Treatment method for cooperative disposal of polluted soil via cement kiln

A technology for co-processing and soil pollution, applied in cement production and other directions, can solve the problems of secondary hazardous waste, waste of resources, restrictions on use applicability, etc., to improve the effect of treatment and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

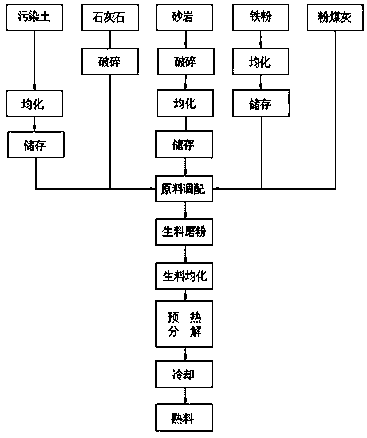

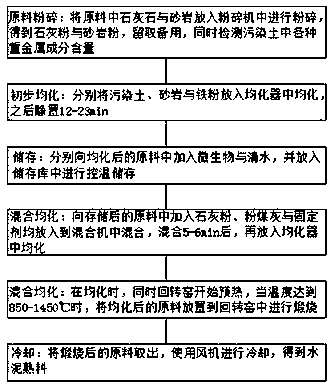

[0028] Such as Figure 1-2 As shown, a cement kiln co-processing contaminated soil treatment method, comprising the following steps:

[0029] (1) Crushing of raw materials: Put the limestone and sandstone in the raw material into a pulverizer for crushing to obtain lime powder and sandstone powder, which are kept for later use. At the same time, the content of various heavy metal components in the polluted soil is detected. Put into the drying machine to dry, the drying temperature is 110 ℃, the drying time is 55min, when pulverizing, the stirring speed is 1000r / min, and the stirring time is 22min, and the raw material is made of the following components by weight: 110 parts of pollution Soil, 140 parts of limestone, 90 parts of sandstone, 55 parts of iron powder, 70 parts of fly ash, 900 parts of clear water, 30 parts of microorganisms, 40 parts of fixative;

[0030] (2) Preliminary homogenization: Put the contaminated soil, sandstone and iron powder into the homogenizer to ...

Embodiment 2

[0036] Such as Figure 1-2 As shown, a cement kiln co-processing contaminated soil treatment method, comprising the following steps:

[0037] (1) Crushing of raw materials: Put the limestone and sandstone in the raw material into a pulverizer for crushing to obtain lime powder and sandstone powder, which are kept for later use. At the same time, the content of various heavy metal components in the polluted soil is detected. Put into the drying machine to dry, the drying temperature is 110 ℃, the drying time is 55min, when pulverizing, the stirring speed is 1000r / min, and the stirring time is 22min, and the raw material is made of the following components by weight: 110 parts of pollution Soil, 140 parts of limestone, 90 parts of sandstone, 55 parts of iron powder, 70 parts of fly ash, 900 parts of clear water, 30 parts of microorganisms, 40 parts of fixative;

[0038] (2) Preliminary homogenization: Put the contaminated soil, sandstone and iron powder into the homogenizer to ...

Embodiment 3

[0044] Such as Figure 1-2 As shown, a cement kiln co-processing contaminated soil treatment method, comprising the following steps:

[0045] (1) Crushing of raw materials: Put the limestone and sandstone in the raw material into a pulverizer for crushing to obtain lime powder and sandstone powder, which are kept for later use. At the same time, the content of various heavy metal components in the polluted soil is detected. Put into the drying machine to dry, the drying temperature is 110 ℃, the drying time is 55min, when pulverizing, the stirring speed is 1000r / min, and the stirring time is 22min, and the raw material is made of the following components by weight: 110 parts of pollution Soil, 140 parts of limestone, 90 parts of sandstone, 55 parts of iron powder, 70 parts of fly ash, 900 parts of clear water, 30 parts of microorganisms, 40 parts of fixative;

[0046] (2) Preliminary homogenization: Put the contaminated soil, sandstone and iron powder into the homogenizer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com