Deferrization method of iron-containing liquor

A technology of solution and weak base solution, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as narrow pH control range, long reaction time, and incomplete iron removal. Achieve the effects of easy control of operating conditions, less adsorption and co-precipitation, and high iron removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

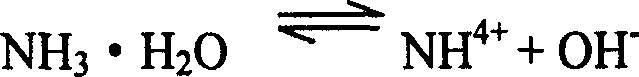

Method used

Image

Examples

Embodiment 1

[0024] Iron removal of nickel, cobalt and iron-containing waste liquid in nickel sulfate and cobalt production enterprises.

[0025] Waste liquid composition: total iron Fe: 13.49g / L, Ni 2+ .90.82g / L,Co 2+ : 13.47g / L

[0026] 1. Preparation of iron citrine seeds:

[0027] Weigh 2kg, 50kg, and 500kg of EDTA, green vitriol, and water, mix and stir until the green vitriol is completely dissolved; then, slowly add 2mol / L ammonia water at a rate of 70L / hour until the solution pH=8.5 , stop dripping ammonia water; continue to stir for 15 minutes, start oxygen oxidation, until the pH drops to about 4 and stabilize, continue to add ammonia water dropwise, when the pH is adjusted to about 5, stop dripping ammonia water, with the progress of the oxidation reaction If the reaction is carried out, the pH will gradually decrease and become stable. Similarly, add ammonia water in the interval and gradually increase the pH to about 7. At this time, the pH has stabilized and will not decre...

Embodiment 2

[0031] Iron removal of manganese-containing solution in manganese sulfate production enterprises.

[0032] Solution composition: total iron Fe: 13.18g / L, Mn 2+ : 49.91g / L.

[0033] One, preparation ferric citrine seed: with embodiment one.

[0034] 2. Iron removal steps:

[0035] Add hydrogen peroxide to reduce Fe in manganese solution 2+ fully oxidized to Fe 3+ , then use Na 2 CO 3 After adjusting the pH of the solution to about 1, add 500L of newly prepared iron citrine seed solution (containing about 20g / L iron) to the 2000L reactor, stir at a speed of 60r / min, and drop the oxidized manganese-containing solution at the same time and a concentration of 15% Na 2 CO 3 Solution, the dropping rate of manganese solution is about 1000L / hour, Na 2 CO 3 The drop rate of the solution is about 500L / hour and the pH of the reaction solution is controlled at 4.5-5.0. After 60 minutes of reaction, stop adding Na 2 CO 3 and manganese-containing solution, continue to stir for 5-...

Embodiment 3

[0038] Iron removal for zinc-containing solution in zinc oxide production enterprises.

[0039] Solution composition: total iron Fe: 11.53g / L, Zn 2+ : 68.42g / L.

[0040] One, preparation ferric citrine seed: with embodiment one.

[0041] 2. Iron removal steps:

[0042] Add KClO 3 Fe in zinc-containing solution 2+ fully oxidized to Fe 3+ , then use Na 2 CO 3 After adjusting the pH of the solution to about 1, add 500L of newly prepared iron citrine seed solution (containing about 20g / L iron) to the 2000L reactor, stir at a speed of 60r / min, and add the oxidized zinc solution dropwise at the same time And ammonia water with a concentration of 6%, the dropping rate of the zinc-containing solution is about 680L / hour, the flow rate of the ammonia water is about 320L / hour, and the pH of the reaction solution is controlled at 4.0-4.5. After 90 minutes of reaction, stop adding ammonia water and zinc-containing solution, continue to stir for 5-10 minutes, then stand still for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com