Method for recycling municipal sludge

A technology for urban sludge and resource utilization, which is applied in the preparation and application of sewage/sludge fertilizer and organic fertilizer, can solve the problems of agricultural product quality and safety, ecological environment deterioration, soil degradation, etc. The effect of reducing body temperature and nitrogen loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

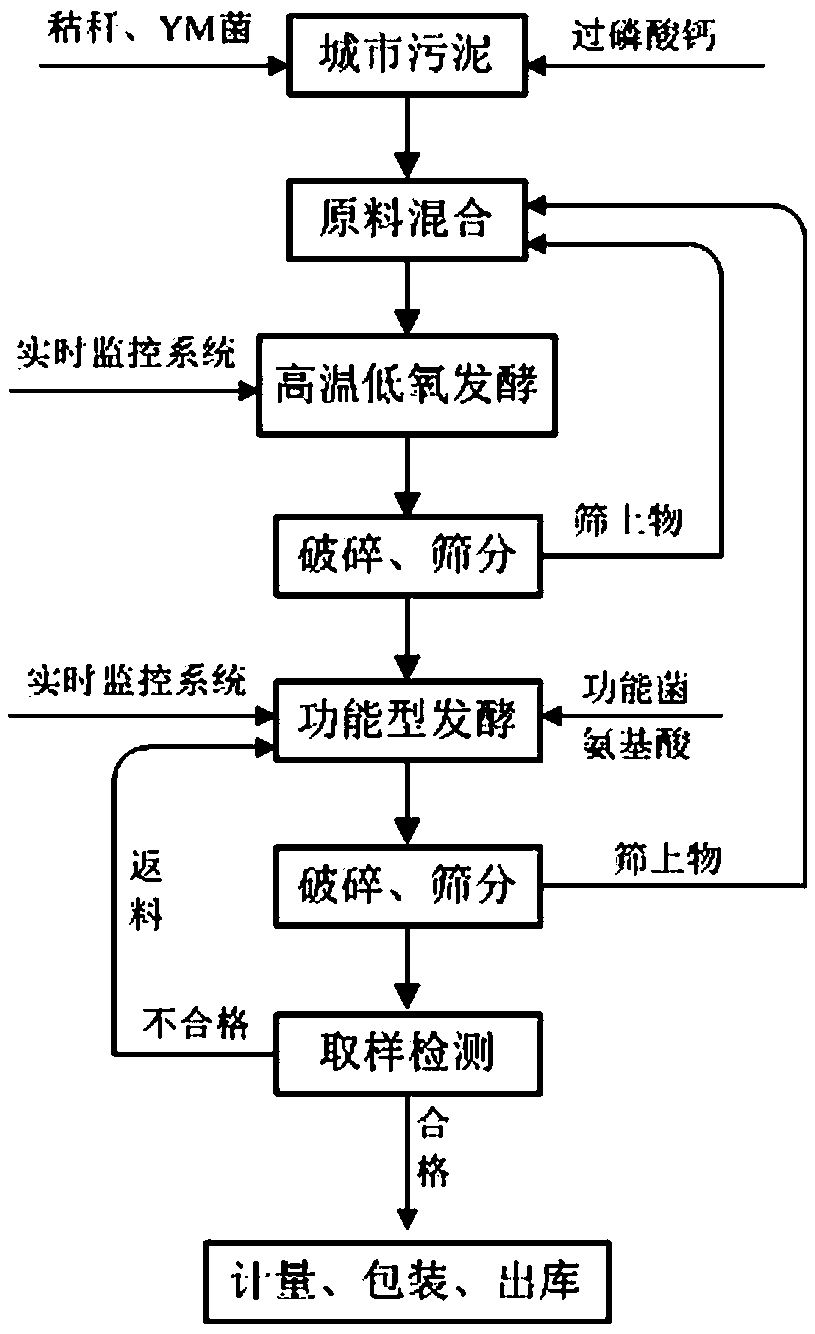

Image

Examples

Embodiment 1

[0033] Get 100 parts of sludge in parts by weight, 20 parts of straw, 20 parts of YM bacteria, 10 parts of amino acid stock solution, 2 parts of Bacillus amyloliquefaciens SQR9 functional bacteria, 2 parts of Trichoderma harzianum T37 functional bacteria The fungus is ready for use; the straw is crushed by a pulverizer; the sludge is spread on the pile of crushed straw, and the sludge is fully mixed with the crushed straw, YM bacteria and amino acid stock solution; the mixed materials are piled up by a loading truck. Bar stacks, install fans, temperature and humidity, pH and oxygen monitors, lay ventilation pipes at the bottom, and carry out high-temperature and low-oxygen fermentation. During the fermentation process, the pH value of the pile is monitored between 5.5 and 8.5, and the humidity of the pile is between 55 and 65%. During the whole process, the oxygen concentration of the heap is between 5 and 15%. The whole process controls the fermentation temperature above 80°C ...

Embodiment 2

[0036] Referring to Example 1, get 120 parts of sludge in parts by weight, 30 parts of stalks, 30 parts of YM bacteria, 20 parts of amino acid stock solution, 5 parts of Bacillus amyloliquefaciens SQR9 functional bacteria, 5 parts of Trichoderma harzianum T37 functional fungus is ready for use; crush the straw through a pulverizer; spread the sludge on the pile of crushed straw, fully mix the sludge with the crushed straw, YM bacteria and amino acid stock solution; put the mixed materials Use loading trucks to stack into stacks, install fans, temperature and humidity, pH and oxygen monitors, lay ventilation pipes at the bottom, and carry out high-temperature and low-oxygen fermentation. During the fermentation process, the pH value of the stack is monitored between 6 and 7, and the humidity of the stack is between 6 and 7. 60~65%, the oxygen concentration of the heap is between 10~15%, the whole process controls the fermentation temperature above 80°C for 8~10 days, and the ini...

Embodiment 3

[0038] Referring to Example 1, get 110 parts of sludge in parts by weight, 25 parts of stalks, 25 parts of YM bacteria, 15 parts of amino acid stock solution, 3 parts of Bacillus amyloliquefaciens SQR9 functional bacteria, 3 parts of Trichoderma harzianum T37 functional fungus is ready for use; crush the straw through a pulverizer; spread the sludge on the pile of crushed straw, fully mix the sludge with the crushed straw, YM bacteria and amino acid stock solution; put the mixed materials Use loading trucks to stack into stacks, install fans, temperature and humidity, pH and oxygen monitors, lay ventilation pipes at the bottom, and carry out high-temperature and low-oxygen fermentation. During the fermentation process, the pH value of the pile is monitored between 6.5 and 7.5, and the humidity of the pile is between 6.5 and 7.5. 60~62%, the oxygen concentration of the heap is between 8~10%, the whole process controls the fermentation temperature above 80°C for 7~9 days, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com