Patents

Literature

166results about How to "Avoid white pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-polylactic acid-content film and preparation method thereof

The invention relates to a high-polylactic acid-content film and a preparation method thereof, belonging to the technical field of high-polymer materials. The high-polylactic acid-content film is prepared from the following raw materials in parts by weight: 50-65 parts of polylactic acid, 35-50 parts of toughener, 1-10 parts of plasticizer, 0.1-2 parts of chain extender, 0.1-4 parts of antioxidant and 0.5-5 parts of anti-block agent. The polylactic acid content is dominant in the film content and is higher than that in the existing film; and meanwhile, the raw material formula cost is lowered, and the market competitiveness is enhanced. The prepared film is completely biodegradable, and thus, is beneficial to environment protection.

Owner:JILIN COFCO BIOCHEM +2

Biaxial drawing polylactic acid compound film with barrier property and preparation method thereof

ActiveCN102501529AAvoid white pollutionAvoid polluting the environmentSynthetic resin layered productsThin membraneAnoxomer

The invention discloses a biaxial drawing polylactic acid compound film with a barrier property and a preparation method thereof. The compound film comprises two polylactic acid layers and a barrier layer arranged between the two polylactic acid layers, wherein each polylactic acid layer comprises the following components in weight percentage: 75-100 percent of crystalline polylactic acid, 0-5 percent of melt reinforcing agent, 0-5 percent of toughening agent, 0-5 percent of antistatic agent, 0-5 percent of antioxygen, 0-5 percent of slipping agent and 0-5 percent of antiblocking agent, and the barrier layer is fully biodegradable and is provided with a carbon dioxide copolymer with the gas barrier property. According to the preparation method, a multilayer co-extrusion gradual or synchronous biaxial drawing process is adopted. The compound film can be fully biodegradable, has very good oxygen, carbon dioxide and moisture barrier property, higher tensile strength, high puncture resistance and high deflection, and can be used for packages of foods, cosmetics, electronic products, chemicals and the like.

Owner:FSPG HI TECH

Degradable composite film and preparation method thereof

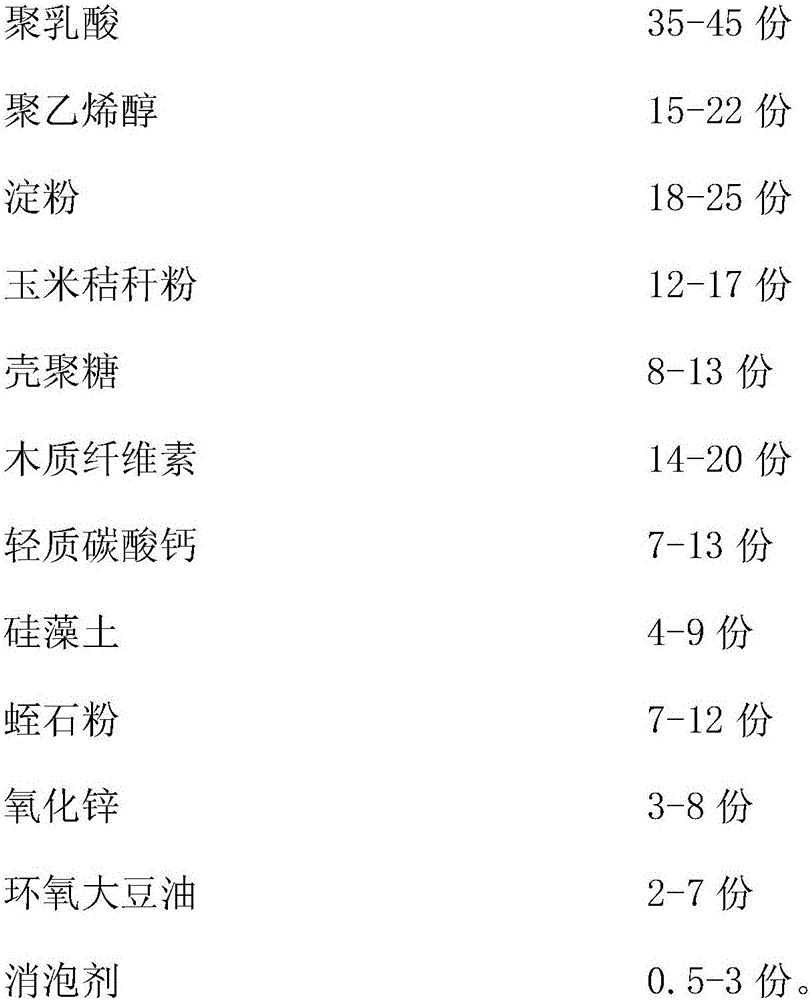

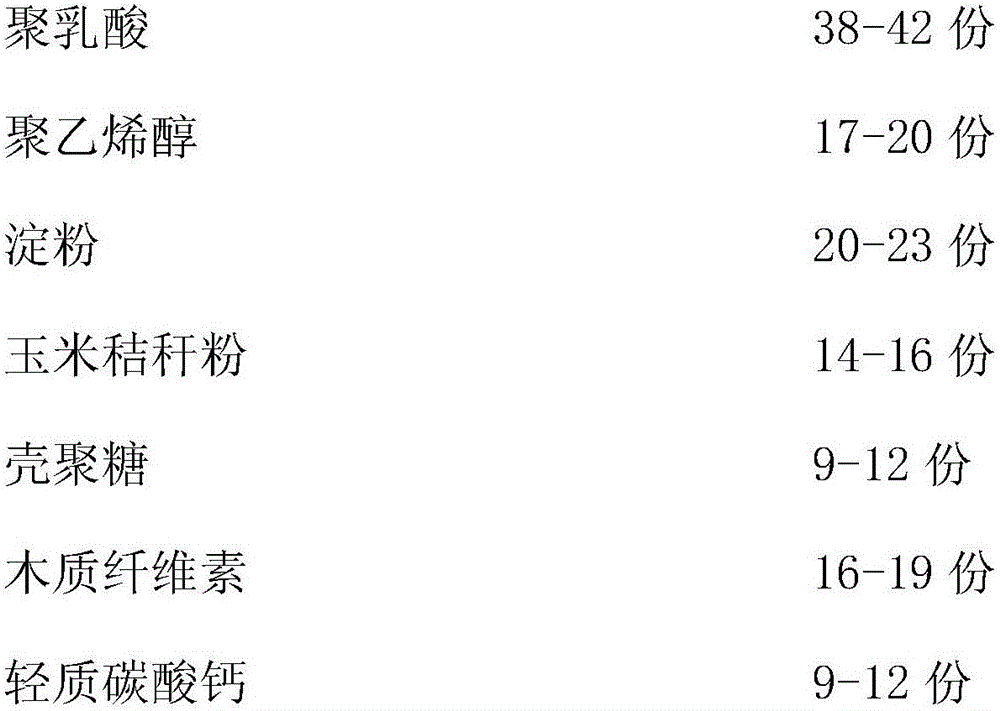

The invention relates to a degradable composite film and a preparation method thereof. The degradable composite film comprises, by weight, 35-45 parts of polylactic acid, 15-22 parts of polyvinyl alcohol, 18-25 parts of starch, 12-17 parts of corn stalk powder, 8-13 parts of chitosan, 14-20 parts of lignocelluloses, 7-13 parts of light calcium carbonate, 4-9 parts of diatomite, 7-12 parts of vermiculite powder, 3-8 parts of zinc oxide, 2-7 parts of epoxidized soybean oil and 0.5-3 parts of defoamers. The degradable composite film and the preparation method thereof have the advantages that the film is mainly prepared from the polylactic acid, and the starch, the corn stalk powder, the chitosan and the lignocelluloses are added compatibly, so that the film has high biological degradability and is safe and environment friendly, and white pollution is avoided; the zinc oxide, the diatomite and the vermiculite powder serve as activating agents, strength and tenacity of the film can be improved, and migration rate of plasticizers can be lowered; the raw materials are easy to get, the price is low, the preparation process is simple, and good economic benefit is achieved.

Owner:安徽省天乐塑业有限公司

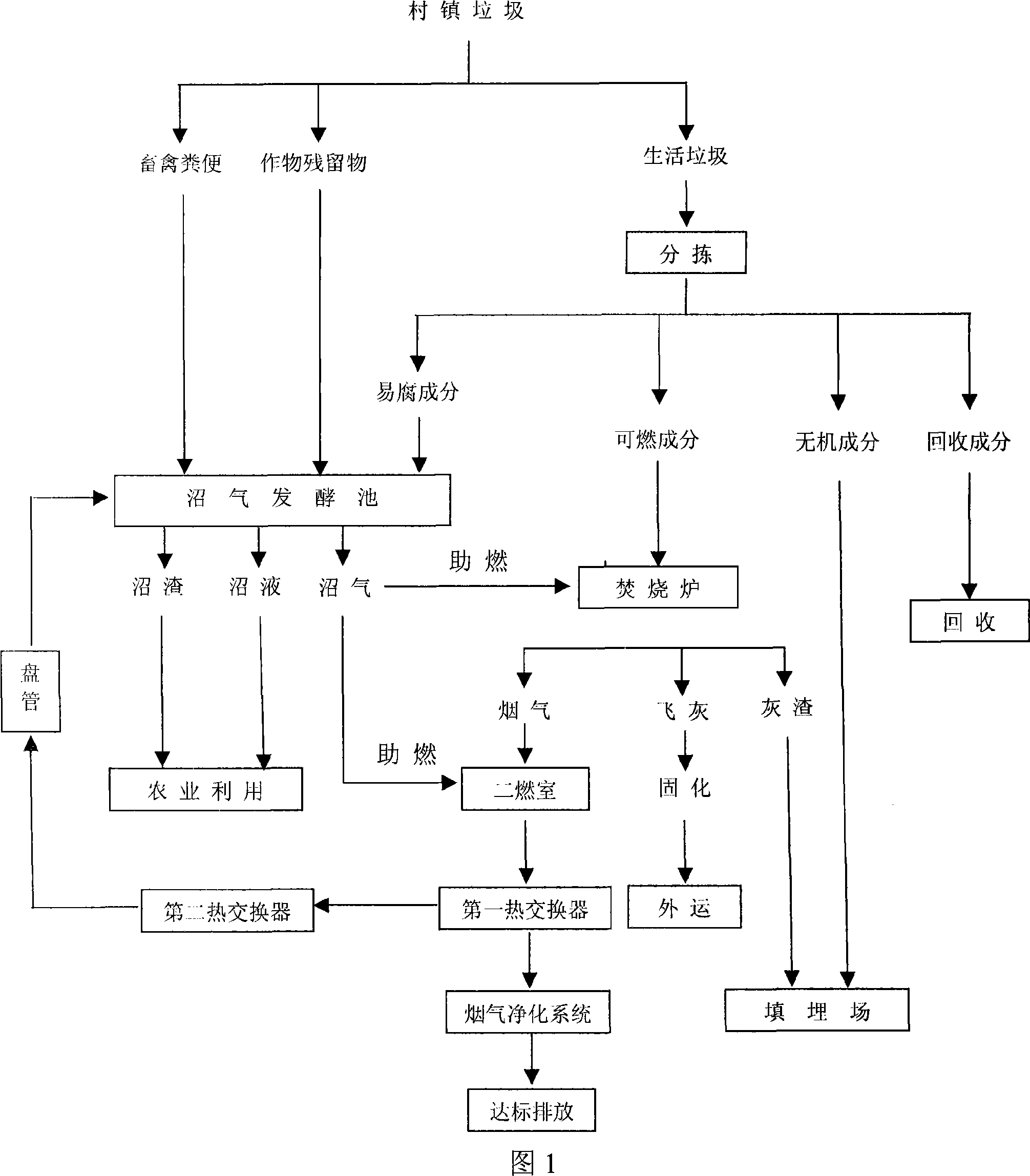

Rubbish comprehensive processing method adapted for village and small town

InactiveCN101062825AIncineration harmlessIncineration reductionBio-organic fraction processingChemical industryThermal energyResource utilization

The invention discloses a garbage comprehensive treatment method for village, which comprises the following steps: sorting life garbage of village to perishable element, combustible constituent, reclaiming element; inorganic element; allocating the perishable element, residues of crop, animal and poultry manure and water with mass ratio at 0. 8-1. 2:0. 8-1. 2:8; proceeding anaerobic fermentation under the insulation action of burning lose heat; generating marsh gas; burning the combustible constituent with combustion-supporting marsh gas completely; getting high temperature smoke gas; recovering thermal energy through the first and second heat exchanger; maintaining the temperature of marsh gas fermenting tank; obtaining resource utilization of marsh liquid or slag, marsh gas and reclaiming component; health-filling the inorganic element and burning ash slag. This invention can prevent twice pollution of the burning smoke gas, which can increase the efficiency and output of mash gas.

Owner:ZHEJIANG UNIV

Method for preparing polyol by using bio-oil and application

ActiveCN104341297AWide variety of sourcesPromote degradationOrganic compound preparationPolyureas/polyurethane adhesivesPtru catalystPotassium fluoride

The invention discloses a method for preparing polyol by using bio-oil. The method comprises the following steps: firstly performing methyl esterification, namely, performing ester exchange on biolipid and methanol under the catalysis of potassium fluoride loaded magnesium oxide solid alkali, converting the obtained product into fatty acid methyl ester with small molecular weight and byproduct glycerol, filtering to recycle the catalyst, and separating lower-layer glycerol; performing epoxidation on upper-layer fatty acid methyl ester in 30% of hydrogen peroxide under the catalysis of ionic liquid so as to form epoxidized fatty acid methyl ester.; then adding the glycerol in the methyl esterification process, continuously performing alkoxide ring-opening under the catalysis of ionic liquid, introducing hydroxyl, and finally separating liquid to recycle the ionic liquid catalyst, reducing pressure and distilling the upper-layer to remove water so as to obtain low-viscosity bio-oil-based polyol. The raw material is easily available, recyclable and good in biodegradability, the preparation process is environmental friendly, the industrial three-waste emission is small, the product structure and a hydroxyl value are adjustable, the application range is wide, and the environment influence level is low.

Owner:ZHEJIANG HENGFENG NEW MATERIAL

Fully degradable biomaterial and product thereof

InactiveCN102702696AGood technical effectSave storage spaceFlexible coversWrappersLow-density polyethyleneMasterbatch

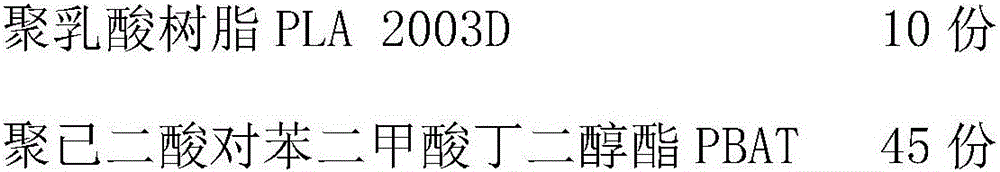

The invention relates to a fully degradable biomaterial and a thin film product thereof, and discloses the fully degradable biomaterial which consists of 75-90 percent by weight of PBAT (Poly (Butylene Adipate-co-Terephthalate)) and the balance of PLA (Poly Lactic Acid) and a thin film product prepared by taking the fully degradable biomaterial as a master batch. The fully degradable biomaterial and the thin film product thereof have the advantages of full degradability, water resistance, oil resistance, high tensile strength, high flexibility, physical and chemical properties similar to those of an LDPE (Low-Density Polyethylene) plastic thin film, single component, simple process, low energy consumption required for production and being a superior alternative for the LDPE plastic thin film.

Owner:ZHEJIANG HUAXIA PACKING CO LTD

High-barrier-property biodegradable mulching film and preparation method thereof

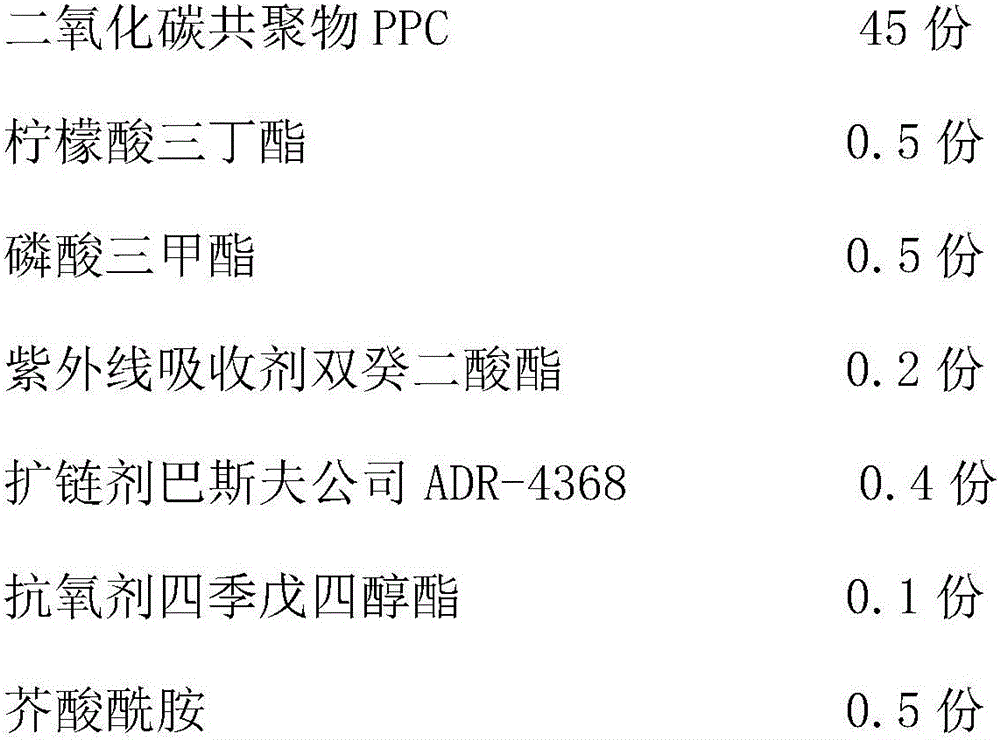

InactiveCN106046725AFully biodegradableGood mechanical propertiesLow-density polyethyleneAntioxidant

The invention relates to a high-barrier-property biodegradable mulching film and a preparation method thereof, belonging to the field of high-polymer materials. The high-barrier-property biodegradable mulching film is prepared from a polylactic acid resin, a toughener, a heat stabilizer, an ultraviolet absorbent, a chain extender, an antioxidant, an opening agent and the like by using a film blowing machine set. The high-barrier-property biodegradable mulching film can be automatically degraded under the actions of rich oxygen and microbes, does not pollute the environment, has higher barrier property than the LDPE (low-density polyethylene) film with the same thickness by 1.5-2.0 times, and satisfies the functions of moisture retention, water preservation and yield increase for crops. The method has the advantages of simple production technique and high production efficiency, and can easily implement industrial production.

Owner:JILIN COFCO BIOCHEM

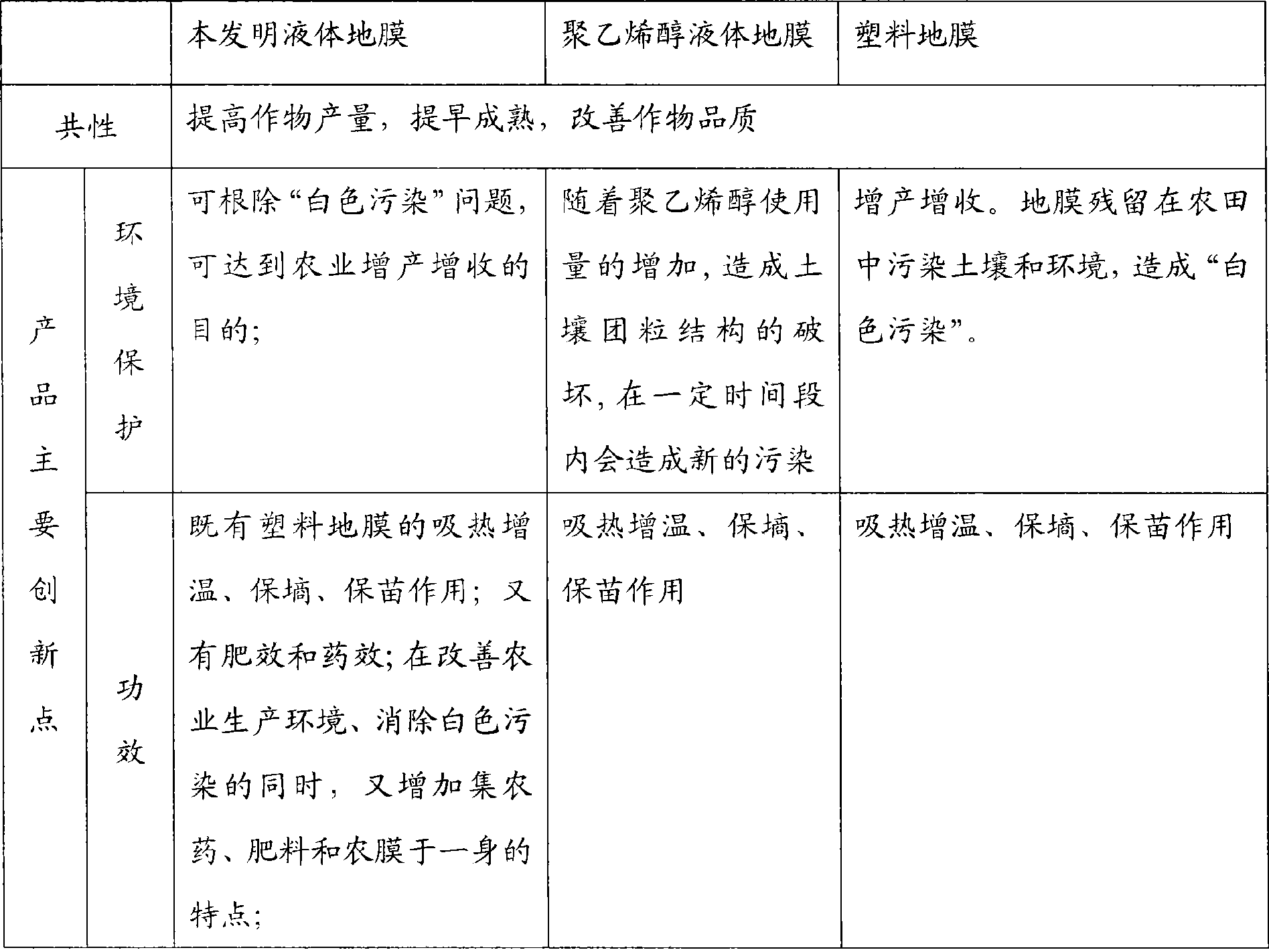

Pasty degradable mulch film and preparation thereof

InactiveCN101280116AEasy to usePlay the role of mulching filmClimate change adaptationGreenhouse cultivationFilm-forming agentSoil surface

The invention discloses a paste-type degradable plastic film and belongs to the agricultural plastic film production field. Humic acid, film forming agents, surfactants, modifiers, fertilizers and water are used to prepare black or brown paste; the paste is then diluted by water and sprayed out to form a film-shaped structure on the soil surface. Compared with the prior art, the paste-type degradable plastic film of the invention has low cost, good effect, convenient packaging and transportation, as well as good promotion and application value.

Owner:田秋喜

Degradable liquid mulching film and production method thereof

InactiveCN101445731AEfficient captureInhibition lossAgriculture tools and machinesOrganic fertilisersCelluloseEvaporation

The invention relates to a degradable liquid mulching film and a production method thereof, particularly to an environment-friendly degradable liquid mulching film with straws as a basic raw material and a production method thereof. The degradable liquid mulching film is prepared from steaming slurry of crop straws (such as wheat straws, rice straws, cotton straws, wood shavings, and the like) or straws paper-making black liquor as a main raw material by a series of reactions, such as sulfonation, crosslinking and copolymerization, of macromolecules in the slurry or the black liquor, such as lignin, cellulose and polysaccharides, under the action of a film formation additive. The macromolecules in the degradable liquid mulching film have a large amount of hydrophilic groups which can effectively catch the water molecules evaporated and diffused from soil to the air, so as to prevent water evaporation and heat loss arising therefrom, thereby increasing the temperature and preserving soil moisture. The degradable liquid mulching film is helpful for increasing crop yield and improving crop quality; and the yield is higher than that by use of a plastic mulching film, and the per mu yield is increased by more than 5%. The degradable liquid mulching film can replace the conventionally used plastic mulching film.

Owner:SHANDONG SI DA KE BIODEGRADABLE TECH CO LTD

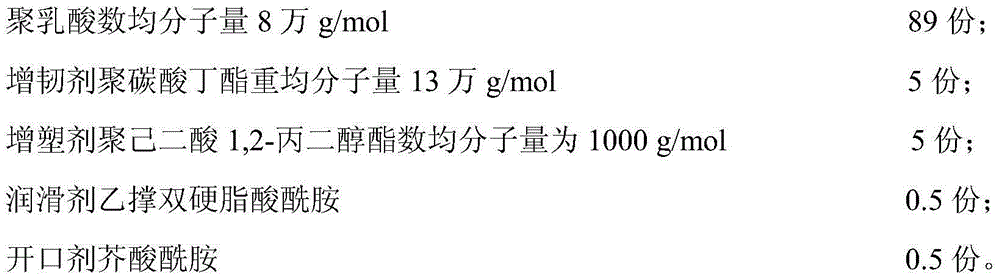

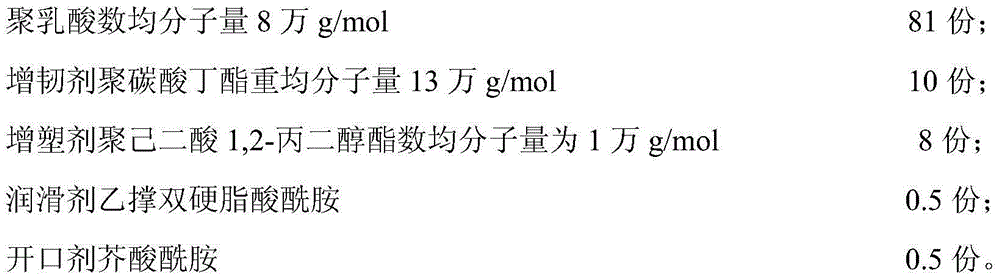

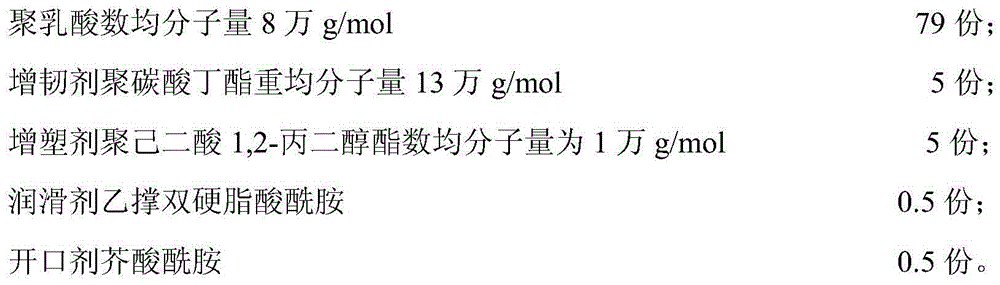

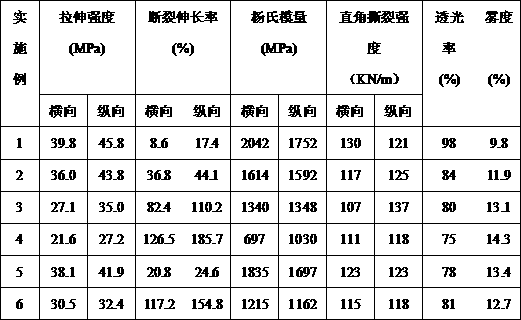

Transparent, tear-resistant and biodegradable polylactic acid thin film and preparation method thereof

InactiveCN104387732AIncreased tensile elongation at breakHigh tear strengthPolymer sciencePlasticizer

The invention provides a transparent, tear-resistant and biodegradable polylactic acid thin film and a preparation method thereof, belonging to the field of high molecular material and solving the technical problem of high brittleness, poor tear resistance and poor flexibility of the polylactic acid thin film in the prior art. The transparent, tear-resistant and biodegradable polylactic acid thin film comprises a mixture of polylactic acid, a toughening agent, a plasticizer, a lubricant and a plastic lubricant. The preparation method comprises the following steps: mechanically mixing polylactic acid, the toughening agent, the plasticizer, the lubricant and the plastic lubricant to obtain a premix at first; feeding the premix from the feeding opening of a twin-screw extruder; metering the plasticizer and adding the metered plasticizer from the liquid feeding opening of the twin-screw extruder; and pelleting by melt extrusion to finally obtain the transparent, tear-resistant and biodegradable polylactic acid thin film. The elongation at break and tearing strength of the polylactic acid thin film provided by the invention are improved obviously, the transparency of polylactic acid is retained, the brittleness defect of the polylactic acid thin film is solved, the rheological behavior of the material is improved obviously, the tensile strength is 43.2MPa at most, the elongation at break is 48%, and the right angle tear strength is 127KN / m.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Transparent and toughening polylactic acid resin and method for preparing the same

The invention provides a transparent and toughening polylactic acid resin and method for preparing the same. The polylactic acid resin consists of polylactic acid, methyl methacrylate-butyl acrylate copolymer as the flexibilizer, citrate plasticizer, pentaerythritol toltetranitrate (Benzenepropanoic acid, 3,5-bis(1,1-dimethylethyl)-4-hydroxy-) as the antioxidant and tris (2,4-ditert-butylphenyl) phosphate. First, premix is prepared by mixing polylactic acid, flexibilizer, plasticizer and antioxidant mechanically. Then the premix is subject to melt extrusion and granulation by utilizing double-screw extruder. The above method has the advantages of increasing the anti-impact strength, tensile strength and elongation at break of polylactic acid and maintaining the transparency thereof. In addition, the viscosity of the blends is decreased, thereby remedying the defects of brittleness of polylactic acid and improving the rheological behavior of materials obviously. The impact strength is up to 60.1KJ / M2.The light transmittance and the haze of the products are 89% and 8.5% respectively when the thickness thereof is 0.04mm.The above polylactic acid resin, instead of PE and PVC, is applicable to the preparation of films, plates, sheet materials, foamings and injection moulding plastics.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing conductive plastics taking recovered plastics as matrix

The invention relates to the field of high polymer material processing, and discloses a method for preparing conductive plastics taking recovered plastics as a matrix. The technical scheme is that: the conductive plastics consist of the following raw materials in percentage by weight: 80 to 90 percent of plastic matrix, 7 to 18 percent of conductive carbon black, 1.5 to 5 percent of dispersing agent and 0.2 to 1 percent of coupling agent; and the preparation method comprises the following steps of: (1) atomizing the coupling agent and the dispersing agent, uniformly mixing with the conductive carbon black at the temperature of between 80 and 110 DEG C to obtain processed carbon black; and (2) with high speed stirring, uniformly mixing the processed carbon black and the plastic matrix, extruding and granulating, wherein the plastic matrix is one or a mixture of more than two of recovered polyethylene glycol terephthalate, polycarbonate, polyethylene and polypropylene. Through the method, the conductive plastics with easy machine-shaping and good dispersing effect are obtained; and the recovered plastics maintain the mechanical properties of the universal engineering plastics and the waste non-conductive plastics are endowed with better conductivity.

Owner:江苏英纳新材料有限公司

Liquid mulching film and its producing method

InactiveCN1415698ASimple structureIncreased Water Stability AgglomeratesOrganic fertilisersSoil conditioning compositionsLiquid stateSoil conditioner

A liquid-state ground film for improving soil and preventing loss of water and soil contains goudron and / or asphalt, water, cationic surfactant, stabilizer, protecting agent and additive. Its advantages are low cost, and high filming performance and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Green, sustainable and high-yield planting method of sugarcane

InactiveCN105830710AReduce dosageReduce the amount of applicationSugarcane cultivationHarvestersEcological environmentSaccharum

The invention relates to a green, sustainable and high-yield planting method of sugarcane. The method comprises seven steps as follow: selection of healthy and high-quality sugarcane seeds, digging of sugarcane furrows, scientific fertilizer application, seed sowing and soil covering, mulching and soil covering, harvesting of sugarcane and management of perennial roots. Scientific planting and harvesting are strengthened in two key periods including sugarcane planting and harvesting. In the period of sugarcane planting, the consumption of fertilizers is reduced, special slow-release fertilizers for sugarcane and bio-organic fertilizers are applied, mulching films capable of being completely biodegraded are used for complete covering, and accordingly, growth of the sugarcane is promoted; in the period of sugarcane harvesting, a traditional cutting method is changed, cutting at depth of soil is adopted, fertilizers required by the perennial roots of the sugarcane are directly applied to the sugarcane furrows, soil dressing and complete film covering are performed, and management of the perennial roots of the sugarcane can be finished. Green production of the sugarcane is realized, the yield and the sucrose content are increased, the consumption of the fertilizers is reduced, the soil fertility is improved, the utilization rate is increased, the ecological environment of a sugarcane field is improved, growth of the sugarcane and increase of income of sugarcane growers are promoted, and popularization and application are facilitated.

Owner:SUGARCANE RES INST OF YUNNAN ACADEMY OF AGRI SCI +1

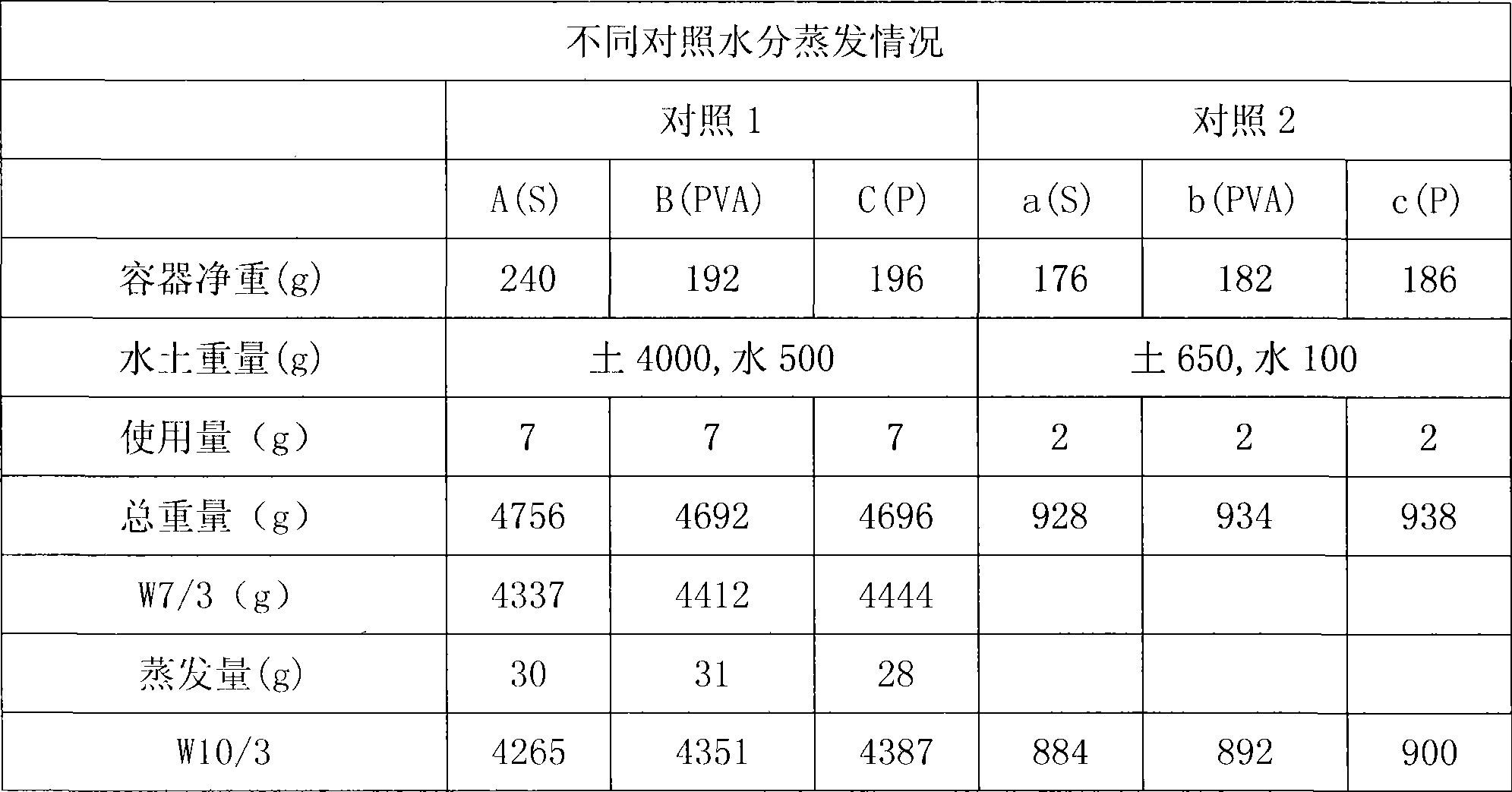

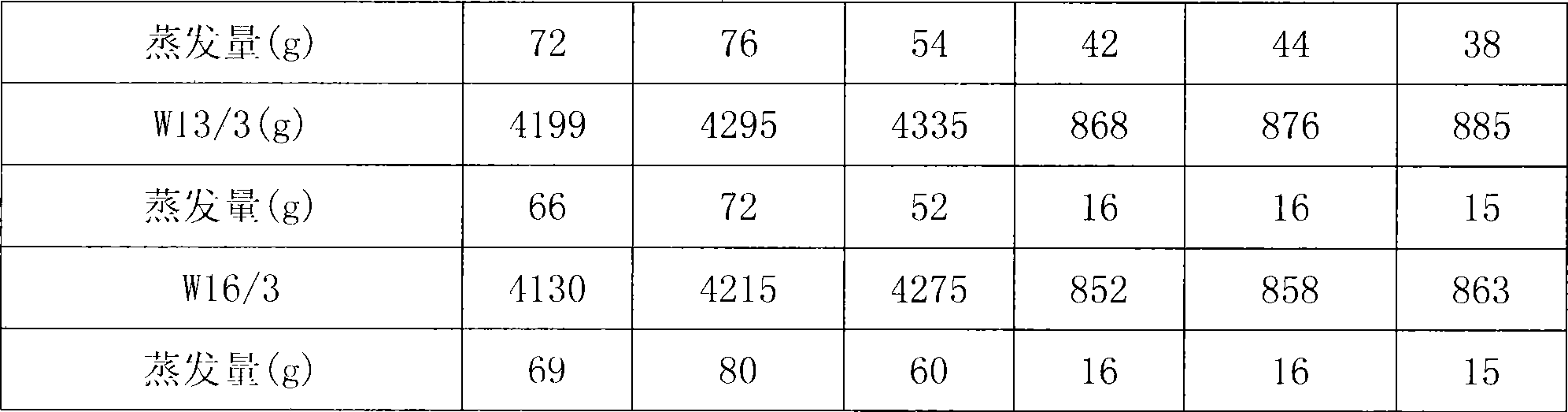

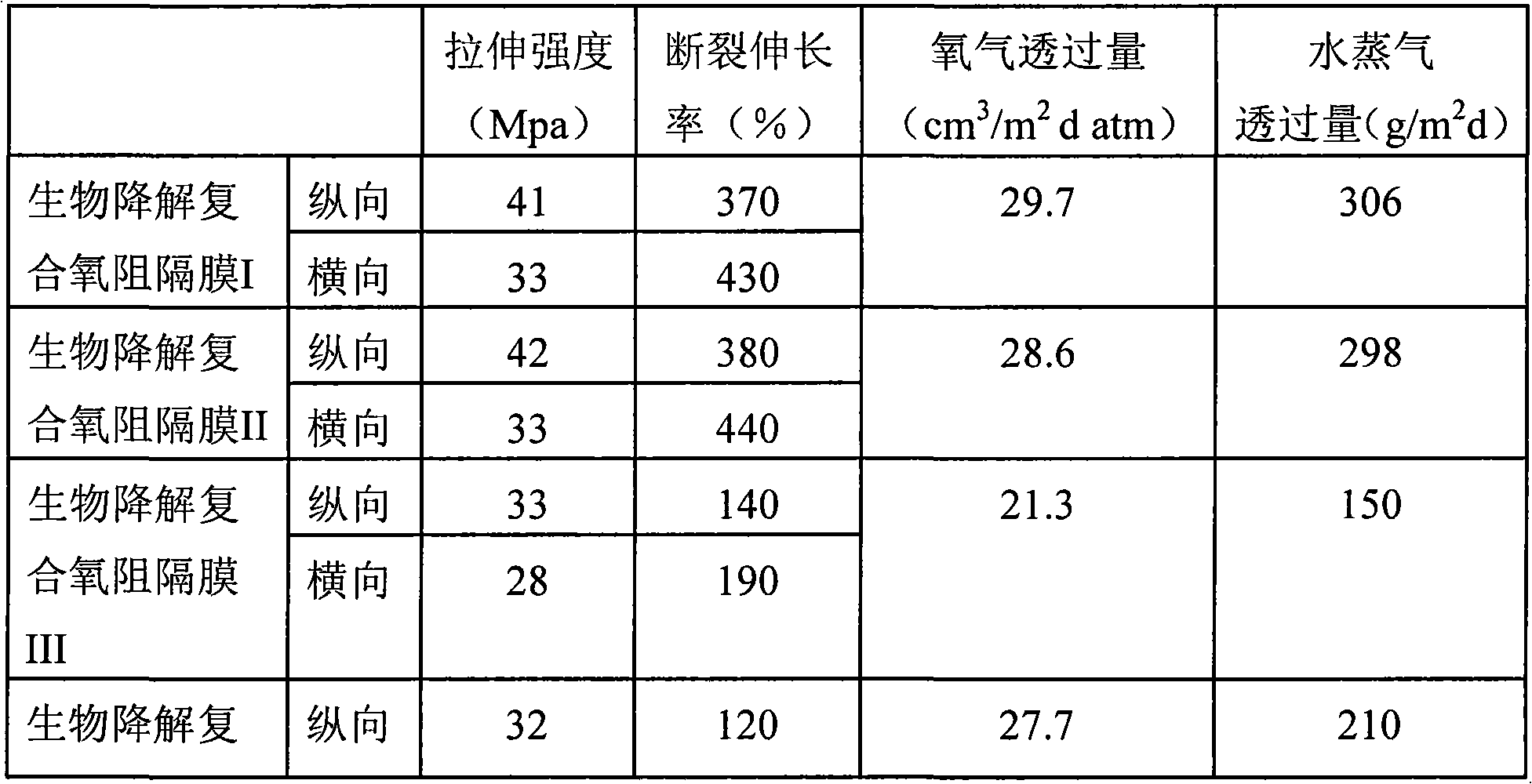

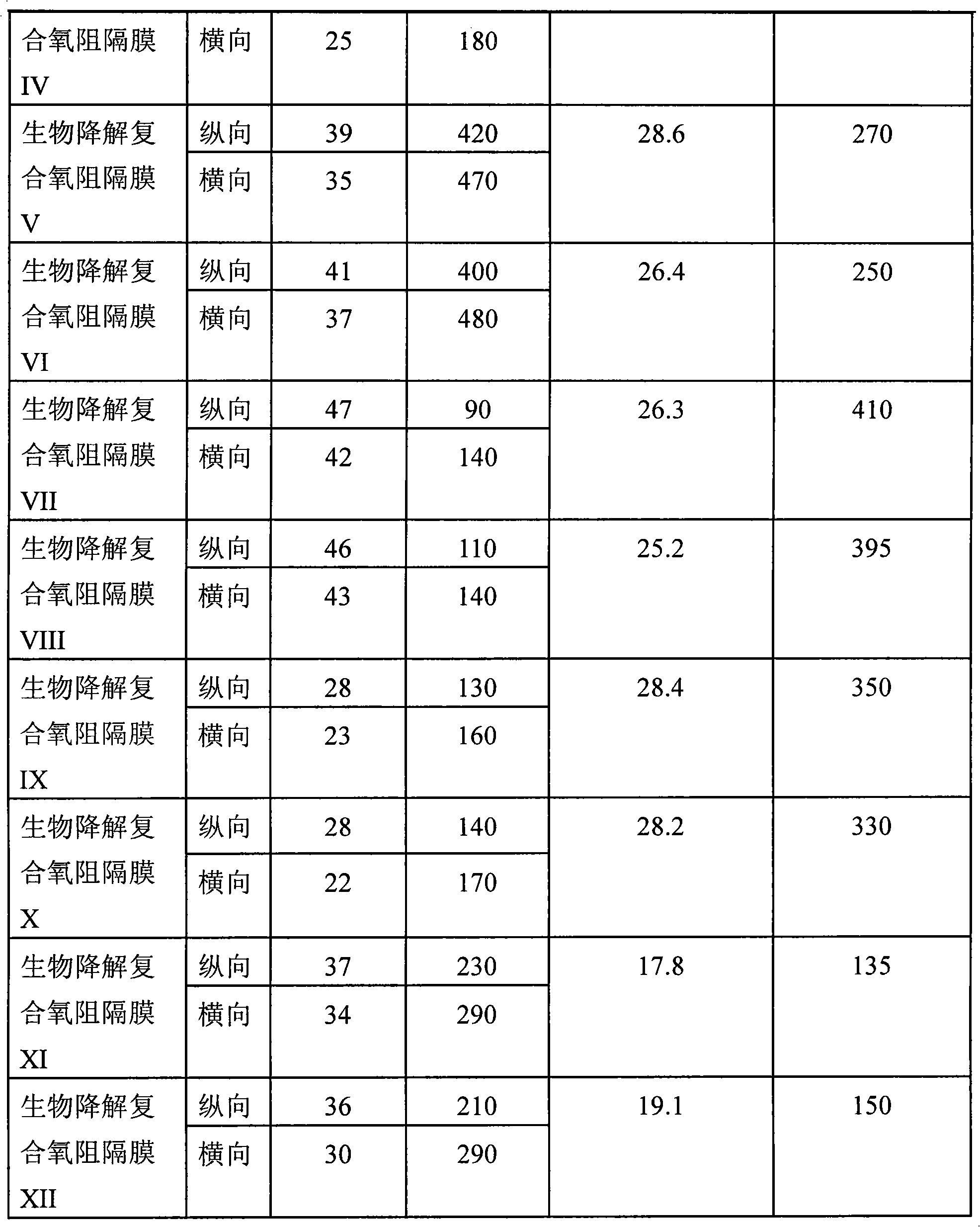

Biodegradable composite oxygen-barrier film and use thereof

ActiveCN102007001AExtended shelf lifeExtend your lifeFlexible coversWrappersEngineeringPoly(butylene succinate)

The invention discloses a biodegradable composite oxygen-barrier film and its preparation method and use. The biodegradable composite oxygen-barrier film is composed of at least two support layers and barrier layer which is located in each of the two support layers. Said support layer is selected from at least one of the following materials: polylactic acid, polybutylene succinate, polycaprolactone, poly(butylene adipate-co-terephthalate), poly(beta-hydroxybutyrate) and poly(beta-hydroxybutyrate-co-hydroxyvalerate); said barrier layers located in each of the two support layers are same or different, and the barrier layer is selected from poly(1,2-propylene carbonate) and nano-montmorillonite modified poly(1,2-propylene carbonate). The biodegradable composite oxygen-barrier film can be used as food or medicine package, and it will help to prolong shelf-life of food and medicine and the like; it can also prevent white-pollution.

Owner:CHINA NAT OFFSHORE OIL CORP +3

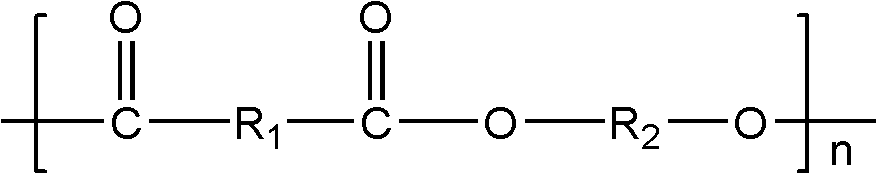

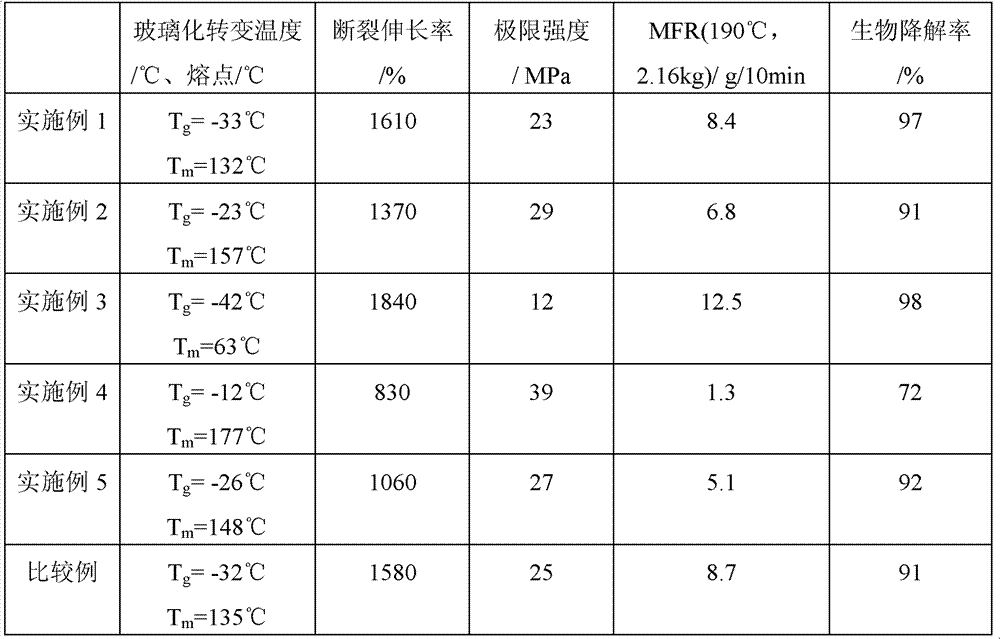

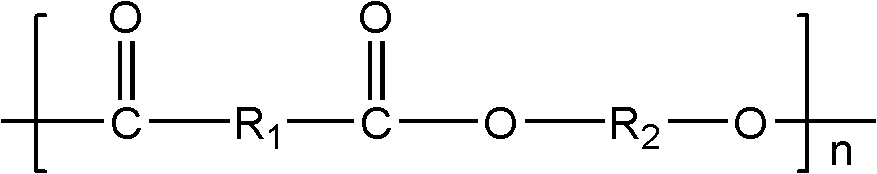

Biodegradable aromatic-aliphatic copolyester and preparation method thereof

ActiveCN103087305AExcellent thermodynamic propertiesPromote degradationMaterial synthesisCopolyester

The invention belongs to the technical field of polymer material synthesis and preparation, and discloses biodegradable aromatic-aliphatic copolyester and a preparation method thereof. The biodegradable aromatic-aliphatic copolyester disclosed in the invention has the a constitutional repeating unit as shown in the specification, wherein R1 is selected from groups as shown in the specification; R3 is selected from Li, Na, K, Rb, Cs, Fr, Be, Mg, Ca, Sr, Ba or Ra; R4 is selected from Li, Na, K, Rb, Cs, Fr, Be, Mg, Ca, Sr, Ba or Ra; R2 is selected from groups as shown in the specification; n=1-1000; p=0-11; q=2-13. According to the invention, binary acid or ester containing a sulfonate group is added, which effectively improves the hydrophilic performance of the copolyester, makes polyester plastics be easier to be adsorbed, decomposed, and absorbed by microbe such as bacteria and the like, and provides plastics with better biodegradability.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for preparing polyol from waste grease and application thereof

ActiveCN104326911ALow costSolve pollutionFatty acid esterificationOrganic compound preparationSaturated fatty acid esterOil and grease

The invention discloses a method for preparing polyol from waste grease, comprising the following steps: a solid acid catalyst which has large hydrophobic surface and has both a sulfonic group and a carboxylic group is adopted to catalyze esterification and transesterification between waste grease and methanol so as to convert waste grease to fatty acid methyl ester and a by-product glycerin; saturated fatty acid ester in fatty acid methyl ester is separated; under the catalysis of a dual acid site solid acid and in cooperation of the dual acid site, 30% hydrogen peroxide is directly catalyzed for epoxidation of fatty acid methyl ester, an intermediate product is not separated, and the by-product glycerin is added for ring opening of alkoxylation after direct heating-up; and finally, filtration is carried out to recycle the catalyst, and reduced pressure distillation is carried out to remove water so as to obtain biological oil-based polyol. According to the method, waste grease is used as a raw material, thus turning waste into wealth. The polyol product obtained has good biodegradability; the preparation process is green; emission of three industrial wastes is low; product structure and hydroxyl value can be adjusted; the range of application is wide; and the level of effect on the environment is low.

Owner:ZHEJIANG HENGFENG NEW MATERIAL

Starch based biodegradable flexible packing materials, and preparation method

A biological degradable soft packing material of starch base is a type of soft film packing material made of starch, plasticizer and filler. The material can be degraded thoroughly under natural condition after it is buried underground for 3-4 monthes.

Owner:郭志伟

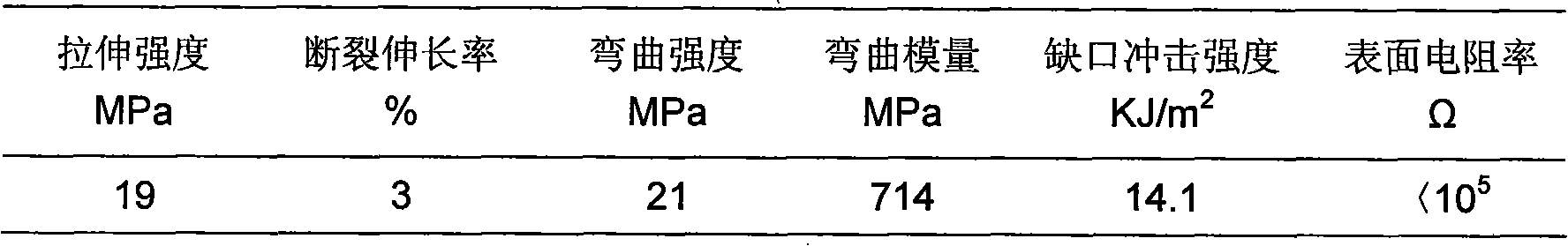

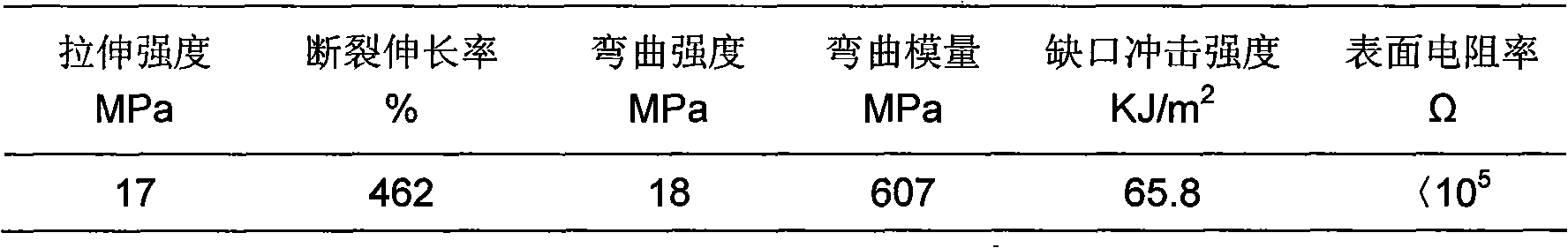

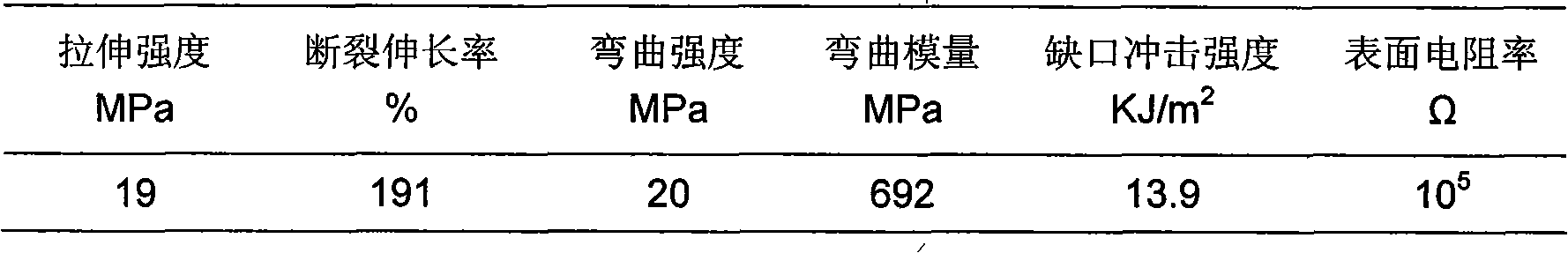

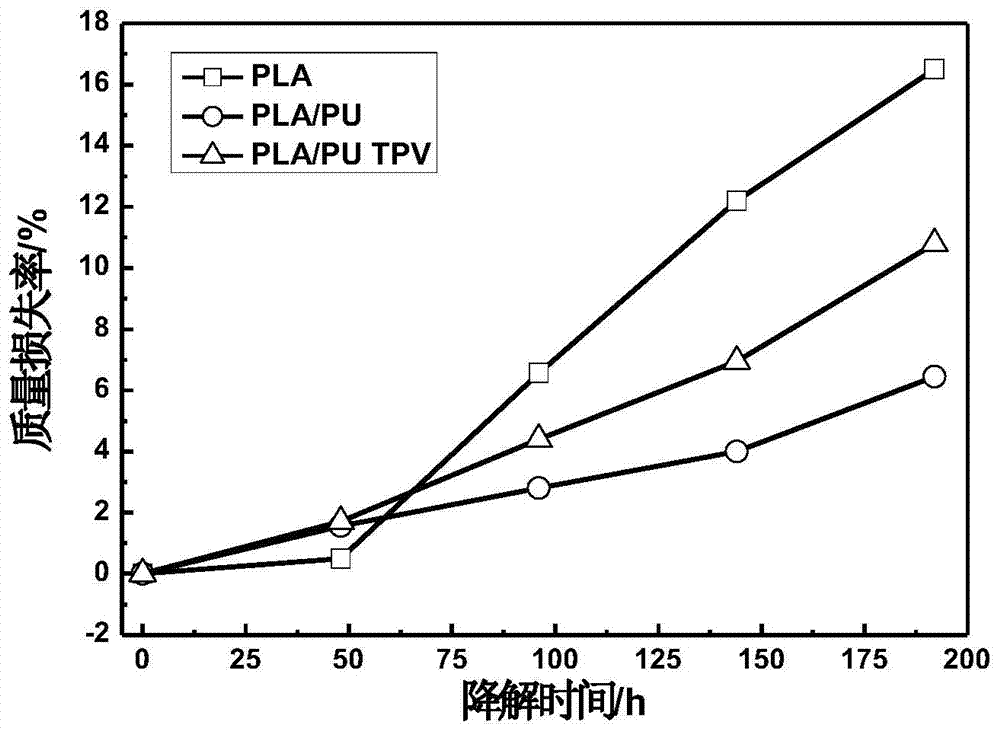

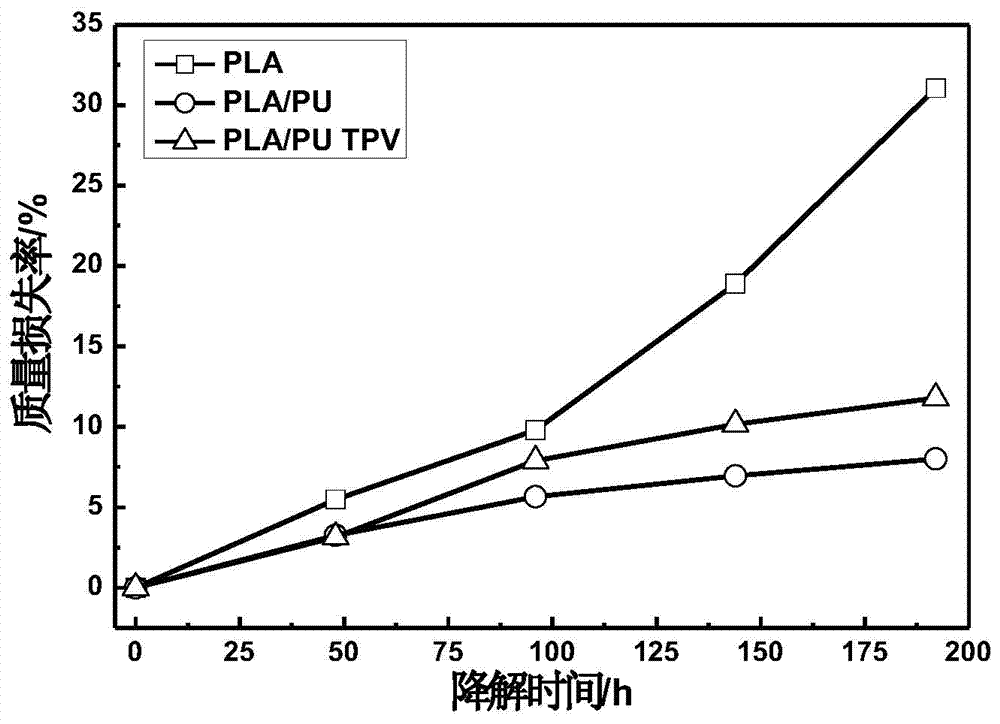

Polyurethane/polylactic acid thermoplastic vulcanized rubber and preparation method thereof

The invention relates to polyurethane / polylactic acid thermoplastic vulcanized rubber and a preparation method thereof. Through dynamic vulcanization, under the action of a shearing force produced by a high-temperature internal mixer, polyurethane rubber is vulcanized, the vulcanized polyurethane rubber is crushed into micron-sized rubber particles, and the micron-sized rubber particles are dispersed in a polylactic acid continuous phase so that the high-rubber content polyurethane / polylactic acid mixed thermoplastic vulcanized rubber is obtained. The polyurethane / polylactic acid thermoplastic vulcanized rubber obtained by the preparation method widens a polylactic acid material application field and provides a biodegradable and recyclable novel elastomer material.

Owner:张家港市美特高分子材料有限公司

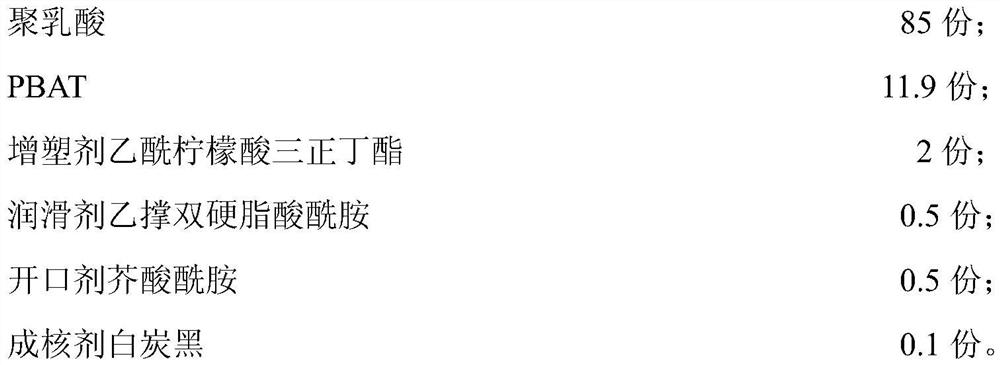

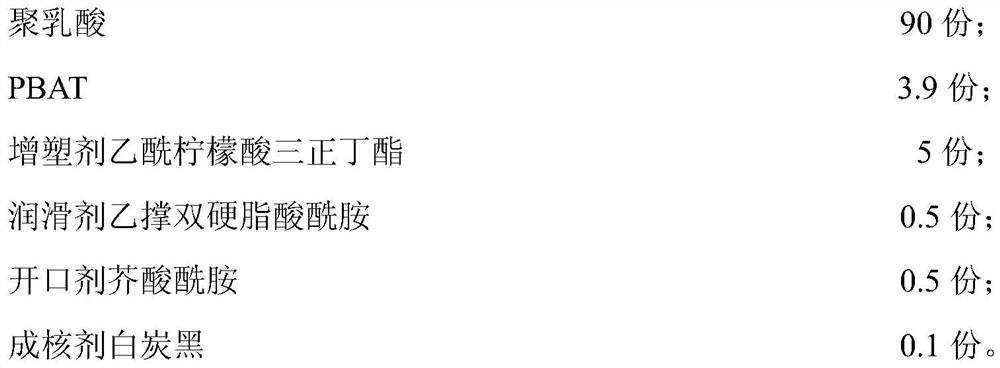

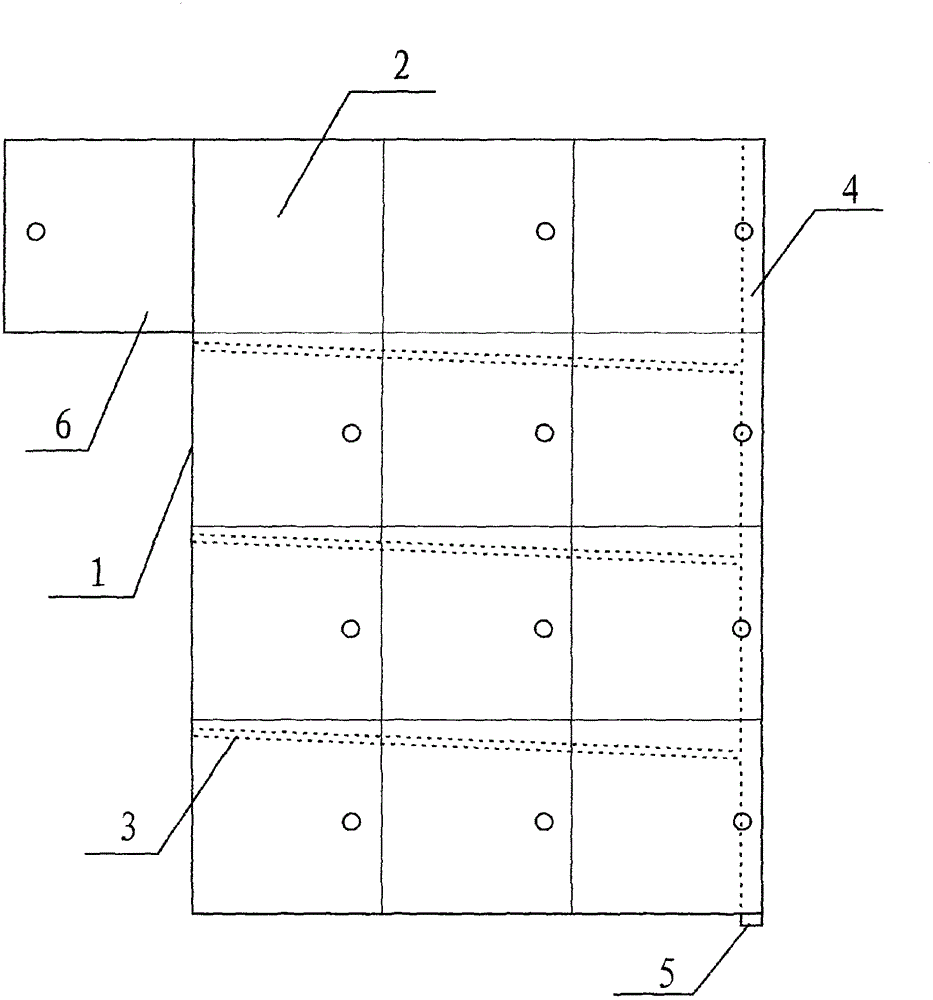

Preparation method of high-transparency easy-to-tear polylactic acid blown film

PendingCN111944287AIncreased tensile elongation at breakSolve serious brittle defectsTensile fractureCarbon black

The invention provides a preparation method of a high-transparency easy-to-tear polylactic acid blow-molded film. The high-transparency easy-to-tear polylactic acid blow-molded film is composed of a mixture of polylactic acid (PLA), polyterephthalic acid-adipic acid-butanediol ester (PBAT), a plasticizer acetyl tributyl citrate, a lubricant ethylene bisstearamide, an opening agent erucyl amide anda nucleating agent white carbon black. The preparation method comprises the following steps: weighing PLA, PBAT, a plasticizer, a lubricant, an opening agent and a nucleating agent in proportion, adding into a mixer, uniformly mixing, adding from a feeding hole of a double-screw extruder, carrying out melt extrusion, water cooling, pelletizing and drying to obtain special modified polylactic acidfilm-blowing resin, and carrying out water cooling blow molding film formation by a film blowing machine through a down-blowing method to obtain the high-transparency easily-torn polylactic acid blow-molded film. According to the invention, the PBAT, the plasticizer, the lubricant, the opening agent and the nucleating agent have a synergistic effect, so that the tensile elongation at break of thepolylactic acid film can be effectively improved, the polylactic acid film has high transparency, the flat wrinkle-free easy-to-tear high-transparency complete biodegradable film is obtained, the tensile strength is as high as 54.6 MPa, and when the thickness of the film is 0.025 mm, the light transmittance reaches 94% or above and the haze reaches 5.3%; and the film has good mechanical properties and excellent transparency, and can replace PE, PP, PVC and other films.

Owner:江苏碧升生物新材料有限公司

Umbrella storage box

The invention relates to an umbrella storage box which comprises a box body, wherein multiple layers of umbrella storage cases are longitudinally and horizontally arranged in the box body; a hollowed-out grid with a permeable function is arranged at the bottom of each umbrella storage case; a downpipe is mounted on one side of the inside of the box body; a guide plate is arranged below each layer of umbrella storage cases, a water outlet of the guide plate is connected with the downpipe, and a water outlet of the downpipe can be mounted in the connecting port position of a floor drain or an underground water pipe; and each umbrella storage case is provided with an umbrella storage case door which can be independently opened or locked. The umbrella storage box has the benefits as follows: wet umbrellas or raincoats are prevented from wetting the floor, the umbrella storage box is particularly suitable for public places such as a shopping mall or a market and the like, and the environment is protected.

Owner:朱俐敏

Edible plant starch-cellulose composite packaging film for meat products

InactiveCN104610580AStrong physical and mechanical propertiesAvoid white pollutionFlexible coversWrappersWaxSodium carboxymethylcellulose

The invention discloses an edible plant starch-cellulose composite packaging film for meat products and relates to the technical field of edible packaging films. The packaging film is prepared from raw materials in parts by mass as follows: 80-100 parts of plant starch, 50-60 parts of hydroxypropyl methylcellulose, 30-35 parts of sodium carboxymethyl cellulose, 15-18 parts of sodium alginate, 12-15 parts of curdlan, 10-12 parts of low-methoxyl pectin, 8-10 parts of calcium citrate, 10-15 parts of cloves, 10-15 parts of cassia bark, 10-15 parts of spices, 5-8 parts of tea polyphenols, 10-12 parts of rapeseed oil, 8-10 parts of agar, 6-9 parts of genipin, 5-8 parts of polyglycerol fatty acid ester, 3-6 parts of edible wax and 800-1000 parts of water. The plant starch and the cellulose are used as main raw materials, and proper aids are used as auxiliary materials, so that the prepared packaging film for the meat products has higher physical and mechanical properties, the barrier property and antibacterial and anti-oxidation effects; besides, the packaging film can be eaten together with the products, so that the ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

PLA-PBSA blown film and preparation method thereof

InactiveCN108017887AIncreased tensile elongation at breakHigh tear strengthFlat articlesDiethylene glycol monobutyl etherPolymer science

The invention provides a polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film and a preparation method thereof. The blown film comprises a mixture of PLA, PBSA, plasticizer diethylene glycol monobutyl ether adipate, a lubricant, a plastic lubricant and an antioxidant. The PLA, the PBSA, the lubricant, the plastic lubricant and the antioxidant are first mechanically mixed into a premix, the premix is added through a feeding port of a twin-screw extruder, meanwhile the plasticizer diethylene glycol monobutyl ether adipate is metered and added in through a liquid feeding port of the twin-screw extruder, modified polylactic acid blown film special resin is prepared by melt-extruding, water-cooling, pelletizing and drying, the modified polylactic acid blown film special resin is blown by a film blowing machine to form a transparent tear-resistant biodegradable film. The PBSA, the plasticizers, the lubricant, the plastic lubricant and the antioxidant can effectively increase the tensile elongation at break and tear strength of polylactic acid films, maintains the transparency of the polylactic acid, and solves the brittleness defects of the polylactic acid films. The polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film has good mechanical properties and excellent transparency, and can replace PE, PP, PVC and the like for preparation of films and sheets.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP +1

Plastic-wood-metal composite structure material and method for producing the same

InactiveCN1467075ARealize multiple compoundImprove stress resistanceCoatingsFlexural strengthMetallic materials

A structural plastics-wood-metal composition is prepared from waste or used thermoplastic plastics, reinforcing particles, metallic structural member and modifier. Its advantages are high compression strength and bending strength, and environmental friendlinezz.

Owner:张书证 +1

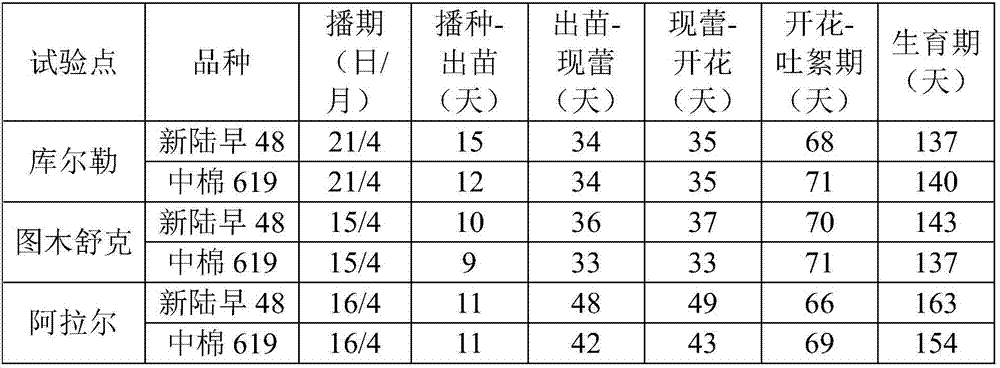

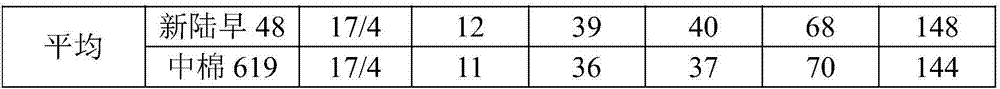

Cultivation method of southern XinJiang film-free cotton

InactiveCN107135782AIncrease productionQuality improvementFertilising methodsPlant protectionDiseaseAnimal science

The invention relates to the field of cotton planting, in particular to a cultivation method of southern XinJiang film-free cotton. The method comprises the steps of choosing early-maturing upland cotton varieties for use, wherein the cotton varieties mature within 120 days under the film-mulching cultivation condition and mature within 135-140 days under the film-free cultivation condition; conducing fertilization and ploughing for sowing, wherein the planting density is 240,000-255,000 plants.hm<-2>; when cotyledons stretch flat, conducting continuous chemical regulation twice, wherein the usage amount of mepiquat chloride is 1.4-1.6 g.hm<-2> and 0.8-1.2 g.hm<-2> respectively, and the usage amount of mepiquat chloride is 4.3-4.8 g.hm<-2> after topping is conducted; conducting water and fertilizer management and disease pest and weed prevention and control in a growing period. According to the cultivation method of the southern XinJiang film-free cotton, the cotton does not need to be covered with mulching film, and thus white pollution caused by the mulching film is prevented; the specific early-maturing upland cotton varieties are selected and adopted, by adding a proper amount of base fertilizer and with the assistance of chemical regulation and water and fertilizer management, sufficient nutrients are provided for all stages of growth of the cotton, later maturity, yield reduction and quality lowering caused by later sowing are overcome in the cultivated cotton, and thus the yield is steadily increased, and the quality is gradually improved.

Owner:INST OF COTTON RES CHINESE ACAD OF AGRI SCI

Peanut protein isolate and chitosan compounded fruit and vegetable packaging film

InactiveCN104610760AEasy to degradeStrong physical and mechanical propertiesFlexible coversWrappersPropolisEcological environment

The invention discloses a peanut protein isolate and chitosan compounded fruit and vegetable packaging film, and relates to the technical field of fruit and vegetable packaging films. The peanut protein isolate and chitosan compounded fruit and vegetable packaging film is prepared from raw materials in parts by mass as follows: 60-80 parts of peanut protein isolate, 40-50 parts of chitosan, 20-25 parts of sodium carboxymethyl cellulose, 15-20 parts of polyvinyl alcohol, 10-15 parts of propolis, 10-12 parts of sodium alginate, 10-12 parts of nano calcium carbonate, 8-10 parts of calcium citrate, 8-10 parts of fumed silica, 6-9 parts of agar, 5-8 parts of tea polyphenol, 5-8 parts of epoxidized soybean oil, 3-5 parts of genipin, 3-5 parts of polyglycerol fatty acid ester, 2-3 parts of plant essential oil and 800-1,000 parts of water. Peanut protein isolate and chitosan are taken as main raw materials and supplemented by a suitable auxiliary, so that the prepared packaging film has higher physical and mechanical property, selecting permeability and antioxidation; the selected raw materials are easy to degrade, so that the ecological environment is protected.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

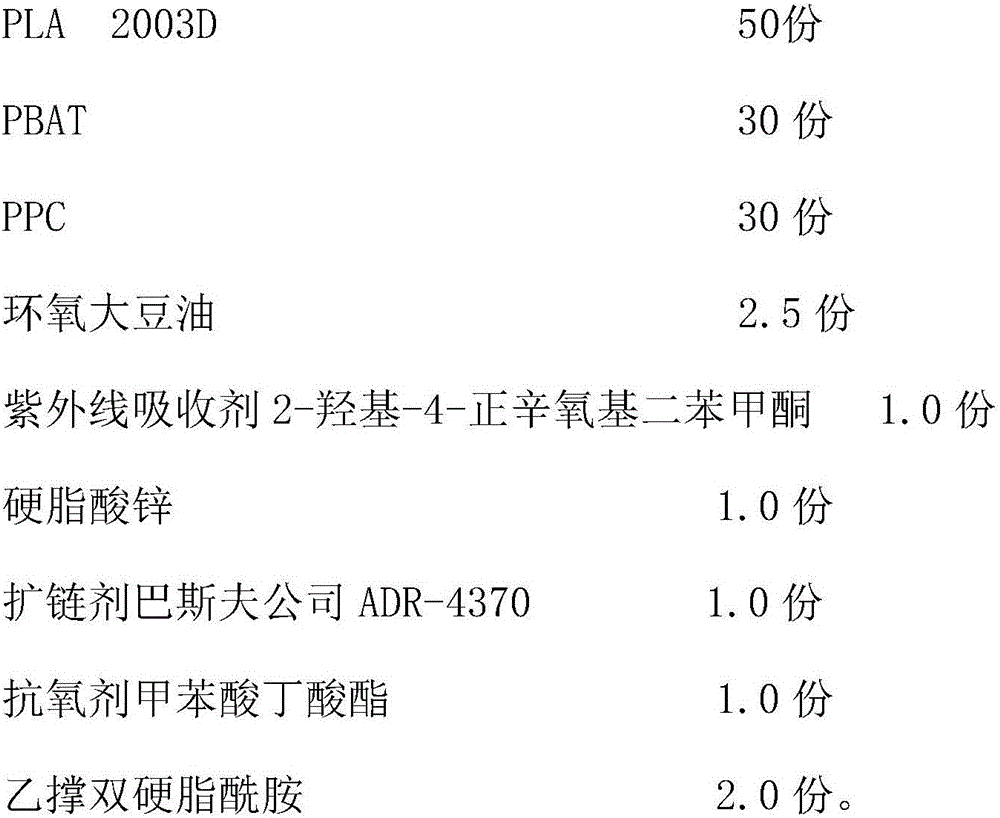

Three-layer co-extrusion full-biodegradable delivery packaging bag and preparation method thereof

InactiveCN109229812AFully biodegradableImprove mechanical propertiesBio-packagingBagsBlow moldingEngineering

The invention relates to a three-layer co-extrusion full-biodegradable delivery packaging bag and a preparation method thereof, and belongs to the field of high polymer materials. Raw material components of an inner layer, a middle layer and an outer layer are mixed to be uniform respectively according to the formula, master batches are prepared through a twin-screw extruding machine, and then a three-layer full-biodegradable film is prepared through a three-layer co-extrusion blow molding process. The film is subjected to the gluing, heat sealing and cutting procedures of a delivery packagingbag making machine, and the delivery packaging bag is prepared. The material formula good in opening performance and film forming performance is adopted on the middle layer and the inner layer, and the material formula good in mechanical performance and film forming performance is adopted on the middle layer and the outer layer. The delivery packaging bag has full biodegradability, has excellentmechanical performance, heat sealing performance and seal adhesive sealing performance and can replace a delivery packaging bag prepare from a non-biodegradable plastic PE film.

Owner:JILIN COFCO BIOCHEM

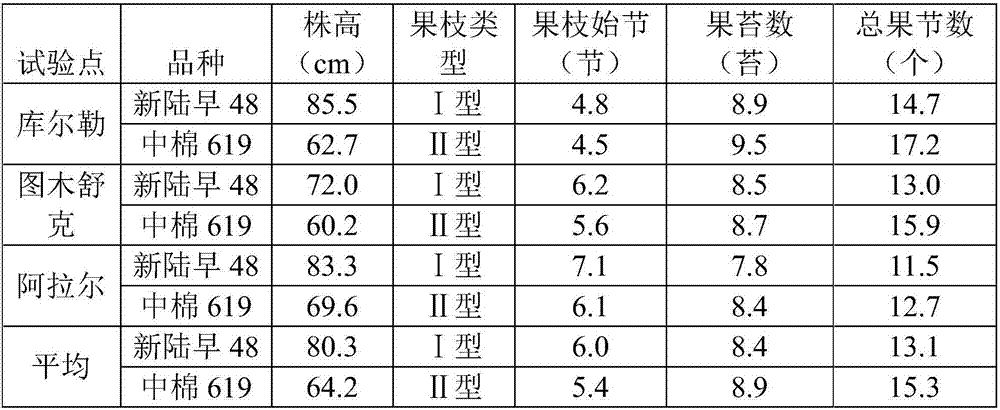

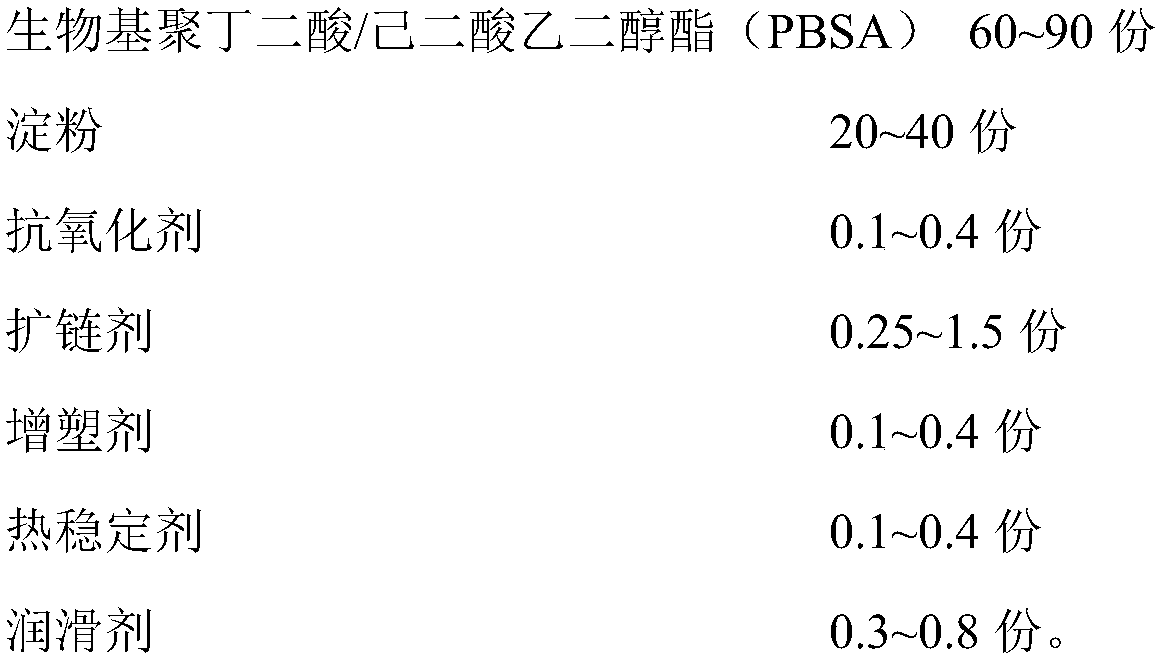

Starch modified full-biobased PBSA biodegradable plastics and preparation method therefor

The invention discloses starch modified full-biobased PBSA biodegradable plastics and a preparation method therefor. The preparation method comprises the steps: (1) providing full-biobased polybutylene succinate / adipate (PBSA); (2) subjecting the full-biobased PBSA and starch to vacuum drying separately; (3) adding the dried full-biobased PBSA, the dried starch, a chain extender, an antioxidant, aplasticizer, a lubricant and a thermal stabilizer into a high-speed mixer, and carrying out uniform mixing; (4) subjecting the obtained mixed material to extruded granulating by a twin-screw extruder; and (5) carrying out film blowing on the composite plastic granules at a certain temperature, thereby obtaining the starch modified full-biobased PBSA biodegradable plastics. According to the starchmodified full-biobased PBSA biodegradable plastics prepared by the method disclosed by the invention, after composite modification, the requirements on complete degradation are met, meanwhile, the mechanical properties of pure PBSA resin are enhanced, the production cost is reduced effectively, and thus, the marketing is better facilitated.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

High self-cleaning inorganic heat insulation composite system

InactiveCN102304965AImprove insulation effectImprove cohesionCovering/liningsClimate change adaptationInsulation layerEmissivity

The invention relates to a high self-cleaning inorganic heat insulation composite system comprising a substrate wall body, as well as interface mortar, a heat insulation layer, an anti-cracking protection layer and a veneer layer in sequence from the substrate wall body to the outside. The invention has the advantages of simple structure, comprehensive functions, favorable heat insulation effect, strong anti-cracking and shock resistance, obvious fireproof and antiflaming effect, favorable high temperature stability, high self-cleaning and the like. Anti-cracking mortar is selected for the anti-cracking protection layer and alkaline-resistant fiberglass gridding cloth or an AJ hot zinc-plating electrowelding net is arranged in the mortar, therefore, the anti-cracking and shock resistant effects are better; the polystyrene particles of the heat insulation layer are made from recycled polystyrene plates, therefore, the processing is simple, a large number of white pollution can be solved, and the heat insulation property of the material can be greatly improved due to excellent heat insulation property of the polystyrene particles per se; and an energy-saving coating material has the advantages of favorable visible light and near infrared light reflectivity, higher thermal infrared emissivity, excellent high temperature stability, high intensity, high temperature resistance, wear resistance, high tenacity, convenience for construction and cost saving.

Owner:青岛格尔美环保涂料有限公司

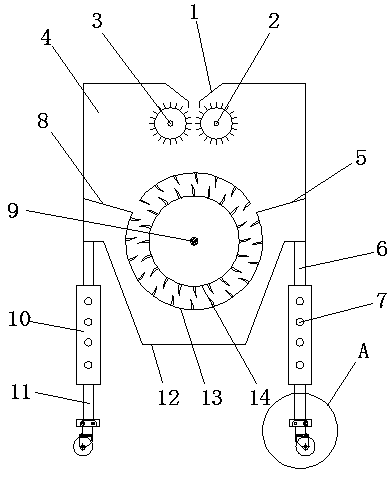

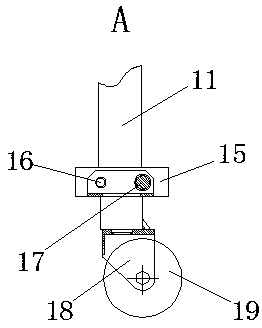

Movable lifting type plastic garbage crushing device

InactiveCN107599239ANovel structureWorking principle is clearPlastic recyclingGrain treatmentsMechanical engineeringPollution

The invention discloses a movable lifting type plastic garbage crushing device, and belongs to the technical field of garbage recycling equipment. The device comprises fixed supporting legs and a machine cover, wherein a sleeve is arranged on each fixed supporting leg in a sleeving mode; a movable supporting leg is arranged below each sleeve; a supporting block is arranged below each movable supporting leg; a wheel plate frame with a rolling wheel is arranged on each supporting block; a rotary drum cutter is arranged in the middle position of the interior of the machine cover; a fixed drum cutter is arranged on the outer side of the rotary drum cutter; left and right partition plates are arranged on the shell of the fixed drum cutter; left and right hobs are arranged above the fixed drum cutter; a feeding port is arranged above the left hob and the right hob; and a material collecting cylinder is arranged at the outer bottom end of the fixed drum cutter. The movable lifting type plastic garbage crushing device is novel in structure and clear in working principle, and compared with traditional waste plastic equipment, height adjustment can be carried out and mobile operation can becarried out, thus the crushing efficiency is improved, the development of the waste plastic recycling industry is promoted, prevention of the problem that the white pollution is intensified is facilitated, and the device has important significance on the environment protection.

Owner:江都区众扬物资经营部

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com