Lithium extraction adsorbent for raw brine and preparation method thereof

A technology of adsorbent and solvent, which is applied in the field of lithium extraction adsorbent for raw halogen and its preparation, can solve the problems of long time required for working adsorption capacity, low content of lithium in raw halogen, and low lithium extraction efficiency, so as to improve lithium adsorption efficiency , Improve the adsorption rate and improve the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

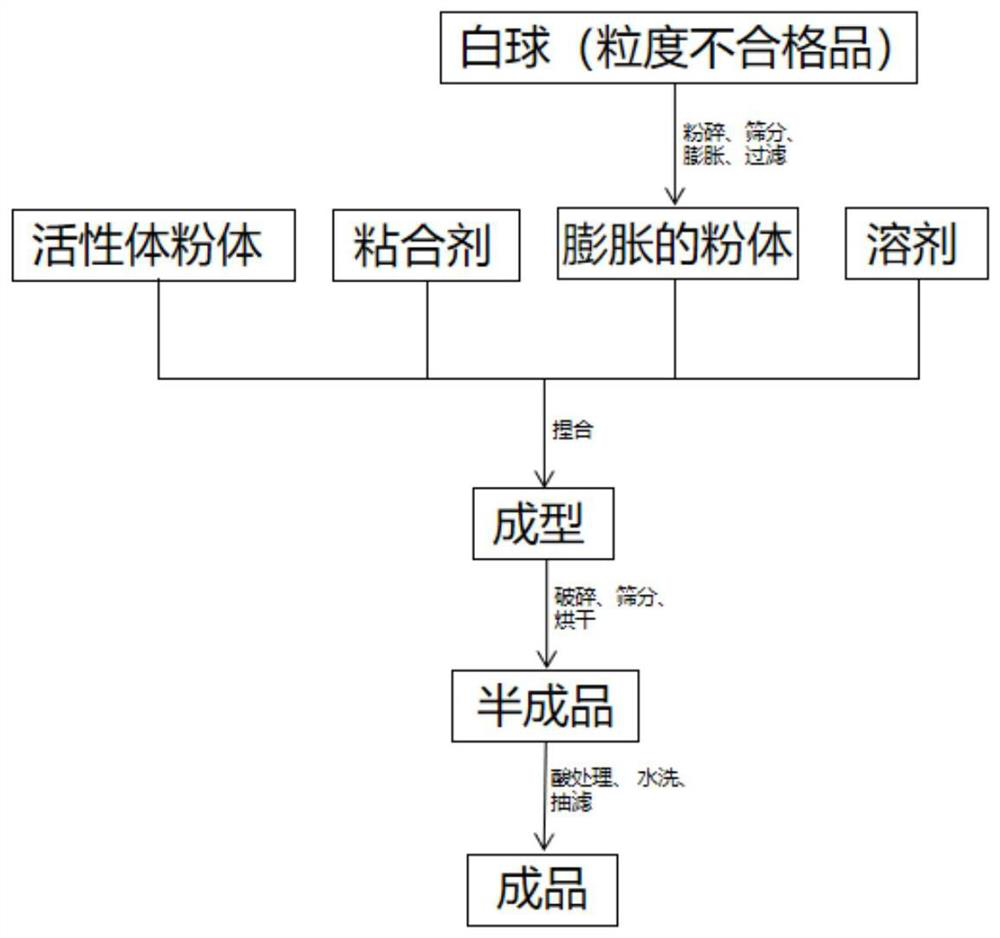

[0035] The invention provides a preparation method of an adsorbent for extracting lithium with lithium, comprising the following steps:

[0036] S1. Crush 0-0.3 parts of cross-linked polystyrene resin (referred to as white balls, provided by Shaanxi Lanshen Special Resin Co., Ltd.), soak in a sufficient amount of solvent, fully expand, and then filter off the free solvent;

[0037] White balls are unqualified particle size products produced during the production process of the factory. The basic skeleton is styrene and divinylbenzene. The particle size of the powder obtained after crushing is 60-200 mesh.

[0038]Solvents include N,N-dimethylformamide, ethyl acetate, dichloromethane, chloroform, carbon tetrachloride, dichloroethane, trichloroethane, acetone, toluene, etc. The expansion and kneading process uses the same a solvent.

[0039] S2, the lithium extraction adsorbent active body powder (provided by Shaanxi Lanshen Special Resin Co., Ltd.), binder, white ball powder a...

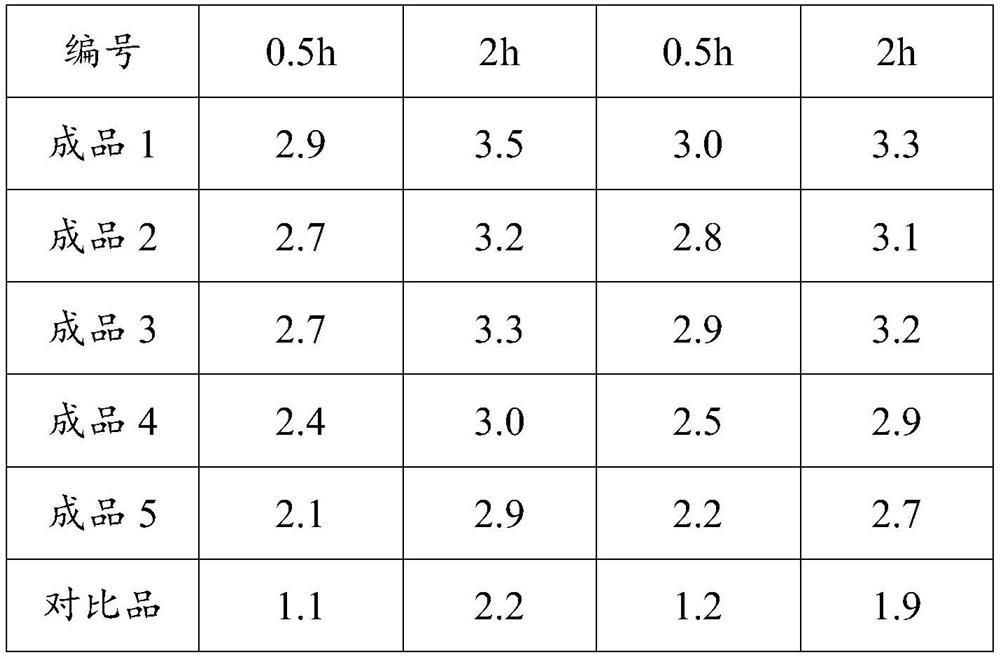

Embodiment 1

[0049] 30.0 g of white balls (provided by Shaanxi Lanshen Special Resin Co., Ltd.) were crushed into a powder with a particle size of 200 mesh, fully expanded with sufficient amount of carbon tetrachloride, and then free carbon tetrachloride was filtered off.

[0050] Knead 100.0g lithium extraction adsorbent active body powder (provided by Shaanxi Lanshen Special Resin Co., Ltd.), 30.0g polyvinyl chloride, expanded white ball powder, and 150.0g carbon tetrachloride evenly. Extrude, crush, and sieve, collect all particles with a particle size in the range of 0.8-1.2mm, and dry at 100°C for 2 hours as a semi-finished product. The semi-finished product was washed with 1 mol / L dilute hydrochloric acid, then washed with pure water until neutral, and the free water was removed by suction filtration to obtain the finished product 1.

Embodiment 2

[0052] 15.0 g of white balls (provided by Shaanxi Lanshen Special Resin Co., Ltd.) were crushed into a powder with a particle size of 130 mesh, fully expanded with sufficient amount of chloroform, and then free chloroform was filtered off.

[0053] Knead 100.0 g of lithium extraction adsorbent active body powder (provided by Shaanxi Lanshen Special Resin Co., Ltd.), 10.0 g of polyvinyl chloride, expanded white ball powder, and 150.0 g of chloroform evenly. Extrude, crush, and sieve, collect all particles with a particle size in the range of 0.8-1.2mm, and dry at 70°C for 4 hours as a semi-finished product. The semi-finished product was washed with 0.5 mol / L dilute hydrochloric acid, and then washed with pure water until neutral, and the free water was removed by suction filtration to obtain the finished product 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com