Patents

Literature

60results about How to "Additional processing steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

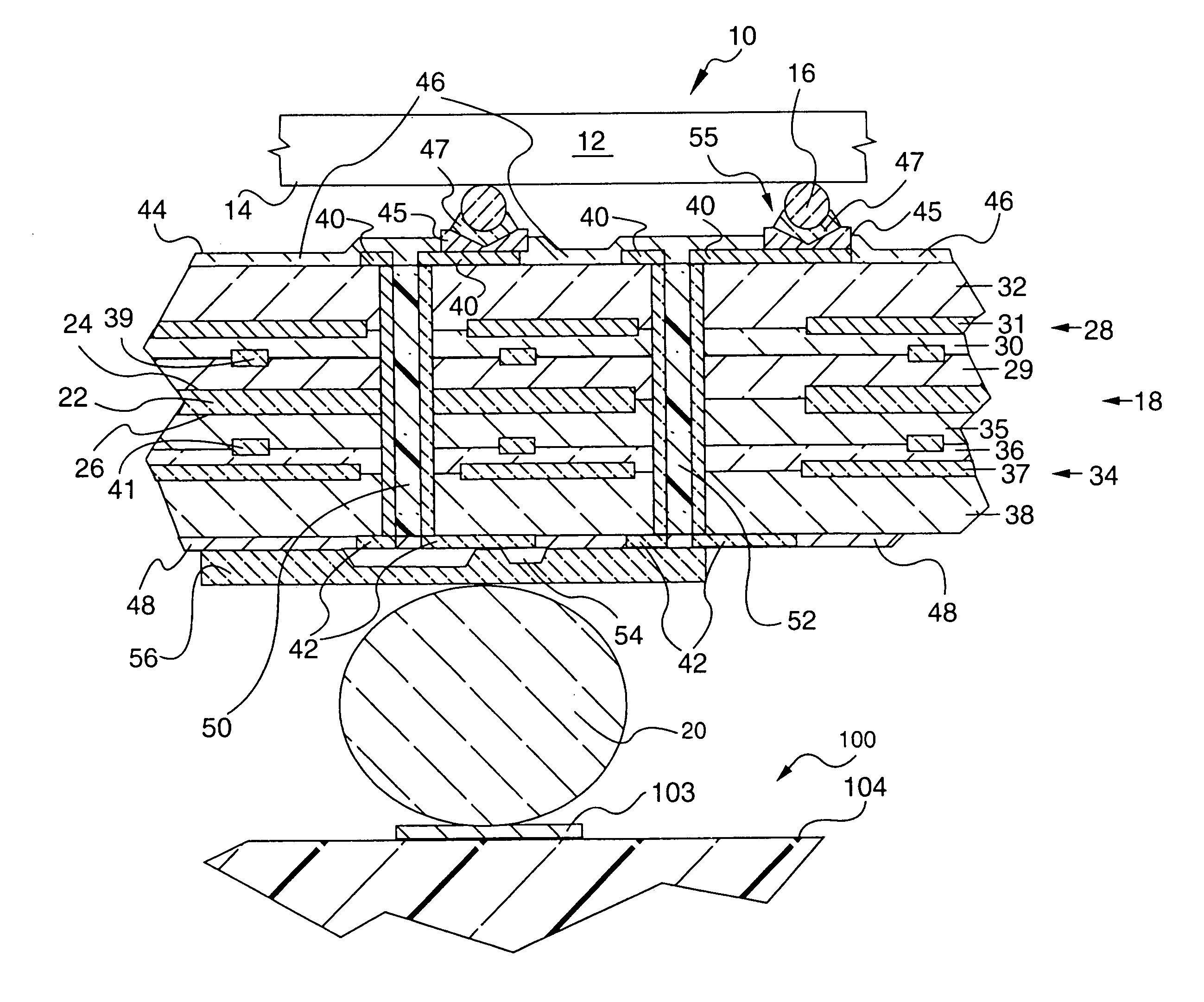

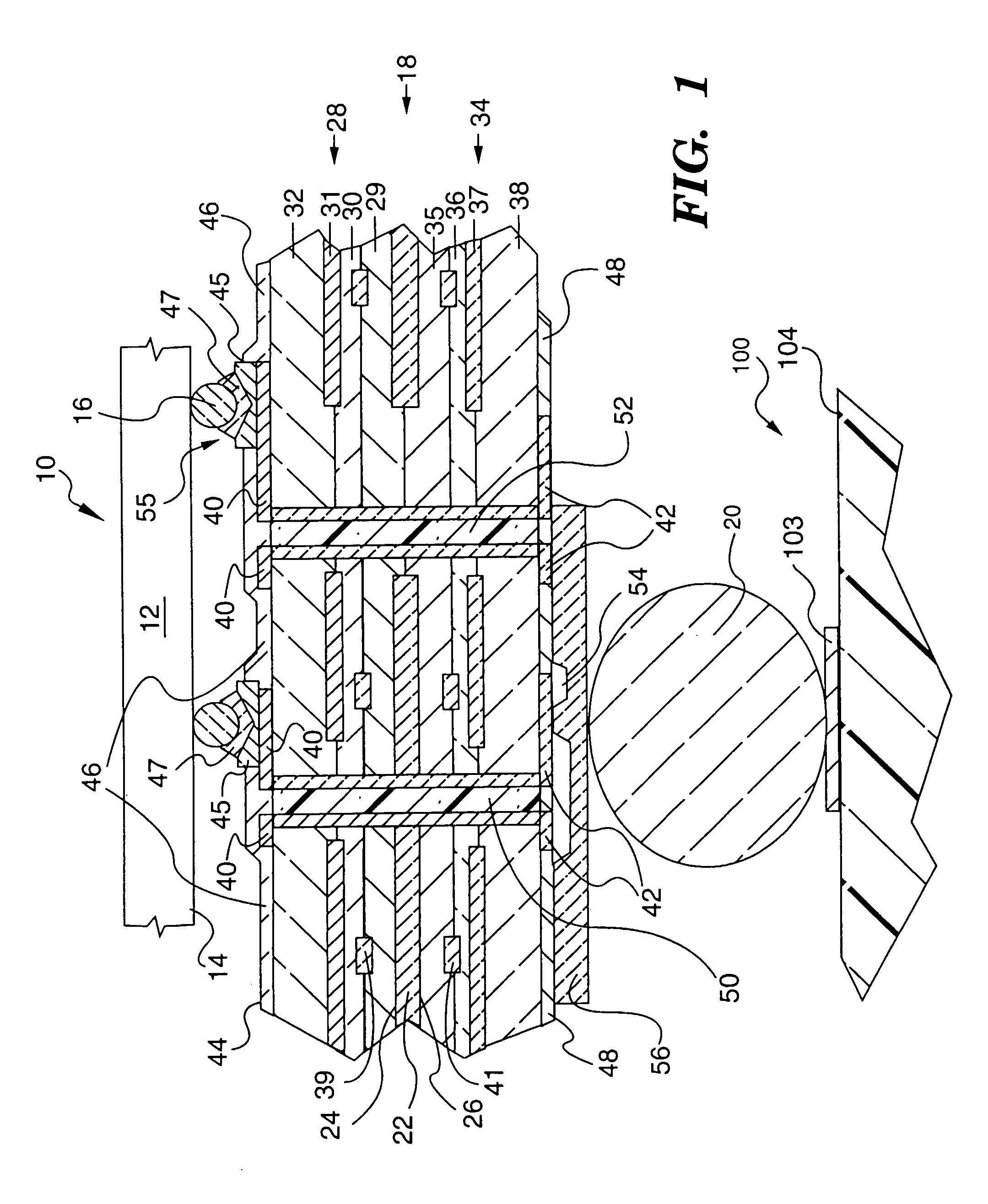

Metal-over-metal devices and the method for manufacturing same

ActiveUS20050077581A1Easy to integrateAdditional processing stepsTransistorSemiconductor/solid-state device detailsFour quadrantsMetal device

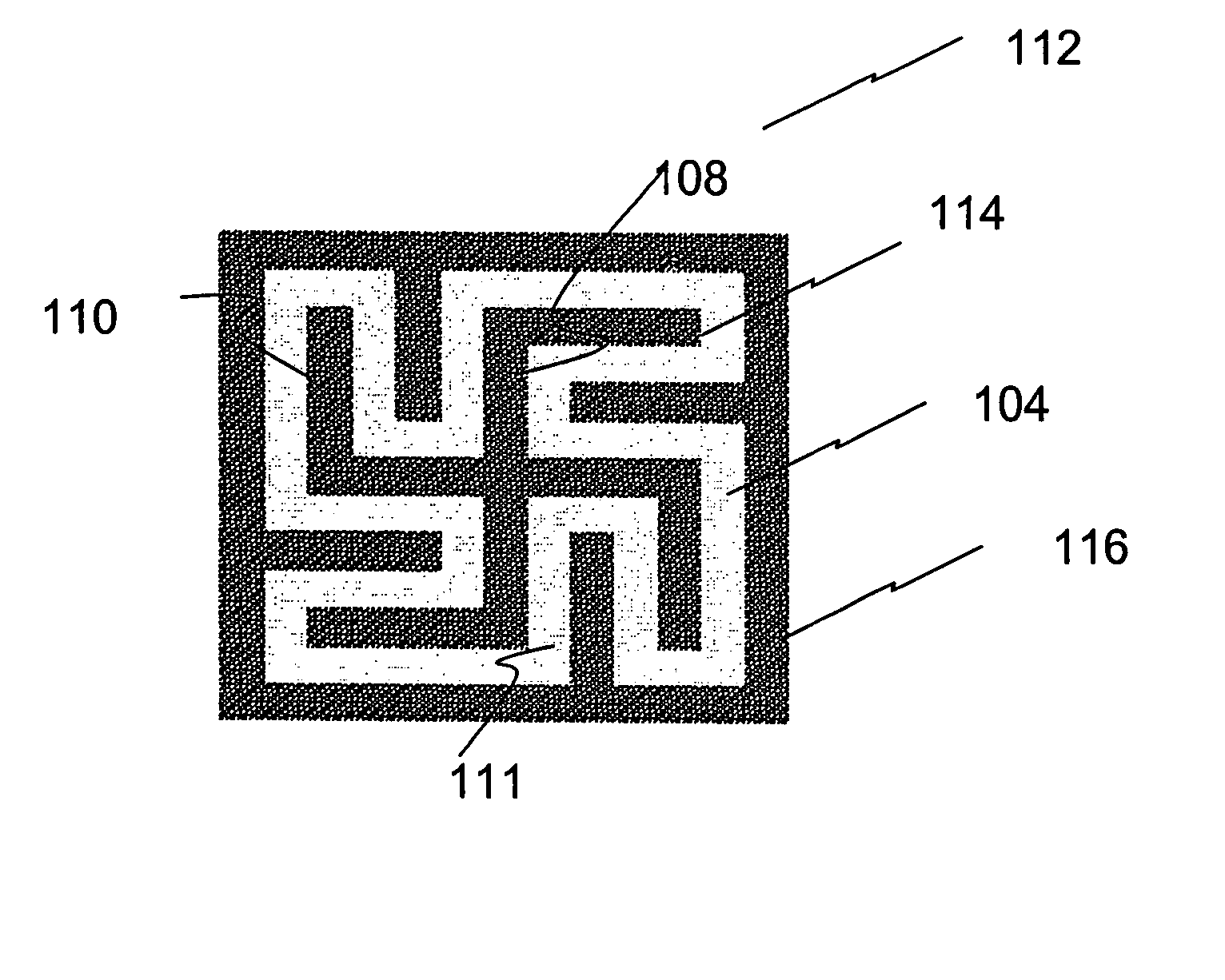

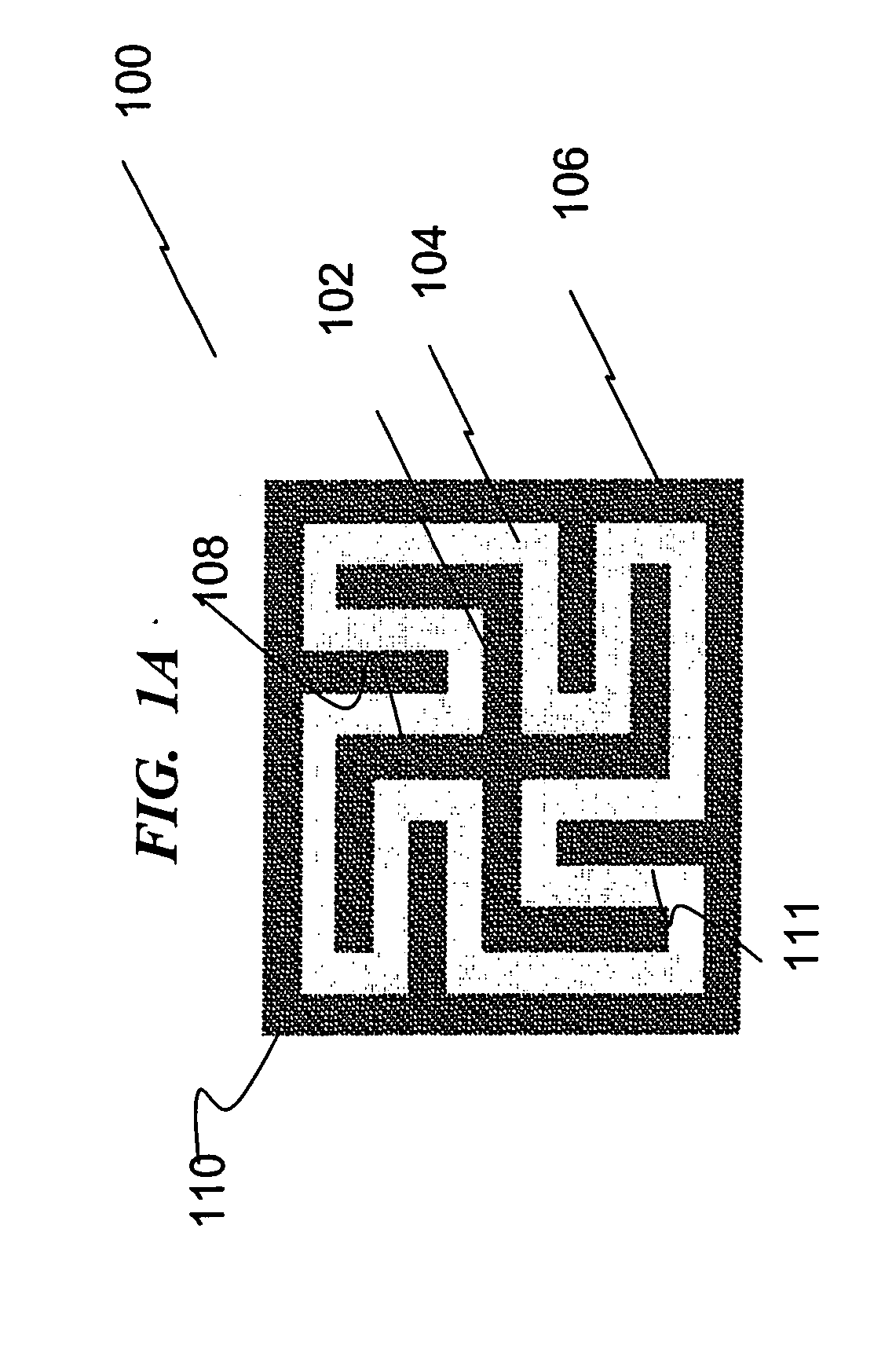

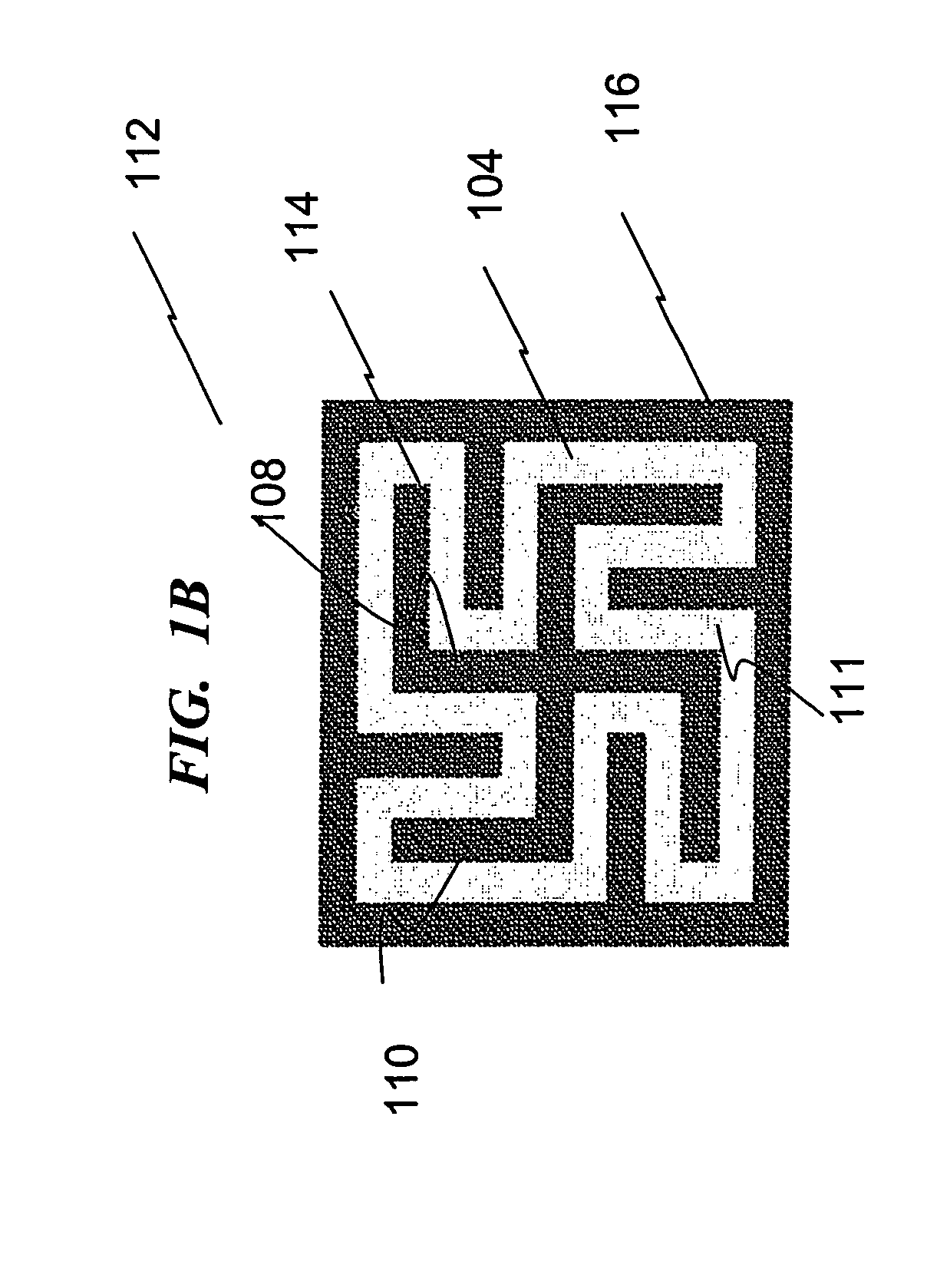

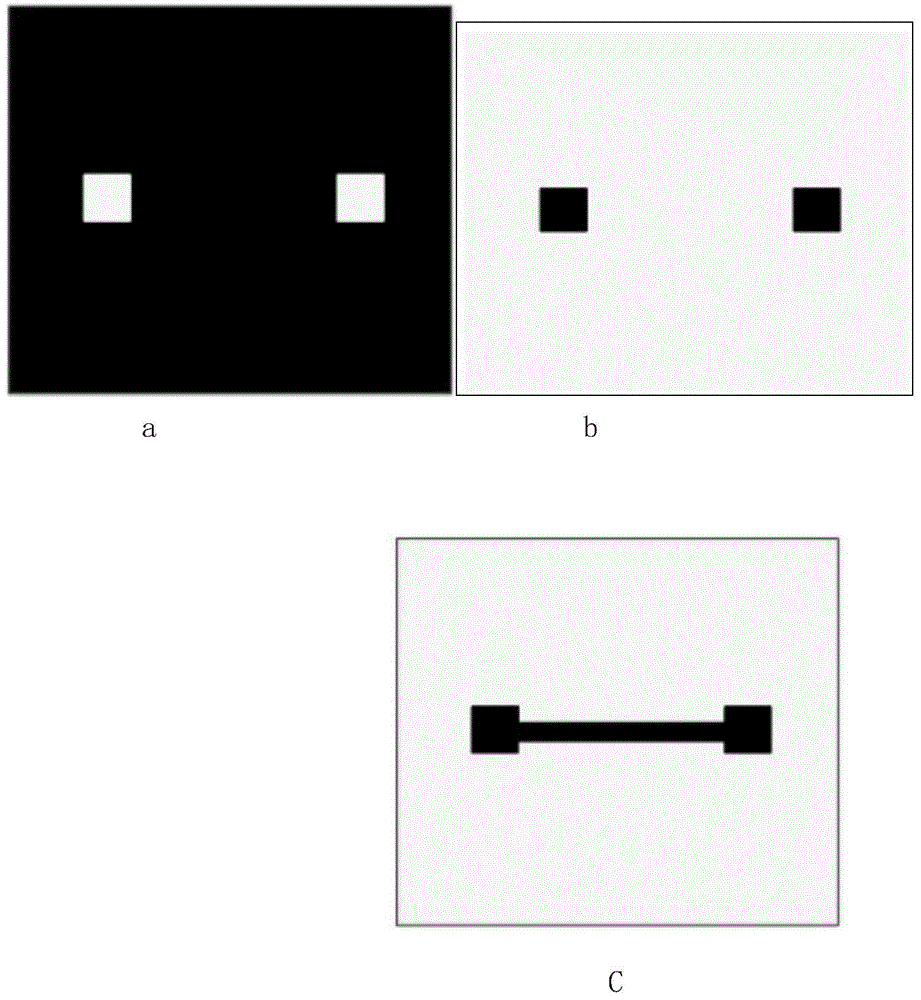

A metal-over-metal (MOM) device and the method for manufacturing same is provided. The device has at least one device cell on a first layer comprising a frame piece and a center piece surrounded by the frame piece. The center piece has a cross-shape center portion defining four quadrants of space between the frame and center pieces. The center piece has one or more center fingers each extending from at least one of the four ends thereof within a quadrant. The frame piece also has one or more frame fingers extending therefrom, each being in at least one quadrant and not being overlapped with the center finger in the same quadrant.

Owner:TAIWAN SEMICON MFG CO LTD

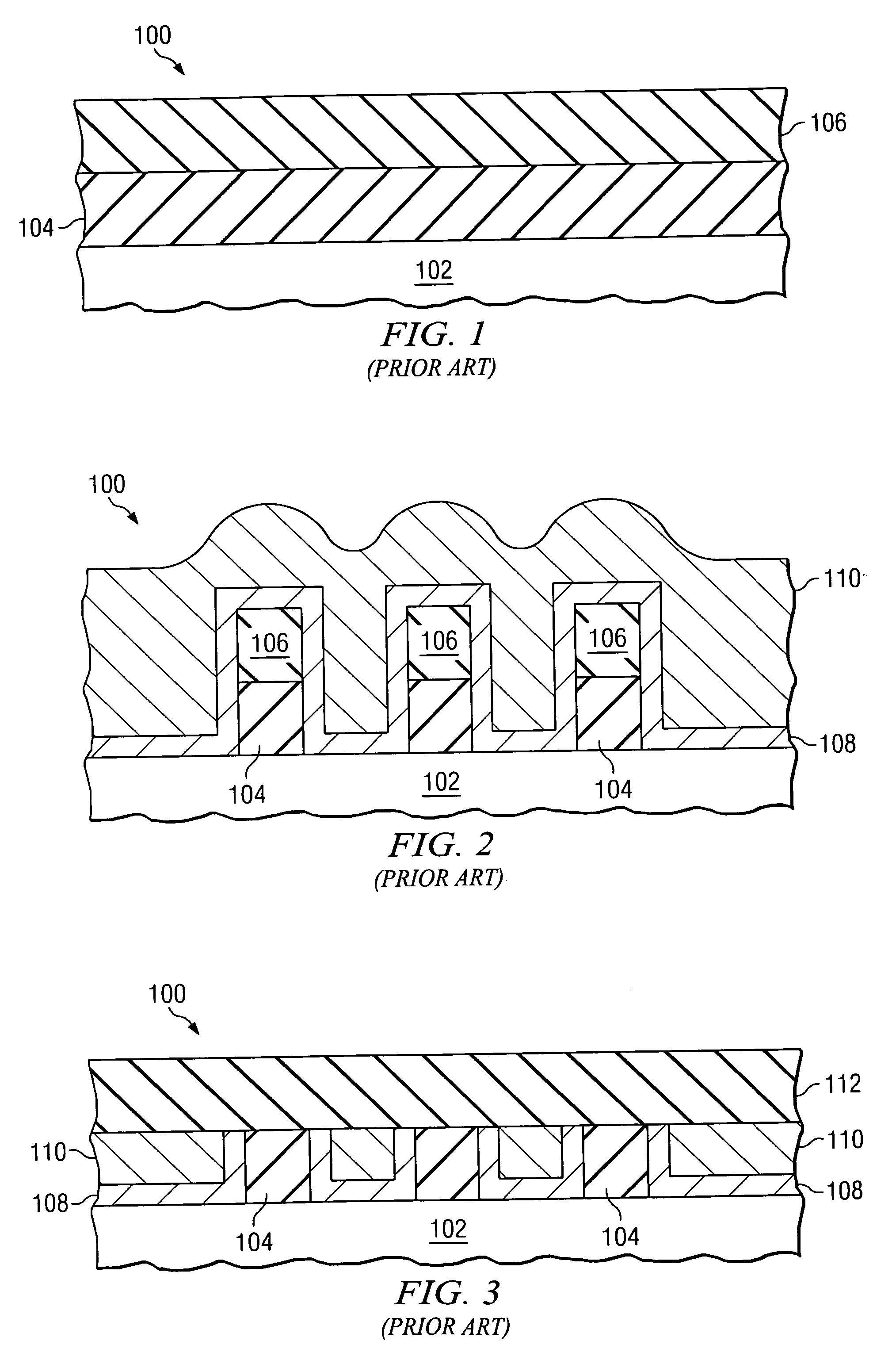

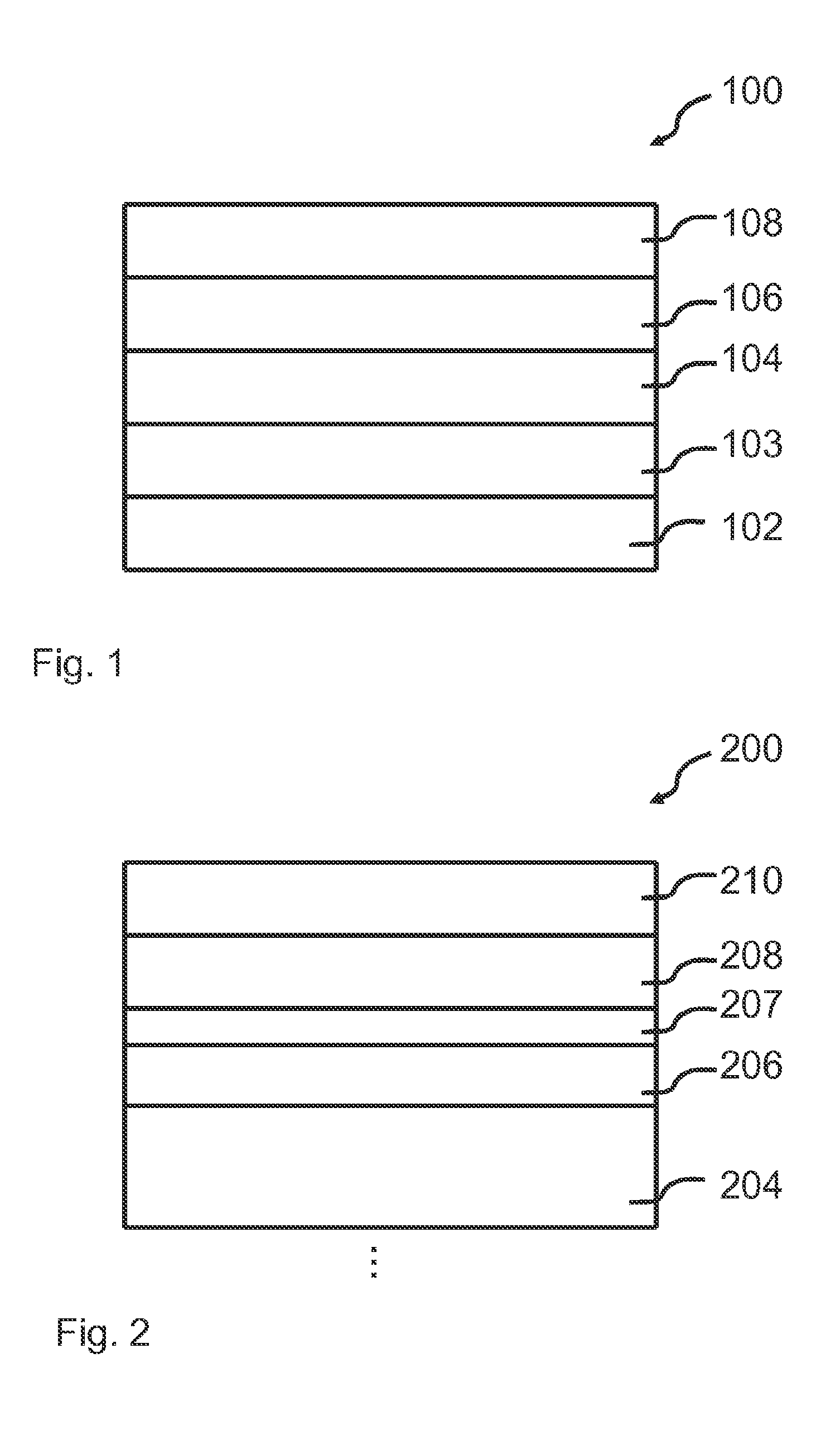

Methods of manufacturing semiconductor devices and structures thereof

InactiveUS20060281295A1Strong structural supportStrong mechanical strengthSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor

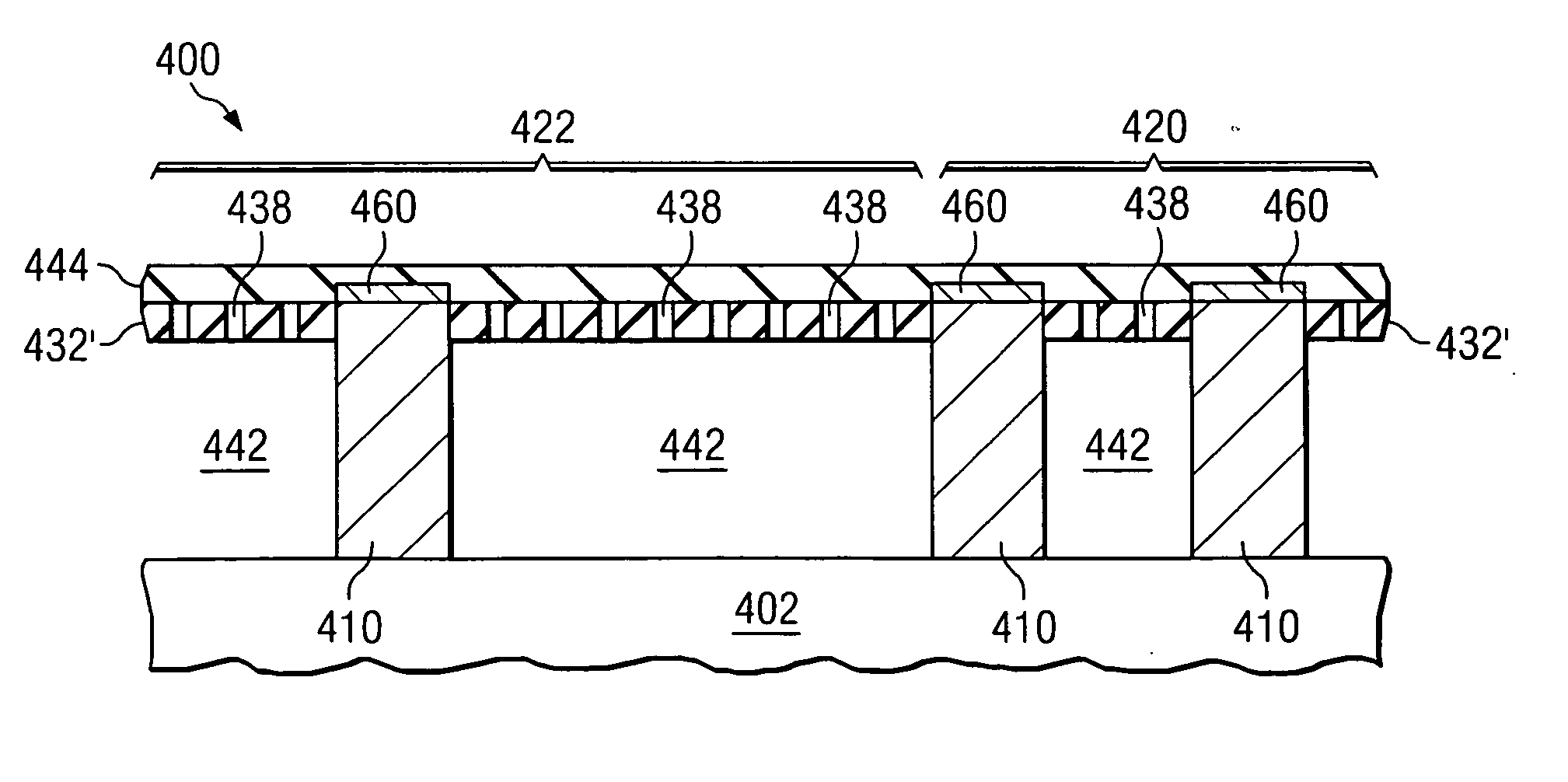

Methods of forming air gaps between interconnects of integrated circuits and structures thereof are disclosed. A first insulating material is deposited over a workpiece, and a second insulating material having a sacrificial portion is deposited over the first insulating material. Conductive lines are formed in the first and second insulating layers. The second insulating material is treated to remove the sacrificial portion, and at least a portion of the first insulating material is removed, forming air gaps between the conductive lines. The second insulating material is impermeable as deposited and permeable after treating it to remove the sacrificial portion. A first region of the workpiece may be masked during the treatment, so that the second insulating material becomes permeable in a second region of the workpiece yet remains impermeable in the first region, thus allowing the formation of the air gaps in the second region, but not the first region.

Owner:INFINEON TECH AG

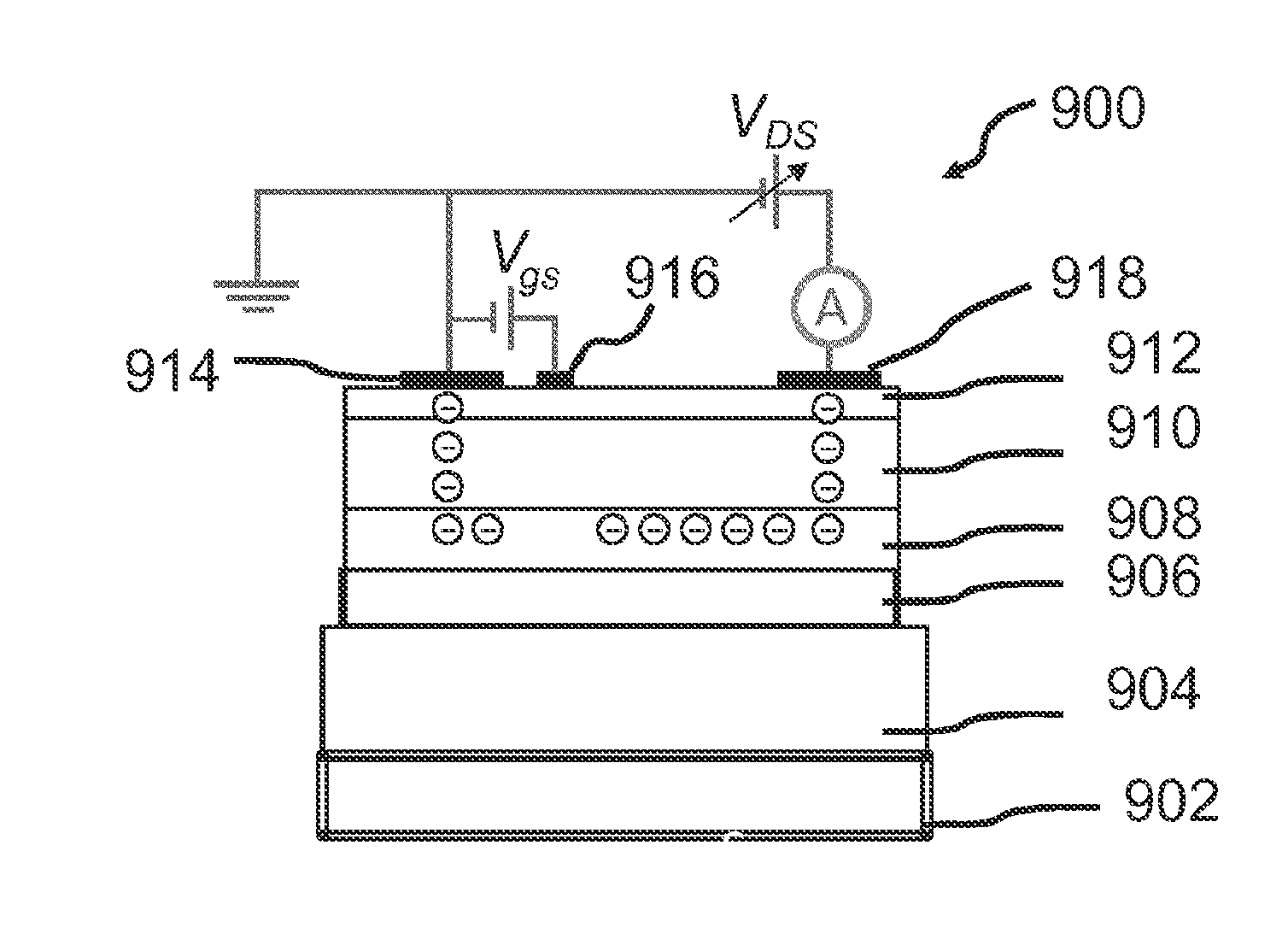

Layer structure for a group-iii-nitride normally-off transistor

A layer structure for a normally-off transistor has an electron-supply layer made of a group-III-nitride material, a back-barrier layer made of a group-III-nitride material, a channel layer between the electron-supply layer and the back-barrier layer, made of a group-III-nitride material having a band-gap energy that is lower than the band-gap energies of the other layer mentioned. The material of the back-barrier layer is of p-type conductivity, while the material of the electron-supply layer and the material of the channel layer are not of p-type conductivity, the band-gap energy of the electron-supply layer is smaller than the band-gap energy of the back-barrier layer. In absence of an external voltage a lower conduction-band-edge of the third group-III-nitride material in the channel layer is higher in energy than a Fermi level of the material in the channel layer.

Owner:AZUR SPACE SOLAR POWER

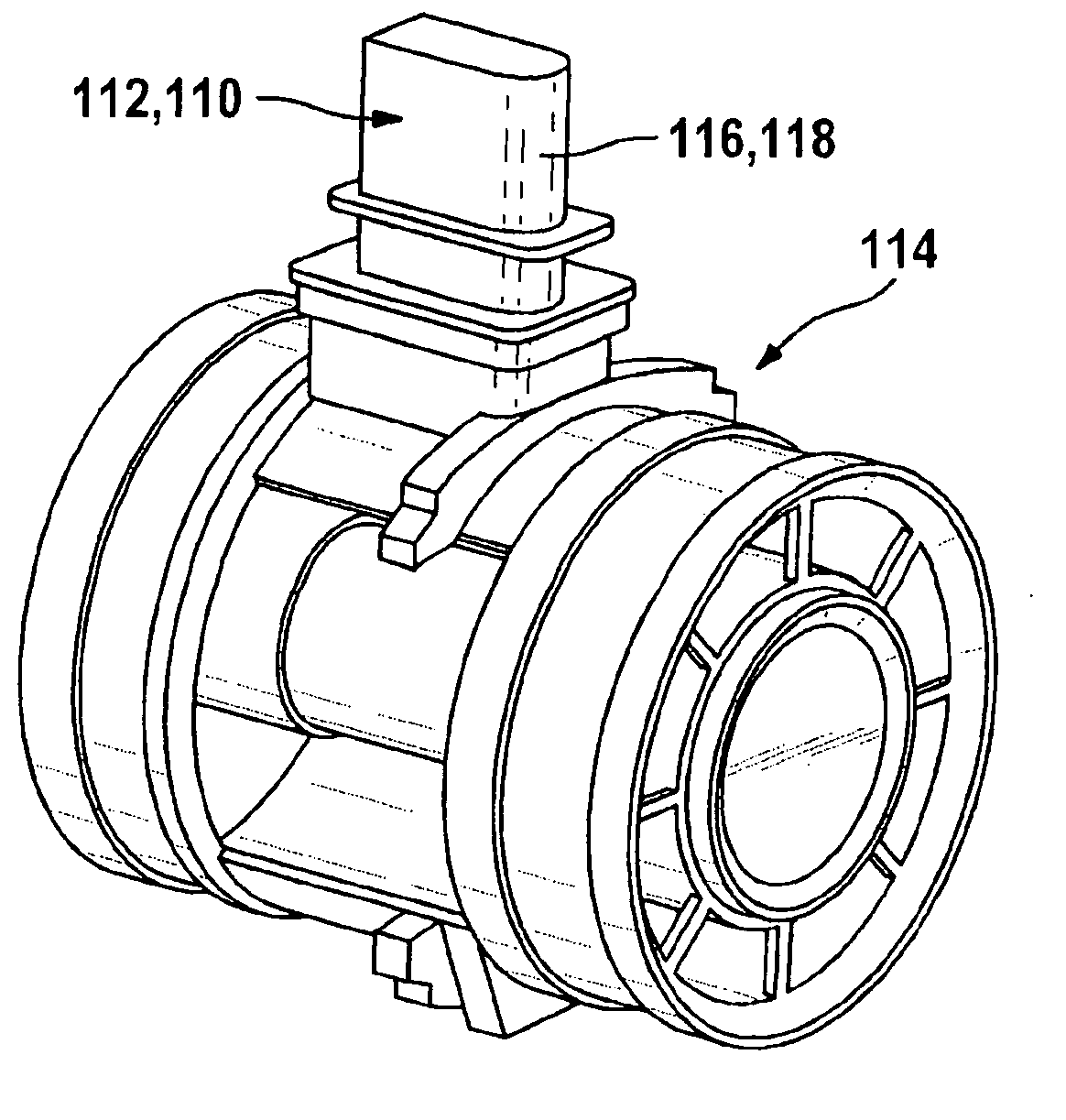

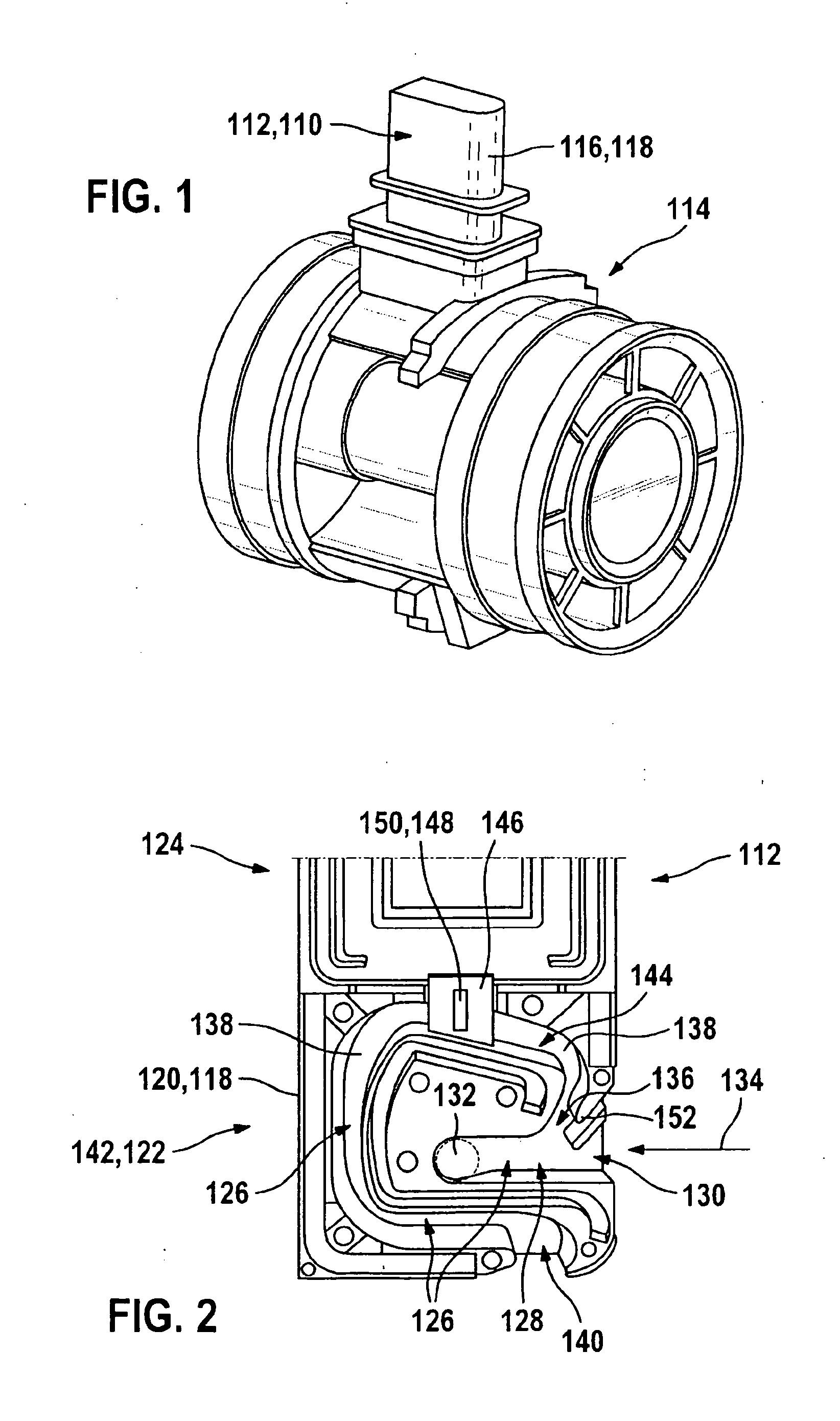

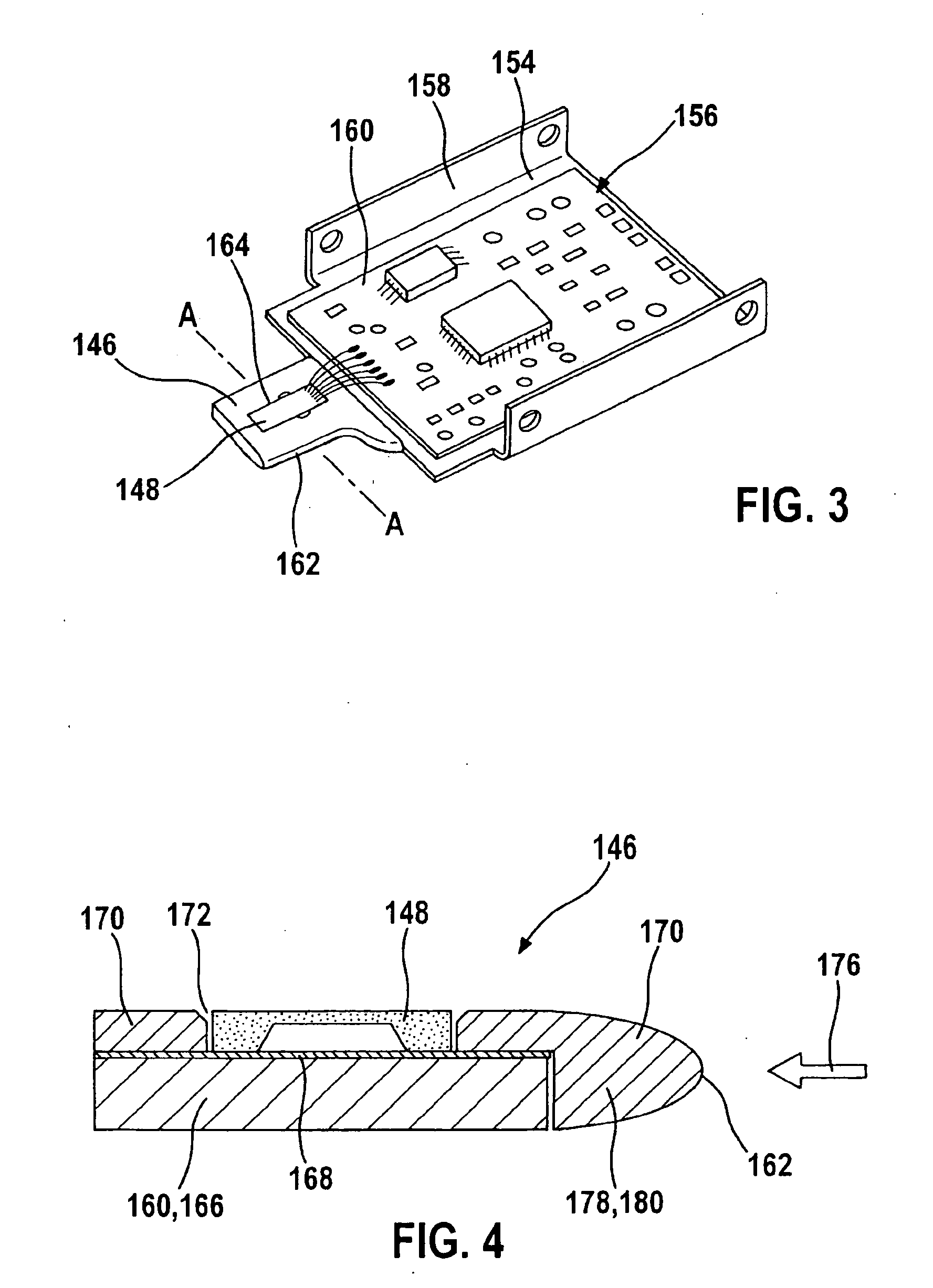

Hot film air mass meter and method for its manufacture

ActiveUS20100180675A1Reduce decreaseReduce manufacturing costInternal-combustion engine testingWave amplification devicesEngineeringInternal combustion engine

A device for determining at least one parameter of a fluid medium, in particular an intake air mass of an internal combustion engine. The device comprises a sensor chip for measuring the parameter and a control and evaluation electronics having a circuit carrier. The sensor chip is situated on a chip carrier capable of being introduced into the fluid medium. The chip carrier comprises a projection of the circuit carrier developed in one piece with circuit carrier, the sensor chip

Owner:ROBERT BOSCH GMBH

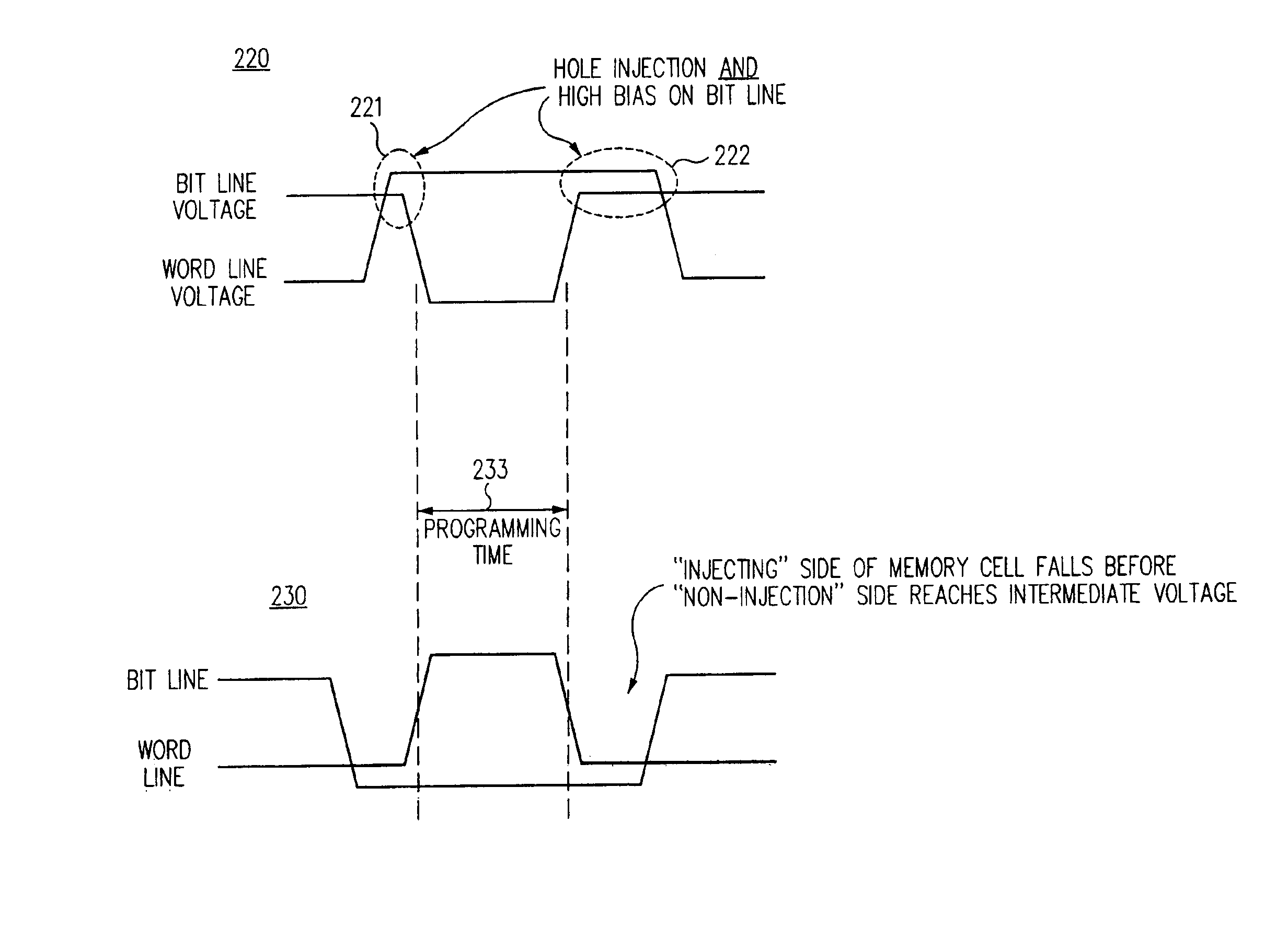

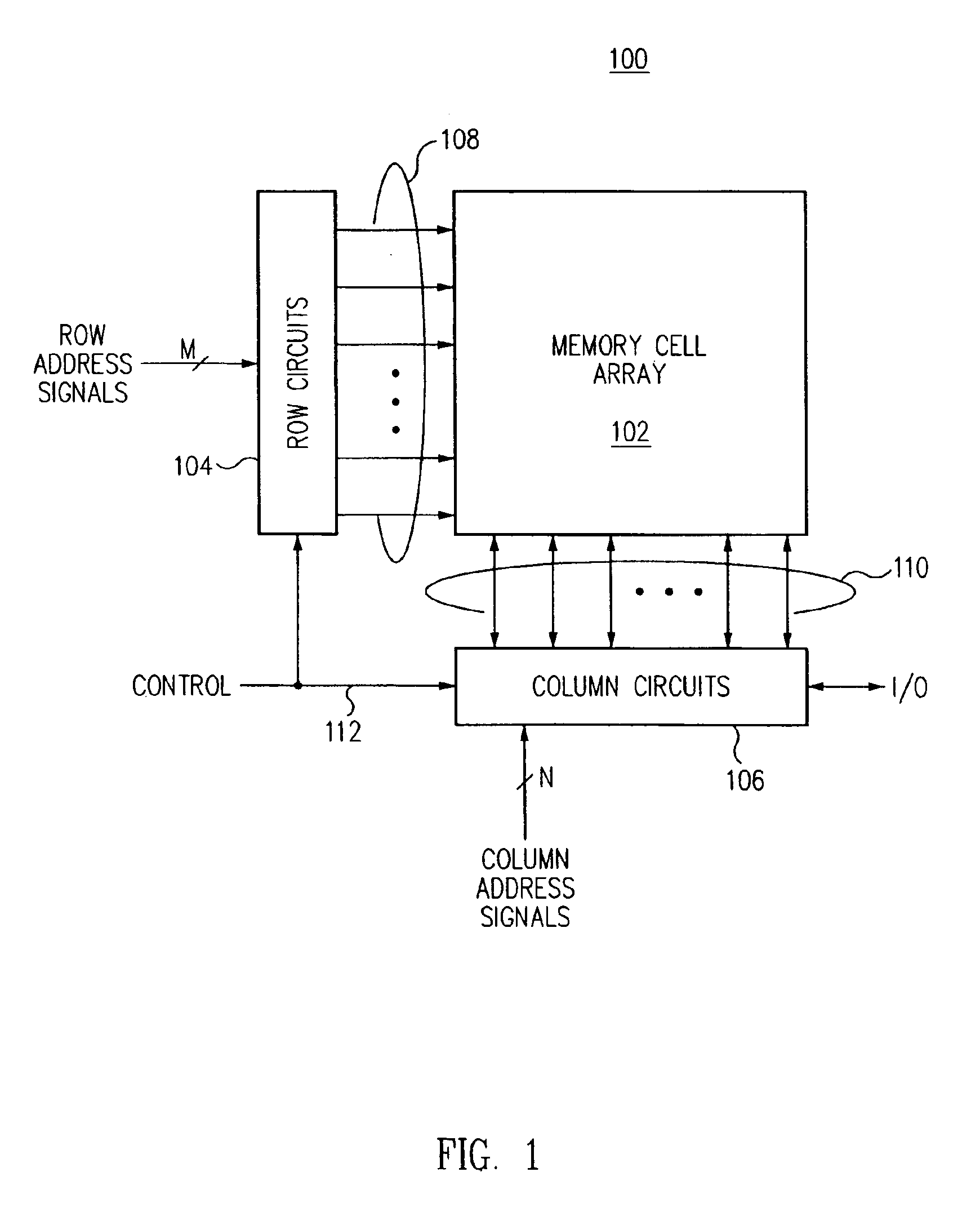

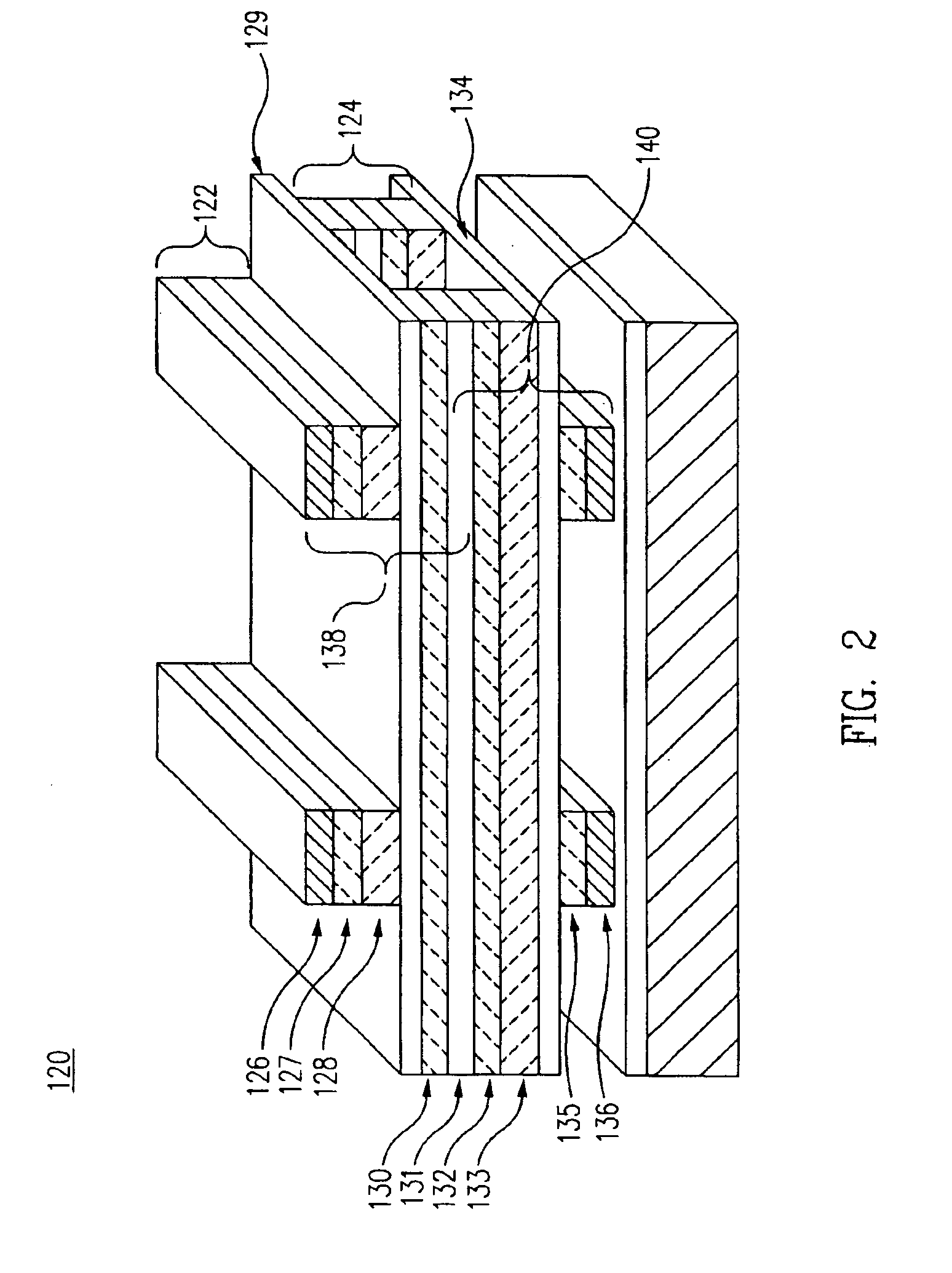

Apparatus and method for disturb-free programming of passive element memory cells

InactiveUS6963504B2Additional processing stepsIncrease manufacturing costNanoinformaticsRead-only memoriesEngineeringAntifuse

In a passive element memory array, such as a rail stack array having a continuous semiconductor region along one or both of the array lines, programming a memory cell may disturb nearby memory cells as result of a leakage path along the array line from the selected cell to the adjacent cell. This effect may be reduced substantially by changing the relative timing of the programming pulses applied to the array lines for the selected memory cell, even if the voltages are unchanged. In an exemplary three-dimensional antifuse memory array, a positive-going programming pulse applied to the anode region of the memory cell preferably is timed to lie within the time that a more lightly-doped cathode region is pulsed low.

Owner:SANDISK TECH LLC

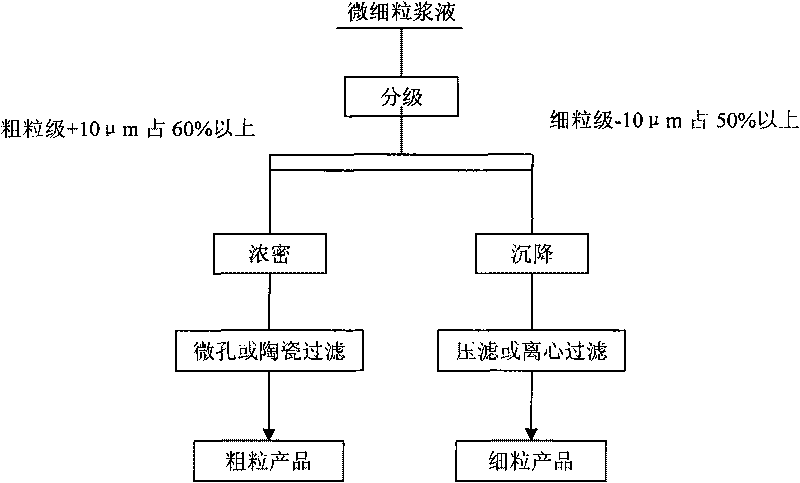

Method for dehydrating micro-particle slurry

InactiveCN101716439AAvoid cloggingSave capacityFiltration circuitsSedimentation settling tanksFilter cakeMoisture

The invention relates to a method for dehydrating micro- particle slurry, in particular to a method for dehydrating the micro-particle products, which is suitable for ore-dressing practice. The method comprises the processes of grading, sedimentating and filtering. The method is characterized in that the micro-particle slurry is graded firstly in the dehydration process to obtain the particle slurry and fine particle slurry, wherein the coarse particle slurry is sedimentated via a thickening machine, and then is filtered by using a micropore material or device. After the fine particle slurry is sedimentated, a membrane chamber-type filter press or a centrifugal hydroextractor is used to dehydrate and filter. The method is easy and simple, solves the problems of low productive capacity of filtering the micro-sized particle slurry and enhances the sedimentating and filtering performance of the micro-sized particle slurry and the moisture of a filter mass so as to greatly reduce the energy consumption of metallurgy and the mineral separation cost.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

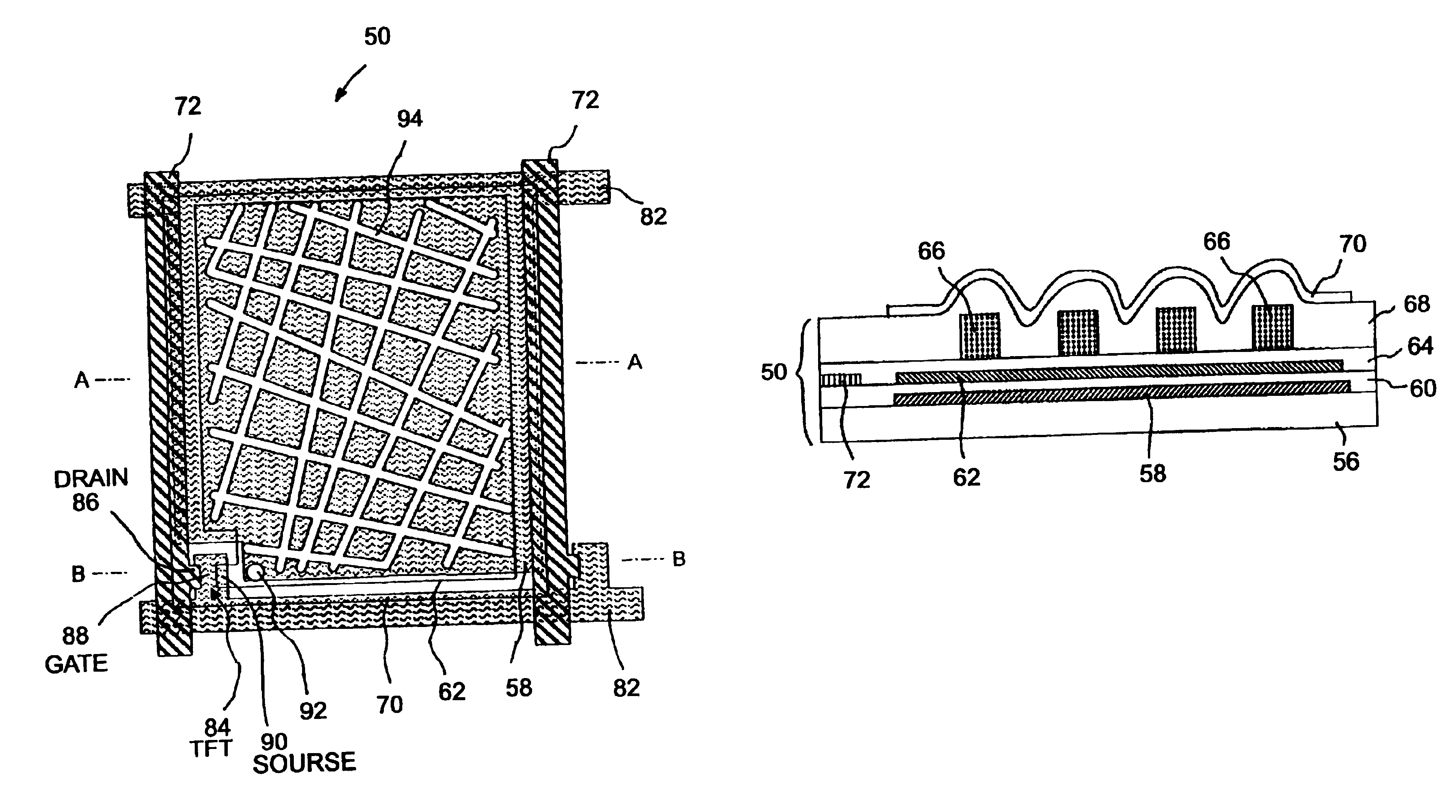

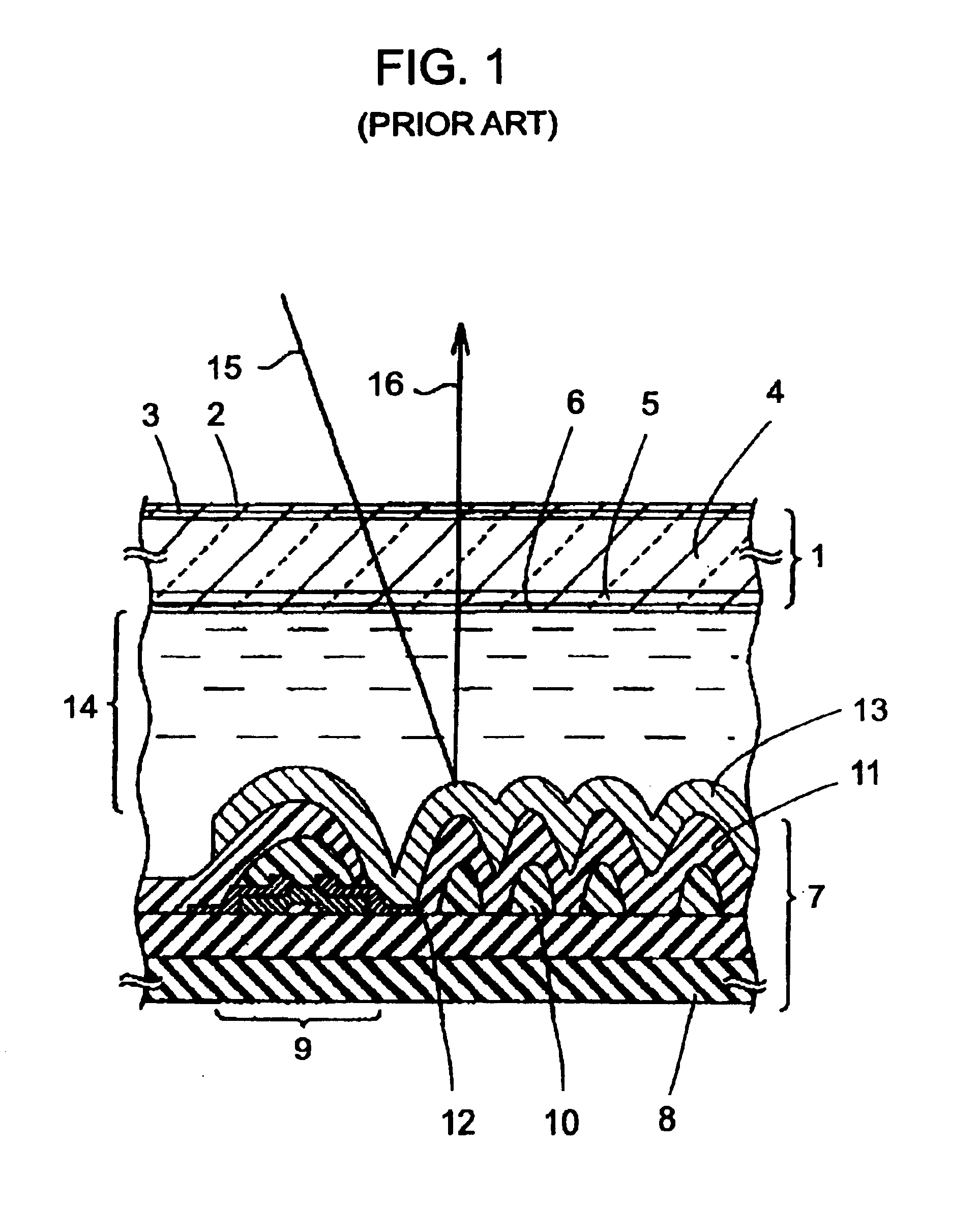

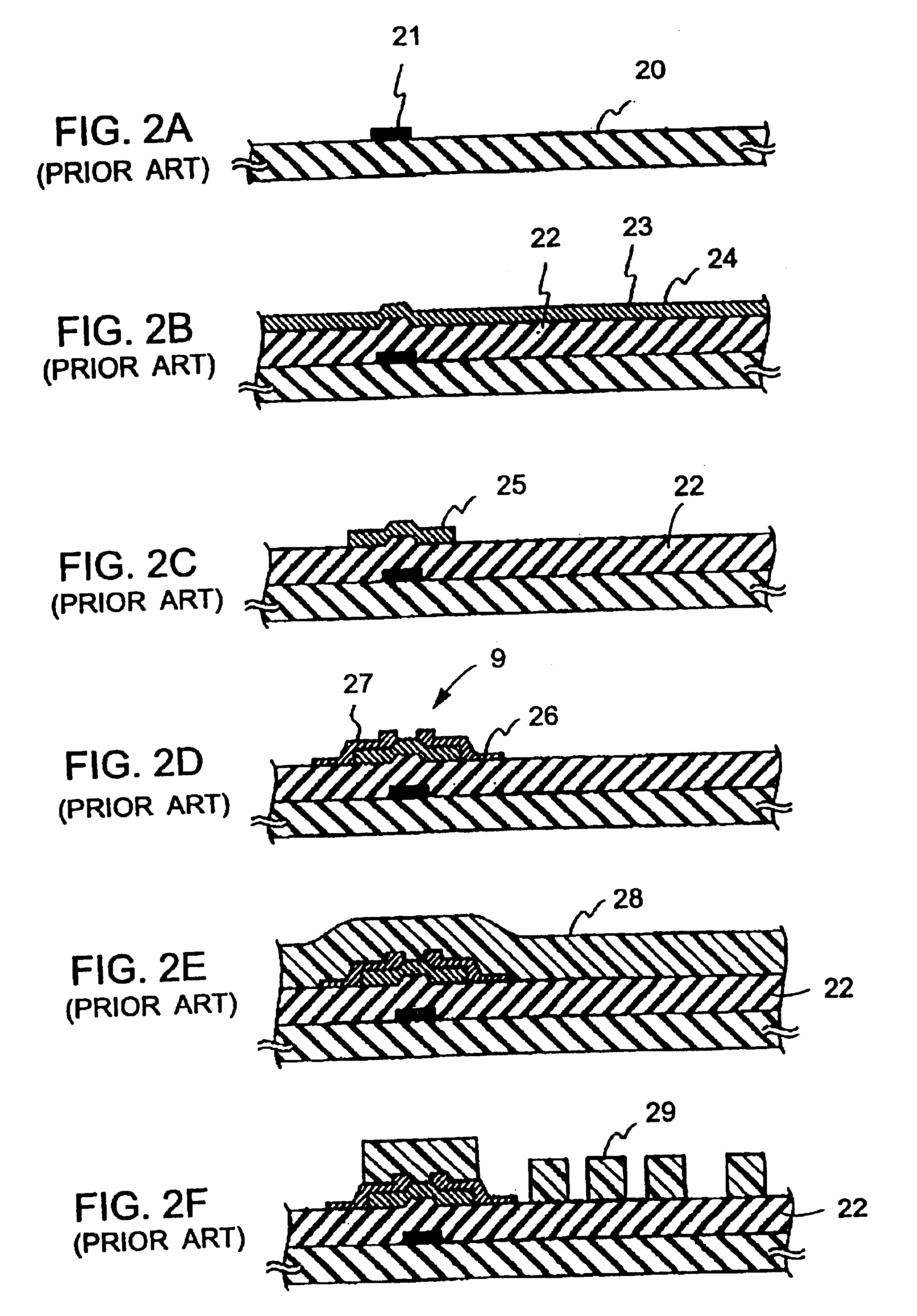

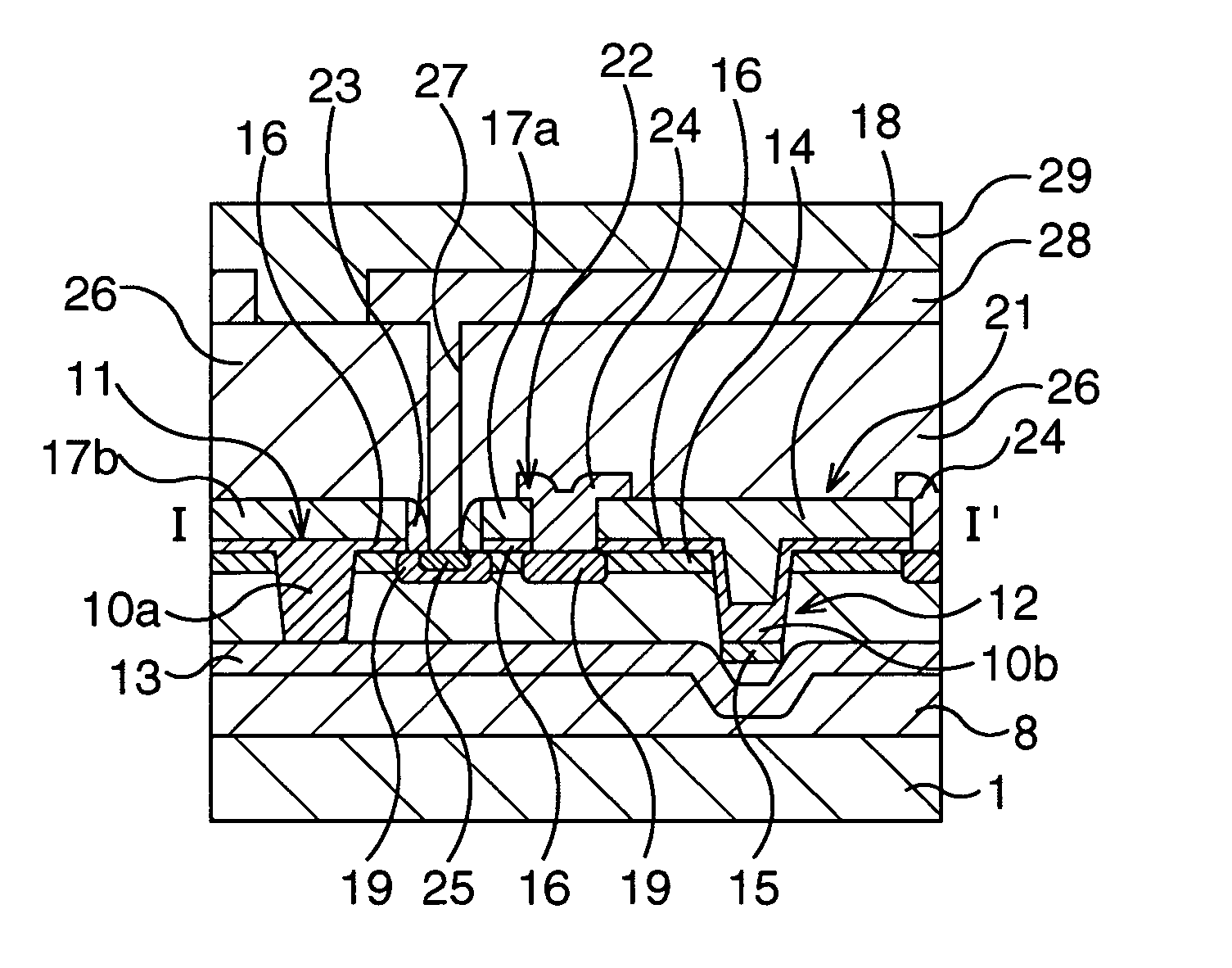

Active-matrix addressed reflective LCD and method of fabricating the same

InactiveUS6862057B2Additional processing stepsReduce intensityTransistorSemiconductor/solid-state device manufacturingElectricityLiquid-crystal display

In order to improve processing steps of fabricating an active-matrix addressed reflective liquid crystal display, a lower substrate, which is positioned at one side with respect to a liquid crystal layer, is provided with two electrodes in parallel with each other and in parallel with the liquid crystal layer. One of the two electrodes is electrically coupled to a source electrode of a switching element assigned to one pixel, and the other electrode is electrically couple to a constant potential source. Each of the two electrodes has characteristics of light reflectivity, which is able to reduce the intensity of exposing light when an insulating layer provided above the electrodes is patterned.

Owner:NEC LCD TECH CORP

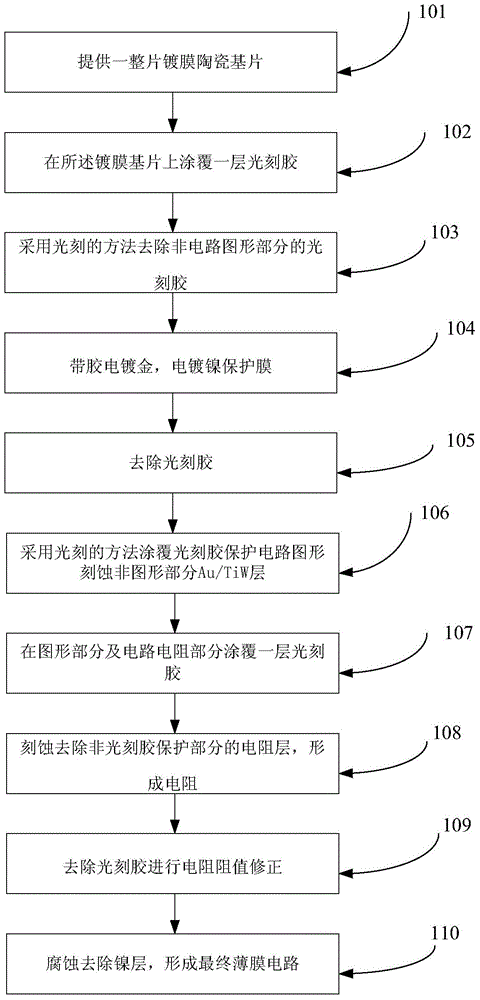

Method for manufacturing metal protective film used for film circuit test

InactiveCN103606520AReduce manufacturing costAdditional processing stepsSemiconductor/solid-state device manufacturingResistorsTectorial membraneEtching

The invention discloses a method for manufacturing a metal protective film used for a film circuit test. The method includes the following steps that a ceramic substrate plated with a TaN / TiW / Au metal film is coated with a layer of photoresist, and the photoresist on the non-circuitous-pattern part of the ceramic substrate plated with the film is removed through a photo-etching method; a self-adhesive gold electroplated protective film and a self-adhesive nickel electroplated protective film are performed on the ceramic substrate plated with the film after photo-etching treatment, and then the photoresist is removed; the photo-etching method is adopted for performing photoresist coating to protect a circuitous pattern, and an Au / TiW layer of the non-pattern part is etched; the pattern part and circuitous resistance part of the ceramic substrate plated with the film are coated with layers of photoresist by the adoption of the photo-etching method, and a resistor layer of a non-photoresist-protection part is etched to form circuitous resistors; then, all the photoresist is removed, correction is performed on resistance values of the resistors, finally, the nickel electroplated protective film is removed through corrosion, and a film circuit is obtained. The machining steps of the nickel layer electroplating and nickel layer corroding are added, a gold strip line can be well protected from damage by a test probe through the nickel electroplated metal protective film, machining quality and the finished product rate of the film circuit are improved, and manufacturing cost of the film circuit is reduced.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Copper plating method on brass base material

The invention discloses a copper plating method on a brass base material, comprising the following processes in order: (1) oil removing process which successively contains degreasing and oil-removing process, a first electrolytic degreasing process and a second electrolytic degreasing process; (2) pickling process which successively contains activation and pickling processes; (3) nickel preplating process; (4) nickel plating process; (5) copper plating process; (6) passivation process; and (7) coating processing. The technology provided by the invention is simple. By the adoption of the technology, mass production cost is reduced. The processed product copper coating is compact and tight, is wear resistant and impact resistant, and has good conductivity and ductility. In addition, as the brass base material is used to replace a titanium copper material, the cost and weight of the material are greatly reduced, and shelf-life of the product is long.

Owner:尼尔金属(苏州)有限公司

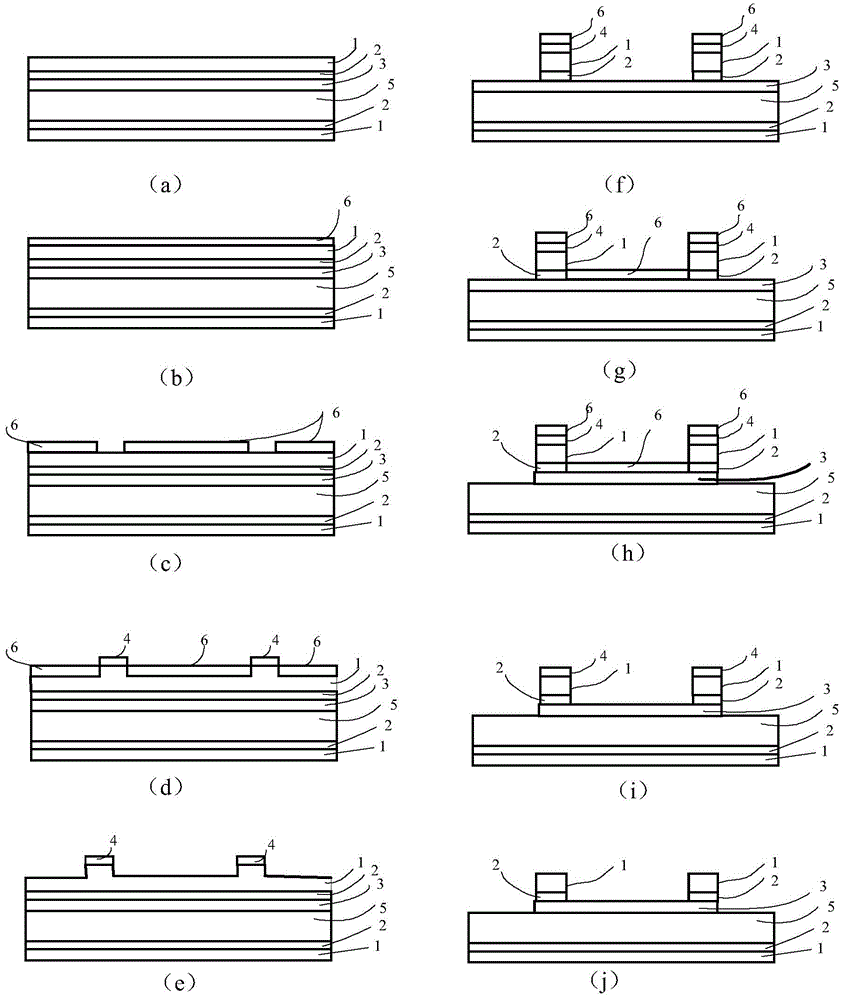

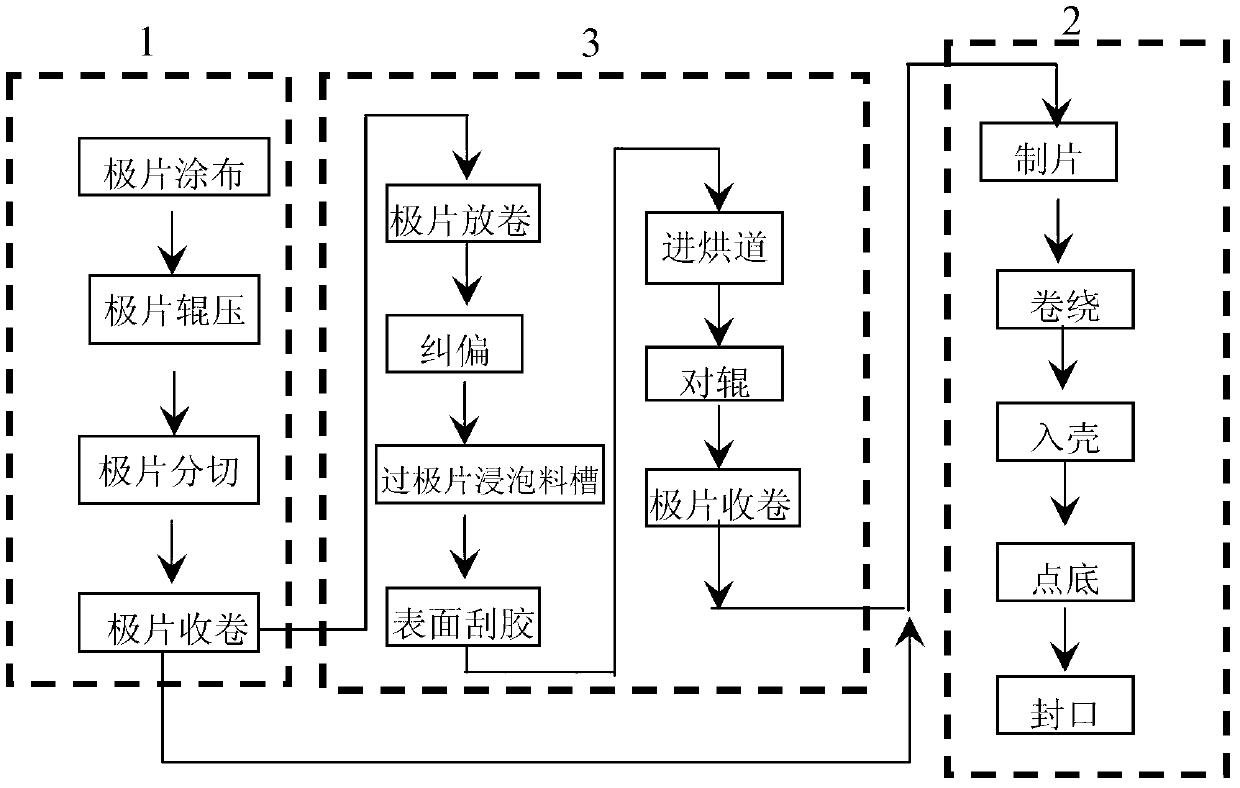

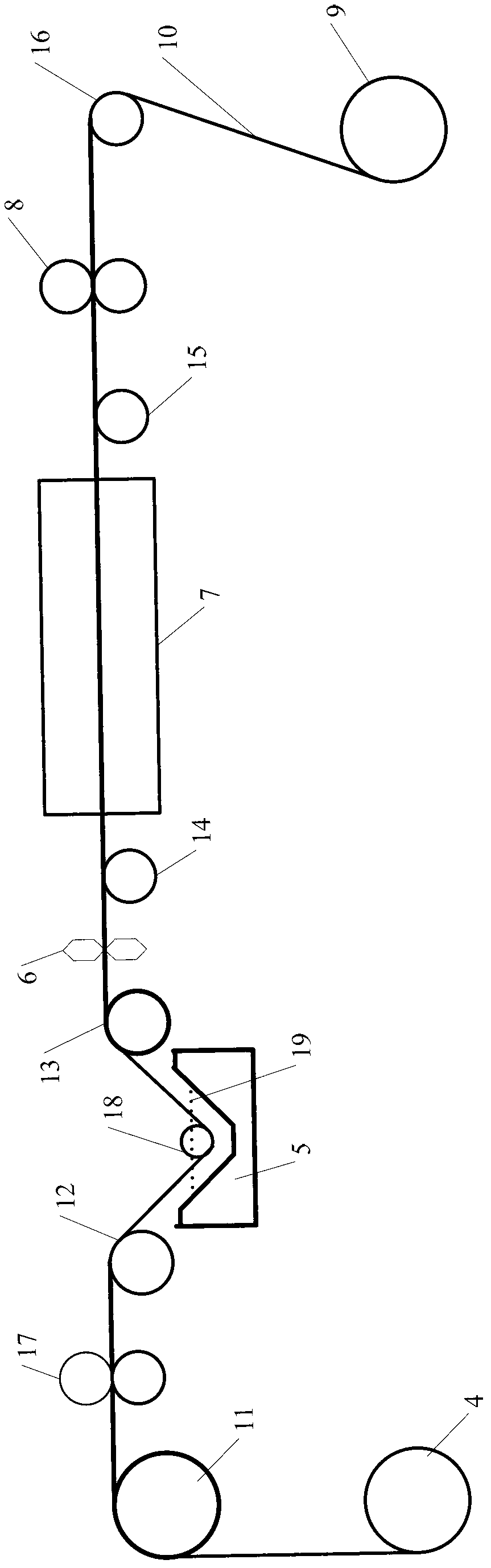

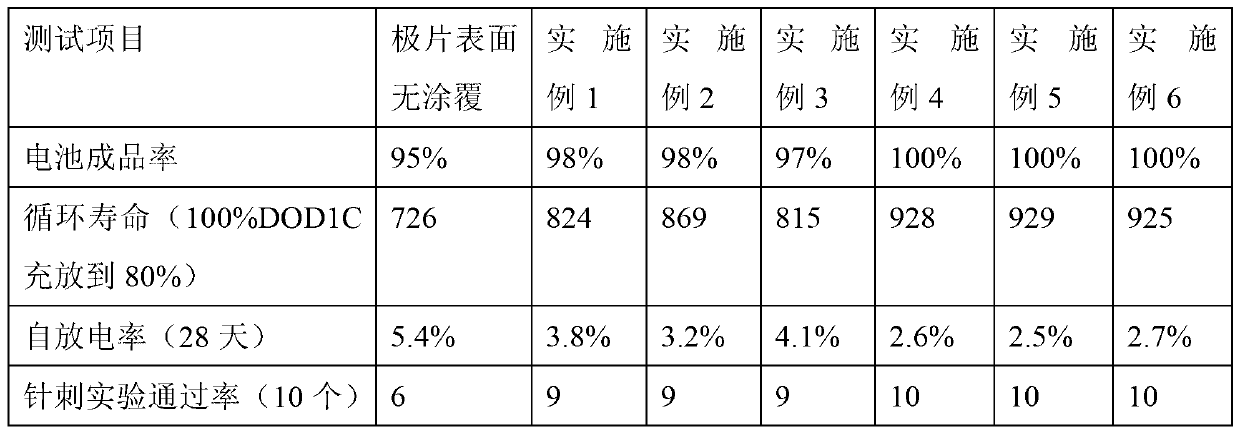

Lithium ion battery pole sheet making method and lithium ion battery pole sheet surface treatment device

InactiveCN103137945AImprove adhesionImprove cycle lifeCell electrodesElectrical batteryLithium electrode

The invention discloses a lithium ion battery pole sheet making method. The method comprises: a pole sheet coating slitting operation; a pole sheet surface treatment operation comprising a step of immersing a coat-slitted pole sheet in an aqueous high-polymer treatment liquid, and a step of drying to obtain a high-polymer film on the surface of the pole sheet; and a made sheet packaging operation. The method which allows the pole sheet surface treatment operation to be increased and the high-polymer film to be formed on the surface of the pole sheet can effectively prevent the powder fall of the lithium ion battery pole sheet, reduce the floatation powder generated in the making process of a battery, improve the bonding force of active substances, and improve the comprehensive electrochemical performances of the lithium ion battery. The invention also discloses a surface treatment device of the lithium ion battery pole sheet. The device comprises, sequentially arranged, an unreeling wheel, a pole sheet immersion material tank, a spreading knife, a drying tunnel, roller machines and a reel wheel, and can automatically and efficiently complete the surface treatment of the pole sheet, so the industrialized continuous production is convenient.

Owner:湖南三迅新能源科技有限公司

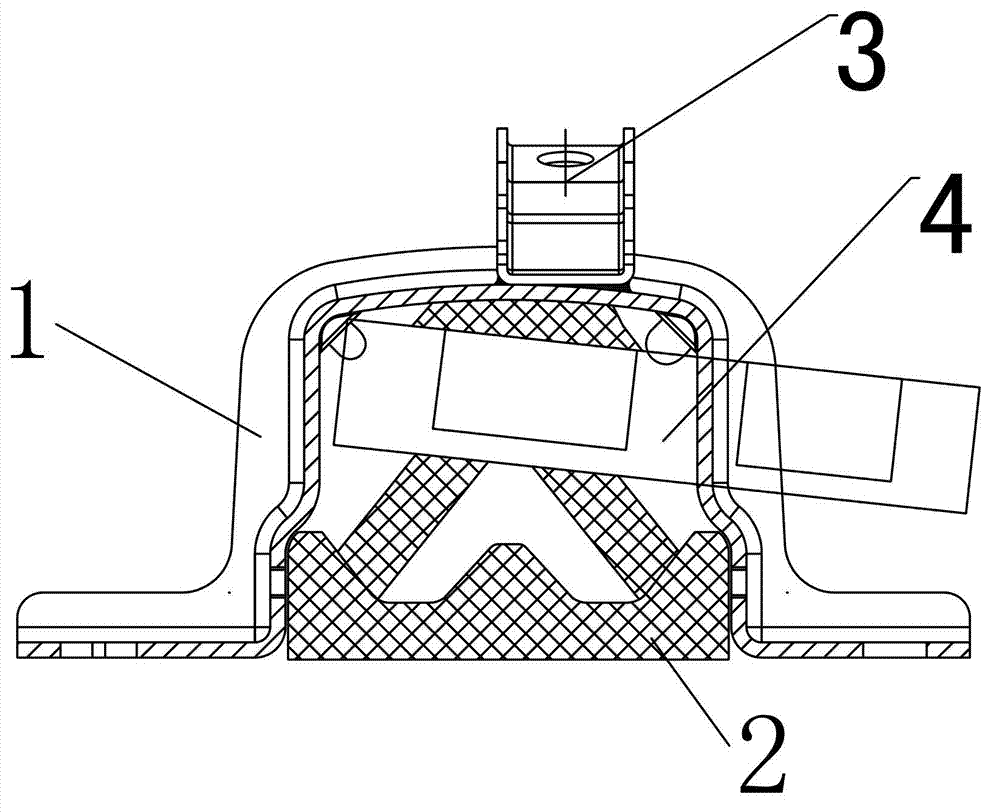

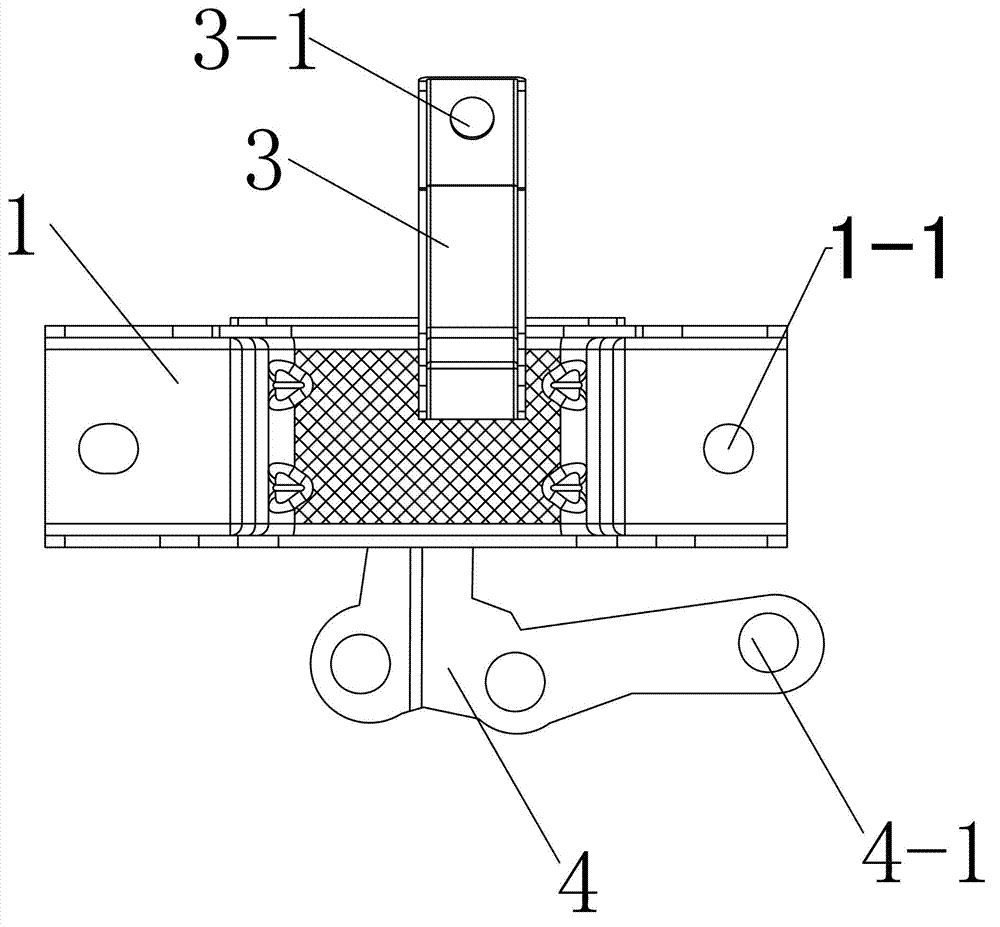

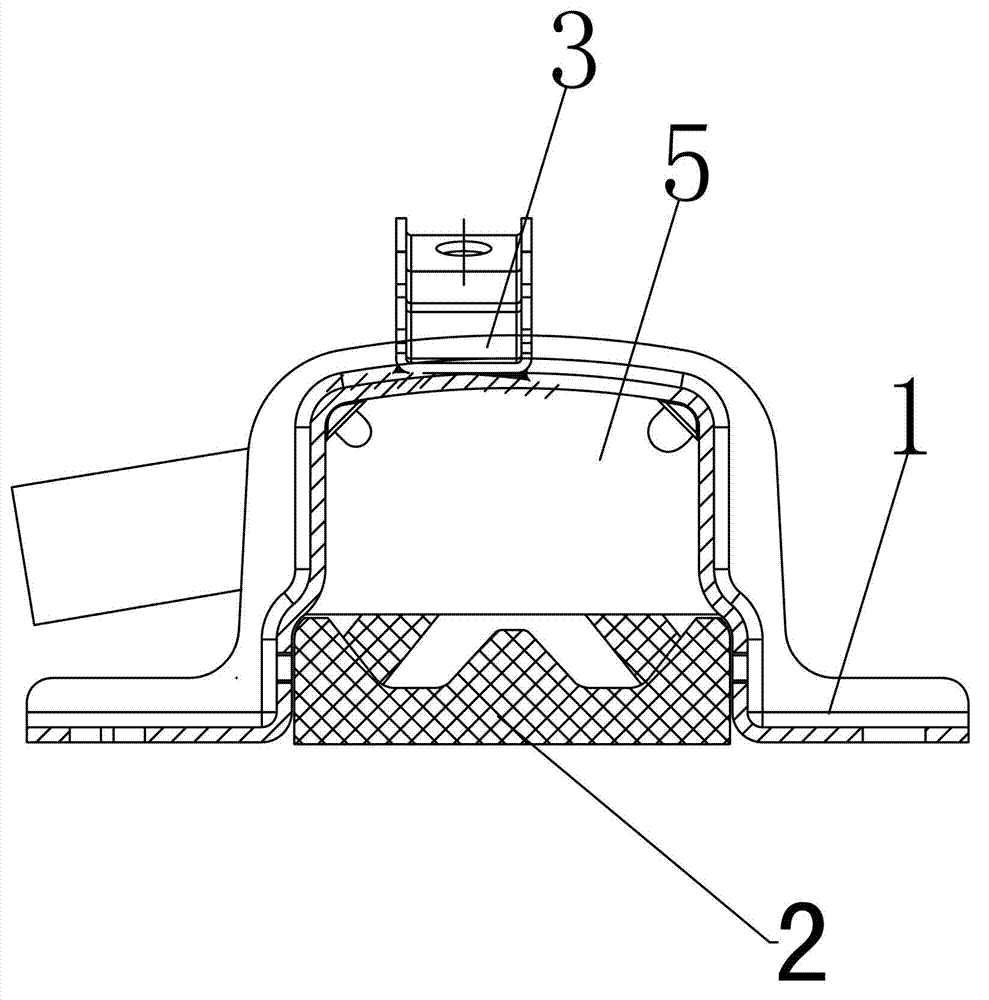

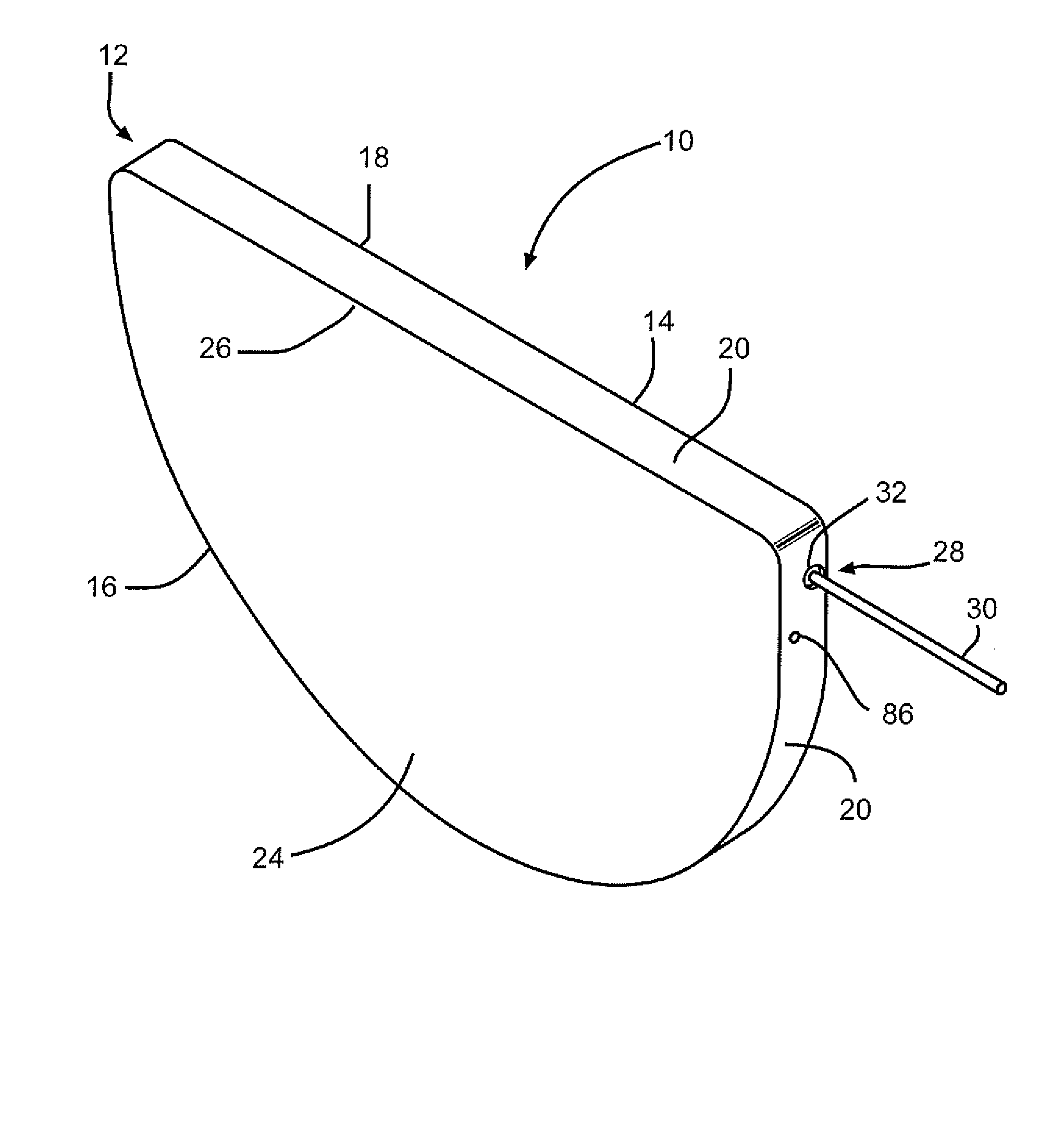

Shock-absorbing device for engine support

ActiveCN102774261ALess materialSimple structureJet propulsion mountingInternal combustion mountingEngineeringUltimate tensile strength

The invention relates to a shock-absorbing device for an engine support, specifically relates to a shock-absorbing connection used for an automobile engine and an automobile chassis and belongs to the technical field of machinery. The shock-absorbing device comprises a metal support, a shock-absorbing rubber, a chassis connecting support, an engine connecting rod and a support plate, wherein the metal support is in a bow-shaped structure, the shock-absorbing rubber is inlaid in the metal support, and the engine connecting rod is fixed in the shock-absorbing rubber. The top end of the metal support is in a welding connection with an engine connecting support, and the position of an opening in the rear of the metal support is in the welding connection with the support plate. The shock-absorbing device has the advantages that the structure is simple, compact and reasonable; the metal support with a bow-shaped structure is utilized so that the structural intensity of products is increased and service lives of the products are improved; and consumable materials are reduced, costs are lowered, processing procedures are simple, and the yield is increased.

Owner:WUXI ZHONGJIE VIBRATION ISOLATORS

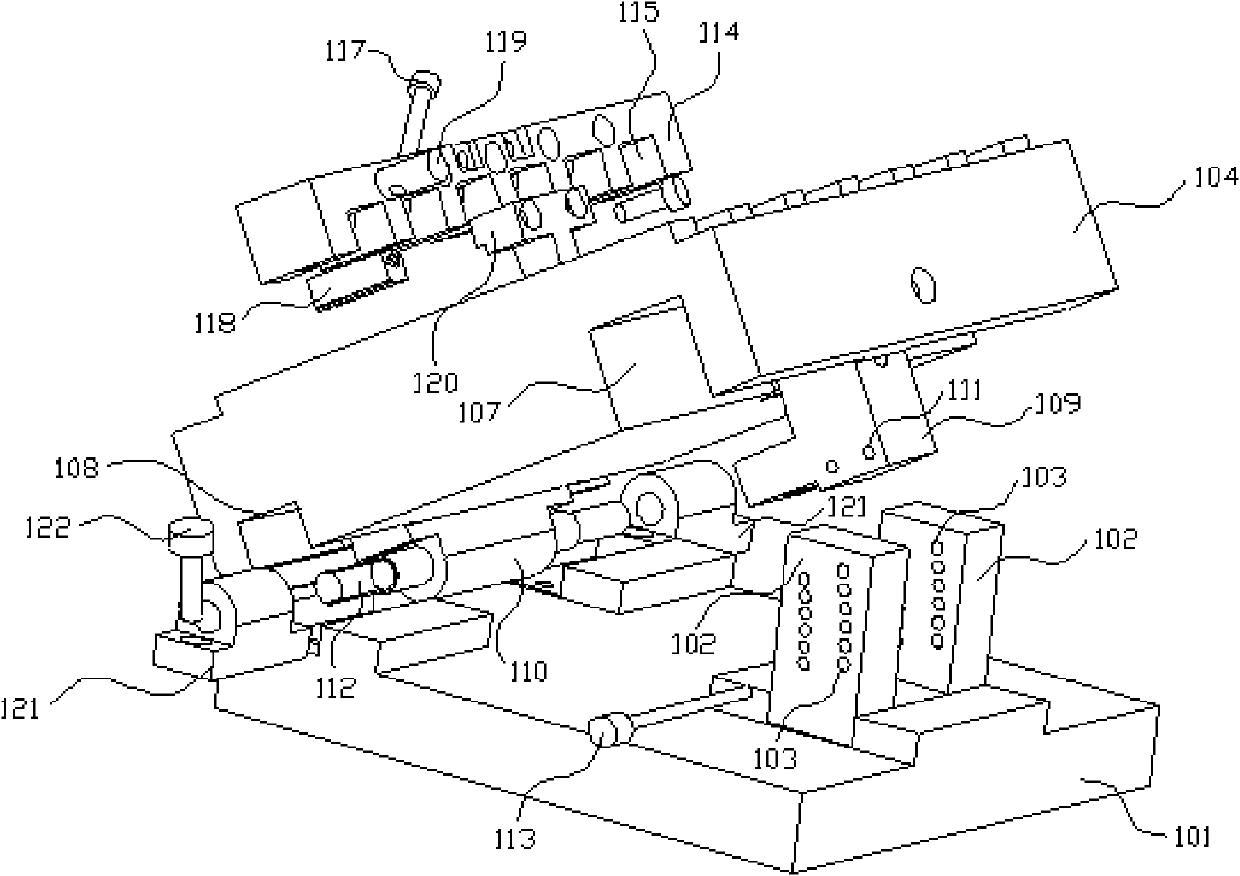

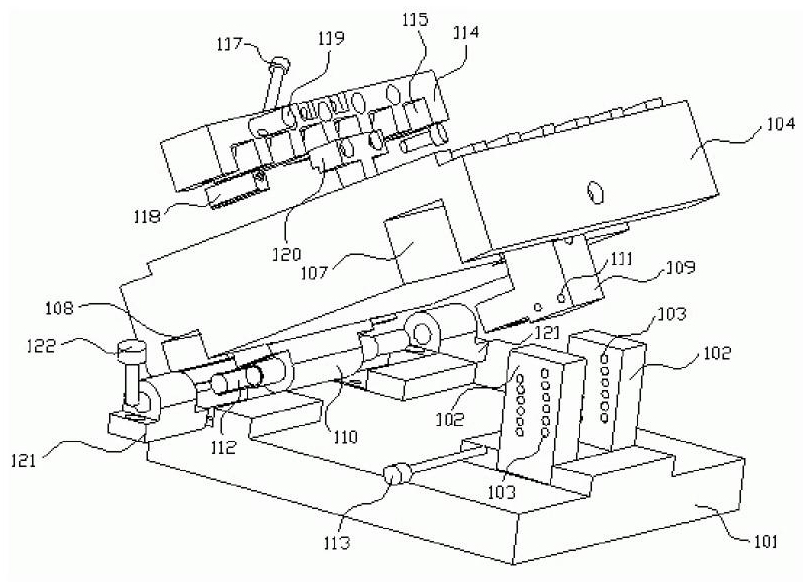

Multifunctional angle pin discharging fixture

InactiveCN102019475ASimplify processing stepsImprove processing stepsPositioning apparatusElectrical-based auxillary apparatusPhysicsEngineering

The invention provides a multifunctional angle pin discharging fixture, which comprises a base, a clamping body, an upper angle adjusting block and a rotating shaft mechanism. The base is provided with two lower-angle adjusting blocks; the two lower-angle adjusting blocks are provided with angle adjusting holes; an angle pin groove and a square groove are formed on the clamping body; the upper angle adjusting block is provided with an angle pin hole, and is arranged inside the square groove at the bottom of the clamping body; a square groove and a screw hole are formed on an upper fixing base; a compression screw is arranged inside the screw hole; one end of the compression screw is connected with a compression block; a supporting pin is arranged on a side surface of the upper fixing base; an upper rotating shaft base of the rotating shaft mechanism is fixed inside the square groove on a bottom surface of the clamping body; two lower rotating shaft bases are arranged at two ends of the base; and the rotating shaft is inserted into rotating shaft holes of the rotating shaft base and the upper rotating shaft base. The fixture can clamp a plurality of angle pins at the same angle at one time for continuous machining, angle pins at different angles also can be directly machined after the inclination of the clamping body is adjusted, and the plurality of angle pins are not needed to be clamped for multiple times; therefore, the machining steps are simplified and the machining efficiency is improved.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

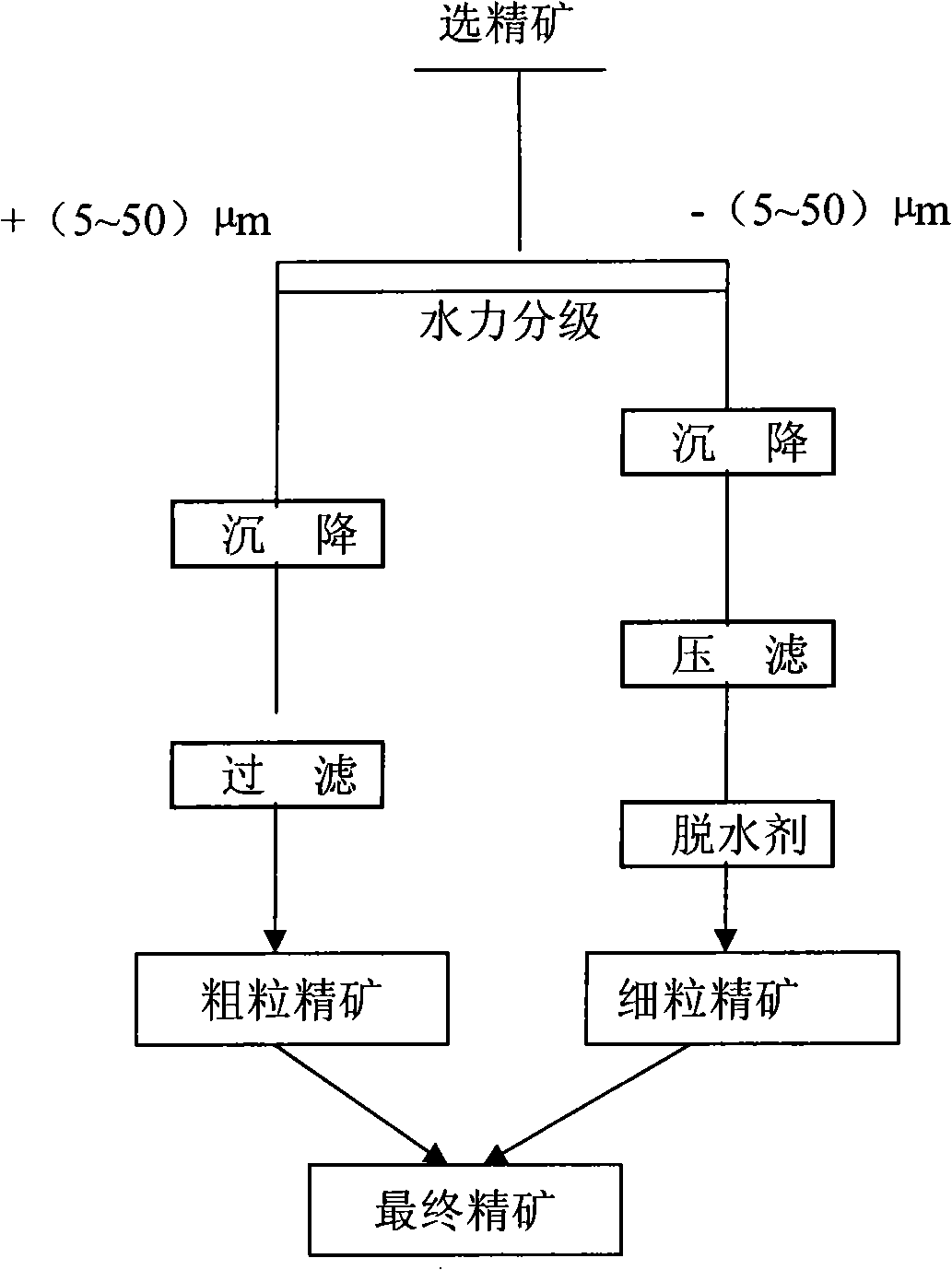

Dewatering process screening fine ore of alumyte

InactiveCN101254375AAccelerated settlementImprove filtering effectAluminium compoundsFiltration circuitsCycloneEngineering

The invention relates to a dewatering method for bauxite concentrate, and the method is used in the solid-liquid separation processes of a diasporite positive flotation concentrate product. The method comprises the operations such as classification, sedimentation, filtration, etc. The invention is characterized in that the diasporite positive flotation concentrate product is classified by adopting classifying equipment such as a hydraulic cyclone, etc., the classification size is 5 to 50 micrometer; after the classification the coarse concentrate and the fine-sized concentrate undergo the sedimentation and the filtration respectively, and are combined into the final concentrate. The method of the invention is simple and feasible, and can obviously improve the sedimentation and the filtration performances as well as the filter cake moisture of the bauxite concentrate, thereby greatly reducing the energy consumption and the mineral processing cost of the aluminum oxide production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

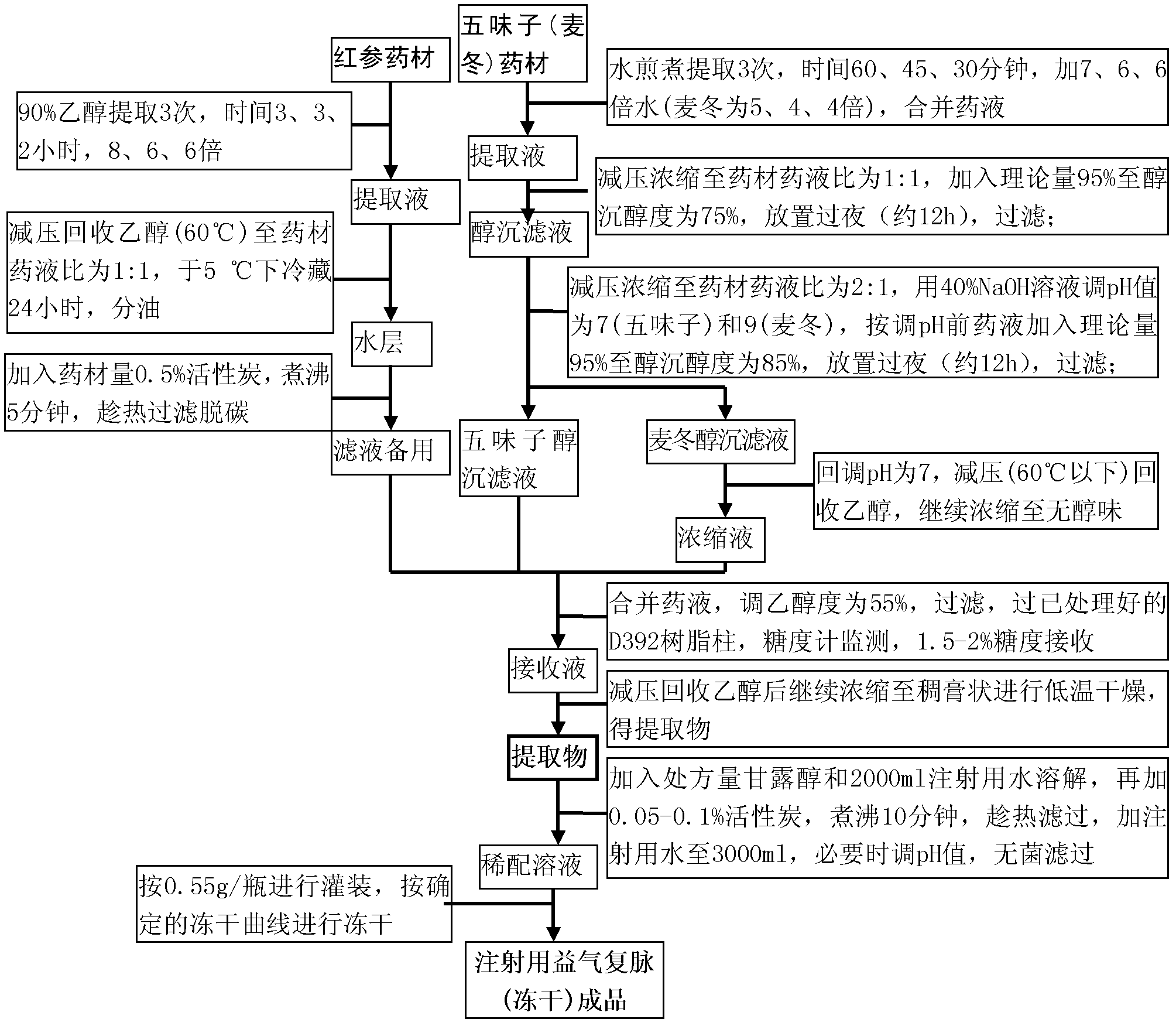

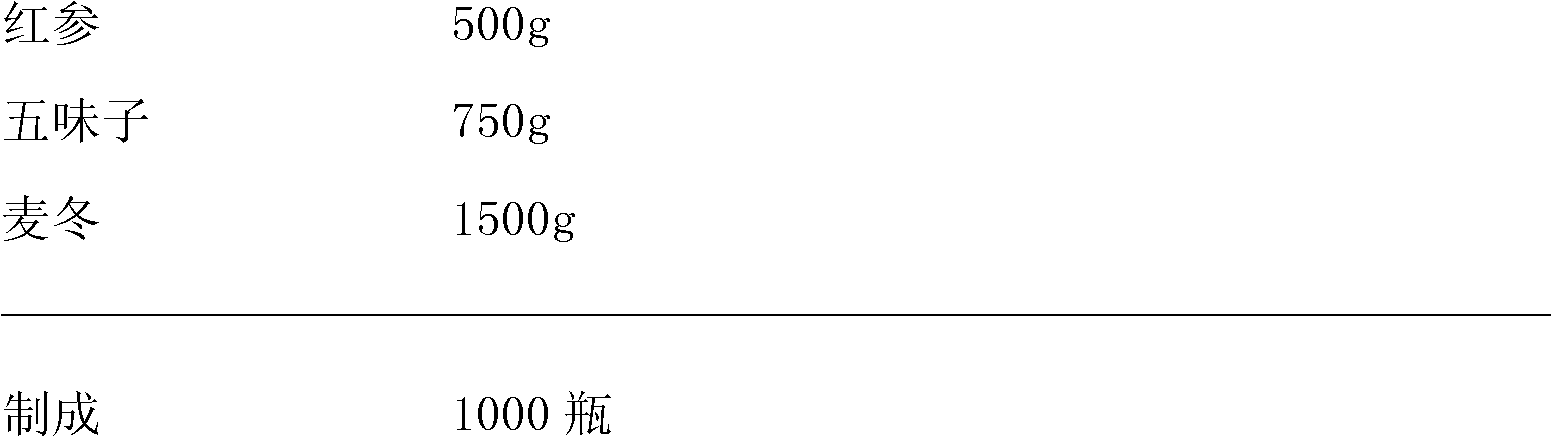

Qi tonifying and pulse restoring preparation

ActiveCN102988719ALight colorImprove solubilityPowder deliveryLyophilised deliveryActive componentMedicine

The invention relates to a traditional Chinese medicinal preparation, and especially relates to a qi tonifying and pulse restoring preparation. The preparation is prepared through an improved method. The method comprises the following steps: 1, extracting Radix Ginseng Rubra by ethanol; 2, extracting Radix Ophiopogonis and Chinese magnoliavine by water, and precipitating twice by ethanol; 3, mixing a Radix Ginseng Rubra extract liquid obtained in step 1, and a Radix Ophiopogonis extract liquid and a Chinese magnoliavine extract liquid obtained in step 2 to obtain a mixed liquid, allowing the mixed liquid to pass through a D392 resin column, receiving the eluant when glucose flows out, concentrating, and drying to obtain extract products; and 4, using the extract products as medicinal active components to prepare the medicinal preparation.

Owner:TIANJIN TASLY ZHIJIAO PHARMA

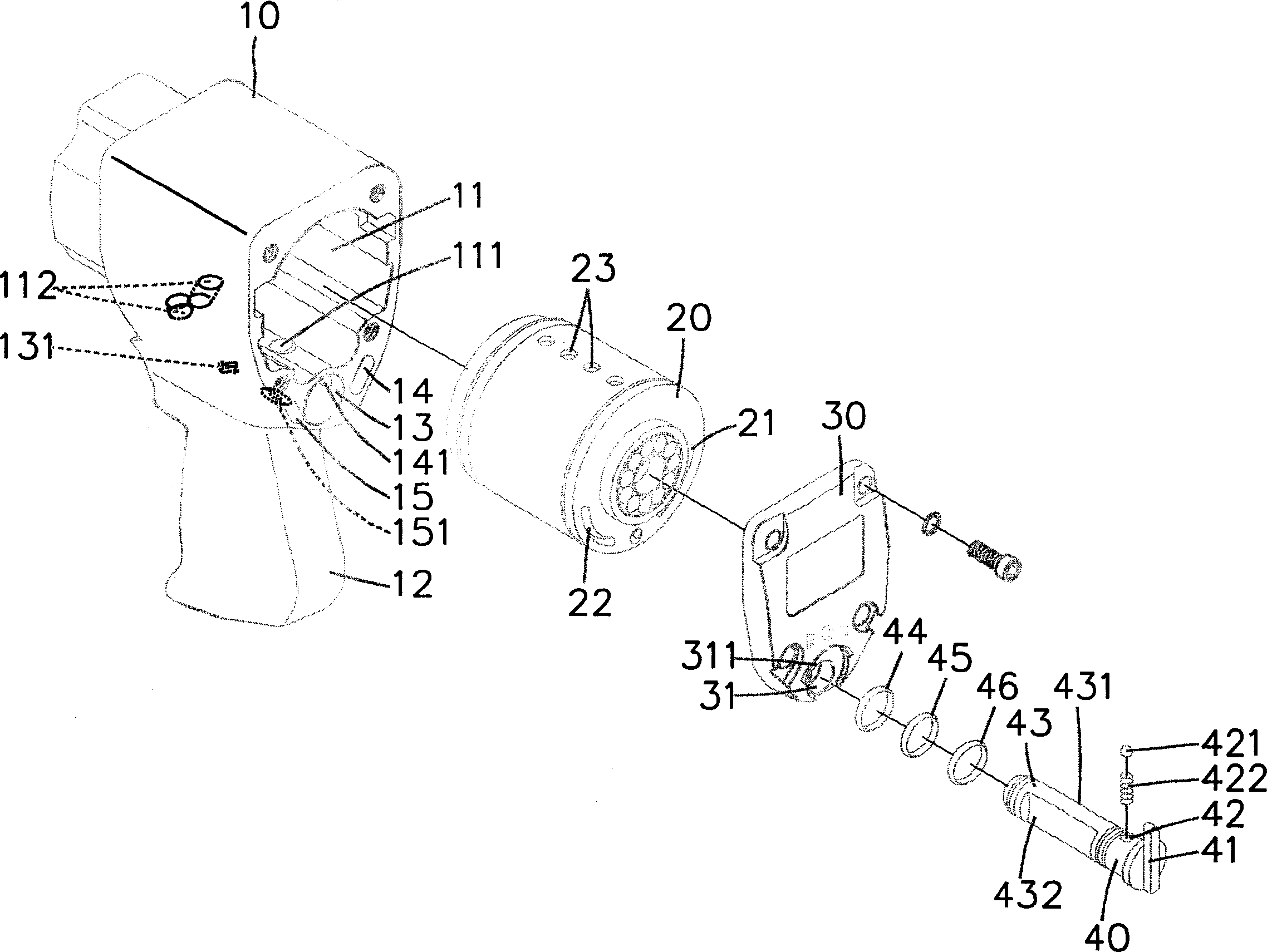

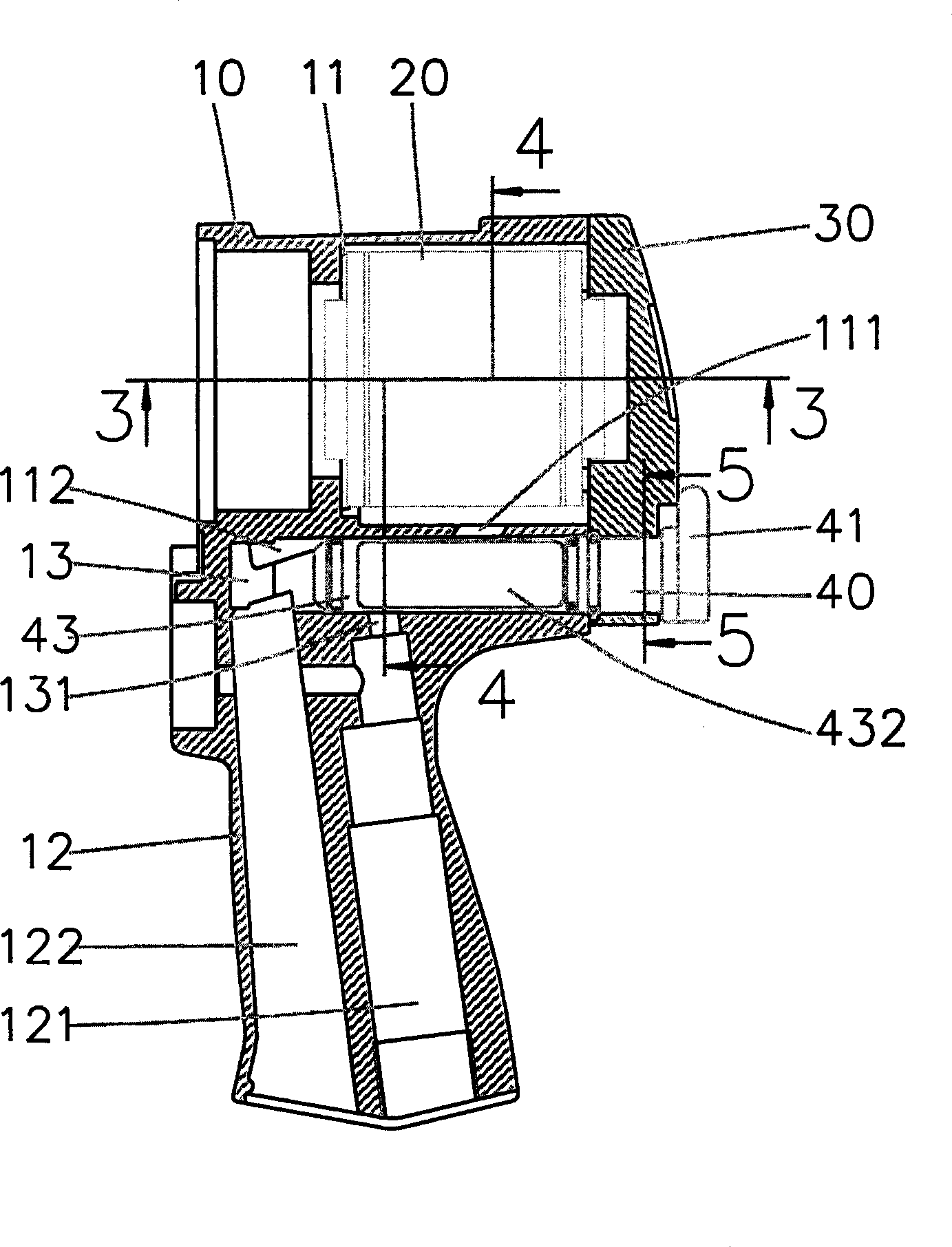

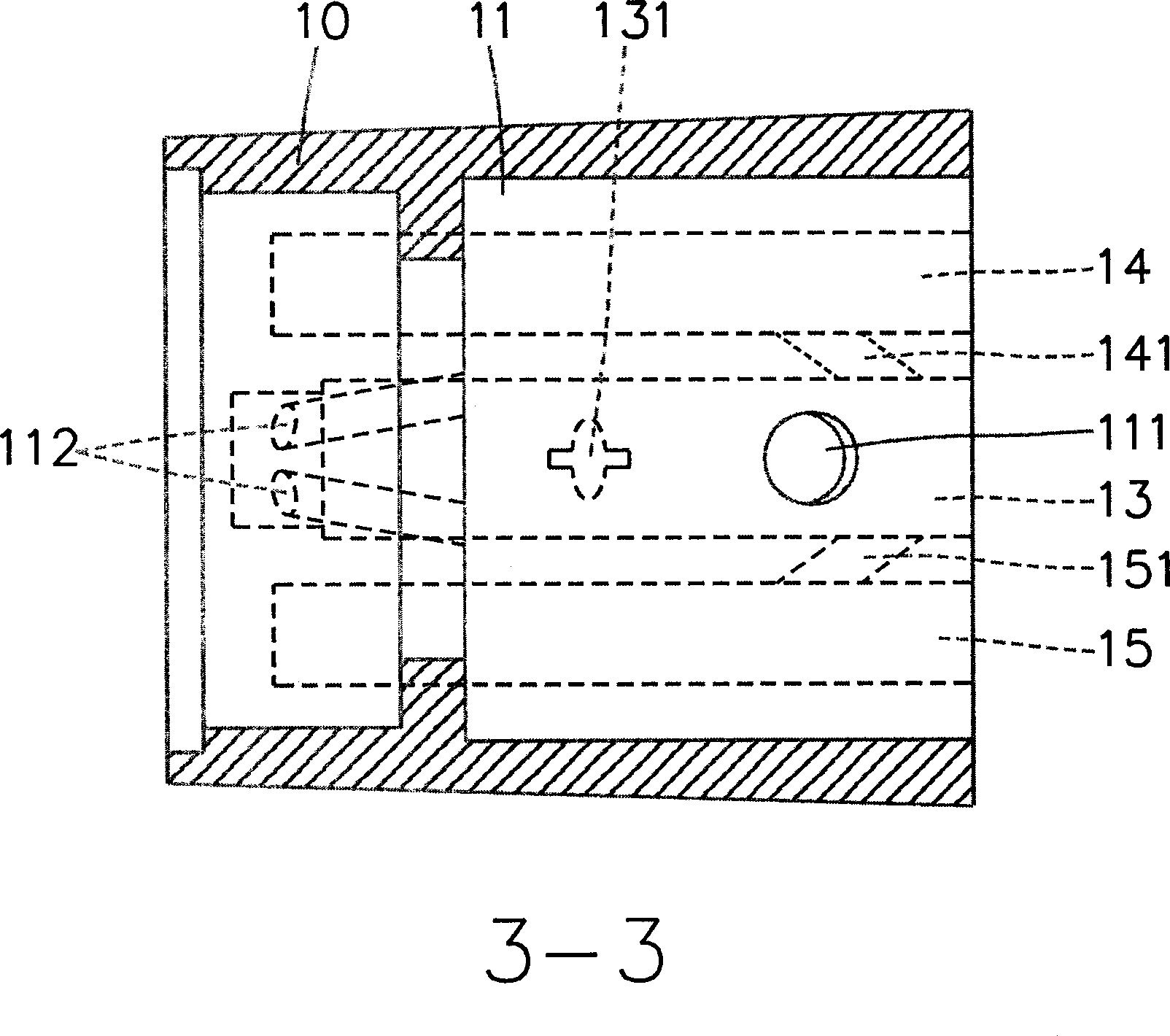

Pneumatic tool with improved structure

InactiveCN1880028ASimple structureReduce manufacturing costStapling toolsPortable percussive toolsEngineeringFlux control

The invention relates to an air powered tool, which comprises: a main body, a cylinder group, a sealing cover and a controller, wherein the main body has air room, control groove, and positive rotation air channel and passive rotation air channel connected to two sides of control groove; said control groove is arranged with flux control hole with cross shape; the cylinder group is inside the air room, whose one end has positive outlet and passive outlet; said sealing cover is at the air room, while it has one through hole at the position opposite to the control groove; the part of sealing cover near the main body has the positive air groove connecting the positive air channel and the positive outlet, and a passive air groove connecting passive rotation air channel and the passive outlet; one end of controller is axially arranged on the through hole of sealing cover to extend into the control groove of main body; two sides of controller are independently arranged with the positive and passive guide grooves that axially extending and not crossed; positive and passive guide grooves can be processed easily, to simplify the process and reduce producing cost.

Owner:MIGHTY SEVEN INT

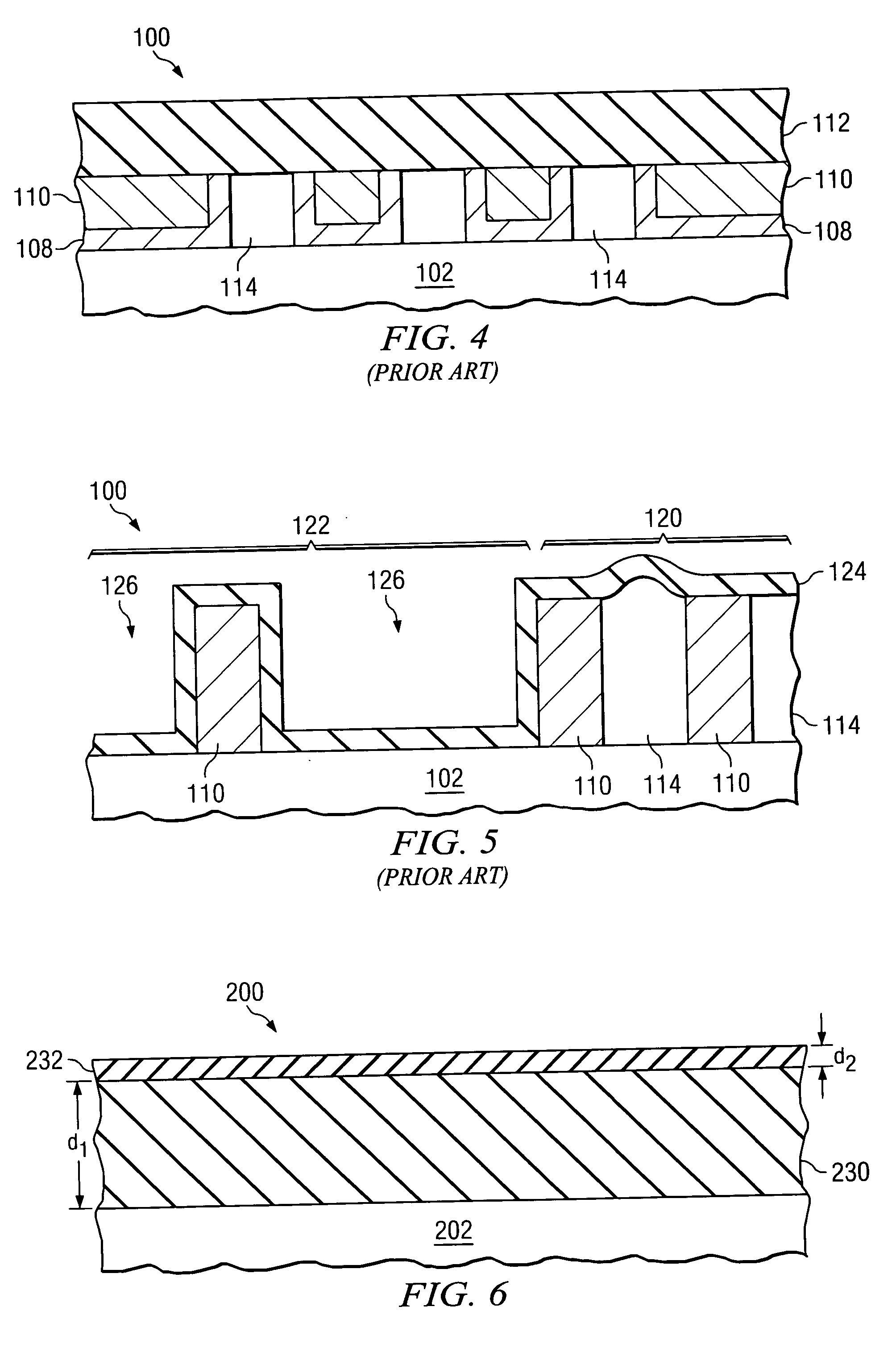

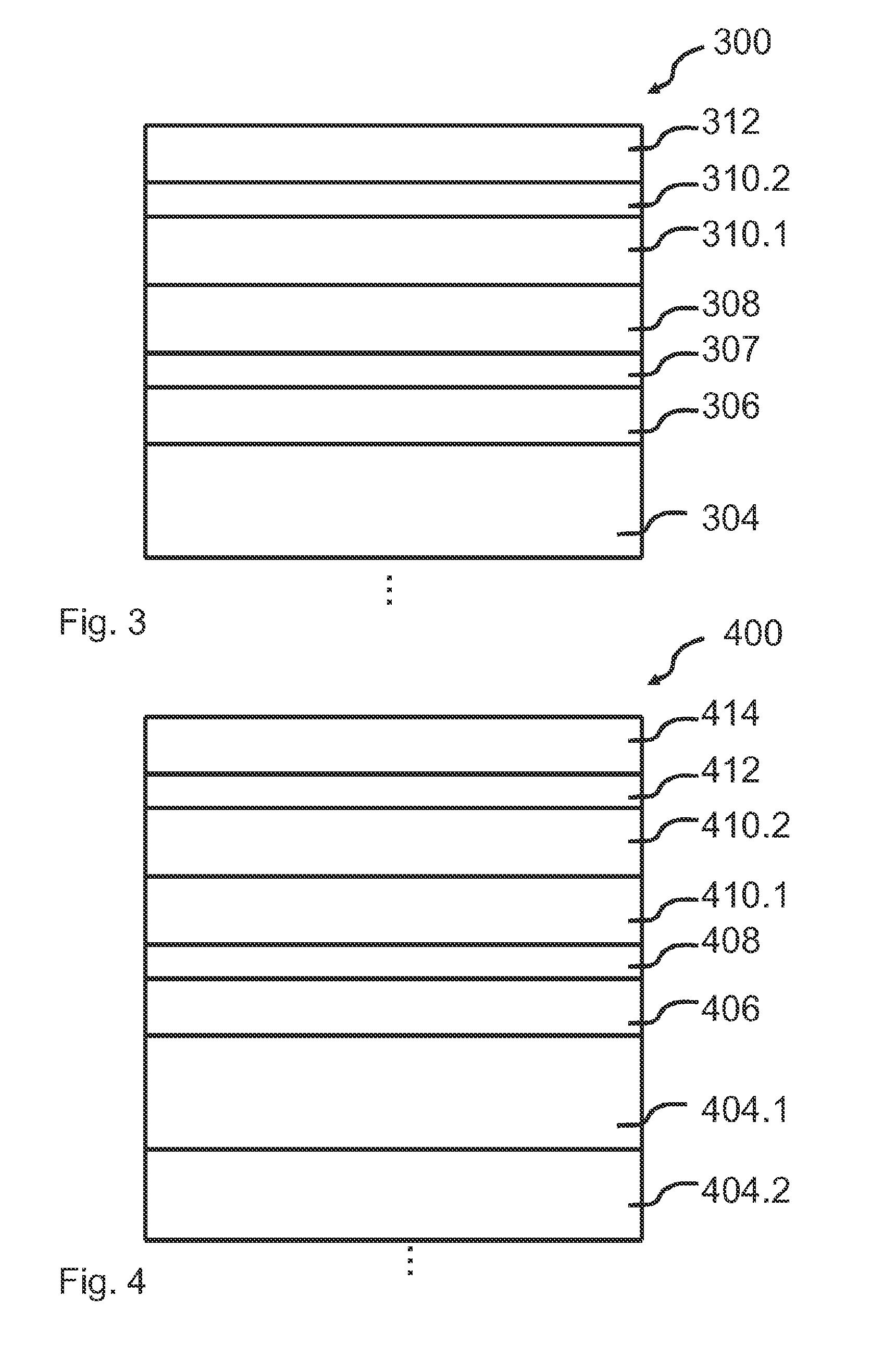

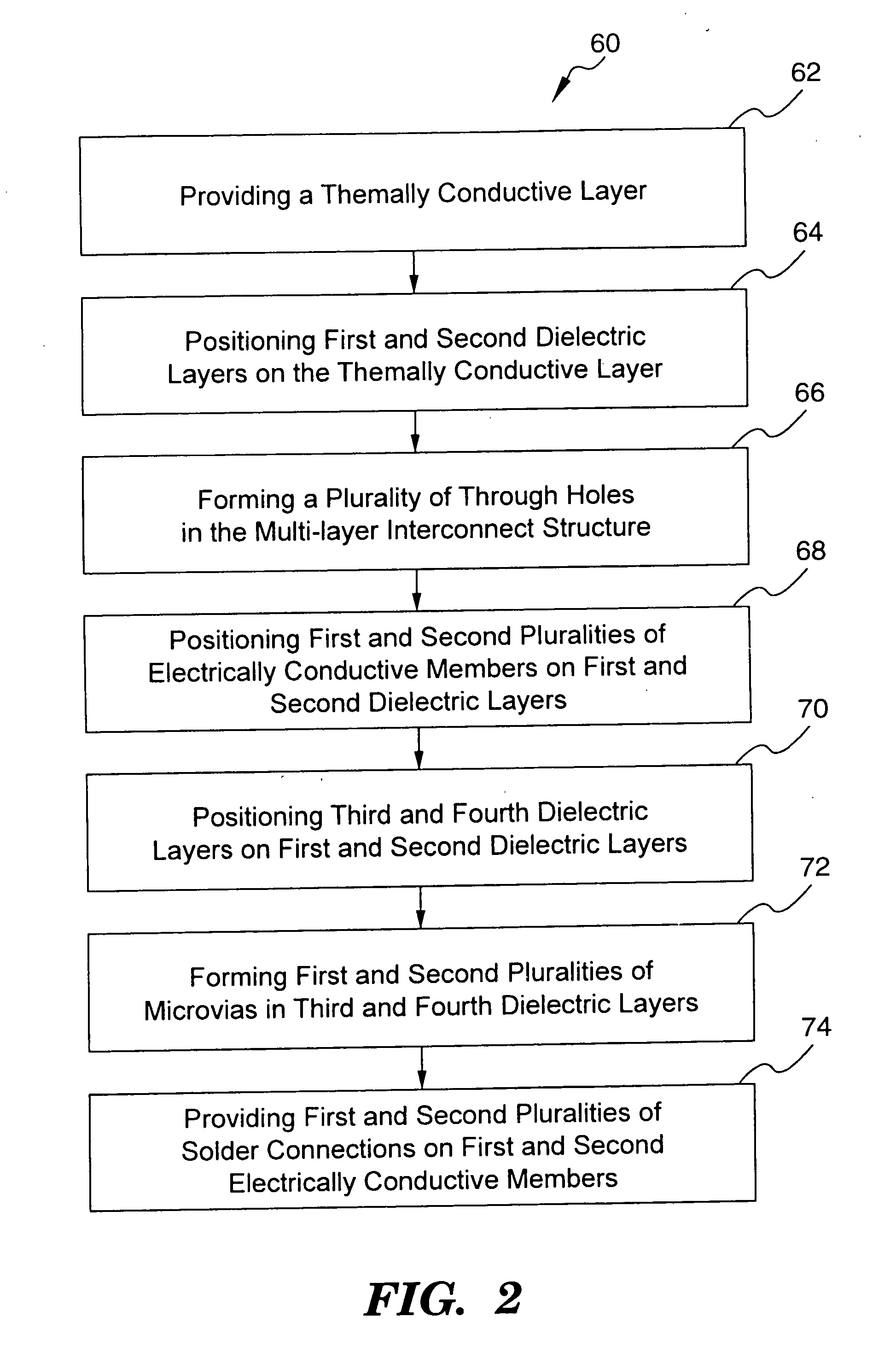

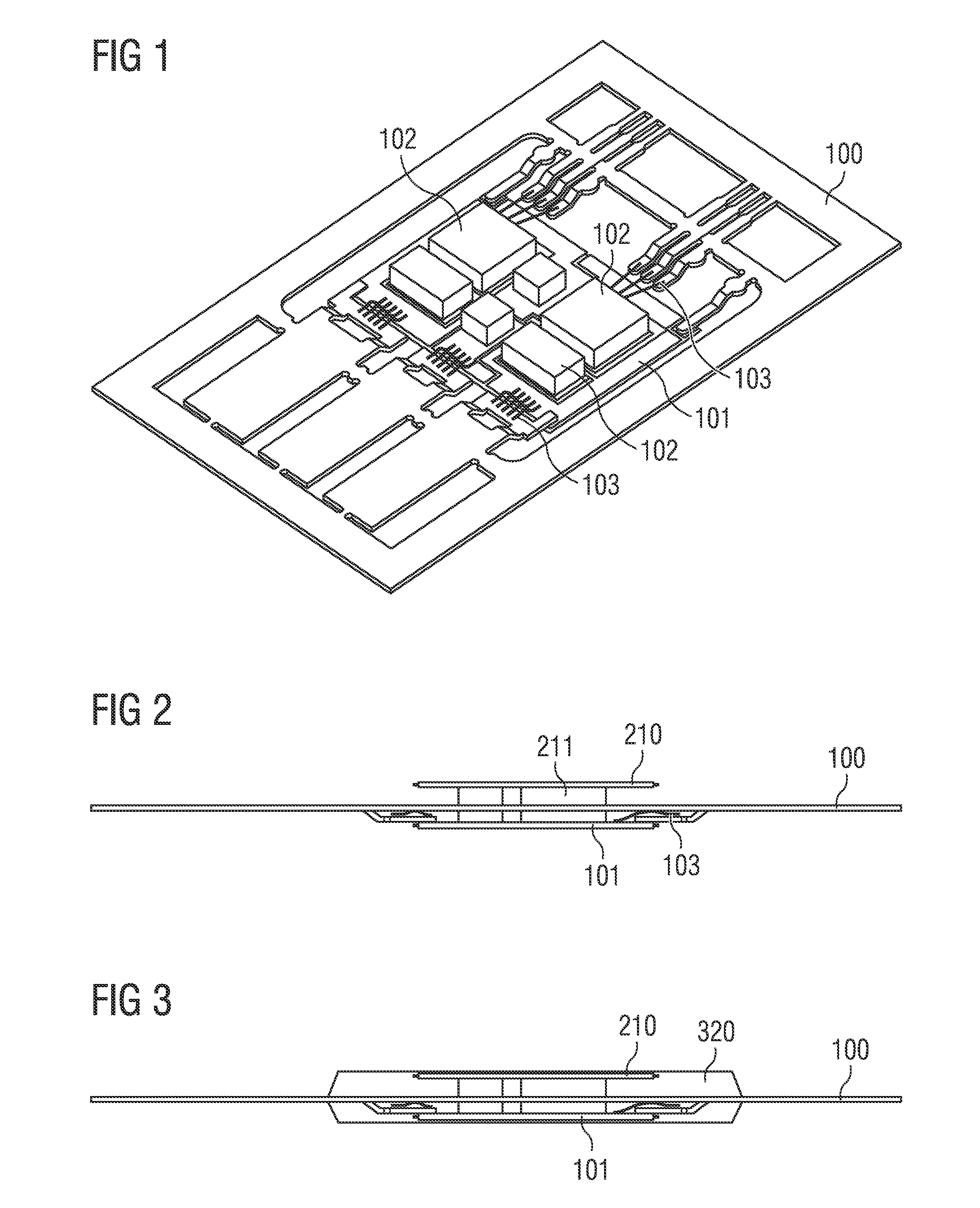

Electronic package with optimized lamination process

InactiveUS20050224961A1High densityFacilitates subsequent depositionDielectric materialsSemiconductor/solid-state device detailsDielectric layerMaximum temperature

An electronic package and method of formation. A thermally conductive layer having first and second opposing surfaces is provided. A first dielectric layer is laminated under pressurization to the first opposing surface of the thermally conductive layer, at a temperature between a minimum temperature T1MIN and a maximum temperature T1MAX. T1MAX constrains the ductility of the first dielectric layer to be at least D1 following the laminating. T1MAX depends on D1 and on a first dielectric material comprised by the first dielectric layer. A second dielectric layer is laminated under pressurization to the second opposing surface of the thermally conductive layer, at a temperature between a minimum temperature T2MIN and a maximum temperature T2MAX. T2MAX constrains the ductility of the second dielectric layer to be at least D2 following the laminating. T2MAX depends on D2 and on a second dielectric material comprised by the second dielectric layer.

Owner:VEECO INSTR

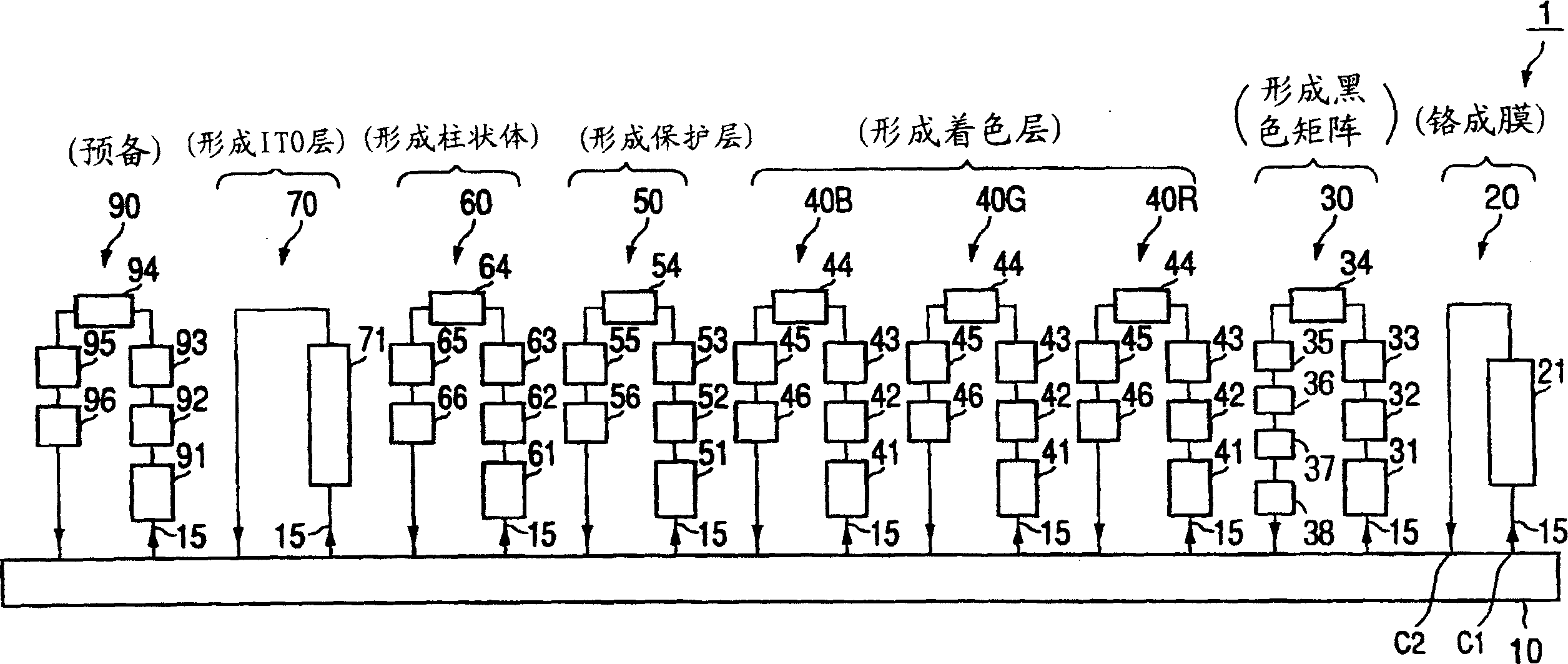

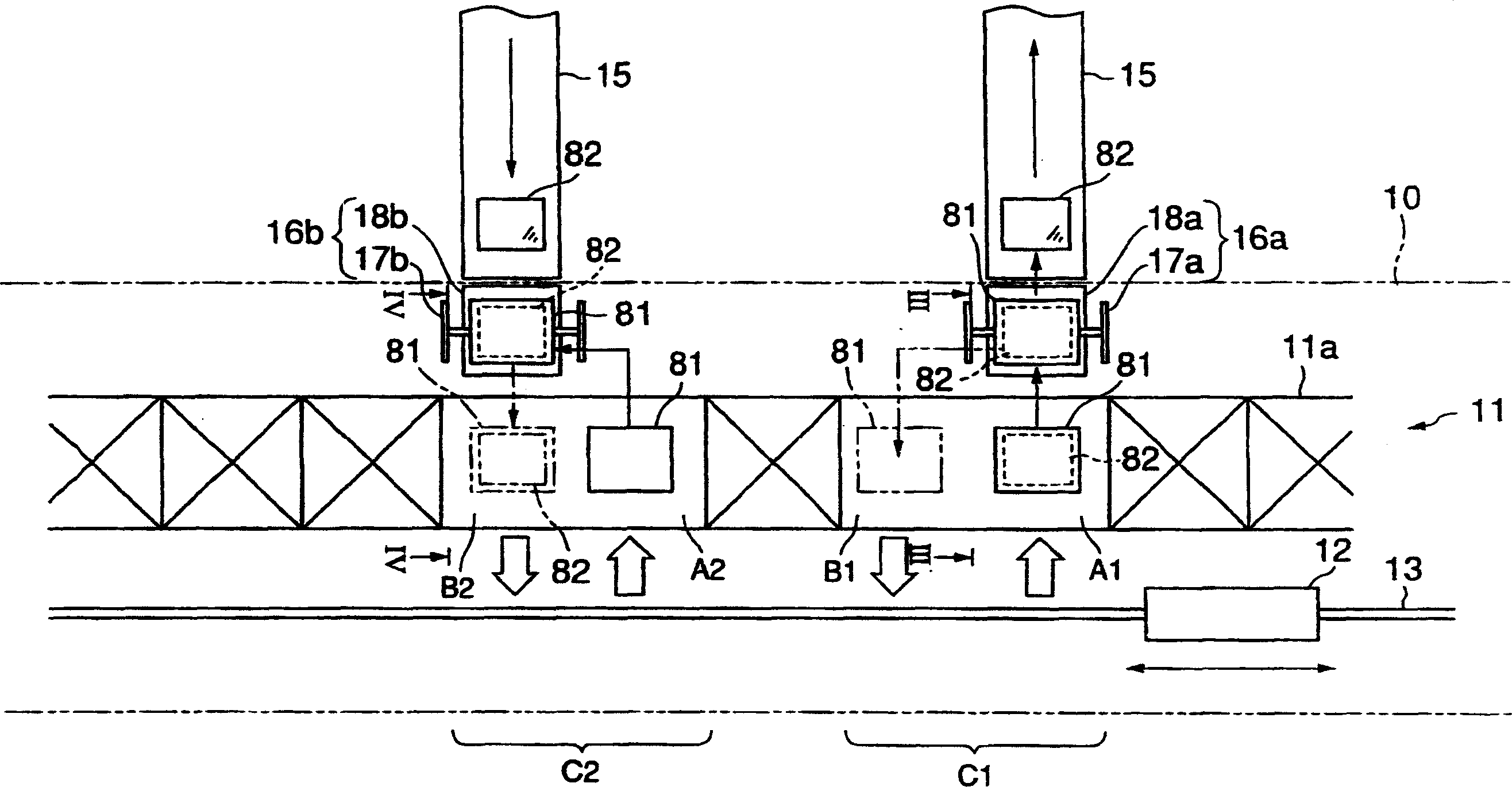

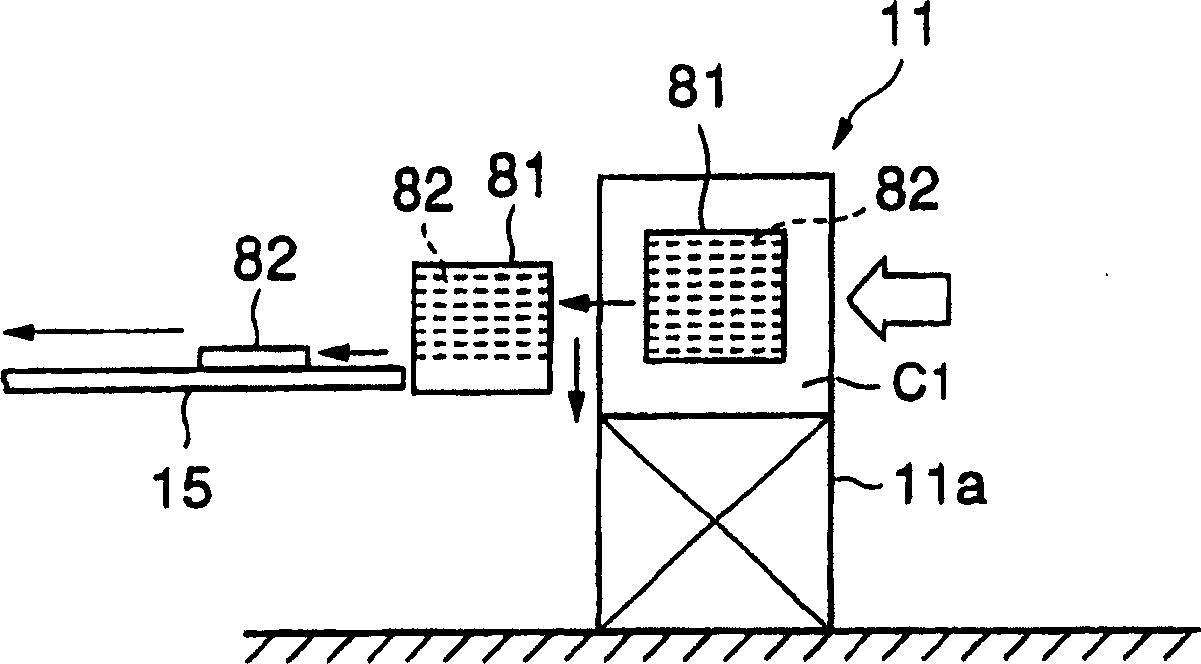

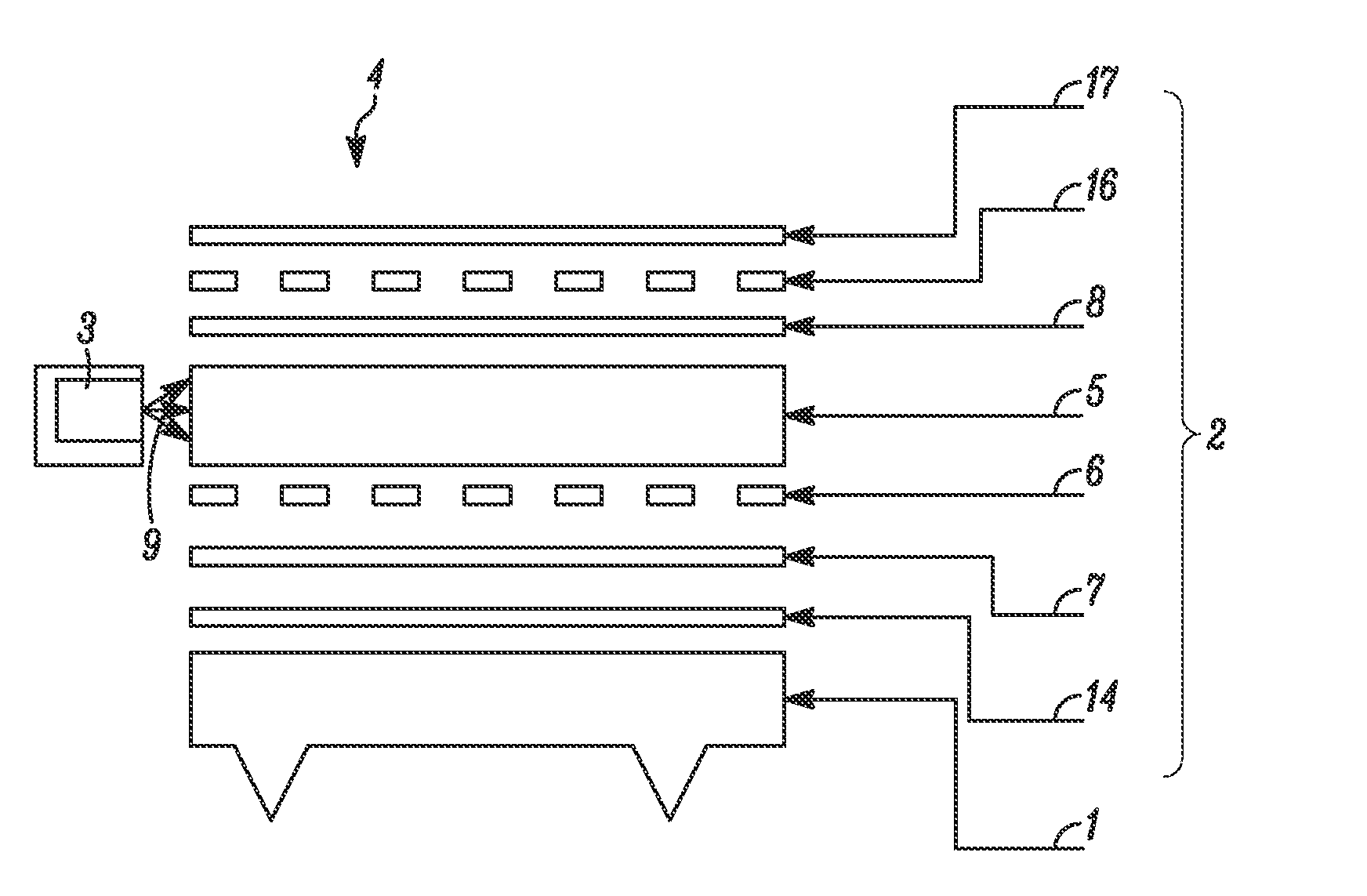

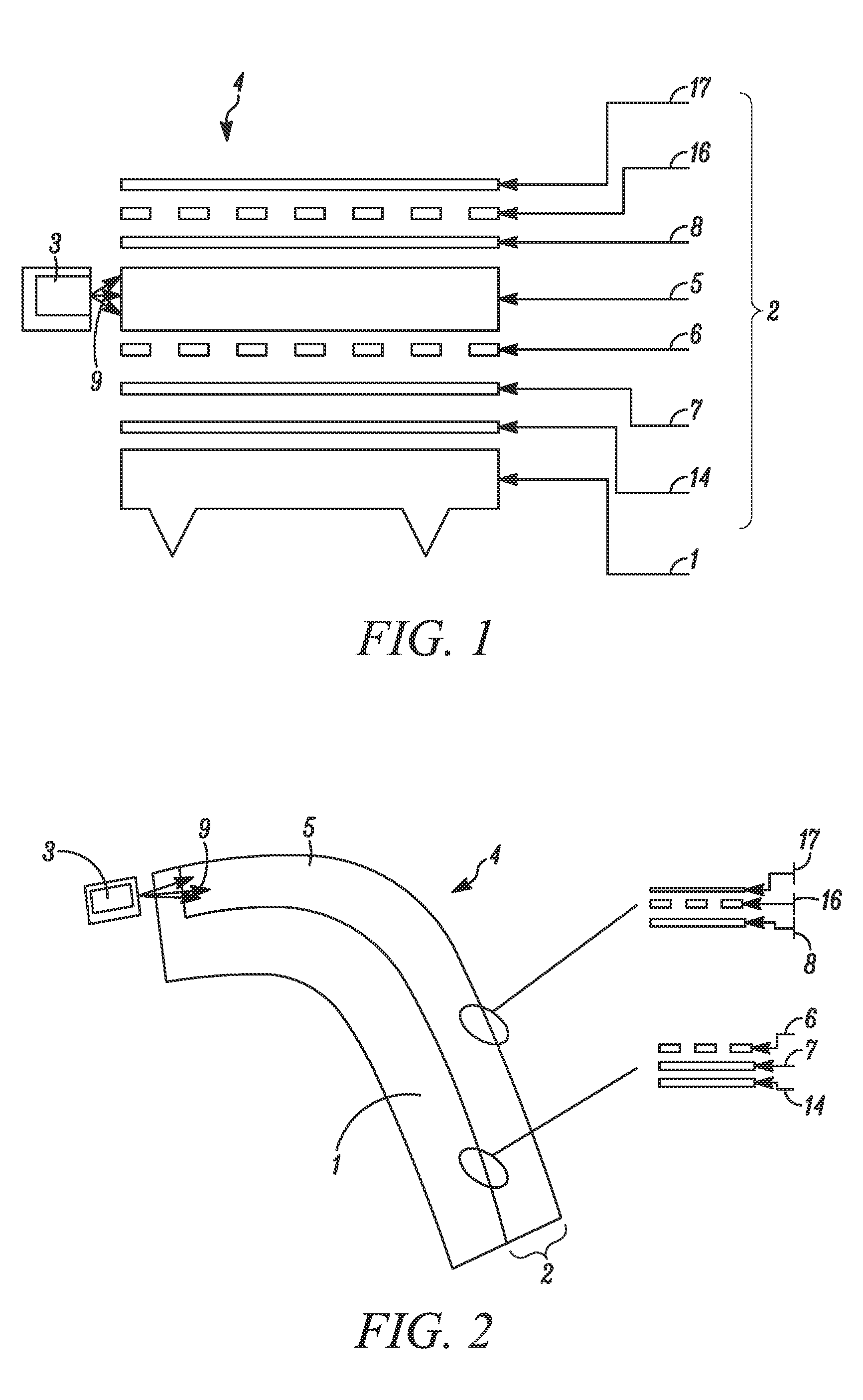

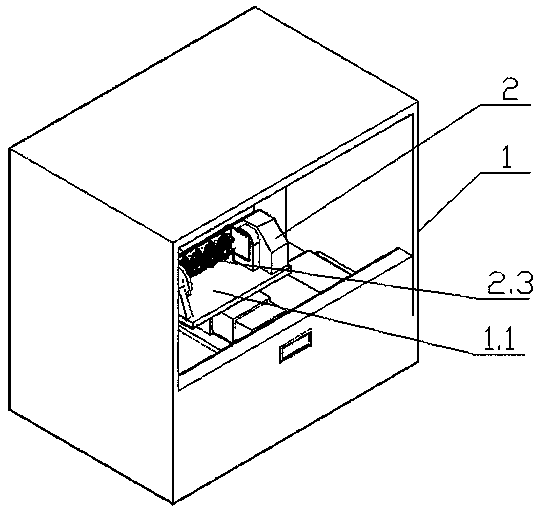

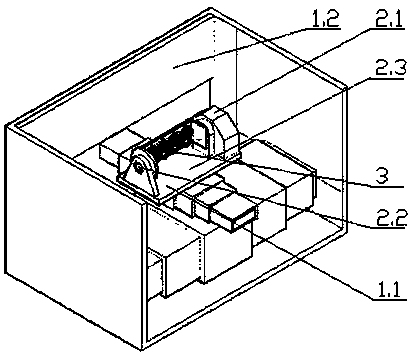

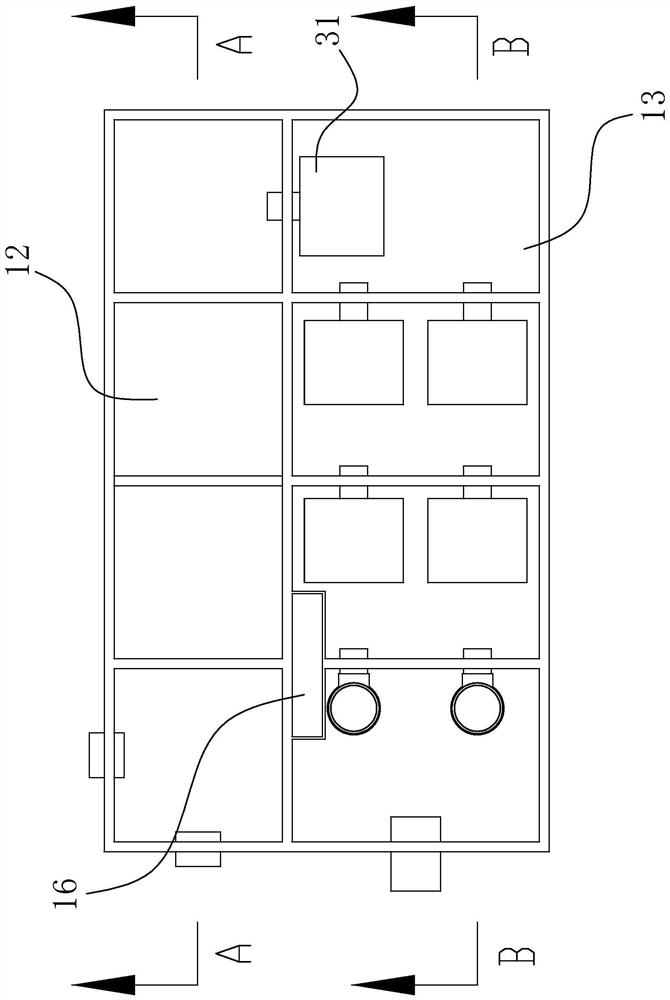

Production line system and automated warehouse used in the system

InactiveCN1672068AEasy to changeReduce operating rateOptical filtersSemiconductor/solid-state device manufacturingProduction lineEngineering

A production line system (1) comprises a core apparatus (10) of a stacker crane form and various processing lines (20, ..., 110) for performing various processes on a glass substrate that is received in a substrate receiving cassette stored in the core apparatus (10) and connected at plural loading / unloading positions (C1, C2) of the core apparatus (10) through a substrate loading / unloading mechanism (16a, 16b). At this time, the processing lines (20, ..., 90) are production lines that are used to perform various process for producing color filters, wherein the processing lines (20, ..., 70) are main screen-making lines for performing the processing steps including photolithography process, while the processing line (90) is a reserve screen-making line for performing the same process. Further, processing line (100) is a substrate inspection line that inspects a processed glass substrate that has been processed in the processing lines (20, ..., 90), and the processing line (110) is a substrate regeneration line that regenerates a glass substrate in which a defect was detected. Further, in a conveying path (15) of the processing lines (30, ..., 70), common defect inspection machines (39-77) are arranged for inspecting a common defect occurring at the same position in a plurality of glass substrates of the processed object. Further, the cassette that is stored and conveyed by the core apparatus (10) is preferably a frame line type cassettes that uses a plurality of frame lines suspending between left and right frames to support the substrate in a horizontal status.

Owner:DAI NIPPON PRINTING CO LTD

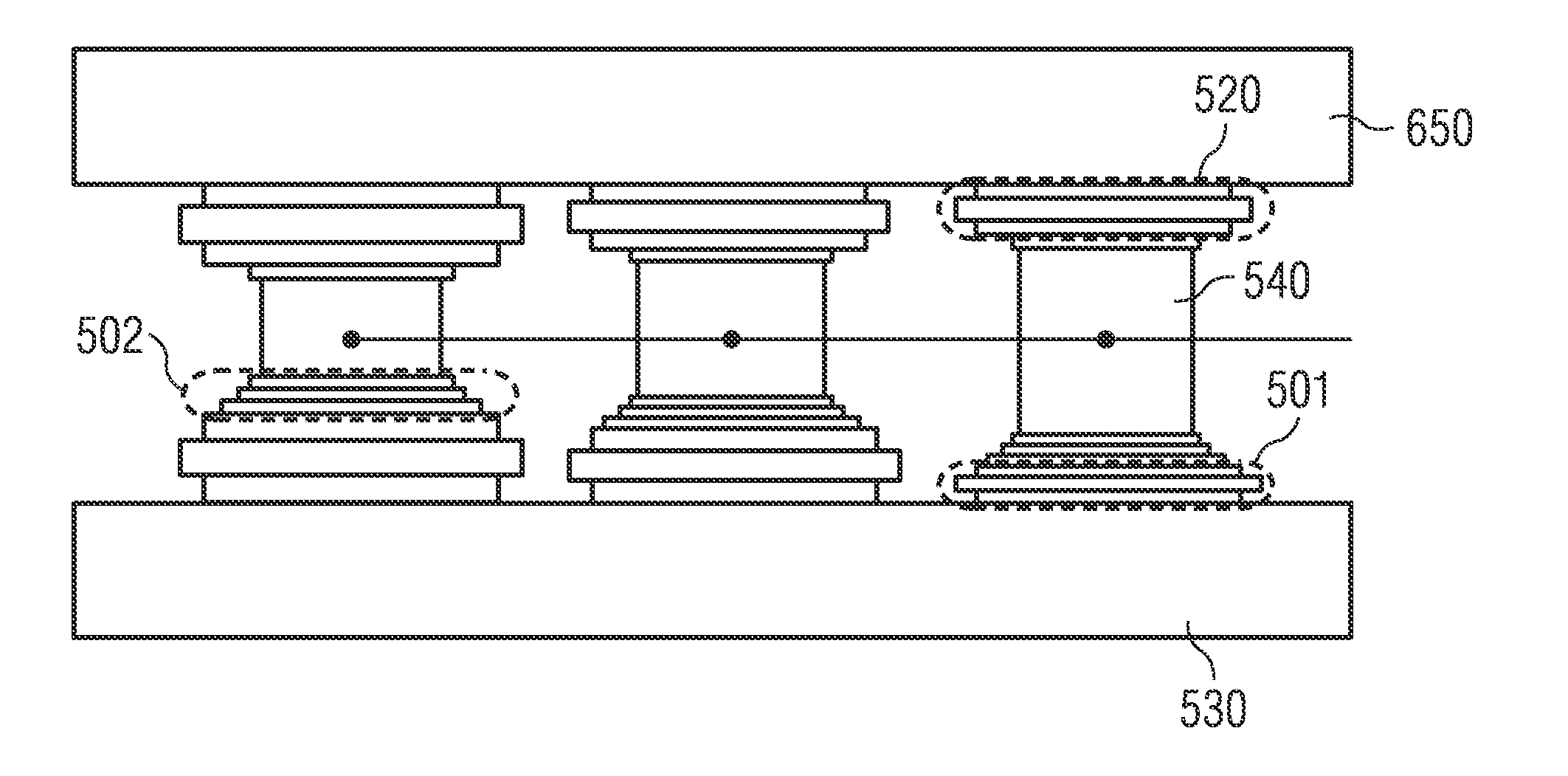

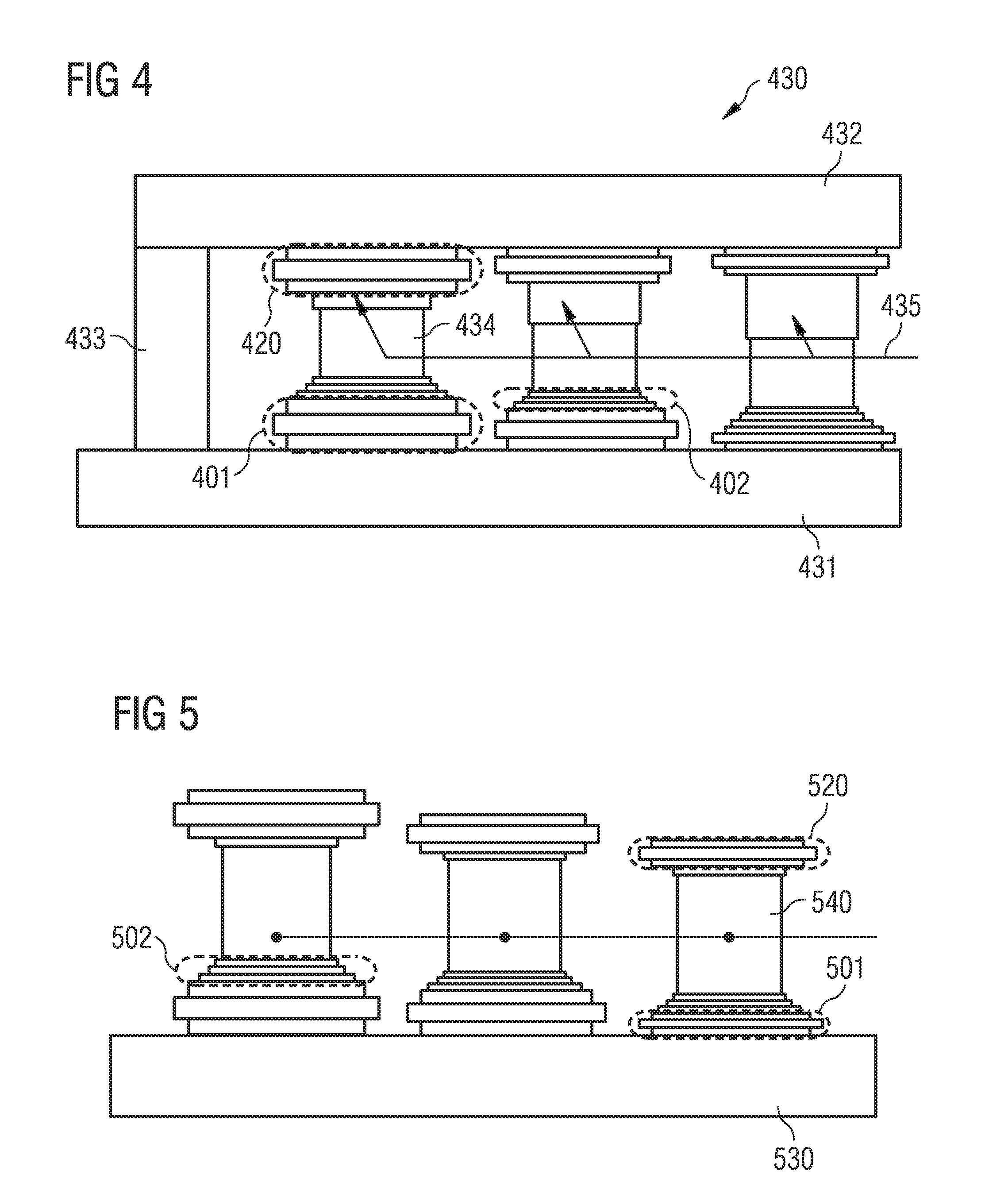

Power module comprising two substrates and method of manufacturing the same

ActiveUS20140353818A1Reduce thicknessImprove accuracySemiconductor/solid-state device detailsSolid-state devicesEngineeringPower module

A method of manufacturing a power module comprising two substrates is provided, wherein the method comprises disposing a compensation layer of a first thickness above a first substrate; disposing a second substrate above the compensation layer; and reducing the thickness of the compensation layer from the first thickness to a second thickness after the second substrate is disposed on the compensation layer

Owner:INFINEON TECH AG

Cryogenic grinding of tantalum for use in capacitor manufacture

InactiveUS20160336115A1Easy millingExemption stepsLiquid electrolytic capacitorsCapacitor electrodesElectrolysisEngineering

An electrolytic capacitor comprising an anode comprised of cryogenically milled anode material is described. The cryogenic milling process prepares the active anode material for anode fabrication. The capacitor further comprises a casing of first and second casing members secured to each other to provide an enclosure. A feedthrough electrically insulated from the casing and from the casing and extending there from through a glass-to-metal seal, at least one anode electrically connected within the casing, a cathode, and an electrolyte. The cathode is of a cathode active material deposited on planar faces of the first and second casing members.

Owner:WILSON GREATBATCH LTD

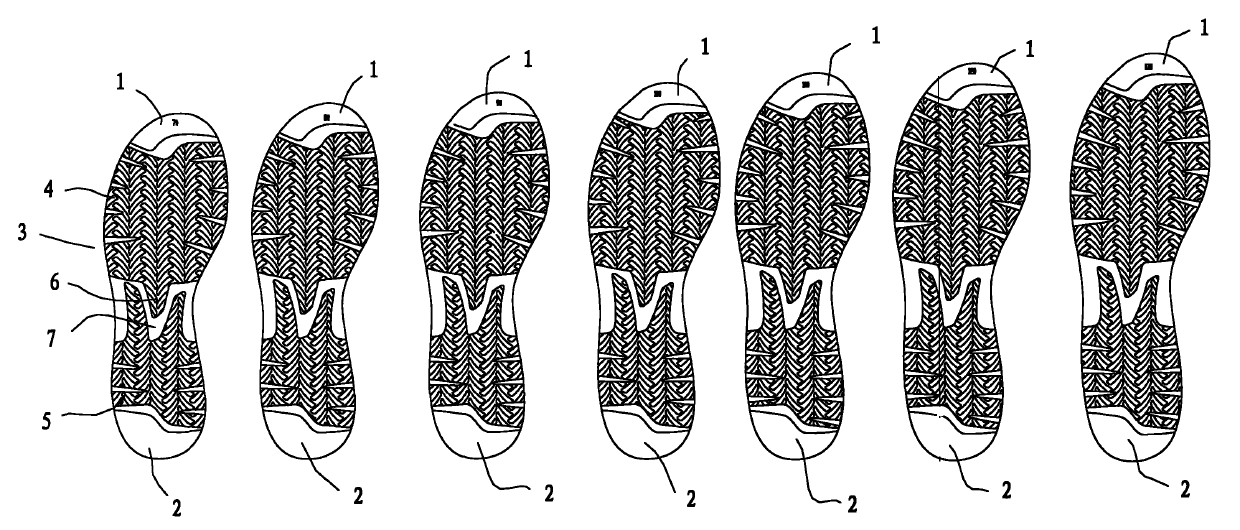

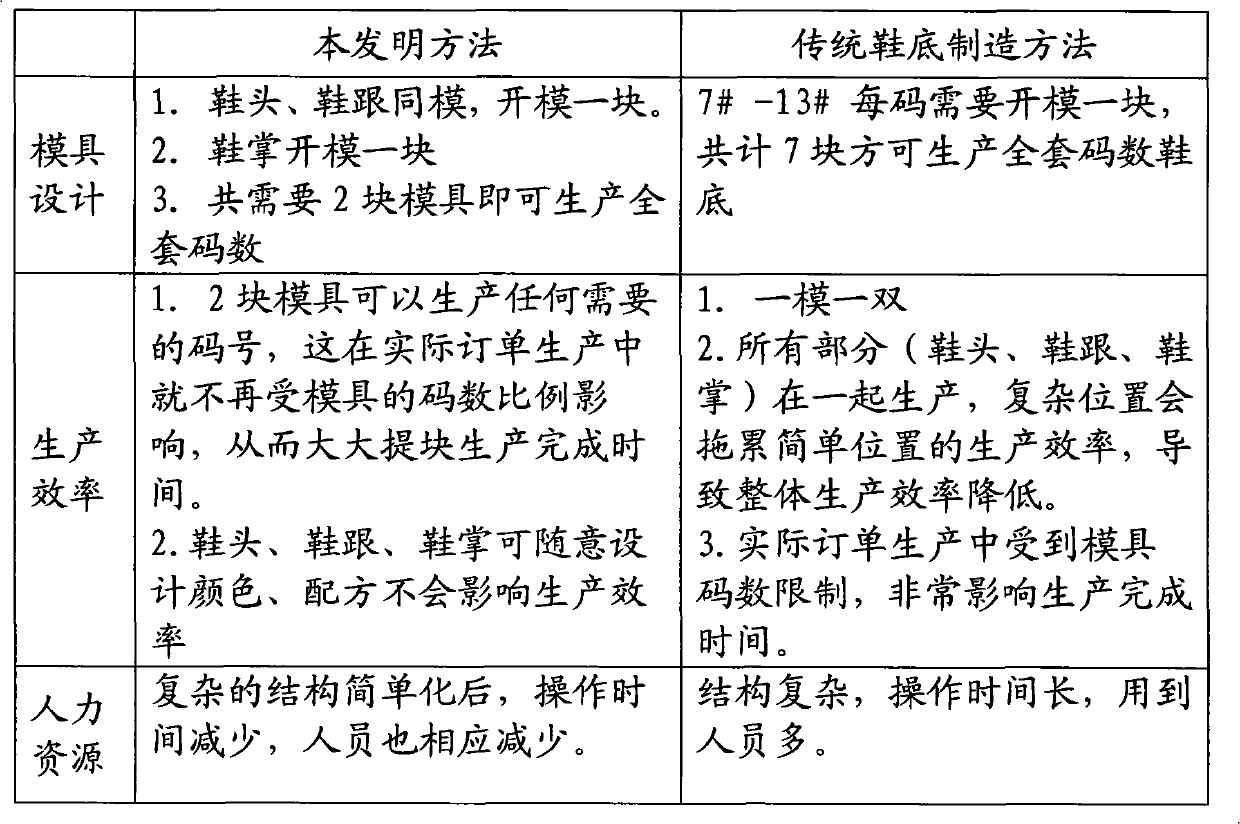

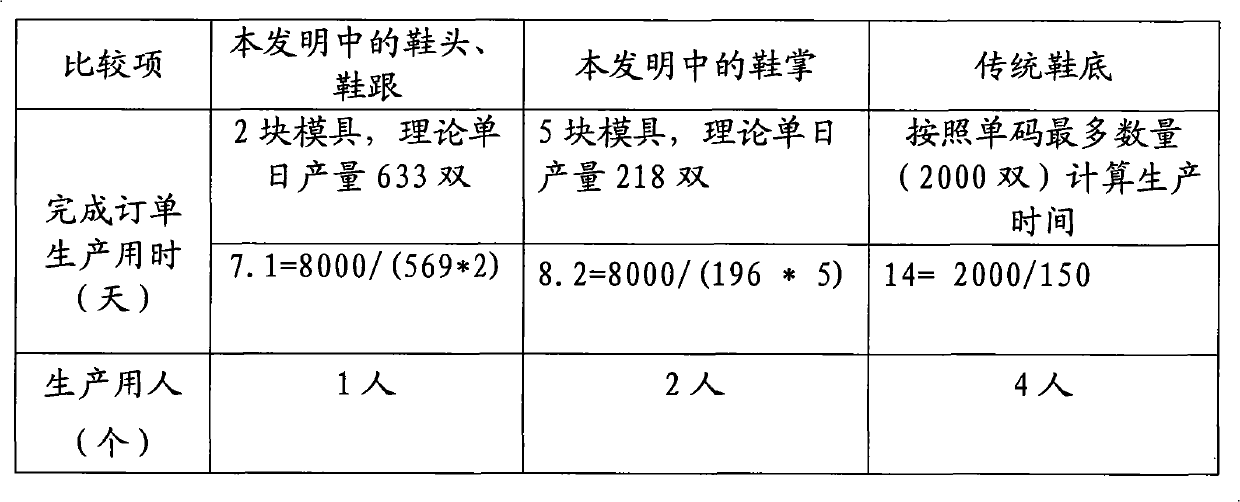

Soles with grading design and manufacturing method thereof

The invention discloses grading soles, wherein, the soles of different sizes are composed of shoe heads, heelpieces formed by clipping the soles of the maximum size, and shoe heels, and the shoe heads and the shoe heels of different sizes are identical respectively. The manufacturing method of the grading soles comprises the following steps: a. manufacturing the shoe heads and the shoe heels; b. manufacturing the heelpieces according to the maximum size in a grading design; c. tailoring the excess parts of the heelpieces to form the heelpieces of different sizes; and d. splicing the shoe heads, the heelpieces and the shoe heels respectively to obtain the soles of different sizes. The invention has the advantages of reducing the quantity of dies of a complete set of the soles, greatly lowering the die expenses, obviously improving the production efficiency of the soles and lowering the production cost; and in addition, as the sole design is changed into a fragmented form, different formulas or decorative patterns can be selected according to different positions, thus enhancing the use effect of the soles.

Owner:黄贻钧

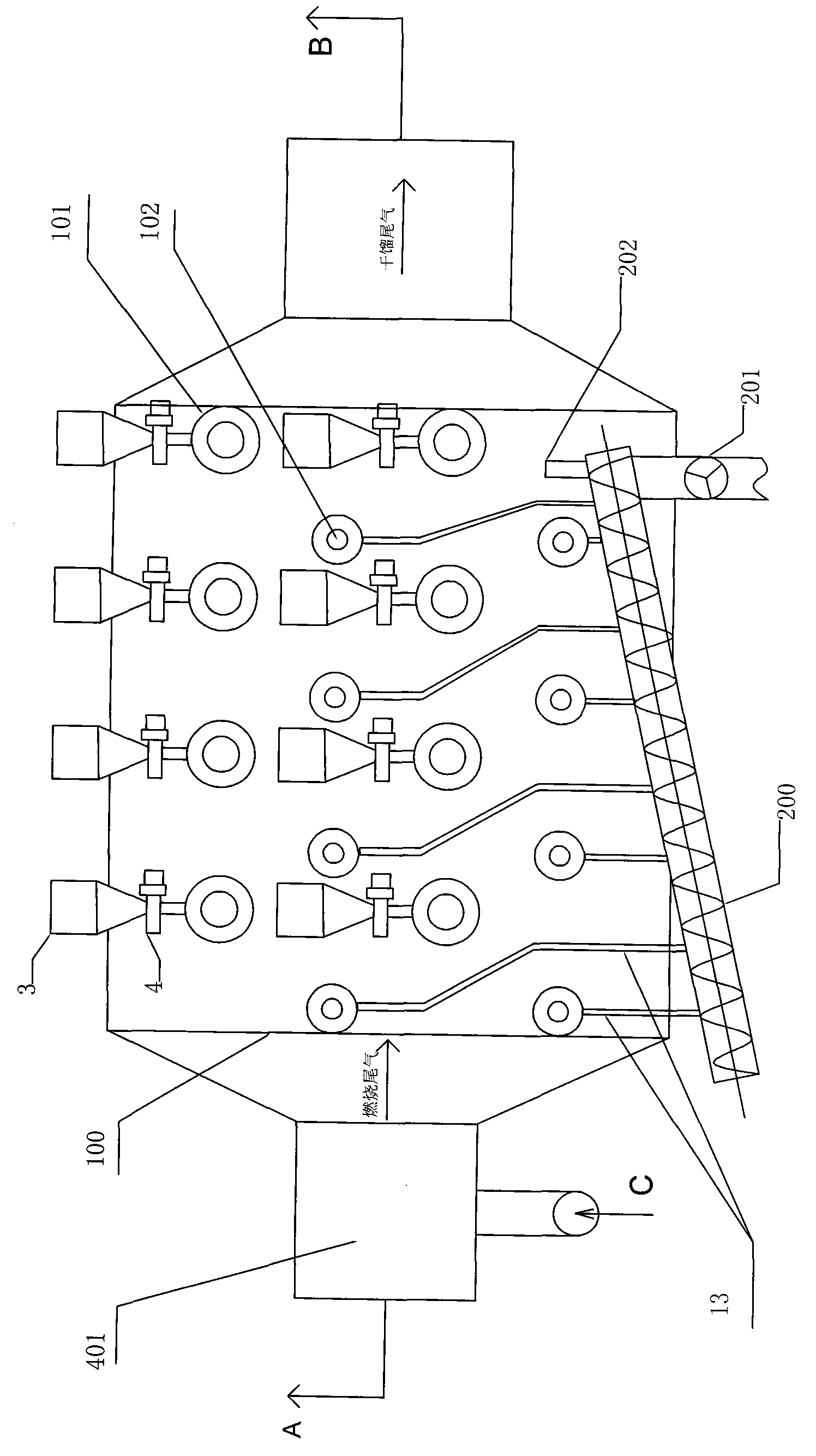

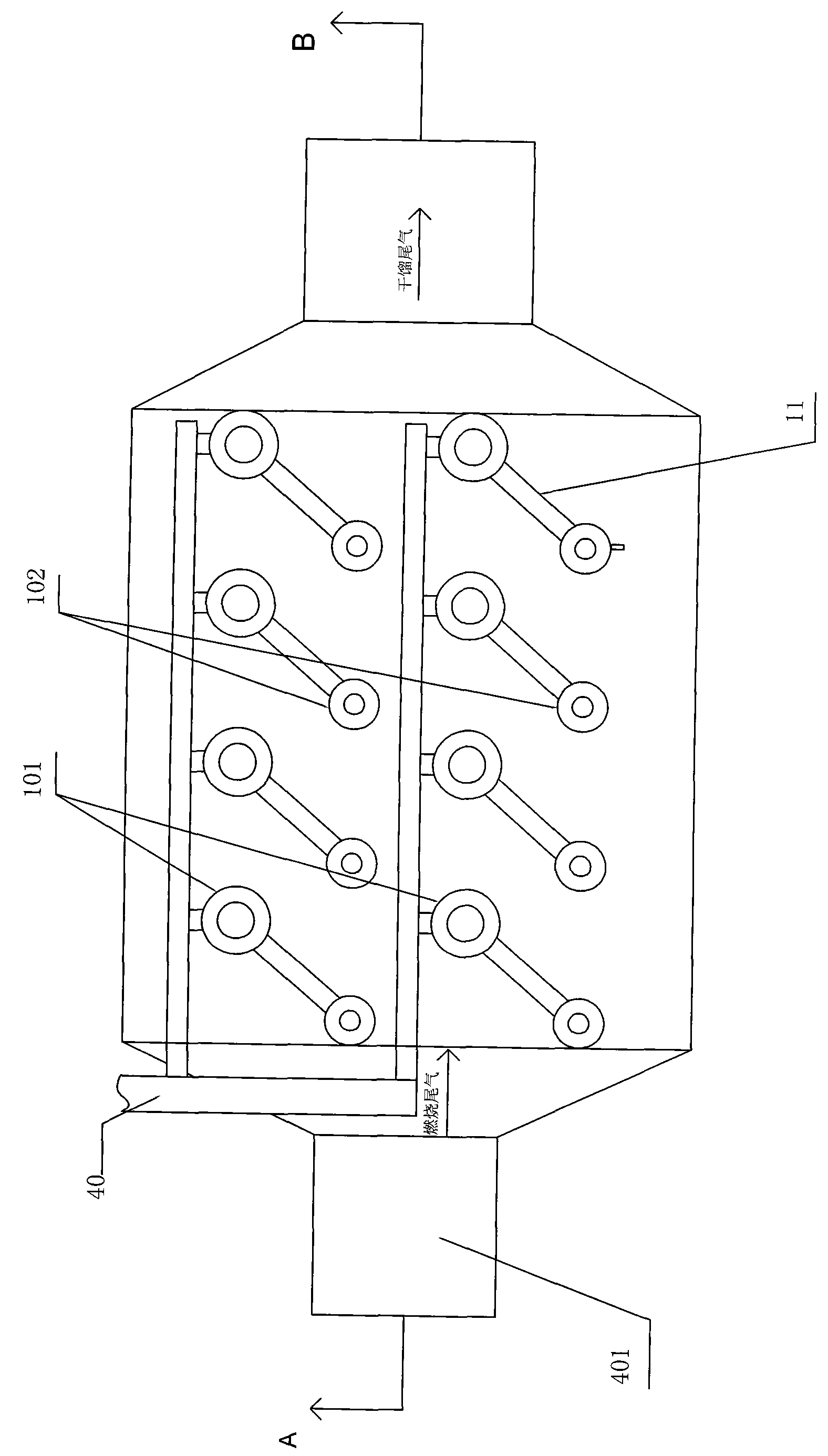

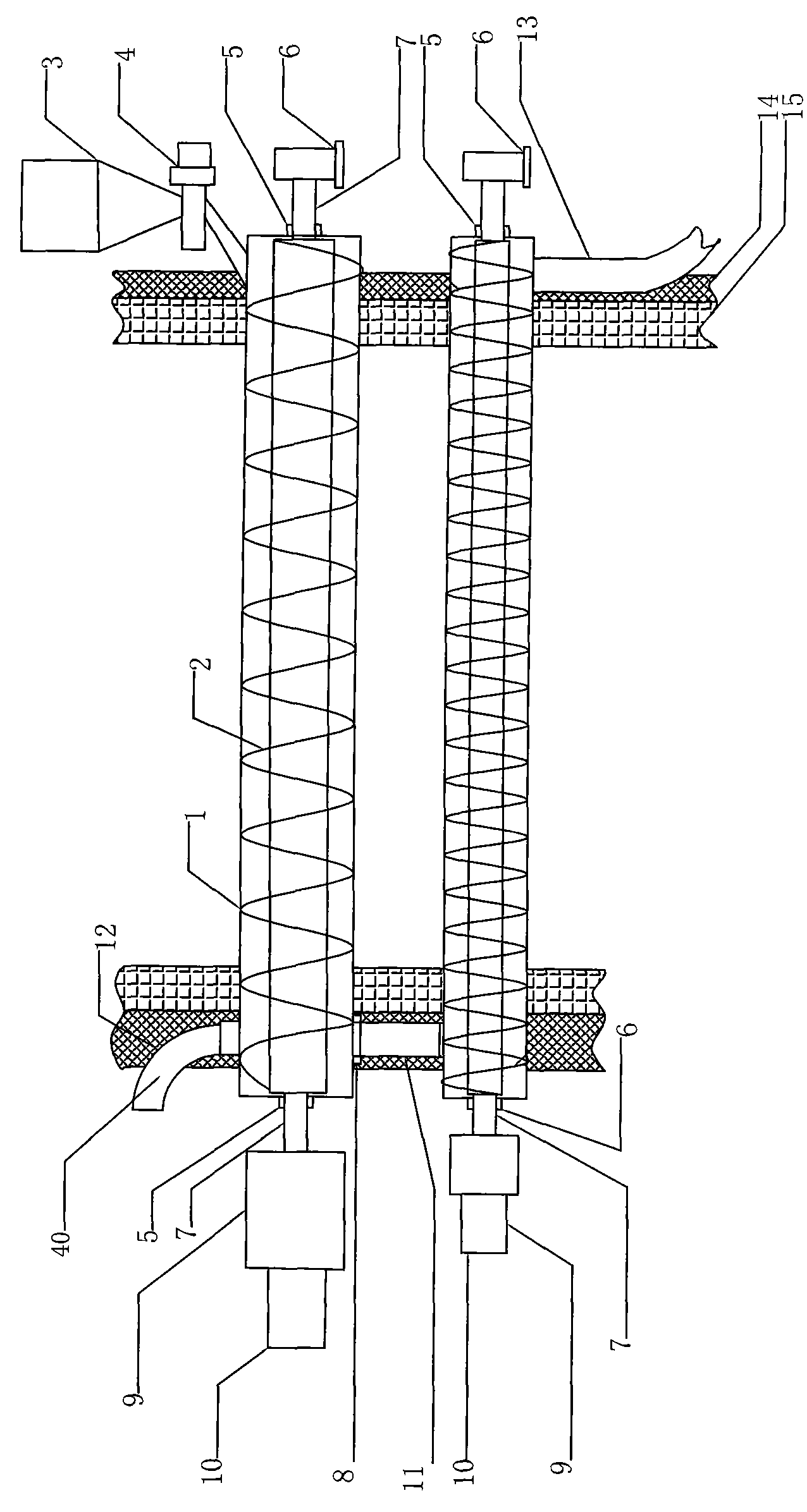

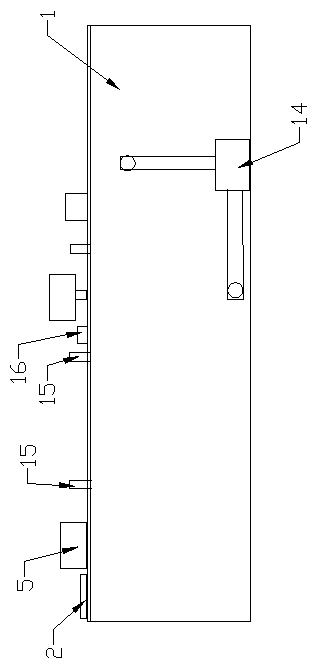

Combined sludge treatment method and dry distillation device applied by same

ActiveCN101671099ATake advantage ofLow costSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustionSludge

The invention provides a combined sludge treatment method. In the treatment method, by combining the technologies of semidrying, dry distillation and cracking as well as combustion treatment, dewatering sludge is treated step by step; the sludge with water content of 75 percent is treated, and then inorganic substances are converted into solid residues by high-temperature treatment, and organic substances are converted into CO2, H2O and recyclable resource of fluid oil; and in the treatment process, heat energy can be fully and comprehensively utilized, all treatment technologies are reasonably distributed, the treatment energy consumption is not increased when treatment processes are increased, and heat energy from coal combustion is used in balance. The invention also provides a dry distillation device for treating sludge, comprising a dry distillation box, wherein a group of or a plurality of groups of two-stage dry distillers for treating sludge are arranged, and the two-stage drydistiller comprises a first-stage dry distiller and a second-stage dry distiller. In the dry distillation process, the material process and the stirring force are different, the materials are mainly dried continuously in the first-stage dry distiller, and the cracking is mainly carried out in the second-stage dry distiller; and the hierarchical arrangement is beneficial to process control, waste gas treatment and heat recovery.

Owner:沈洪来

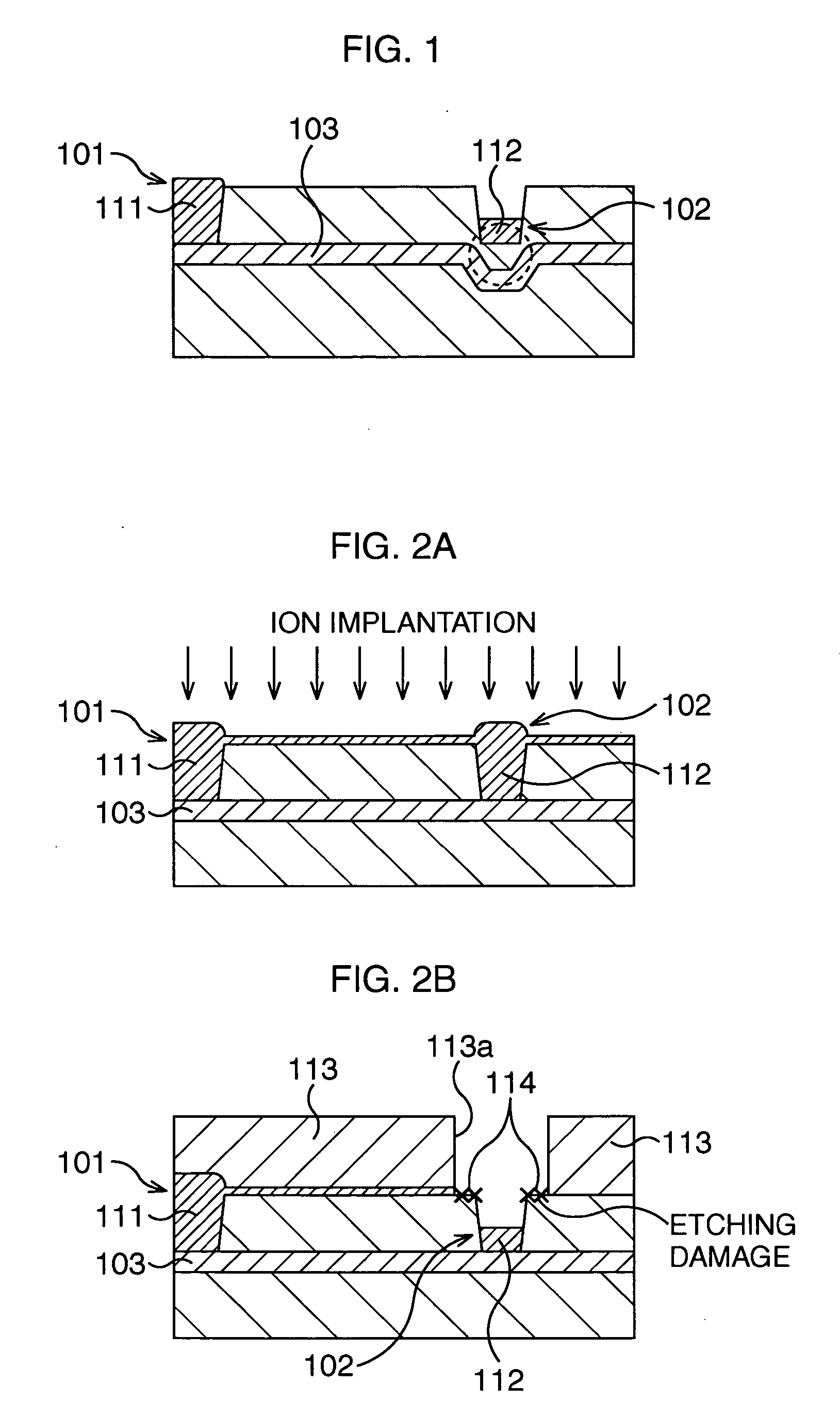

Semiconductor device and manufacturing method thereof

InactiveUS20070164339A1Highly integratedAdditional processing stepsTransistorSolid-state devicesDevice materialIon implantation

A channel stop region is formed immediately under an STI, and thereafter, an ion implantation is performed with conditions in which an impurity is doped into an upper layer portion of an active region, and at the same time, the impurity is also doped into immediately under another STI, and a channel dose region is formed at the upper layer portion of the active region, and another channel stop region is formed immediately under the STI.

Owner:FUJITSU SEMICON LTD +1

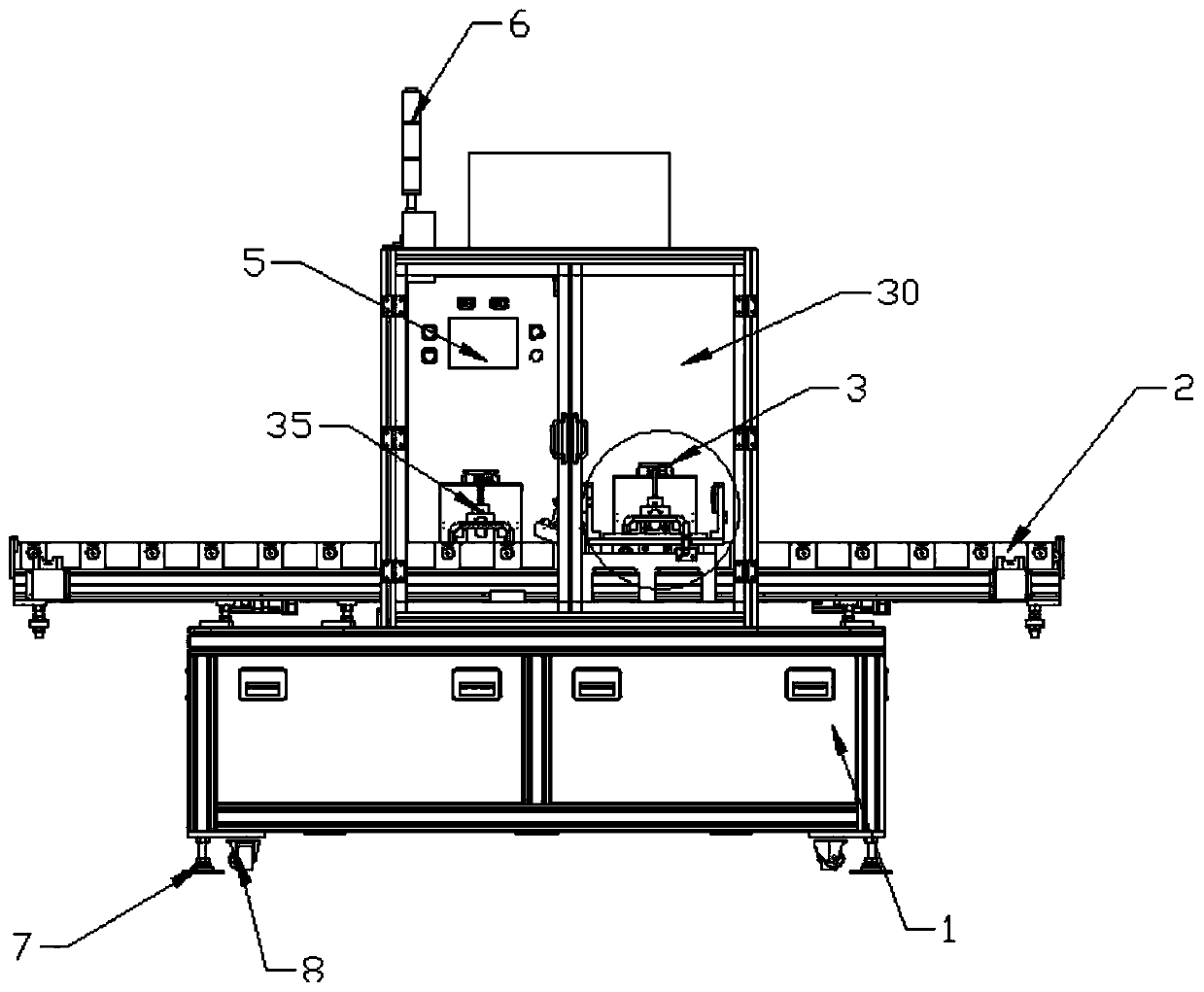

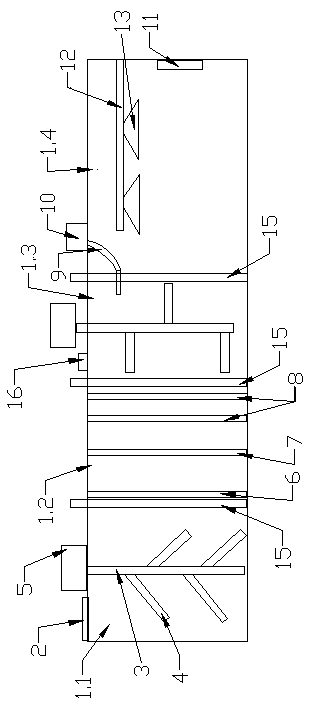

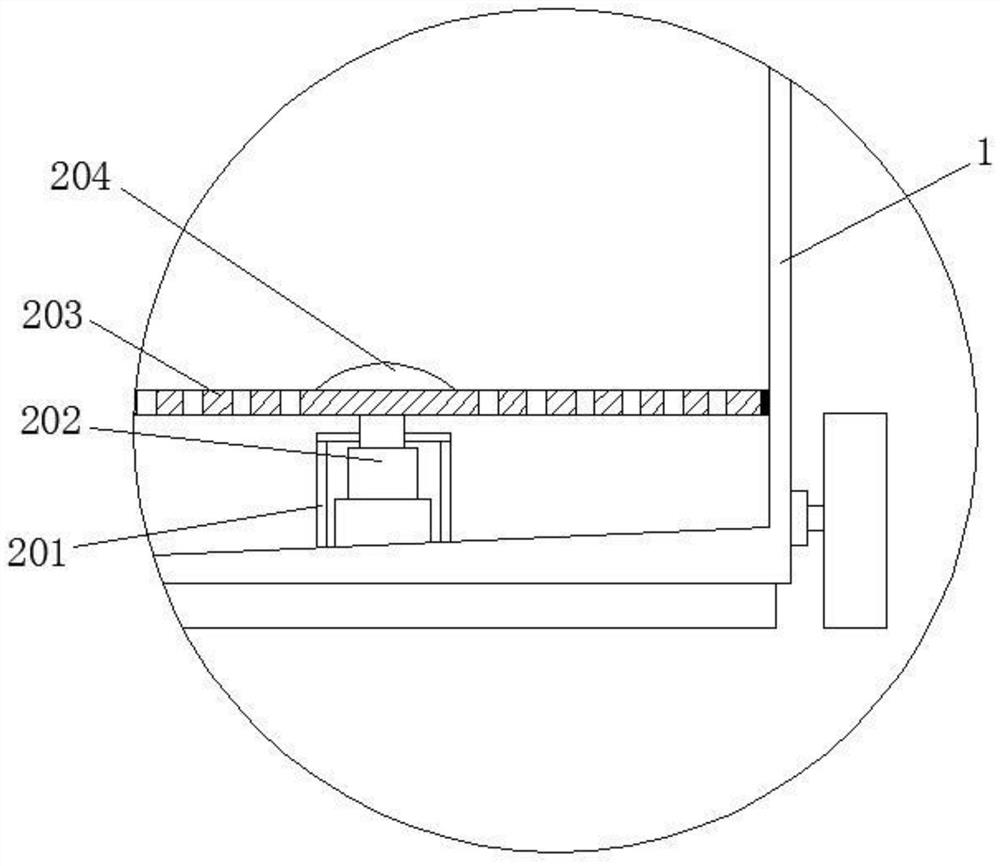

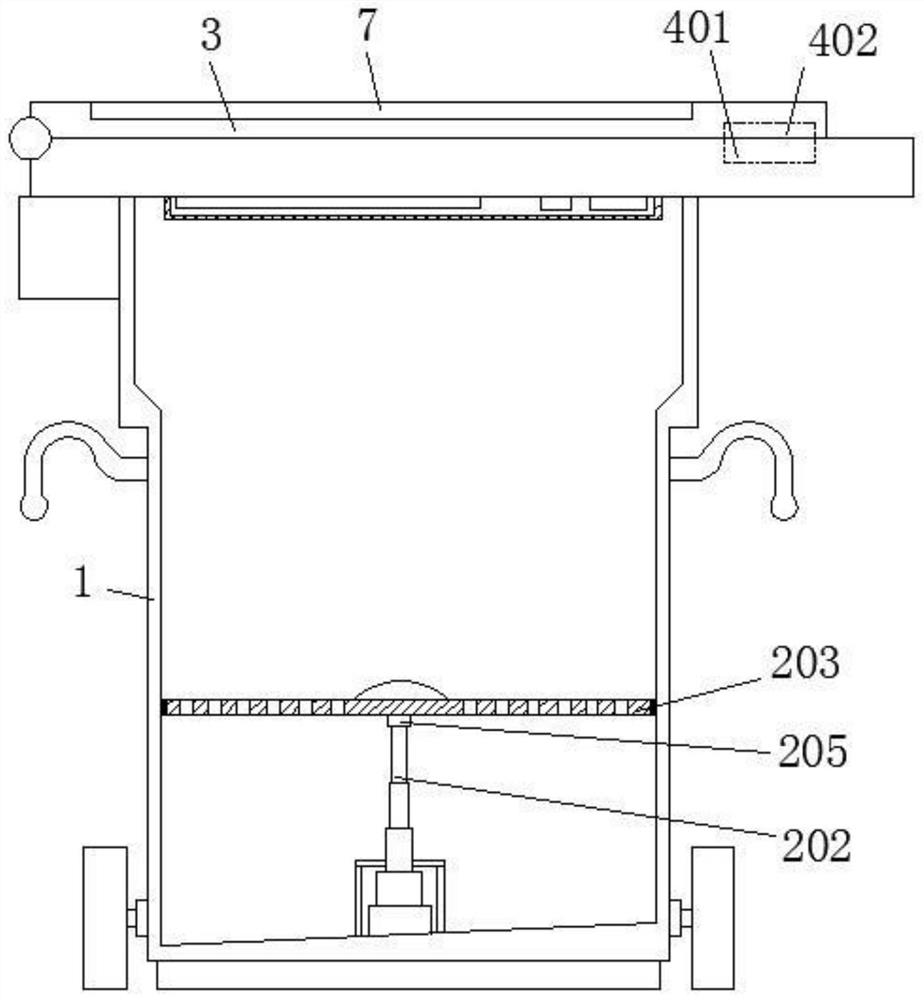

Energy-saving cleaning machine and method

InactiveCN109954704AAdditional processing stepsReduce consumptionDrying gas arrangementsCleaning using liquidsWater sourceSewage

The invention discloses an energy-saving cleaning machine and method. The energy-saving cleaning machine comprises a machine body, a conveying mechanism, a cleaning and drying unit, a sewage recoverytank, a control display interface panel, a tricolor alarm lamp, supporting foot stools and moving idler wheels; the conveying mechanism is detachably mounted on the machine body, the cleaning and drying unit is fixedly mounted on the machine body and arranged above the conveying mechanism, the sewage recovery tank is mounted at the bottom of the cleaning and drying unit, and a controller is arranged on the machine body; the bottom of the machine body is provided with a circulation pipeline communicating with the bottom of the sewage recovery tank; another port of the circulation pipeline is connected with a water replenishing tank; and the water replenishing tank communicates with a water feeding pipe through an electromagnetic valve, and the controller controls the capacity of water in the water replenishing tank through a pressure sensor. After a cleaning piece is cleaned, the sewage recovery tank is arranged under a cleaning frame, sewage is filtered and purified through the sewagerecovery tank and recycled again through the circulation pipeline, and thus water source consumption is reduced.

Owner:NANJING HANMINGZHI INTELLIGENT TECHNOLOGY CO LTD

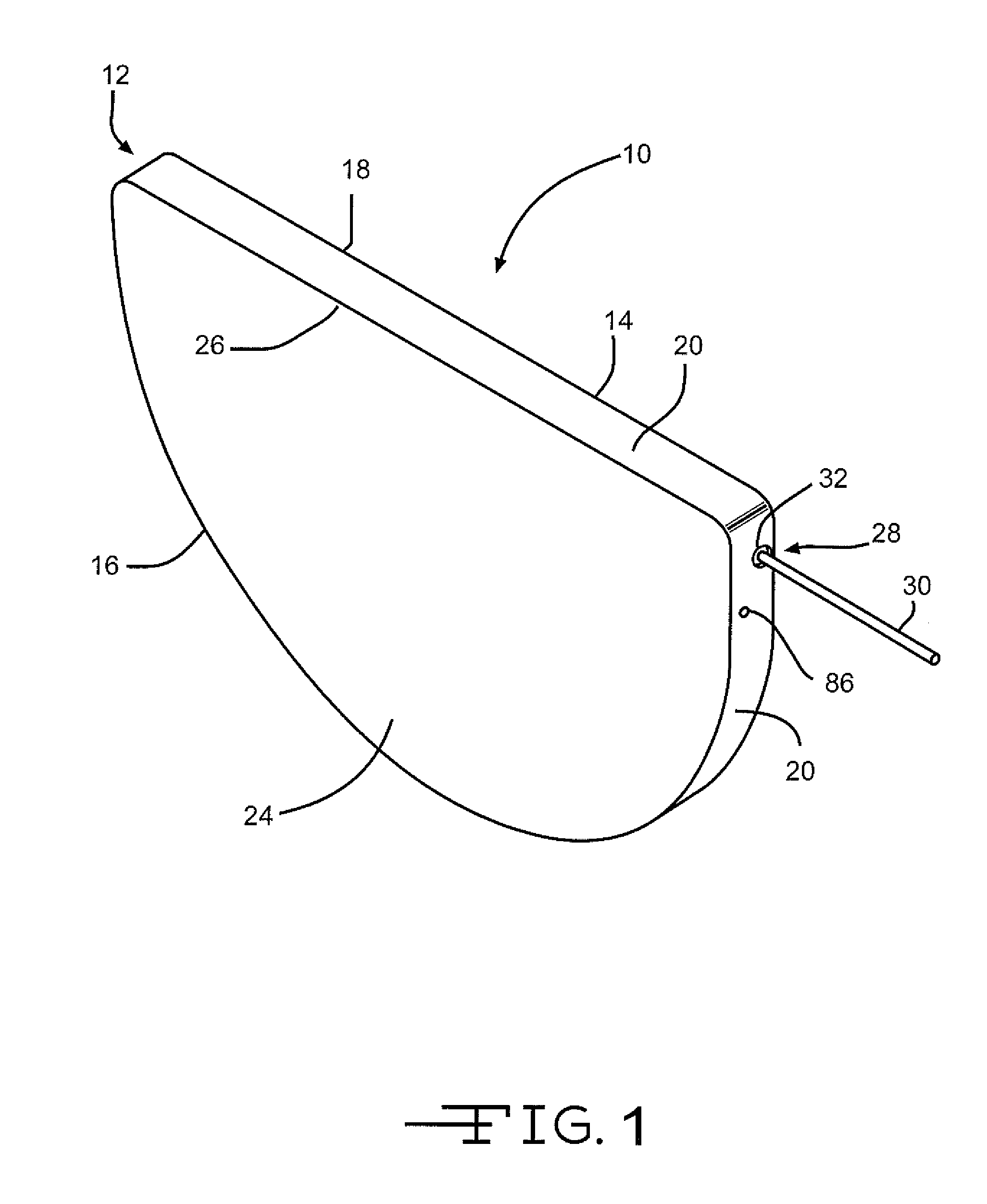

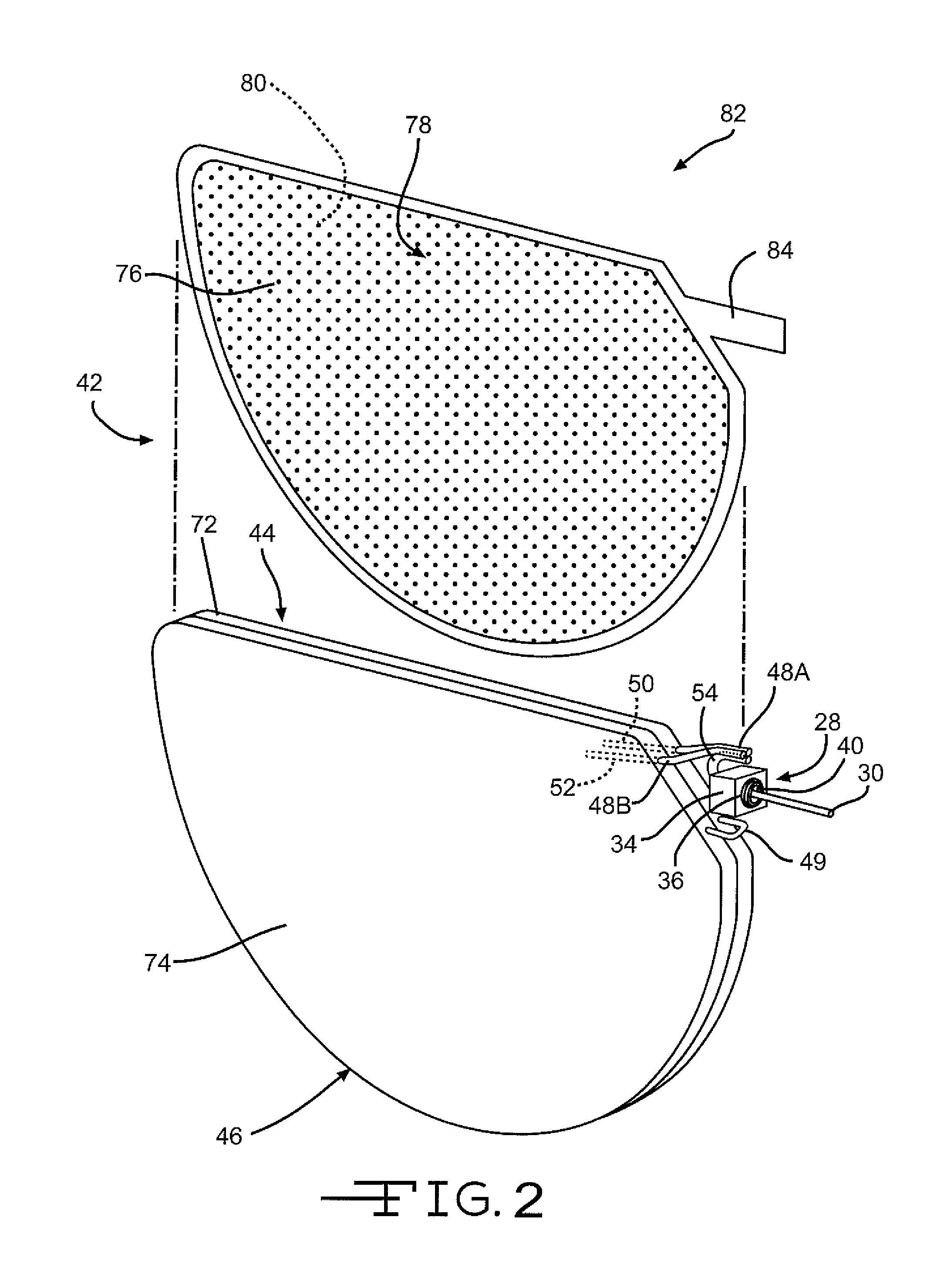

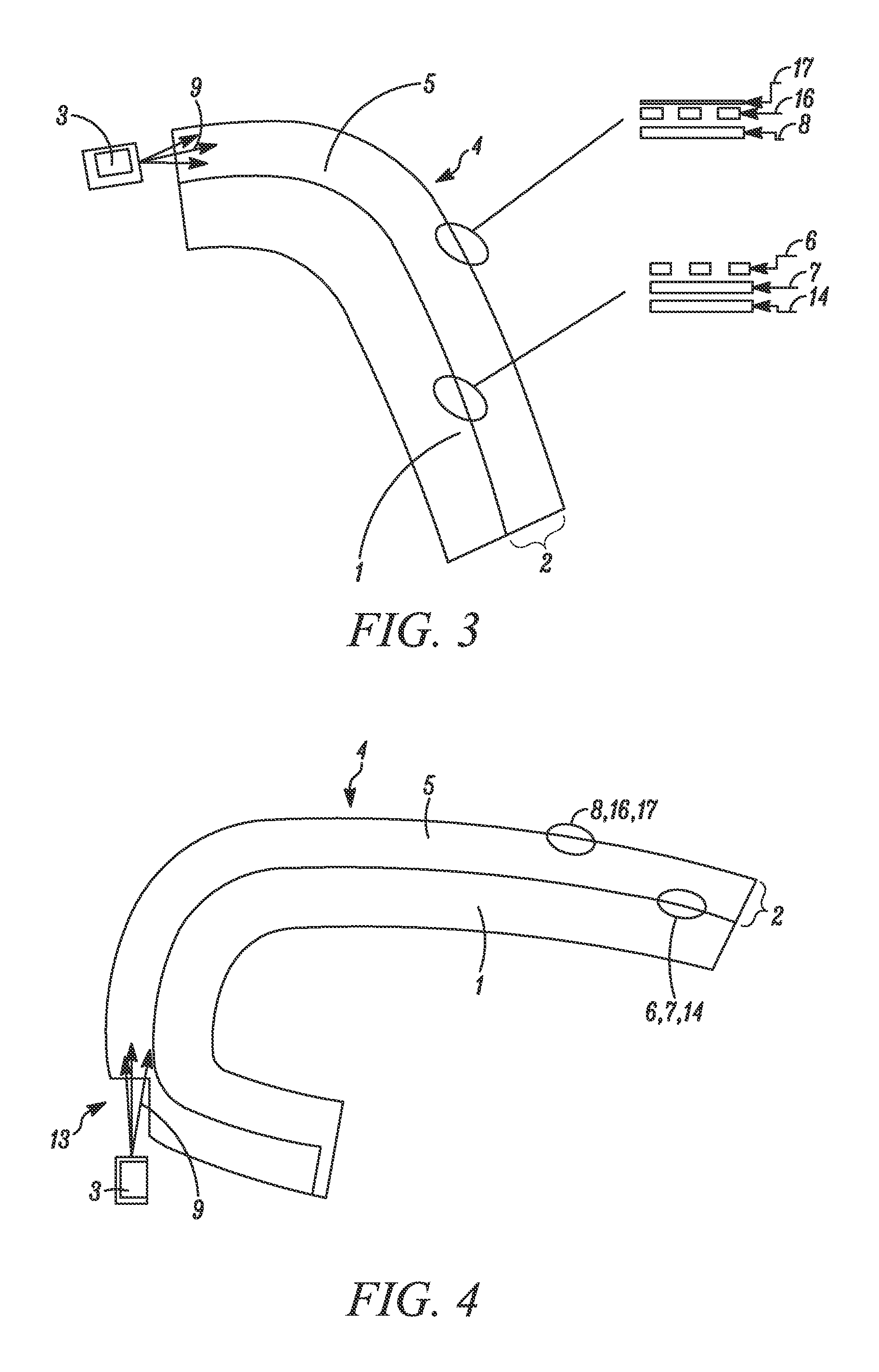

Equipment part having luminous visible side

ActiveUS20160062022A1Reliable connectorHigh melting pointMechanical apparatusLamination ancillary operationsComposite filmEngineering

The present invention relates to an equipment part, in particular for a motor vehicle, comprising a carrier (1), a composite film (2), and a light source (3). The composite film (2) is disposed on the carrier (1) and forms the visible side (4) of the equipment part. The composite film (2) comprises a light-conducting layer (5), a scatter layer (6), and two paint layers (7, 8), so that light rays (9) generated by the light source (3) can be coupled into the composite film, and the visible side (4) of the equipment part is extensively illuminated with the aid of the composite film (2). The present invention further comprises a method for the production of such an equipment part.

Owner:LISA DRAXLMAIER GMBH

Fat-reducing protein powder

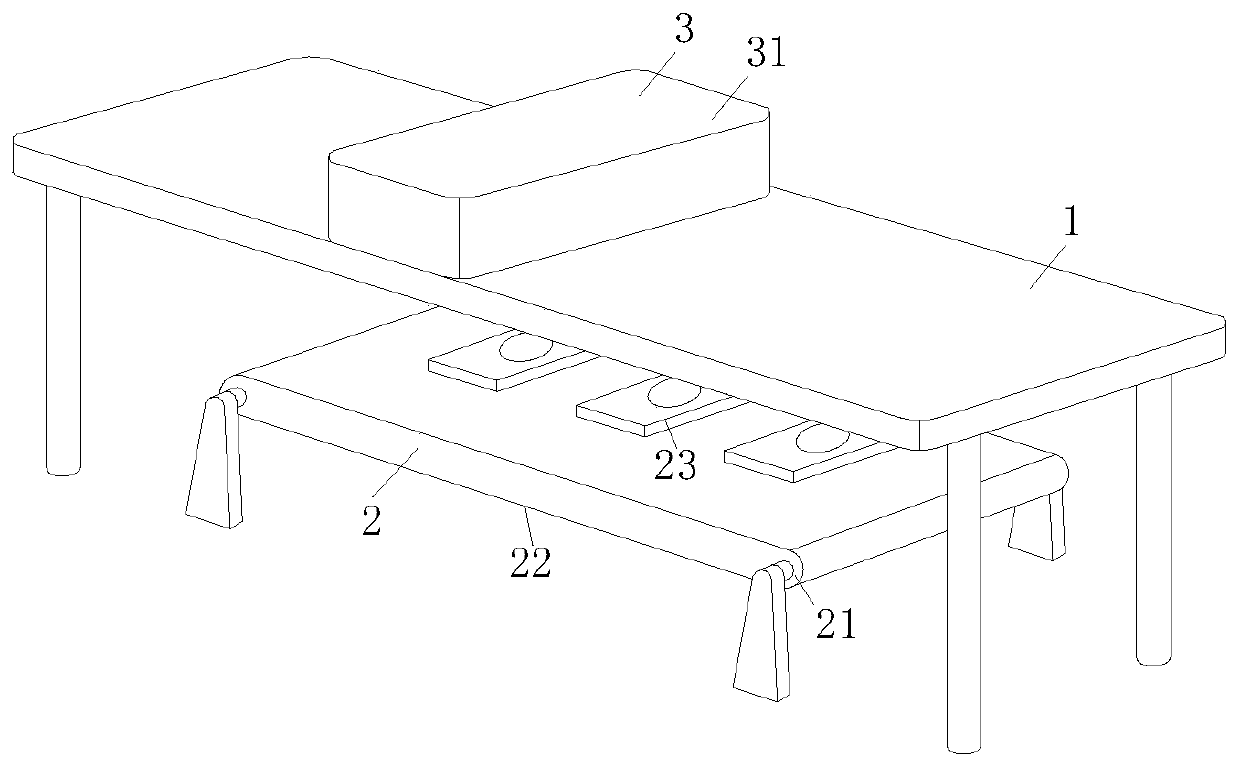

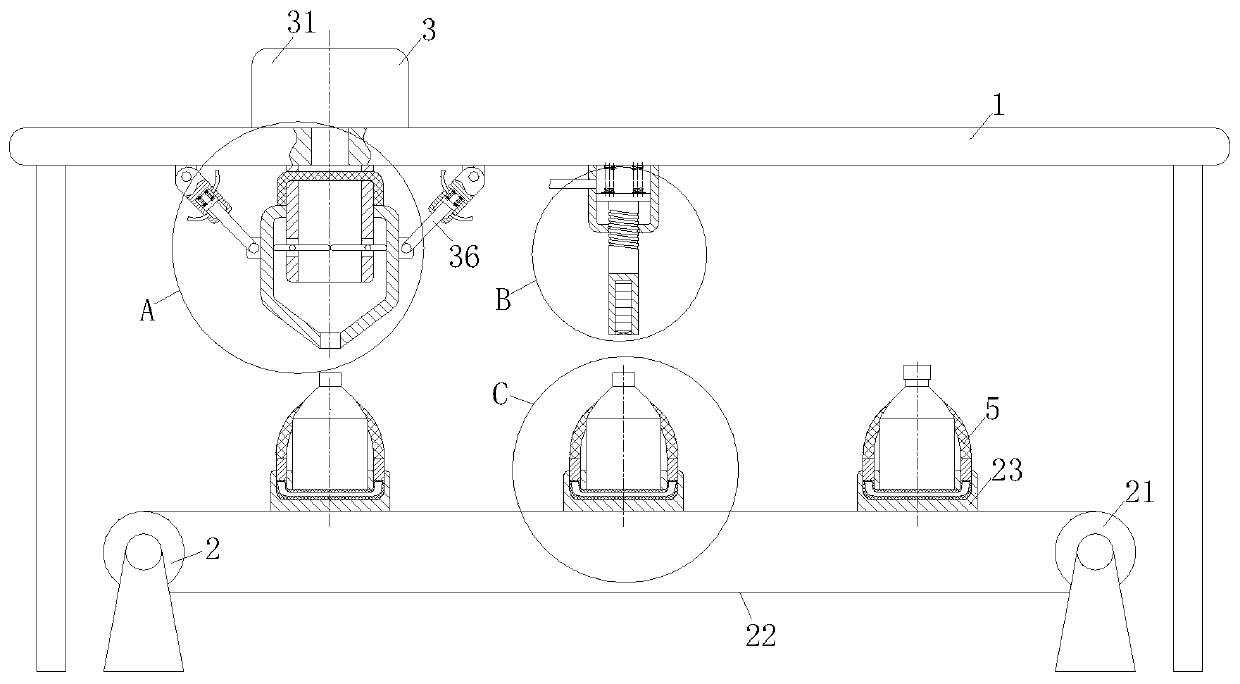

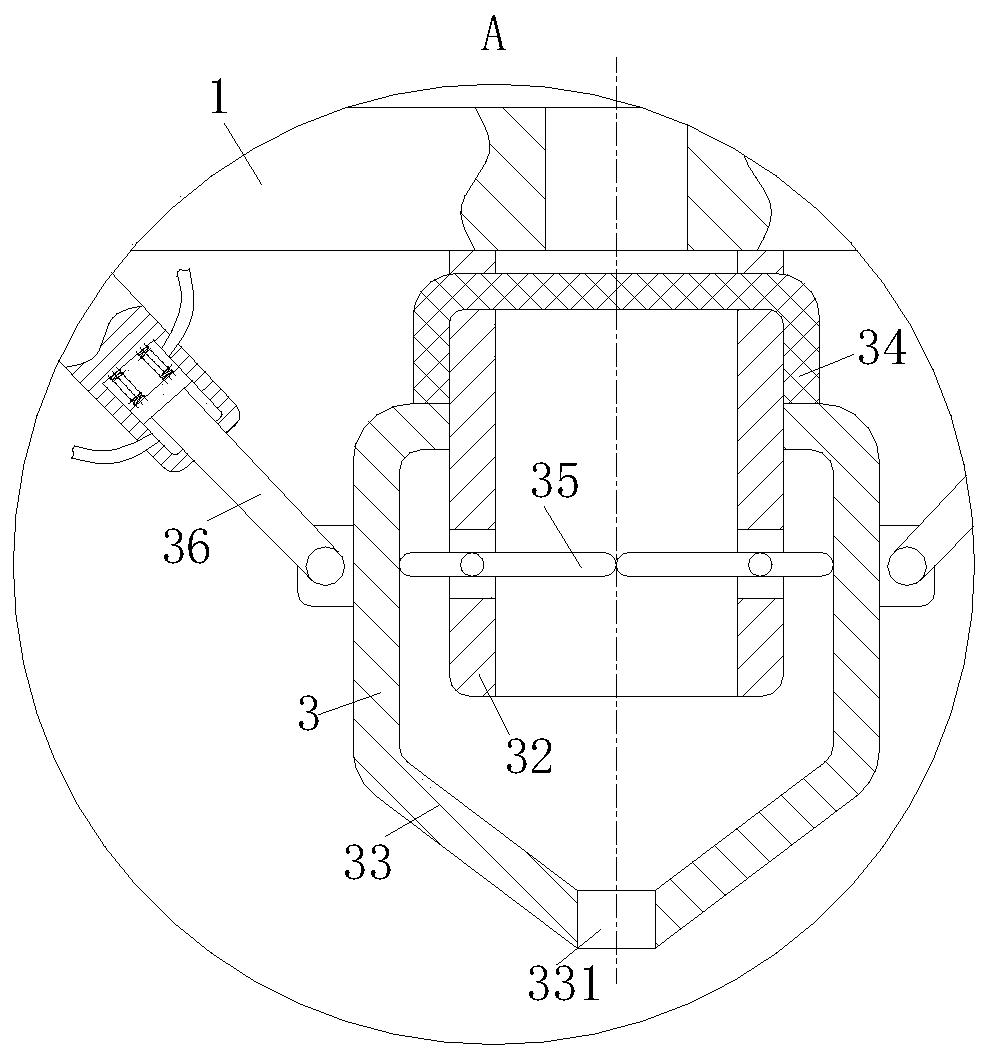

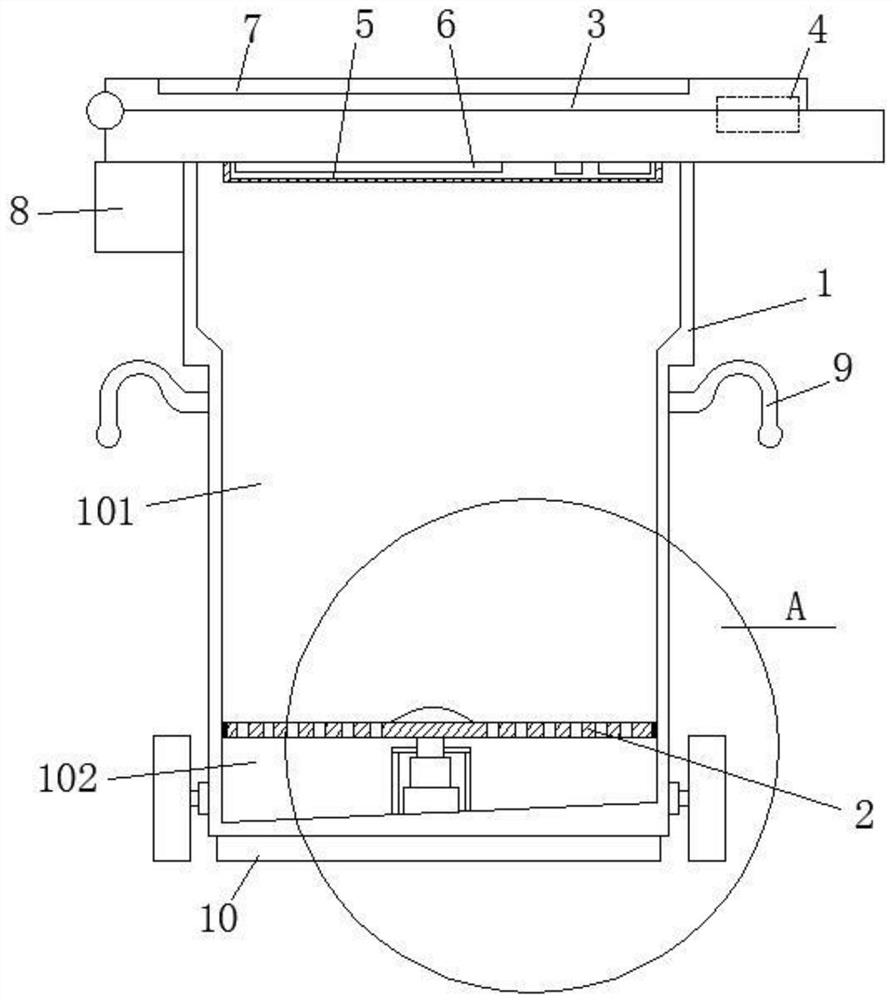

InactiveCN111184223AReduce peristalsisPromote peristalsisSugar food ingredientsThreaded caps applicationPROTEIN S HEERLENBiology

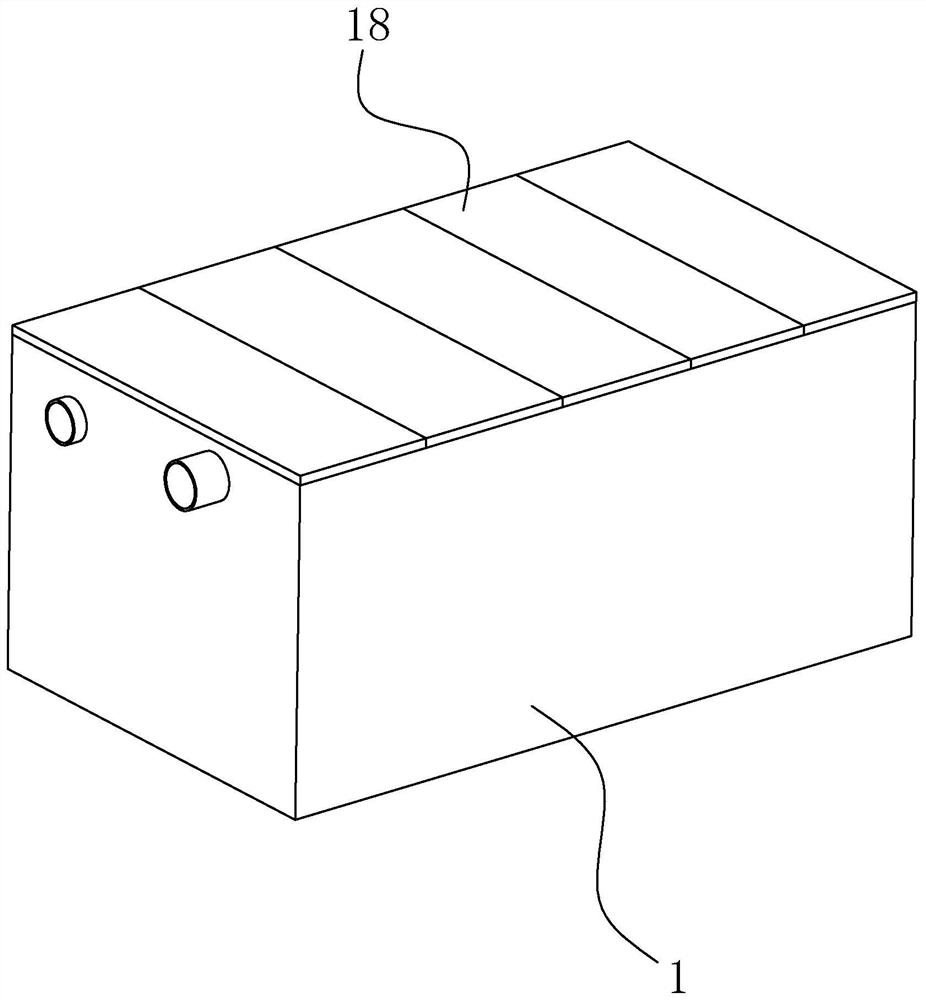

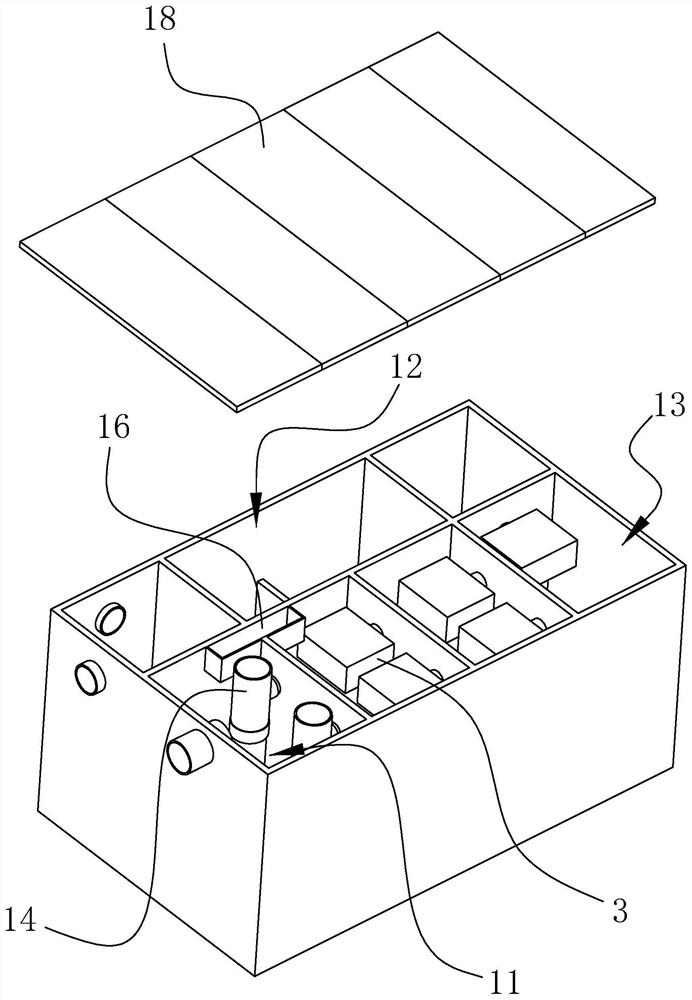

The invention belongs to the technical field of protein powder, and specifically relates to fat-reducing protein powder. The fat-reducing protein powder is packed into a glass bottle through a material charging device, wherein the material charging device includes a workbench, a conveying device, a material charging unit and a controller, wherein the conveying device includes rotating wheels and abelt, and the material charging unit includes a storage box, a No. 1 cylinder, a No. 2 cylinder, flexible shafts, swing plates and No. 1 cylinders. Since the fat-reducing protein powder in the storage box is packed into the glass bottle through the material charging unit, the fat-reducing protein powder in the storage box is prevented from falling directly into the glass bottle, therefore, outputof the fat-reducing protein powder is prevented when the glass bottle is not directly under a material discharge mouth, and waste, caused by contamination, of the fat-reducing protein powder is avoided through no packing of the fat-reducing protein powder into the glass bottle; and even if the fat-reducing protein powder which is not packed into the glass bottle can be eaten again, a procedure for processing the contaminated fat-reducing protein powder is needed, and the production cost of the fat-reducing protein powder is increased.

Owner:王晓伟

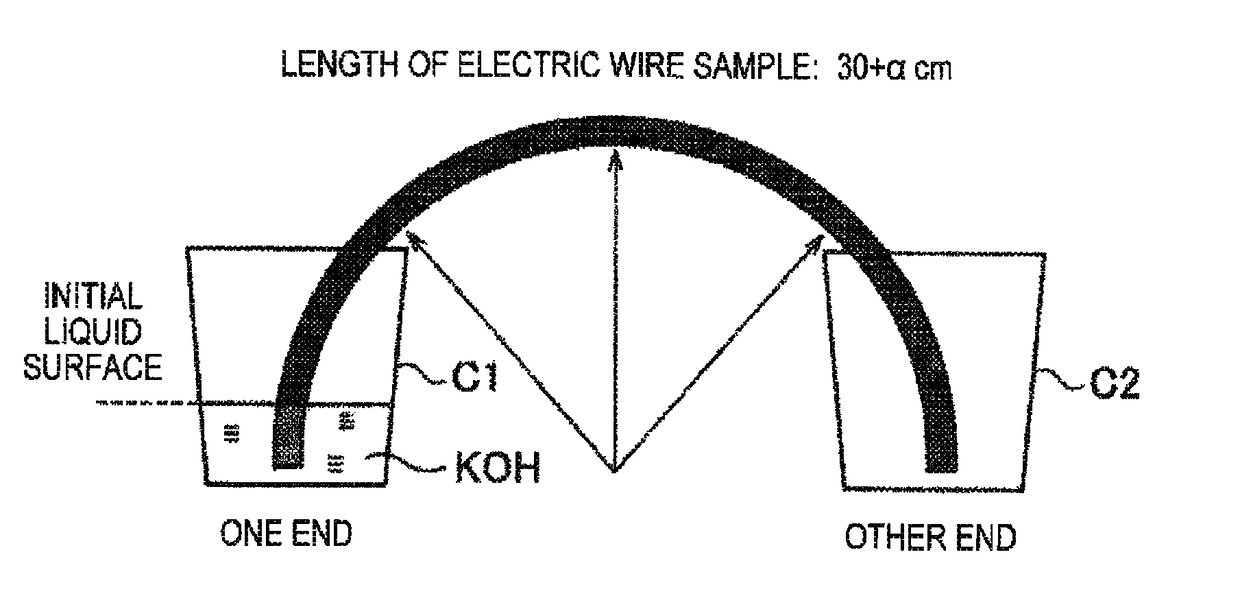

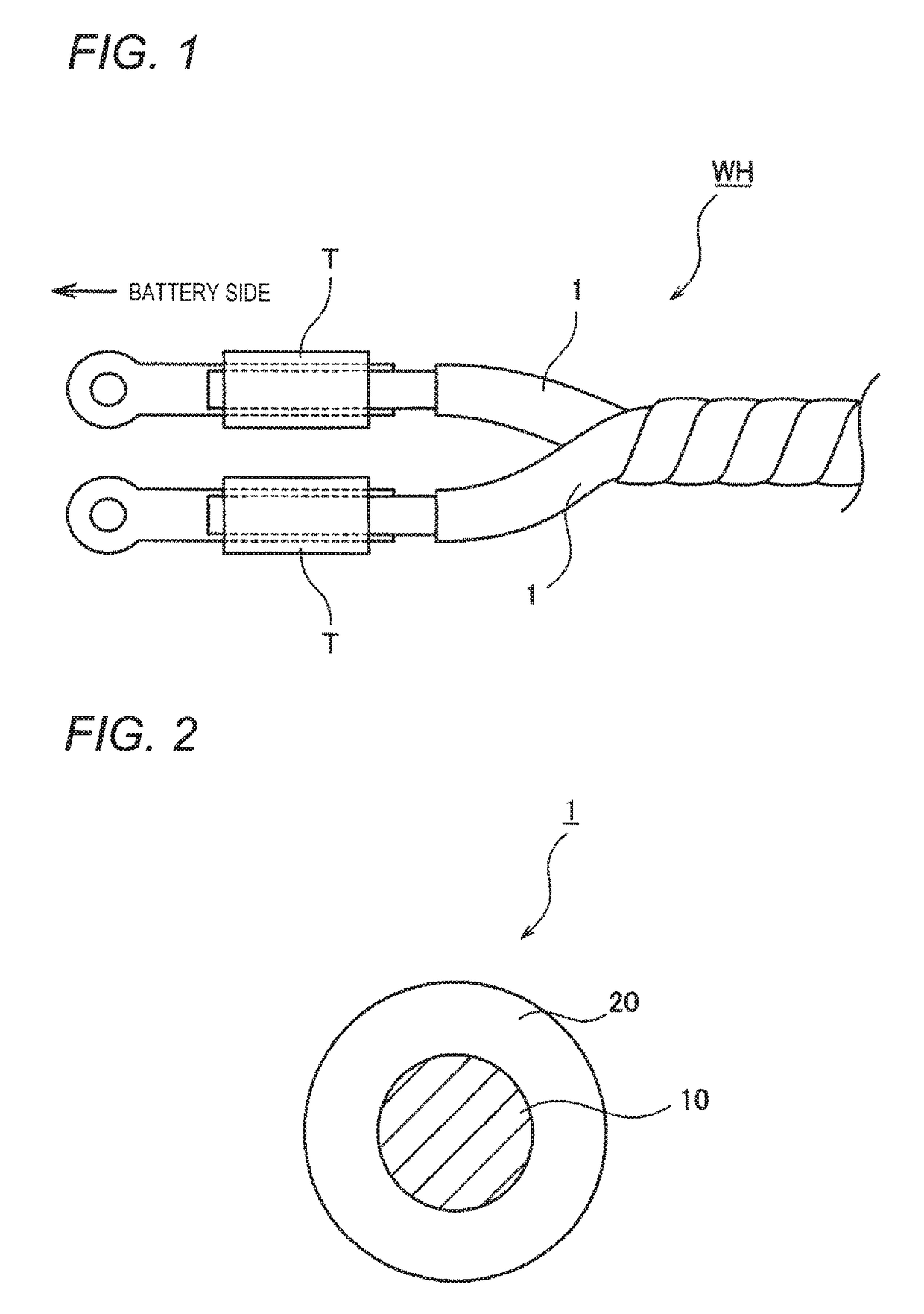

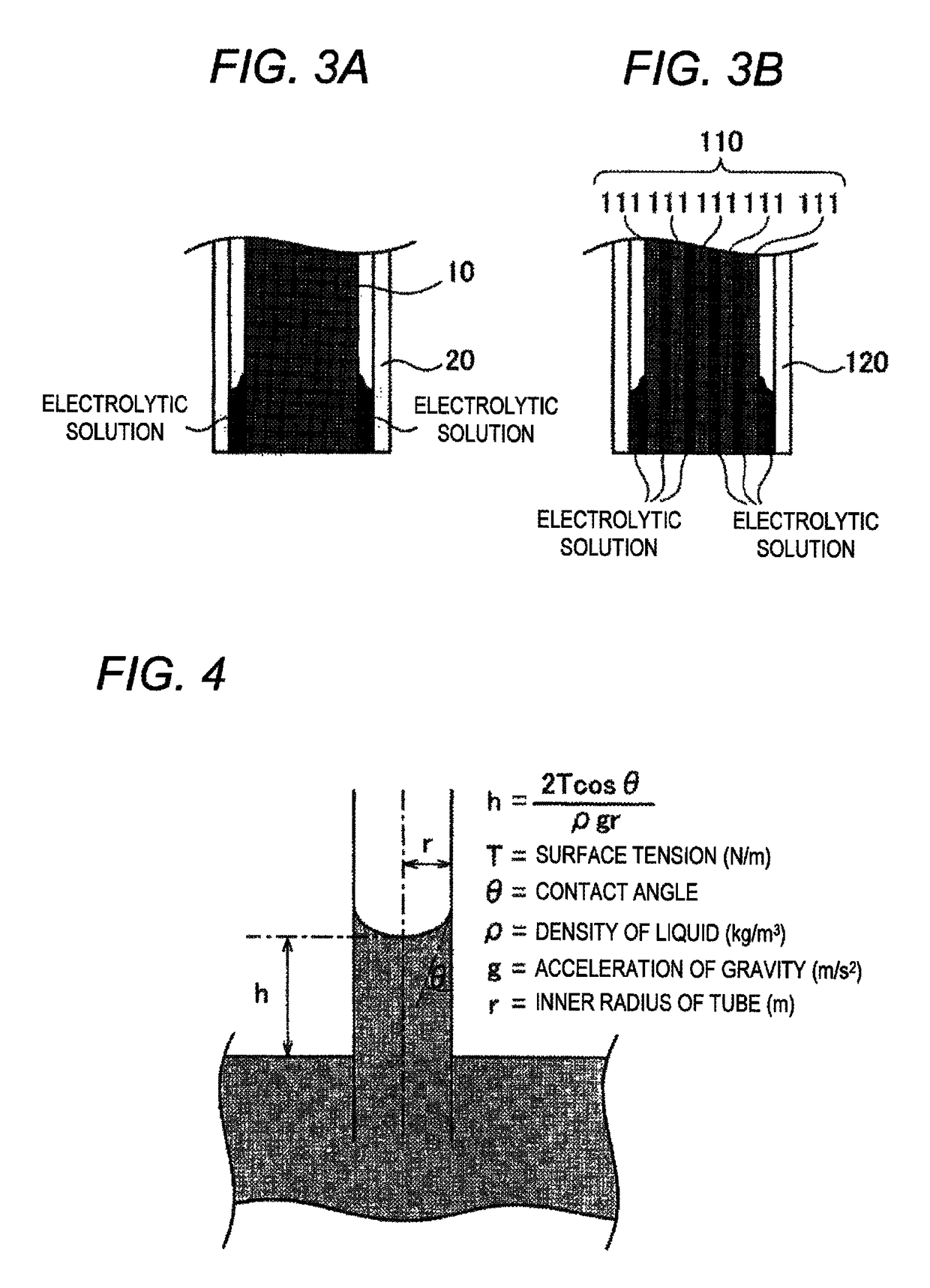

Battery routing electric wire and wire harness

ActiveUS9929395B2Additional processing stepsAvoid breakingPlastic/resin/waxes insulatorsInsulated cablesElectrical batteryPolyvinyl chloride

Owner:YAZAKI CORP

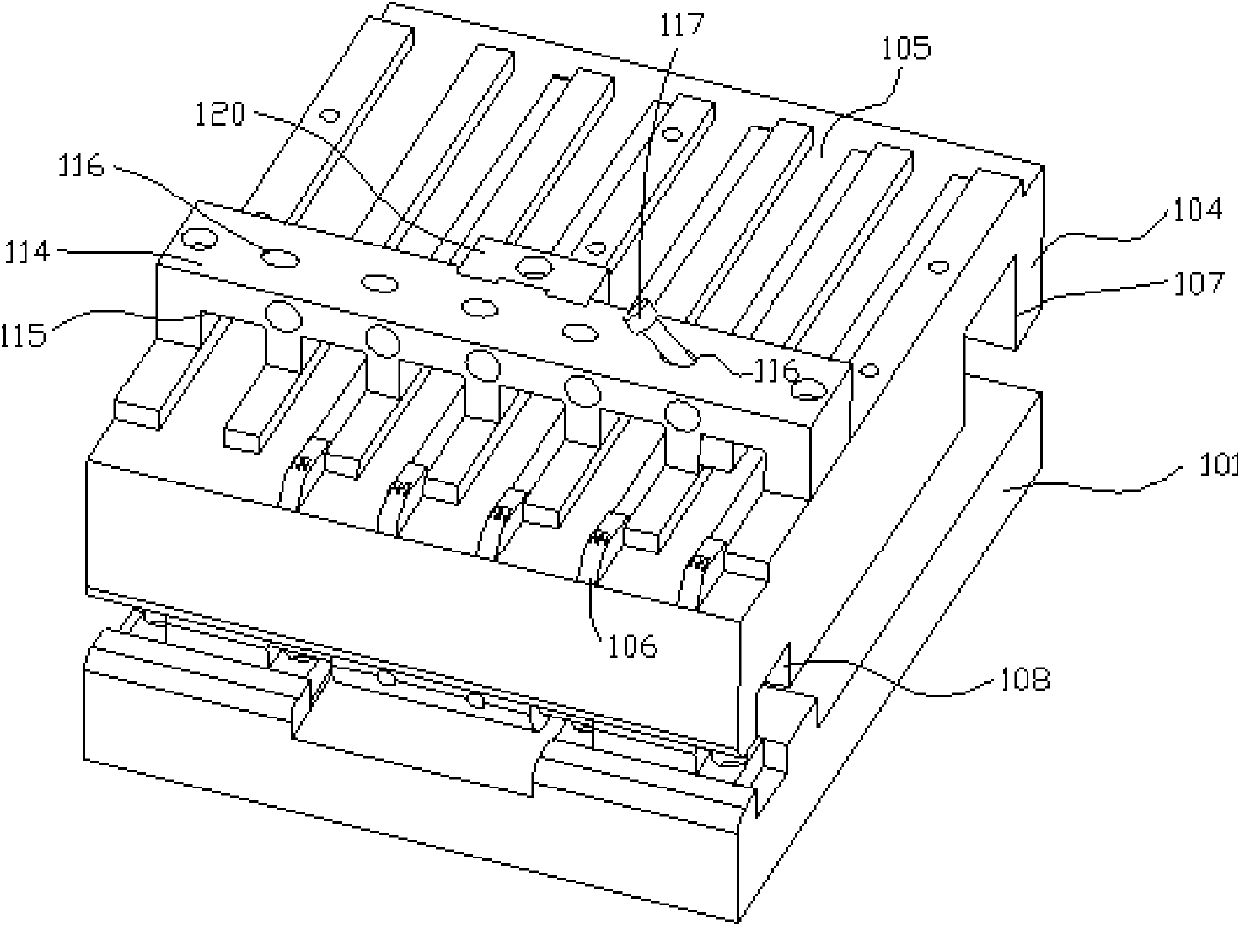

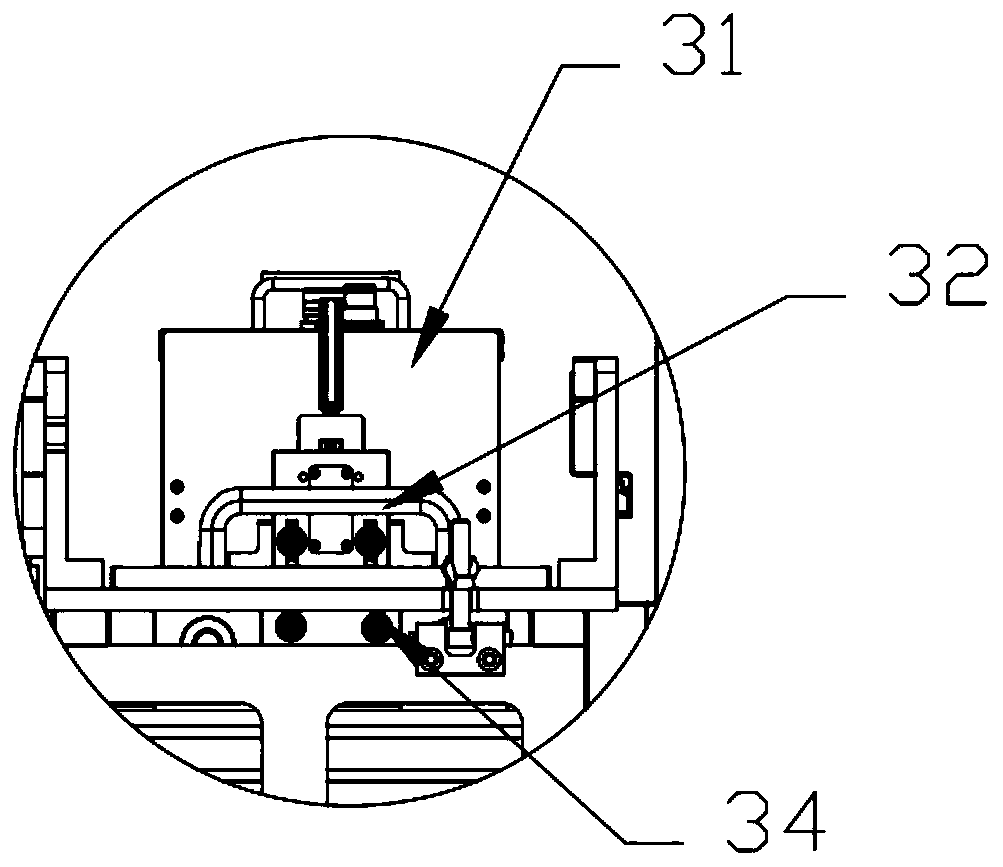

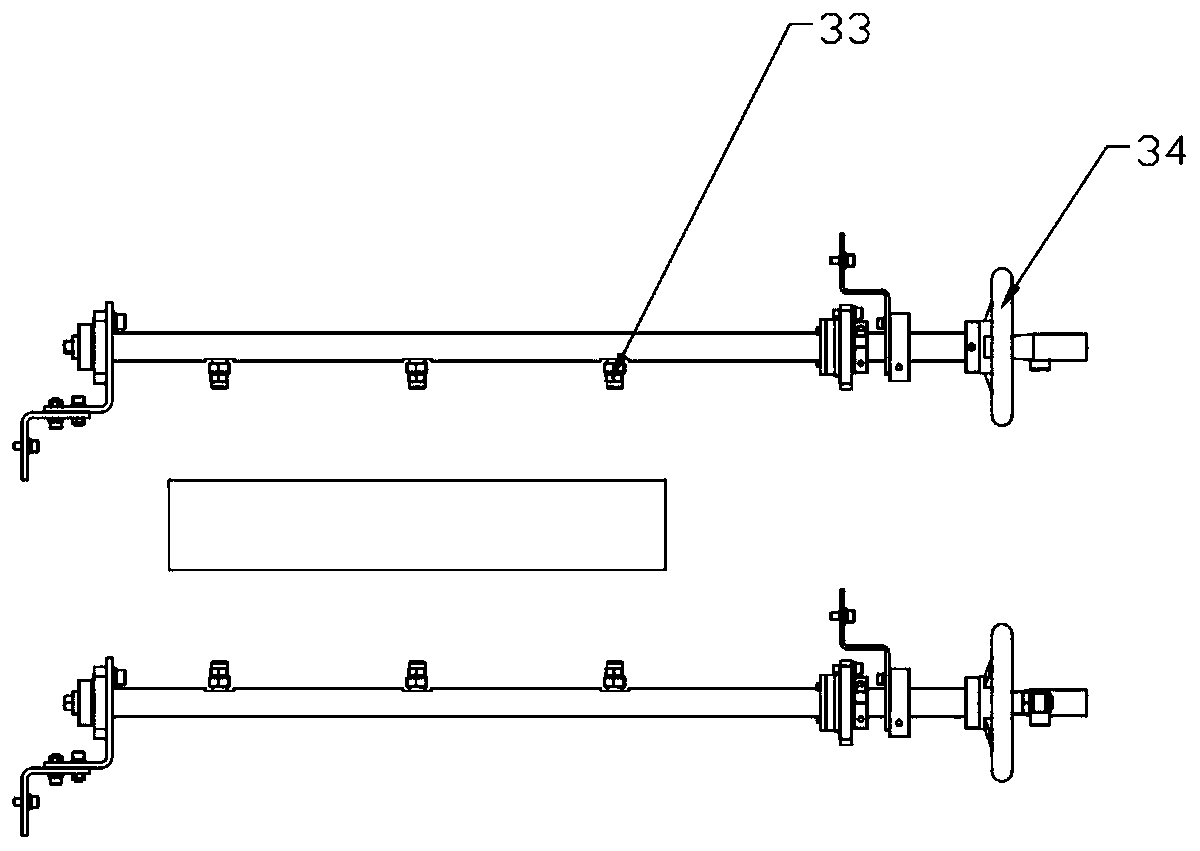

Sewing machine bottom plate machining method and lower shaft hole and edge shaft hole machining device

ActiveCN110170840AReduce processing stepsIncrease production capacityOther manufacturing equipments/toolsPositioning apparatusSewing machineDeep hole

The invention discloses a sewing machine bottom plate machining method and a lower shaft hole and edge shaft hole machining device. According to the sewing machine bottom plate machining method and the lower shaft hole and the edge shaft hole machining device, the machining efficiency of a sewing machine bottom plate is improved conveniently, and meanwhile, when a deep hole is machined, a cutter cannot be affected by gravity, the coaxiality of a lower shaft hole and an edge shaft hole is high, and the machining condition of a workpiece can be observed in time.

Owner:湖南凯斯机械股份有限公司

Method and device for treating waste residues and waste water coming from kudzuvine root starch processing

InactiveCN109430816AHigh economic valueFull of nutritionFood dryingFood treatmentCelluloseIron removal

The invention discloses a method and device for treating waste residues and waste water coming from kudzuvine root starch processing. The method comprises the working procedures: pre-mixing of waste water and waste residues, enzymolysis, solid-liquid separation, multiple iron removal, grit removal, impurity removal, seasoning, decompression concentration, and drying. Through the method, waste water and waste residues generated in the processing process of the kudzuvine root powder are recycled, so that the treated waste water meets the standard and is discharged, substances such as starch, cellulose and some saccharides are recycled, and the economic value is improved.

Owner:湖南犟哥生态农业有限公司

Safe and reliable intelligent garbage can

InactiveCN113306921AIncrease the use of functionsEasy to useWaste collection and transferRefuse receptaclesSpontaneous combustionControl engineering

The invention discloses a safe and reliable intelligent garbage can. The safe and reliable intelligent garbage can comprises a garbage can body, a pushing and pressing mechanism and an intelligent controller; a can cover is connected to the garbage can body through a pin shaft; the pushing and pressing mechanism is installed in the garbage can body and used for compressing garbage from bottom to top so as to achieve solid-liquid separation work of the garbage; and the intelligent controller is mounted at the bottom end of the can cover. The garbage can integrates the automatic opening and closing function of the can cover, the automatic solid-liquid separation function of the garbage and the automatic dumping and discharging function of solid-liquid garbage, the use function of the garbage can is increased, the intelligent and automatic degree of the garbage can is improved, the functions of intelligently achieving vibration prevention, theft prevention and spontaneous combustion prevention of the garbage can are achieved, vibration abrasion of the garbage can in the using process is reduced, the firmness, durability and safety performance of the garbage can are improved, and the garbage can is safer and more reliable to use.

Owner:SHENZHEN LUHUAN REGENERATION RESOURCE DEV CO LTD

Oil stain wastewater treatment method

PendingCN112093999AFully filteredRealize pollution-free treatmentFatty/oily/floating substances removal devicesTreatment involving filtrationMicroorganismTreatment pond

The invention relates to an oil stain wastewater treatment method which comprises the following steps of conveying sewage into a water inlet cavity, enabling the sewage to enter the filter cavity to filter oil stains, enabling the sewage to enter the water outlet cavity from the filter cavity, enabling the sewage to flow along a U-shaped path in the treatment tank, enabling the sewage to enter thetreatment tank from a sewage inlet in one side of the treatment tank, and enabling the sewage to be discharged out of the treatment tank from a sewage outlet in the same side of the sewage inlet after treatment, enabling the sewage to sequentially pass through N oil stain filter cavities of the filter cavities, filtering oil stains in the sewage by the oil stain filter, and intercepting the oil stains on the oil stain filter screen and decomposing the oil stains by microorganisms, due to the flow guide plate, enabling filtered water entering the water outlet cavity to flow up and down in an Sshape, and discharging filtered water which flows up and down in an S shape from one end of the water outlet cavity to the other end of the water outlet cavity out of the treatment tank from the water outlet cavity. The method has the advantages that oil stains in sewage are filtered and treated without power, the flow path of the sewage in the treatment tank is prolonged, and the sewage is subjected to more treatment processes in the same treatment space.

Owner:丽瑾浙江环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com