Method of manufacturing back contact heterojunction single crystalline silicon solar cell

A technology of solar cells and monocrystalline silicon, applied in the field of solar photovoltaics, to achieve the effects of overcoming technical barriers, low cost, and simple process routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

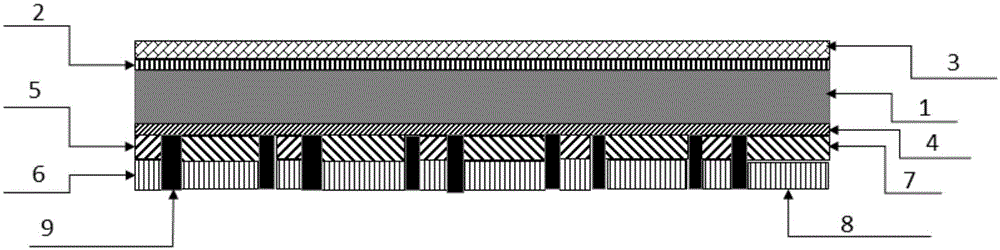

[0081]The structure of the back contact heterojunction solar cell prepared by the three-layer mask coating technology and electroplating technology provided in this example is as follows: figure 1 shown, including the following steps:

[0082] (1) Single crystal silicon cleaning, damage removal, texturing

[0083] Select an N-type monocrystalline silicon substrate with a resistivity of 0.5-50 Ω cm and a thickness of 50-500 μm for cleaning, removing the damaged layer, and making texture, which consists of the following steps:

[0084] Cleaning before texturing->remove surface damage of silicon wafer before texturing->texturing silicon wafer->cleaning after texturing->drying

[0085] The sliced wafers were placed in CH 2 In the COOH organic solution, O is passed through the solution 3 , by ultrasonic cleaning. Immediately put the silicon wafer into 20% NaOH alkali solution after cleaning, and corrode it at 78°C for 0.5-1 minute, with an etching rate of 6-10 μm / min, to achi...

Embodiment 2

[0103] The structure of the back contact heterojunction solar cell prepared by the three-layer mask coating technology and electroplating technology provided in this example is as follows: figure 1 shown, including the following steps:

[0104] 1) Monocrystalline silicon cleaning, damage removal, texturing

[0105] Select a P-type monocrystalline silicon substrate with a resistivity of 0.5-50 Ω cm and a thickness of 50-500 μm for cleaning, removing the damaged layer, and making texture, which consists of the following steps:

[0106] Cleaning before texturing->remove surface damage of silicon wafer before texturing->texturing silicon wafer->cleaning after texturing->drying

[0107] The sliced wafers were placed in CH 2 In the COOH organic solution, O3 was introduced into the solution and cleaned by ultrasonic waves. Immediately put the silicon wafer into 20% NaOH alkali solution after cleaning, and corrode it at 78°C for 0.5-1 minute, with an etching rate of 6-10 μm / min, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com