Combined sludge treatment method and dry distillation device applied by same

A combined technology for sludge treatment, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. Sludge treatment and high treatment costs in small and medium-sized sewage treatment plants, to achieve the effect of increasing treatment energy consumption, low equipment investment and maintenance costs, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

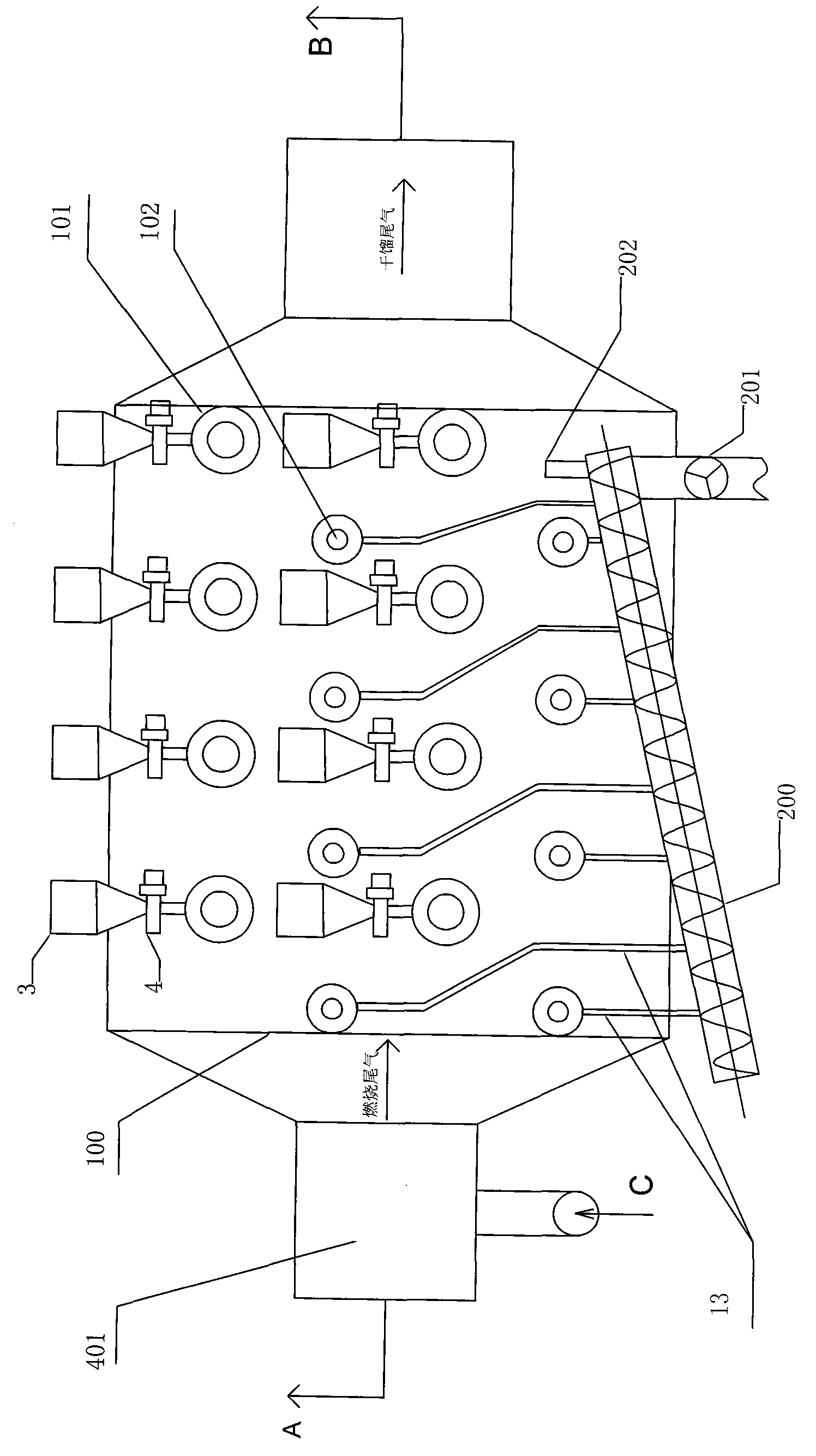

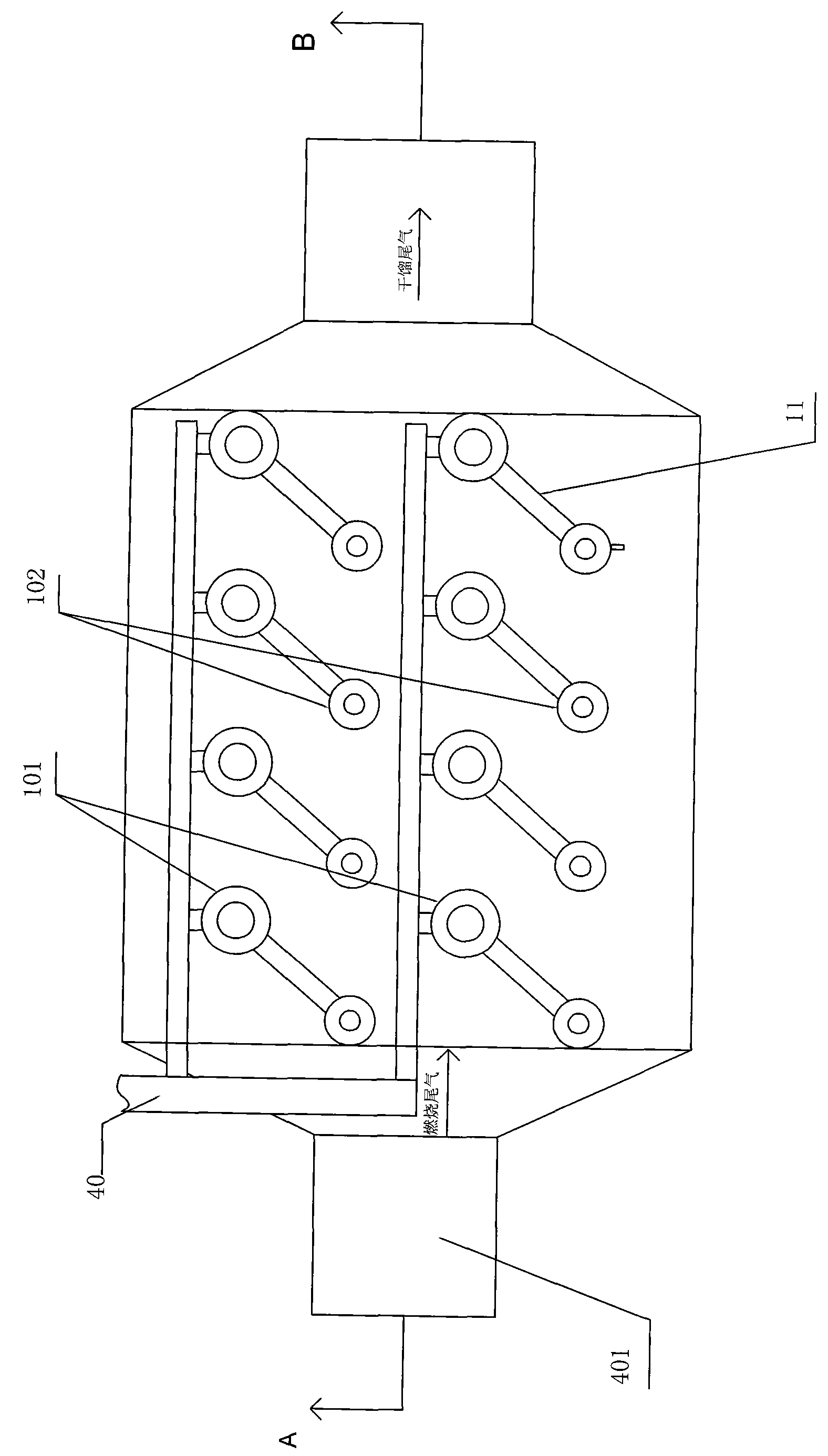

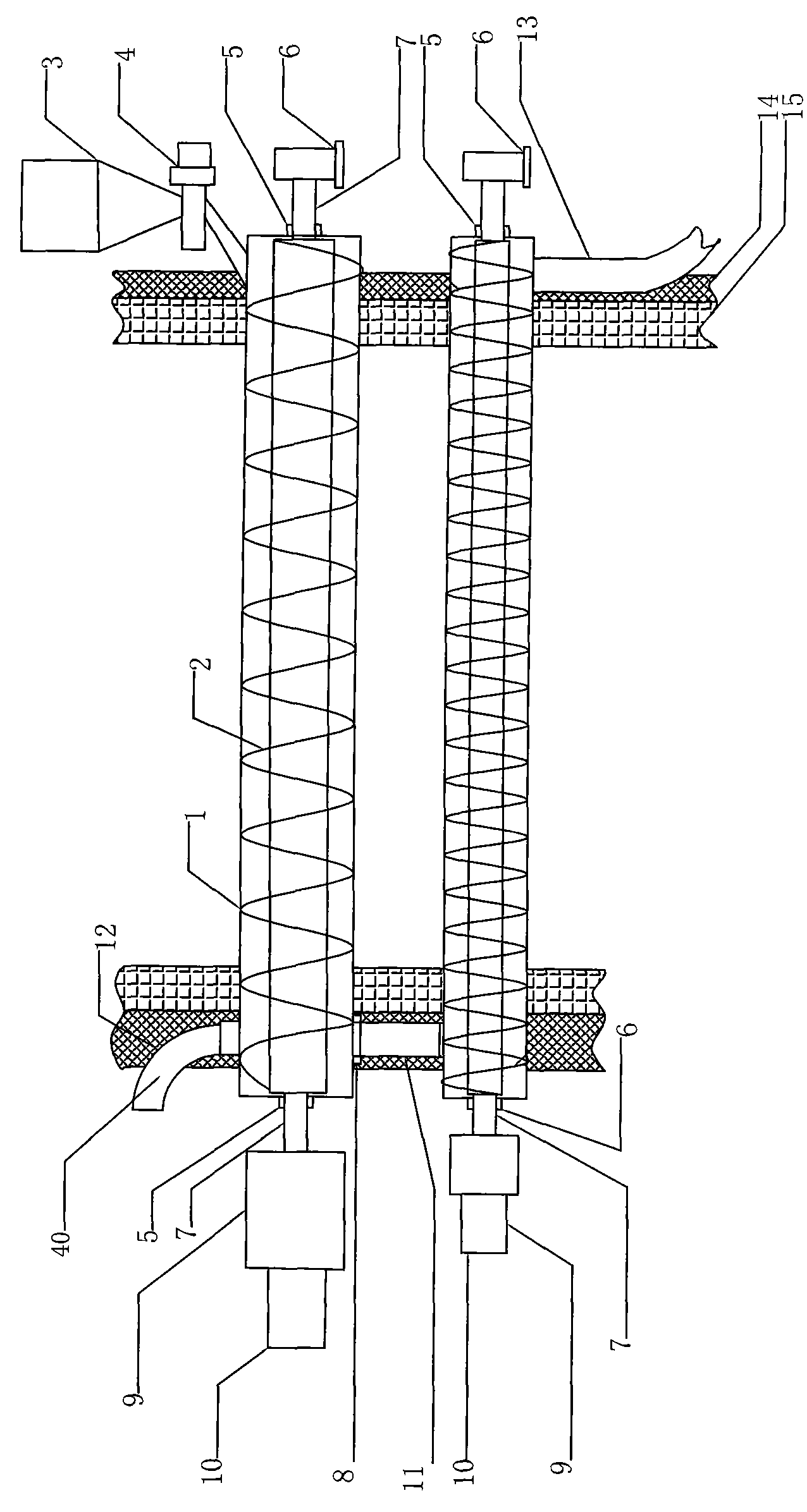

[0018] Embodiment 1, the dry distillation equipment that sludge treatment adopts, refer to attached figure 1 , 2 , 3.

[0019] The retort equipment provided by the present invention includes a retort box 100, the wall 15 is the main body of the retort box, is the basis for equipment installation, and is also a high temperature heat insulation layer. The wall is also provided with an insulation material 14 to reduce heat dissipation and improve thermal efficiency. Improve working environment. In the whole sludge treatment process equipment, the dry distillation box 100 is figure 1 , 2 The combustion chamber can be connected in the A direction, and the rotary kiln hot blast stove can be connected in the B direction.

[0020] There are multiple groups of two-stage retorts in the retort box, and each group of retorts is modularized. The groups are independent of each other and can be disconnected from the system. The maintenance of equipment is more convenient, which is conduc...

Embodiment 2

[0028] Embodiment 2, combined sludge treatment, with reference to figure 1 , 2 , 3, 4, 5, 6.

[0030] Dewatered sludge (after being dehydrated by the sewage treatment plant, the water content is generally 75%) is a sticky plastic solid, which is pushed into the rotary kiln 300 through the feeder 301 (a hot blast stove can be used for small factories) ), heat source gas and sludge enter from the same end of the equipment. During the transportation of the sludge in the rotary kiln or hot blast furnace, it is in full contact with the heat source gas, and with the rotation of the kiln body, the material is continuously turned, and the material and the air flow flow together to the kiln tail, where the sludge is discharged through the discharge device Rotary kiln. According to the temperature of the heat source gas, by adjusting the amount of sludge feed and kiln speed, the sludge moisture at the discharge port is controlled to 20-35% (referred to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com