Method for treating tank bottom oil-containing sludge and treatment system

A treatment system and technology for oily sludge, applied in pyrolysis treatment of sludge, sludge treatment, separation methods, etc., can solve the problems of many skids, increased treatment cost, and long process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

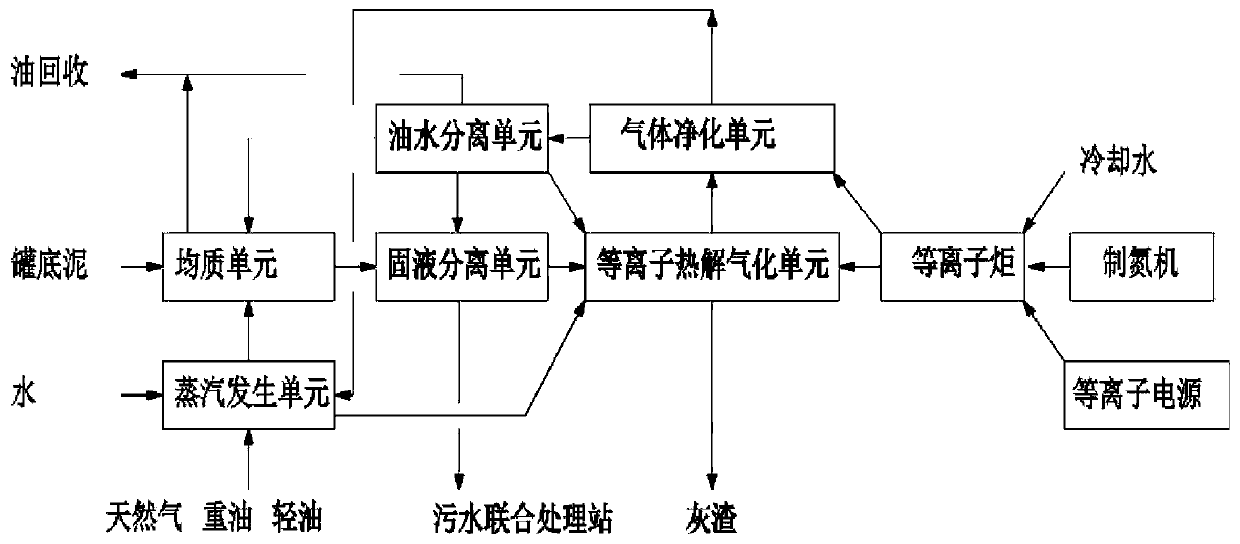

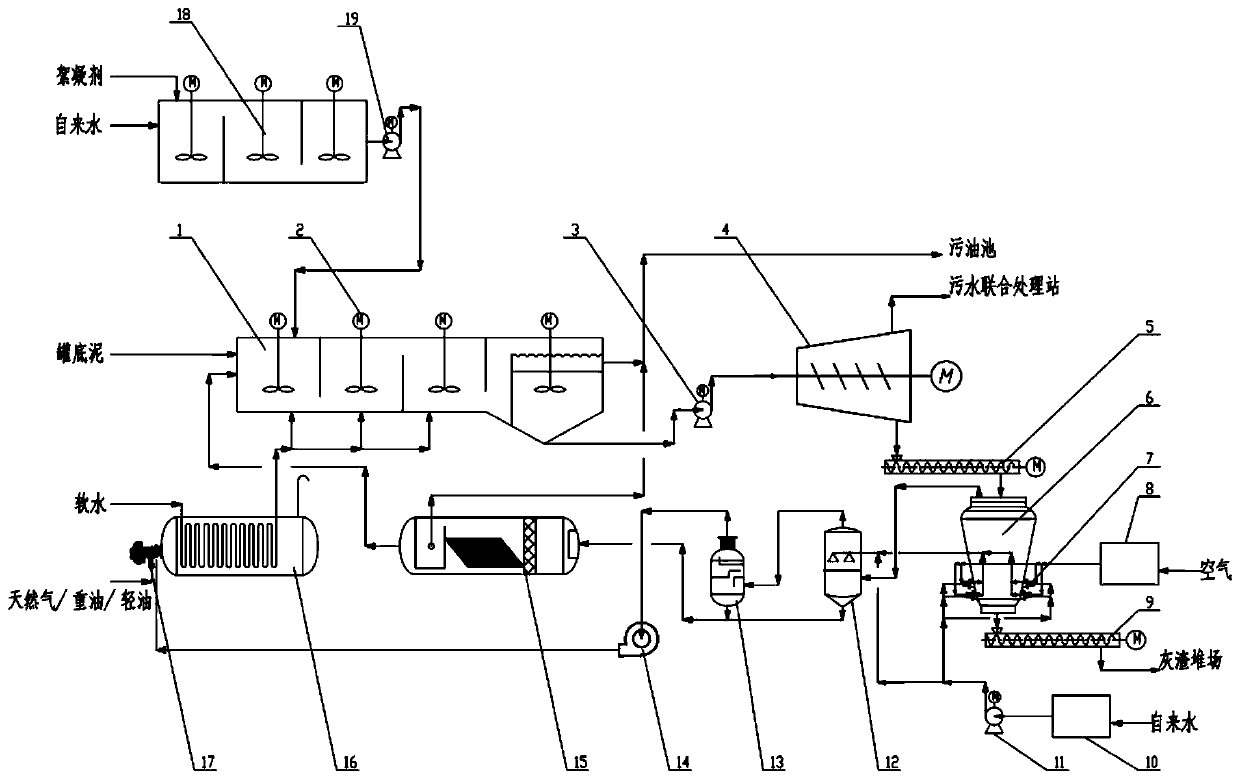

[0056] A tank bottom oily sludge treatment system, such as figure 1 As shown, it consists of a homogeneous unit, a solid-liquid separation unit, a plasma pyrolysis gasification unit, a gas purification unit, an oil-water separation unit and a steam generation unit;

[0057] The homogenizing unit includes a dosing device 18 and a homogenizing tank 1, and the dosing device communicates with the homogenizing tank to add a degreaser or flocculant required for processing in the homogeneous phase; the homogenizing tank is equipped with Stirrer, homogenizing tank consists of 2 reaction chambers, suspension chamber and oil chamber. The dosing device is composed of a hopper, a metering screw, a solution tank, an agitator and a dosing pump 19. After the medicine is metered by the metering and metering screw, it enters the solution tank from the hopper, and is mixed and stirred with someone to obtain a medicine material liquid. Pump into the homogenization tank.

[0058] The solid-liqu...

Embodiment 2

[0064]Adopt embodiment 1 processing system to process the oily sludge at the bottom of the oil storage tank as follows:

[0065] (1) homogeneous

[0066] The oily sludge cleaned out of tank cleaning is transported to the homogenization tank 1 through the conveying equipment (it can be a screw pump or a screw conveyor). The homogenization tank includes 2 reaction chambers, a suspension chamber and an oil chamber, and PAM, etc. are added to the dosing In the device 18, the water and the medicament are uniformly mixed by the agitator, and then transported to the reaction chamber of the homogenizing tank 1 by the dosing pump 19. The oily sludge is diluted with hot water separated from the oil-water separation unit, and the solid-liquid ratio in the homogeneous tank reaches 1:4 to 1:6 according to the solid content of the cleaned tank bottom sludge. The steam in the homogeneous tank is fed into the homogeneous tank so that the temperature in the homogenized unit reaches 60-80 ° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com