Method for preparing solid bricks from solid wastes generated by zinc hydrometallurgy

A technology of hydrometallurgy and solid waste, which is applied in the field of preparation of building materials, can solve the problems of environmental pollution, alum slag and sewage treatment sludge resource utilization, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

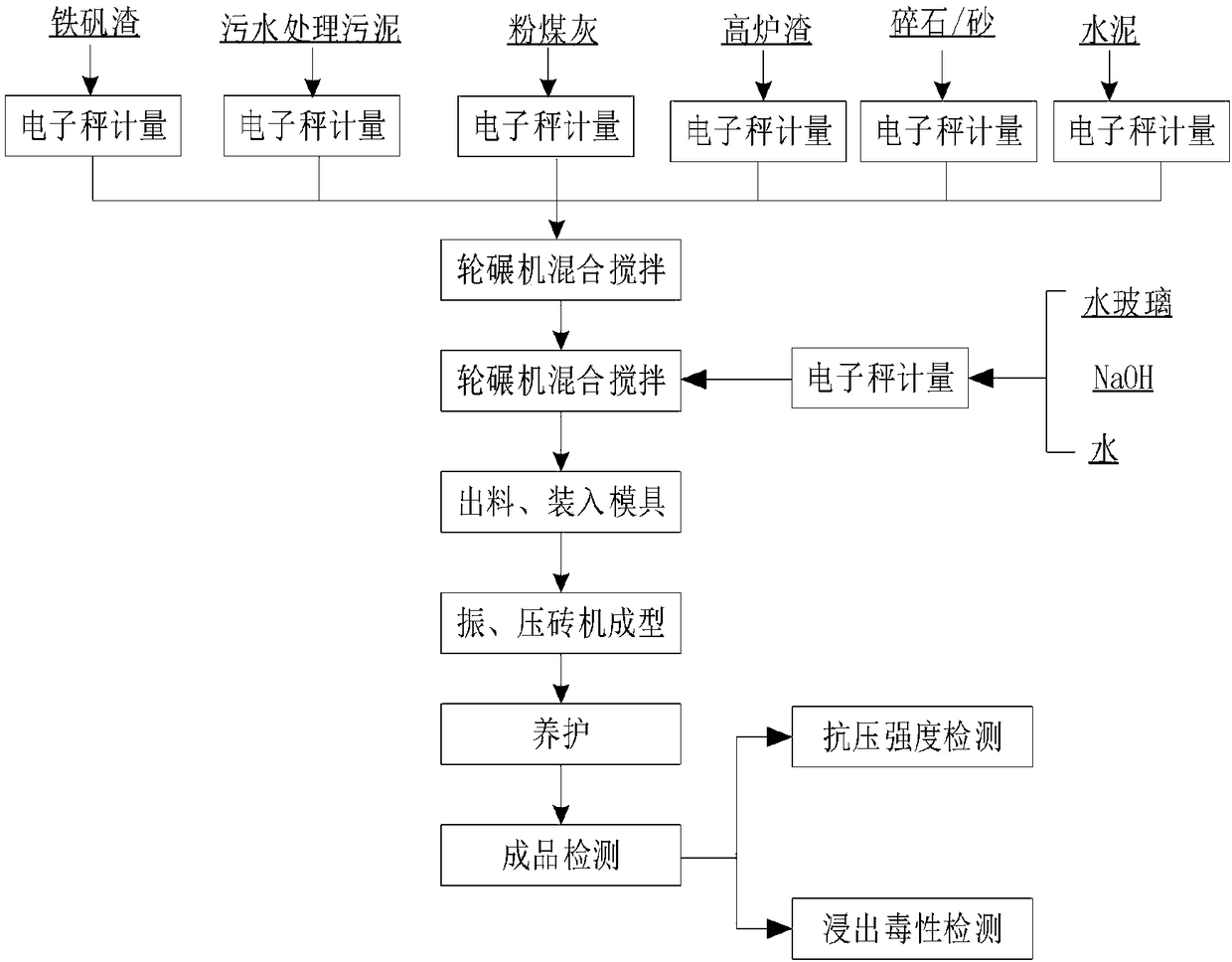

[0047] In order to further describe the present invention, a method for preparing solid bricks from solid waste produced by hydrometallurgy of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0048] The raw material of the project mainly comes from the ferrite slag produced in the system leaching process of the wet zinc smelting plant of a non-ferrous metal group, with an annual slag volume of 40,000t. The main components of the alum slag are shown in Table 1:

[0049] Table 1 List of Main Components of Auxinite Slag / %

[0050] name

SO 3

Fe 2 o 3

SiO 2

ZnO

al 2 o 3

As 2 o 3

MgO

Na 2 o

CuO

CaO

Alum slag

38.9

31.2

13.1

10.4

2.51

1.09

0.83

0.44

0.33

0.33

name

MnO

TiO 2

PbO

P 2 o 5

SrO

Cl

Sb 2 o 3

Ga 2 o 3

Cr 2 o 3

K 2 o

Alum slag

0.29...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com