Method for preparing conductive plastics taking recovered plastics as matrix

A technology for conducting plastics and recycling plastics, applied in the field of polymer material processing, can solve problems such as the decline of mechanical properties and toughness, and achieve the effects of easy processing and molding, cost saving, and good dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

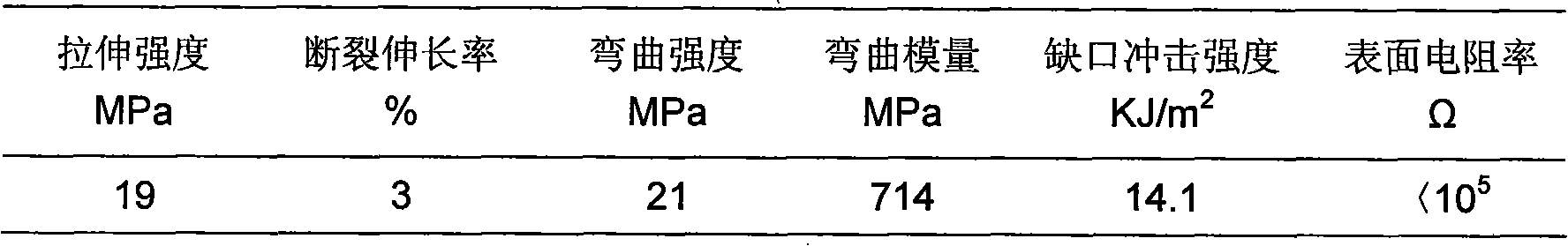

Embodiment 1

[0030] Take 25Kg of recovered PP particles, 4Kg of conductive carbon black, 1Kg of dispersant (3# white oil, molecular weight 250-450, flash point 90°C), 0.15Kg of tetrabutyl orthotitanate (titanate coupling agent), antioxidant Agent 1680.1Kg; recovered PP particles were vacuum dried at 107°C for 2 hours, and carbon black was vacuum dried at 105°C for 5 hours;

[0031] Put the conductive carbon black into the high-speed mixer, then use the atomizer to atomize the titanate coupling agent and dispersing oil into the high-speed mixer, stir at 100°C at high speed; mix for 15 minutes; under the condition of high-speed stirring Add recycled PP particles and stir at high speed for 10 minutes to mix evenly, and then extrude, granulate, and inject the mixed materials through a twin-screw extruder. The dispersant can be recycled after devolatilization.

[0032] The TSE-65D co-rotating twin-screw extruder is used for granulation. The temperature of the first zone of the twin-screw extru...

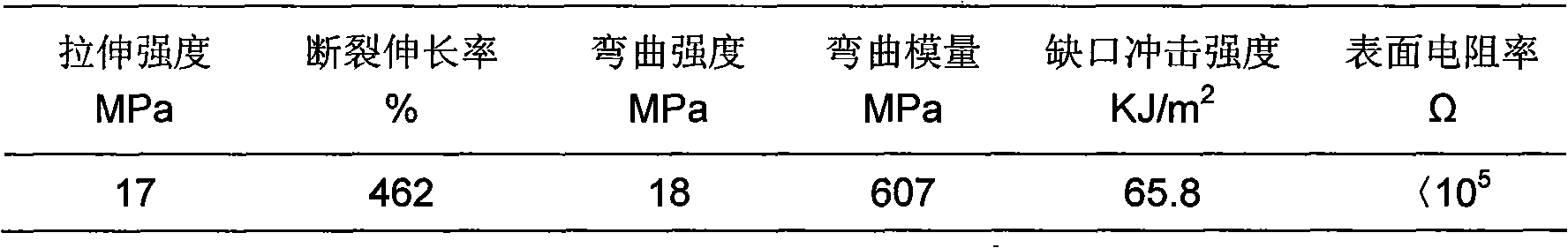

Embodiment 2

[0036] Take 26Kg of recovered PE particles, 3Kg of conductive carbon black, 1Kg of dispersant (3# white oil, molecular weight 250-450, flash point 90°C), 0.15Kg of quaternary ammonium titanate (titanate coupling agent), antioxidant Agent 10100.1Kg; recovered PP was vacuum dried at 107°C for 2 hours, conductive carbon black was vacuum dried at 105°C for 5 hours;

[0037] Put the conductive carbon black into the high-speed mixer, then use the atomizer to atomize the titanate coupling agent and dispersing oil into the high-speed mixer, stir at 100°C at high speed; mix for 20 minutes; under the condition of high-speed stirring Then add recycled PE particles and stir at high speed for 10 minutes to mix evenly, and then extrude, granulate, and inject the mixed materials through a twin-screw extruder. The dispersant can be recycled after devolatilization.

[0038]TSE-65D co-rotating twin-screw extruder is used for granulation. The temperature of the first zone of the twin-screw extr...

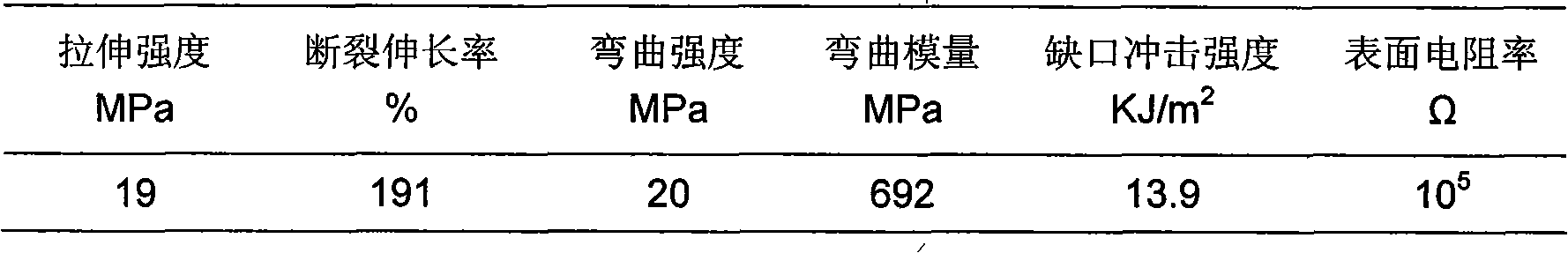

Embodiment 3

[0042] Take 10.8Kg of recovered PE particles, 16.2Kg of recovered PP particles, 2.4Kg of conductive carbon black, 0.6Kg of dispersant (polyethylene wax with a molecular weight of 1000-4000), 0.1Kg of tetraisopropyl titanate (titanate coupling agent) Kg, each 0.05Kg of antioxidant 168 and antioxidant 1010; the recovered PE and PP particles were dried in vacuum at 100°C for 2 hours, and the conductive carbon black was dried in vacuum at 105°C for 5 hours;

[0043] Put the conductive carbon black into the high-speed mixer, and then use an atomizer to atomize the titanate coupling agent and dispersing oil into the high-speed mixer, stir at 100°C at high speed; mix for 30 minutes; under the condition of high-speed stirring Add recycled PE particles at the bottom, stir at high speed for 15 minutes to mix evenly, and extrude, granulate and inject the mixed materials through a twin-screw extruder.

[0044] The TSE-65D co-rotating twin-screw extruder is used for granulation. The temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com