High-barrier-property biodegradable mulching film and preparation method thereof

A technology of degrading mulch film and high barrier property, applied in the field of polymer materials, can solve problems such as insufficient tensile strength and water retention performance, and achieve the effects of easy industrialization, high production efficiency, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

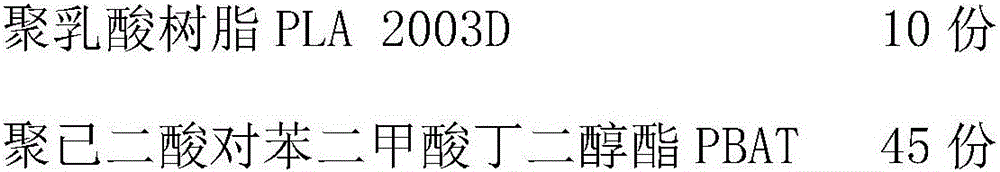

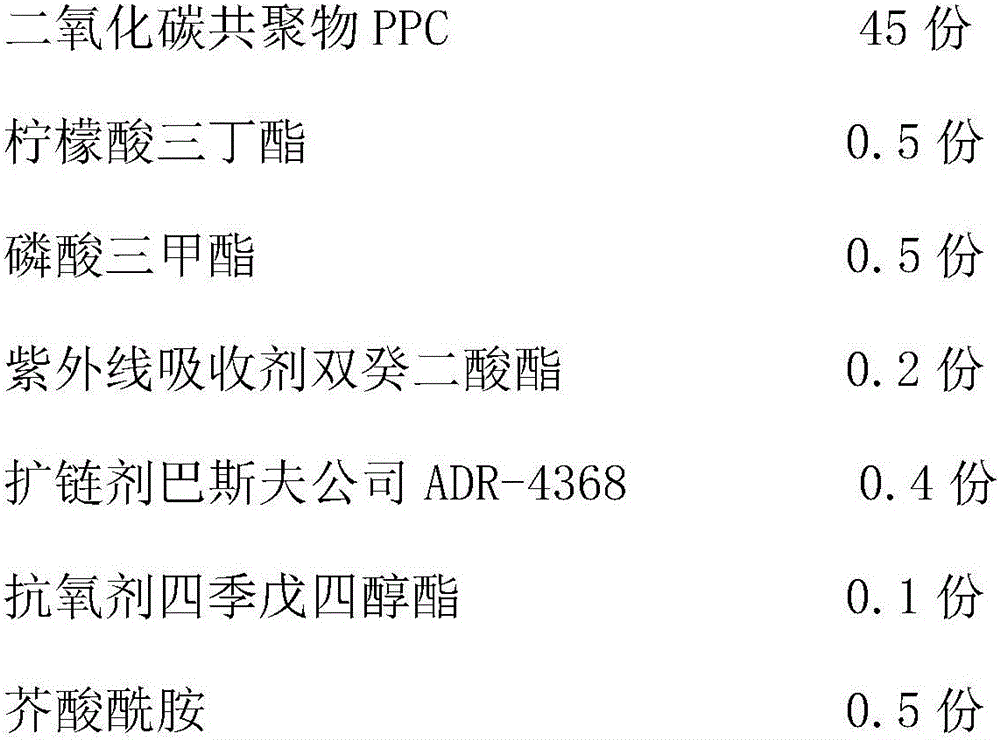

[0030] It is made from the following raw materials in parts by weight:

[0031]

[0032]

[0033] (1) earlier polylactic acid resin PLA, polybutylene adipate terephthalate PBAT, polypropylene carbonate resin PPC are mixed with a low-speed mixer, crystallized and dried to prepare mixture 1; Add ultraviolet absorber bis-sebacate, chain extender ADR-4368, antioxidant tetraerythritol ester, and erucamide into the feeder for stirring and mixing, and then mixture 2 can be obtained; finally, mixtures 1 and 2 are added to Melting and blending in the twin-screw extruder, the temperature in each zone of the twin-screw granulation system is 160°C, 200°C, 200°C, 200°C, 200°C, 195°C, 195°C, 195°C, 195°C, 180°C, 170°C, 170°C, after underwater pelletizing, dehydration, and screening to obtain granular resin composite materials, dry at 50°C to remove excess water, and the selected twin-screw extruder has a screw length-to-diameter ratio of 50:1. Keep airtight to prevent moisture;

[0...

Embodiment 2

[0037] Made from the following raw materials in parts by weight:

[0038]

[0039] (1) earlier polylactic acid resin PLA, polybutylene adipate terephthalate PBAT, polypropylene carbonate resin PPC are mixed with a low-speed mixer, crystallized and dried to prepare mixture 1; Add ultraviolet absorber bis-sebacate, chain extender ADR-4368, antioxidant tetraerythritol ester, and erucamide into the feeder for stirring and mixing, and then mixture 2 can be obtained; finally, mixtures 1 and 2 are added to Melting and blending in the twin-screw extruder, the temperature in each zone of the twin-screw granulation system is 160°C, 200°C, 200°C, 200°C, 200°C, 195°C, 195°C, 195°C, 195°C, 180°C, 170°C, 170°C, after underwater pelletizing, dehydration, and screening to obtain granular resin composite materials, dry at 55°C to remove excess water, and the selected twin-screw extruder has a screw length-to-diameter ratio of 50:1. Keep airtight to prevent moisture;

[0040] (2) Film blow...

Embodiment 3

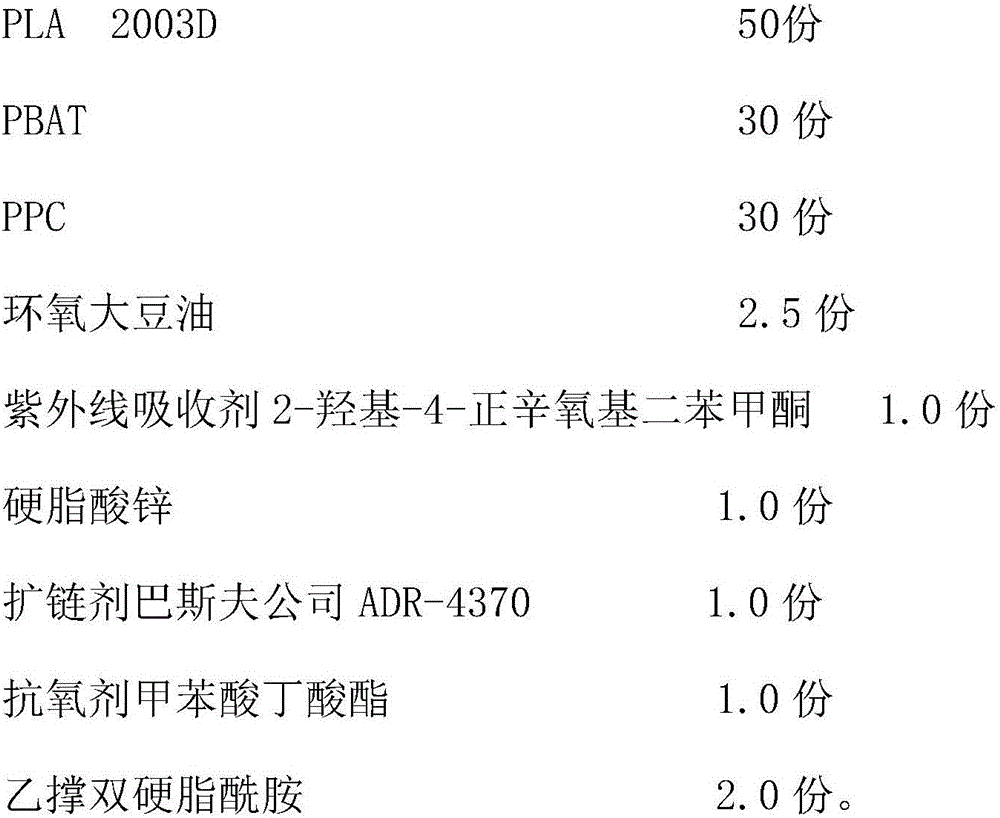

[0043] Made from the following ingredients by weight:

[0044]

[0045](1) earlier polylactic acid resin PLA, polybutylene adipate terephthalate PBAT, polypropylene carbonate resin PPC are mixed with a low-speed mixer, crystallized and dried to prepare mixture 1; Add ultraviolet absorber bis-sebacate, chain extender ADR-4368, antioxidant tetraerythritol ester, and erucamide into the feeder for stirring and mixing, and then mixture 2 can be obtained; finally, mixtures 1 and 2 are added to Melting and blending in the twin-screw extruder, the temperature in each zone of the twin-screw granulation system is 160°C, 200°C, 200°C, 200°C, 200°C, 195°C, 195°C, 195°C, 195°C, 180°C, 170°C, 170°C, after underwater pelletizing, dehydration, and screening to obtain granular resin composite materials, dry at 60°C to remove excess water, and the selected twin-screw extruder has a screw length-to-diameter ratio of 50:1. Keep airtight to prevent moisture;

[0046] (2) Film blowing: film bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com