Microalgae type microbial fuel cell

A microbial fuel and fuel cell technology, applied in the direction of biochemical fuel cells, etc., can solve problems such as difficult management and maintenance, incomplete treatment, and high technical difficulty, and achieve the effects of improving power production efficiency, alleviating energy shortage, and improving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

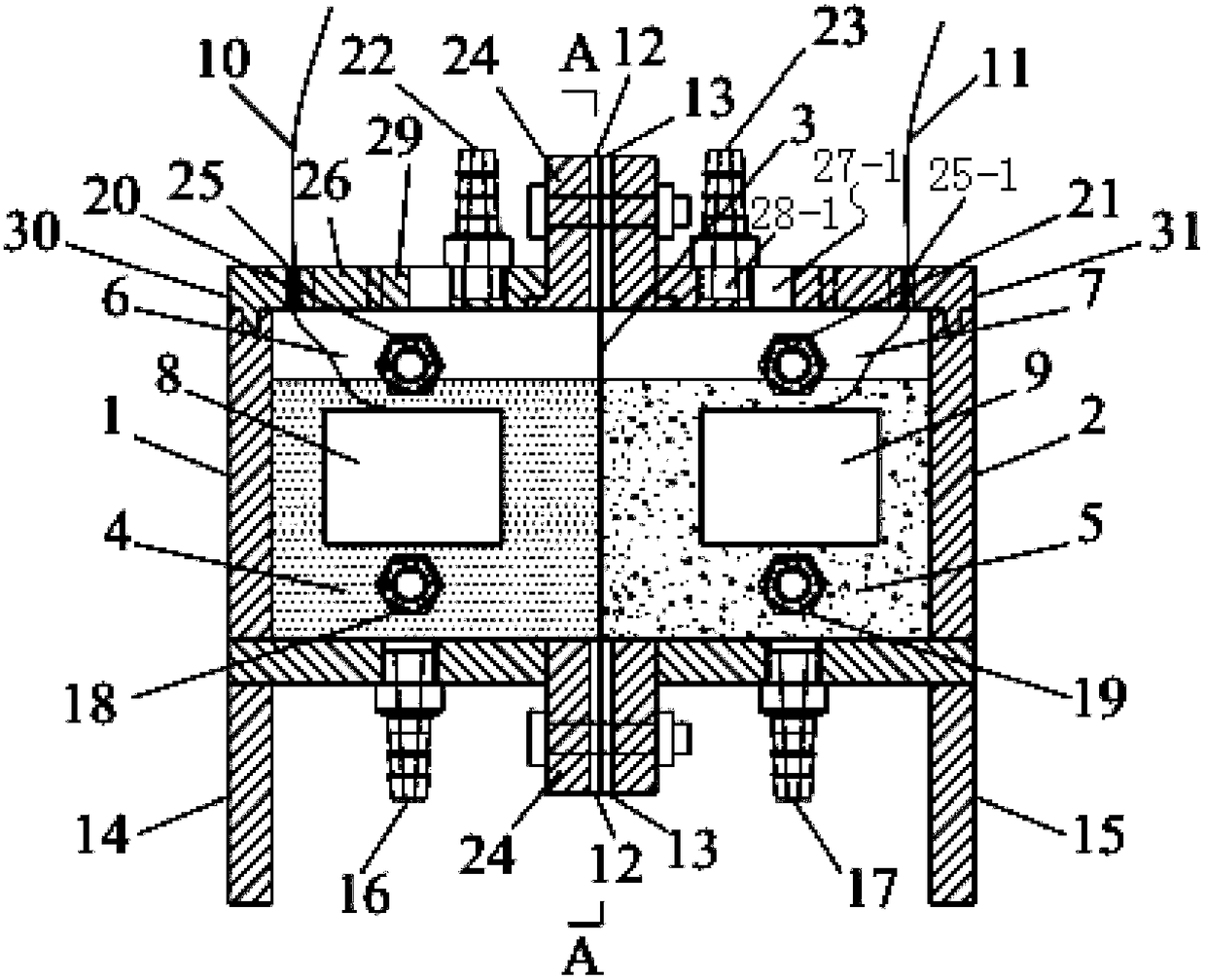

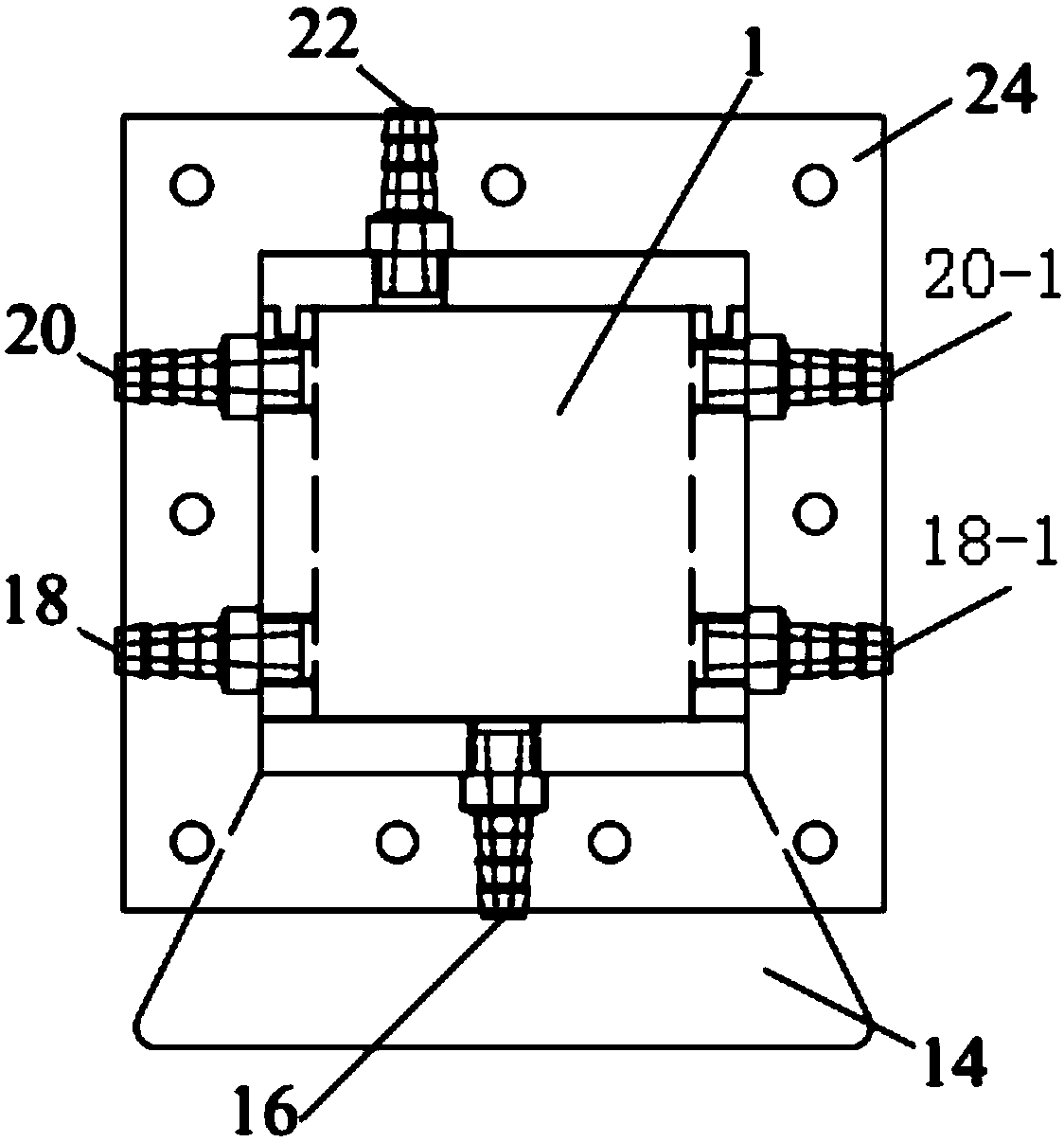

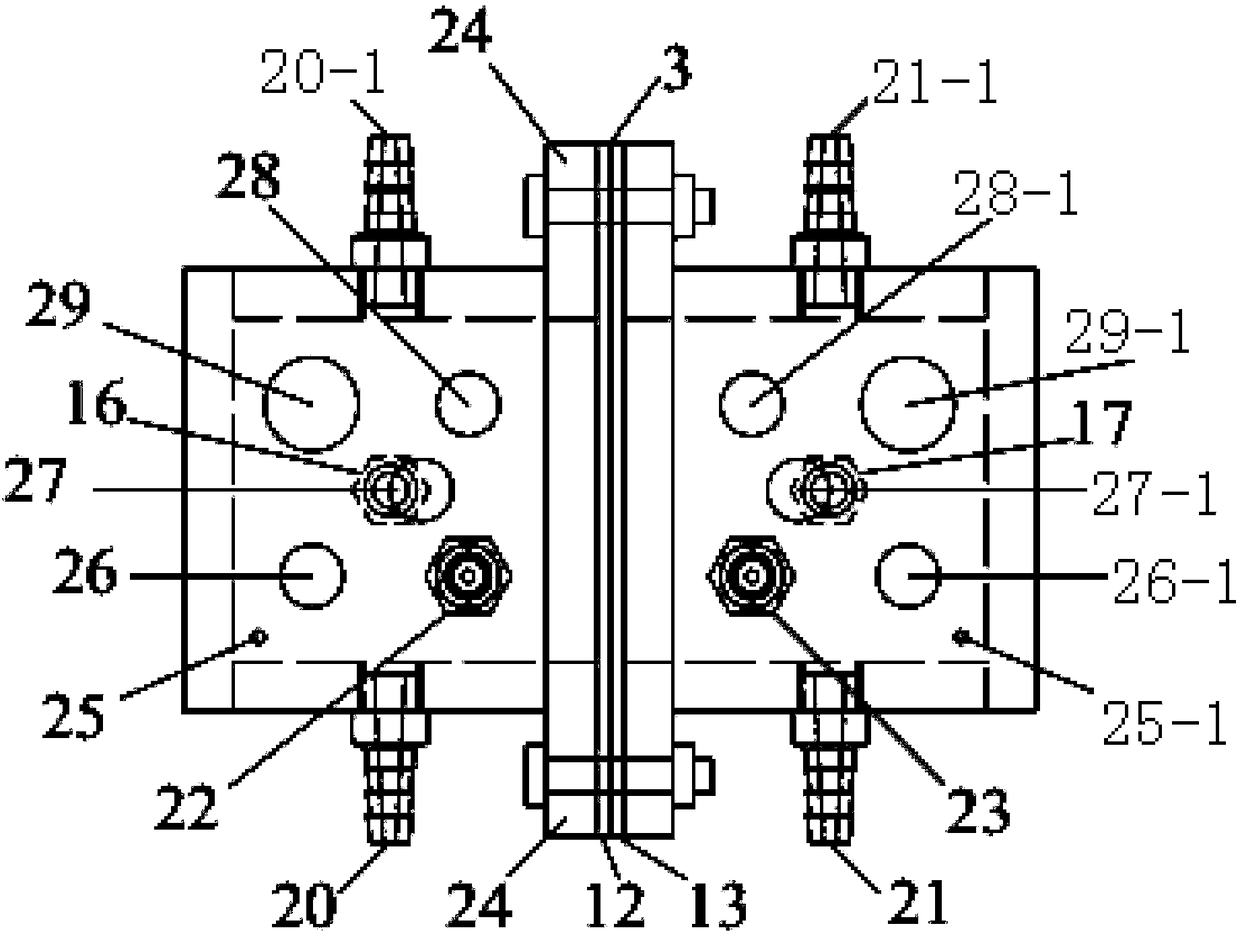

[0042] Such as figure 1 , figure 2 and image 3 As shown, the microalgae-type microbial fuel cell of the present embodiment comprises an anode chamber 1, a cathode chamber 2, and a proton exchange membrane 3 sealed by two pieces of silica gel (12, 13) and fixed by a flange 24; An anode end reaction electrode 8 is installed and filled with a reaction matrix, and anaerobic sludge is placed in the reaction matrix, containing anaerobic bacteria; the anode end reaction electrode 8 is connected with a wire 10, and the anode top cover 30 adopts an open design, which can be opened, and the anode The top cover 30 fits closely with the anode chamber 1. There are five openings on the anode top cover 30. The five openings are respectively the first outlet hole 25, the first reference electrode fixing hole 26, the first reserved opening 27, and the second opening. Two reserved openings 28 and the first top water inlet 29, in addition, the anode top cover 30 is also provided with anode t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com