Biodegradable composite oxygen-barrier film and use thereof

A technology of oxygen barrier and barrier layer, which is applied in the field of biodegradable composite oxygen barrier film and its application, can solve the problems such as inappropriate preparation of fully biodegradable oxygen barrier film, and achieve the goals of preventing white pollution, prolonging shelf life and improving physical and mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

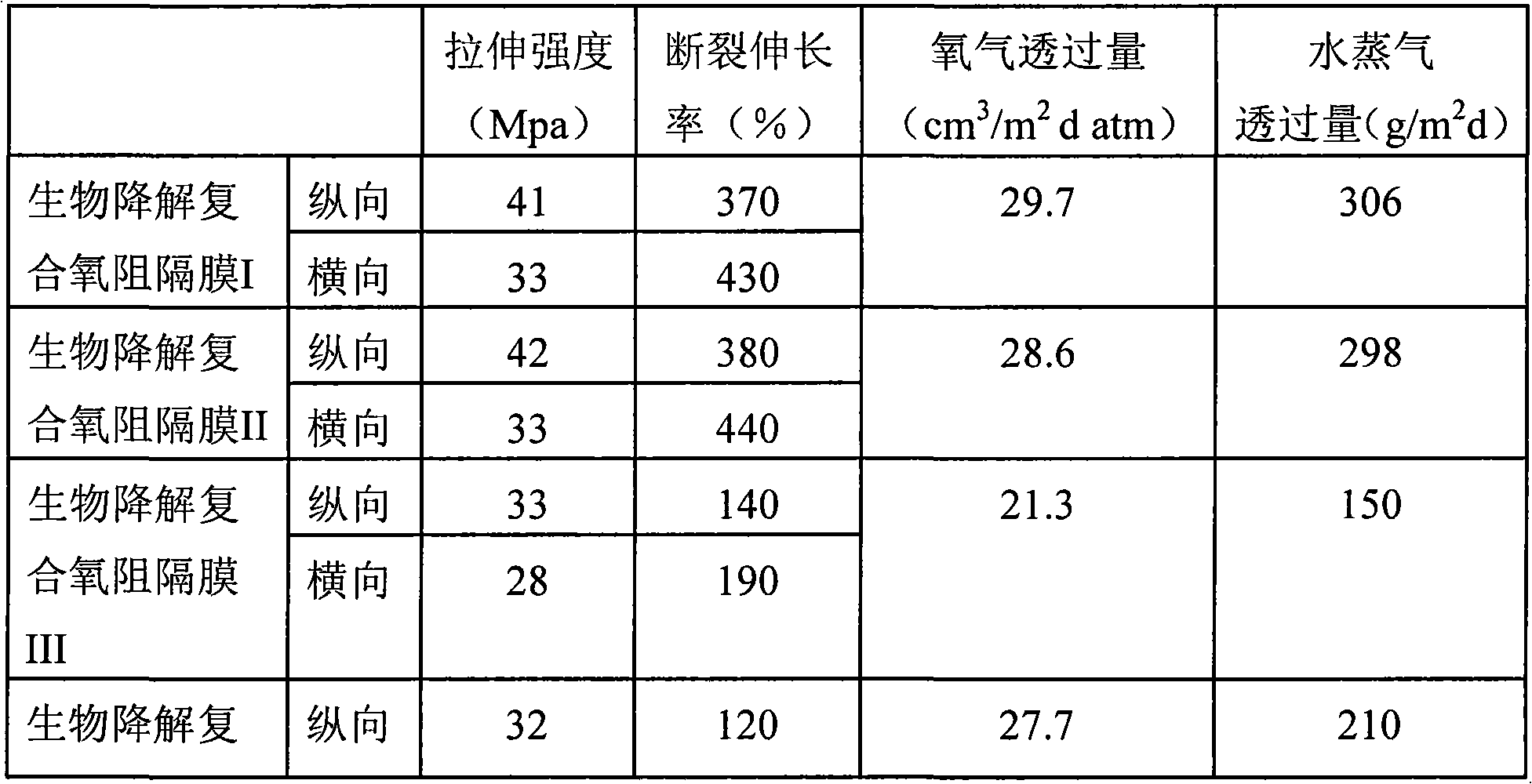

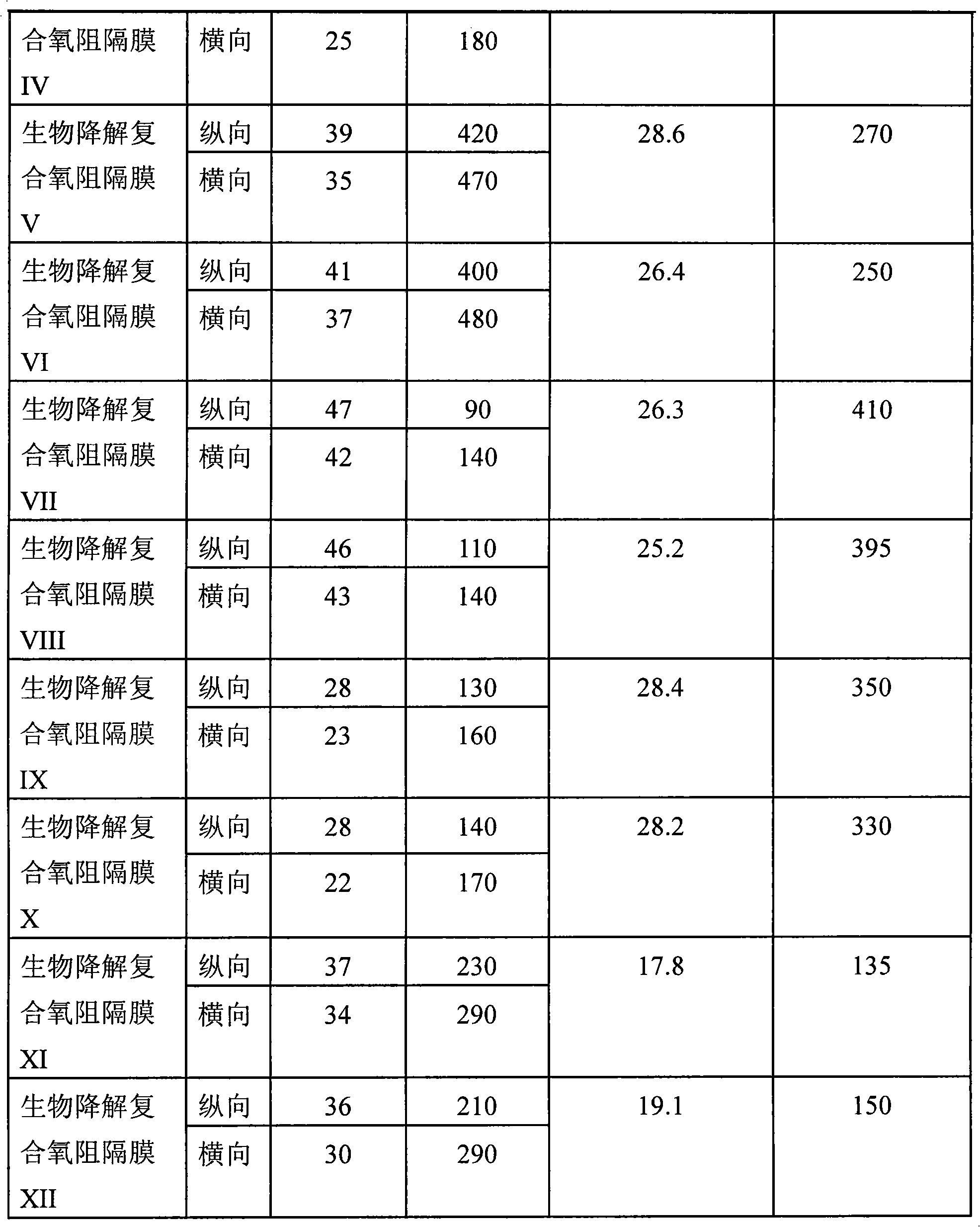

Examples

Embodiment 1

[0022] Embodiment 1, preparation biodegradable composite oxygen barrier film

[0023] 1) Preparation of biodegradable composite oxygen barrier film I

[0024]Polybutylene adipate-terephthalate (number-average molecular weight is 40000g / mol, molecular weight distribution is 2.5) 20kg, polycarbonate 1,2-propylene glycol (number-average molecular weight is 80000g / mol, molecular weight distribution 2.5) 20kg, polybutylene adipate-terephthalate 20kg (the number average molecular weight is 40000g / mol, and the molecular weight distribution is 2.5) as outer, middle and inner layer input in common three-layer single-screw film blowing unit, The temperature of the three sections of the inner and outer screw is 140°C, 160°C and 170°C, the temperature of the middle layer is 100°C, 140°C and 140°C, and the head temperature is 165°C. Simultaneously start three extruding units to prepare biodegradable composite oxygen barrier film I. Biodegradable composite oxygen barrier film I is a compos...

Embodiment 2

[0030] Embodiment 2, preparation biodegradable composite oxygen barrier film

[0031] 1) Preparation of Biodegradable Composite Oxygen Barrier Film III

[0032] Respectively polylactic acid (PLA) (number average molecular weight is 80000g / mol, and molecular weight distribution is 2.0) 30kg, nanometer montmorillonite modified polycarbonate 1,2-propanedicarbonate I 30kg and polybutylene succinate (number average The molecular weight is 60000, and the molecular weight distribution is 2.0) 15kg are respectively used as the outer, middle and inner layers, and put into the ordinary three-layer single-screw blown film unit. The temperature is: 100°C, 140°C and 140°C, and the head temperature is 165°C. Simultaneously start three extruding units to prepare the biodegradable composite oxygen barrier film III, the biodegradable composite oxygen barrier film III is a composite film composed of three layers of films, from bottom to top followed by polylactic acid (PLA) (number average mol...

Embodiment 3

[0037] Embodiment 3, preparation biodegradable composite oxygen barrier film

[0038] 1) Preparation of biodegradable composite oxygen barrier film V

[0039] Respectively polybutylene succinate (number average molecular weight is 60000, molecular weight distribution is 2.0) 20kg, polycaprolactone (number average molecular weight is 85000, molecular weight distribution is 1.8) 10kg, polycarbonate 1,2-propylene glycol (number average molecular weight is 80000g / mol, molecular weight distribution is 2.5) 40kg, polycaprolactone (number average molecular weight is 85000, molecular weight distribution is 1.8) 10kg and polybutylene succinate (number average molecular weight is 60000, molecular weight distribution 2.0) 20kg is put into the five-layer single-screw co-extrusion film blowing unit from the outside to the inside, in which the temperature of the three-stage screw of the material polybutylene succinate is: 140 ° C, 160 ° C and 170 ° C, the material polybutylene succinate Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com