Patents

Literature

60results about How to "To achieve resource" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibiotic pharmaceutical wastewater processing method and device

ActiveCN103183403AAchieve continuous separationTo achieve resourceSemi-permeable membranesDispersed particle separationAntibiotic YMembrane reactor

The invention discloses an antibiotic pharmaceutical wastewater processing method and an antibiotic pharmaceutical wastewater processing device, and belongs to a wastewater processing technology. According to the invention, a porous filtering membrane is specifically arranged between an anion-exchange membrane and a cation-exchange membrane of an electrodialyzer membrane reactor, such that electrodialysis is intrinsically coupled with a membrane filtering process. Macromolecular substances such as mycelia, proteins, and colloidal are retained with a sieving effect of the porous filtering membrane, such that ion-exchange membrane surface pollution is reduced. Also, under an effect of a direct current electric field, with a selective permeability of the ion-exchange membranes upon charged ions, separation and concentration of anions and cations, and charged antibiotic ions are realized. With an adopted external direct current electric field, a specific solute can be effectively prevented from forming membrane pollution on the surface of the porous filtering membrane, such that the processing process can be safely and stably operated. With the method and the device, antibiotic wastewater processing system investment and operation cost can be greatly reduced; and salt ions and residual antibiotics can be highly efficiently recovered from pharmaceutical wastewater. The method and the device have important application values in antibiotic production and wastewater processing.

Owner:天津大远科技有限公司

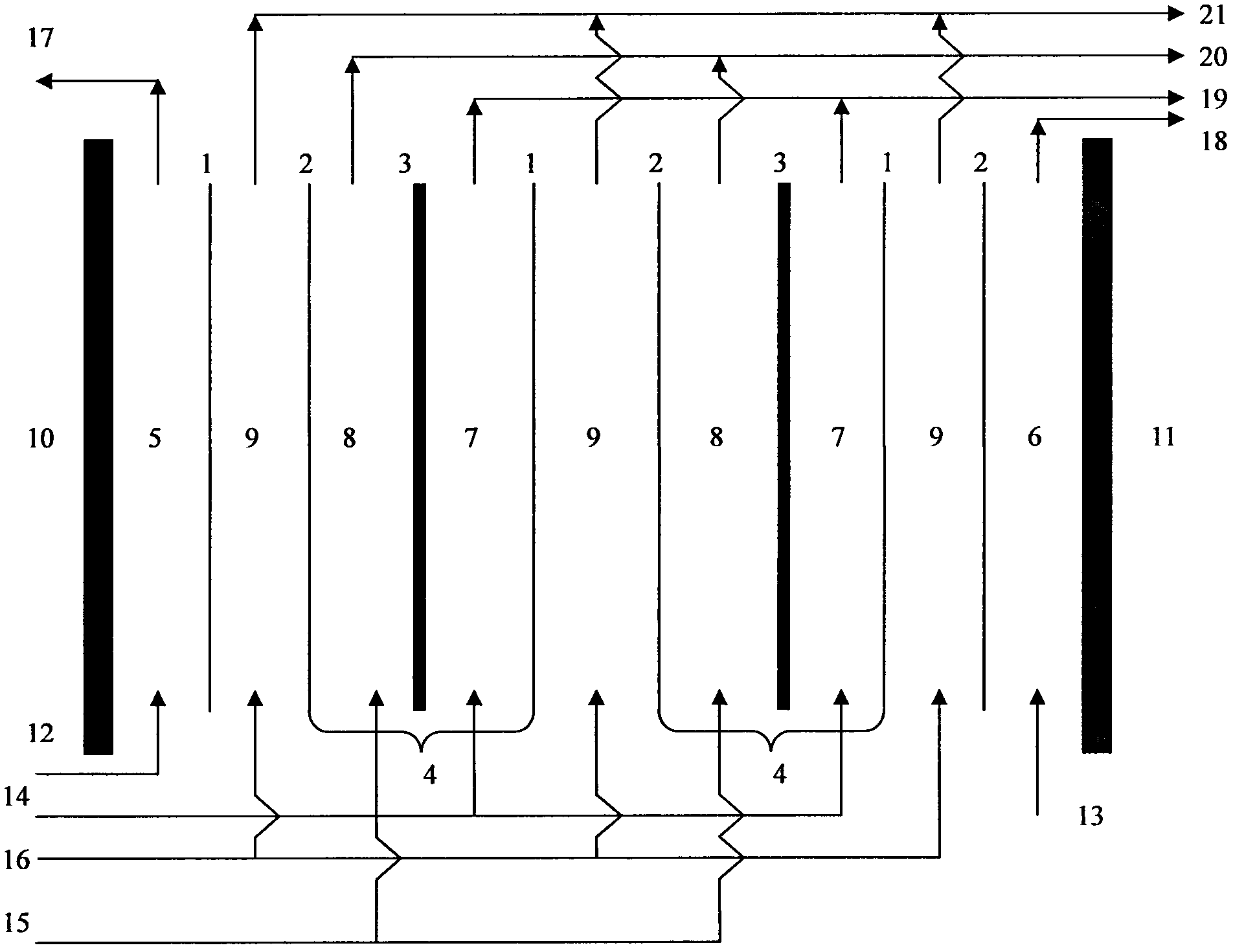

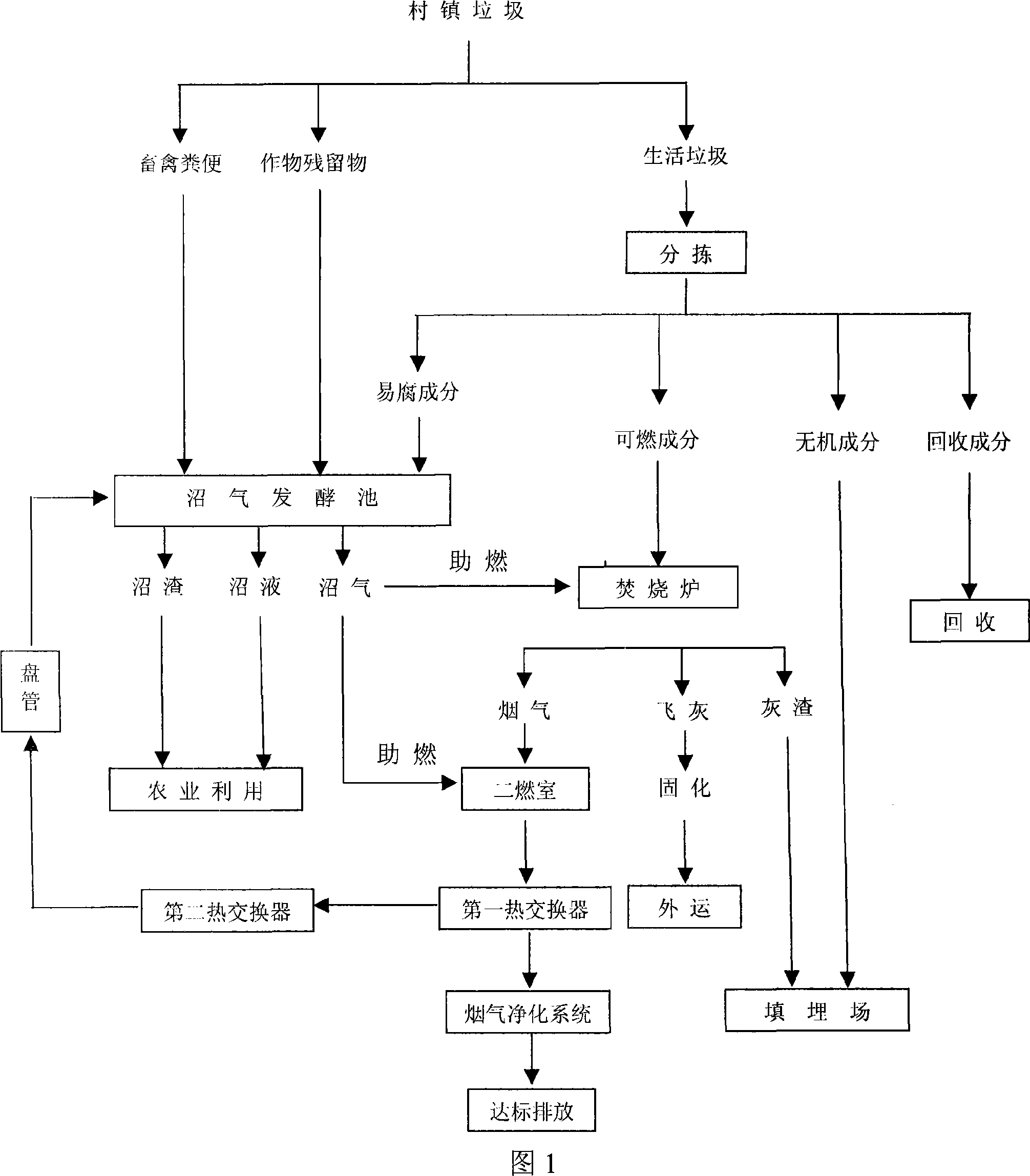

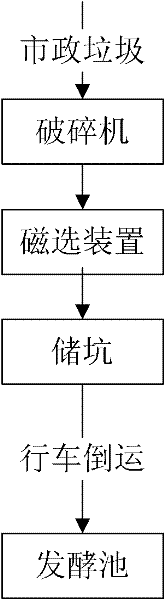

Rubbish comprehensive processing method adapted for village and small town

InactiveCN101062825AIncineration harmlessIncineration reductionBio-organic fraction processingChemical industryThermal energyResource utilization

The invention discloses a garbage comprehensive treatment method for village, which comprises the following steps: sorting life garbage of village to perishable element, combustible constituent, reclaiming element; inorganic element; allocating the perishable element, residues of crop, animal and poultry manure and water with mass ratio at 0. 8-1. 2:0. 8-1. 2:8; proceeding anaerobic fermentation under the insulation action of burning lose heat; generating marsh gas; burning the combustible constituent with combustion-supporting marsh gas completely; getting high temperature smoke gas; recovering thermal energy through the first and second heat exchanger; maintaining the temperature of marsh gas fermenting tank; obtaining resource utilization of marsh liquid or slag, marsh gas and reclaiming component; health-filling the inorganic element and burning ash slag. This invention can prevent twice pollution of the burning smoke gas, which can increase the efficiency and output of mash gas.

Owner:ZHEJIANG UNIV

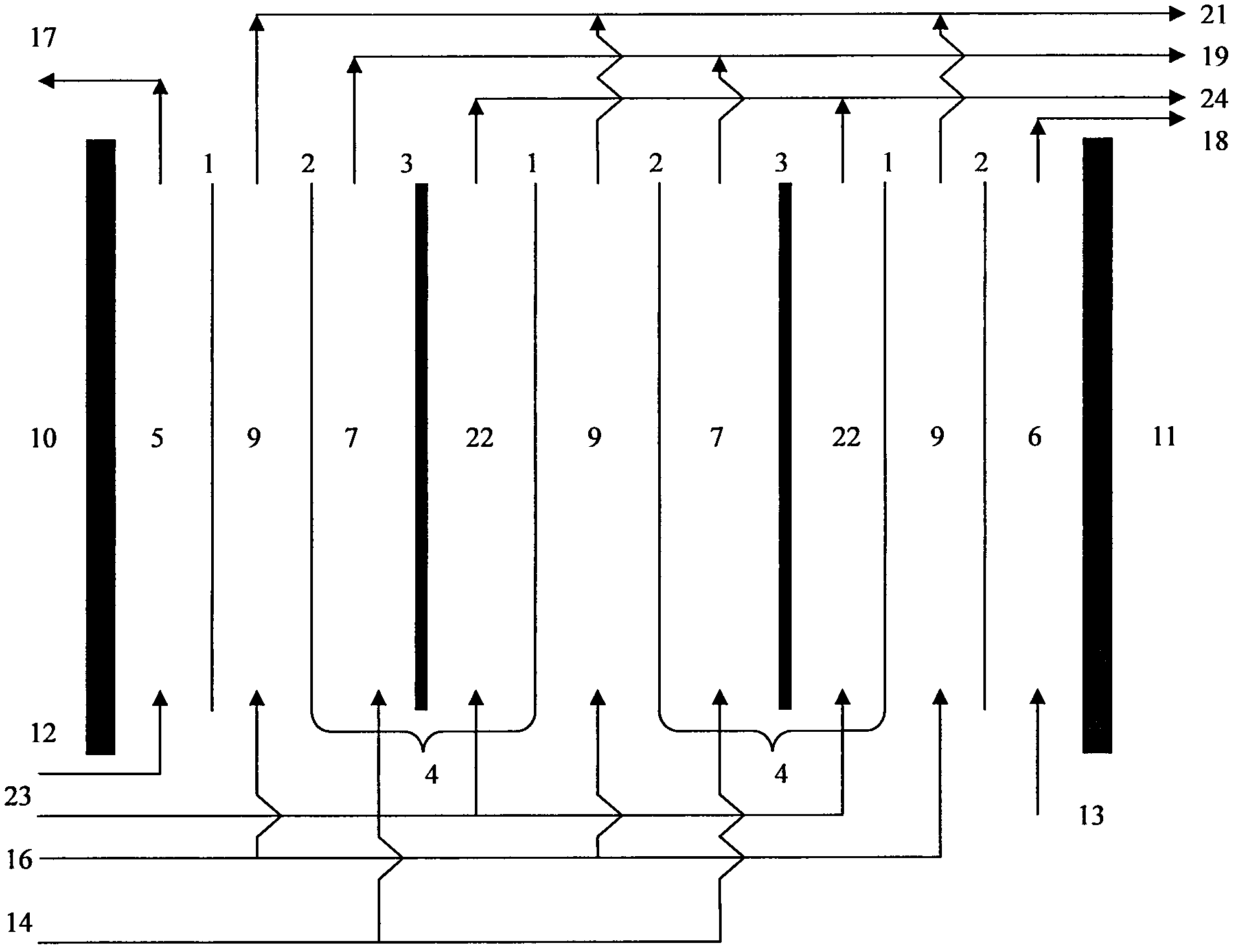

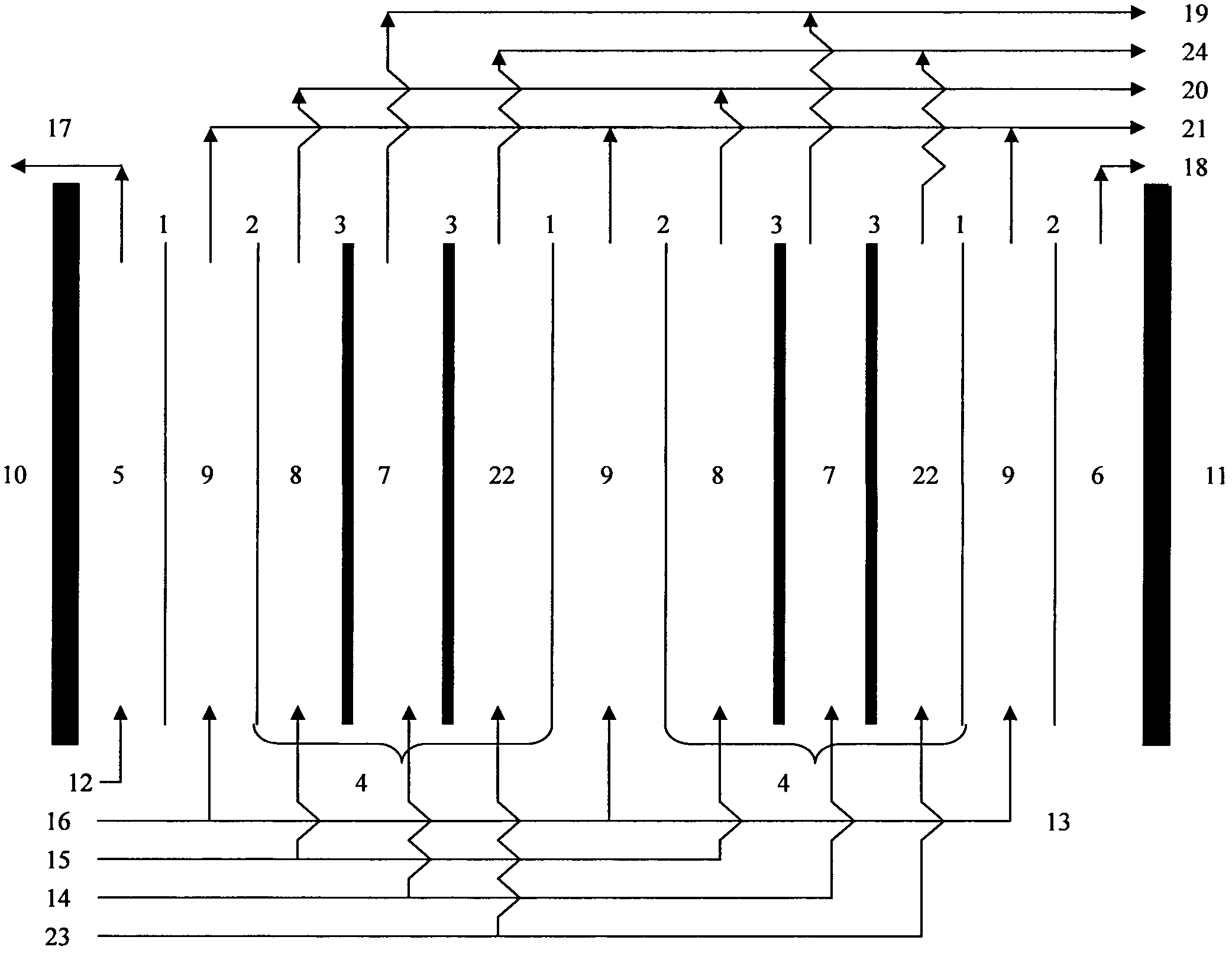

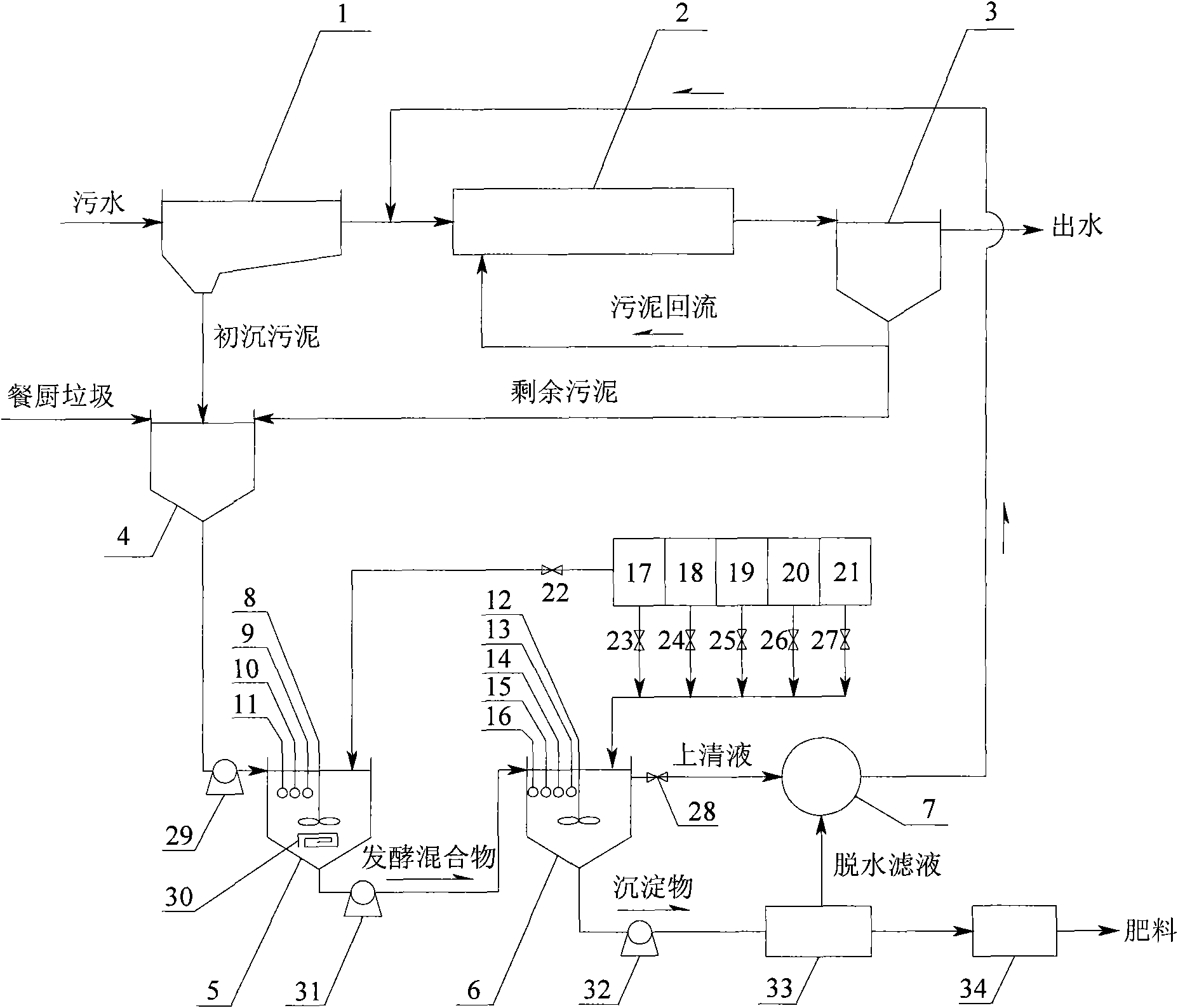

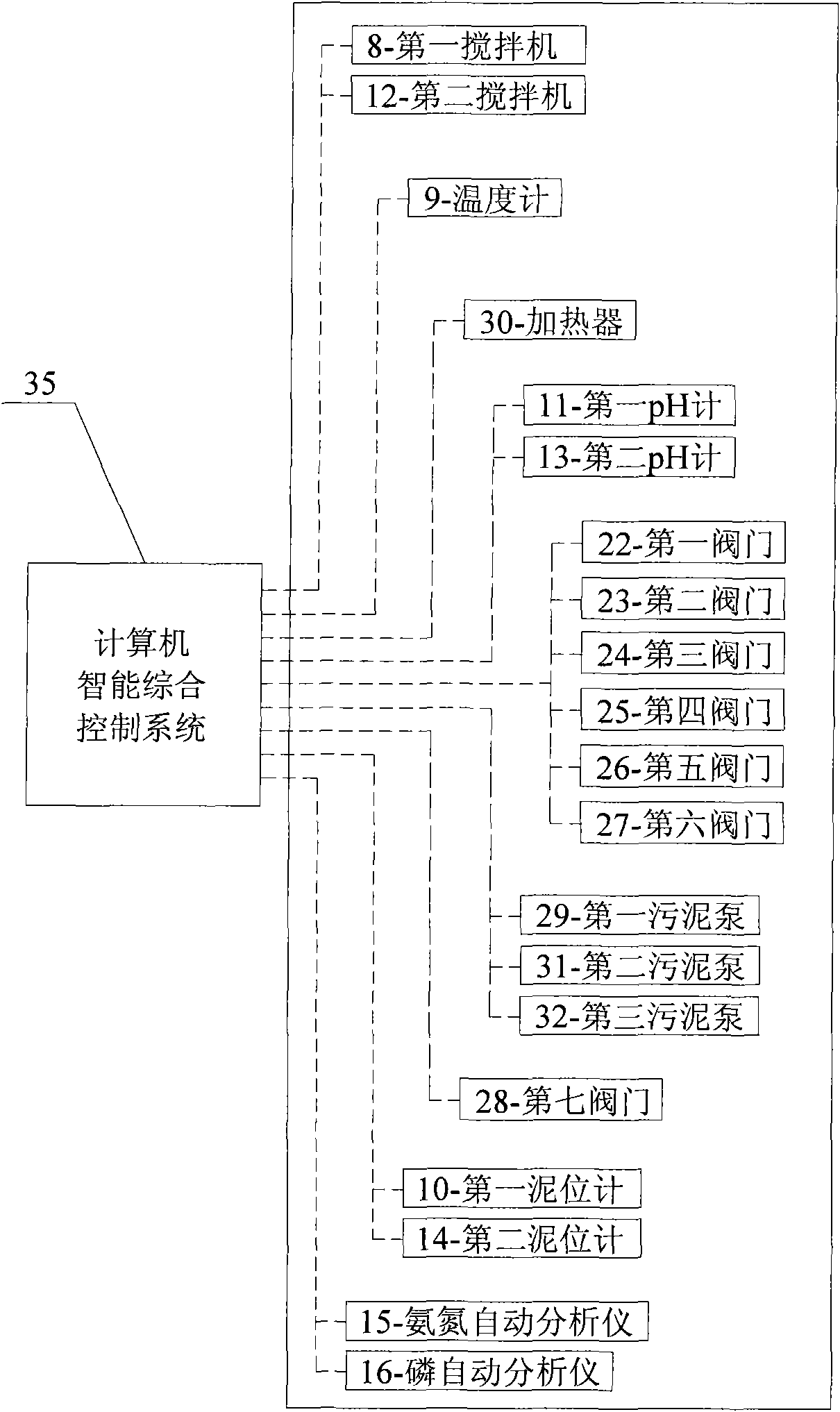

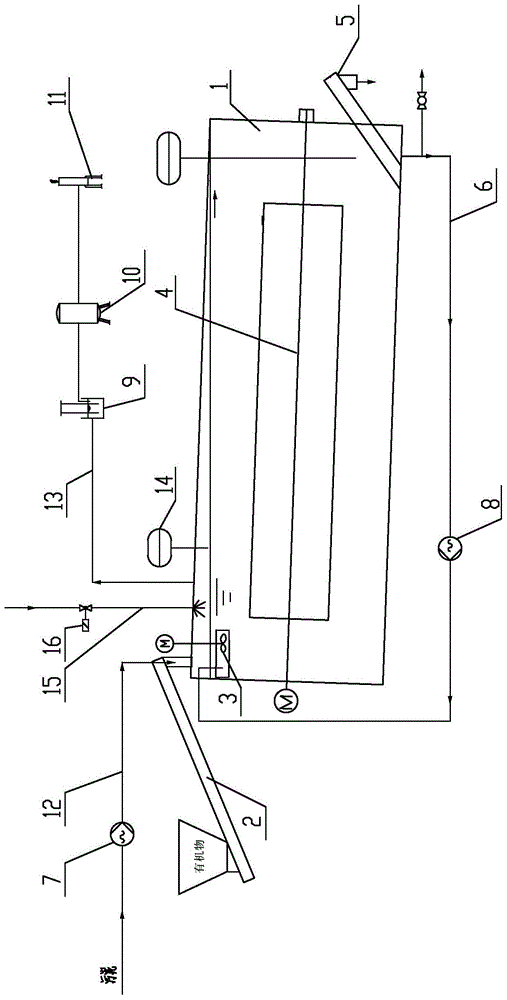

Home position strengthening fermentation regenerated carbon source sewage disposal system for sewage plant

ActiveCN101538101ASolve the problem of insufficient carbon sourcesSolve the poor effect of nitrogen and phosphorus removalSludge treatment by de-watering/drying/thickeningClimate change adaptationSludgeFermentation

The invention belongs to the technical field of environment protection, particularly relates to a home position strengthening fermentation regenerated carbon source sewage disposal system for sewage plant. The system comprises structures including a primary adjusting tank, an alkaline fermentation tank, an adjusting tank a carbon source storage and the like tank, and devices including a pipeline, a meter and a dehydration, anhydration control system and the like. Primary sludge, excess sludge and urban utensil garbage from sewage plant are taken as the raw materials for strengthening fermentation to regenerate carbon source in the alkaline fermentation tank under certain temperature and certain pH after being adjusted by the primary adjusting tank, and then chemical agent is added into the adjusting tank, thus not only obtaining high-quality carbon source simply but also obtaining a byproduct which can be used as a fertilizer, and realizing stabilization, reduction, decontamination and utilization of waste sewage. The technique has the advantages of low investment, low running cost, steady quality of regenerated carbon source, high-value byproduct and the like.

Owner:TONGJI UNIV

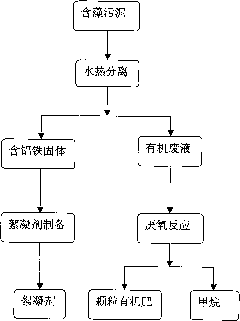

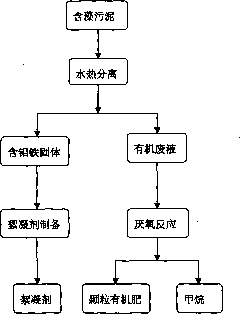

Method for preparing flocculant, fertilizer and methane with algae-containing sludge

InactiveCN101823768ATo achieve resourceRealize multi-channel resource utilizationSludge treatment by oxidationGas production bioreactorsLiquid productLiquid waste

The invention relates to a method for preparing flocculant, fertilizer and methane with sludge containing algae, which relates to a process for turning the sludge containing algae into resources. First, a hydrothermal oxidation technology is adopted to separate organic matter and inorganic matter in the sludge containing algae under the conditions of 150 to 180DEG C of temperature and 0.8 to 1MPa of pressure to obtain brown organic residual waste liquid and solid sludge containing aluminum and iron inorganic matter; and then the solid sludge is dried, ground and screened; hydrochloric acid is added into screen underflow to react for 1 to 2h at 90 to 100DEG C, and stays still; the pH value of a supernatant is regulated to 2.5 to 4, and the supernatant is cured for 12h at 50 to 60DEG C to obtain a PAC iron liquid product; the PAC iron liquid product is dried, and a PAC iron solid product is obtained; and the pH value of the organic residual waste liquid is regulated to 8 to 9, and the organic residual waste liquid enters an upflow anaerobic sludge bed reactor to react for 24h at 35DEG C to obtain granular organic fertilizer and combustible gas with 65 percent of methane content. The method for preparing flocculant, fertilizer and methane with algae-containing sludge has the advantages of simple process, low cost and high economic and social benefit, and can be widely applicable to the zero algae-containing sludge discharge and the clean production of sewage plants which treat lake sewage polluted by algae.

Owner:TONGJI UNIV

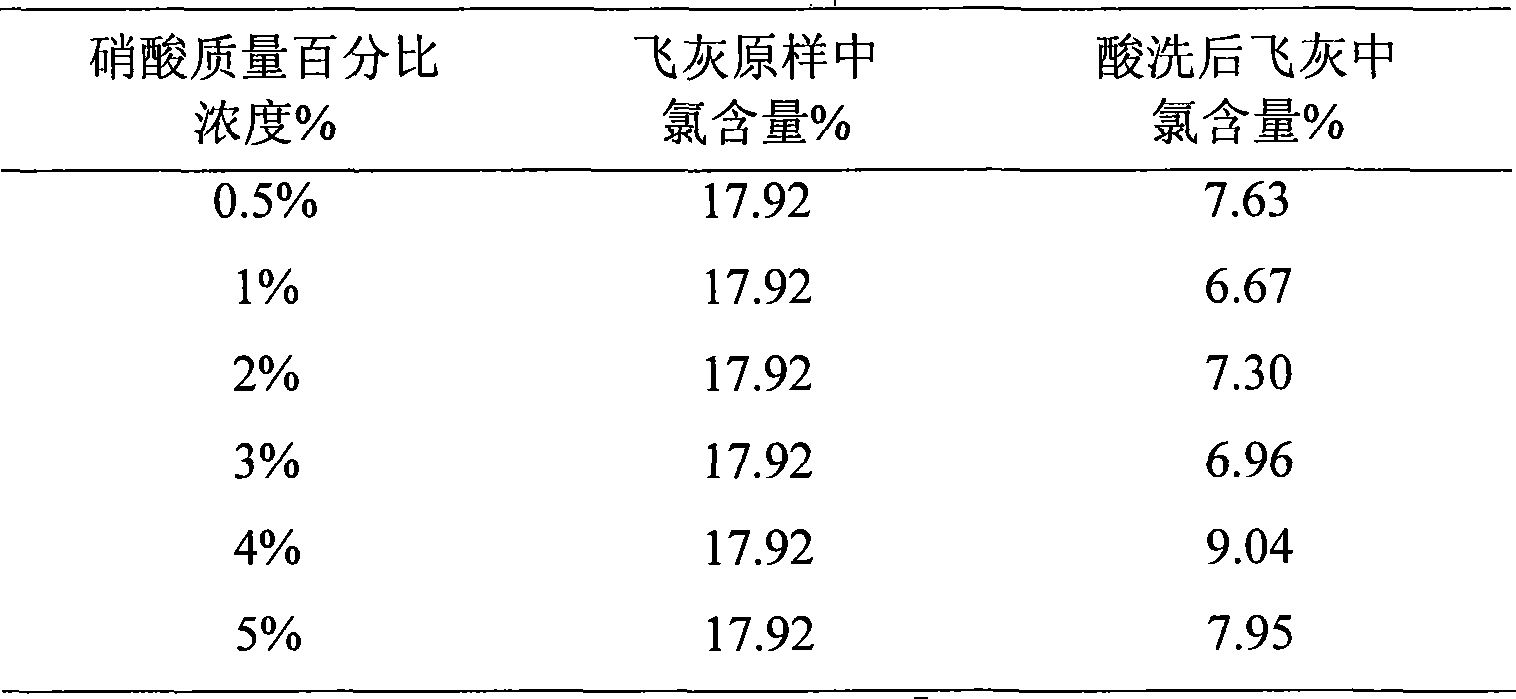

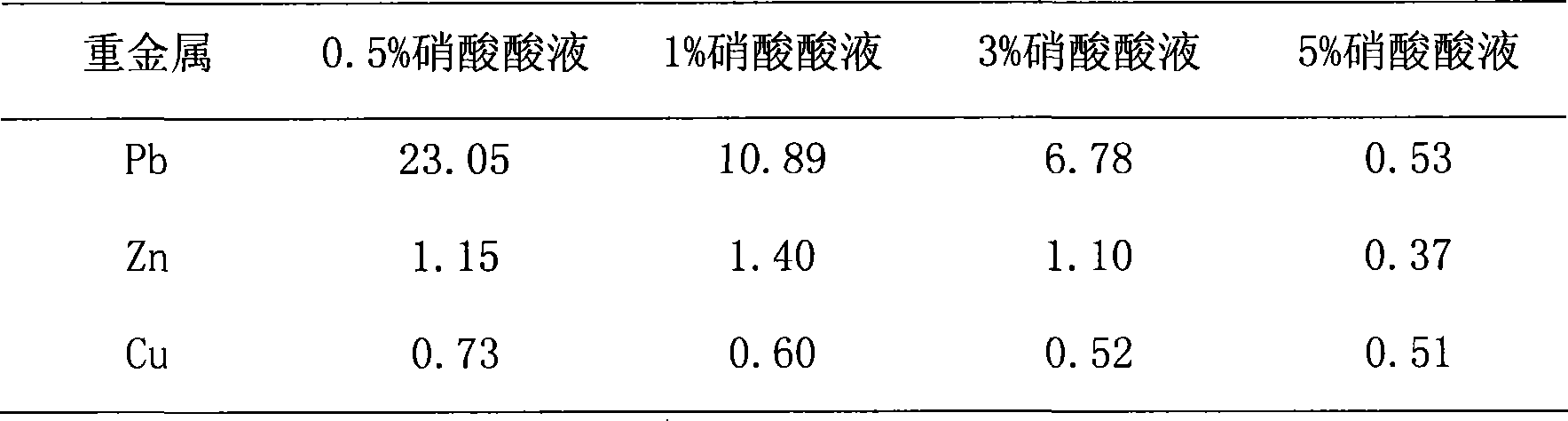

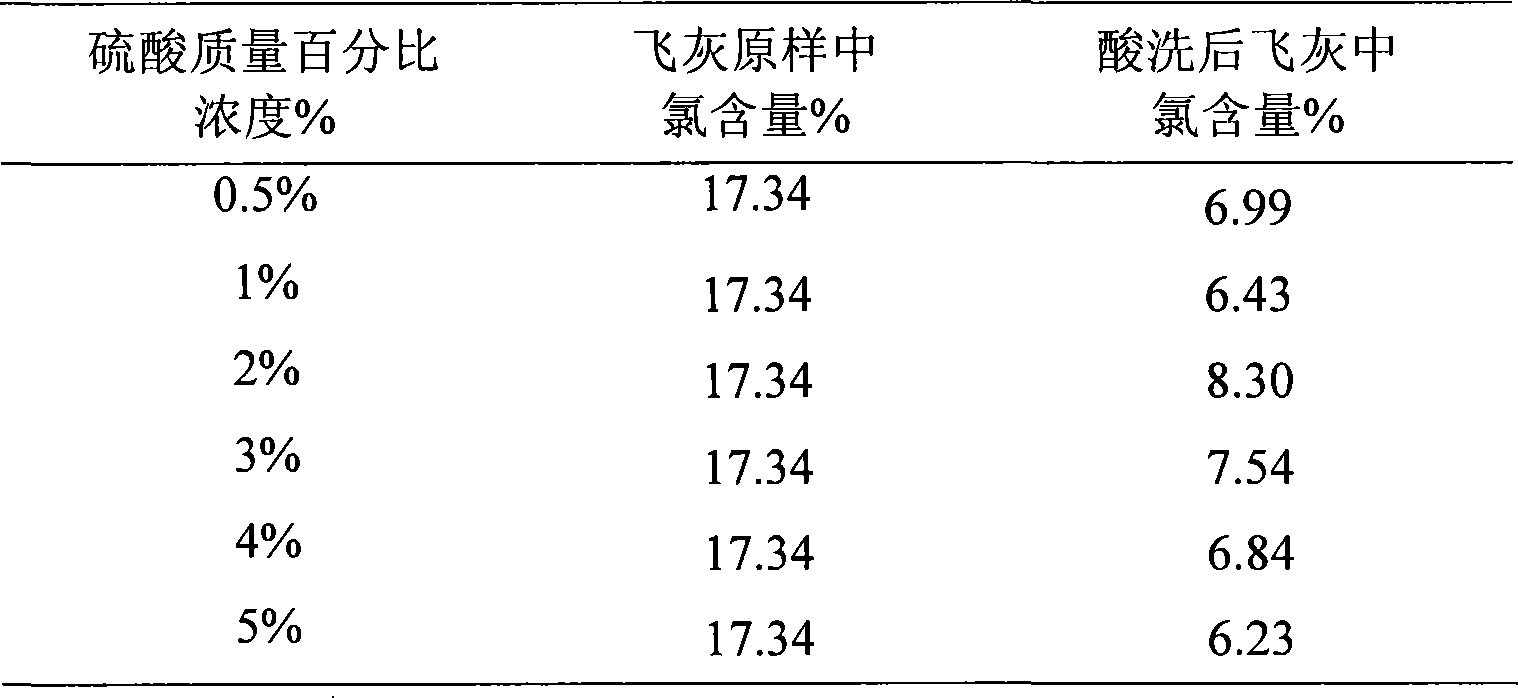

Sulfuric acid refining preprocessing method of life refuse burning flying ash

InactiveCN101239298AReduce leaching toxicityHarmless landfill resource utilizationGaseous chemical processesChemistryHeavy metals

The present invention provides an acid cleaning pretreatment method of household garbage fly ash, belonging to the environmental engineering technical field. The method is separating supernatant fluid to fly ash by mixing the household garbage fly ash with sulphuric acid, hydrochloric acid, citric acid, phosphoric acid etc under the normal temperature, blending and static settlement. The invention also can remove a mass of contamination such as soluble chloride salt and part heavy metalin the household garbage fly ash; the fly ash after acid cleaning achieves harmless aim, futher filled or resource utilization.

Owner:SHANGHAI UNIV

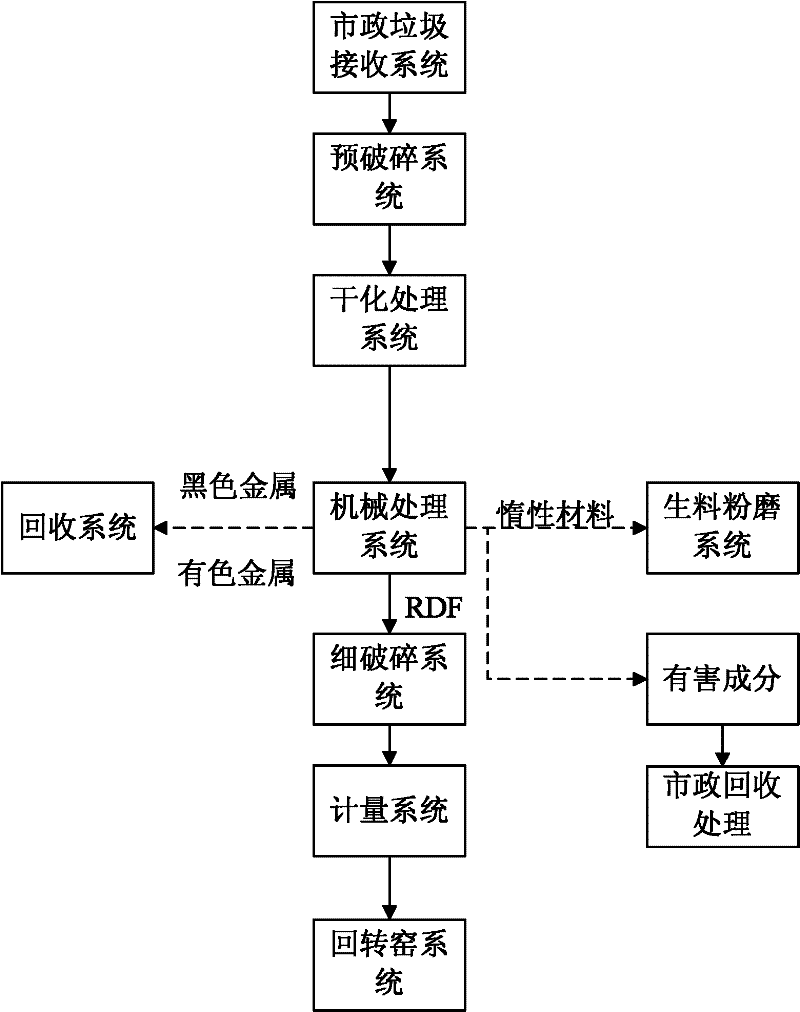

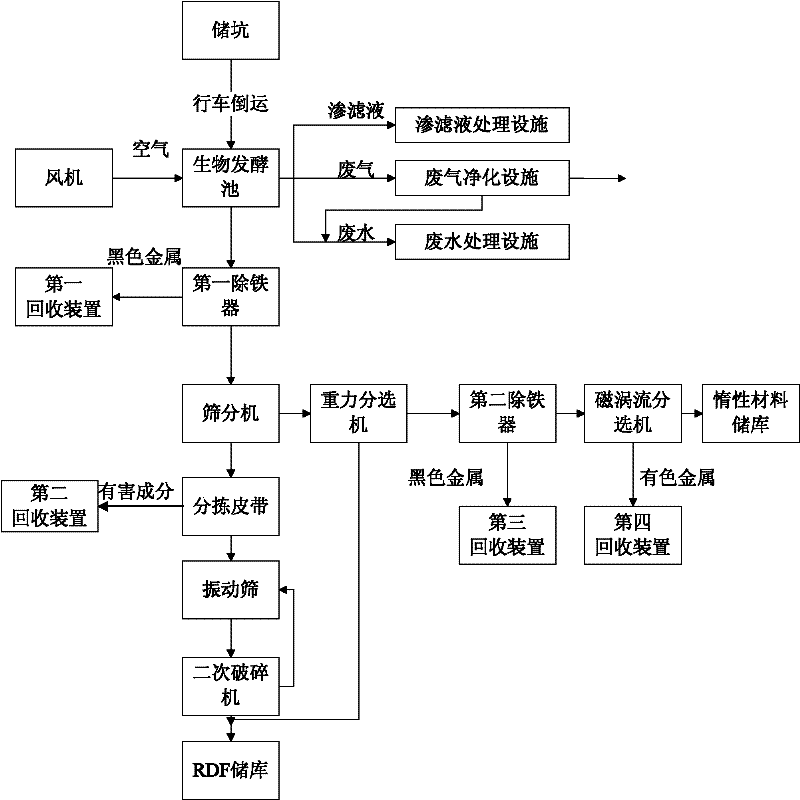

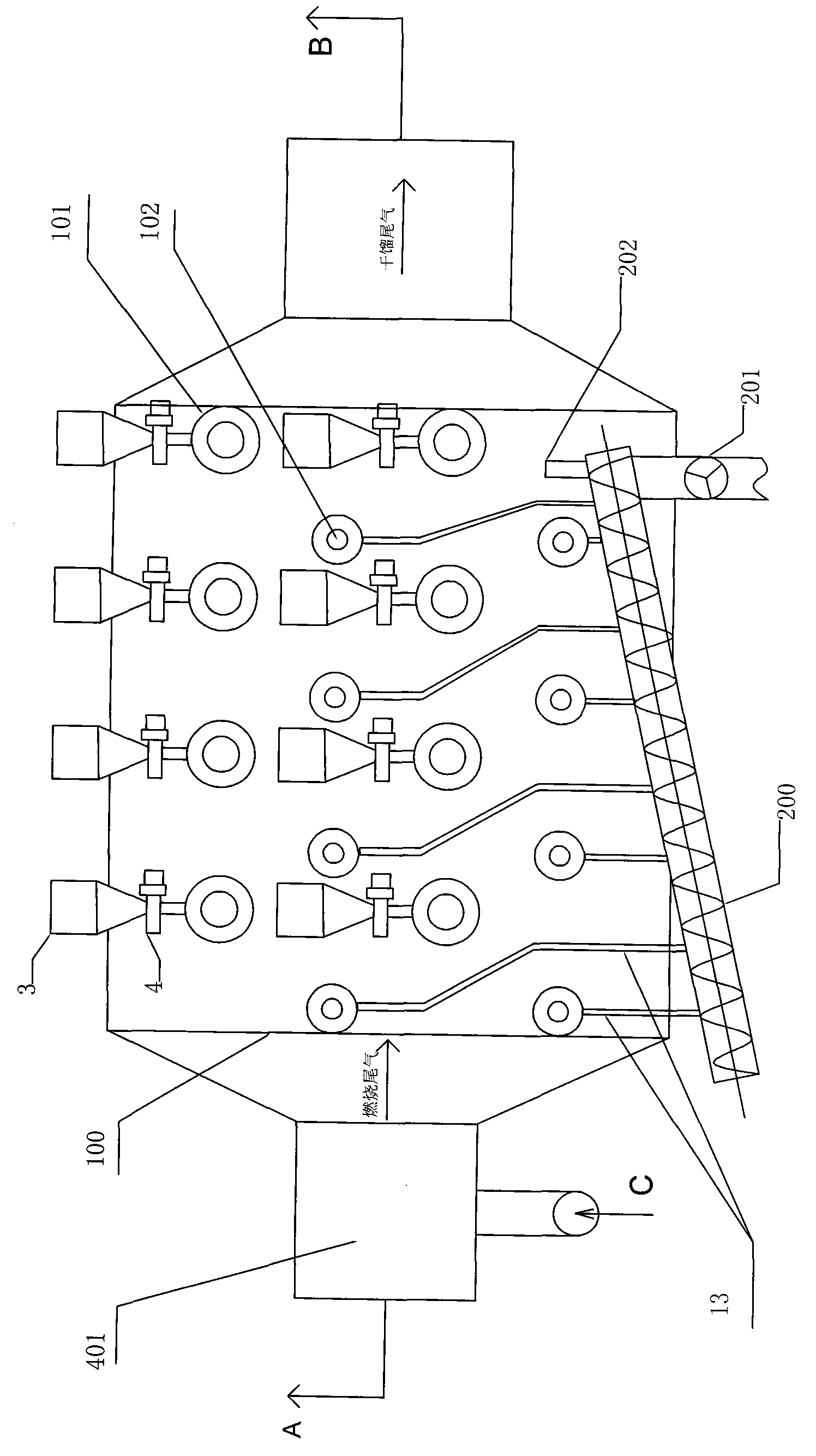

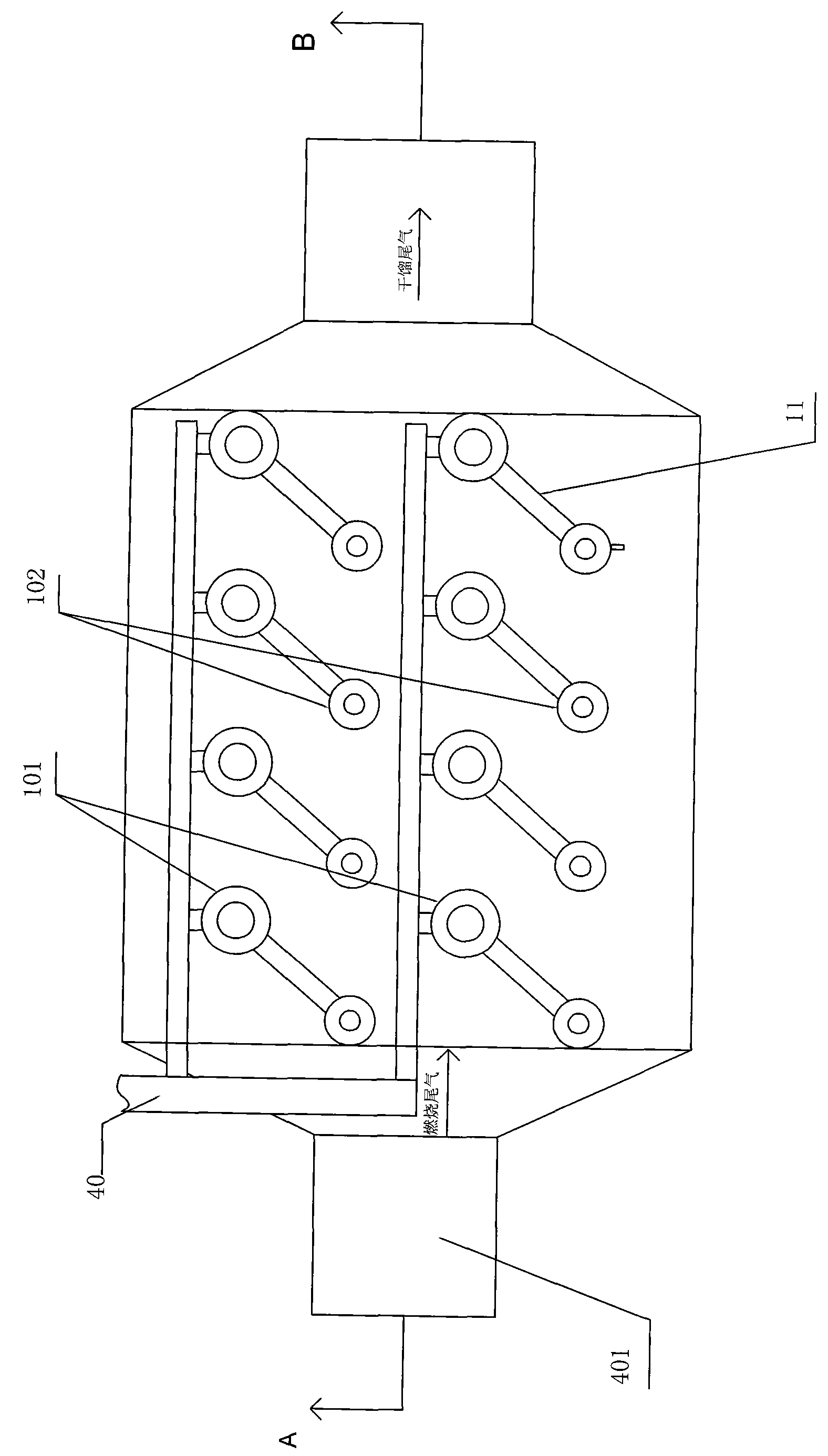

Linkage process of municipal waste pre-treatment and cement kiln resource comprehensive utilization and system thereof

ActiveCN102357516AHigh fuel substitution rateConserve traditional fossil fuelsSolid waste disposalPre treatmentCement kiln

The invention relates to a linkage process of municipal waste pre-treatment and cement kiln resource comprehensive utilization and a system thereof. The linkage process of municipal waste pre-treatment and cement kiln resource comprehensive utilization is characterized by comprising the steps as follows: 1 municipal waste enters a waste receiving system after measurement and radioactivity detection; 2 the municipal waste is crushed in advance; 3 crushed waste is dried and stabilized through a drying treatment system; 4 dried waste is treated in mechanical mode through a mechanical treatment system; and 5 separated flammable materials are refined by a refining system, measured by a measuring system and sent to a kiln head burner, a kiln tail decomposing furnace or a pre-burning chamber of a cement kiln system for burning, and traditional fuel used in the process of cement production is replaced. Separated inert components participate in dosing of cement raw materials and enter the cement kiln system from a raw meal mill. The process achieves safe, harmless, recycling and energy-saving treatment and utilization of the municipal waste.

Owner:华新环境工程有限公司

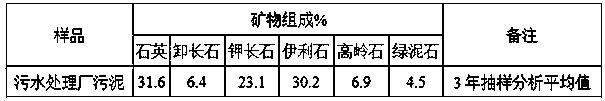

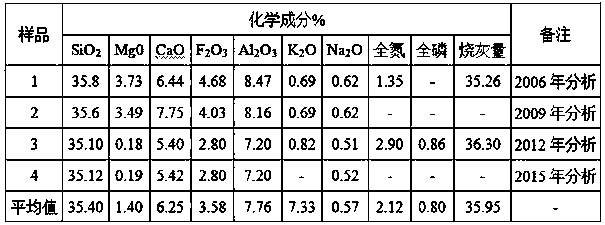

Method for pressing steaming-free and baking-free wall body block from dehydrated sludge in sewage treatment plant

The invention discloses a method for pressing a steaming-free and baking-free wall body block from dehydrated sludge in a sewage treatment plant. The method specifically comprises the following steps:dehydrating sludge of the sewage treatment plant, modifying the dehydrated sludge by virtue of seashell dust, ferrous sulfate and calcium hydroxide, so as to obtain modified sludge; mixing the modified sludge, the seashell dust, calcium sulfate, silica fume, slag charge, an F14 liquid activating agent and water, so as to obtain a mixture; digesting the mixture, so as to obtain a digested material; mixing the digested material, a solidifying agent and a YW-type surfactant, so as to obtain a blank preparing material; preparing a product workblank from the blank preparing material by virtue of apunching system; and carrying out pre-maintenance on the product workblank, and carrying out thermal air circulating reaction maintenance on the product workblank, so as to obtain the wall body block. The method has the beneficial effects that the problems in the effective treatment and resource utilization of the dehydrated sludge and industrial waste residue or engineering muck in the sewage treatment plant are solved, the cost is low, an obtained baking-free brick has excellent compressive strength, has no radioactivity, can be used for producing multiple specifications of wall body blocksand can be manufactured into building components for various uses.

Owner:宁波纯恒固废科技有限公司

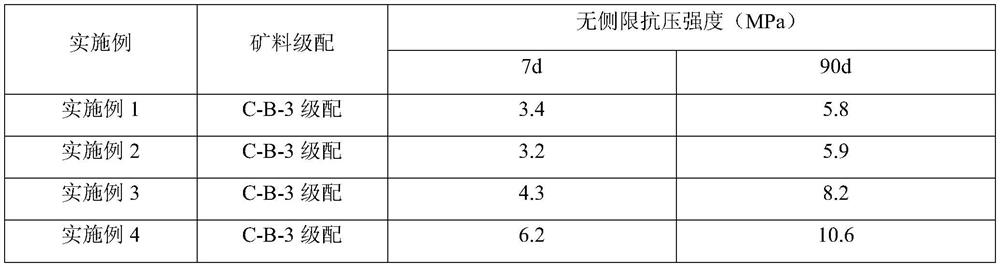

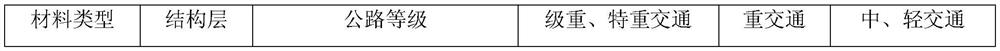

Application of household garbage incineration fly ash composite admixture in cement stabilized macadam mixture

The invention relates to application of a household garbage incineration fly ash composite admixture in a cement stabilized macadam mixture, and belongs to the technical field of crossing of environmental engineering and highway engineering. According to the invention, the household garbage incineration fly ash is used as a stable material; the cement / incineration fly ash stabilized macadam mixture is mainly prepared by blending domestic waste incineration fly ash with an active mixed material and an excitant to form a composite admixture and then forming a composite cementing system togetherwith cement to stabilize graded macadam mineral aggregate; and the cement / incineration fly ash stabilized macadam mixture can be used in highway pavement base layers and subbase layers. According to the invention, component complementation and activity excitation effects in the composite admixture are utilized; the potential gelatinization activity of the incineration fly ash is released to the greatest extent to provide a high-activity cementing effect; meanwhile, heavy metal components contained in the incineration fly ash are stably solidified through the solidification effect of the composite cementing system, so that the cement / incineration fly ash stabilized macadam mixture with good performance is prepared, the recycling and harmless disposal target of the household garbage incineration fly ash is achieved, the use amount of cementing materials is reduced for highway engineering, and the engineering cost is reduced.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +2

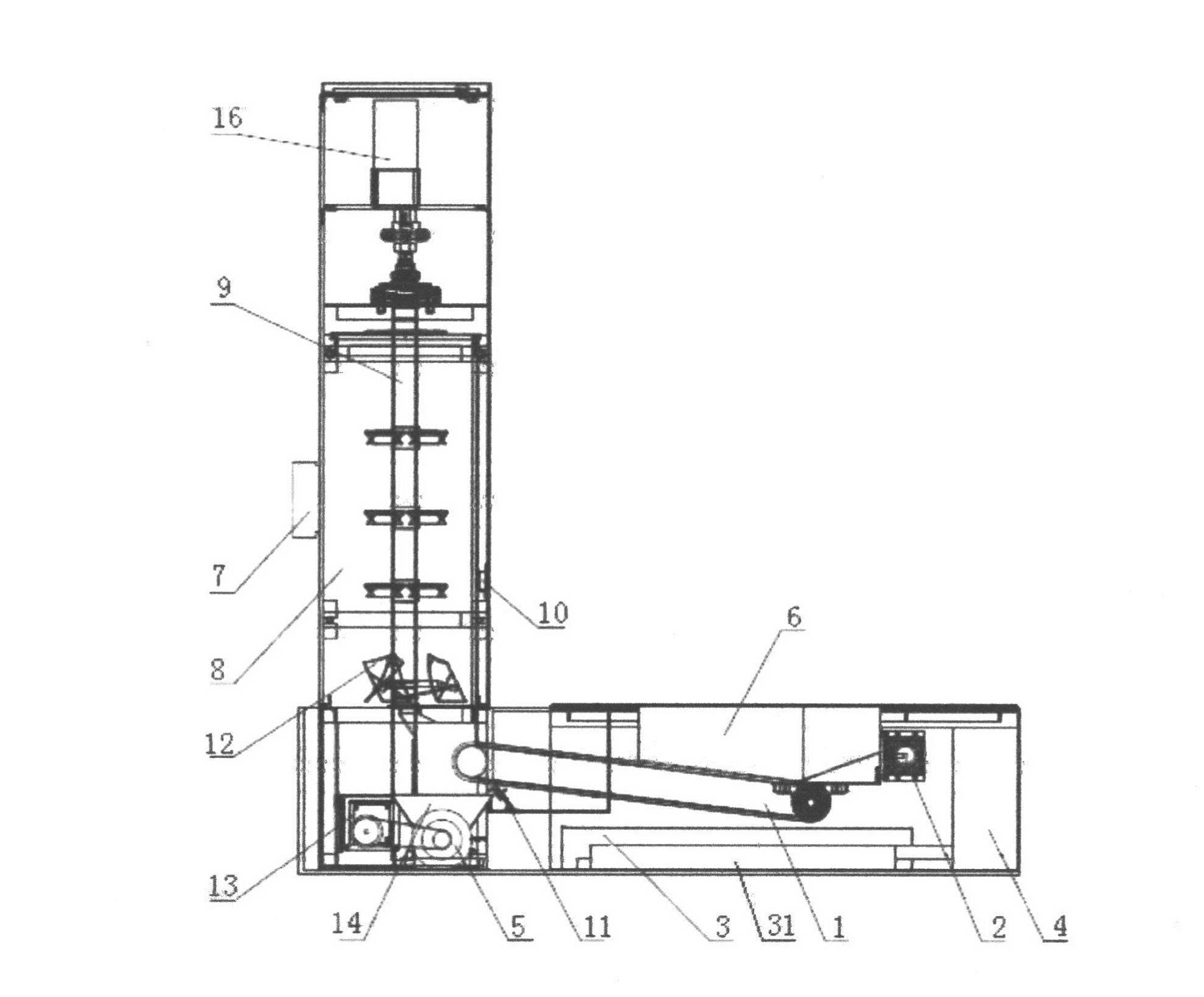

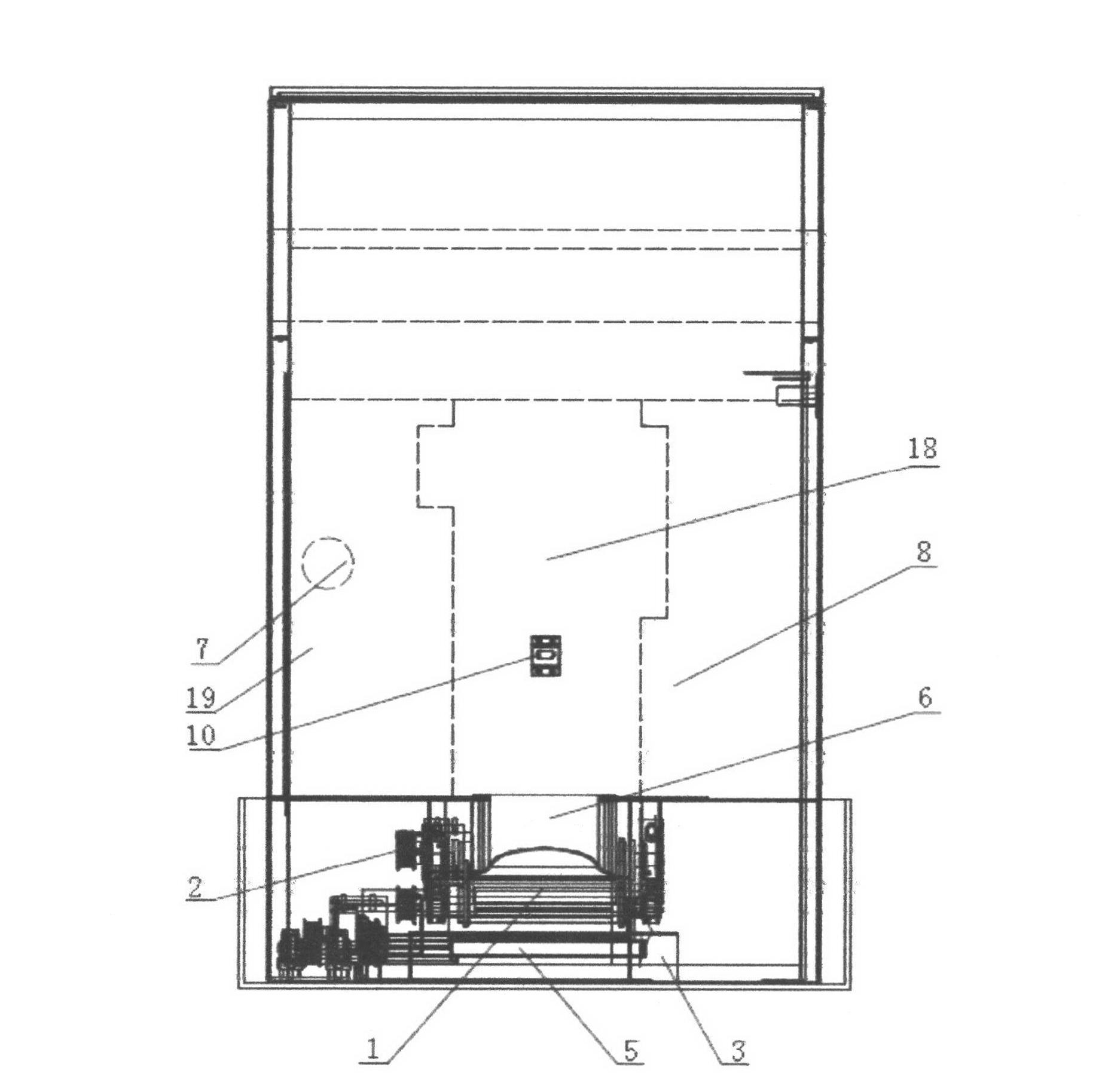

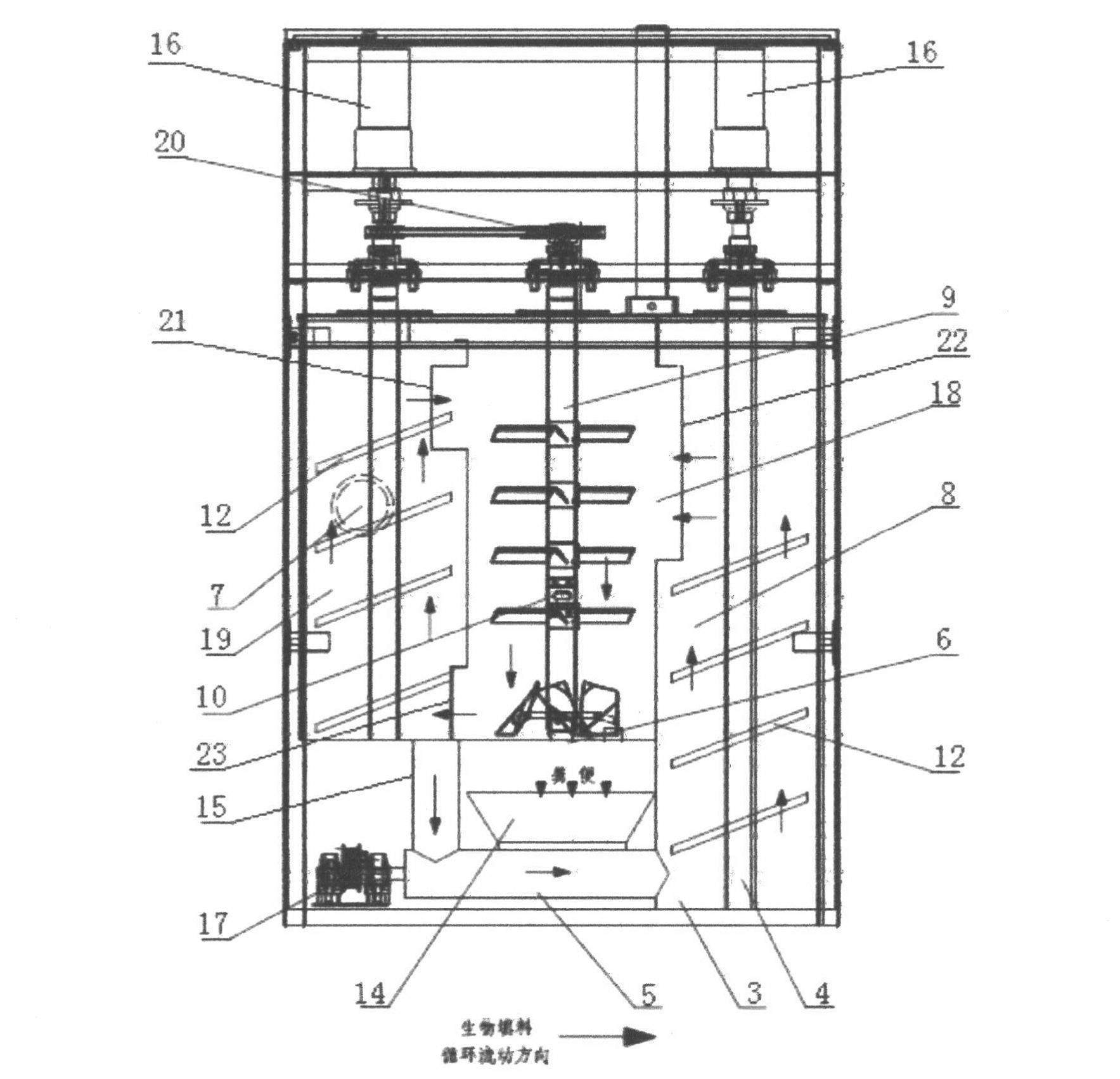

Source separated recycling water-free ecological restroom

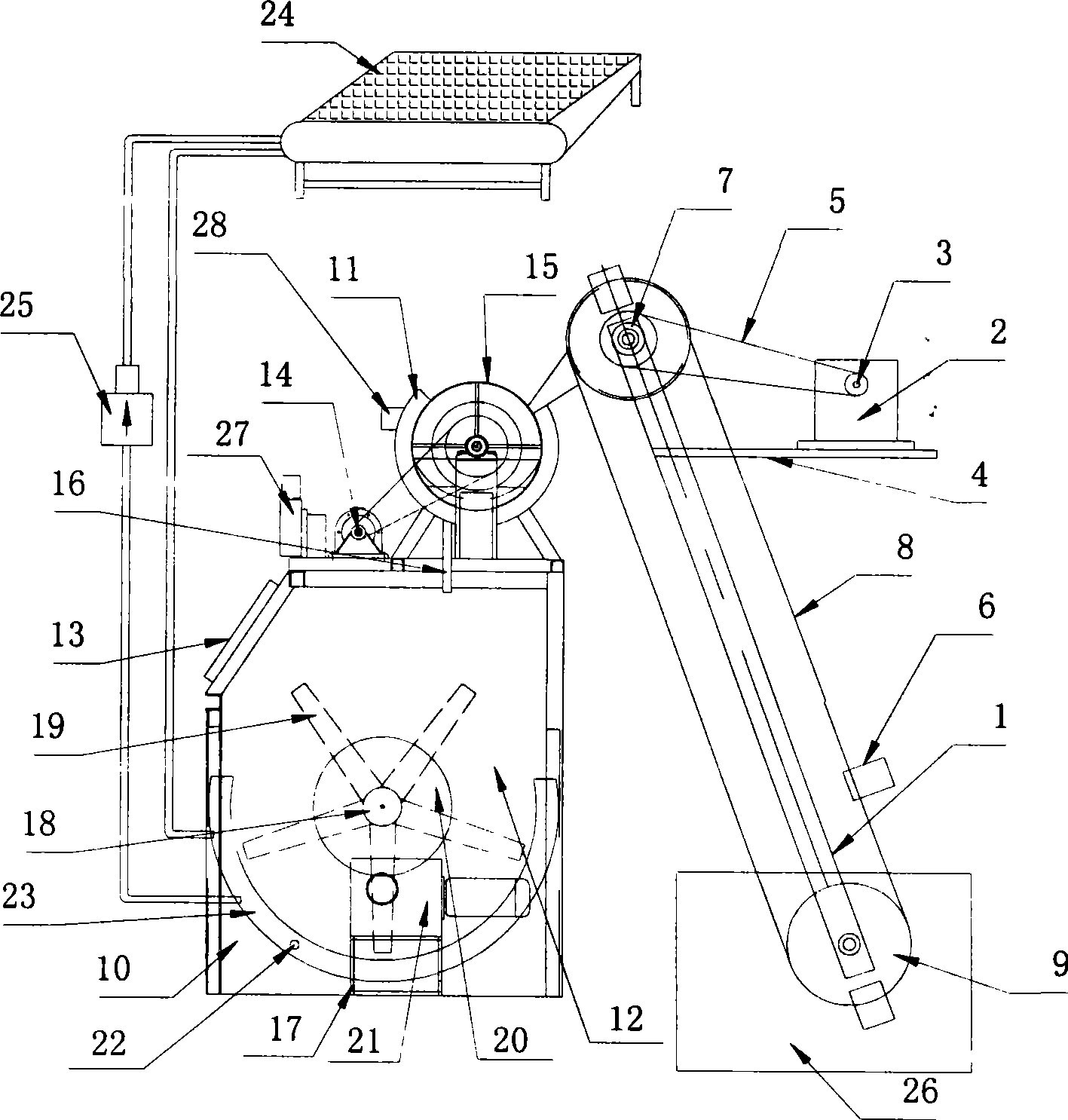

ActiveCN102641092AAchieve reductionAchieve harmlessBathroom accessoriesMultistage water/sewage treatmentTherapeutic effectConveyor belt

The invention discloses a source separated recycling water-free ecological restroom comprising a source separation system and a dry bioreactor, wherein the source separation system comprises a closestool, a conveyor belt located below the closestool and inclining forward, a urine collecting tank located below the conveyor belt, and a urine nitrogen fixation and phosphorus extraction device communicated with the urine collecting tank; the dry bioreactor comprises three vertical reaction chambers; a stirring device is arranged in the first reaction chamber and vertical screws are arranged in both of the second reaction chamber and the third reaction chamber; the lower parts of the second reaction chamber and the third reaction chamber are communicated with each other through a transverse auger conveyor which is located below the rear end of the conveyor belt; and the auger conveyor is provided with an opening corresponding to the rear end of the conveyor belt. The source separated recycling water-free ecological restroom has the advantages of being completely free of water, capable of recycling materials, simple to maintain, low in operating cost, free of secondary pollution and limit on the number of people using the restroom, odorless, good in sanitation condition, excellent in treatment effect, low in occupied space and on the like.

Owner:CHANGSHA HYSO ENVIRONMENTAL BIOTECH

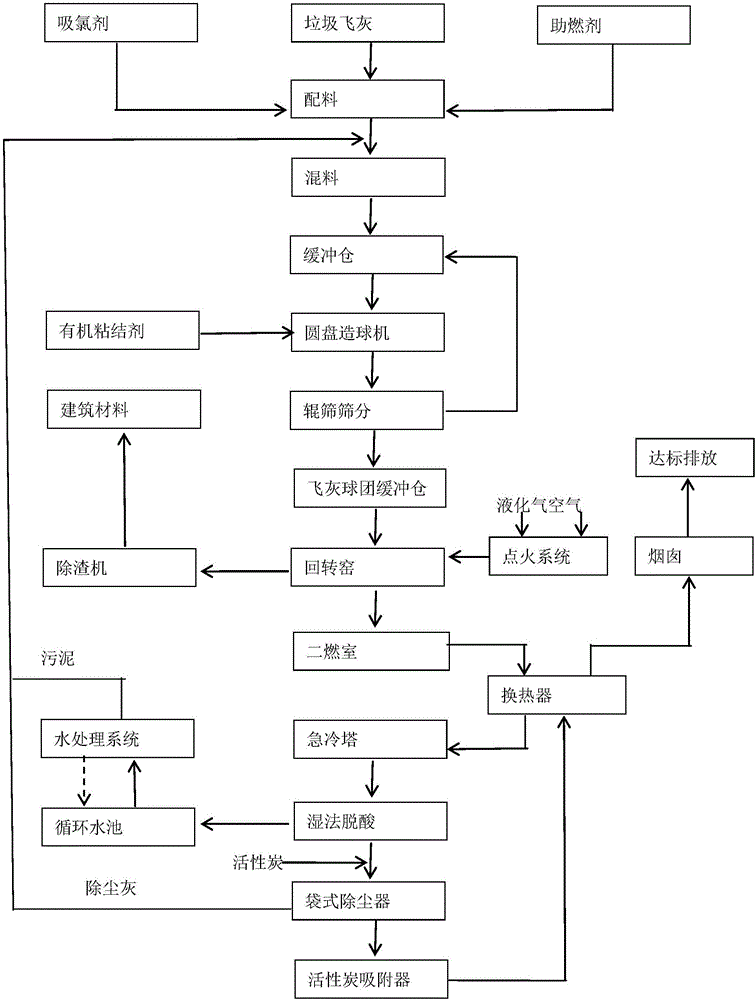

Method for achieving harmless disposal of garbage fly ash by means of rotary kiln technology

InactiveCN106524183ANo secondary pollutionAchieve harmlessEmission preventionCombustion technology mitigationFlue gasFly ash

The invention provides a method for achieving harmless disposal of garbage fly ash by means of a rotary kiln technology. According to the method, the rotary kiln technology is utilized, the processes of burdening, uniform mixing, pelleting, screening, feeding, igniting, calcining, residue collecting, flue gas purifying and the like are used for achieving harmless disposal of the garbage fly ash, harmless disposal is achieved, and meanwhile residues can be used as building materials, so that the purposes of harmlessness, stabilization, reduction and reclamation of the garbage fly ash are achieved.

Owner:重庆兴满和企业管理咨询有限公司

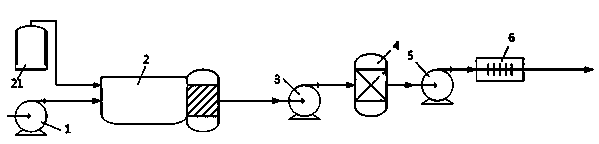

Sludge ozonization dehydration treatment method and device

InactiveCN103833193AReduce processing loadEfficient mixingSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationSludgePulp and paper industry

The invention relates to a sludge ozonization dehydration treatment method and a sludge ozonization dehydration treatment device. The method comprises the following steps in sequence: A, pumping original sludge into a sludge ozonization reaction device for ozonization so as to release interstitial water and cell water in the original sludge; B, mechanically concentrating; C, pumping the sludge into a box-type diaphragm filter press, and adding a macromolecule flocculant at an outlet of a pump; and D, filter-pressing; E, blowing the residual sludge in a sludge feeding tube towards the sludge feeding direction, and subsequently discharging the sludge. The device comprises an original sludge conveying pump, a sludge ozonization reaction device, an after-ozonization sludge conveying pump, a mechanical concentration device, an after-mechanical concentration sludge conveying pump and the box-type diaphragm filter press which are connected in sequence through pipelines, wherein an air conveying pipeline is arranged at the tail end of the sludge feeding tube of the box-type diaphragm filter press. By adopting the method and the device, the moisture content of the sludge is stably reduced to be less than 50%, the treatment burden of the box-type diaphragm filter press is alleviated, the working efficiency is remarkably improved, and the purposes of lightening, harmlessness and resourceful treatment on the sludge are ultimately achieved.

Owner:HANGZHOU QINGSE ENVIRONMENTAL PROTECTION TECH

Process of synthesizing high purity iolite material with industrial sludge from aluminium section plant

InactiveCN1609034ATo achieve resourceAchieve benefitsSolid waste managementSolid waste disposalSludgeSolid reaction

The present invention is process of synthesizing high purity iolite material with industrial sludge from aluminum section plant. The materials include industrial sludge from aluminum plant 48-50 wt%, talcum powder 24-25 wt%, clay 25-27 wt% and TiO2 0-3 wt%; and the synthesized product has iolite content over 95 % and mullite content of 0.5-5 wt%. The present invention uses the sludge from aluminum plant with large surface area and high activity favorable to solid phase reaction and sintering as main material, and has high economic utility and social utility.

Owner:FUZHOU UNIV

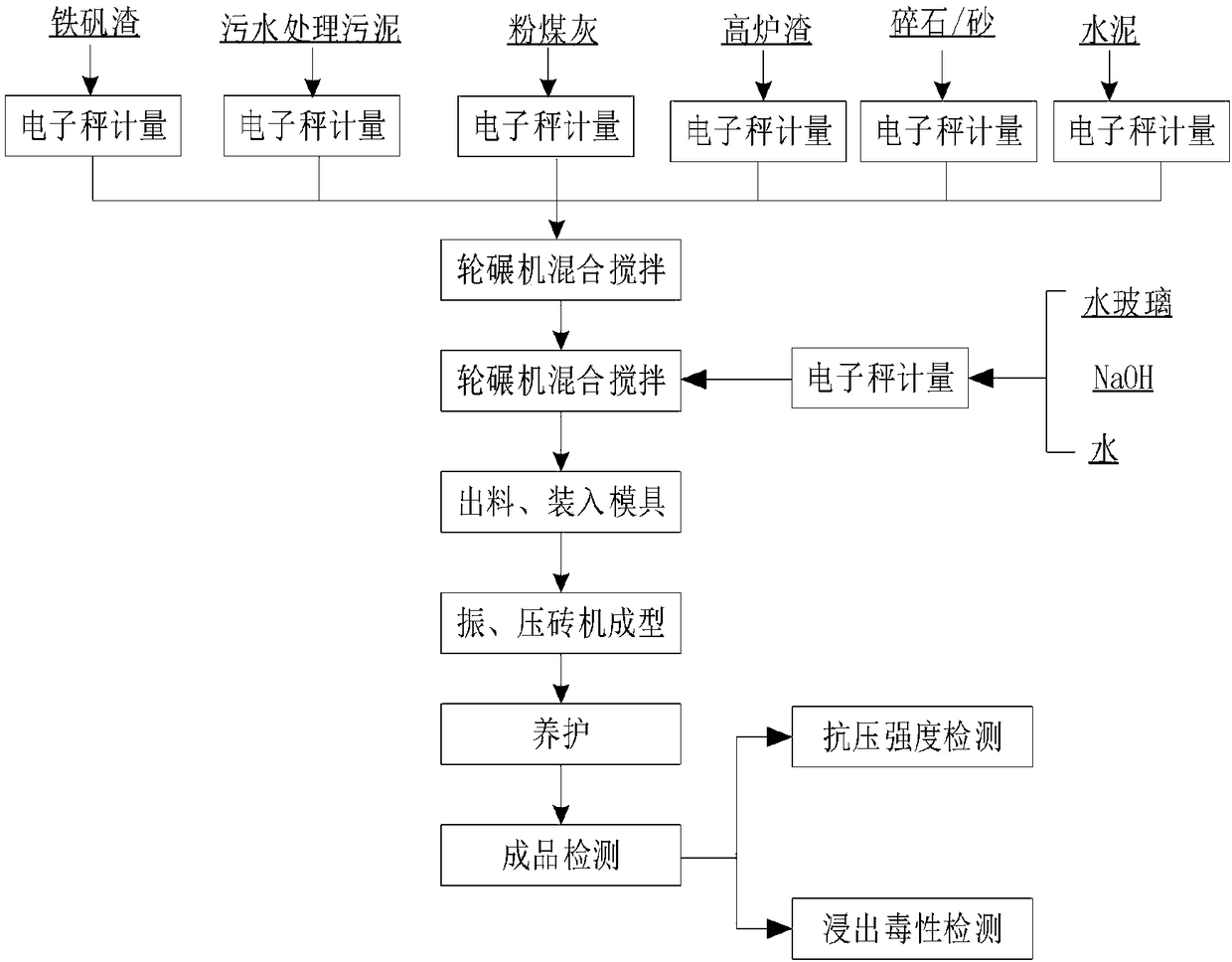

Method for preparing solid bricks from solid wastes generated by zinc hydrometallurgy

The invention discloses a method for preparing solid bricks from solid wastes generated by zinc hydrometallurgy. According to the method disclosed by the invention, adopted raw material components andthe mass percent content of each component are as follows: 15.5 to 18.5 percent of aggregate, 4.7 to 6.5 percent of fly ash, 4.7 to 6.5 percent of blast furnace slag, 12.4 to 16.0 percent of cement,12.4 to 16.0 percent of an alkali activator and 40.0 to 50.0 percent of jarosite slag of the zinc hydrometallurgy and sewage treatment sludge of the zinc hydrometallurgy, wherein the mass ratio of thejarosite slag of the zinc hydrometallurgy to the sewage treatment sludge of the zinc hydrometallurgy ranges from (4 to 1) to (5 to 1). According to the method disclosed by the invention, wastes are treated by wastes, and the jarosite slag of the zinc hydrometallurgy and the sewage treatment sludge are wholly treated and utilized in a large batch; zero emission of the jarosite slag of the zinc hydrometallurgy and the sewage treatment sludge can be realized; meanwhile, the reducing, harmless and recycling aims of the jarosite slag of the zinc hydrometallurgy and the sewage treatment sludge arerealized.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +2

Incineration treatment method of nitrile-containing waste residues

InactiveCN107243505AStrong applicabilityStable effectTransportation and packagingSolid waste disposalSlagFlue gas

The invention relates to an incineration treatment method of nitrile-containing waste residues, and belongs to the technical field of treatment of hazardous wastes. According to the incineration treatment method of the nitrile-containing waste residues, a high temperature reclamation furnace is utilized, the nitrile-containing waste residues are subjected to harmless treatment through processes like batching, mixing, feeding, incineration and flue gas purification, treated slag is utilized as aggregate for preparing cementing materials, reduction, harmlessness and resource purposes of the nitrile-containing waste residues are achieved, a high temperature incineration treatment technology is mature, the industrialized operation effect is stable, and the flue gas standard reaches the national flue gas emission standard (GB18484-2001).

Owner:云南大地绿坤环保科技有限公司

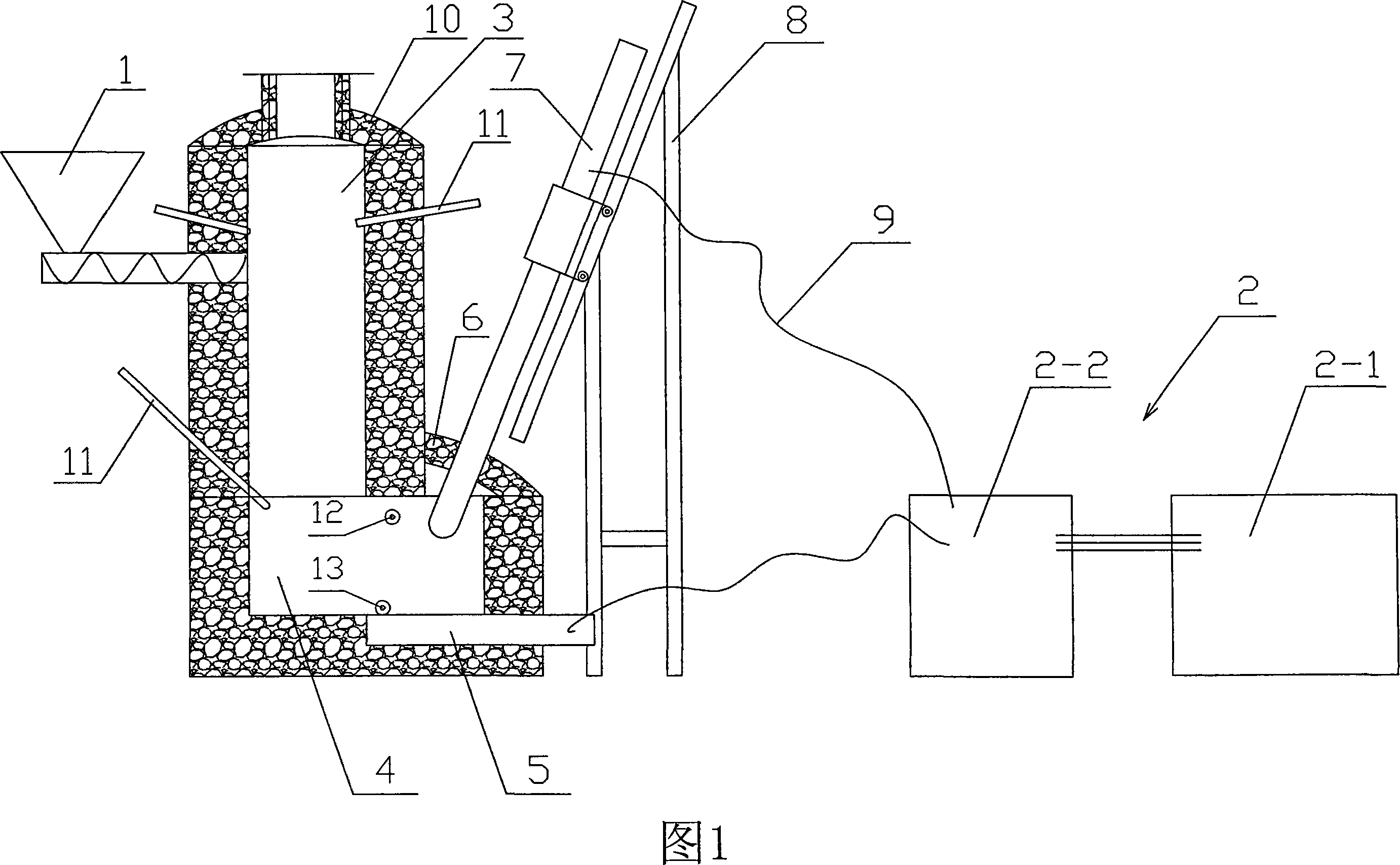

Blast electroslag furnace dedicated for treating electronic waste

The invention relates to a special blowing electroslag furnace for treating electronic waste. The invention provided special blowing electroslag furnace for treating electronic waste can thoroughly incinerate of and decompose the waste, and has high recovery rate. The technical scheme to solve the problem is that: the special blowing electroslag furnace for treating electronic waste has spiral feeding machine, power supply device, and which is characterized in that an output terminal of the spiral feeding machine is connected to blowing melting furnace which is fixed to upper portion of a slag separating furnace and connected to the same, and the slag separating furnace has a black lead plate extending out of the furnace body and disposed at the bottom of the furnace, and a lower furnace cover having electrode holes and disposed at one side of top of the furnace and seal connected to the furnace body. Black lead electrodes are fixed at electrode elevating mechanism disposed at one side of the slag furnace, and one end of the electrode inserts into the slag separating furnace via the electrode hole, and the black lead plate and the black lead electrodes are electrically connected to rectifier and electric furnace transformer in sequence by water cooling cable. The invention can be used for recovery, disinfection, waste utilization of metal, nonmetal, and combination thereof.

Owner:杭州大洲物资再生利用有限公司

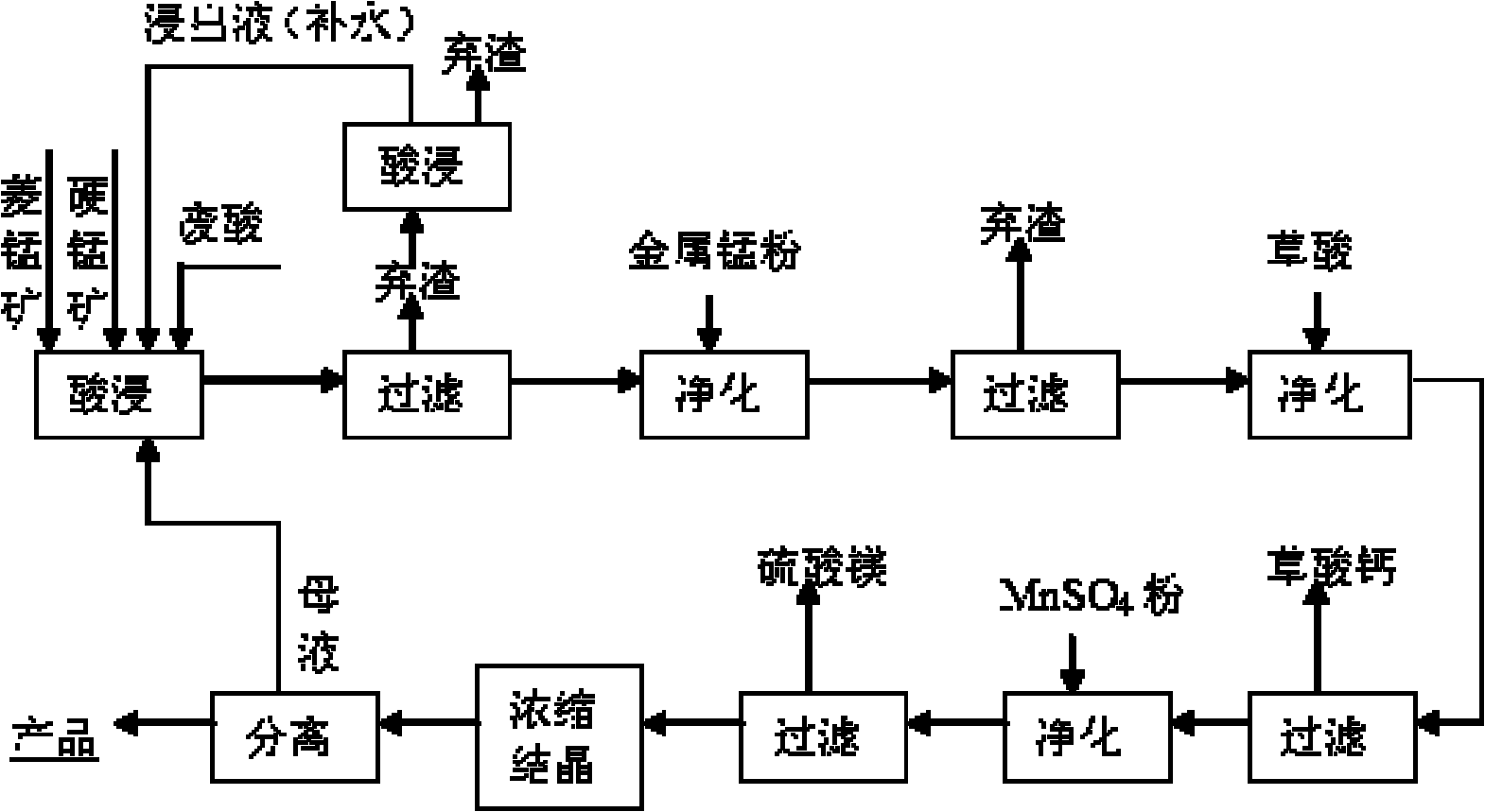

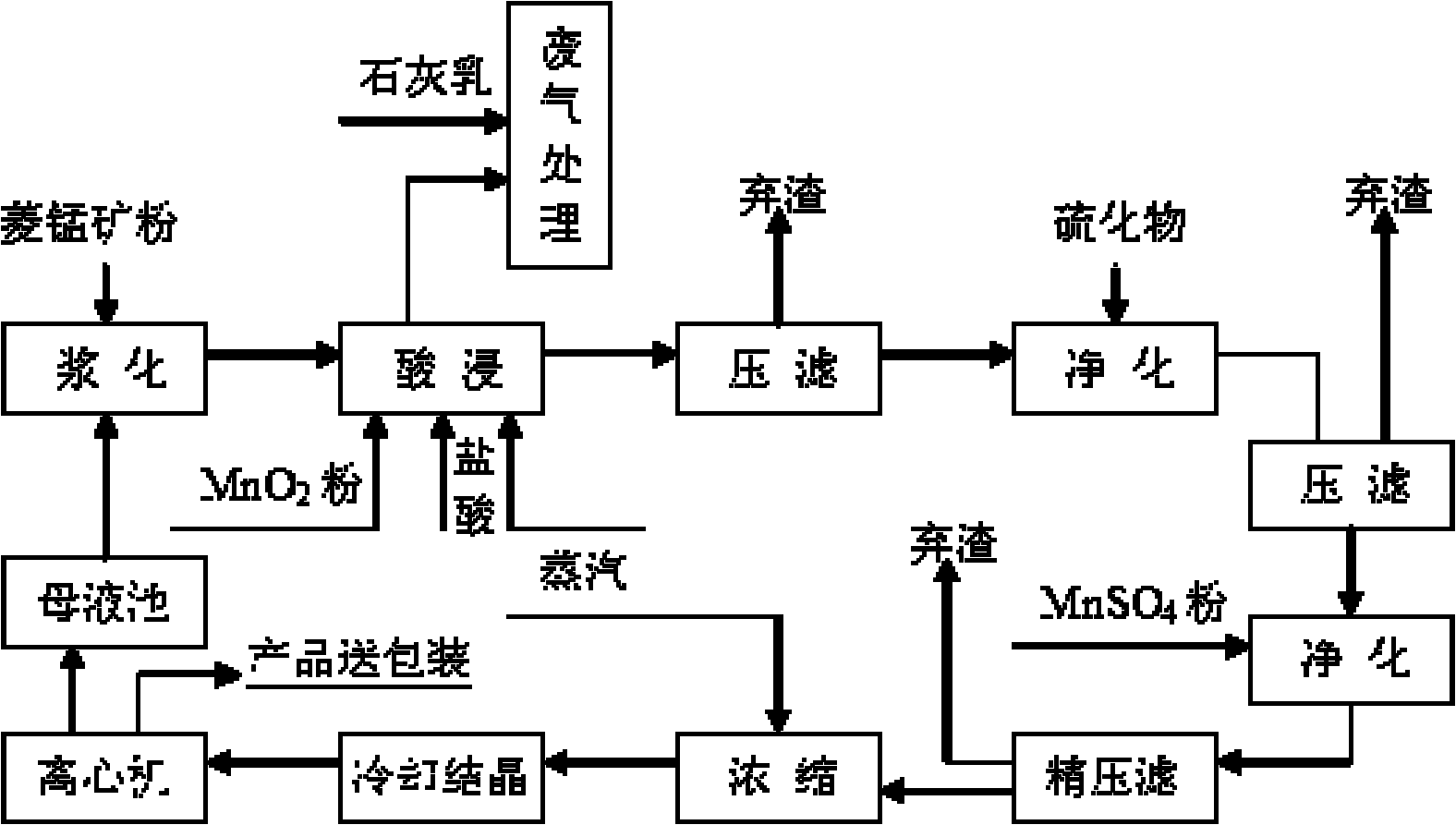

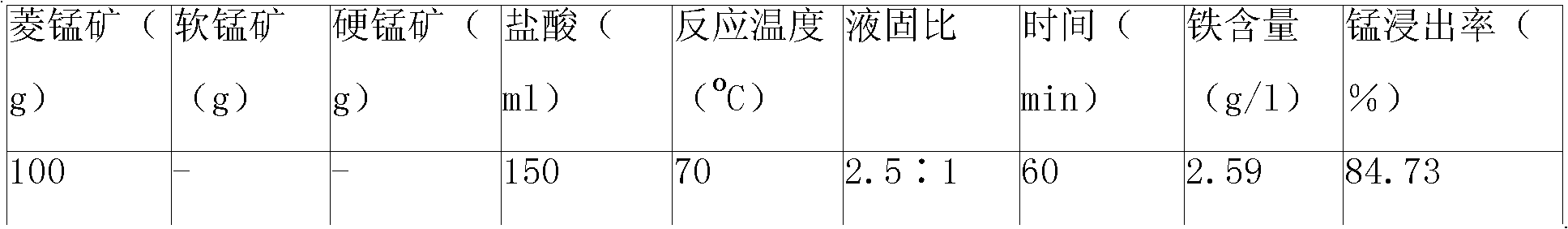

Process for preparing tetrahydrate manganese chloride by leaching out rhodochrosite with waste acid

InactiveCN102050495ATo satisfy the market's needsReduce manufacturing costManganese halidesSlagPsilomelane

The invention discloses a process for preparing tetrahydrate manganese chloride by leaching out rhodochrosite with waste acid. The process comprises the following steps of: adding waste hydrochloric acid to rhodochrosite step by step for leaching, meanwhile, adding pyrolusite or psilomelane which is used as an oxidant; filtering the generated mixed solution, and leaching the filter residue with acid once again; adding metal manganese powder to filter liquor for precipitating, filtering and abandoning slag; adding oxalic acid in the filter liquor for settling, filtering; adding manganese sulfate powder to the filter liquor for precipitating, and filtering; quantitatively adding BaCl2 to the filter liquor, standing still and filtering to remove excessive SO4 <2->; and finally, carrying out concentrating crystallization and centrifugal separation on the filter liquor to obtain a tetrahydrate manganese chloride product. Compared with the prior art, the process has the advantages of simple process flow, convenience of operation, less investment, high efficiency and easy utilization of industrialization. In the invention, low-concentration waste acid is used for leaching the rhodochrosite to produce tetrahydrate manganese chloride, which not only solves the treatment problem of waste acid, but also efficiently utilizes a large quantity of low-grade rhodochrosite resources and realizes the sustainable utilization of resources.

Owner:沈新财

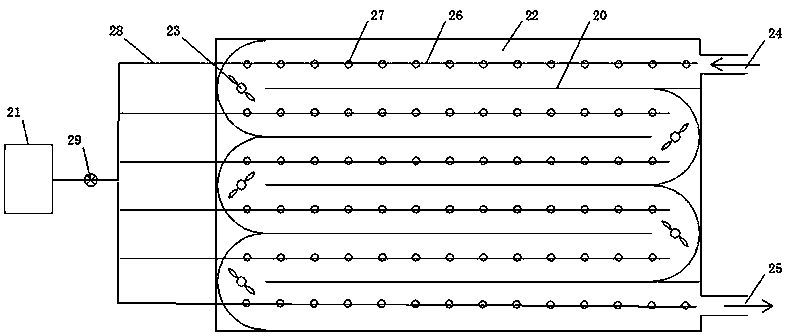

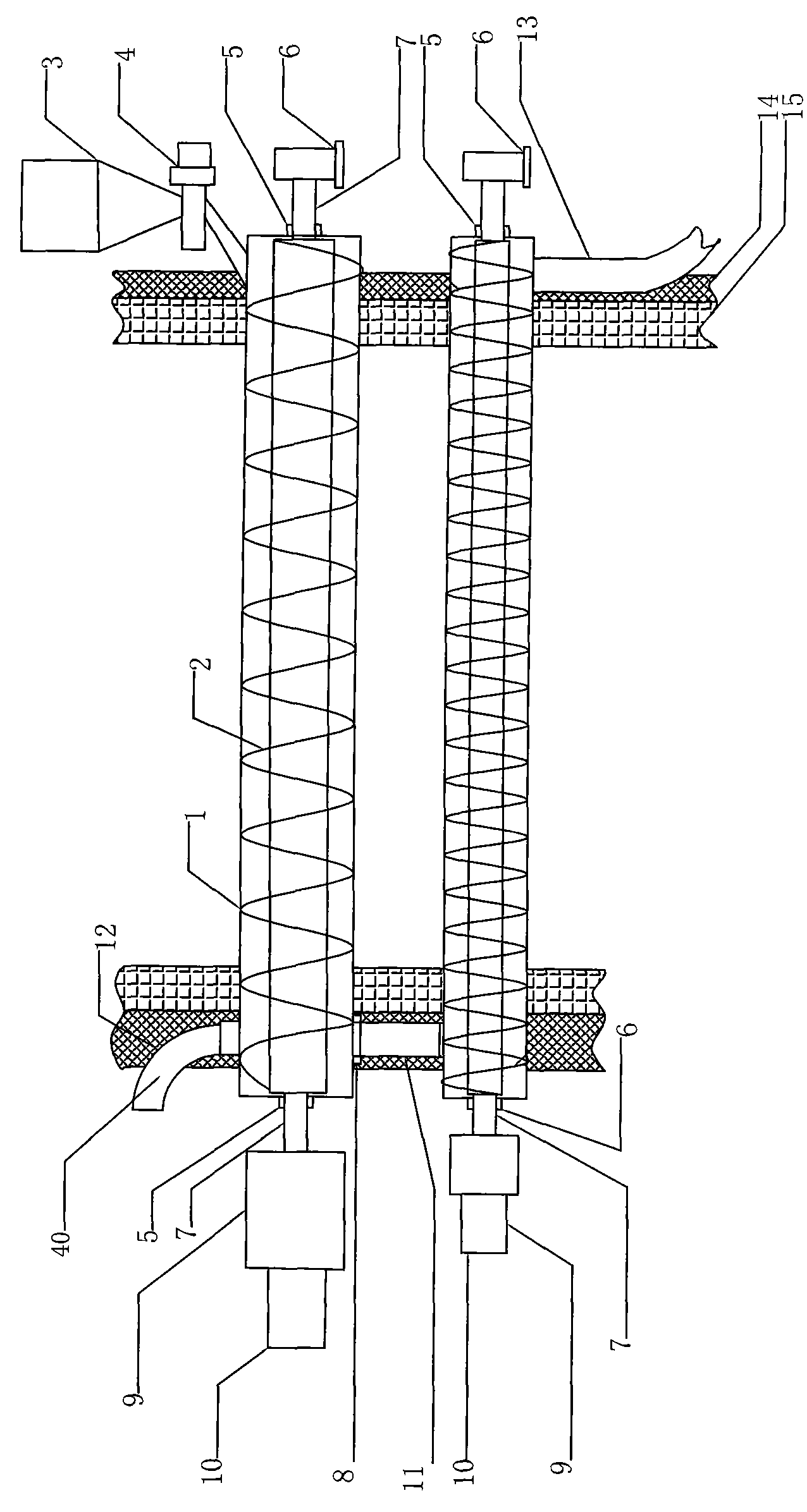

Anaerobic fermentation system and method for producing biogas by carrying out sludge digestion reaction through anaerobic fermentation system

ActiveCN104673629AGuaranteed long stayGuaranteed reflowBioreactor/fermenter combinationsBiological substance pretreatmentsSludgeDigestion

The invention relates to the technical field of waste treatment and in particular relates to an anaerobic fermentation system and a method for producing biogas by carrying out a sludge digestion reaction through the anaerobic fermentation system. The anaerobic fermentation system comprises a fermentation tank, wherein the fermentation tank is of a sealed structure, and a horizontal stirring device is arranged inside the fermentation tank; a feeding end and a discharging end are respectively arranged at two ends of the fermentation tank in the horizontal direction; a biogas pipe is arranged on the top of the fermentation tank; a feeding hole is formed in the top, which is close to the feeding end, of the fermentation tank; the feeding hole is respectively connected with a feeding screw conveying device and a sludge conveying pipeline; a device for stirring and mixing the materials is arranged below the feeding hole and inside the fermentation tank; a discharge opening is formed in the discharging end and is connected with the screw conveying device; a return pipeline is arranged on one side of the discharging end; and the other end of the return pipeline is connected with the feeding end. The system has the advantages of small size, reasonable design, continuous operation and the like.

Owner:AQSEPTENCE GRP HANGZHOU CO LTD

Animal waste fermented organic feed and preparation method thereof

PendingCN111802510AImproves levels of nutrient absorptionGood for healthFungiBacteriaNutritionHermetia

The invention discloses an animal waste fermented organic feed and a preparation method thereof. The organic feed comprises the following components in parts by weight: 50 parts of animal waste, 50 parts of dried materials and 0.1 part of enzymes, wherein the enzymes comprise 25 parts of potato streptomyces scabies, 10 parts of lactobacillus casei, 10 parts of cetobacter xylinium, 15 parts of saccharomyces cerevisiae, 10 parts of bacillus subtilis and 15 parts of bifidobacterium. The organic feed contains various high-quality lactic acid bacteria, anti-nutritional factors in the feed can be effectively degraded, the nutritional value and the digestibility of the feed are improved, the feed flavor and palatability are improved, feed mildewing and aflatoxin generation are effectively prevented, the safety of the fermented feed is guaranteed, nutrient and weight losses caused by fermentation heat production and gas production are avoided, and the purposes of animal waste recycling, reduction and harmlessness can be achieved at the same time by adopting animal waste-fermented organic feed to breed hermetia illucens.

Owner:昆山理清生物科技有限公司

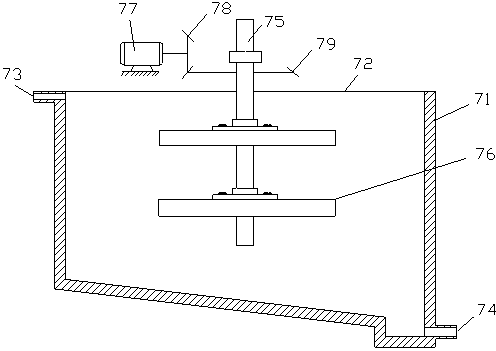

Combined sludge treatment method and dry distillation device applied by same

ActiveCN101671099ATake advantage ofLow costSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisCombustionSludge

The invention provides a combined sludge treatment method. In the treatment method, by combining the technologies of semidrying, dry distillation and cracking as well as combustion treatment, dewatering sludge is treated step by step; the sludge with water content of 75 percent is treated, and then inorganic substances are converted into solid residues by high-temperature treatment, and organic substances are converted into CO2, H2O and recyclable resource of fluid oil; and in the treatment process, heat energy can be fully and comprehensively utilized, all treatment technologies are reasonably distributed, the treatment energy consumption is not increased when treatment processes are increased, and heat energy from coal combustion is used in balance. The invention also provides a dry distillation device for treating sludge, comprising a dry distillation box, wherein a group of or a plurality of groups of two-stage dry distillers for treating sludge are arranged, and the two-stage drydistiller comprises a first-stage dry distiller and a second-stage dry distiller. In the dry distillation process, the material process and the stirring force are different, the materials are mainly dried continuously in the first-stage dry distiller, and the cracking is mainly carried out in the second-stage dry distiller; and the hierarchical arrangement is beneficial to process control, waste gas treatment and heat recovery.

Owner:沈洪来

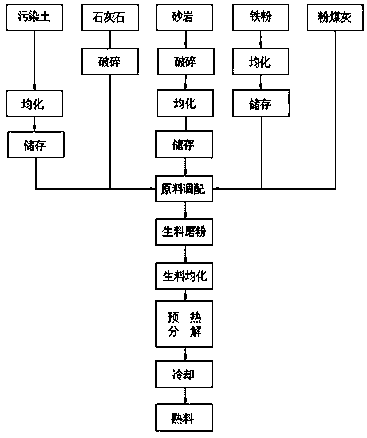

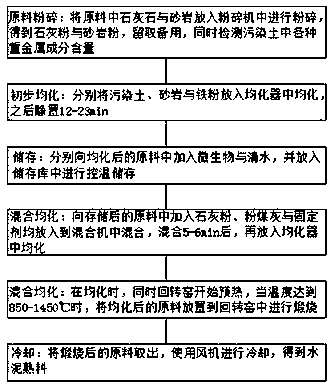

Treatment method for cooperative disposal of polluted soil via cement kiln

InactiveCN110683776AImprove utilizationTo achieve resourceCement productionMicroorganismEnvironmental engineering

The invention discloses a treatment method for cooperative disposal of polluted soil via a cement kiln. The method comprises the following steps: crushing of raw materials: crushing limestone and sandstone in raw materials in a crusher to obtain lime powder and sandstone powder, reserving the lime powder and sandstone powder for later use, and detecting the contents of various heavy metal components in the polluted soil; and primary homogenization: respectively homogenizing the polluted soil, sandstone and iron powder in a homogenizer, and carrying out standing for 12-23 min. According to theinvention, the polluted soil and other raw materials are reasonably proportioned, so the utilization of the polluted soil can be improved, the waste is comprehensively utilized, and recycling and harmlessness of the waste are realized; reduction of the content of heavy metals in the soil is well realized through the addition of microorganisms capable of absorbing the heavy metals in the soil; andthe heavy metal absorption effect of the microorganisms is improved by strictly controlling the growth temperature of the microorganisms.

Owner:BEIJING URBAN CONSTR NORTH CONSTR

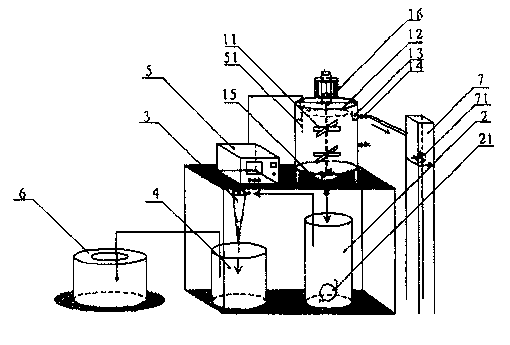

Process equipment for oily sludge

InactiveCN103130387AAchieve stabilizationComplete designSludge treatmentElectricityProcess equipment

The invention provides process equipment for oily sludge. The process equipment comprises an oily sludge cleaning tank 1, a sludge containing tank 2, a rotary jet flow separator 3, a sludge containing tank 4, a controller 5, a centrifugal machine 6 and a clean water sink 7. An annular downflow weir 12 is arranged above the oily sludge cleaning tank 1, a groove type oil separation tank 13 is formed between the downflow weir 12 and the wall of the oily sludge cleaning tank 1, the oily sludge cleaning tank 1 is communicated with the clean water sink 7 through a drain valve 14, a stirrer 11 and a temperature sensor 51 are arranged in the oily sludge cleaning tank 1, the temperature sensor 51 is electrically connected with the controller 5, the sludge containing tank 2 is installed below the oily sludge cleaning tank 1, the sludge containing tank 2 is connected with a pipeline of the rotary jet flow separator 3, the sludge containing tank 4 is arranged below the rotary jet flow separator 3, the sludge containing tank 4 is communicated with a pipeline of the centrifugal machine 6, a slush pump 21 is installed in the sludge containing tank 2, and a clean water pump 71 is installed in the clean water sink 7. The process equipment for the oily sludge is complete in design, high in mechanization degree, capable of reducing device construction investment by 50% under the same sludge process capacity, reducing occupied space by 60% and achieving the purposes of stabilization, harmless, minimization and reclamation of the sludge effectively.

Owner:XIAN REJE BIOLOGICAL TECH

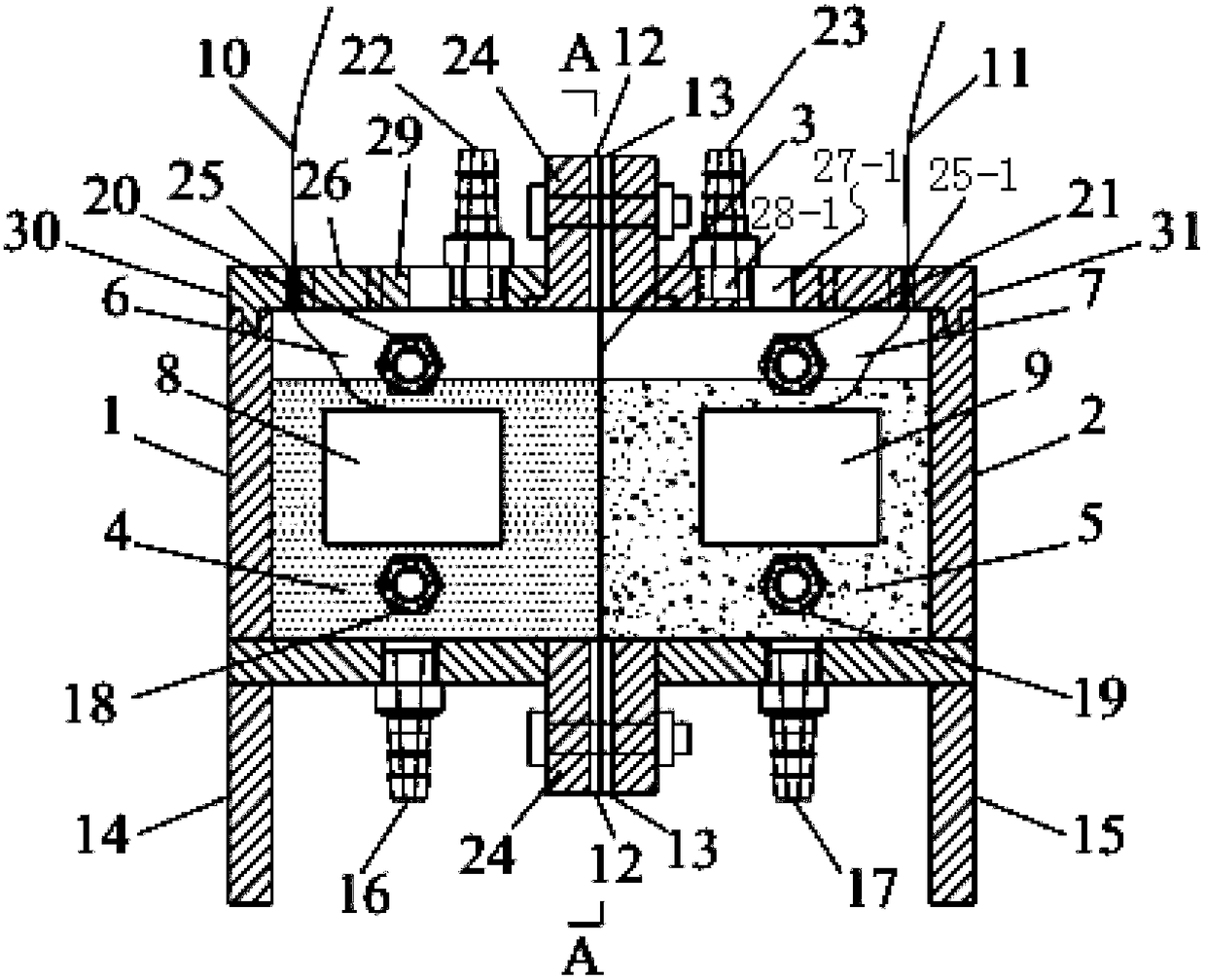

Microalgae type microbial fuel cell

PendingCN108155407ATo achieve resourceSimple structureBiochemical fuel cellsMicrobial fuel cellFuel cells

The invention discloses a microalgae type microbial fuel cell. An anode chamber is provided with a top cover, the lower portion of the anode chamber is provided with an air release opening, the side surface is provided with four water outlets which are used for discharging water and sampling; anaerobic sludge is placed on a reaction matrix in the anode chamber, and the top cover of a reaction areais provided with a top water inlet, a reference electrode as well as an anode conducting wire fixing opening and two reserved holes; a cathode chamber is provided with a sealing cover, the lower portion is provided with an air release opening, the side surface is provided with four water outlets, the cathode chamber is used for culturing algae, the top cover is provided with a top water inlet, areference electrode as well as a cathode conducting wire fixing opening and two reserved holes of different sizes; and the anode chamber and the cathode chamber are connected into a whole by virtue ofa flange, a silicone plate is arranged on the junction for sealing, and the silicone plate is provided with a proton exchanging membrane to separate the anode chamber and the cathode chamber. The cell is simple in structure and easy in implementation, and not only can the research use in the experimental period be satisfied, but also the theoretical foundation can be provided for the actual use of the microalgae microbial fuel cell.

Owner:CHANGAN UNIV

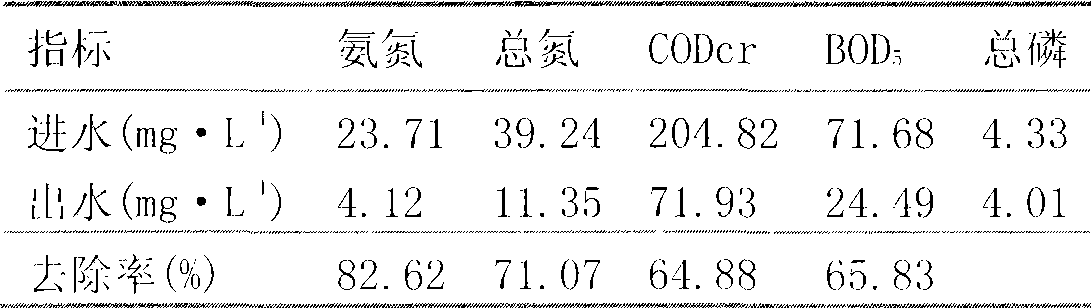

Composite technique treatment method of sewage

InactiveCN101423308ATo achieve resourceWater/sewage treatment by irradiationMultistage water/sewage treatmentCombined techniqueSewage

The invention relates to a method for treating domestic sewage by a combination technique. The method comprises a first potassium ferrate treatment and a second microwave treatment. The method comprises the following steps: domestic sewage is subjected to denitrification treatment with potassium ferrate, removal of CODcr and BOD5 and sedimentation; supernatant sewage is separated, radiated by microwaves, denitrified to remove a majority of CODcr and BOD5, and then directly used for irrigation of agriculture and forestry, municipal engineering and so on, or added with lime for dephosphorization and settled to be reused or discharged. The method has advantages of greatly reduced treatment time, purification, strong impact bearing capacity, low operation and management cost, and has obvious sewage recycling benefits.

Owner:李宗辉

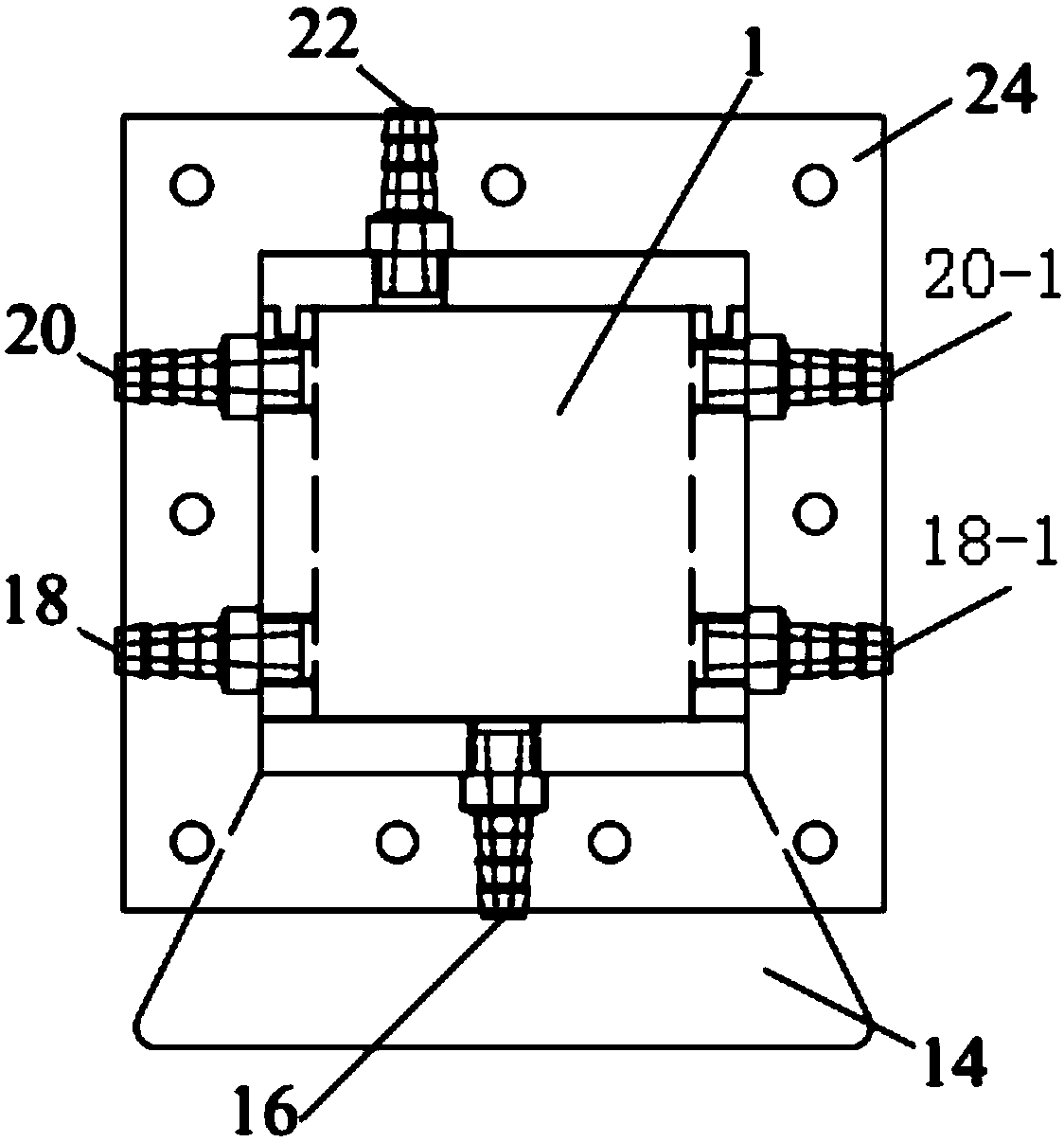

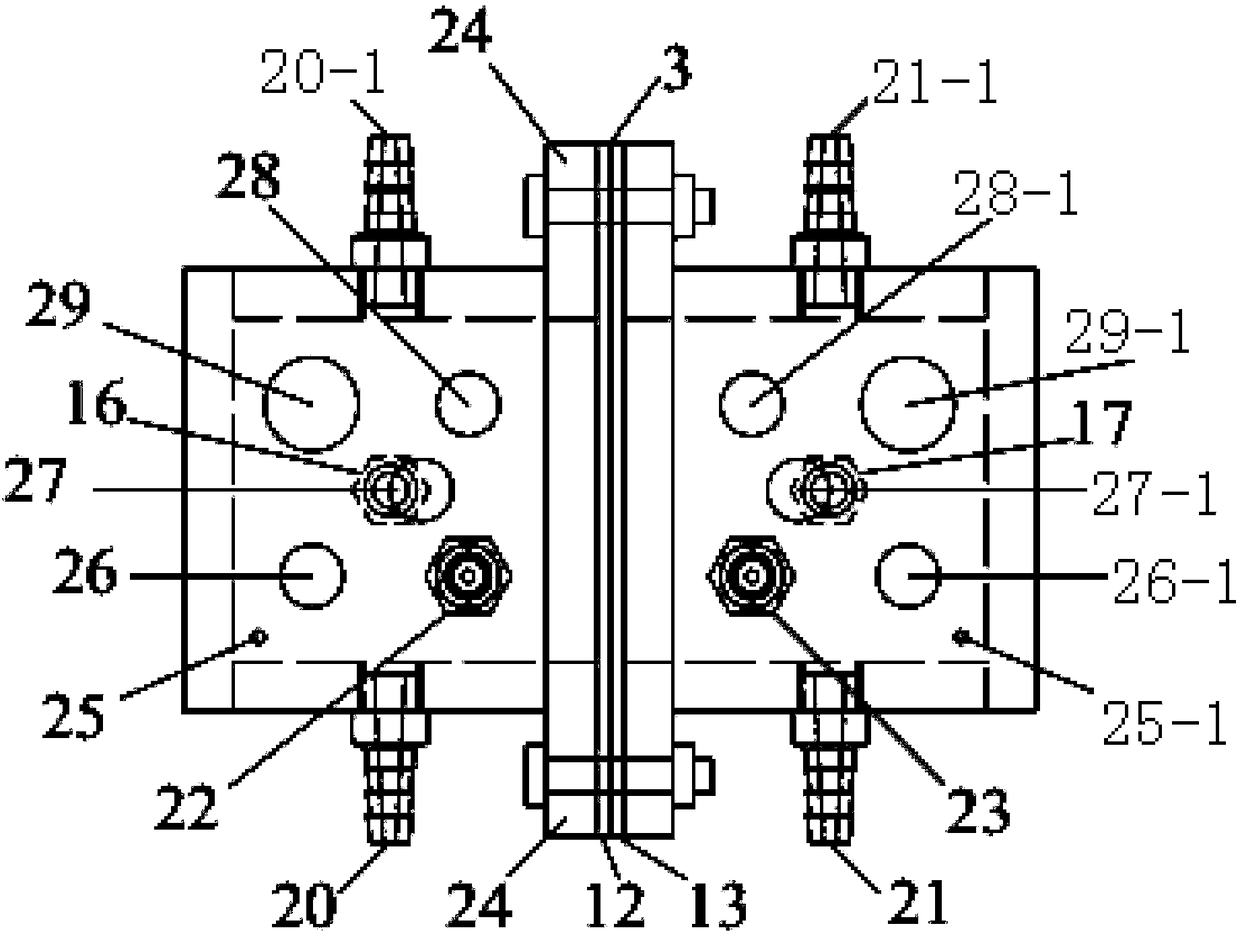

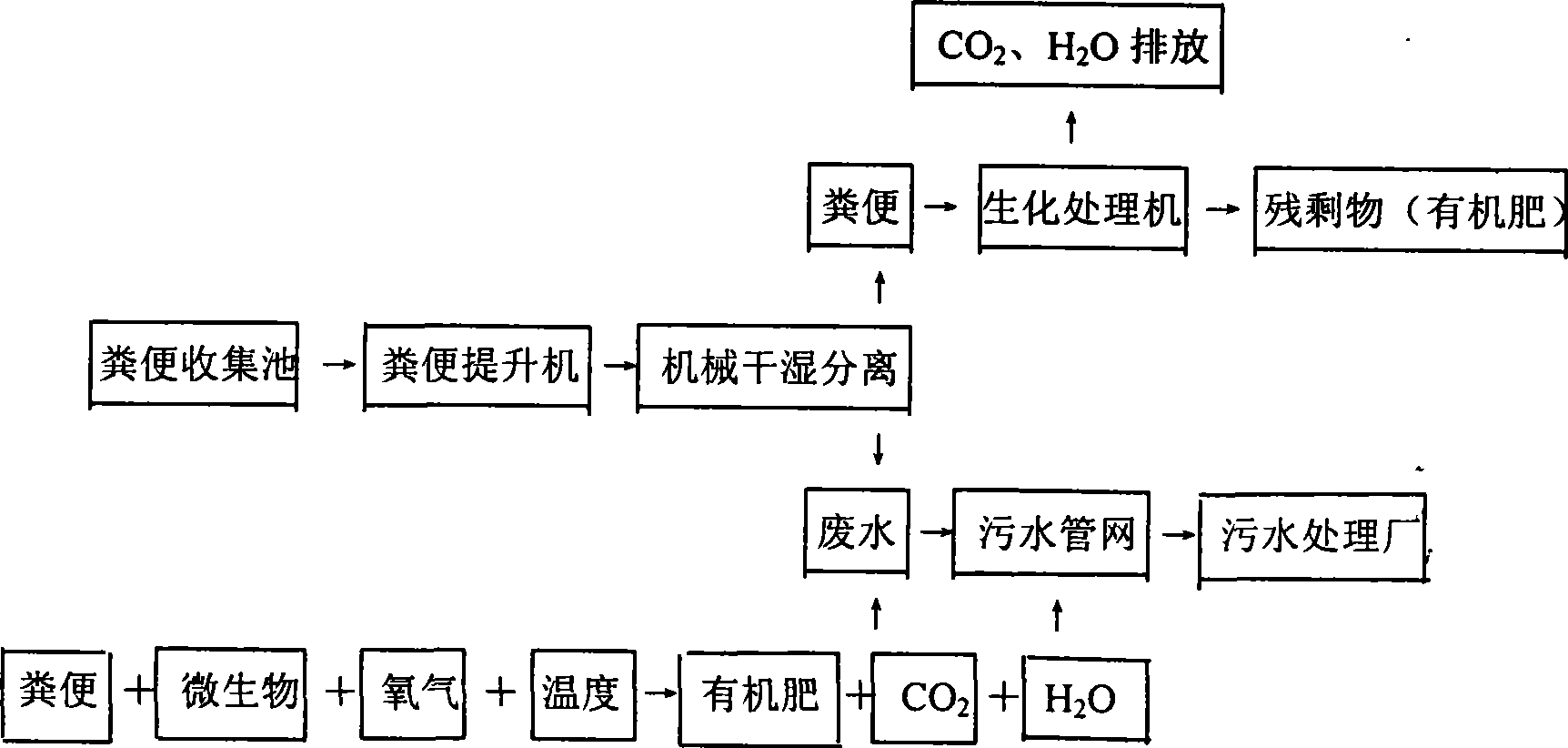

Dry-wet separating type microbiology faeces processor

InactiveCN101391910AImprove biochemical treatment to release fruitImprove soil qualityClimate change adaptationExcrement fertilisersAnimal fecesSewage

The invention provides a microorganism feces treatment device of a dry and wet separation type, relating to a feces treatment device. A feces treatment device of a dry and wet separation type is required to be provided. The device comprises a feces hoisting machine and a feces biochemical treatment machine, and is characterized in that: the feces hoisting machine adopts a chain bucket feces hoisting machine composed of a motor, a drive sprocket wheel, a bracket, a conveyor chain and a hoisting dustpan; the lower end of the feces hoisting machine extends to a feces collecting pool; the upper end of the bracket extends above a dry and wet separation machine arranged at the top of the biochemical treatment machine; the hoisting dustpan is installed outside the conveyor chain and hoists and pours the feces in the feces pool to the dry and wet separation machine arranged at the top of the biochemical treatment machine when running; the dry and wet separation machine is installed at the top of the case of the biochemical treatment machine and composed of a groove shaped casing and a rotating grid driven by the motor; the dry feces separated by the dry and wet separation type machine is led into the case of the feces biochemical treatment machine from a tilted trough arranged at the port of the rotating grid; and the sewage after the separation of the dry and wet separation machine is discharged into a sewage pipe through the bottom of the casing.

Owner:朱瀛江

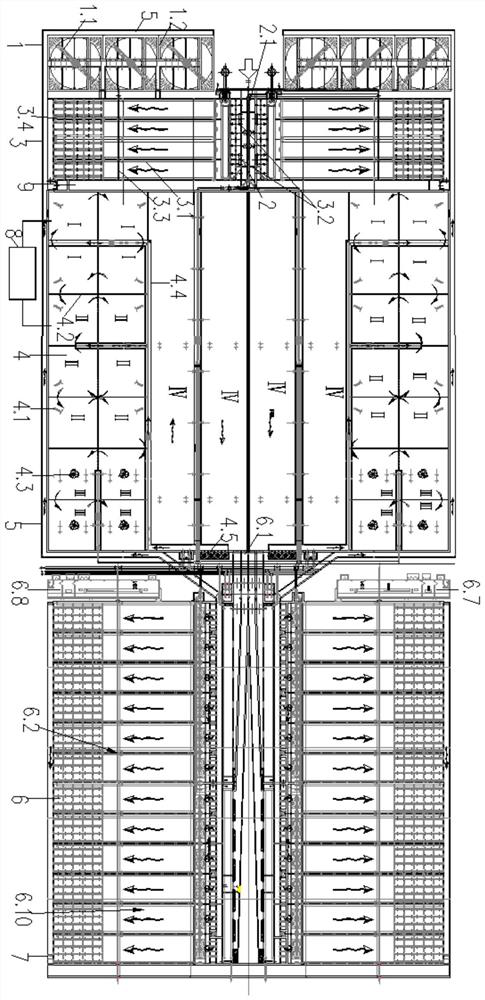

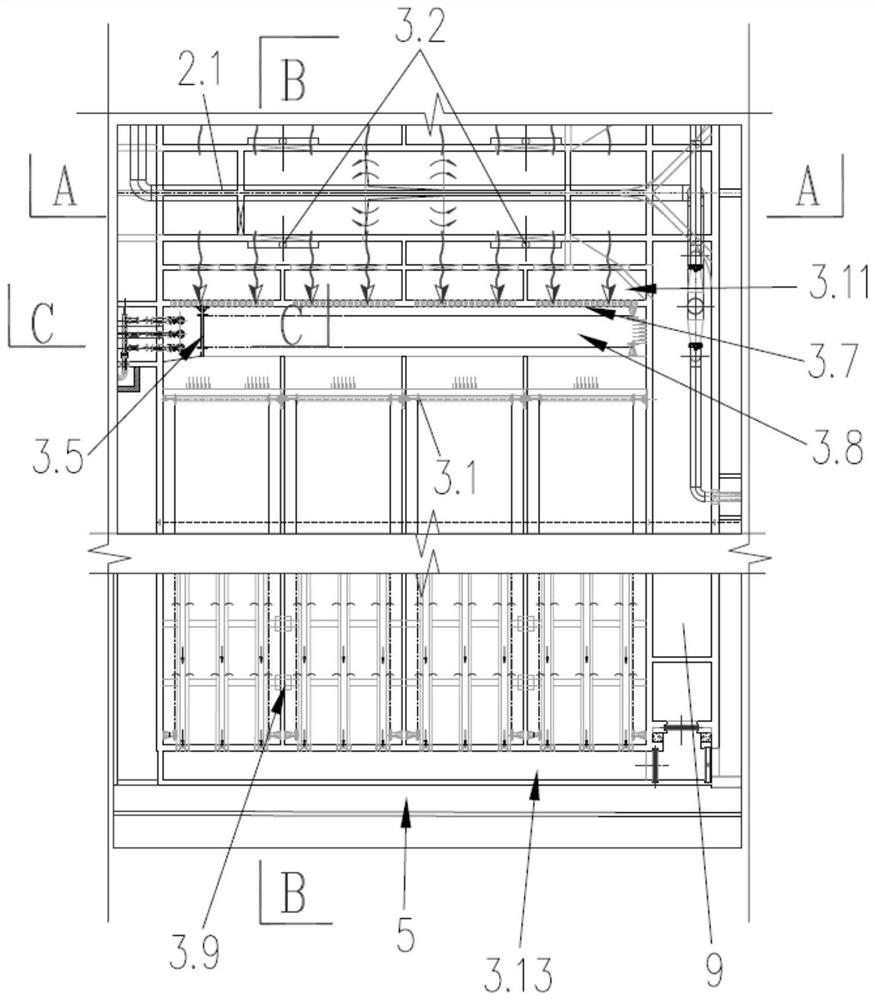

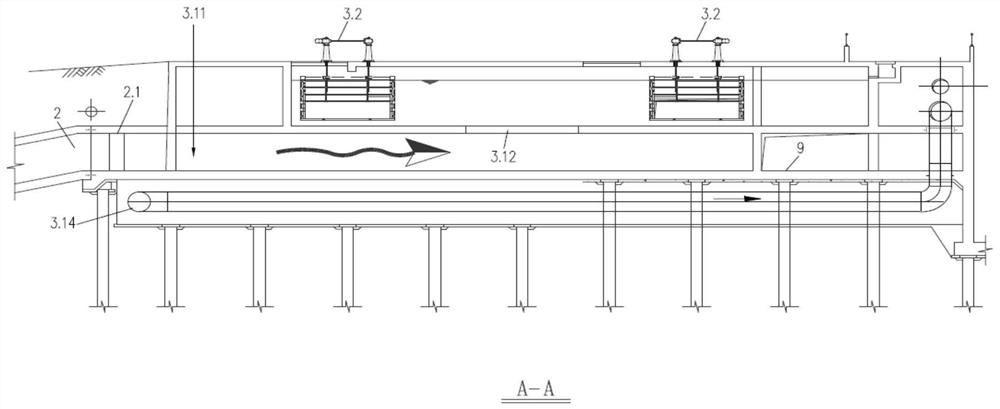

Sewage low-carbon biological treatment system self-adaptive to water quality change and method thereof

ActiveCN114644434AFlexible and convenient switchingMeet the requirements of effluent water qualityWater contaminantsTreatment involving filtrationSludgeMonitoring system

The invention discloses a sewage low-carbon biological treatment system and method self-adaptive to water quality change. The sewage low-carbon biological treatment system comprises a sludge concentration fermentation tank, a rectangular water inlet box culvert, a multifunctional tank, a biological reaction tank, an external reflux sludge channel, a secondary sedimentation tank and an effluent quality online monitoring system, the two sides of the rectangular water inlet box culvert are each connected with one multifunctional pool, and the two sets of multifunctional pools are rectangular. A sludge concentration fermentation tank is arranged on one side of the multifunctional tank, the other side of the multifunctional tank is connected with the biological reaction tank, an overrunning box culvert is arranged between the multifunctional tank and the biological reaction tank, and the water inlet end of the overrunning box culvert is connected with a water outlet port of a rectangular water inlet box culvert; the water outlet end of the biological reaction tank is connected with the secondary sedimentation tank; an outer return sludge channel is arranged on one side of the water distribution channel of the secondary sedimentation tank and extends to surround the peripheries of the biological reaction tank, the multifunctional tank and the sludge concentration and fermentation tank. The invention solves the technical problem that the matrix metabolism balance of the biological treatment system is difficult to realize when the water quality is unstable.

Owner:TONGJI UNIV +1

Deferrization method of iron-containing liquor

ActiveCN100357192CTo achieve resourceReaction conditions are easy to controlWater/sewage treatment by oxidationRoom temperaturePre treatment

The disclosed deironing method for iron-contained solution comprises: oxidizing the solution for pretreatment, preparing ferrite yellow crystal seed; adding the said seed liquid into reactor, dropping oxidized solution and weak base solution simultaneously; when the liquid volume achieves reactor effective volume, extracting the reaction liquid to filter and obtain the objective solution. This invention has fast reaction speed and well effect with small investment at normal temperature.

Owner:SHENZHEN SHENTOU ENVIRONMENT TECH CO LTD

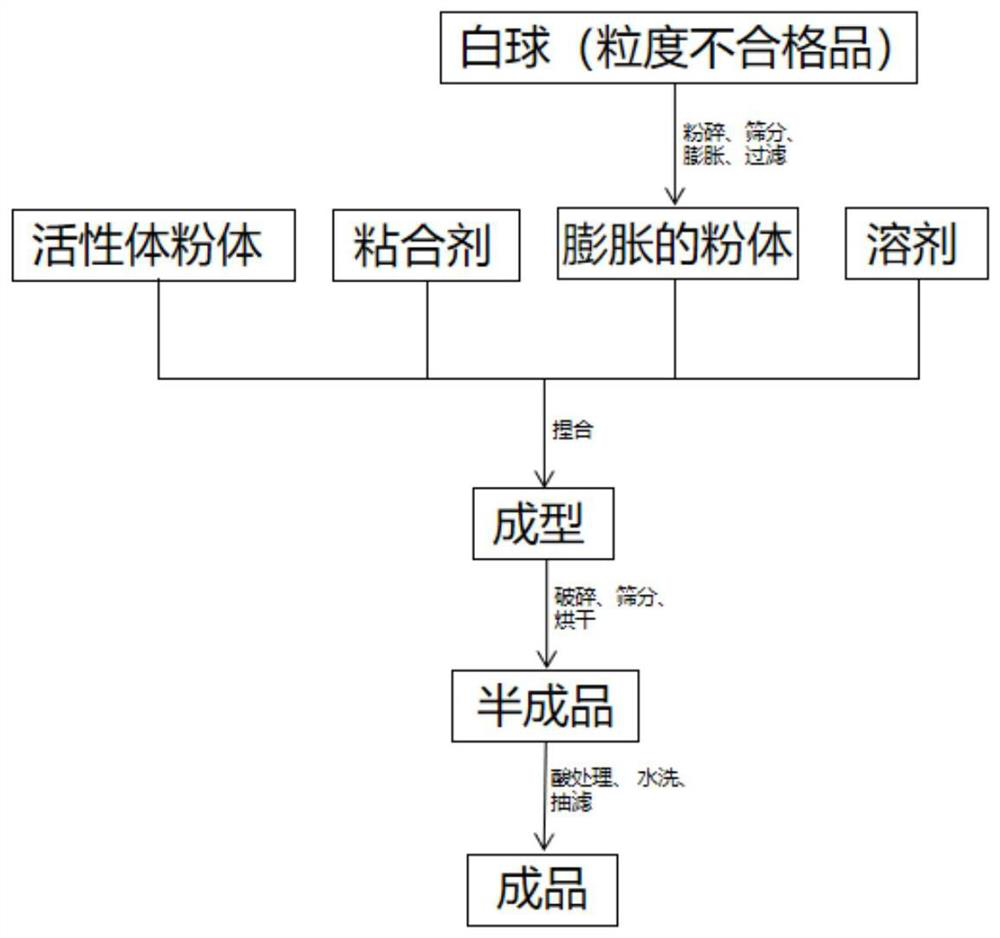

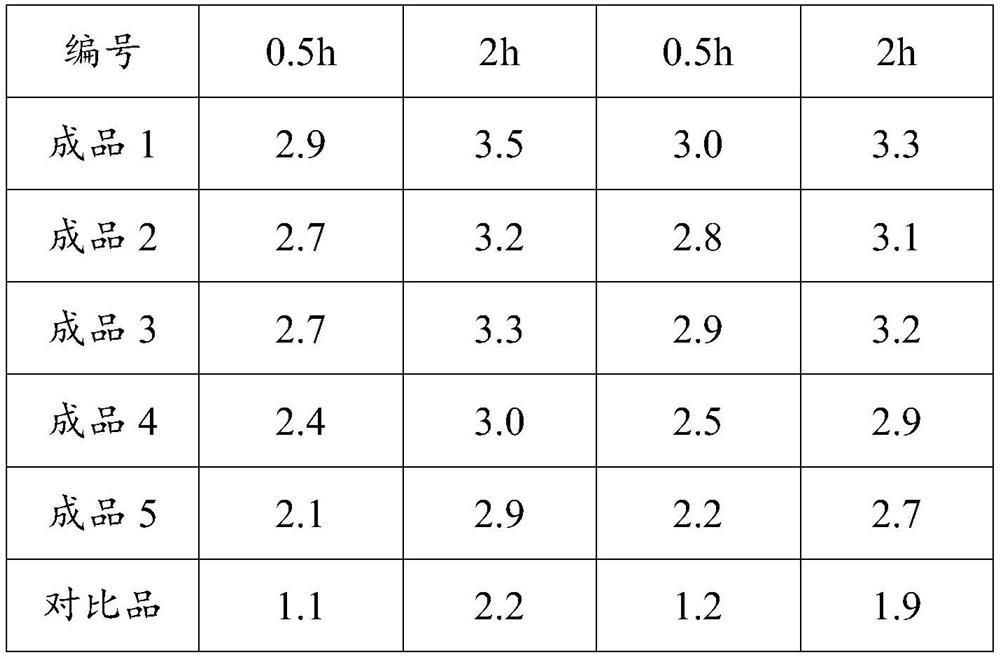

Lithium extraction adsorbent for raw brine and preparation method thereof

ActiveCN112237905AImprove lithium adsorption efficiencyIncrease profitOther chemical processesPhysical chemistryPolystyrene

The invention discloses a lithium extraction adsorbent for raw brine and a preparation method thereof. The preparation method comprises the following steps: crushing cross-linked polystyrene resin, soaking the crushed cross-linked polystyrene resin in a sufficient amount of a solvent, fully expanding the soaked cross-linked polystyrene resin, and filtering out a free solvent to obtain white ball powder; uniformly kneading the lithium extraction adsorbent active body powder, an adhesive, white ball powder and a solvent according to a mass ratio of 1: (0.1-0.5): (0-0.3): (0.5-2.5) to obtain a mixture; carrying out strip extrusion, crushing, screening and drying treatment on the obtained mixture to obtain a semi-finished product; and washing the semi-finished product with dilute acid, washingwith water to be neutral, and performing suction filtration to remove free moisture, thereby obtaining the lithium extraction adsorbent for raw brine. Solid waste in the resin production process is used as a pore-forming agent to prepare the lithium extraction adsorbent with rich pore passage structures for raw brine.

Owner:XIAN LANSHEN NEW MATERIAL TECHNOLOGY CO LTD

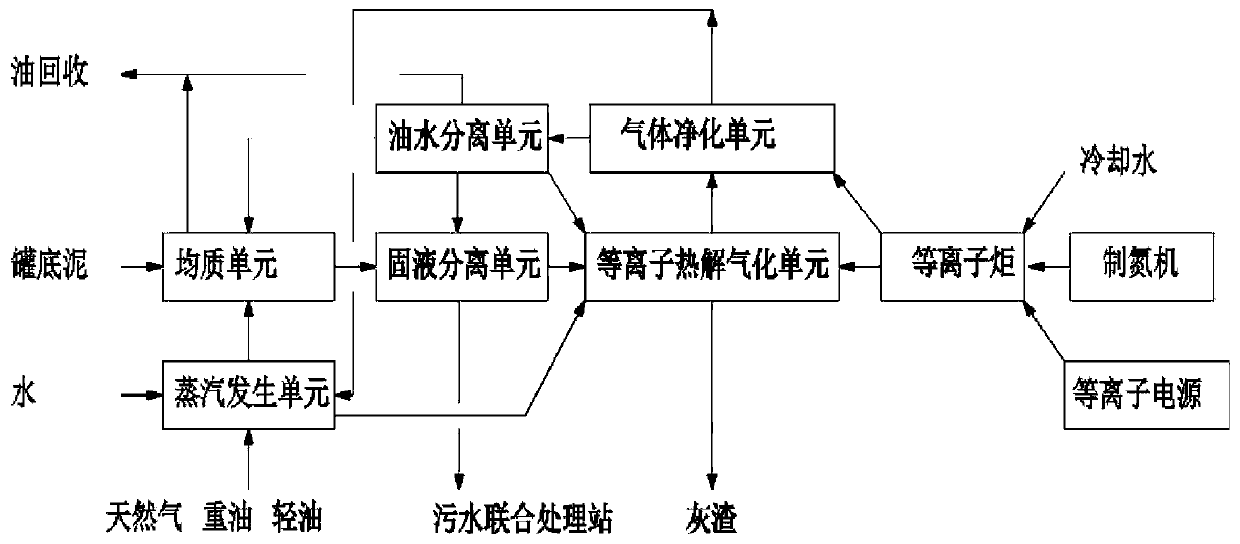

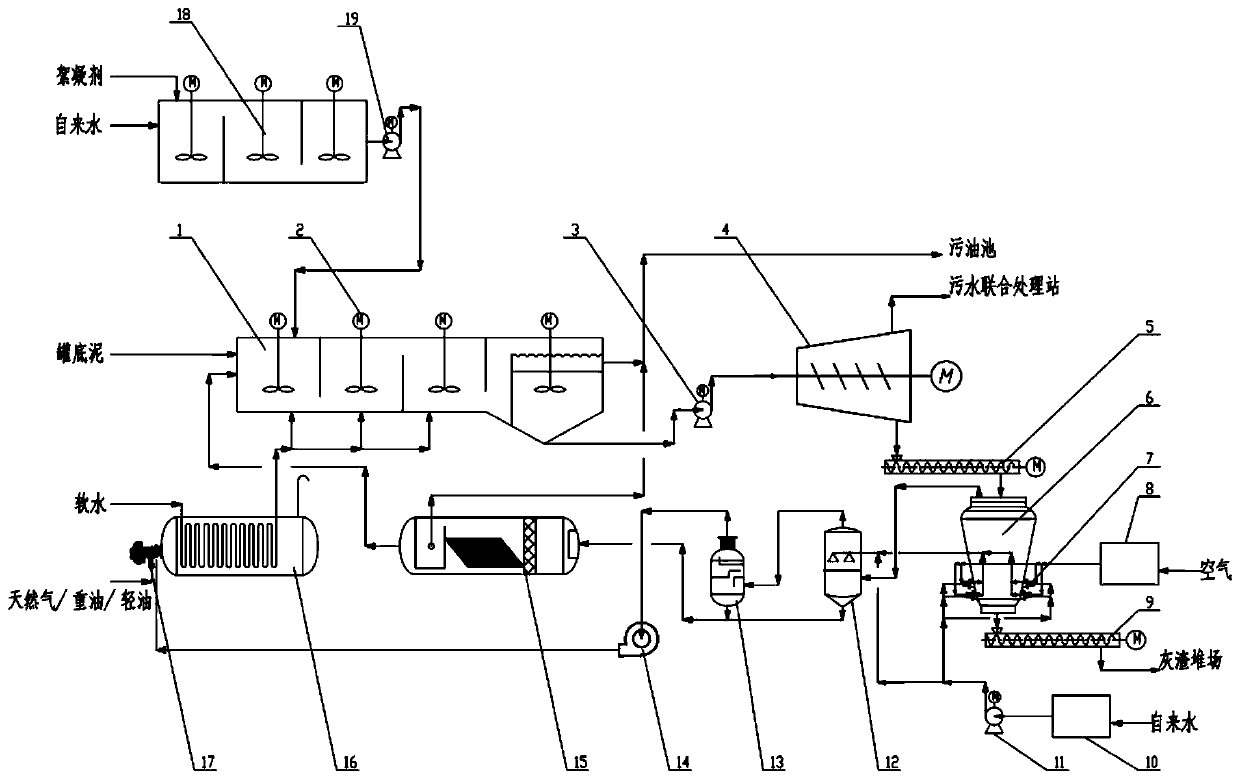

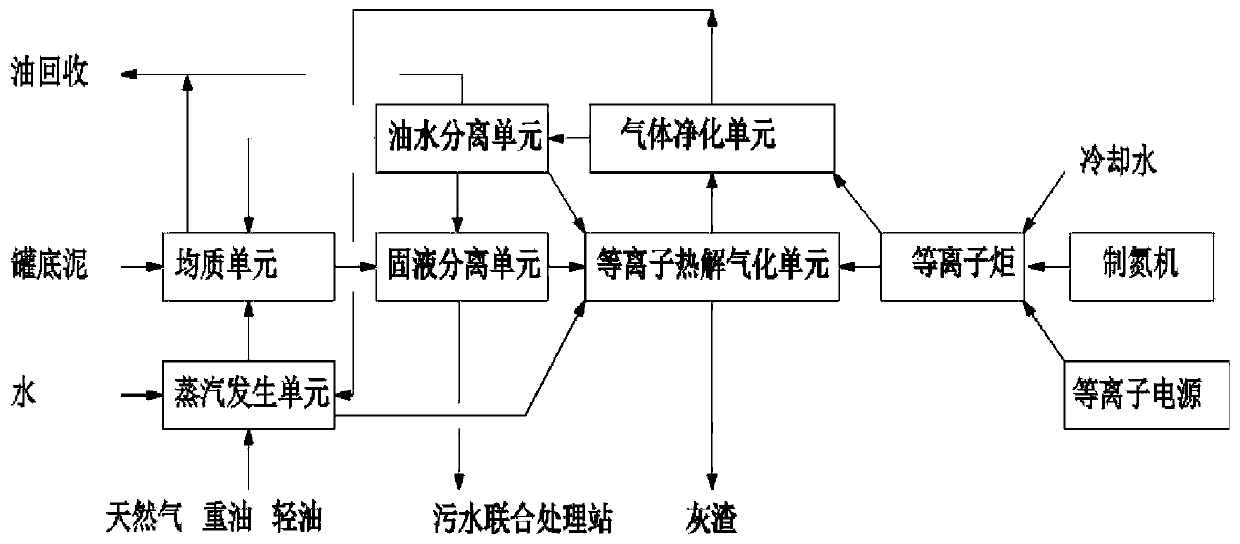

Method for treating tank bottom oil-containing sludge and treatment system

InactiveCN110040922ASuitable for handlingAchieve reductionCatalytic crackingSludge treatment by thermal conditioningPetroleumTotal petroleum hydrocarbon

The invention provides a method for treating tank bottom oil-containing sludge and an oil-containing sludge treatment system. The method comprises the procedures of homogenizing treatment, solid-liquid separation, plasma thermal pyrolysis, gas purification and oil-water separation. The system comprises a homogenizing unit, a solid-liquid separation unit, a plasma thermal pyrolysis unit, a gas purifying unit, an oil-water separation unit and a steam generation unit. By adopting the method, the treatment cost is lowered. The system is simple and convenient in treatment operation, is low in equipment requirement, and can complete innocent treatment of tank bottom sludge while completing tank cleaning (TPH (Total Petroleum Hydrocarbons) in the treated sludge is less than 0.03 percent).

Owner:成都启川新能源科技有限公司

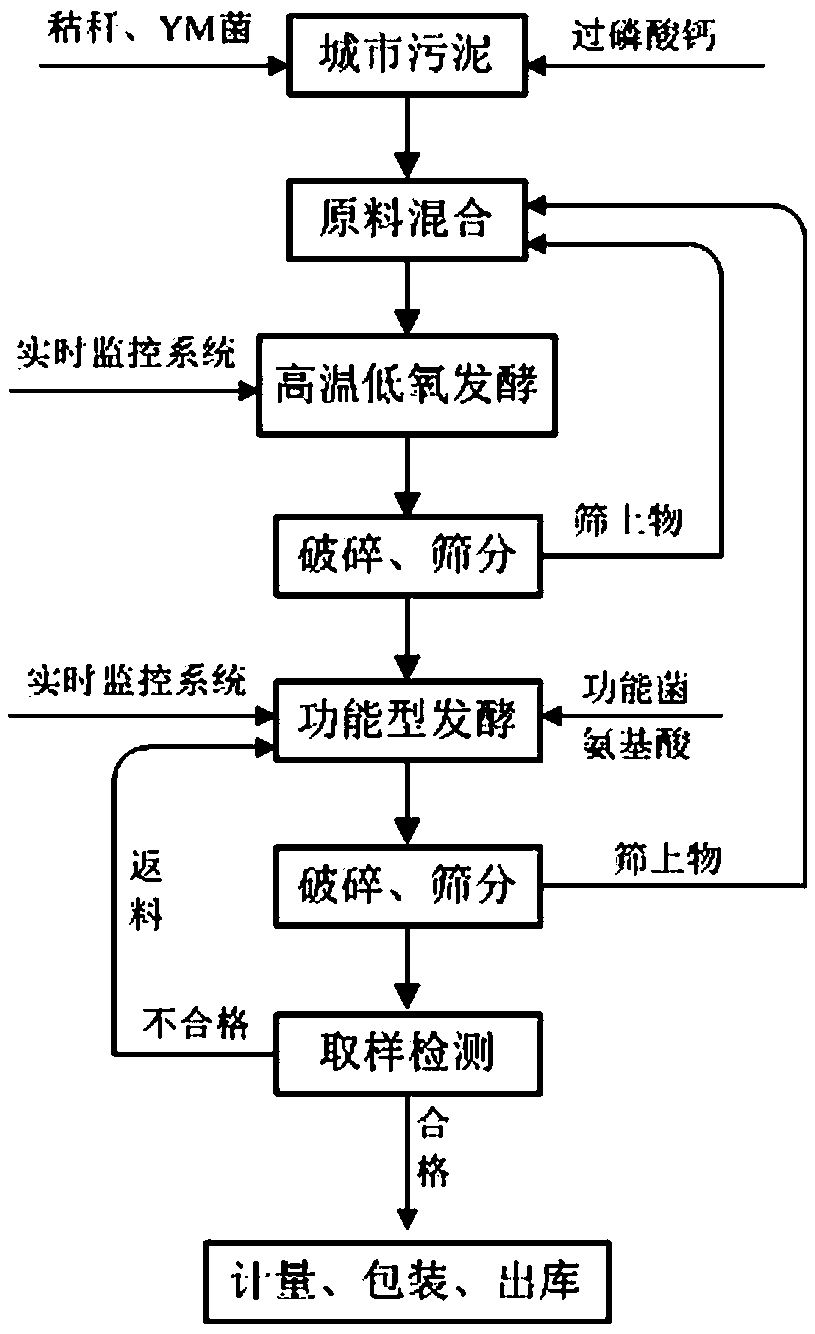

Method for recycling municipal sludge

InactiveCN109265290ASolve the pollution of the environmentAvoid smallSewage/sludge fertilisersNitrogenous fertilisersResource utilizationSludge

The invention discloses a method for recycling municipal sludge. The method comprises mixing sludge, straws, YM bacteria, an amino acid stock solution, bacillus amyloliquefaciens SQR9 functional bacteria and trichoderma harzianum T37 functional fungi, conducting high temperature and low oxygen fermentation, conducting crushing, sieving and functional fermentation, and then crushing and sieving toobtain a finished product. Main raw materials are the municipal sludge and the crop straws that are large in quantity, large-scale and periodic production can be achieved, the sludge is from a local sewage treatment plant and meets the CJ / T309-2009 standard, and a raw material source is safe. The high temperature low oxygen and functional fermentation technology is utilized to solve the problem ofenvironment pollution caused by organic solid waste and achieve organic solid waste resource utilization and stable utilization.

Owner:PENYAO ENVIRONMENTAL PROTECTION

Method for treating zinc-containing solid waste in metallurgy industry by Ouzhi furnace

InactiveCN108456786ASolving RecyclingAchieve harmlessProcess efficiency improvementSludgeCompressive strength

The invention discloses a method for treating zinc-containing solid waste in metallurgy industry by an Ouzhi furnace. The method comprises the following steps of uniformly mixing the zinc-containing solid waste (zinc-containing sludge or converter secondary dust or electric furnace dust) generated in metallurgy industry, coarse ash, oxidized scale powder, lime and bonding agents according to the weight percentage, wherein the zinc-containing solid waste accounts for 50 weight percent; the coarse ash accounts for 12 weight percent; the oxidized scale powder accounts for 27 percent; the lime accounts for 3 percent; the bonding agents account for 8 weight percent; then, pressing the materials into cold solid zinc-containing sludge pellets with the diameter being about 40mm by a cold pressingpelletizing machine; basically maintaining the pressure-resistant intensity of the cold solid zinc-containing sludge pellets at about 800N / pellet; adding the pellets into the Ouzhi furnace to be used.The method has the advantages that the zinc-containing solid waste can be effectively used, so that the metal zinc content is enriched; the total dust generation quantity is reduced.

Owner:XINJIANG BAYI IRON & STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com