Cultivation method of southern XinJiang film-free cotton

A cultivation method and cotton technology, applied in fertilization methods, botanical equipment and methods, horticulture, etc., can solve the problems of further improvement in yield and low cotton yield, and achieve the goal of overcoming late-maturity reduction in yield and quality, and steady improvement in yield and quality. The effect of pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

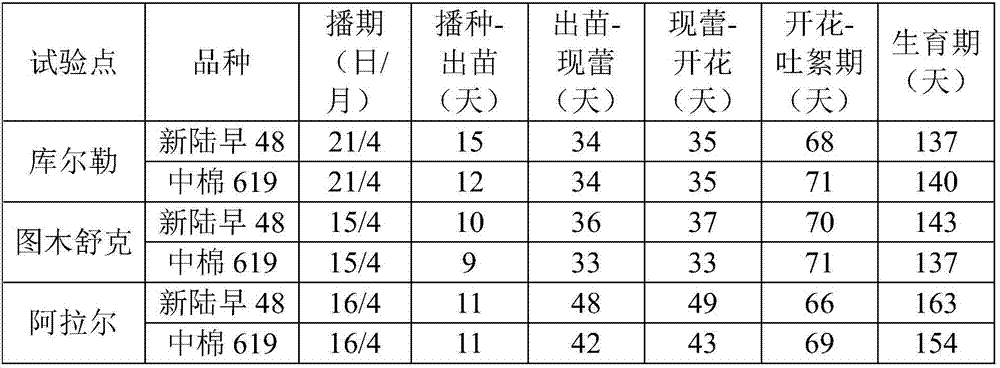

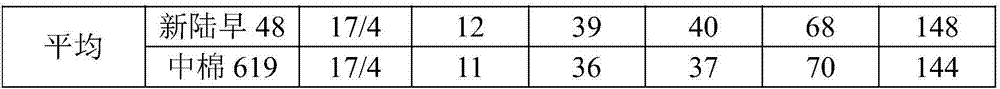

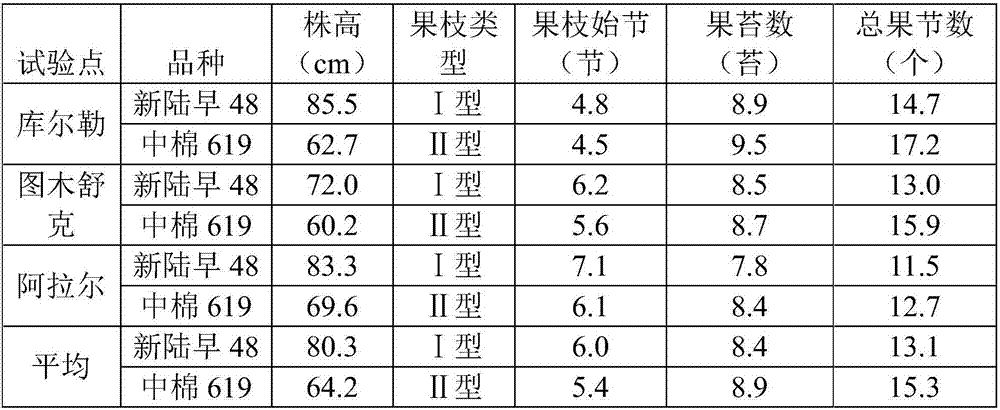

[0041] The three experimental sites are located at the Alar Comprehensive Experimental Station of the National Cotton Industry Technology System, the Tumushuk Yarkand River Comprehensive Experimental Station, and the Korla Kongque River Comprehensive Experimental Station. The Agricultural Science Research Institute of the Third Division of the Corps and the experimental field of the Xinjiang Bazhou Agricultural Science Institute.

[0042] The tested varieties were the short-season cotton early-maturing variety Zhongmian 619 provided by the Early-maturing Research Group of the Cotton Research Institute of the Chinese Academy of Agricultural Sciences, and the early-maturing cotton variety Xinluzao 48 introduced from northern Xinjiang. The test plot was repeated three times, with a total of 6 plots. Each plot had two sowing widths of 36 rows, a row length of 50m, a plot area of 1 mu, and a planting density of 252,000 plants·hm -2 . Other production conditions are the same as f...

Embodiment 2

[0082] Daejeon of Tumu Shuke, the test point. The tested varieties are Zhongmian 619 and Xinluzao 48. Each address is planted with 10 mu of each variety, and the planting density is set to 240,000 plants·hm -2 . Other production conditions are the same as field production.

[0083] 1. Specific steps of the test

[0084] 1.1 Land preparation

[0085] The test field is irrigated in winter and spring, the soil is loamy, the soil salt content is less than or equal to 3g / Kg, and the base fertilizer is applied to the plowed field (three materials phosphorus 58kg hm -2 , urea 145kg·hm -2 , Potassium sulfate 220kg·hm -2 , organic fertilizer 2800kg·hm -2 right). Fine ground preparation.

[0086] 1.2 Seed treatment

[0087] Seed drying, artificial seed selection, and seed dressing with seed coating agent.

[0088] 1.3 sowing date

[0089] Test the moisture content of the soil (volume moisture content within the range of 15% to 25%) and sow seeds. When the moisture content is ...

Embodiment 3

[0109] Daejeon in Aral, the experimental point. The tested varieties are Zhongmian 619 and Xinluzao 48. Each address is planted with 10 mu of each variety, and the planting density is set at 255,000 plants·hm -2 . Other production conditions are the same as field production.

[0110] 1. Specific steps of the test

[0111] 1.1 Land preparation

[0112] The test field is irrigated in winter and spring, the soil is loamy, the soil salinity is ≤3g / Kg, and the base fertilizer (three-material phosphorus 85kg hm -2 , Urea 155kg·hm -2 , Potassium sulfate 230kg·hm -2 , organic fertilizer 3200kg·hm -2 right). Fine ground preparation.

[0113] 1.2 Seed treatment

[0114] Seed drying, artificial seed selection, and seed dressing with seed coating agent.

[0115] 1.3 sowing date

[0116] Test the moisture content of the soil (volume moisture content within the range of 15% to 25%) and sow seeds. When the moisture content is insufficient, drip water in time to replenish moisture....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com