Technique for extracting alumina from materiel containing calcium aluminate

A technology of alumina and calcium aluminate, which is applied in the preparation of alkaline earth metal aluminate/alumina/aluminum hydroxide, can solve the problems of large loss of alumina, large material flow, and large material flow, and achieve expanded production capacity, increase unit capacity, and reduce the effect of material flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

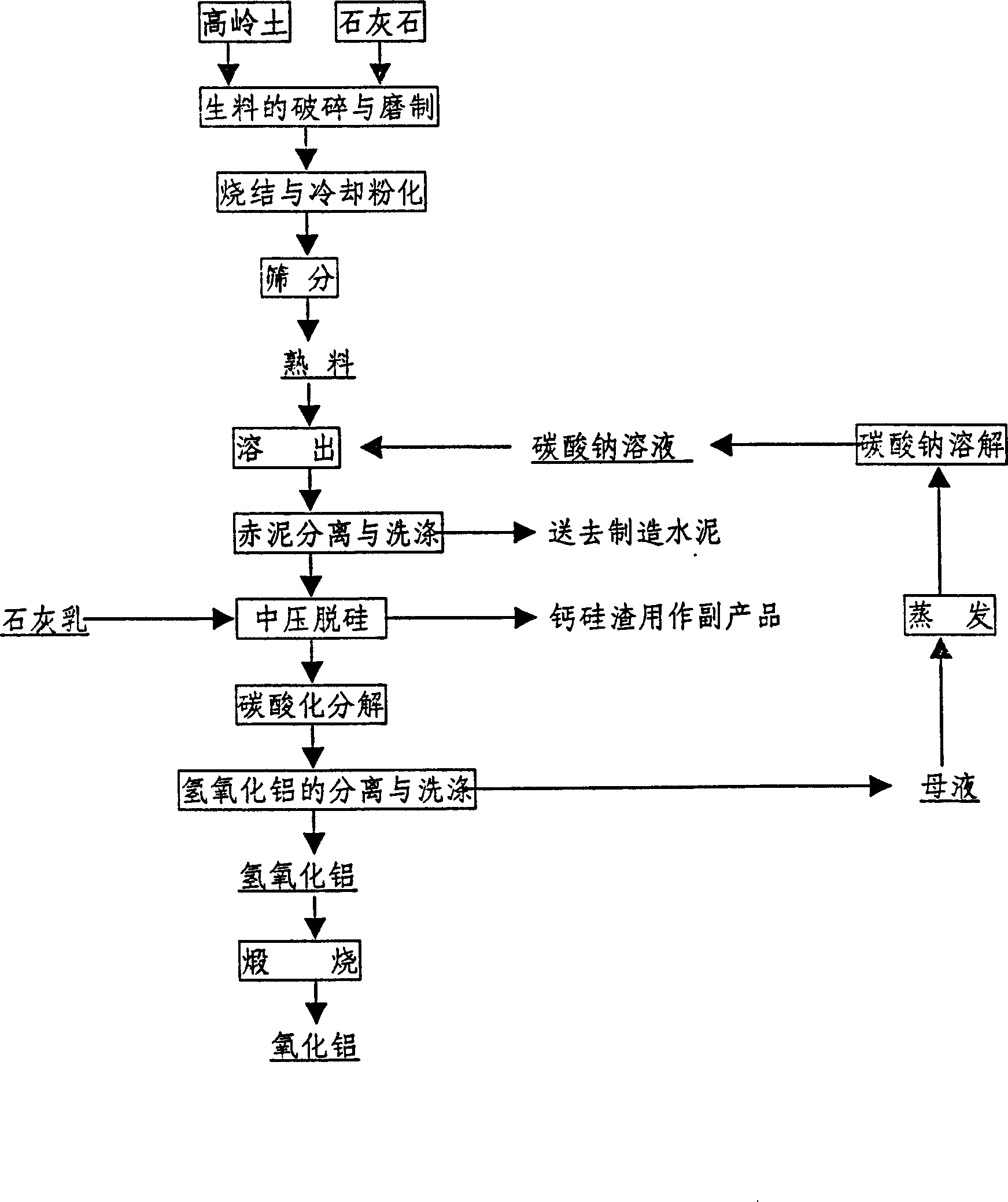

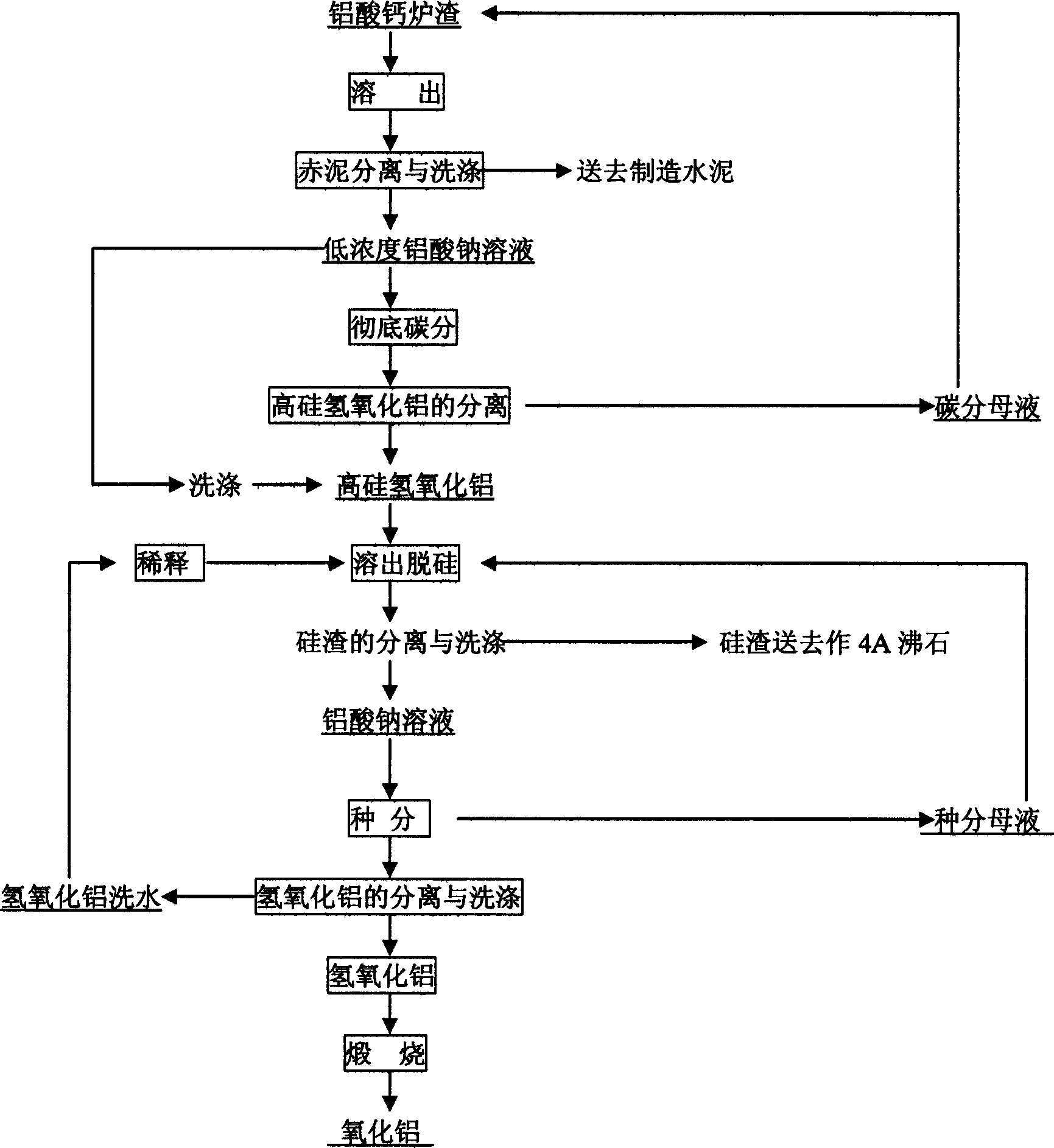

Method used

Image

Examples

Embodiment Construction

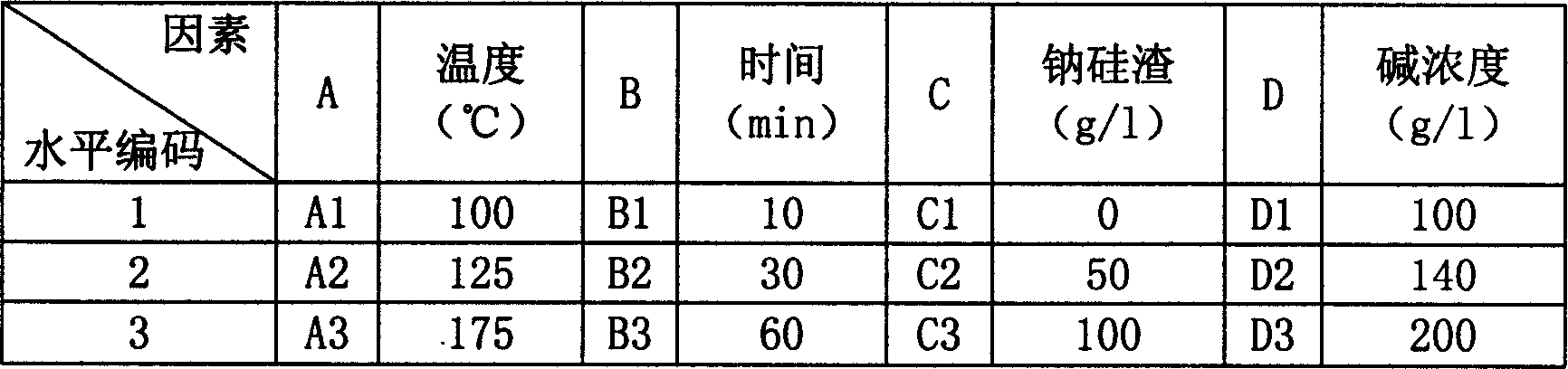

[0030] Test 1: Calcium aluminate dissolution condition test

[0031] 1. Test procedure:

[0032] 1. Calculate

[0033] Calculate the required amount of material according to the conditions of a single test, and make a test record plan to determine the physical properties of the required material, such as weight, volume and density. Make relevant records for each of the following steps, such as sampling time, concentration and moisture content, etc.

[0034] 2. Preparation of adjustment solution

[0035] According to the calculated results, add the required amount of water in the adjustment liquid tank (after the cycle is formed, add the amount of carbon mother liquor, not enough to add from the spare tank), add the required anhydrous sodium carbonate, and heat it to dissolve. After heating up to the required test temperature, pump it into the dissolution tank.

[0036] 3. Add slag

[0037] Weigh the test slag as required, start stirring, add the slag to the dissolution tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com