation baseplate, and the lower thermal-insulation body can slide up and down relative to the upper thermal-insulation body through a lifting mechanism; the crucible is placed on a heat exchange platform in a supporting structure; and the thermal-insulation baseplate is placed on supporting columns of the supporting structure for fixation. In the invention, when a silicon material is heated, melted and thermally preserved for a period of time, in a lifted process of the lower thermal-insulation body, a vertical temperature gradient field is formed on a crystallization face of the silicon material due to the vertical temperature difference inside the thermal field chamber, and the crystallographic orientation of the silicon material can be realized by controlling heat dissipating and heating, so that the quality of a polysilicon cast ingot is improved. Meanwhile, the process time is shortened, the energy consumption is decreased and the unit productivity is improved.

Owner:深圳市石金科技股份有限公司

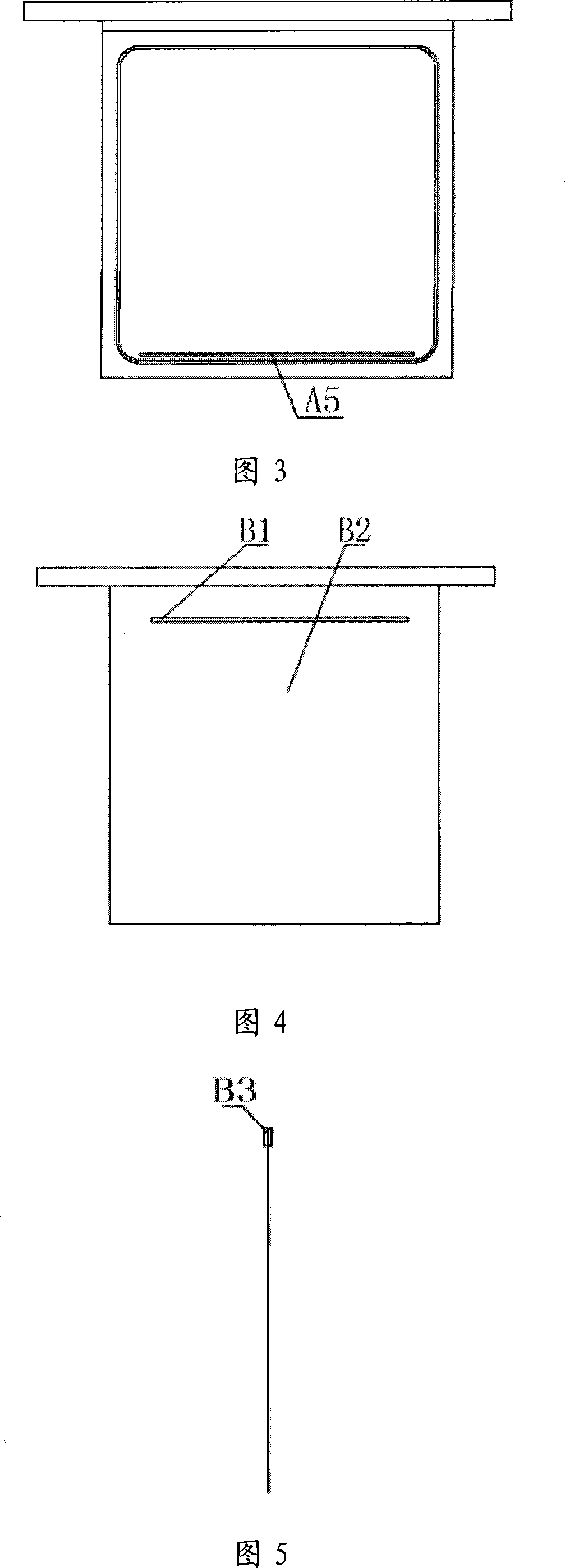

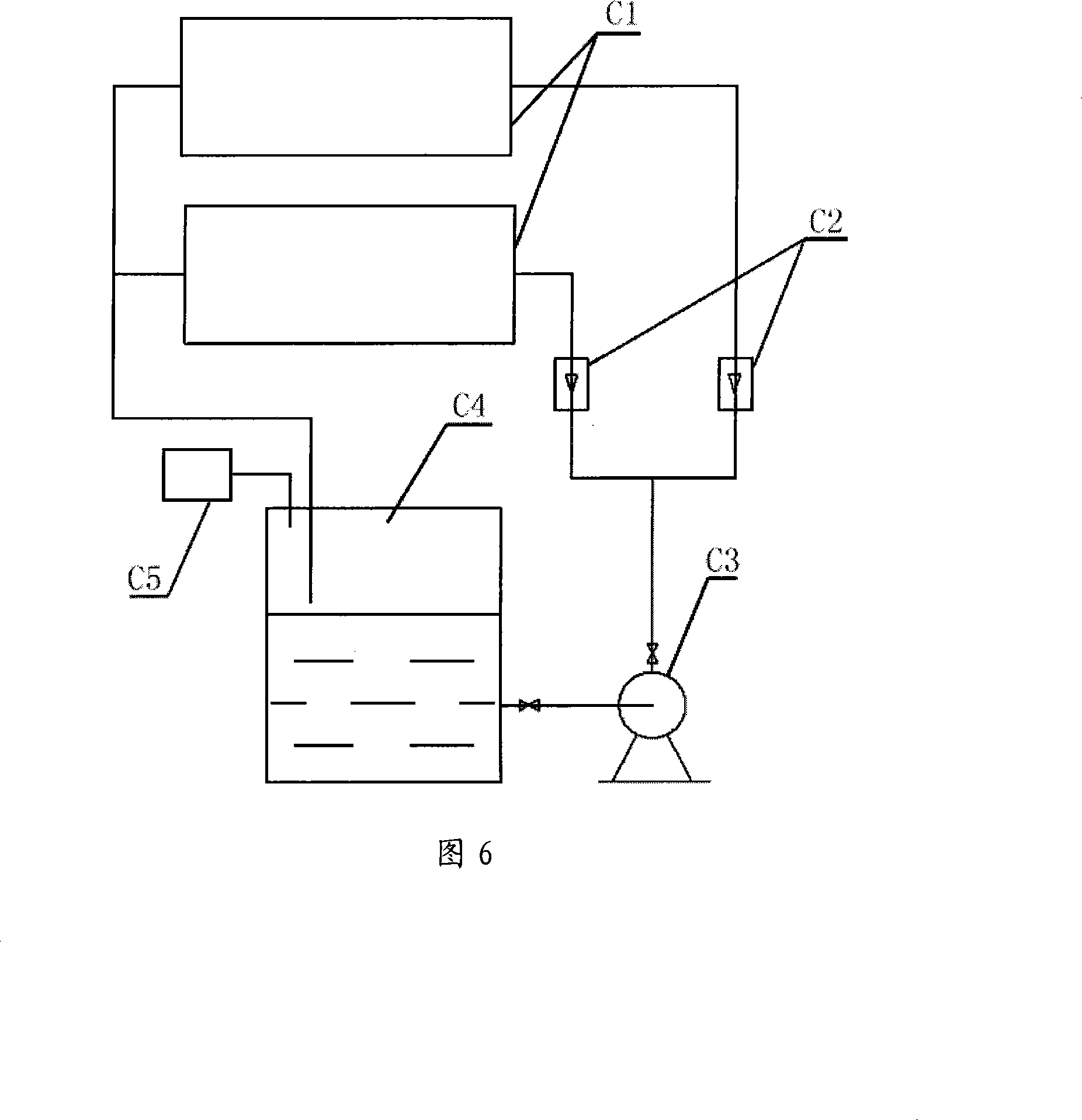

Enclosed type electrolytic tank and electrolytic system

The invention discloses a sealed electrolysis bath and an electrolytic system, the electrolysis bath comprises two end plates, an anode component, a cathode component, sealing components and a compacting device, wherein liquid flowing ports are evenly arranged on the two end plates, liquid flowing through-holes are correspondingly arranged on the anode component and the cathode component, the anode component and the cathode component are separately arranged between the two end plates, a polar chamber is formed between the anode component and the cathode component, the sealing components are evenly arranged on the contact position of the anode component, the cathode component and the end plates, and the anode component, the cathode component and the end plates form a sealed structure after being compacted through the compacting device. The electrolysis bath has simple structure and can increase the circulation speed of electrolyte, the overpotential is effectively lowered, the current density of an anode and a cathode is increased when in electrolysis, the productivity of unit electrolysis bath is increased, and the electrolysis bath can be widely applied in electrowinning various metal and in electrowinning metallic solution with low concentration. The sealed structure avoids the influence of gas which is discharged in the electrolysis process to environment in a workshop.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

X-shaped semiconductor capacitor structure

ActiveUS7859039B2Good capacitance characteristicsIncrease unit capacityTransistorSemiconductor/solid-state device detailsEngineeringDielectric layer

A semiconductor capacitor structure includes a first metal layer, a second metal layer, a first set of via plugs, a second set of via plugs, and a dielectric layer. The first metal layer includes a first portion, a plurality of parallel-arranged second portions, a third portion, and a plurality of parallel-arranged fourth portions. The second metal layer includes a fifth section, a plurality of sixth sections, a seventh section, and a plurality of eighth sections. The first set of via plugs electrically connects the plurality of second sections to the plurality of sixth sections. The second set of via plugs electrically connects the plurality of fourth sections to the plurality of eighth sections.

Owner:REALTEK SEMICON CORP

Continuous production method of high-content high-optical-purity lactate

InactiveCN102675102AReduce moisture contentConfiguration flipPreparation by ester-hydroxy reactionOligomerAlcohol

The invention relates to a continuous production method of high-content high-optical-purity lactate. The continuous production method of high-content high-optical-purity lactate includes the steps of adding catalyst in lactic acid to allow for polycondensation to obtain lactic acid oligomer with 1000-2500 molecular weight; adding catalyst into the lactic acid oligomer to allow for depolymerization to obtain crude lactide; and refining the crude lactide, and subjecting the refined lactide and organic alcohol to full-reflux reaction to obtain lactate. The continuous production method is simple in process, easy and simple to operate and suitable for industrial production and application. The materials can all be utilized. No 'three wastes' emission occurs. Content of the synthetized lactate is more than 99.5%, and optical purity of the lactate can reach more than 99%.

Owner:XIAOGAN ESUN NEW MATERIAL

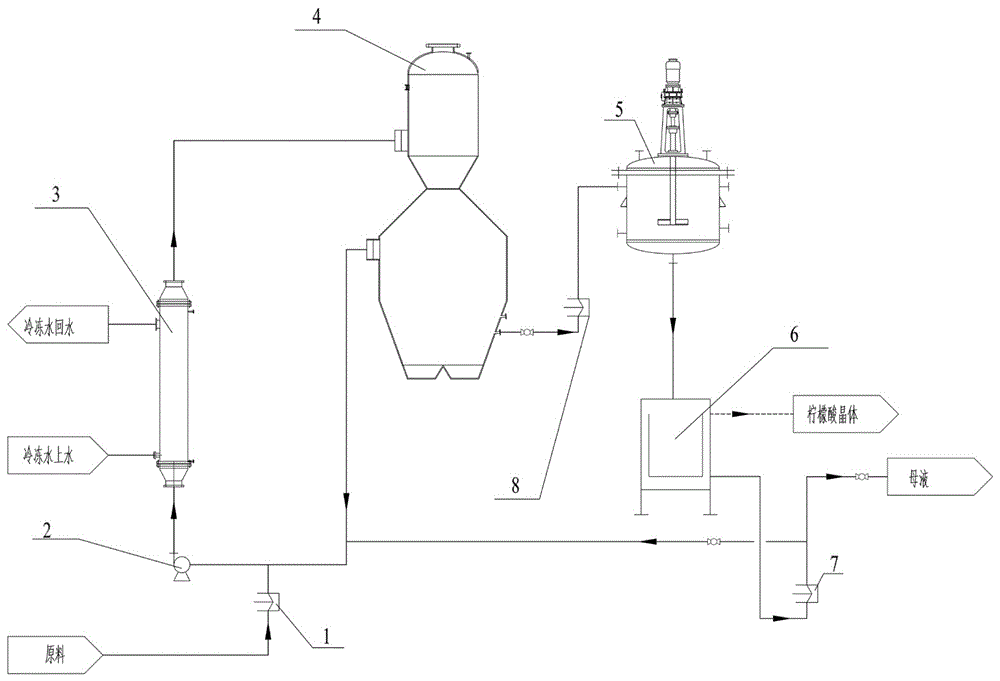

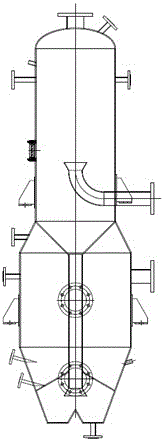

Citric acid continuous cooling crystallization system and method thereof

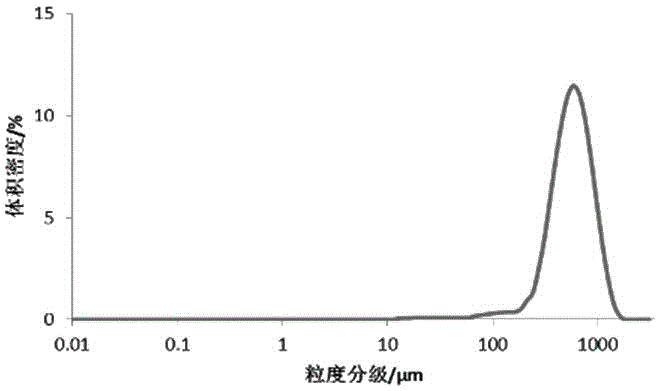

InactiveCN105797422AIncrease productivityStable feeding and dischargingSolution crystallizationHeat exchange cooling cystallizationSlurryCitric Acid Monohydrate

The invention relates to a citric acid continuous cooling crystallization system and a method thereof. In an existing method of producing citric acid monohydrate crystal, intermittent processing equipment is used, product size distribution is uneven, a crystal product is agglutinated seriously, and difference between product batches is large. According to the crystallization method, a citric acid solution is heated and concentrated through two-effect heat exchange, then is input into a circulating pipeline composed of an indirect cooler and a cooling crystallizer through a feed pump and is continuously cooled for cooling crystallization in the circulating pipeline under the action of a circulating pump, and citric acid monohydrate slurry is obtained through cooling crystallization; the citric acid monohydrate slurry is discharged through a discharging pump, conveyed to a crystal slurry buffering tank to be buffered and then input into a centrifugal separation device for solid-liquid separation. According to the continuous cooling crystallization method, intermittent crystallization operation of using a crystallization kettle for feeding and discharging and conducting cooling in the kettle in the past is replaced, the feeding, discharging and cooling flow path is stabilized, continuity and stability of product quality can be effectively ensured, and production efficiency and product quality of citric acid monohydrate are greatly improved.

Owner:西安航天华威化工生物工程有限公司

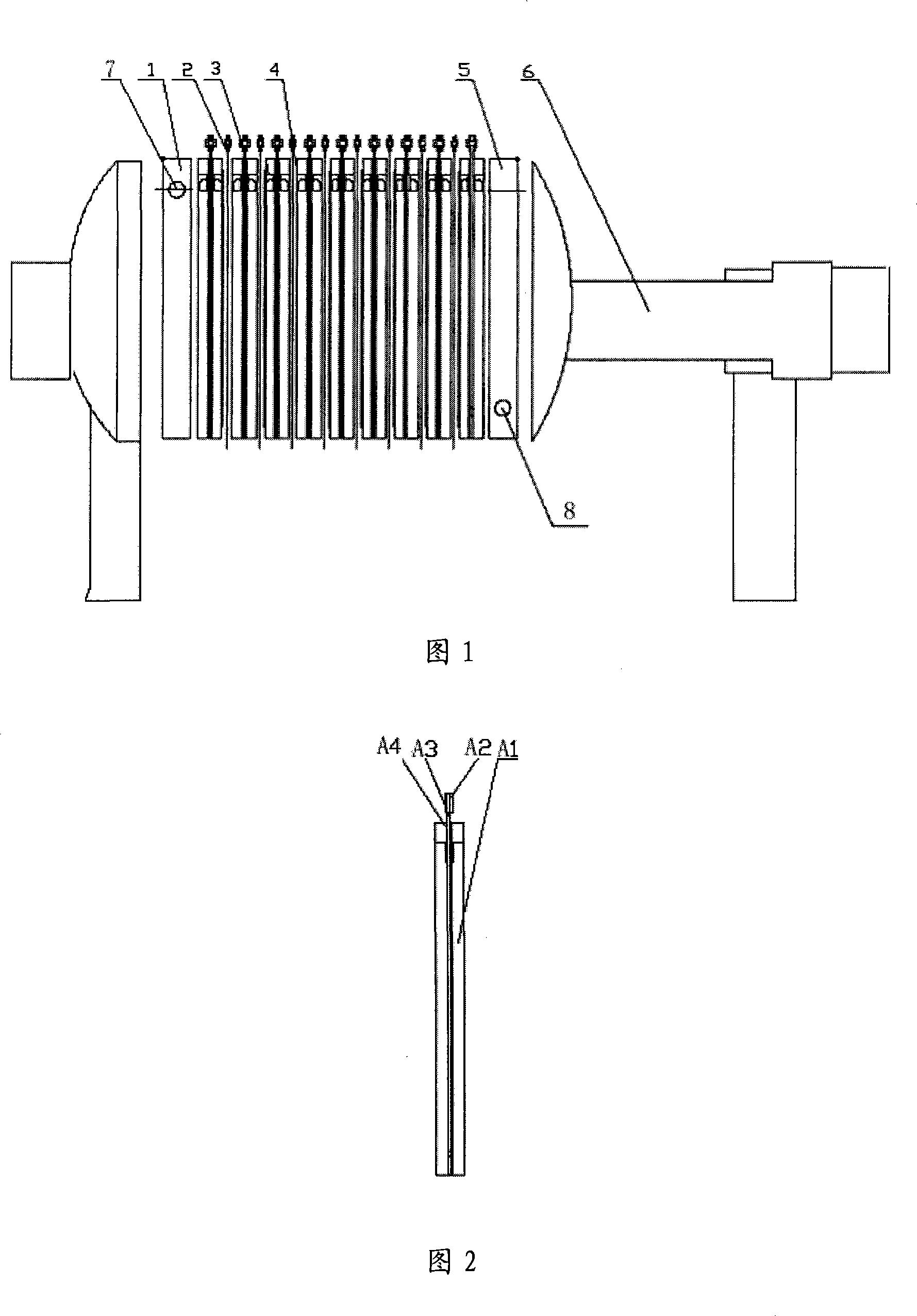

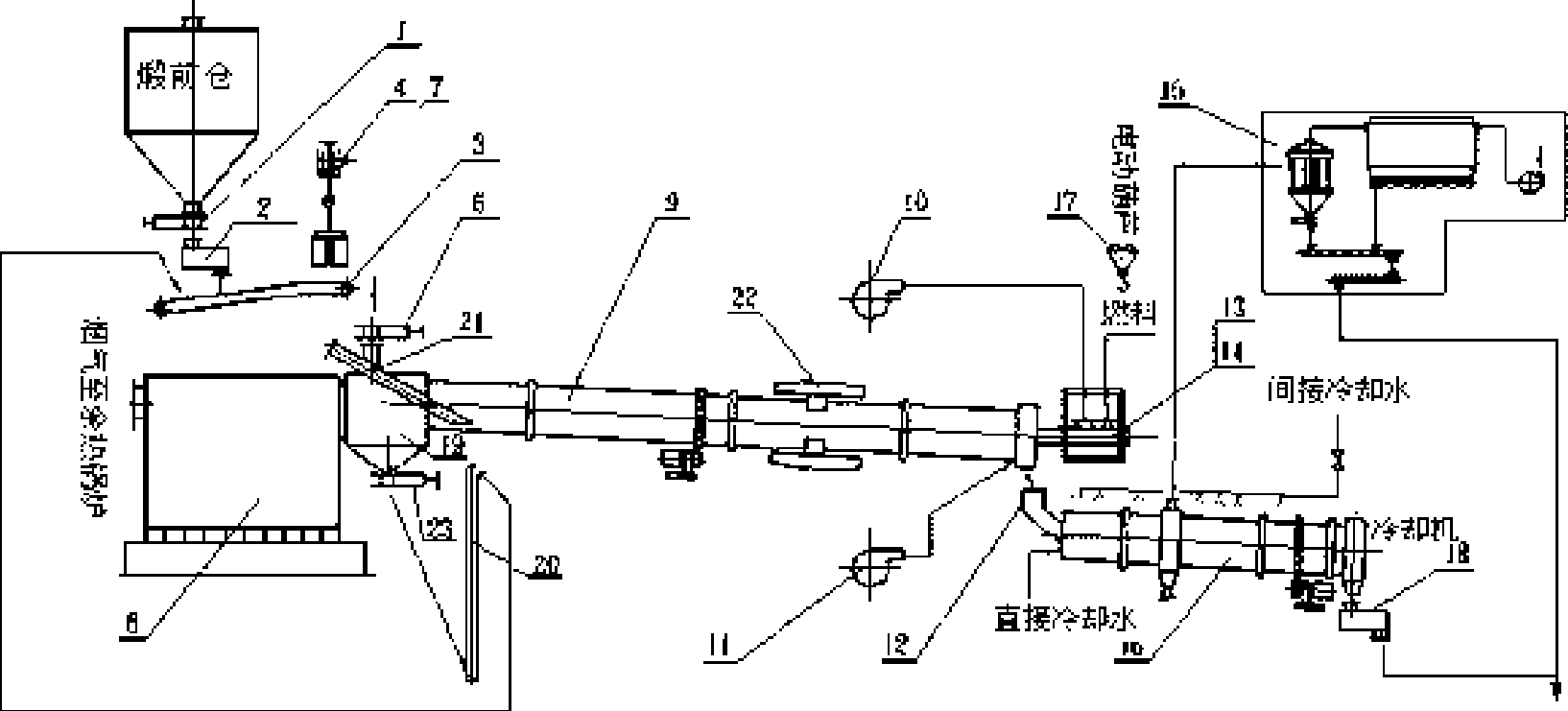

Rotary kiln for calcining refinery coke

The invention discloses a petroleum coke calcining rotary kiln, which comprises a rotary kiln(9); an insert plate valve(1) is arranged below a calcining front chamber; an adhesive tape constant feeder(2) is arranged below the insert plate valve, and an adhesive tape conveyer(3) is arranged behind the adhesive tape constant feeder (2) and connected with the rotary kiln(9) by an oblique cutting feed tipping tube of an electric insert plate valve(6); the tail part of the rotary kiln(9) is connected with a dust deposition chamber(8), and the head part of the rotary kiln(9) is connected with a cooling machine(16) and provided with a burner nozzle(13) and a burner nozzle hanger(14); the petroleum coke calcining rotary kiln is also provided with a one-time combustion fan(10) matched with the burner nozzle; and a dust-containing waste gas processing system(15) is arranged beside the cooling machine(16). The petroleum coke calcining rotary kiln has the advantages of improving the unit volume capacity, greatly enhancing comprehensive utilization of waste heat and adaptability of other calcining materials such as needle coke, anthracite and the like, reducing burning loss of charcoal, saving raw materials and energy, improving automatization level and reducing labor intensity of a worker.

Owner:GUIYANG AL-MG DESIGN & RES INST

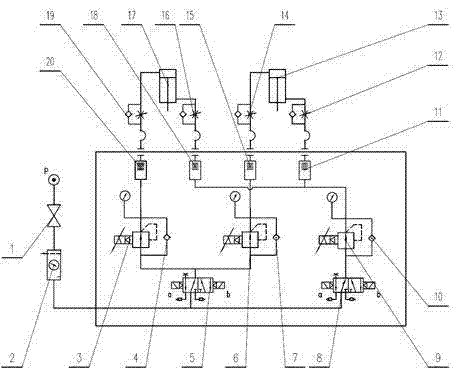

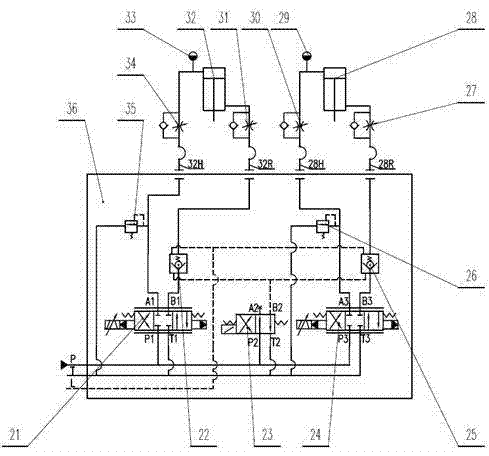

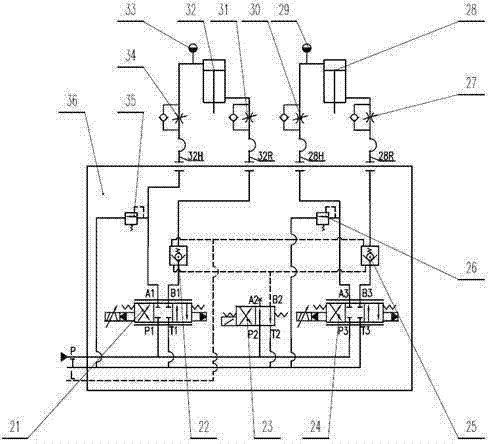

Hydraulic control loop for ironing roller device

ActiveCN102407238AReasonable designReliable designServomotorsMetal rolling arrangementsHydraulic cylinderControl theory

The invention discloses a hydraulic control loop for an ironing roller device, which comprises first and second hydraulic cylinders for driving an ironing roller, first and second pressure sensors arranged on the first and second hydraulic cylinders respectively, and a first servo valve, a second servo valve and an electromagnetic reversal valve which are connected among the first and second hydraulic cylinders and a hydraulic oil source by pipelines. The hydraulic control loop for the ironing roller device can accurately control the ironing pressure of the ironing roller, has high control accuracy, fast response speed, remarkable strip ironing effect and better quality, greatly increases the speed of a unit and increases the finished product ratio of the strip.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

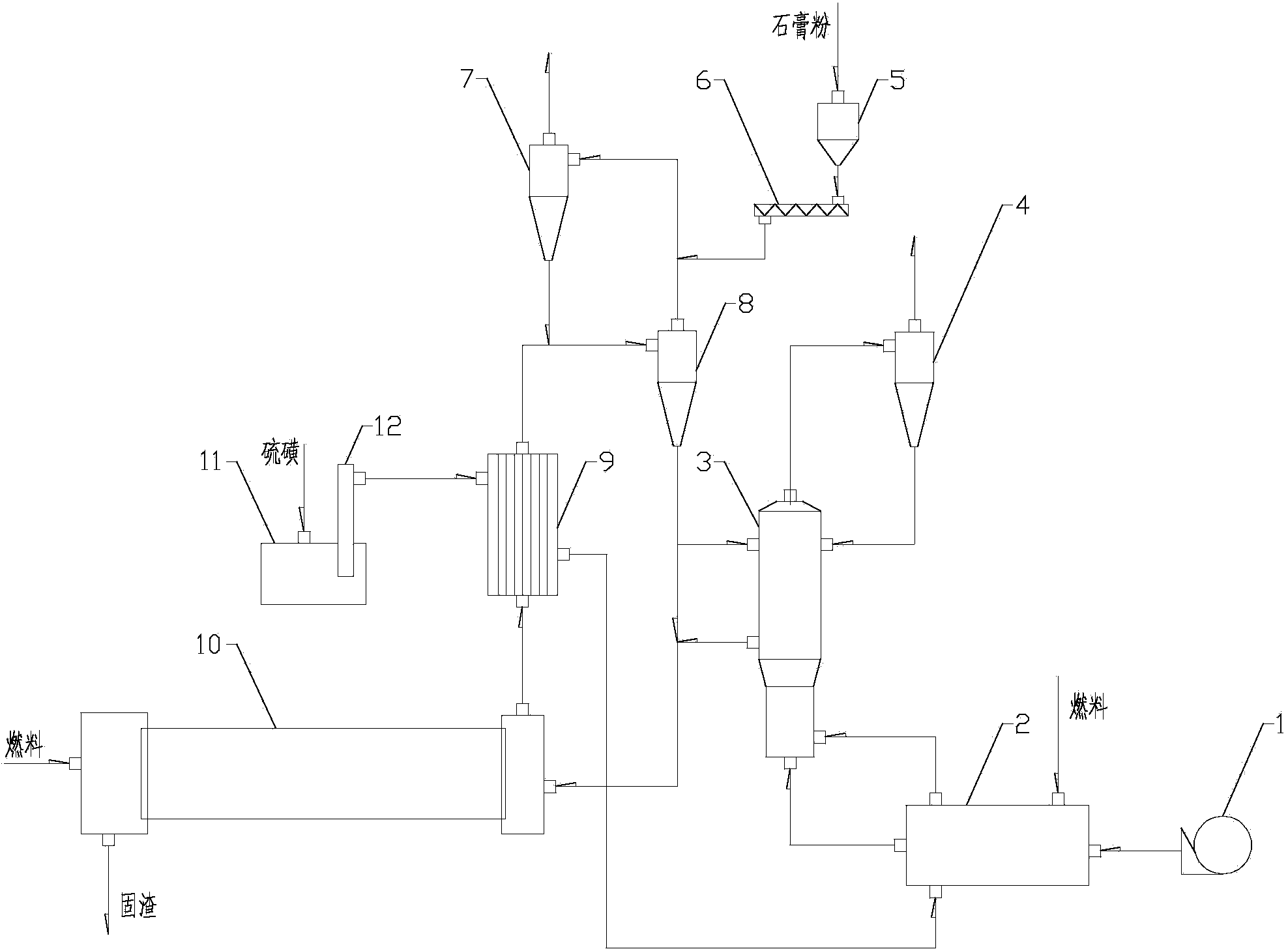

Process for decomposing gypsum through spraying and fluidizing

ActiveCN103818884AHigh partial pressure ratioIncrease contact areaChemical industrySulfur compoundsDecompositionCalcium sulfide

The invention relates to the technical field of fluidized decomposition and calcination of gypsum, and particularly discloses a process for producing sulfuric acid by spraying, fluidizing, decomposing and calcining gypsum efficiently. The process comprises the following steps: gasifying brimstone; preheating raw gypsum; spraying, fluidizing and decomposing gypsum to prepare calcium sulfide and sulfur dioxide; preparing sulfur dioxide by calcining and decomposing the prepared calcium sulfide and heated gypsum; preparing sulfuric acid by treating the tail gas. Through the adoption of spraying and fluidizing technology, out-kiln decomposition of gypsum during acid making is realized; the calcium sulfide can be prepared efficiently with low cost; then the calcium sulfide and the preheated gypsum are calcined together for decomposition to prepare the sulfur dioxide. Therefore, the process is absolutely an excellent process for industrialized continuous production, is high in economic benefits and energy utilization ratio.

Owner:SICHUAN HONGDA

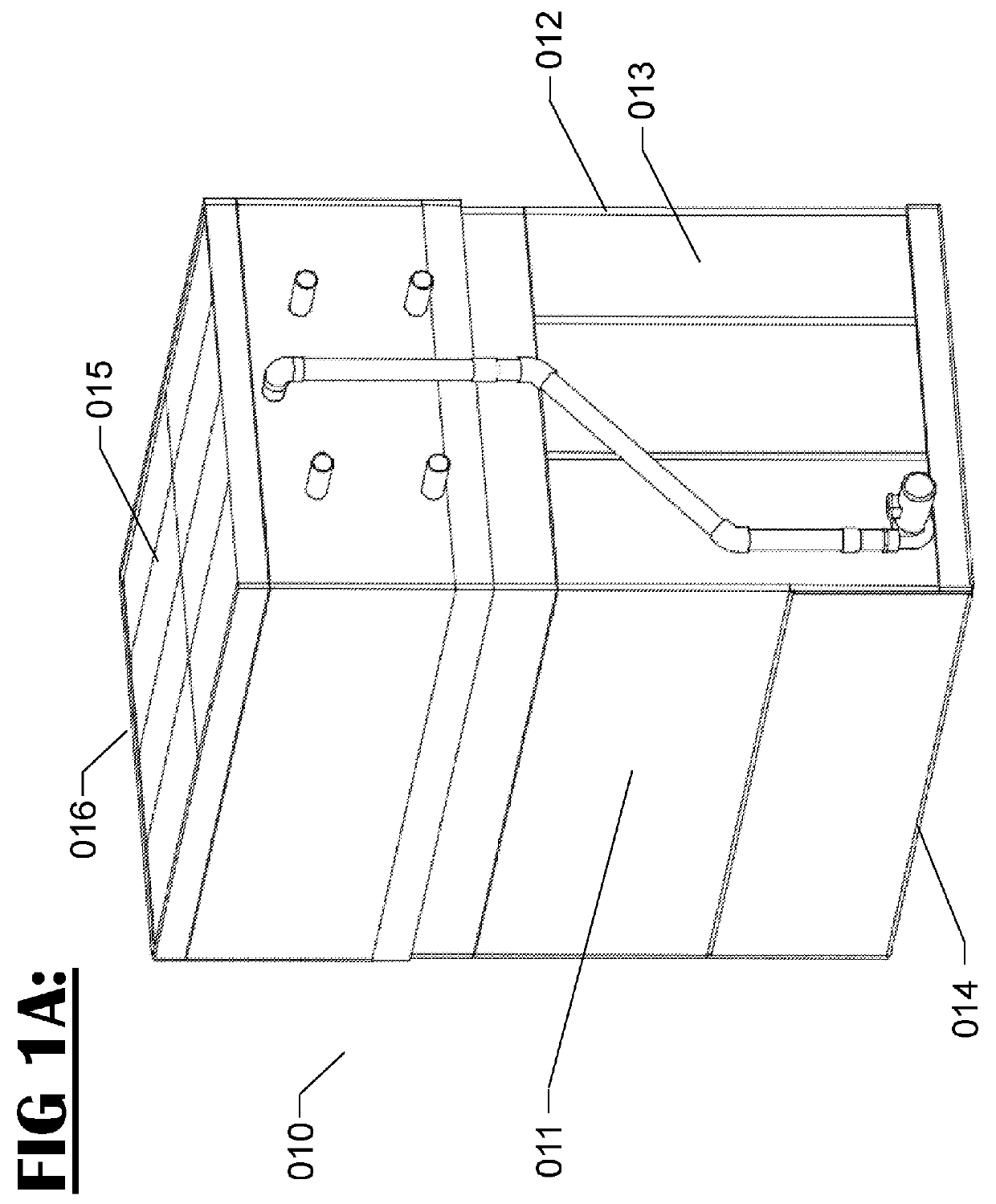

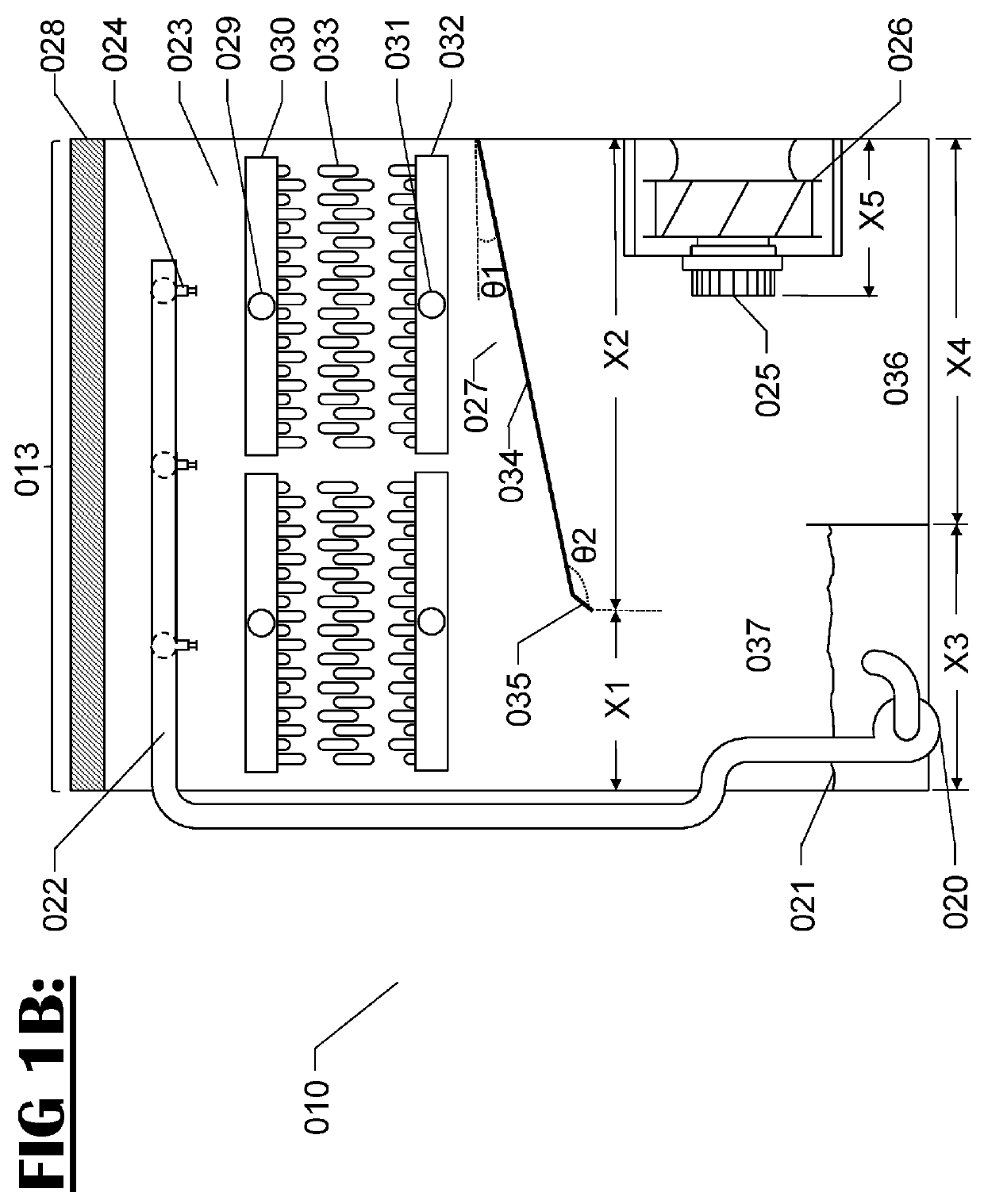

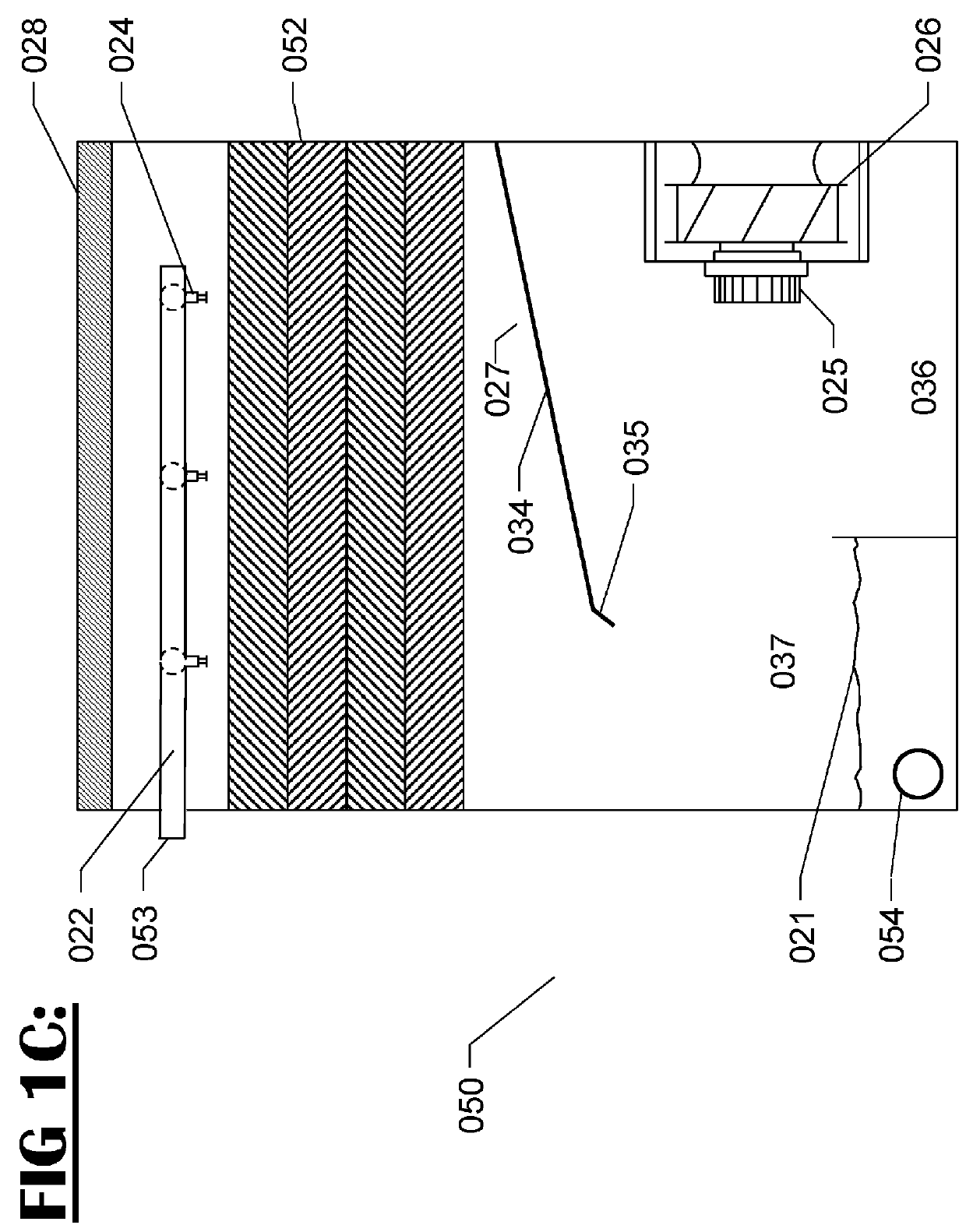

Water Collection/Deflection Arrangements

ActiveUS20180094884A1Amelioration of spray water flowImproved air distributionEfficient regulation technologiesStationary conduit assembliesEvaporative coolerPlate heat exchanger

Improved water management systems which deflect or collect evaporative liquid exiting counterflow heat exchangers and improve airflow distribution are provided. Such heat exchangers include open cooling towers, closed circuit cooling towers, and evaporative condensers. The improved water management systems eliminate water splash out and the noise associated with water splashing. Further, when the fan assemblies are located below the evaporative heat exchanger, the improved water management systems keep the fans dry and prevent freezing in subzero climates.

Owner:BALTIMORE AIRCOIL CO INC

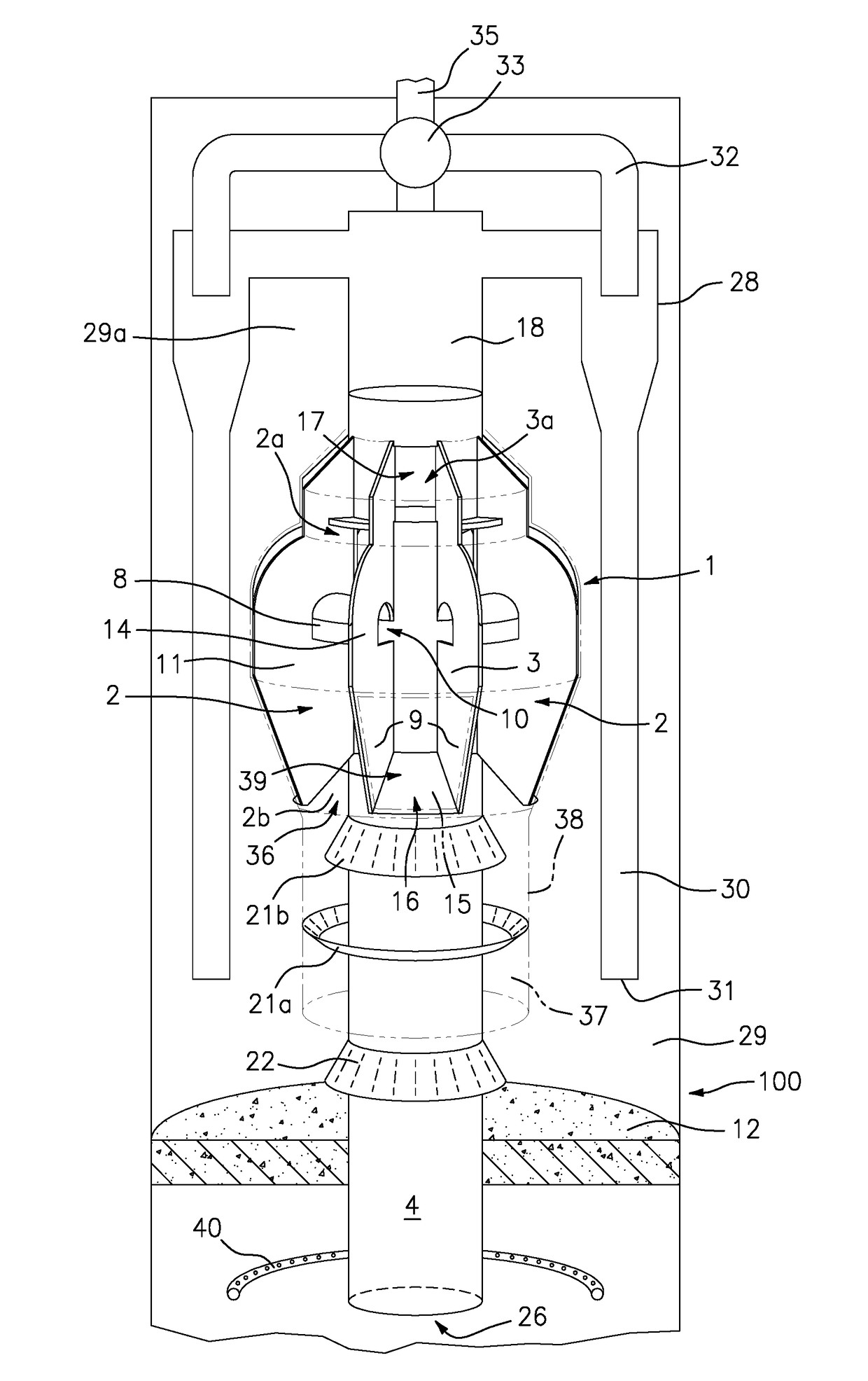

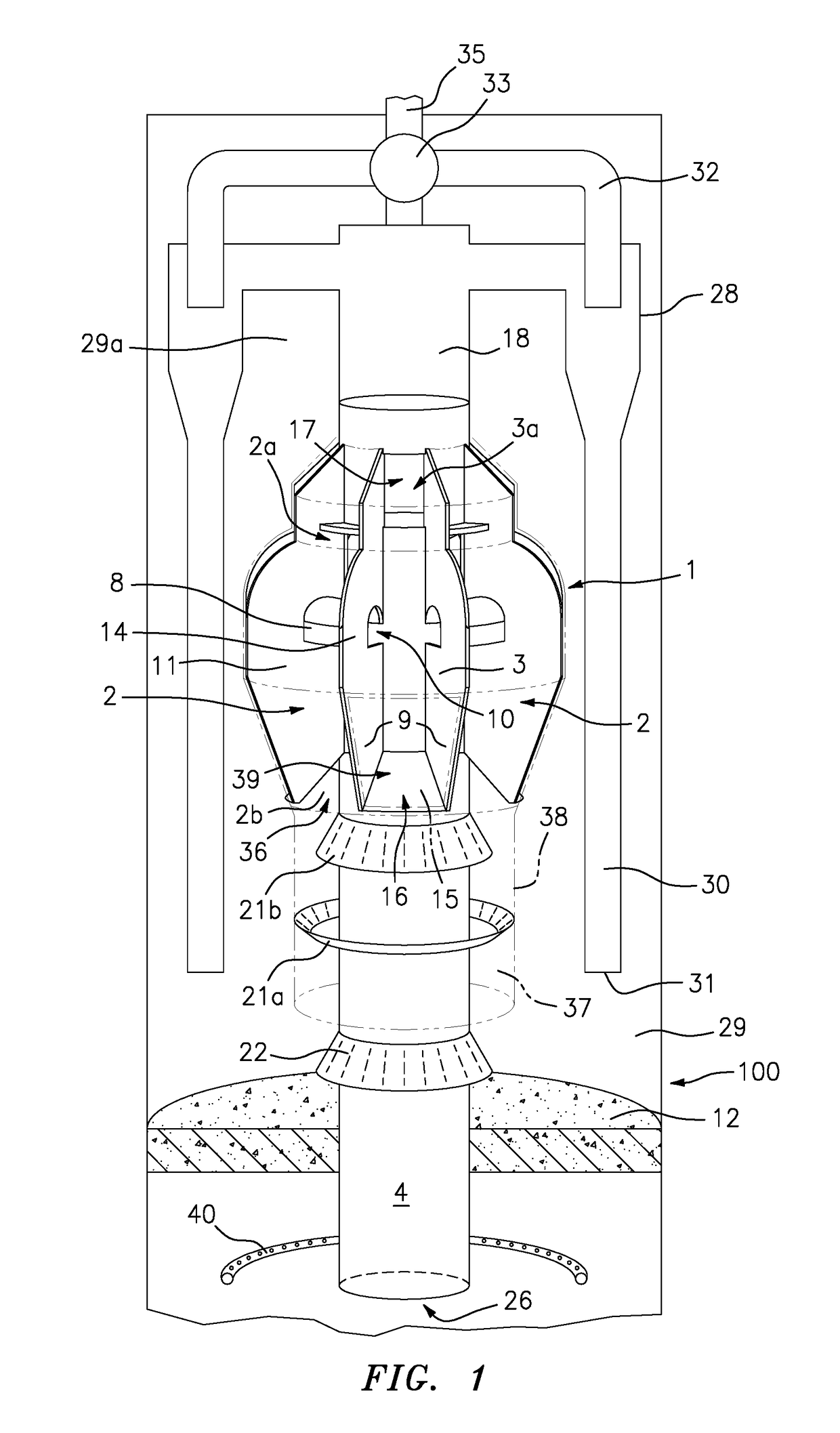

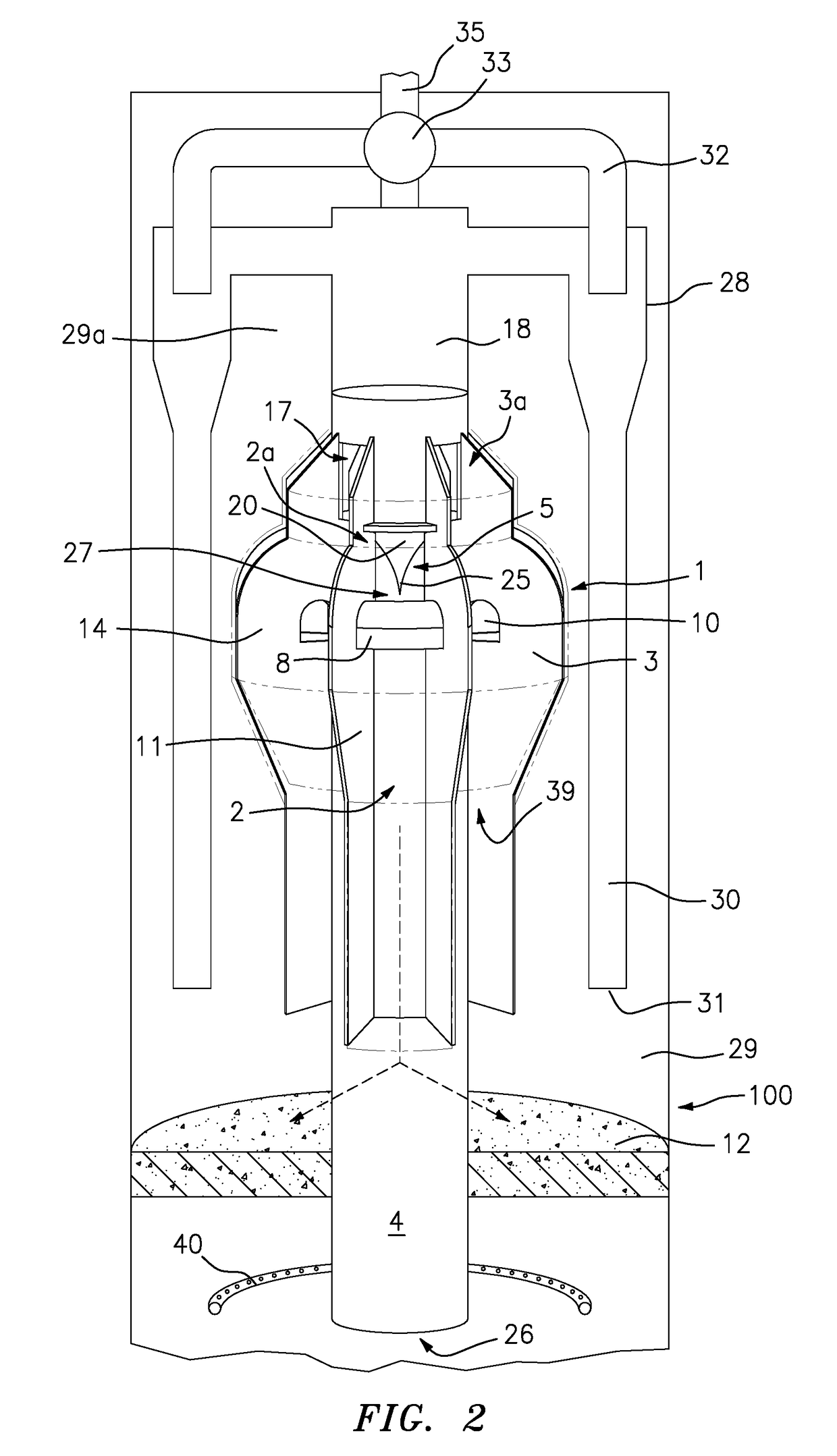

Riser separation system

ActiveUS20180216012A1Improve separationSmoothly flowCatalytic crackingDispersed particle separationProcess engineeringResidence time

The present disclosure is directed to an apparatus and a compact riser separation system for separating a gaseous mixture from a stream of particles entering from a central riser reactor used for cracking a hydrocarbon feed with the stream of particles. The apparatus provides improved gas solid separation efficiency and maximize containment of the hydrocarbon and minimize residence time in the separation system and thereby minimizing undesired post riser cracking reactions.

Owner:TECH PRECESS TECH INC

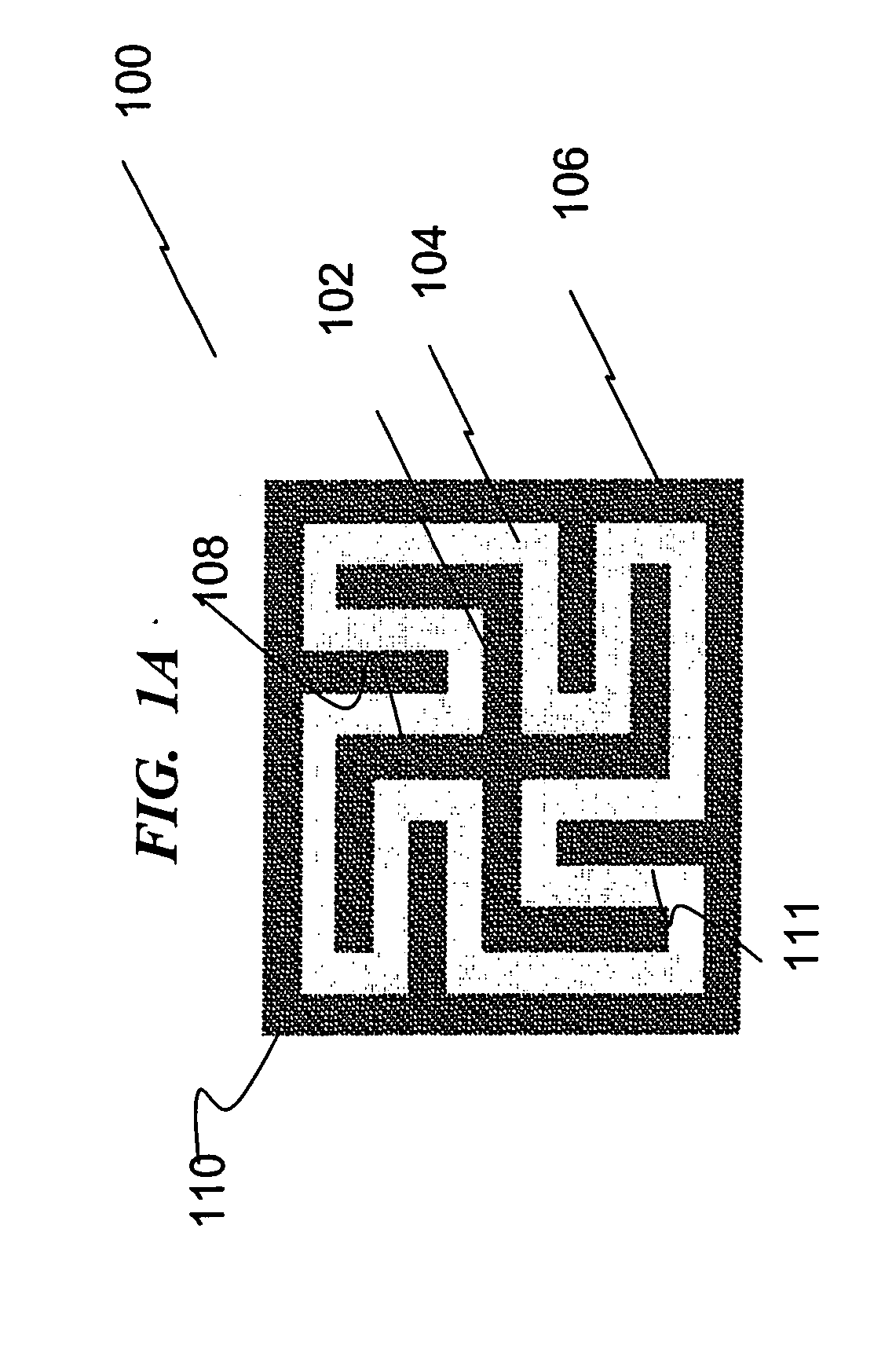

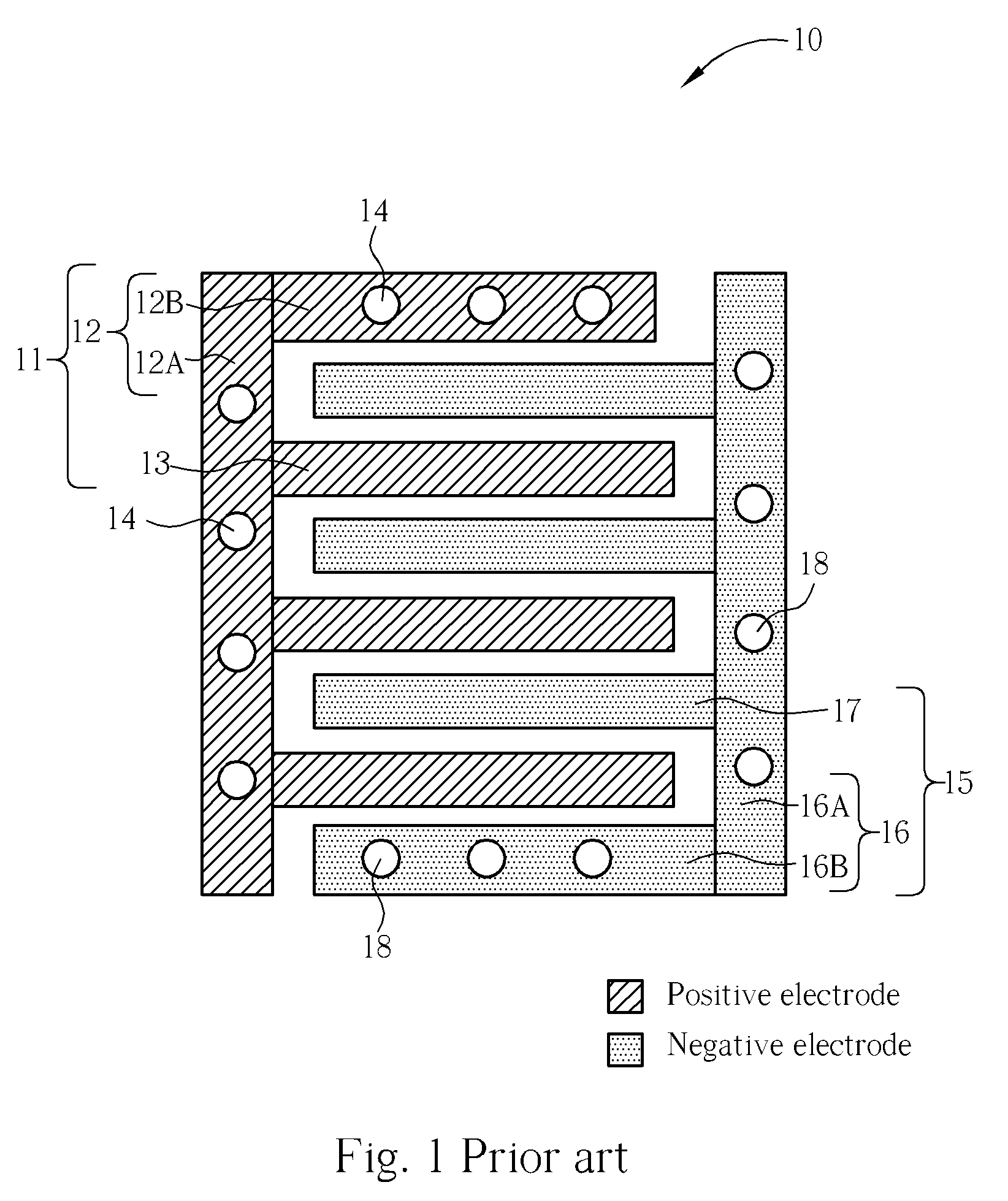

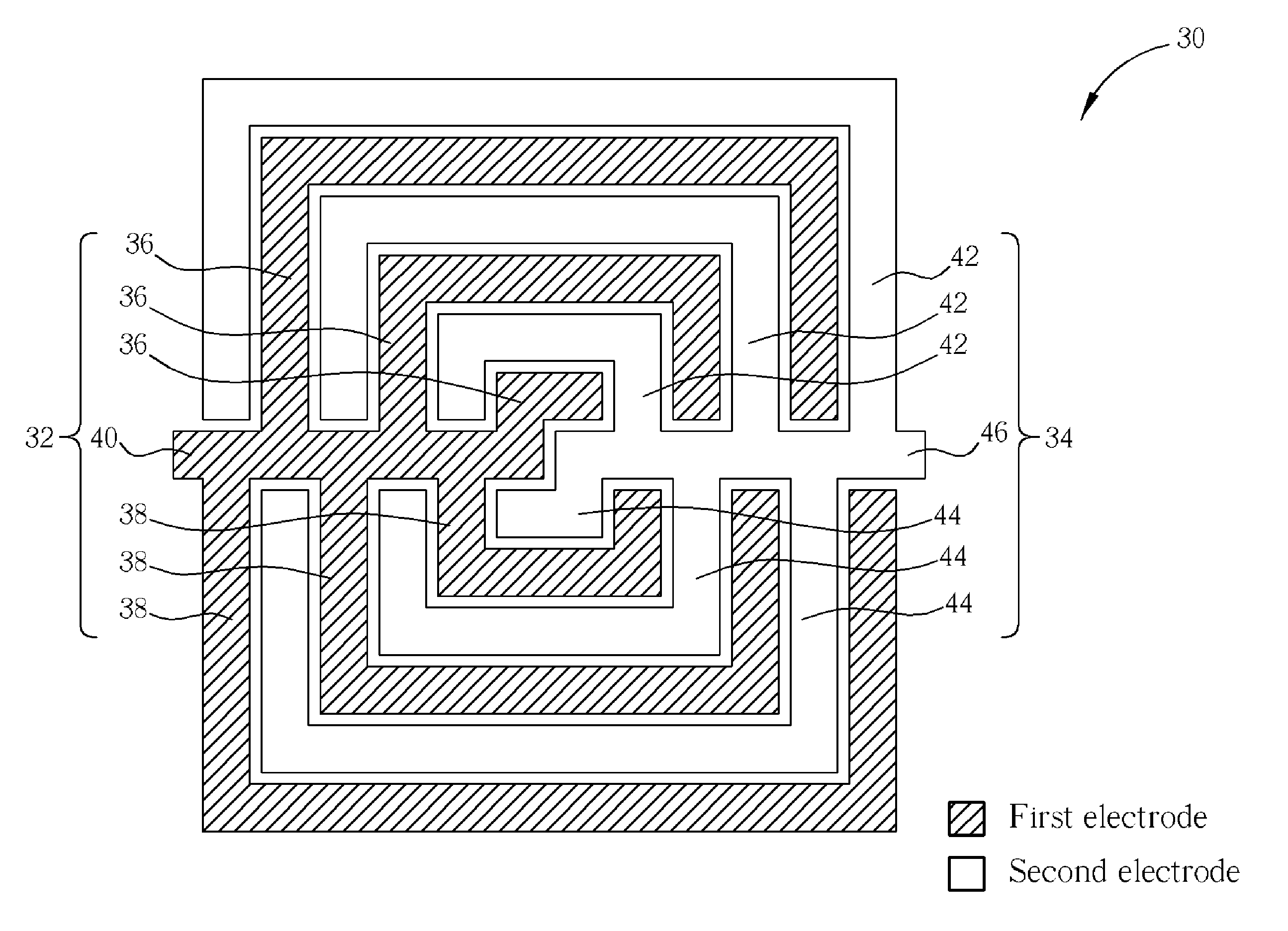

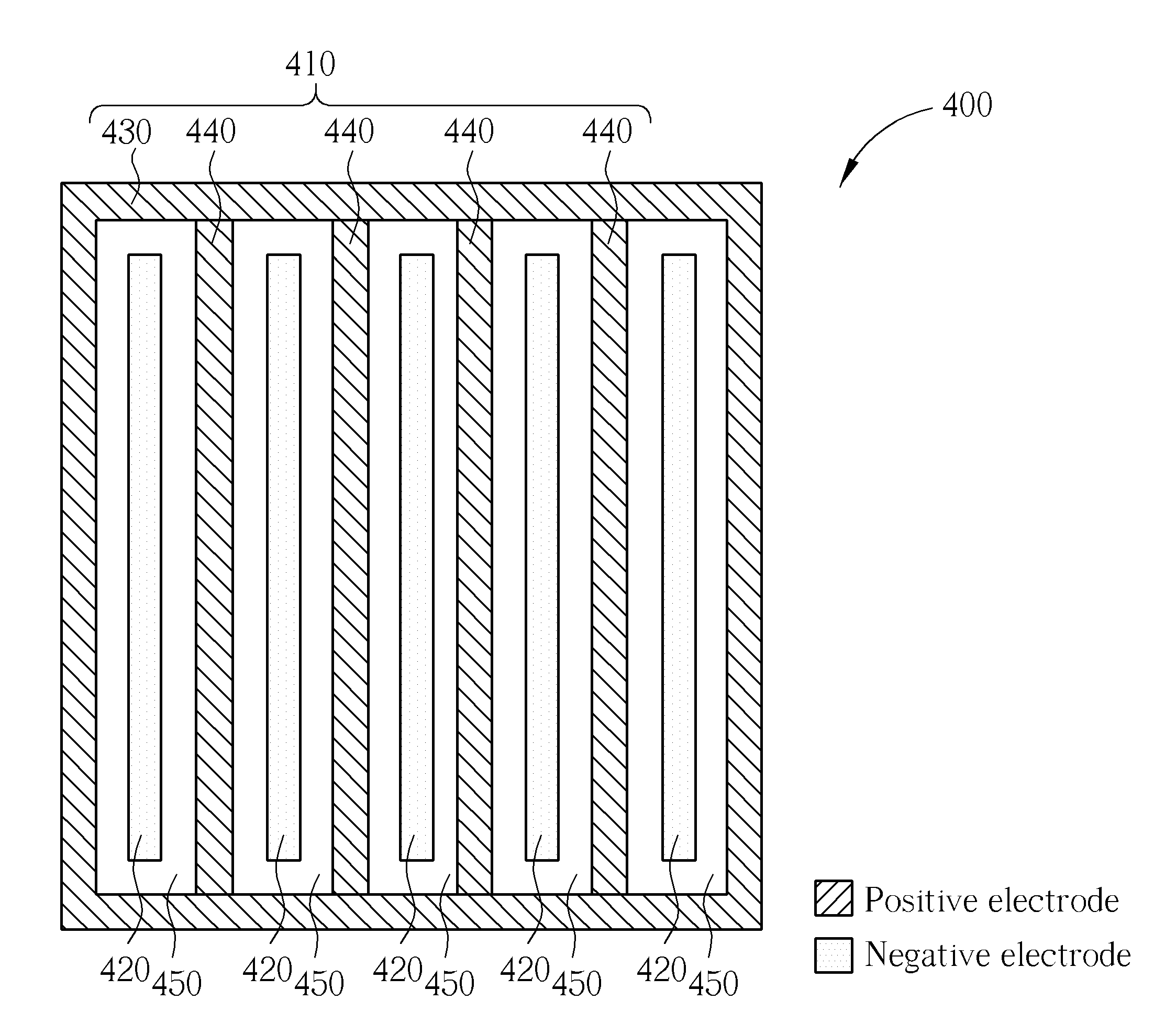

Semiconductor capacitor structure and layout pattern thereof

InactiveUS20080237792A1Improve capacitance effectIncrease unit capacitySemiconductor/solid-state device detailsSolid-state devicesCapacitanceSemiconductor

The present invention provides a metal-oxide-metal (MOM) capacitor structure having a plurality of symmetrical ring type sections. The MOM capacitor structure of the present invention does not need photomasks above standard CMOS process, and thus the process cost is cheaper. In addition, due to the semiconductor process improvement, a significantly large number of metal layers can be stacked in the MOM capacitor structure, and since the distance between the metal layers becomes smaller, the unit capacitance will be increased.

Owner:REALTEK SEMICON CORP

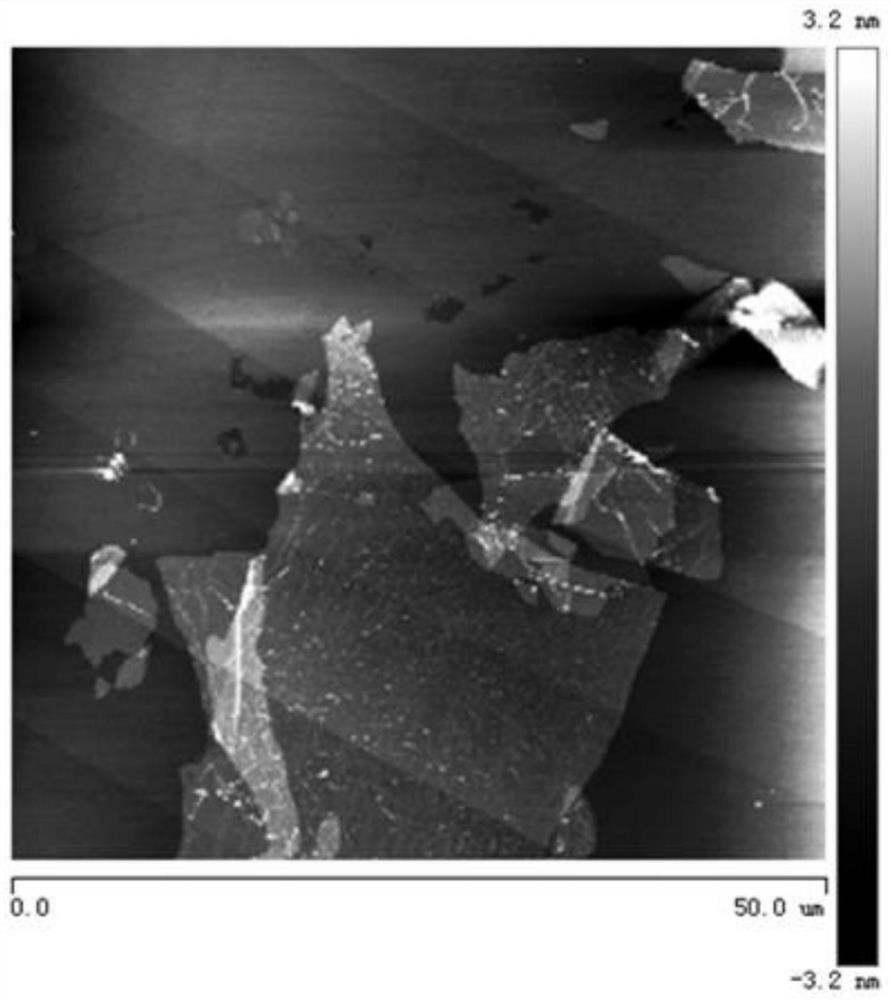

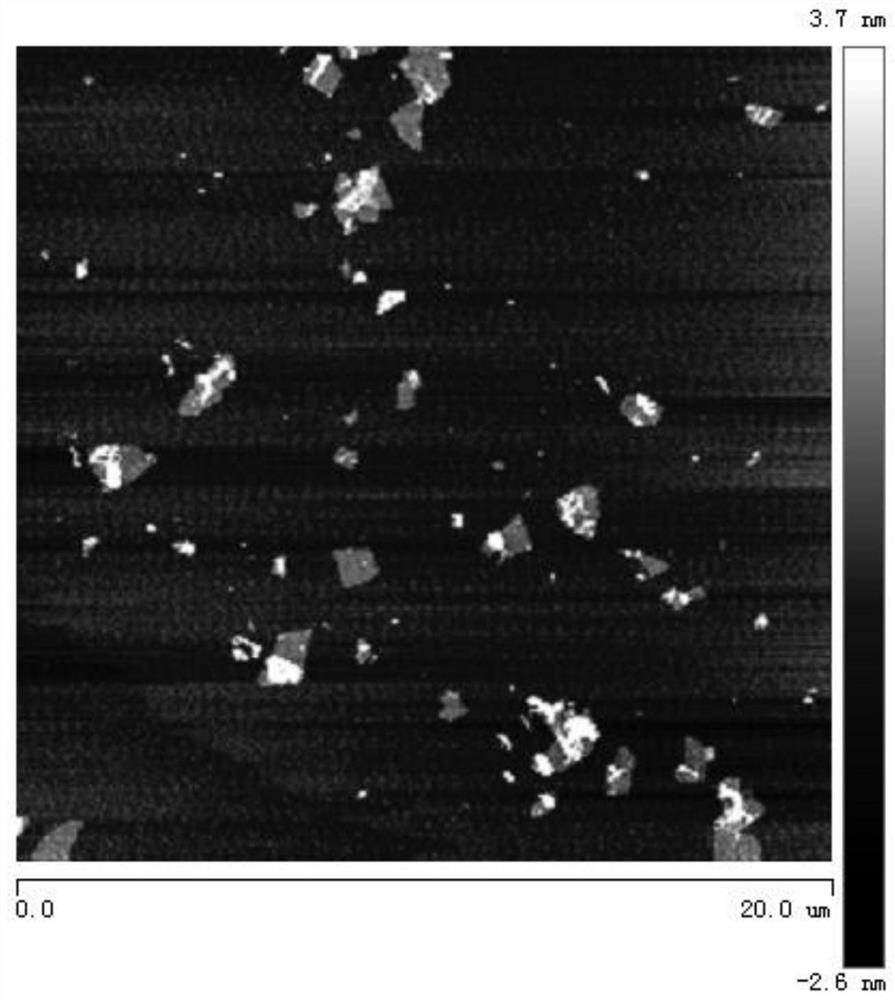

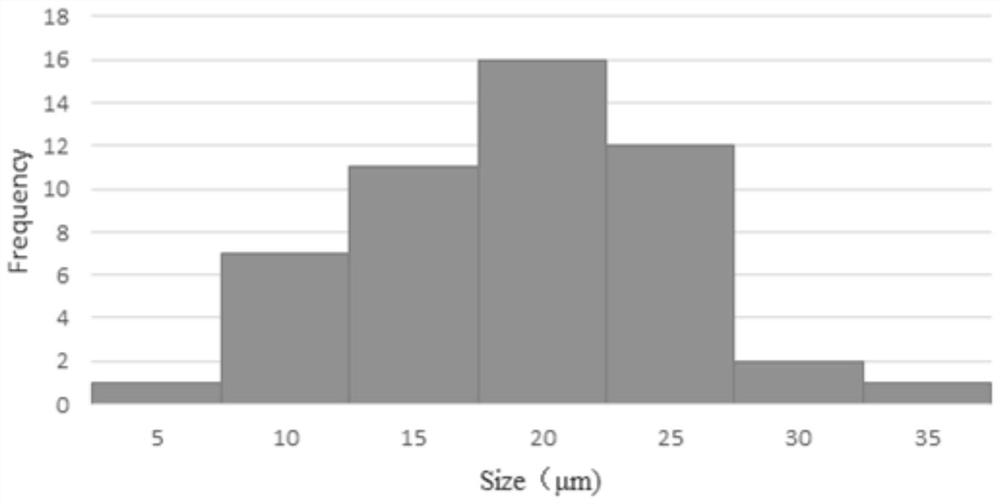

Low-viscosity graphene oxide slurry and preparation method thereof, and graphene oxide film and preparation method thereof

The invention provides low-viscosity graphene oxide slurry and a preparation method thereof, a graphene oxide film and a preparation method thereof, and a graphene heat conduction film and a preparation method thereof. According to the method mainly adopted by the invention, the graphene oxide is subjected to superfine grinding under the actions of high-pressure shearing, high-speed impact and strong holes, and the sheet diameter of the graphene oxide is reduced, so that the viscosity of the graphene oxide slurry is reduced, the solid content of the graphene oxide slurry is improved, and the efficiency of coating the graphene oxide slurry into a graphene oxide film is improved.

Owner:CHANGZHOU FUXI TECH CO LTD

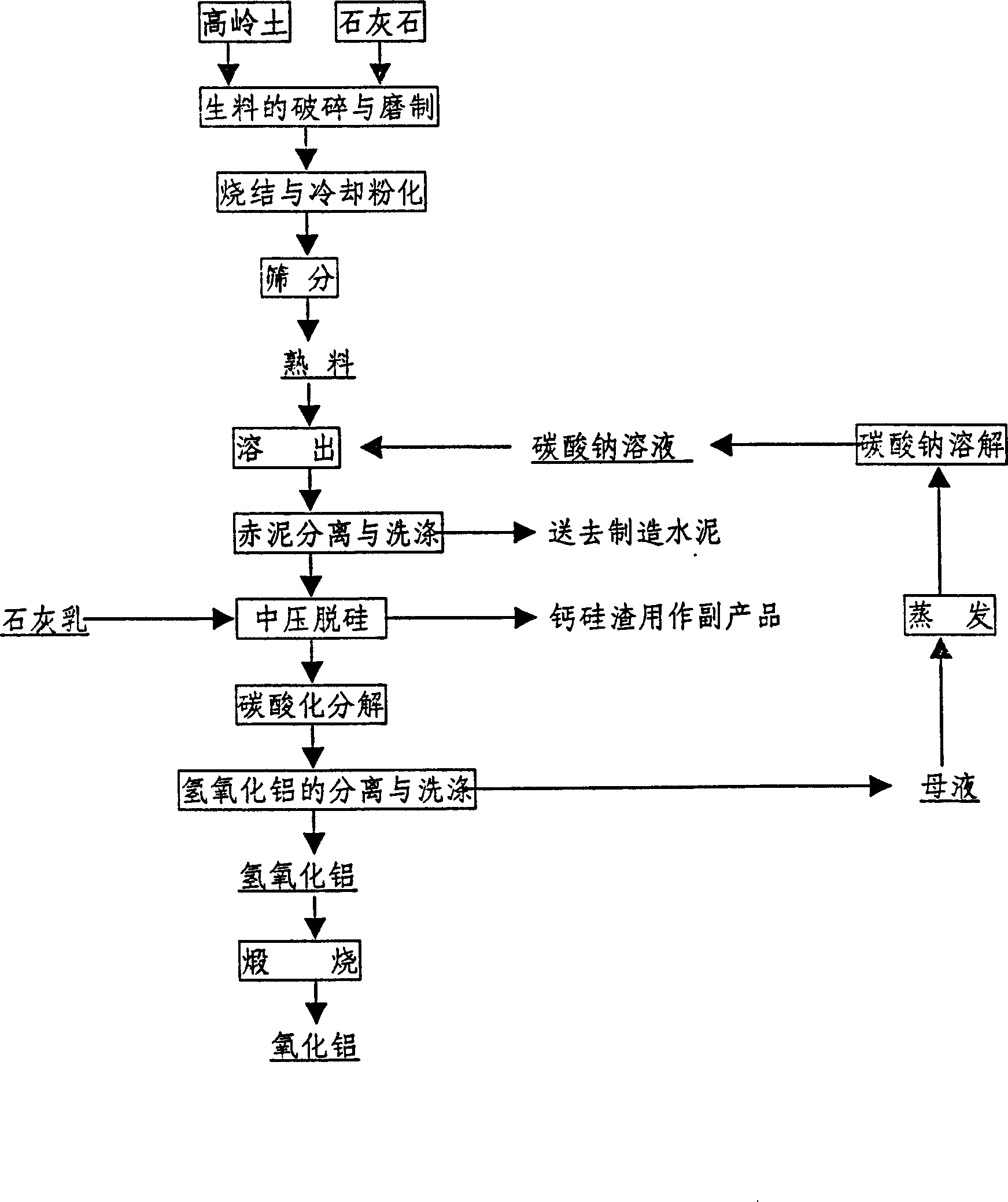

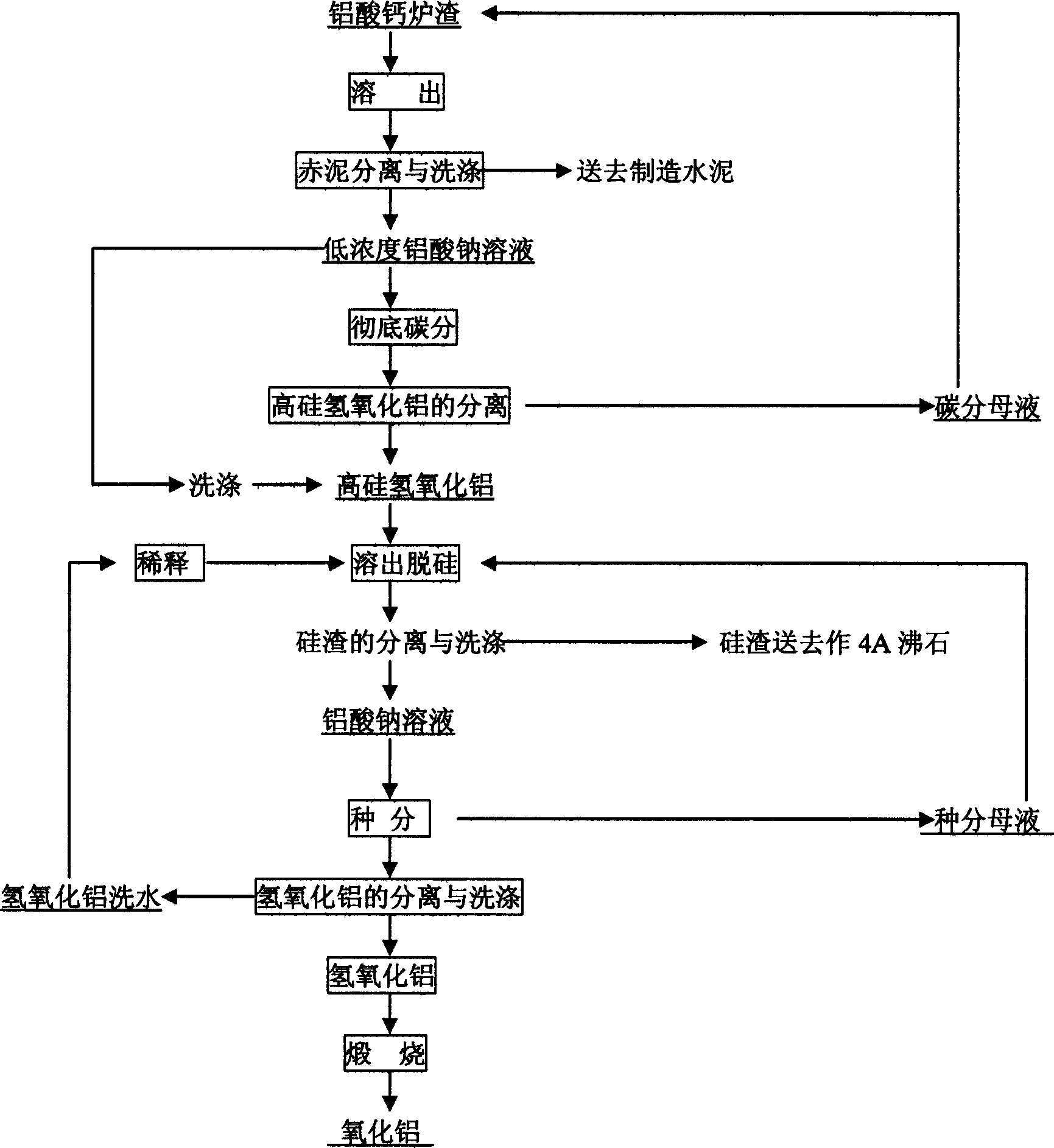

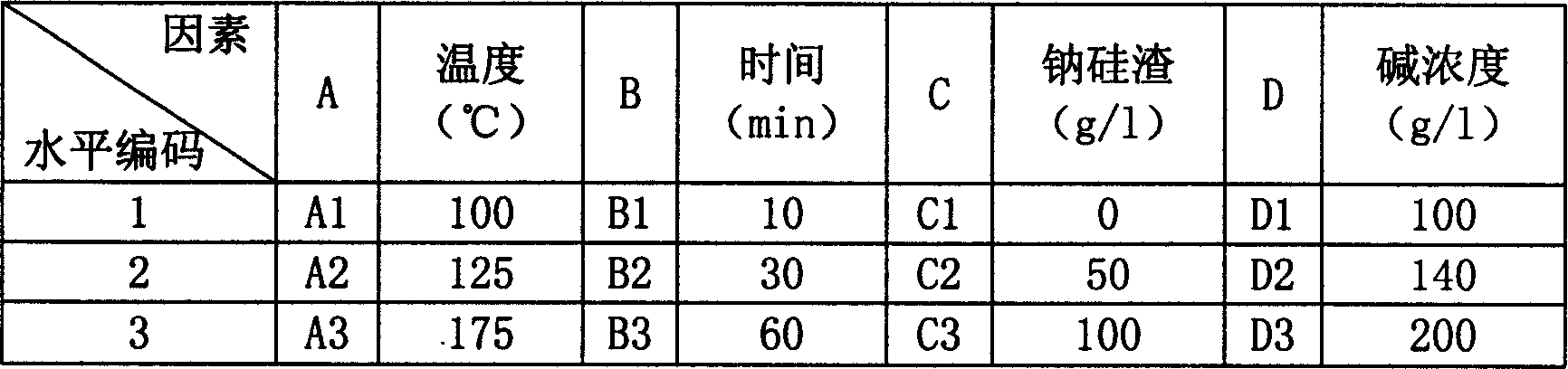

Technique for extracting alumina from materiel containing calcium aluminate

InactiveCN1562756AImprove product qualityStable productionAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminateDecomposition

The invention provides a new technology for extracting aluminium oxide from the material containing carbon aluminate. The carbon aluminate is dissolved out the material by weak sodium carbonate solution to be made into carbon aluminate solution that density is less than 100 g / f, gas CO2 is send into the carbon aluminate solution to do decomposition to generate high-silicon aluminium hydroxide and carbon decomposition mother solution which circulately dissolving out carbon aluminate, the high-silicon aluminium hydroxide is processed by low-temp. dissolving, seed-decomposed decomposing and burning to produce quality sand-type aluminium oxide.

Owner:邝中

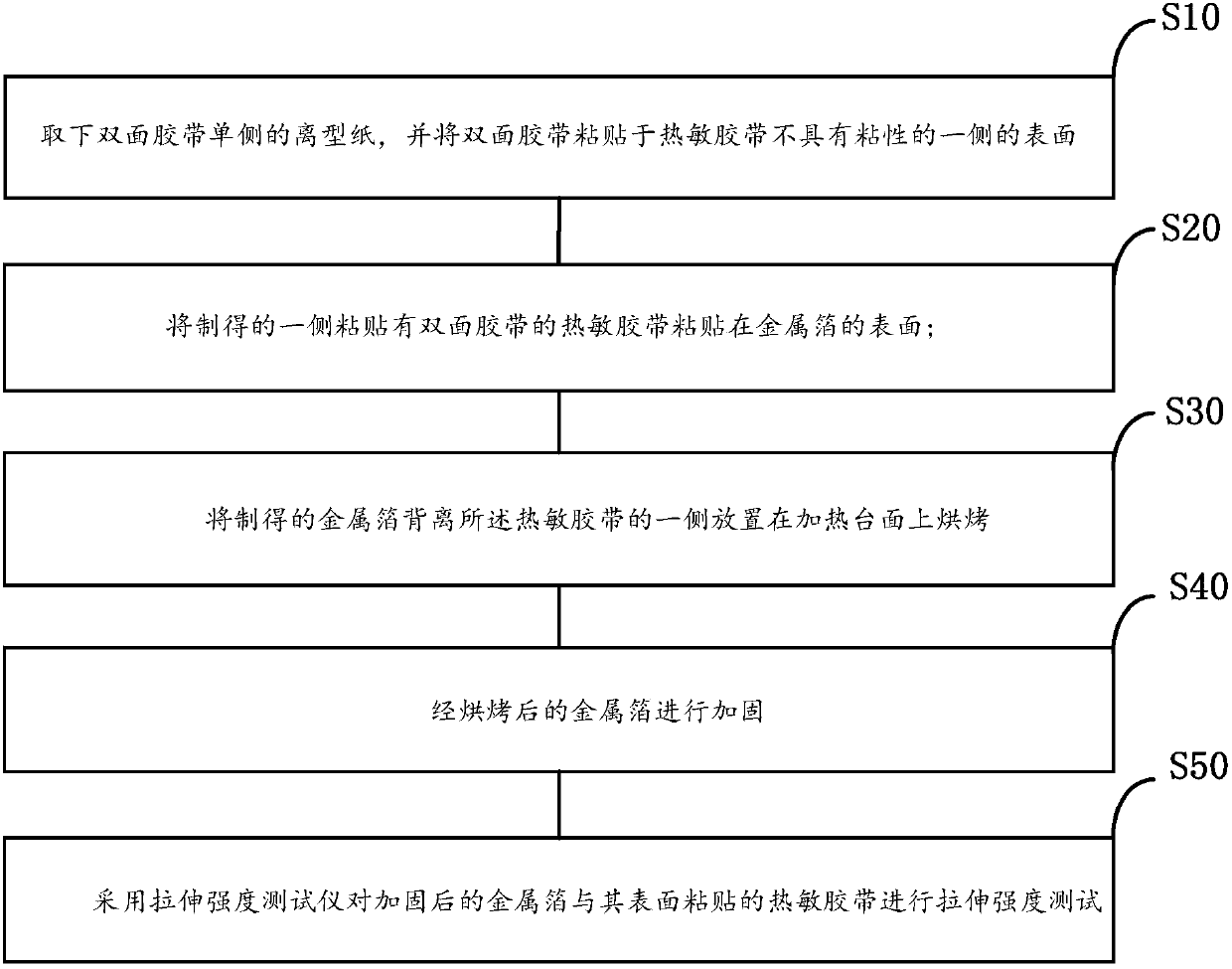

Heat-sensitive adhesive tape adhesion detection method

ActiveCN107643246AAvoid the phenomenon of adhesive performanceThe foaming effect is consistentUsing mechanical meansMaterial analysisCooking & bakingMetal foil

The present invention provides a heat-sensitive adhesive tape adhesion detection method, which comprises: S10: removing release paper from the single side of a double-sided adhesive tape, and adheringthe double-sided adhesive tape onto the surface of the non-sticky side of a heat-sensitive adhesive tape; S20: adhering the prepared heat-sensitive adhesive tape with the double-sided adhesive tape adhered on the non-sticky side onto the surface of metal foil; S30: placing the metal foil side away from the heat-sensitive adhesive tape onto a heating table surface, and baking; S40: strengthening the metal foil baked in the step S30; and S50: testing the tensile strength of the strengthened metal foil and the heat-sensitive adhesive tape adhered on the surface of the metal foil by using a tensile strength tester. According to the present invention, with the detection method, the important parameters of the lithium battery preparation process can be accurately obtained in the case of the lowcost, the economic cost in the lithium battery production can be substantially reduced, and the unit capacity of the lithium-ion battery can be effectively improved.

Owner:新丰杰力电工材料有限公司

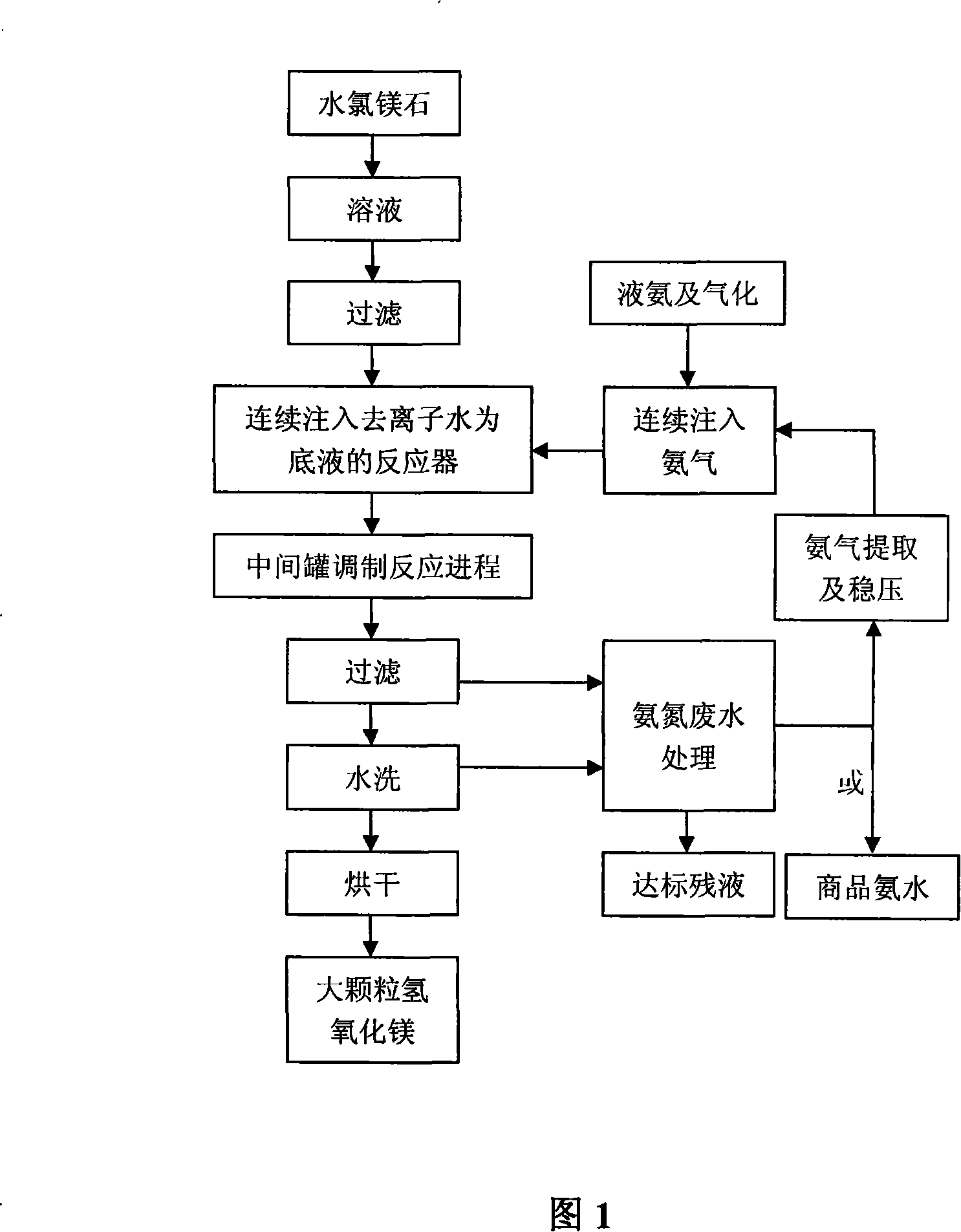

Continuous preparation method of high-purity magnesium hydroxide

The invention provides a method for continuously preparing highly pure magnesium hydroxide which relates to a method for continuously producing highly pure magnesium hydroxide with bischofite as raw material and ammonia as precipitant. The method is characterized in that: a treated bischofite is prepared into a solution with the concentration of 0.5 mol / L-4 mol / L, the bischofite solution and ammonia gas are added continuously after the reaction begins and the chemical reaction for depositing the magnesium hydroxide is carried out continuously. Characteristics of the reaction vessel utilization ratio, the productive capacity of unit volume, technical reliability and stability and so on of the method are greatly improved compared with intermittent reaction technology. The base liquid does not need to be replaced or heated repeatedly, thus energy-saving effect is distinct and labor productivity is high. The method can be used for obtaining magnesium hydroxide with the granularity of 10 microns-100 microns and the purity of 99 percent-99.999 percent. The ammonia nitrogen treatment of the tail solution adopts a commercial method that meets environmental protection requirement. The product produced by the invention has large granule size, high purity, more specifications, low cost, high equipment utilization rate and low one-time investment and has no pollution to the environment.

Owner:DALIAN MARITIME UNIVERSITY +1

Rapid start method for vertical continuous annealing furnace

ActiveCN108070707AExtension of timeIncrease unit capacityFurnace typesHeat treatment furnacesStart timeHydrogen

The invention relates to a rapid start method for a vertical continuous annealing furnace. By adoption of the rapid start method for the vertical continuous annealing furnace, the problem that in theprior art, after a vertical continuous annealing furnace is stopped to be maintained, the furnace start time is long, and consequentially, the production rhythm and productivity are affected is solved. The rapid start method for the vertical continuous annealing furnace comprises the steps that after the vertical continuous annealing furnace is maintained, start conditions of the vertical continuous annealing furnace are confirmed; pure-nitrogen purging is conducted on the inside atmosphere of the vertical continuous annealing furnace; the vertical continuous annealing furnace is heated; hydrogen-containing purging is conducted on the inside atmosphere of the vertical continuous annealing furnace; and strip steel of the vertical continuous annealing furnace is controlled to start to operate. The rapid start method for the vertical continuous annealing furnace is simple and easy to operate, and the production efficiency and productivity of the vertical continuous annealing furnace are effectively improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Continuous production method of epoxy chloropropane by hydrogen peroxide process

The invention provides a preparation method of chloroepoxy propane by chloropropene epoxidation. Chloropropene, a solvent and titanium silicalite molecular sieve catalyst fine particles are put in a reaction kettle for reaction at the temperature of 10-80 DEG C. The method is characterized in that the reaction kettle is a single kettle or multistage slurry bed reaction kettles with same or different volumes which are connected in series; the reaction solution needs not to be homogeneous phase, slurry particles of the chloropropene, the solvent and the titanium silicalite molecular sieve catalyst are added to a first stage reaction kettle by a metering pump, hydrogen peroxide is dropwise added to the first stage reaction kettle or each stage of the reaction kettles, the reaction occurs in a weakly acidic condition, materials are subject to oil-water delamination after the reaction to be divided into oil-phase slurry and water-phase slurry; the catalyst is suspended in the water phase, and the oil phase is sent to a rectification tower to separate the chloropropene, the epichlorohydrin and trace methanol; the water phase slurry is filtered, a catalyst filter cake or concentrated slurry is directly beaten by the solvent, and pumped to a first stage epoxidation reaction kettle, the water phase slurry contains the methanol, trace epichlorohydrin and the water which is generated by the reaction and the water which is taken by the hydrogen peroxide, the trace methanol and the epichlorohydrin are separated out by negative pressure rectification, and the recovered methanol is used for preparation of the catalyst slurry. The method has the advantages of simple process, little solvent consumption and high product separation yield, and is available for industrialized production.

Owner:JIANGSU YANGNONG CHEM GROUP +2

Capacitor structure and metal layer layout thereof

InactiveUS20090296313A1Good capacitance characteristicsIncrease unit capacityFixed capacitor dielectricSemiconductor/solid-state device detailsEngineeringDielectric layer

A capacitor structure includes: a first metal layer including: a first frame structure including a first main frame and at least a first frame strip coupled to the first main frame for separating the first main frame to a plurality of first frame sections; and a plurality of first strips, each of the plurality of first strips positioned and isolated in one of the plurality of first frame sections; a second metal layer including: a second frame structure including a second main frame and at least a second frame strip coupled to the second main frame for separating the second main frame to a plurality of second frame sections; and a plurality of second strips, each of the plurality of second strips positioned and isolated in one of the plurality of second frame sections; and a dielectric layer, formed between the first metal layer and the second metal layer.

Owner:MEDIATEK INC

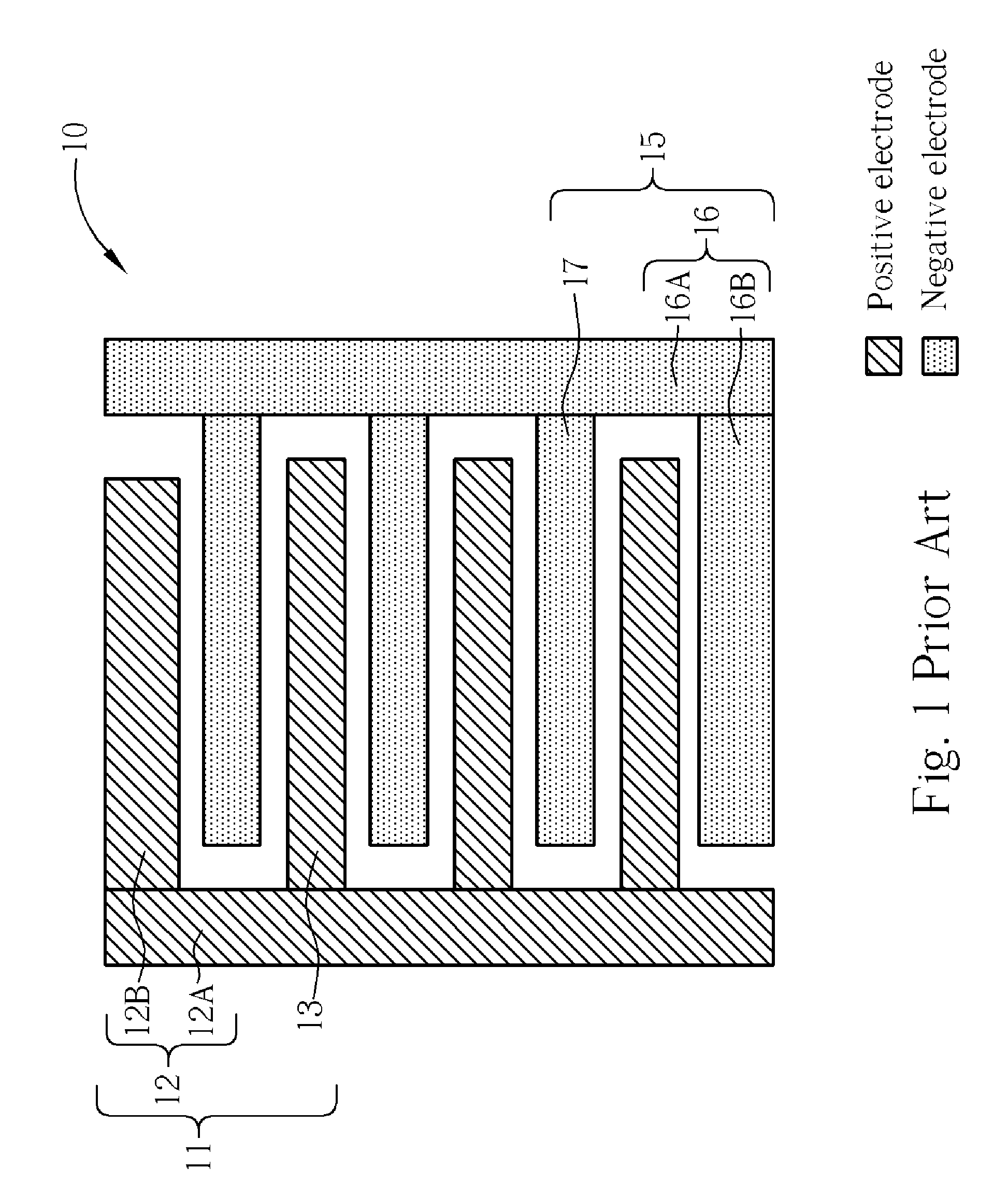

Metal-insulator-metal capacitor and method for manufacturing the same

ActiveUS6989313B2Increase unit capacityAvoid deformationTransistorSolid-state devicesInsulation layerEngineering

A capacitor has a lower electrode formed on an insulation layer, a dielectric layer formed on the lower electrode, an upper electrode layer formed on the dielectric layer, and a first protection layer pattern formed on the upper electrode layer. The upper electrode layer is etched using the first protection layer pattern to form an upper electrode. A second protection layer is formed enclosing the dielectric layer, the upper electrode and the first protection layer pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com