Patents

Literature

195results about How to "Reduce leaching toxicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method of arsenic slag

InactiveCN102218428AReduce leaching toxicityImprove long-term stabilitySolid waste disposalSlagFly ash

The invention discloses a treatment method of arsenic slag. The method is characterized by comprises the following steps: (1) adding fly ash and water in the arsenic slag, and stirring for 0.25-1 hour; (2) adding a stabilizing agent in the mixture obtained from the step (2), and stirring for 0.25-1 hour; (3) adding a curing agent in the mixture obtained from the step (3), and stirring for 0.25-1 hour; and (4) curing the mixture obtained from the step (3) for 1-7 days. According to the invention, the leaching toxity of the arsenic slag can be reduced to the admission requirement of a dangerous and waste landfill site, also the fly ash can be treated to achieve the aim of treating waste by the use of waste; and the method provided by the invention has simple process, the material is easy to obtain, the treatment cost is low, and the method has a favorable application prospect.

Owner:杭州大地环保有限公司

Curing agent for heavy metal contaminated soil restoration and heavy metal contaminated soil restoration method

InactiveCN102876330ASolidified heavy metalReduce leaching toxicityContaminated soil reclamationOrganic fertilisersContaminated soilsChemical bond

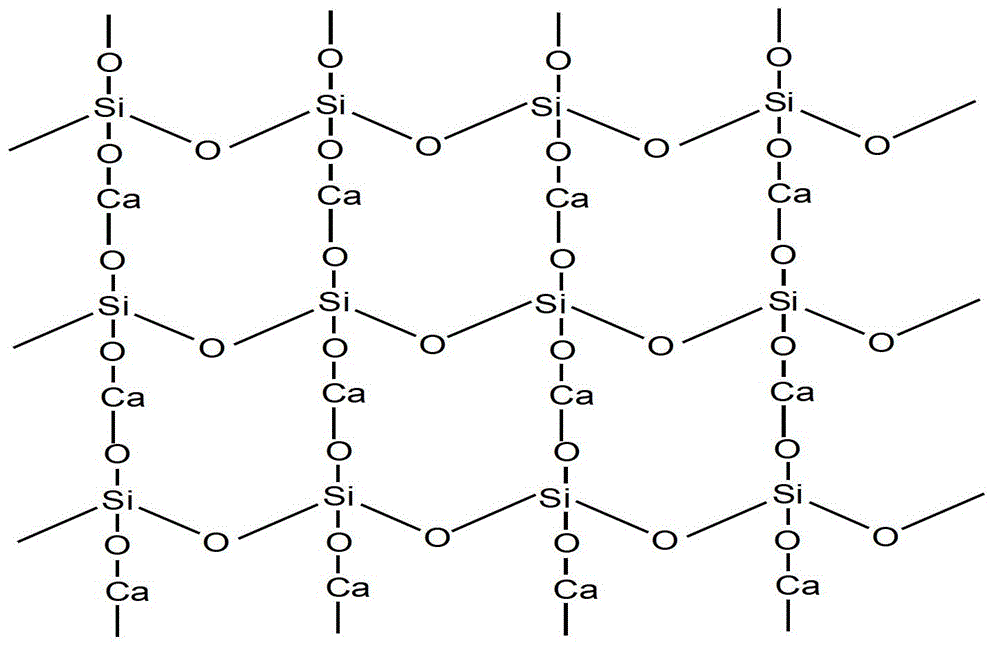

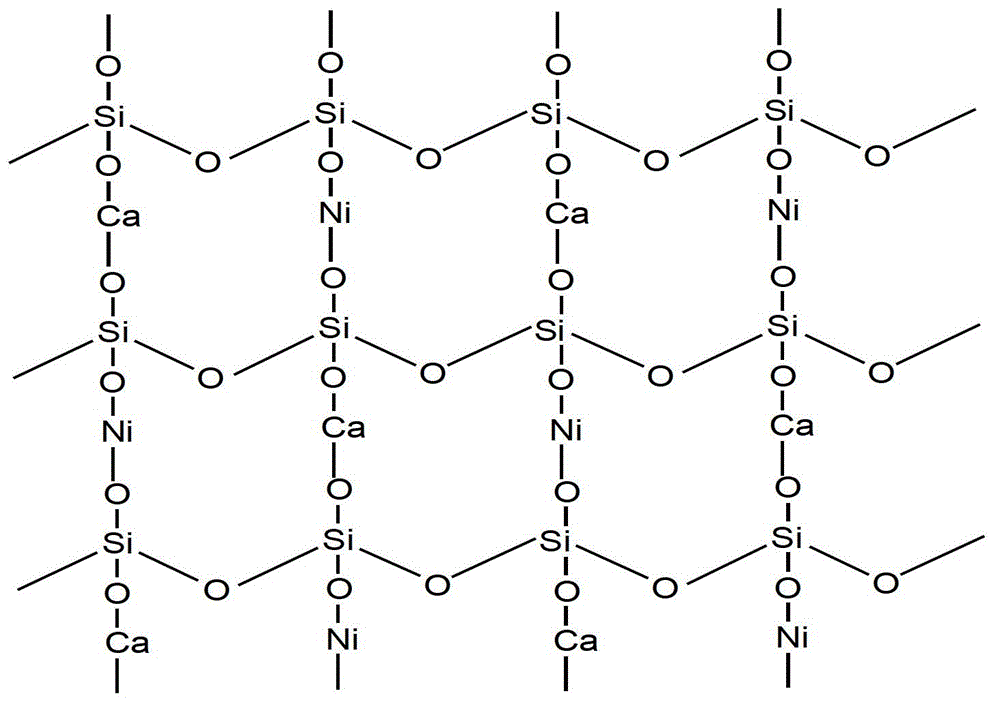

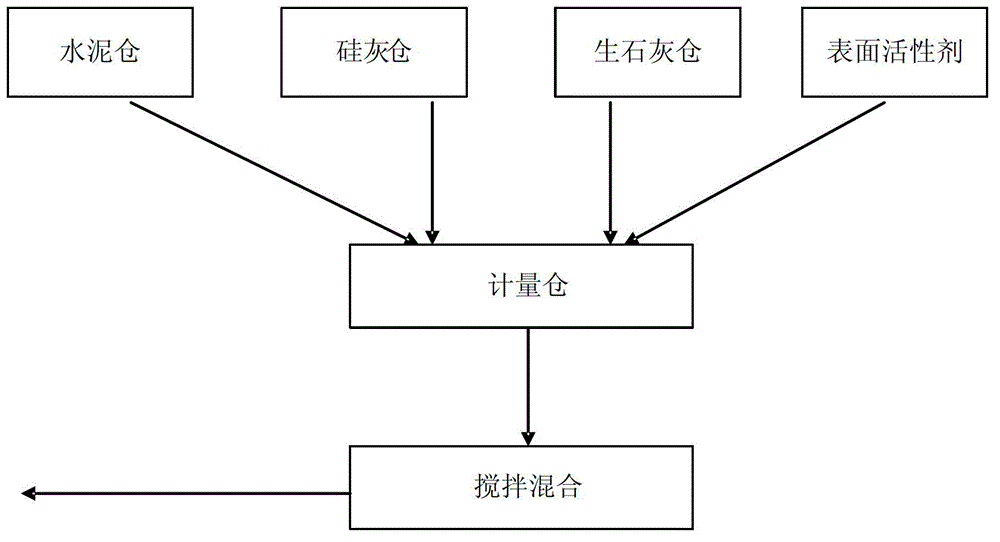

The invention discloses a curing agent for heavy metal contaminated soil restoration and a heavy metal contaminated soil restoration method. The curing agent for the heavy metal contaminated soil restoration comprises sulphoaluminate cement, and composition containing active silica and quick lime can be further added in the curing agent. After the sulphoaluminate cement is mixed with soil contaminated by heavy metal, firstly calcium sulphoaluminate in the sulphoaluminate cement is reacted with water to form monosulfate calcium hydroaluminosulfate, then heavy metal compound chemical bond is broken, heavy metal and atoms in ettringite are subjected to recombination of the chemical bond, metal atoms are constrained in a crystal lattice in space and not prone to be precipitated, thereby the purpose of curing heavy metal can be achieved, and the leaching toxicity of the heavy metal is reduced. A test proves that an obvious restorative effect can be achieved after the sulphoaluminate cement is used for 24 hours, namely after restoration, the soil leaching concentration is reduced and maintained within specified requirements, and the heavy metal can be effectively cured.

Owner:BEIJING CHINA SCI GENERAL ENERGY & ENVIRONMENT CO LTD

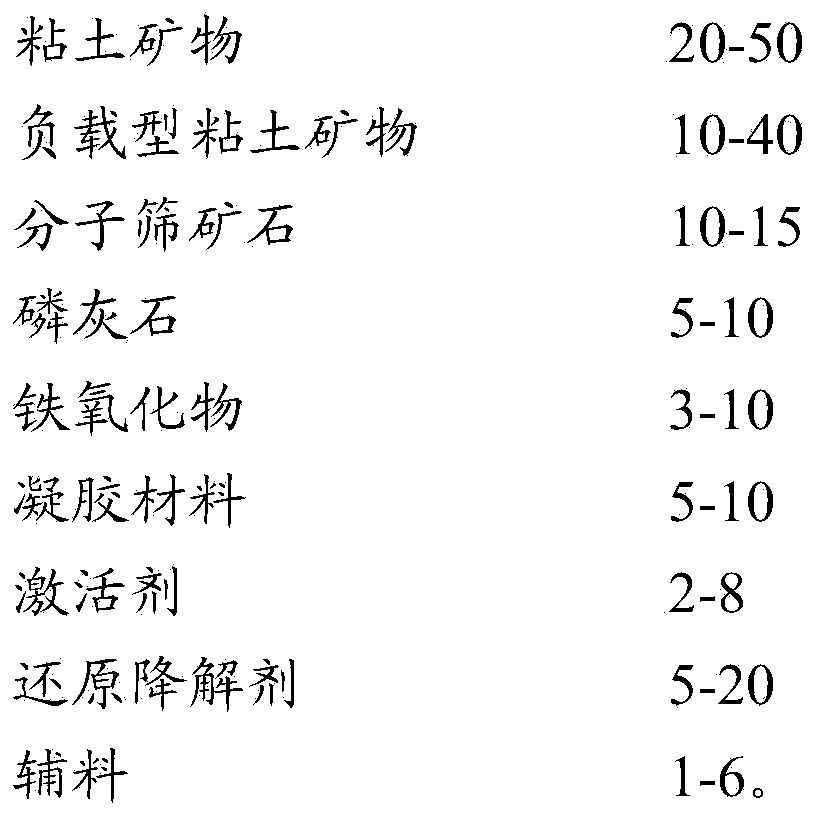

Reductive degradable stabilizer of polluted soil, bottom mud and sludge as well as preparation method and using method of stabilizer

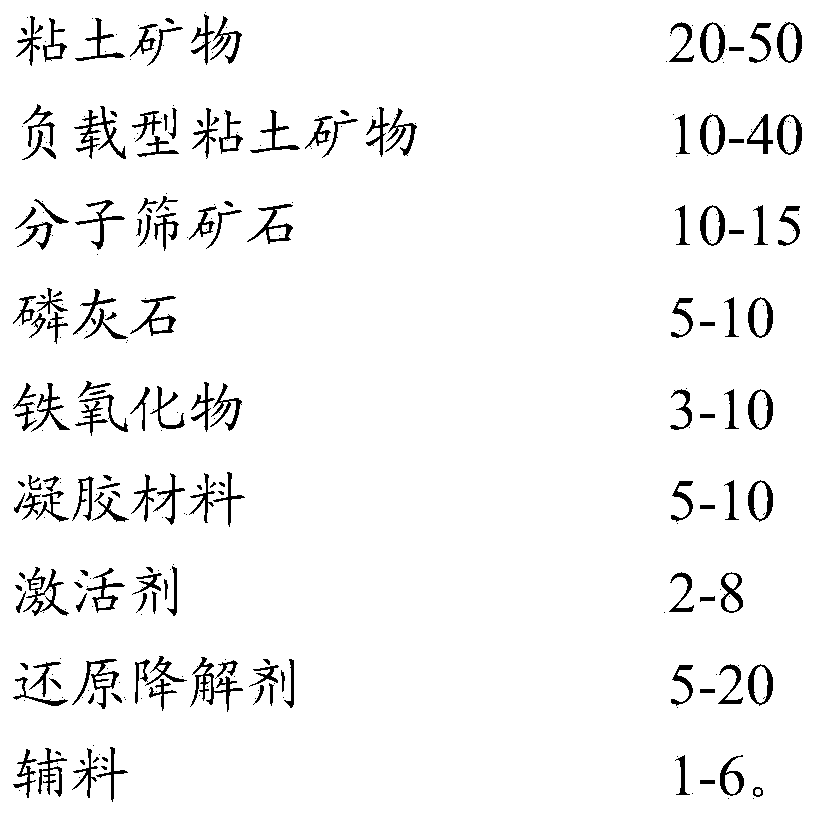

ActiveCN103436265AAchieve partial reductionReduce sizeContaminated soil reclamationOrganic fertilisersHealth riskSludge

The invention relates to a reductive degradable stabilizer for heavy metal and / or organic matter polluted soil as well as a preparation method and use of the stabilizer. The reductive degradable stabilizer can be used for quickly and efficiently stabilizing the heavy metals and the organic matters in the polluted soil by virtue of a synergistic effect of a plurality of active ingredients, and can also be used for further lowering the content of the organic matters, so that the purpose of lowering leaching toxicity of pollutants and health risk is realized; therefore, the reductive degradable stabilizer is a novel and efficient stabilizer which has the advantages of being wide in treatment substrate, capable of reducing the total amount of the organic matters, good in stabilizing effect, convenient to operate and the like, and has a wide range of application in the governance fields including polluted soil, bottom mud, sludge and the like.

Owner:付融冰

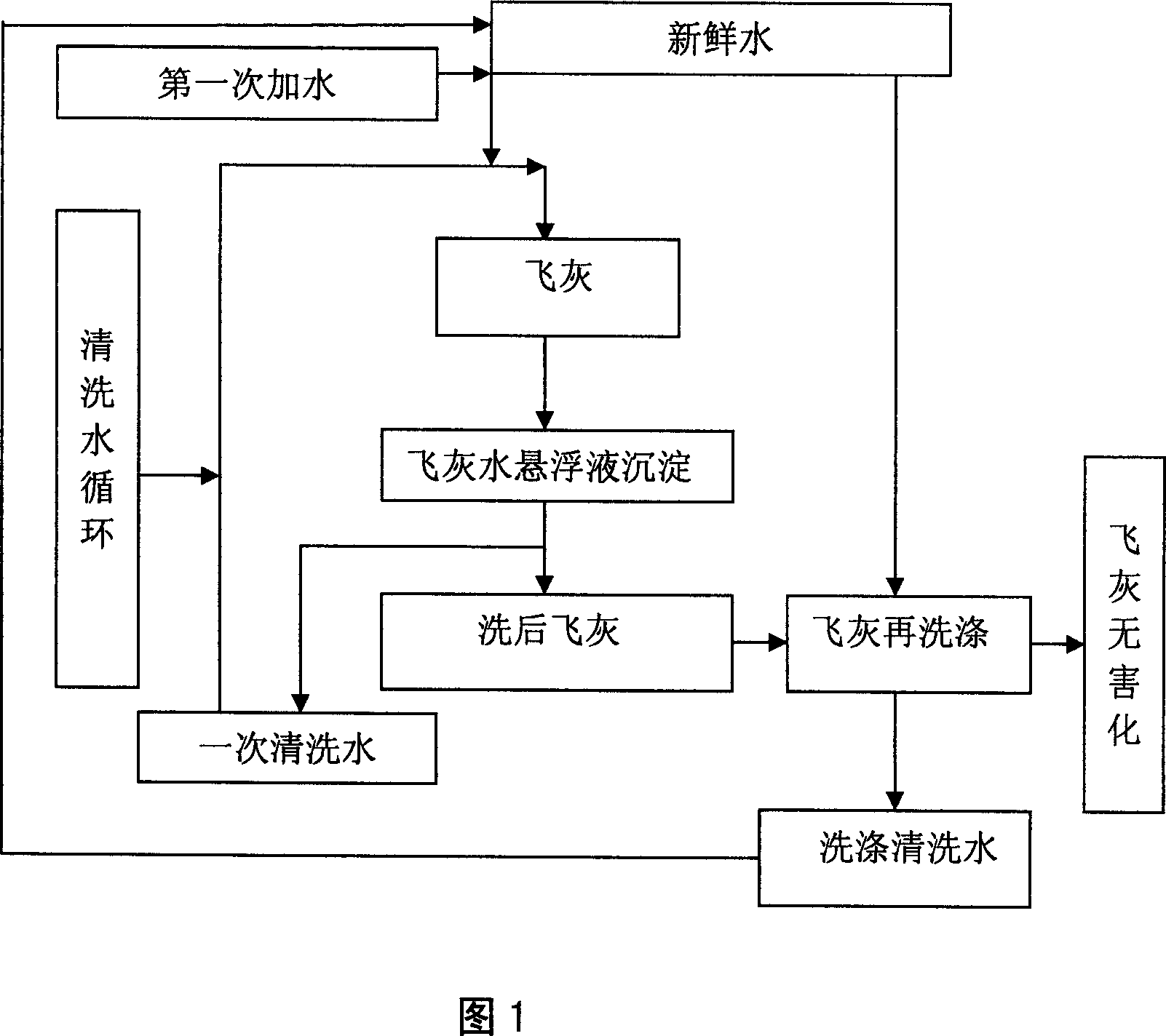

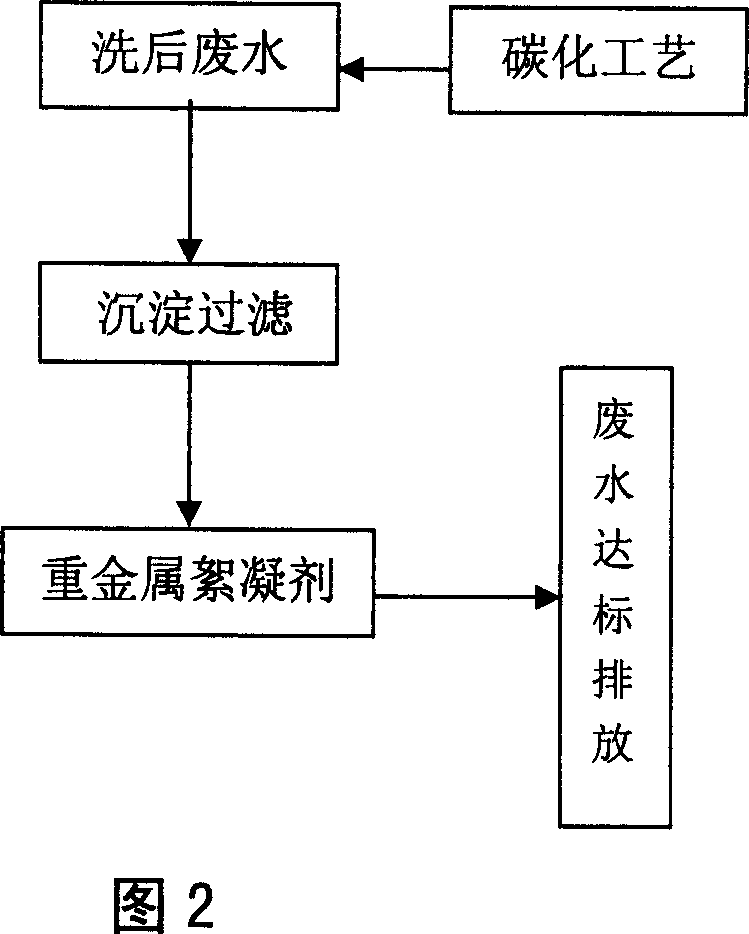

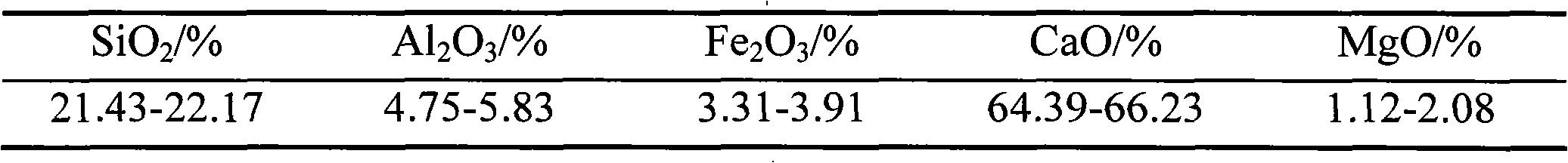

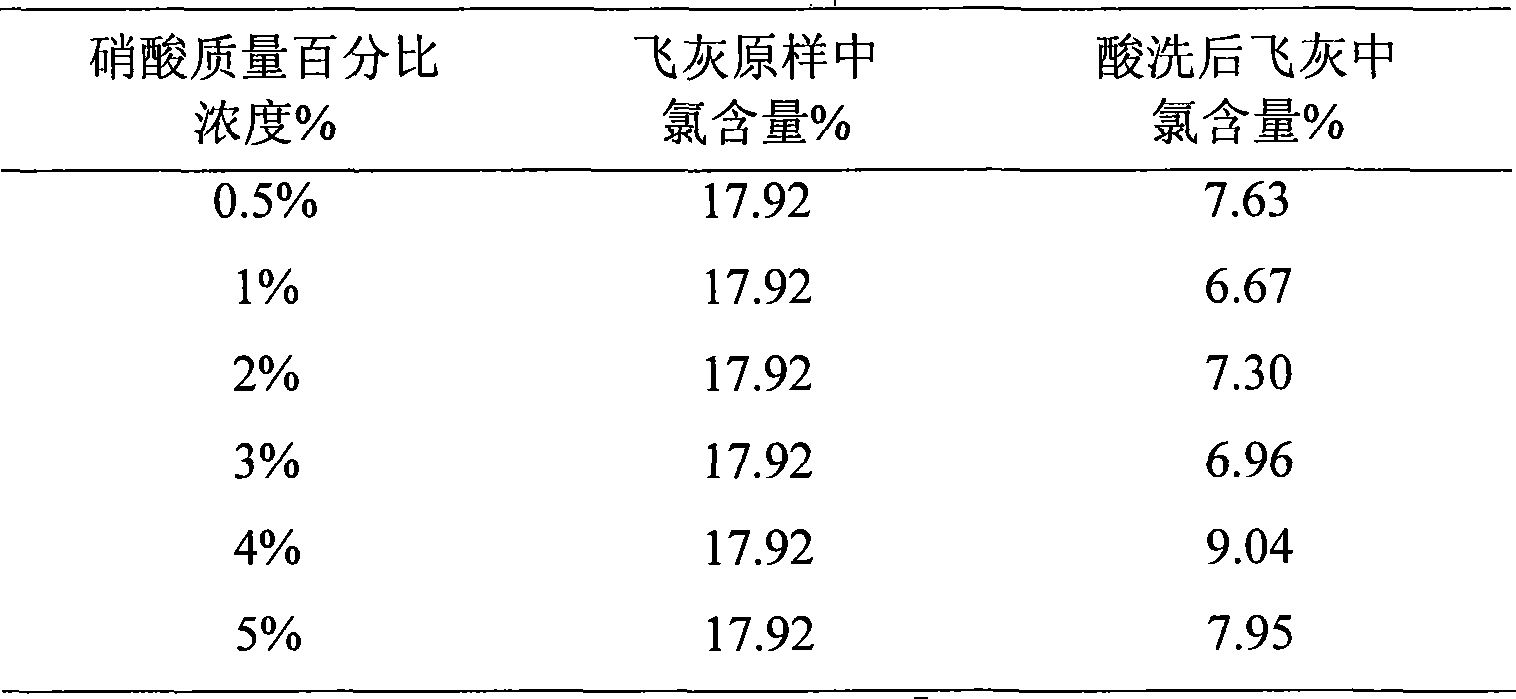

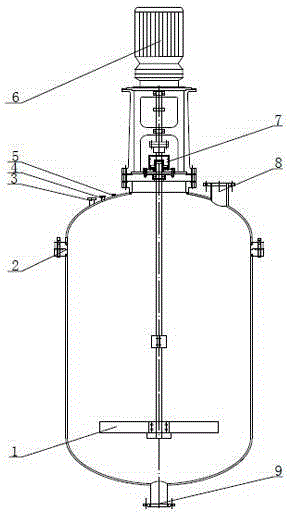

Water washing pretreatment method for making fly-ash from incineration harmless

InactiveCN1947872AReduce leaching toxicityImplement resourcesSolid waste disposalWater/sewage treatment by flocculation/precipitationPretreatment methodWastewater

A process for pre-treating the fly ash generated by incineration without environmental pollution includes such steps as washing the fly ash with water for removing a lot of soluble anions and part of heavy metal ions and carbonizing and flocculating the washing sewage to make it reach draining standard.

Owner:SHANGHAI UNIV

Method for treating arsenic sulfide residue

The invention discloses a novel method for treating arsenic sulfide residue, belonging to the field of the treatment of hazardous wastes. In allusion to the deficiencies of the existing curing drugs, such as large compatibilization ratio, difficult landfill and the like, the invention discloses a method for treating arsenic sulfide residue via a stabilization drug; and by means of the method, thestabilization drug can have complicated physical-chemical reaction with the arsenic sulfide residue so that the leaching toxicity of the arsenic is reduced to the inlet requirement of hazardous wastelandfill sites. The method comprises the following steps: adding inorganic flocculating agent solution in the arsenic sulfide residue and mixing evenly; adding a solid powder adsorbent and mixing evenly; and finally adding asbestos wool to mix. According to the method provided by the invention, the process flow is simple, the operability is strong, the effect is remarkable, and the method is suitable for the treatment of arsenic-containing hazardous wastes.

Owner:中节能大地(杭州)环境修复有限公司

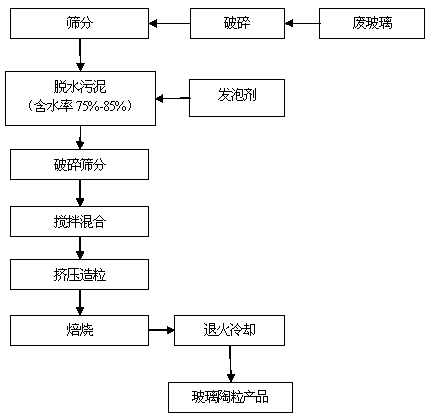

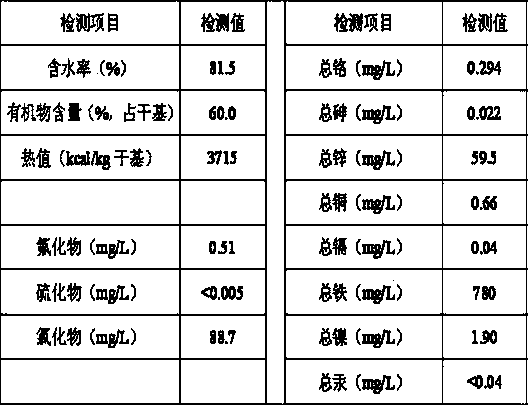

Method of preparing ceramsite by utilizing municipal sewage plant sludge and waste glass

InactiveCN103539426AReduce leaching toxicityEasy to handleHazardous substanceExpanded clay aggregate

The invention relates to a method of preparing ceramsite by utilizing municipal sewage plant sludge and waste glass, belonging to the technical field of solid waste treatment and disposal and recycling. The method comprises the following steps: crushing dehydrated sludge with moisture content of 75%-85%, crushing and ball-milling the waste glass into 200 meshes, and mixing and adding according to a certain proportion; adding 1%-5% of a foaming agent; extruding and pelletizing after stirring, and conveying to a ceramsite rotary kiln for firing through a conveyor. The excellent glass ceramsite fired by the method disclosed by the invention has a compact glaze surface, light weight and high strength, satisfies national standard GB / T17431.2-2010, and mechanical performance and harmful substance content inspection results of the ceramsite satisfies the requirements of the national standard; the obtained glass ceramsite can be used in projects such as houses, road surfaces and bridges. The method disclosed by the invention changes waste into things of value and protects the environment, not only satisfies sustainable development direction of the ecological building material industry, but also is an effective way of recycling the sludge from municipal sewage plants.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

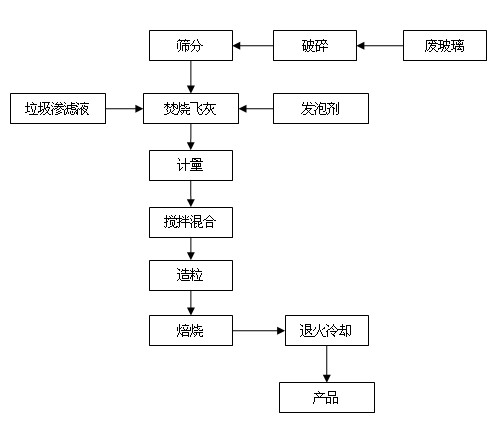

Method for preparing ceramsite by using waste incineration fly ash and waste glass

InactiveCN102643109ACause secondary pollutionEfficient curingSolid waste disposalCeramicwareFoaming agentHardness

The invention relates to a method for preparing ceramsite by using waste incineration fly ash and waste glass. The method includes the steps that waste glass is broken and ball ground to 200 meshes, and then waste incineration fly ash, rubbish leachate and a foaming agent are added according to certain proportion; and the mixture is stirred evenly, granulated and placed in a furnace to go through a pre-heating stage, a temperature rising stage and a heat preservation anneal stage to obtain the glass ceramsite. The glass ceramsite prepared through the preparation method is good in structural strength, low in water absorbing rate, large in hardness, good in chemical stability and wide in an application range. Simultaneously, dioxin pollutant in raw materials can be decomposed and damaged, heavy metal is cured in firing products, a toxic leaching standard of our country is met, and a purpose of disposing the rubbish leachate and the waste incineration fly ash is achieved simultaneously. The glass ceramsite produced through the method meets requirements of building aggregate, and the method not only turns waste into wealth, but also protects environment.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Solidification treatment method for sludge of urban sewage plant

InactiveCN102424511AHigh strengthReduce voidsSludge treatment by de-watering/drying/thickeningAluminatePortland cement

The invention discloses a solidification treatment method for sludge of urban sewage plants. The method comprises the following steps of (1) adding curing agent consisting of lime, sulfate aluminum cement, portland cement and fly ash in dehydrated sludge based on the weight of the dehydrated sludge, wherein the weight percentage of lime, sulfate aluminum cement, portland cement and fly ash in the curing agent are as follows: 1.2-1.9% of lime, 3.0-6.1% of sulfate aluminum cement, 3.0-3.7% of portland cement and 4.7-6.0% of fly ash; and (2) mixing the sludge added with the curing agent to form precursors of solidified blocks, piling the precursors up according to a height of 7 cm, and covering with waterproof membrane, maintaining the precursors for three days with a dry maintaining method, and forming sludge solidified blocks. The method provided by the invention has the advantages of efficiency, low cost, simple operation and the like.

Owner:CHONGQING UNIV

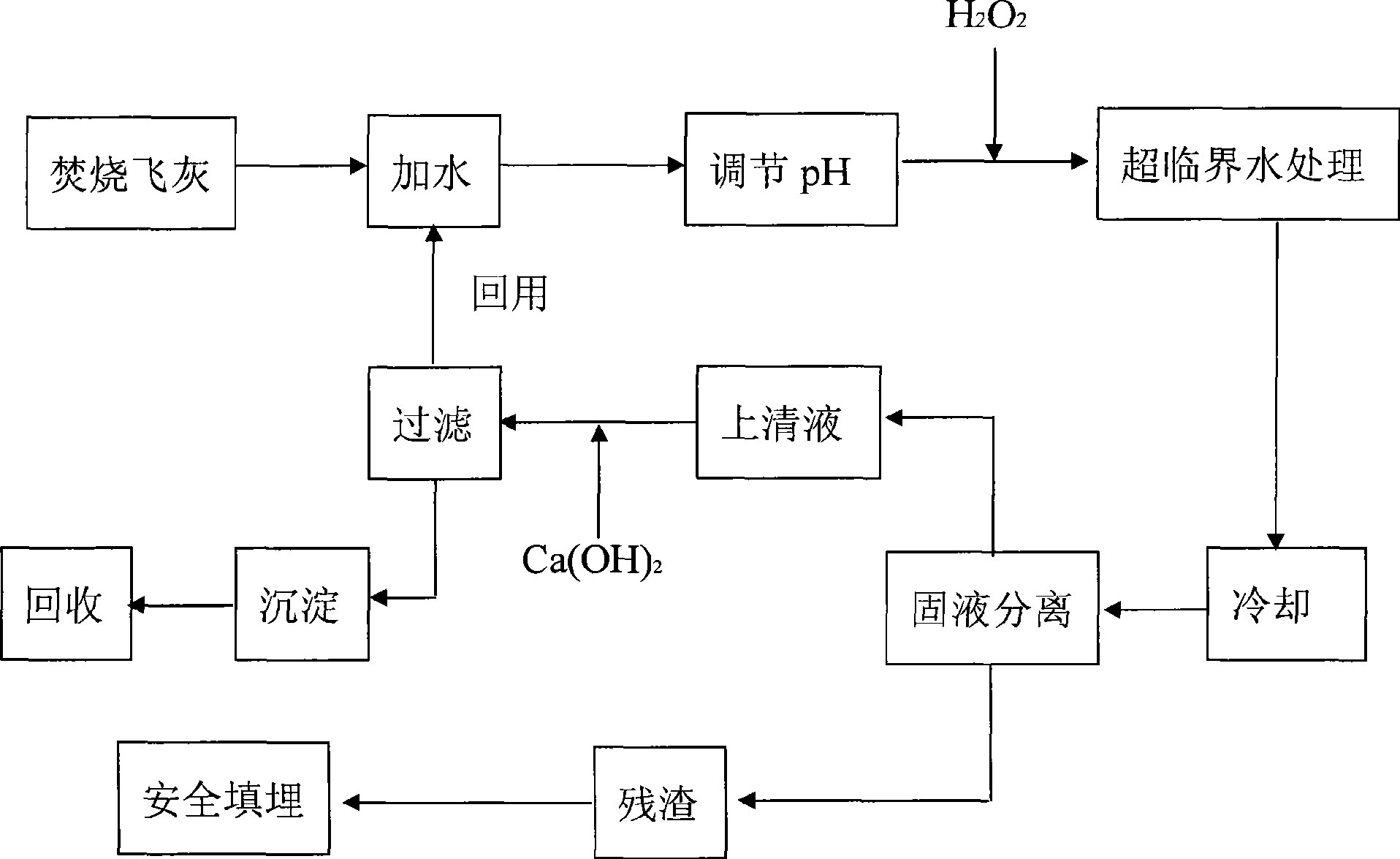

Novel technique for harmless treatment of medical refuse burning flyash

InactiveCN101502838AReduce leaching toxicityLight in massWaste processingSolid waste disposalEngineeringHigh pressure

The invention provides a new technology applicable to decontaminating treatment of flying ash incinerated by a medical waste incinerator. The key point of the technology comprises the steps of mixing the incinerated flying ash with water in a certain solid-to-liquid ratio, adjusting the pH to be approximately neutral, adding a certain amount of oxidant, adding the mixed solution to a high-pressure reaction kettle, raising temperature and pressurizing in a closed manner, keeping for certain time, and then naturally cooling to room temperature, separating the solid and liquid; and the aqueous solution can be recycled. The quality of the processed flying ash residue is obviously reduced, organic pollutants contained in the flying ash are completely degraded, and heavy metals are fixed, thus achieving the aim that the flying ash is decontaminating and can be safely buried or used as resource.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

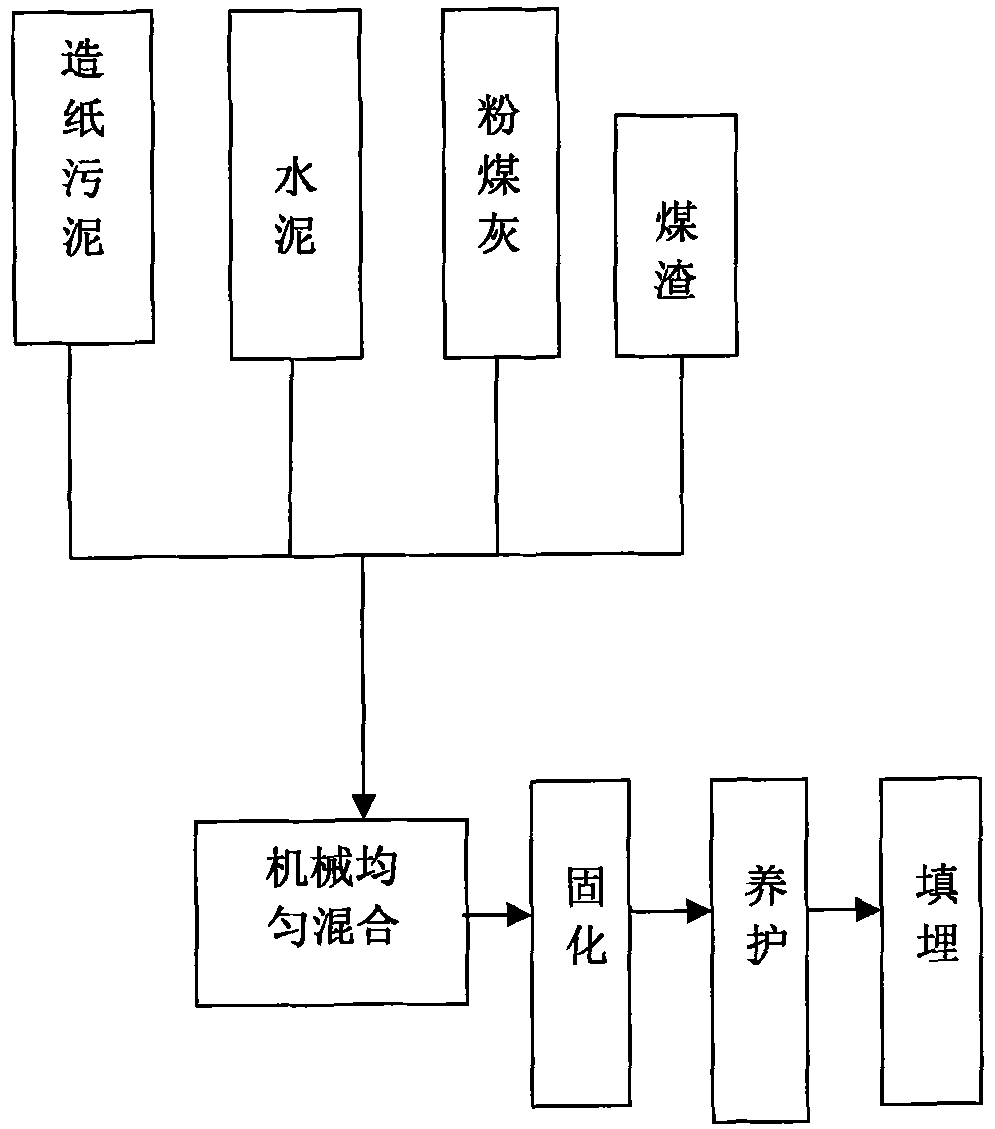

Solidification/stabilization treatment method for papermaking sludge

InactiveCN101885575AHarm reductionReduce cement consumptionSludge treatment by de-watering/drying/thickeningCinderWater content

The invention discloses a solidification / stabilization treatment method for papermaking sludge. The method comprises the following steps of: adding a solidifying agent into the papermaking sludge with water content of 70 to 80 percent according to a weight ratio of the sludge to the solidifying agent of 100:14-24, stirring the mixture to react for 10 to 15 minutes and uniformly mixing the mixture to form solidified block precursors; and laying solidified block precursors which are uniformly stirred in a sludge landfill site according to a thickness of 5 to 100cm, covering a water-proof membrane on the solidified blocks and curing the solidified blocks for 2 to 10 days by using a dry curing method to form sludge solidified blocks, wherein the compressive strength of the sludge solidified block is 160 to 320kPa, the COD concentration in solidified block leaching solution is 110 to 200mg / L, and the water content of the solidified block is 30 to 40 percent; and the solidifying agent comprises the following components in percentage by weight: 40 to 50 percent of aluminate cement, 15 to 25 percent of fly ash and 30 to 40 percent of cinder; toxic heavy metal ions are wrapped after the sludge solidification, so that the pollution of the sludge is reduced; the solidified sludge does not have foul smell of the original sludge and reduces the harm to an operator during the operation; and the method has the advantages of readily available raw material, low cost, stable effect and simple operation procedure.

Owner:GUANGDONG UNIV OF TECH

Refuse incineration flying ash metallurgy sintering treatment fixing agent

InactiveCN101508885AReduce leaching toxicityReduced Possibility of ContaminationOther chemical processesSolid waste disposalStable stateCadmium Cation

The invention relates to a waste incineration flying ash metallurgical sintering stabilizer which is formed by mixing the following components with the mass percent: 20-30% of Fe2O3, 5-35% of CaO, 1-5% of H3BO3, 1-8% of C2FeO4.2H2O, 5-15% of C, 5-10 % of SiO2, 3-10% of Al2O3, 5-10% of MgO and 3-10% of CnH2n+2. The stabilizer is added into waste incineration flying ash according to a certain proportion, so as to lead dioxin in the flying ash to be in a stable state at the temperature below 500 DEG C and ensure elements such as chromium, cadmium and the like to exist as a compound with a stable form, thus reducing the extracting toxicity of the waste incineration flying ash and greatly reducing the possibility of pollution caused by dissolving out the dioxin and heavy metal that are produced in the process of transportation, pelletization, cold solidification and sintering.

Owner:CHONGQING UNIV

Comprehensive treatment method of slag heap of acidified gold ore containing heavy metal

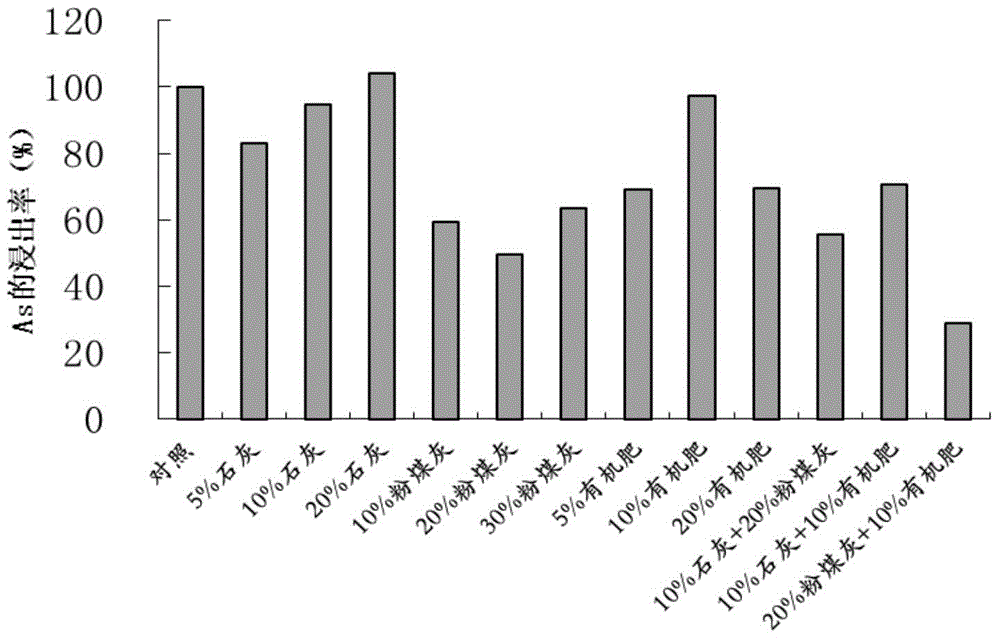

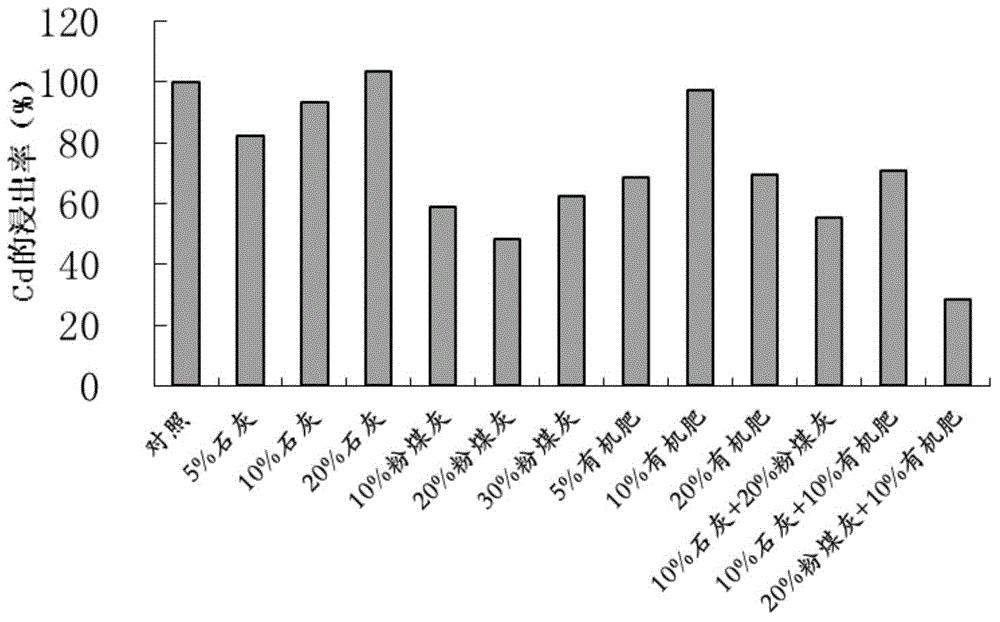

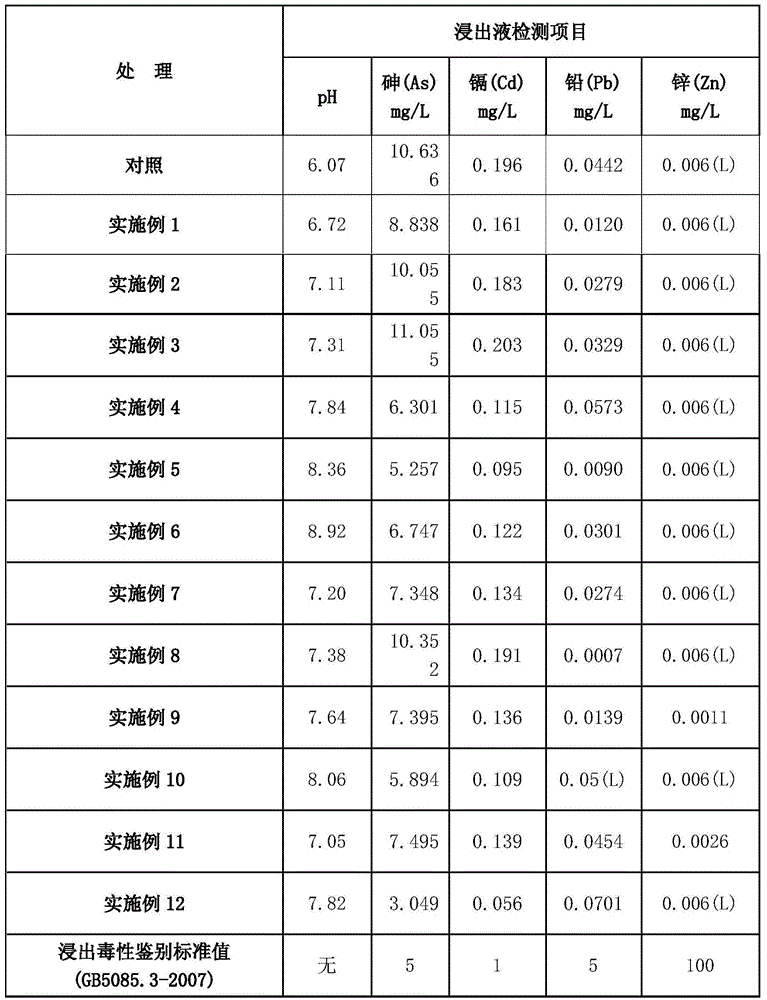

The invention relates to a stabilized and ecological remediation comprehensive treatment method of slag heap of acidified gold ore containing heavy metal, and belongs to the technical field of heavy metal pollution treatment in an ore field. The method comprises the following steps: adding a certain amount of lime, coal ash and organic sludge compost into 0-20cm soil at the upper layer of the slag heap of the gold ore containing heavy metal, mixing the ore slag and the additive according to a certain ratio and stirring so as to mix evenly, adding water into the ore slag, pouring, maintaining at the natural condition for 15-30 days so as to stabilize the slag heap of the gold core containing heavy metal; then, planting heavy metal tolerant plants including ciliate desert-grass, ramie and vetiver grass, so as to further remediate the heavy metal polluted slag heap ecologically. The method can effectively stabilize heavy metal, such as arsenic and cadmium in the gold ore slag, neutralize acid in the ore slag, improve the pH of soil in the ore field, reduce the leaching of heavy metal, enhance the soil structure, increase the soil fertility, and achieve the ecological recovery of the heavy metal polluted ore slag field.

Owner:GUANGDONG XIFU ENVIRONMENTAL PROTECTION TECH +1

Sulfuric acid refining preprocessing method of life refuse burning flying ash

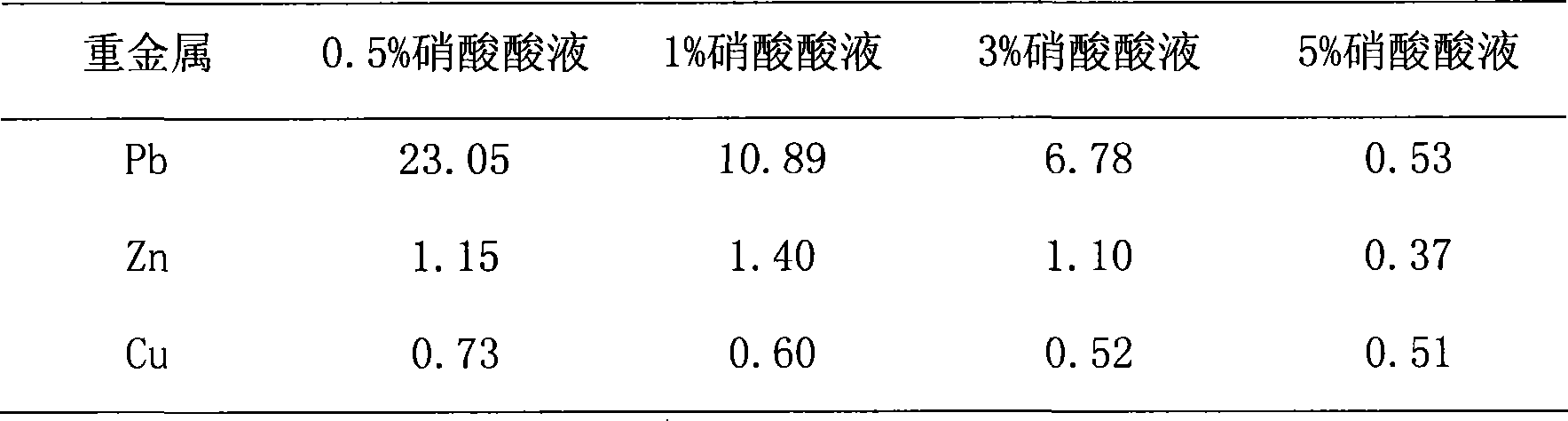

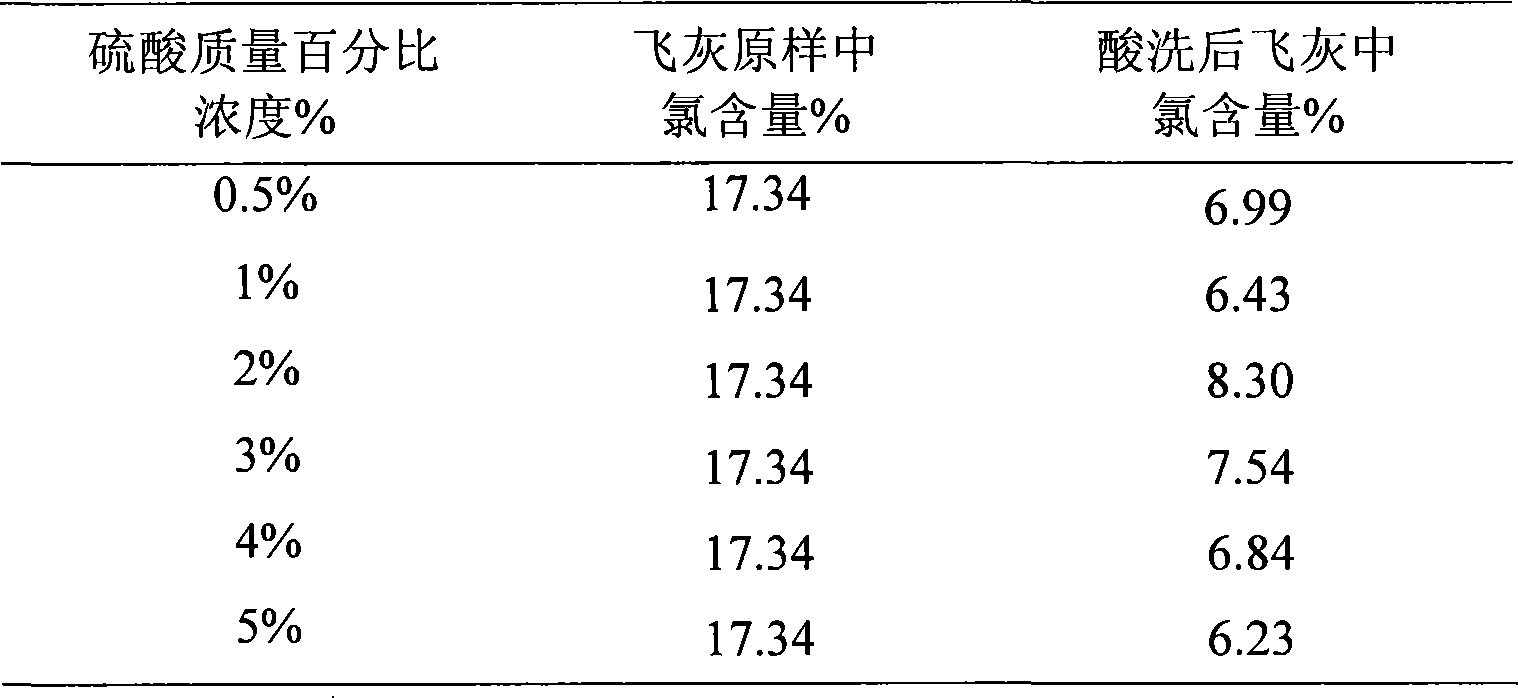

InactiveCN101239298AReduce leaching toxicityHarmless landfill resource utilizationGaseous chemical processesChemistryHeavy metals

The present invention provides an acid cleaning pretreatment method of household garbage fly ash, belonging to the environmental engineering technical field. The method is separating supernatant fluid to fly ash by mixing the household garbage fly ash with sulphuric acid, hydrochloric acid, citric acid, phosphoric acid etc under the normal temperature, blending and static settlement. The invention also can remove a mass of contamination such as soluble chloride salt and part heavy metalin the household garbage fly ash; the fly ash after acid cleaning achieves harmless aim, futher filled or resource utilization.

Owner:SHANGHAI UNIV

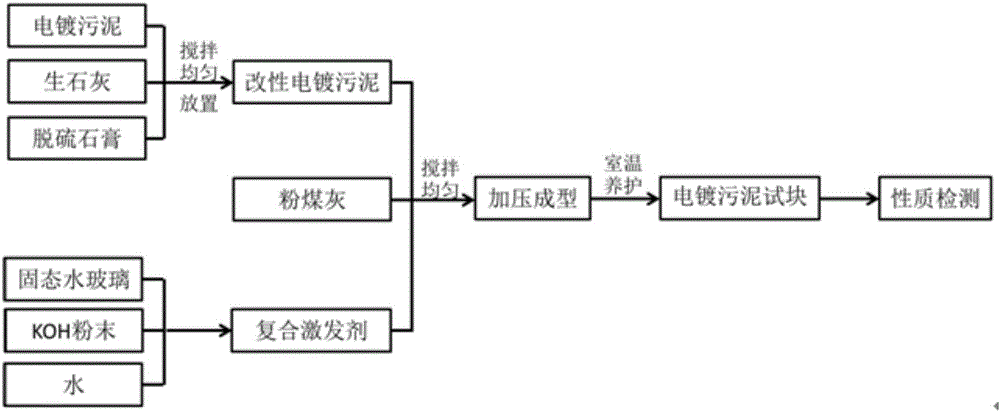

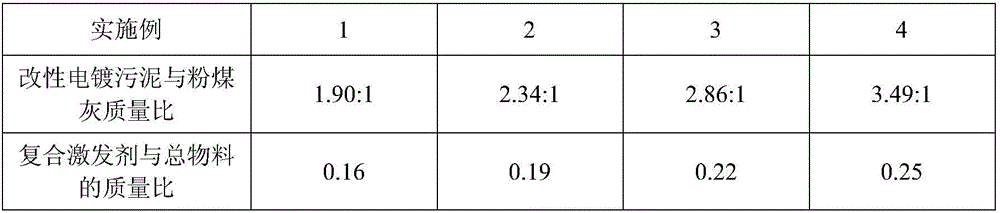

Harmless treatment method for electroplating sludge

ActiveCN105948589AImprove developmentSimple processSolid waste managementCorrosion resistantHeavy metals

The invention belongs to the technical filed of environmental protection engineering and particularly relates to a harmless treatment method for electroplating sludge. The harmless treatment method comprises the following steps: the electroplating sludge is taken, certain amount of quicklime and flue gas desulfurization gypsum is added, crushed sufficiently and stirred uniformly, the mixture is left to stand for a period of time, and modified electroplating sludge is obtained; the modified electroplating sludge and fly ash are taken and stirred uniformly, a certain amount of a composite activator is added and stirred sufficiently again, and a mixture is obtained; an electroplating sludge test block is obtained in a pressure forming manner and cured in a room-temperature environment for 7-28 days, and a solidified electroplating sludge body is obtained. The harmless treatment method adopted for treating the electroplating sludge has the advantages of simple process, low cost, large electroplating sludge curing amount, small capacity increase and the like, meanwhile, the solidified electroplating sludge body obtained after treatment is highly corrosion-resistant, stable for a long time and low in heavy metal leaching toxicity, has certain compressive strength and can be taken as general solid waste to be subjected to landfill treatment.

Owner:SAFECLEEN TECH

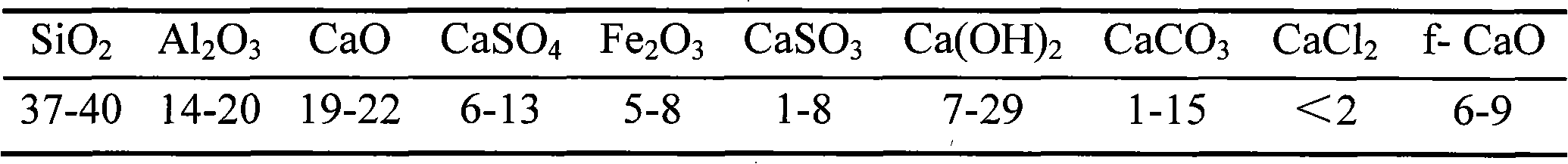

A plasma melted flying ash vitrification method based on adjustment of the ratio of CaO-Al2O3-SiO2 three phases

PendingCN108927398AUniversalPromote formationSolid waste disposalTransportation and packagingVitrificationThree-phase

A plasma melted flying ash vitrification method based on adjustment of the ratio of CaO-Al2O3-SiO2 three phases is provided. Through pretreatment in which broken glass powder or glass bottle package is added, the mass percents of CAS three phases which are CaO, Al2O3 and SiO2 in a pretreated flying ash sample are adjusted to 8-30%, 5-17% and 60-75% respectively so that the pretreated flying ash sample is melted at 1250-1400 DEG C with the melting time being less than 25 min. The ratio of the CAS three phases in the flying ash sample is adjusted to promote formation of vitreous molten slag, pretreated flying ash can form the vitreous molten slag, and the solidification rate of each heavy metal in the pretreated molten slag is increased to a certain degree, thus controlling secondary flyingash separation and heavy metal migration, increasing the solidification rates and stability of heavy metals in the molten slag, and reducing the melting temperature and system energy consumption.

Owner:TIANJIN UNIV

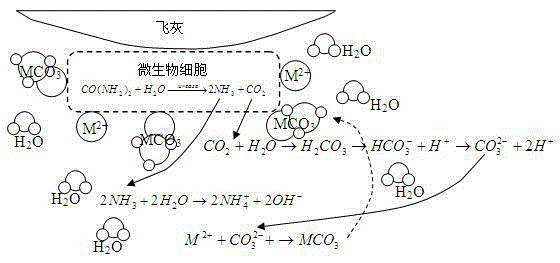

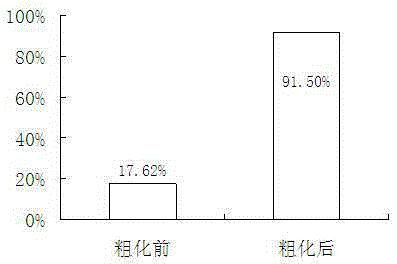

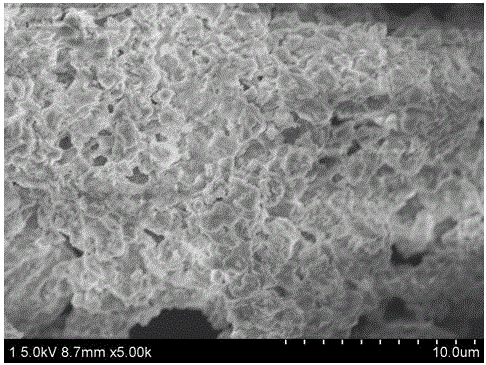

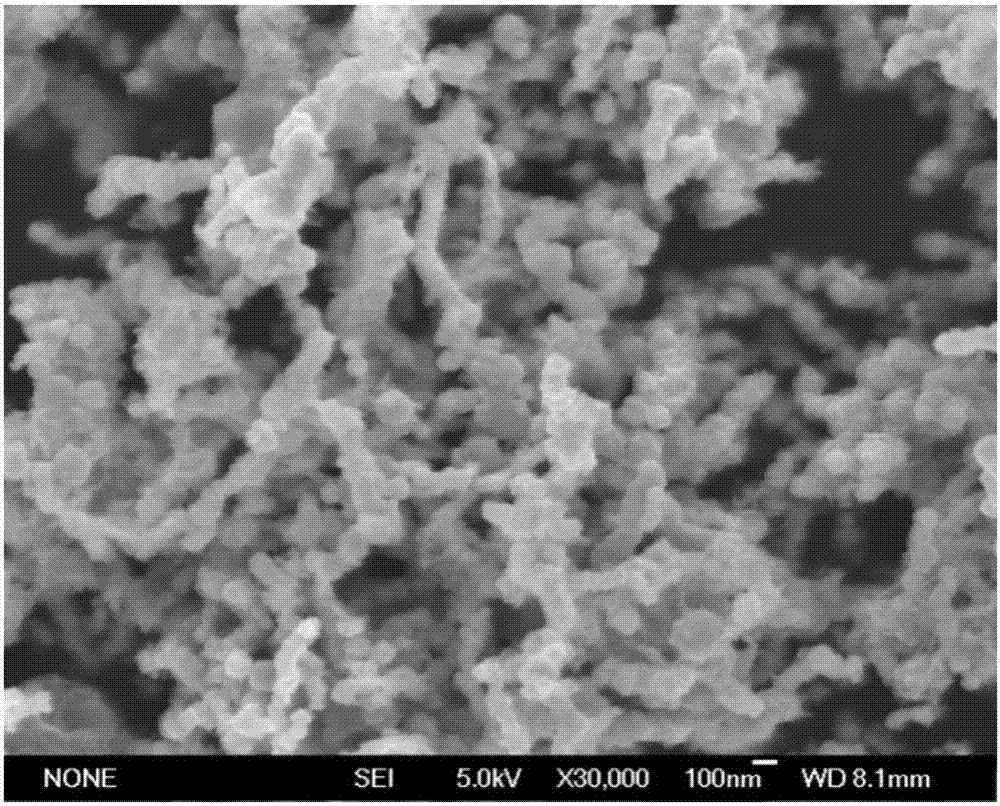

Method for achieving aggregation of waste incineration fly ash through microorganism mineralization

ActiveCN105268727AReduce leaching toxicityReduce consistencyTransportation and packagingSolid waste disposalPrillMass ratio

The invention discloses a method for achieving aggregation of waste incineration fly ash through microorganism mineralization. Peptone, meat extract and urea are placed in distilled water 200 mass folds of peptone according to the mass ratio for preparing a culture medium; after high-temperature and high-pressure sterilization, bacteria with mineralization are inoculated into the culture medium, shaking culture is carried out on a shaking table till bacterial liquid is completely turbid; the prepared bacterial liquid and the waste incineration fly ash are mixed and stirred evenly in proportion, and are horizontally laid on a corrosion-resistant plane; and a urea solution is sprayed, and aggregated waste incineration fly ash can be obtained. The characteristics that the waste incineration fly ash is rich in calcium ion and heavy metal ion and alkaline in lixivium are utilized, only the bacterial liquid of microorganisms with mineralization and the urea solution need to be added to the waste incineration fly ash, and the aggregated waste incineration fly ash can be obtained. The particle diameter of aggregated waste incineration fly ash is remarkably increased, and the mass of the aggregated waste incineration fly ash with the particle diameter large than 80 micrometers is increased to 90% to 95% from 15% to 20%.

Owner:ZHEJIANG SCI-TECH UNIV

Method for stably treating arsenic caustic sludge

ActiveCN104263949AReduce leaching toxicityImprove long-term stabilityProcess efficiency improvementSludgeHazardous waste

The invention discloses a new method for treating arsenic caustic sludge. According to the method, the arsenic caustic sludge is preliminarily crushed; stabilizer ferric salt is added into the arsenic caustic sludge to be evenly stirred; dilute acid solutions are added into the arsenic caustic sludge to be evenly stirred; finally, natural curing is carried out. According to the method, the problem of the pollution or potential menace of existing high-concentration arsenic caustic sludge (pH is larger than 12) to the environment is solved, and the leaching toxicity of the arsenic caustic sludge is reduced so as to meet the entrance requirement of a hazardous waste landfill. The method is simple in technology, raw materials are easily obtained, the disposal cost is low, and the method has the good application prospect.

Owner:POWERCHINA ZHONGNAN ENG +1

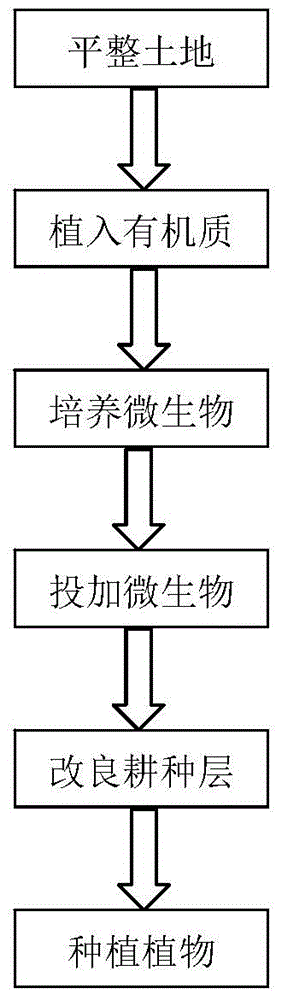

In-situ bioremediation method for soils polluted by nitrocompounds

ActiveCN104907330AEfficient degradationReduce leaching toxicityContaminated soil reclamationNitro compoundNitrobenzene

The invention provides an in-situ bioremediation method for soils polluted by nitrocompounds. The method mainly carries out in-situ remediation treatment of nitrocompounds in polluted soil through combined action of nitrocompound dominant degradation bacteria and plants with strong tolerance. The method comprises the following steps: land leveling, organic matter implantation, culture and adding of microorganisms, improvement of farming layer soil and cultivation and conservation of plants. Pollutants in soil can be degraded rapidly, leaching toxicity of soil can be lowered greatly, the soil remediation cycle is shortened, the remediation cost is low, secondary pollution cannot be generated, the method is simple and practicable, fertility of pollution place soil can be raised, and the method is suitable for in-situ remediation of pollution places with various scales. The method can be suitable for in-situ bioremediation of soils polluted by TNT waste water, DNT waste water, MNT waste water, nitrobenzene waste water, phenyl amine waste water.

Owner:BEIJING FENGZELVYUAN ENVIRONMENT TECH

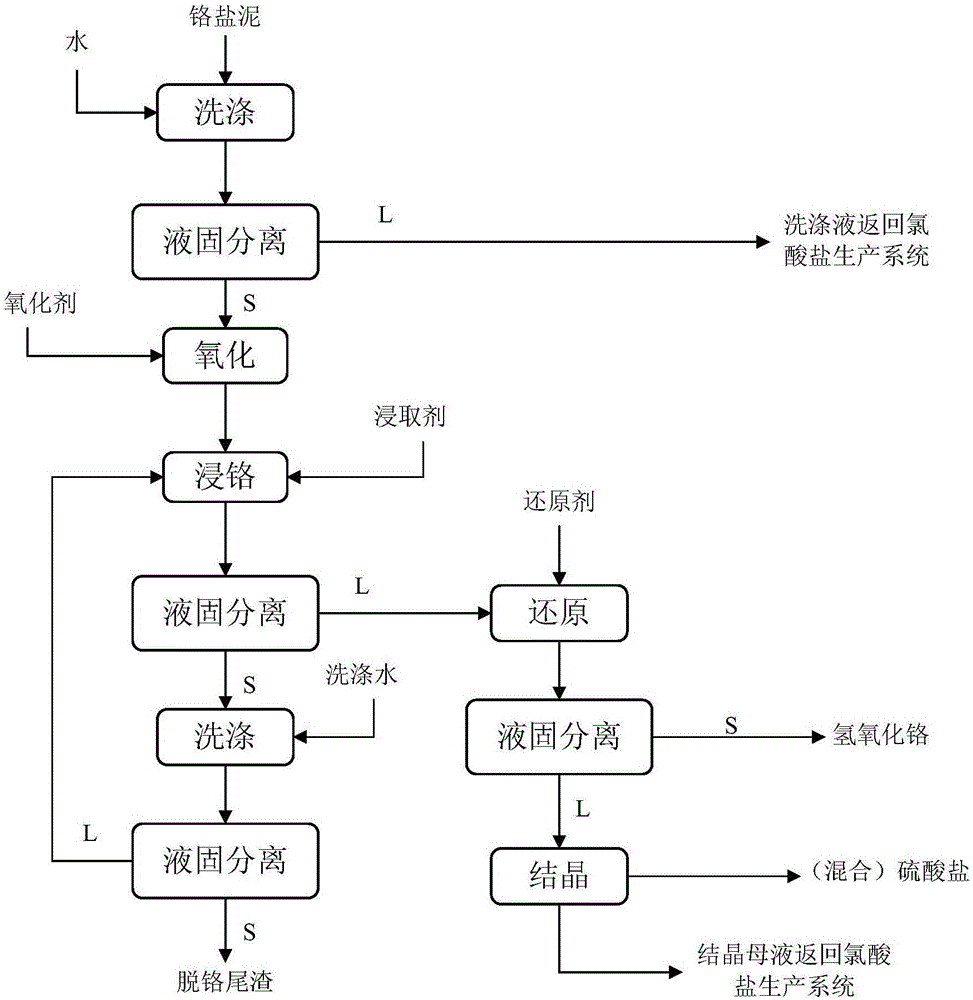

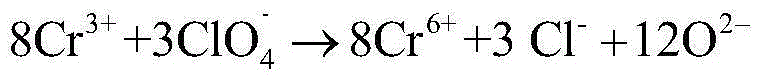

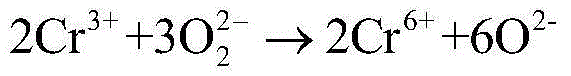

Chromium salt mud treatment method

ActiveCN105016387AAchieving processing powerRealize comprehensive utilizationChromium compoundsRecovery methodPregnant leach solution

The invention relates to a chlorate factory chromium salt mud harmless treatment and chromium separation and recovery method. The method comprises mixing chromium salt mud and water, heating the mixture, carrying out elution, carrying out solid-liquid separation to obtain filtrate and filter residue, mixing the filter residue and water to obtain a uniform mixture, carrying out oxidation and chromium impregnation, carrying out solid-liquid separation to obtain leachate and leaching residue, washing the leaching residue to obtain dechromed tailings, recycling the washing solution after washing, adjusting pH of the leachate, adding a reducer into the leachate for reduction chromium removal, carrying out solid-liquid separation to obtain a dechromed solution and chromium hydroxide, carrying out crystallization separation on the dechromed solution to obtain sulfate and recycling the mother liquid obtained by crystallization separation. The method can realize high efficiency separation and recovery of chromium in chlorate factory chromium salt mud and thorough removal of toxicity of the dechromed tailings. The method has simple processes, a low cost and a good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Expanded ceramisites prepared from residual sludge in combination with FCC spent catalyst and preparation method of expanded ceramisites

InactiveCN109305801AAchieving harmless goalsLow leaching rateCeramic materials productionCeramicwareFoaming agentSludge

The invention discloses expanded ceramisites prepared from residual sludge in combination with an FCC spent catalyst and a preparation method of the expanded ceramisites, and belongs to the technicalfield of environmental waste utilization. The invention solves the technical problem in the prior art that residual sludge and spent catalysts can not be reasonably utilized. The preparation method comprises the following steps: taking the residual sludge and the FCC spent catalyst as raw materials for preparing the expanded ceramisites, adding a fluxing agent to the raw materials to reduce the ceramisite sintering temperature, adding a foaming agent hydrogen peroxide gas production substance to enhance expansibility, fully stirring the obtained ingredients, granulating the stirred ingredients, drying and preheating the granulated ingredients, roasting the preheated ingredients, and cooling the ceramisites obtained after roasting to obtain finished products. The leaching rate of heavy metals in the prepared ceramisites is greatly lowered, the harmless purpose of the spent catalyst is realized, and the ceramisites are prepared from the spent catalyst in combination with the residual sludge, thereby realizing recycling and achieving the aim of treating wastes with other wastes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for repairing heavy metal contaminated soil by nanometer zero-valent iron

InactiveCN106984640AReduce leaching toxicityReduced effectivenessAgriculture tools and machinesContaminated soil reclamationDesorptionElution

The invention discloses a method for repairing heavy metal contaminated soil by nanometer zero-valent iron. The method comprises the following steps of: filling heavy metal contaminated soil in a fiberglass-reinforced column; introducing water until constant weight is obtained; and introducing nanometer zero-valent iron suspension liquid in the fiberglass-reinforced column to perform elution on the heavy metal contaminated soil. Through the adoption of the method disclosed by the invention, heavy metal with high toxicity in the soil can be eliminated or reduced once under the condition that the original ecological structure of the soil is not damaged, and secondary contamination of nanometer zero-valent iron and heavy metal desorption are avoided; and the method has the advantages of being simple in treating technology, low in cost and obvious in treatment effect.

Owner:HUNAN UNIV

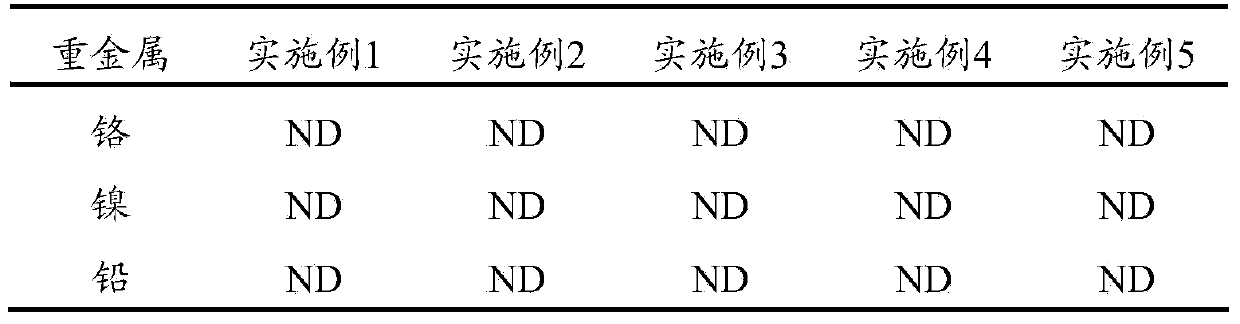

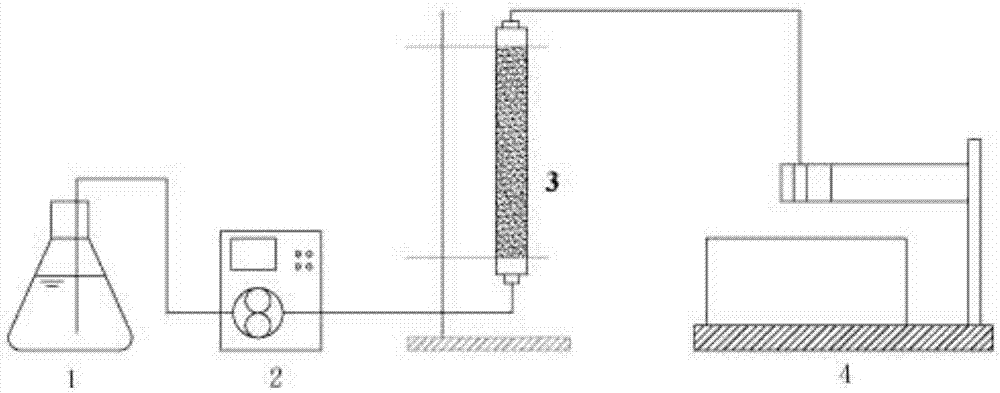

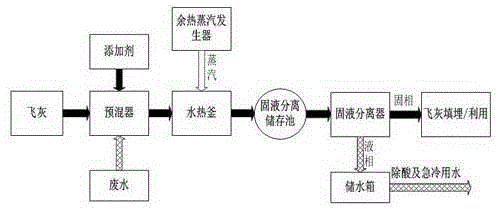

Synergic treatment method of heavy metals in hazardous waste incineration plant wastewater and fly ash

InactiveCN105198129APercolation concentration reductionReduce leaching toxicitySolid waste disposalMultistage water/sewage treatmentIon exchangeSolid phases

The invention relates to a synergic treatment method of heavy metals in hazardous waste incineration plant wastewater and fly ash, which is used for treating high-concentration heavy metals in hazardous waste incineration plant fly ash and wastewater. In the treatment environment of hydrothermal conditions, a certain amount of alkaline and exogenous silicon aluminum additive (incineration power plant fly ash) is added, and hydrothermal reaction is performed, so that the heavy metals in the wastewater are transferred from the liquid phase into the solid phase, thereby removing the heavy metals; and the fly ash has high adsorption capacity for most heavy metals, and especially after the hydrothermal modification, the adsorption capacity of the fly ash for heavy metals is further enhanced. After the hydrothermal reaction, the heavy metals are not simply enriched on the fly ash surface, but coated in the zeolite crystals, and exists in a stable form which is difficult for ion exchange and desorption, thereby stabilizing the heavy metals in the fly ash; and thus, the heavy metal percolation concentration is greatly lowered, and is lower than the relevant standard value, thereby satisfying the requirements for comprehensive utilization and landfill treatment.

Owner:ZHEJIANG UNIV OF TECH

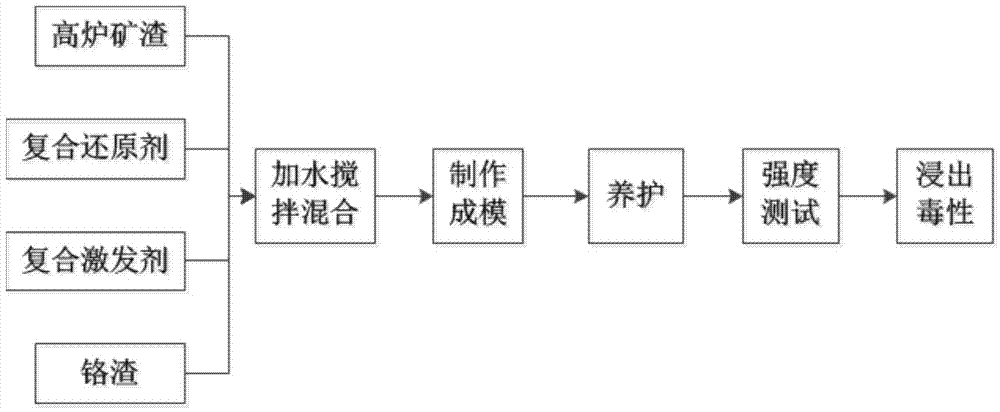

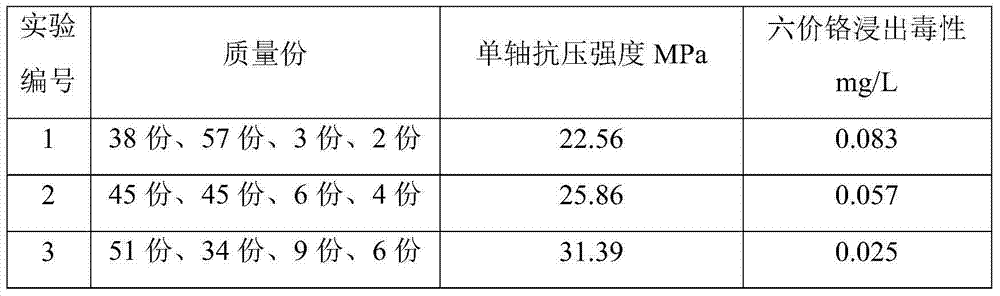

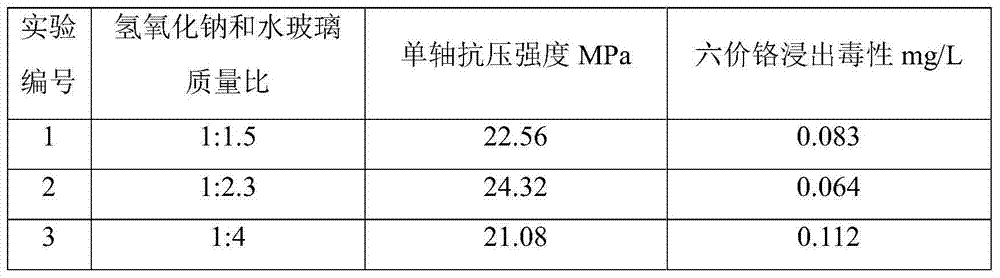

Method for dissolving poison solidified chromium slag

ActiveCN104844126ALarge amount of curingReduce leaching toxicitySolid waste disposalSlagMechanical property

The invention discloses a method for dissolving poison solidified chromium slag. Firstly chromium slag and blast-furnace slag are fetched to be dried and refined. A composite catalyst is made by mixing sodium hydroxide and sodium silicate according to weight ratio of 1: 1.5 to 4. A compounding reducing agent is made by mixing sodium sulfide and ferrous sulfate according to weight ratio of 1:1. According to weight, 34 to 57 portions of refined blast-furnace slag, 34 to 57 portions of chromium slag, 3 to 9 portions of composite catalyst and 2 to 6 portions of compounding reducing agent are mixed, then water is added according to the quality of liquid-solid ratio of 0.23 to 0.27 : 1. And the blast-furnace slag, the chromium slag, the composite catalyst and the compounding reducing agent are evenly stirred. The solidified body of dissolving poison solidified chromium slag is finished after molding, solidifying, removing molding and maintaining. The solidified body prepared by the method has good mechanical property. Not only is the environment problem produced by storing the blast-furnace slag remitted, but also the leaching of chromium ion in the chromium slag is effectively prevented.

Owner:沃德费默循环经济科技发展(北京)有限公司

Preparation method and application of hexavalent chromium contaminated soil conditioner

InactiveCN105694894AReduce leaching toxicityLow toxicityOther chemical processesContaminated soil reclamationSoil remediationSoil conditioner

The invention belongs to the field of soil restoration and provides a preparation method and application of a hexavalent chromium contaminated soil conditioner. The conditioner is composed of a first chemical agent and a second chemical agent. By means of the conditioner, hexavalent chromium in soil can be efficiently reduced into trivalent chromium low in toxicity, the soil structure is improved, the acid-base property of improved soil is effectively stabilized within a certain range, long-time stability of trivalent chromium in soil is guaranteed, and environmental risk is greatly lowered. The preparation method of the conditioner is simple, hexavalent chromium in improved soil is low in leaching toxicity, appropriate in acid-base range and long in stable cycle, environmental benefits are obvious, and it is beneficial to further development and utilization of soil. The conditioner has great application significance on chemical restoration of hexavalent chromium contaminated soil, and market application prospect is wide.

Owner:UNIV OF JINAN

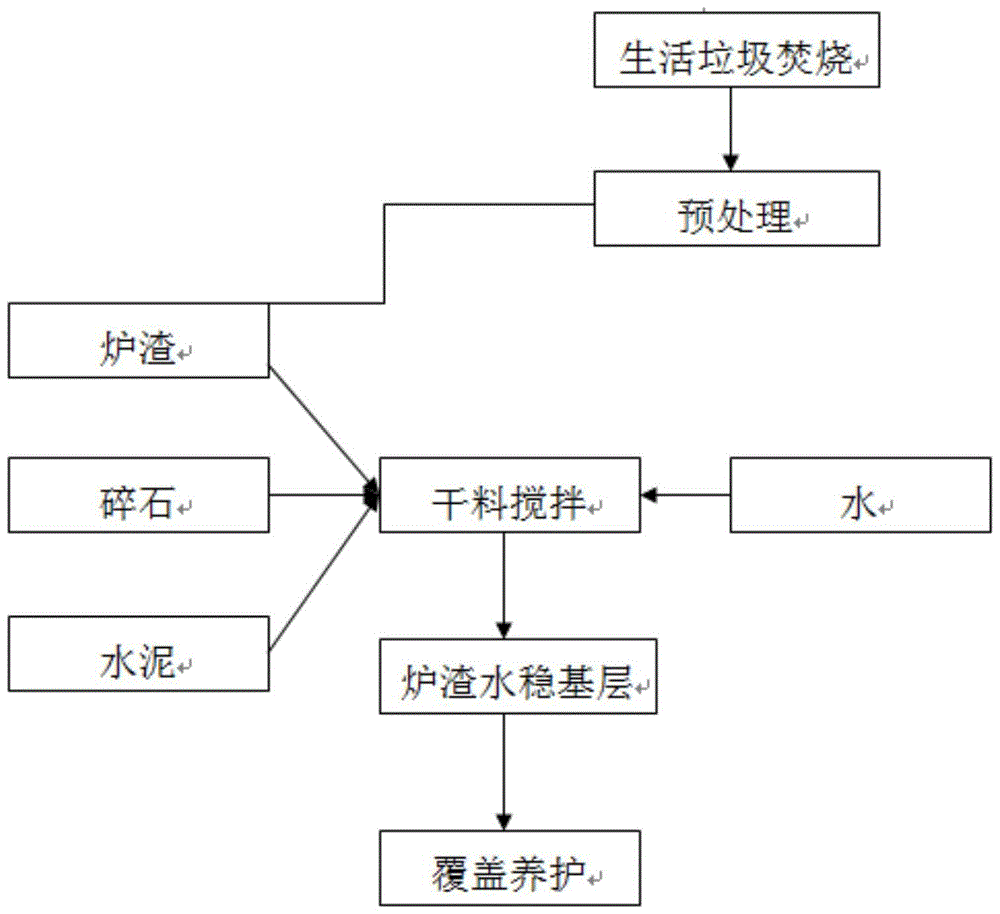

Method for curing dredged sludge by doping incinerated bottom ash of domestic garbage

InactiveCN102941209ASolve the way outImproved soil mechanical propertiesSolid waste disposalSocial benefitsBottom ash

The invention discloses a method for curing dredged sludge by doping incinerated bottom ash of domestic garbage. The ratio between the doping amount of the incinerated bottom ash of the domestic garbage and the weight of the dredged sludge is 0.3-0.5:1, the ratio between the doping amount of a curing agent and the weight of the incinerated bottom ash of the domestic garbage is 0.1-0.2:1, the unconfined compressive strength of a cured body with the 28-day age is 50-80kPa, and the cured body is not collapsed when being soaked by water. The method disclosed by the invention has the beneficial effects that the characteristics of aggregate characteristic, absorbability and potential hydraulicity of the incinerated bottom ash of the garbage are utilized to solve the problems of high clay content, high moisture content and low strength and the like of the dredged sludge in a targeted way, and the dredged sludge after curing treatment can be used as a soil filling material for recycling; the physical and chemical characteristics of the incinerated bottom ash of the garbage are fully utilized, so that the treatment of wastes with wastes is achieved; and compared with the existing dredged sludge curing technology, the method has the advantages that the curing cost is obviously reduced, simultaneously the problem of the treatment way of two types of wastes is solved, and the environmental benefit and the social benefit are obvious.

Owner:ZHEJIANG SCI-TECH UNIV

Hot-pressing sintering curing method for arsenic sulfide slag

ActiveCN108580513AReduce energy consumptionDoes not affect the effectSolid waste disposalTransportation and packagingSulfurSlag

The invention provides a hot-pressing sintering curing method for arsenic sulfide slag. The hot-pressing sintering curing method comprises the following steps that firstly, the pH value of the arsenicsulfide slag is adjusted to be 1-7; the arsenic sulfide slag subjected to a neutralization reaction is dried and dehydrated; then sulfur powder is added, and after even stirring and mixing are conducted, vibrating compaction and briquetting forming are conducted; and finally, a formed arsenic sulfide slag block is placed in a hot-pressing sintering curing reaction device to be subjected to hot-pressing sintering curing so as to obtain the arsenic sulfide slag hot-pressing sintered block. According to the arsenic sulfide slag hot-pressing sintered block obtained by treating through the hot-pressing sintering curing method, the leaching toxicity of arsenic can be reduced by 90% or above, and the compressive strength of the cured block can reach 10 MPa or above. The hot-pressing sintering curing method is simple in treatment technology, low in cost and obvious in economic benefit and environmental benefit.

Owner:CENT SOUTH UNIV

Extractant for treating heavy metals in fly ash and method for extracting heavy metals with the extractant

InactiveCN102312101AAchieving chelation extractionReduce leaching toxicityProcess efficiency improvementKerosenePhosphate

Belonging to the technical field of environmental engineering, the invention discloses an extractant for treating heavy metals in fly ash and a method for extracting heavy metals with the extractant. The extractant of the invention comprises the following components by volume: 50-80% of kerosene and 20-50% of di(2-ethylhexyl)phosphate. The preparation method of the extractant in the invention includes the step of mixing the raw materials in the above ratio uniformly. The invention also discloses a method for extracting heavy metals with the extractant, and the method consists of the steps of:mixing the extractant for treating heavy metals in fly ash with the fly ash in a mass ratio of 1:1-5:1, placing the mixture in a stirrer at room temperature and stirring the mixture continuously for 12-24h, then leaving it for standing and layering. The extractant provided in the invention has wide source, low price and high treating efficiency, and the fly ash after extraction has zinc and lead leaching concentrations lower than the limit value prescribed by domestic waste landfill pollution control standards.

Owner:TONGJI UNIV

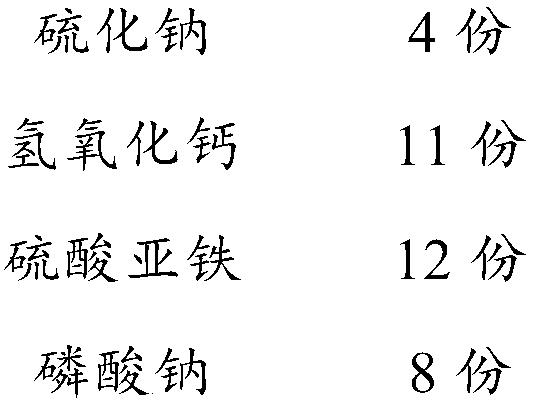

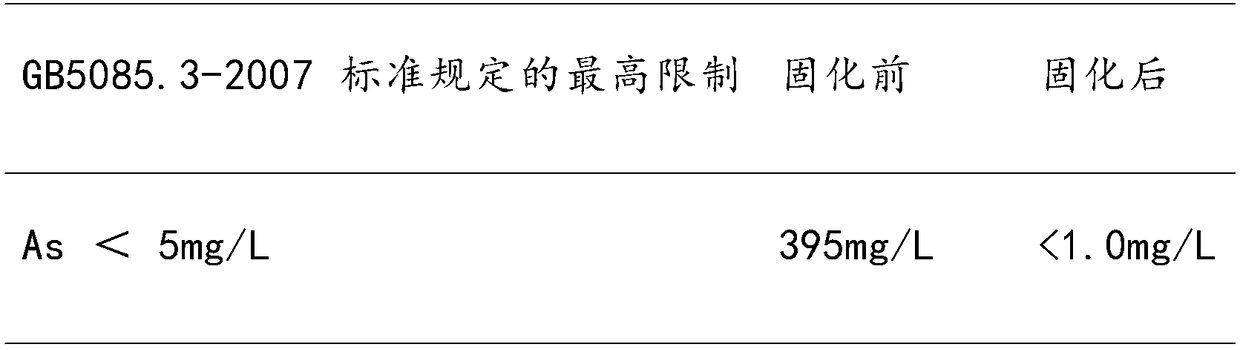

Stable solidification method of arsenic-containing waste residues

ActiveCN109226210AReduce leaching toxicityStable curing treatmentSolid waste disposalHigh intensityLeaching rate

The invention provides a stable solidification method of arsenic-containing waste residues. According to the method provided by the invention, the arsenic-containing waste residues and a soil solidifying agent are combined, so that the arsenic-containing waste residues are solidified in a high-strength solidified body, and the leaching toxicity of the arsenic-containing waste residues is reduced;the leaching rate of solidified arsenic can reach related requirements of Identification Standards for Hazardous Wastes-Identification for Extraction Toxicity (GB5085.3-2007), so that the arsenic-containing waste residues are changed into common solid wastes, stable solidification treatment of the arsenic-containing waste residues is realized, and furthermore, the aim of safety stacking is realized; the method is simple to operate, economical and environmentally friendly; the environment pollution problem caused by the arsenic-containing waste residues in the prior art is solved.

Owner:西安同鑫伟业环保科技有限公司

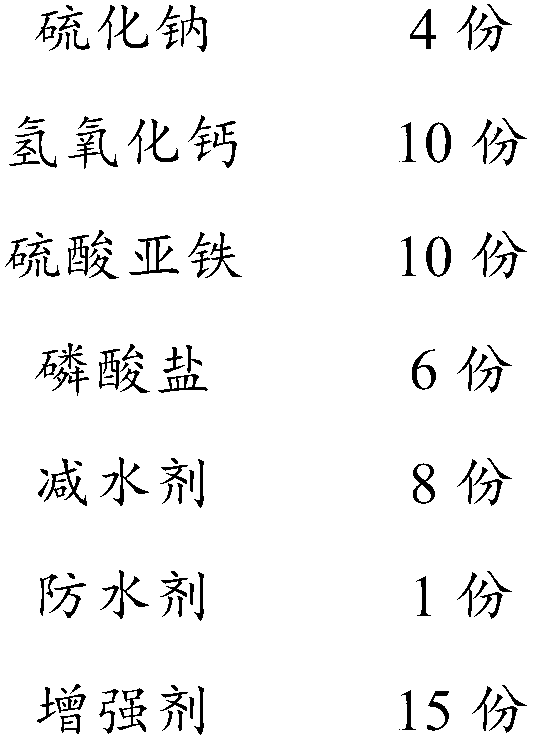

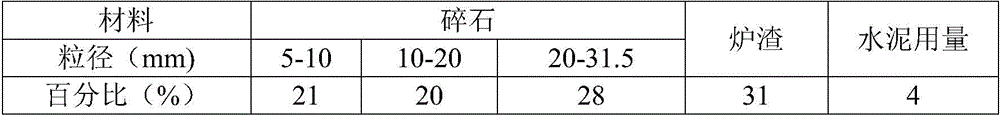

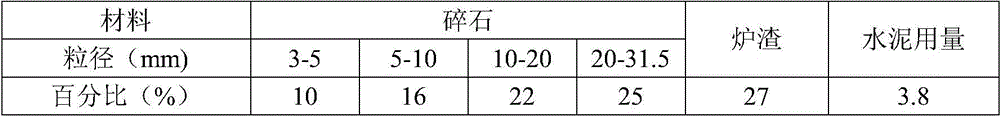

Furnace slag water-stable base material and preparation method thereof

InactiveCN105731920AImprove mechanical propertiesStable structureSolid waste managementMineral SourcesSlag

The invention discloses a furnace slag water-stable base material and a preparation method thereof. The furnace slag water-stable base material is formed by mixing a dry material and water. The dry material comprises the following components in percentage by weight: 3-5% of cement, 20-35% of furnace slag and 65-75% of macadam. The water accounts for 3.5-5.5 wt% of the dry material. The furnace slag is used instead of fine aggregate, thereby reducing the probability of cracking caused by temperature shrinkage when the cement content and water-stable base are reduced. The solid waste is used as the fine aggregate in the water-stable base material, thereby changing wastes into valuable substances, saving the waste piling site and saving the mineral resources of macadam production. The furnace slag material is pretreated, so that the heavy metal content and leaching toxicity are lower than the standard values. The furnace slag water-stable base material is applicable to the water-stable base with higher economic value, and lowers the engineering cost.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

Copper-nickel containing industry sludge harmless recycling method

ActiveCN108796222APromote migrationPromote growthFlotationProcess efficiency improvementFoaming agentSludge

The invention discloses a copper-nickel containing industry sludge harmless recycling method. The content of copper in copper-nickel containing industry sludge and the content of nickel in the copper-nickel containing industry sludge are each 1%-3%. The method comprises the following steps that firstly, after 6%-25% of a vulcanizing agent, 6%-30% of a solvent, 0.5%-2.5% of a fluxing agent and 5%-20% of a reducing agent are added in the copper-nickel containing industry sludge to be evenly mixed, pelletizing is conducted, and green pellets are obtained; secondly, after the green pellets are dried along with a furnace, the green pellets are sintered for 30 min-90 min at the temperature ranging from 1,000 DEG C to 1,150 DEG C, and sinter is obtained; and thirdly, the sinter obtained in the second step is ground till the content of -0.074 mm accounts for 60%-85%, then, 2# oil serves as a foaming agent, butyl xanthate serves as a collecting agent, the usage amounts are 100 g / t and 200 g / t correspondingly, and copper-nickel mixed concentrates and tailings are obtained through flotation. The economical and reasonable method for achieving harmless recycling is provided for overcoming the defects in copper-nickel containing industry sludge treatment in the prior art.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com